Alignment Citroen CX 1981 1.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1981, Model line: CX, Model: Citroen CX 1981 1.GPages: 394

Page 5 of 394

Downloaded from www.Manualslib.com manuals search engine .r.

-/1

LIST OF OPERATIONS

IN MANUAL 818-1

a CX Petrol )) 7,rhifles

--

-

f-7

i---- _--

-

Operation

number

MA. 330-00

MA . . 344-O

MA. 372-00

MA. 390-00

MA. 390-O

MA. 410-00

MA. 410-O

MA. 420-00

MA. 420-O

MA. 430-00

MA. 430-O

MA. 434-O

MA. ,440-00

MA. 440-O DESCRIPTION GEARBOX and GEARBOX CQNTROL

*O 4

Characteristics and special features of the gearbox

- Four-speed gearbox with pedal-operated clutch

- Gearbox.with torque converter

- Draining and refilling the gearbox and the torque converter

- Five-speed gearbox with pedal-operated clutch

Adjusting the gearbox control mechanism DRIVE SttiFTS

Characteristics and special features of the drive-shafts SOURCE AND RESERVE OF PRESSURE

Characteristics and special features of the source and reserve of pressure -

hydraulic system

Checking the hydraulic components on the vehicle FRONT AXLE

+O 7

Characteristics and special features of the front axle

Checking and adjusting the front axle :

- Checking the camber

- Checking and adjusting the castor angle

- Checking and adjusting the wheel alignment

- Checking and adjusting the steering geometry

- Checking the steering for straight line deviation (

whirfes cjq77ippcJrl with REAR AXLE

*O 8

Characteristics and special features of the rear axle

Checking and adjusting the rear axle SUSPENSION SYSTEM

I,0 9

Characteristics and special features of the suspension system

Checking and adjusting the suspension and its controls

Adjusting the anti-roll bar STEERING SYSTEM

*@

Characteristics and special features of the steering system

- Manual steering

- Power steering with powered return

Checking and adjusting the steering (see Op. MA. 410-O )

Ob

4

Ob 5

Ok 6

Ok 7

O+ 8

O1) 9

Page 76 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION N” MA. 142.000 : c ,, P)C rni ,t n i,,, <‘ 0, I/?< < rirheri,/irin.

Op. MA. 142.000

5

2

:

m

2

-

b E

*

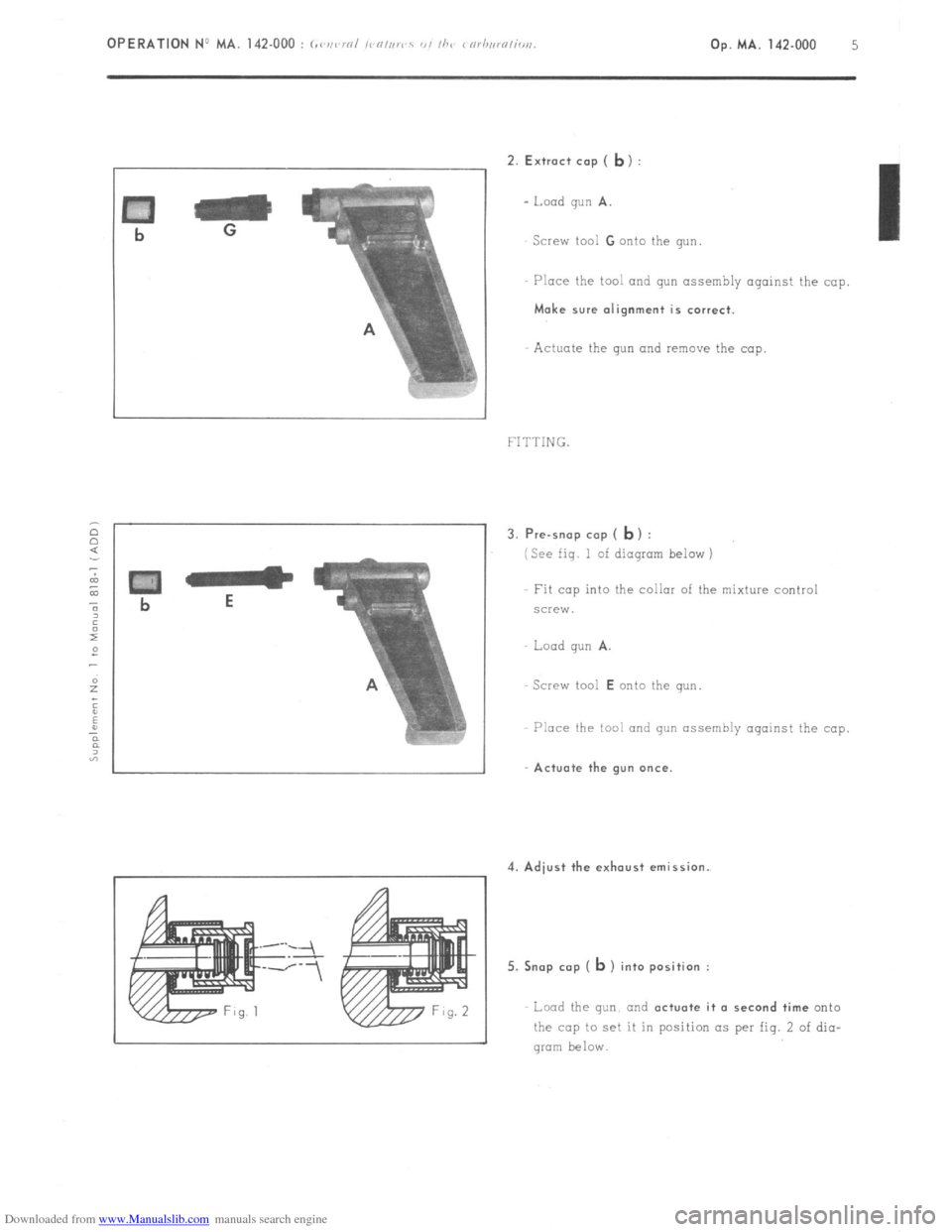

2. Extract cop ( ly) :

- Load gun A.

Screw tool G onto the gun.

Place the tool and gun assembly against the cop

Make sure alignment is correct.

Actuate the gun and remove the cop.

FITTING.

3.

~re-rno~ cap ( b) :

(See fig. I of diagram below )

Fit cap into the collar of the mixture control

screw.

Load qun

A.

Screw tool E onto the wn

Place the tool and gun assembly against the cop

’ 1 1 Actuate the gun once.

4. Adjust the exhaust emission.

I

5. ~nop cop (

b ) into position :

Load the gun. and (~ctuote it o second time onto

the cop to set it in position as per fig. 2 of dio-

gram below.

Page 180 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 236.0 : C h<,rki,,p a,,d nd;r,slh,p I/w jwllr\s aurl /x,//s Op. MA. 2360 I

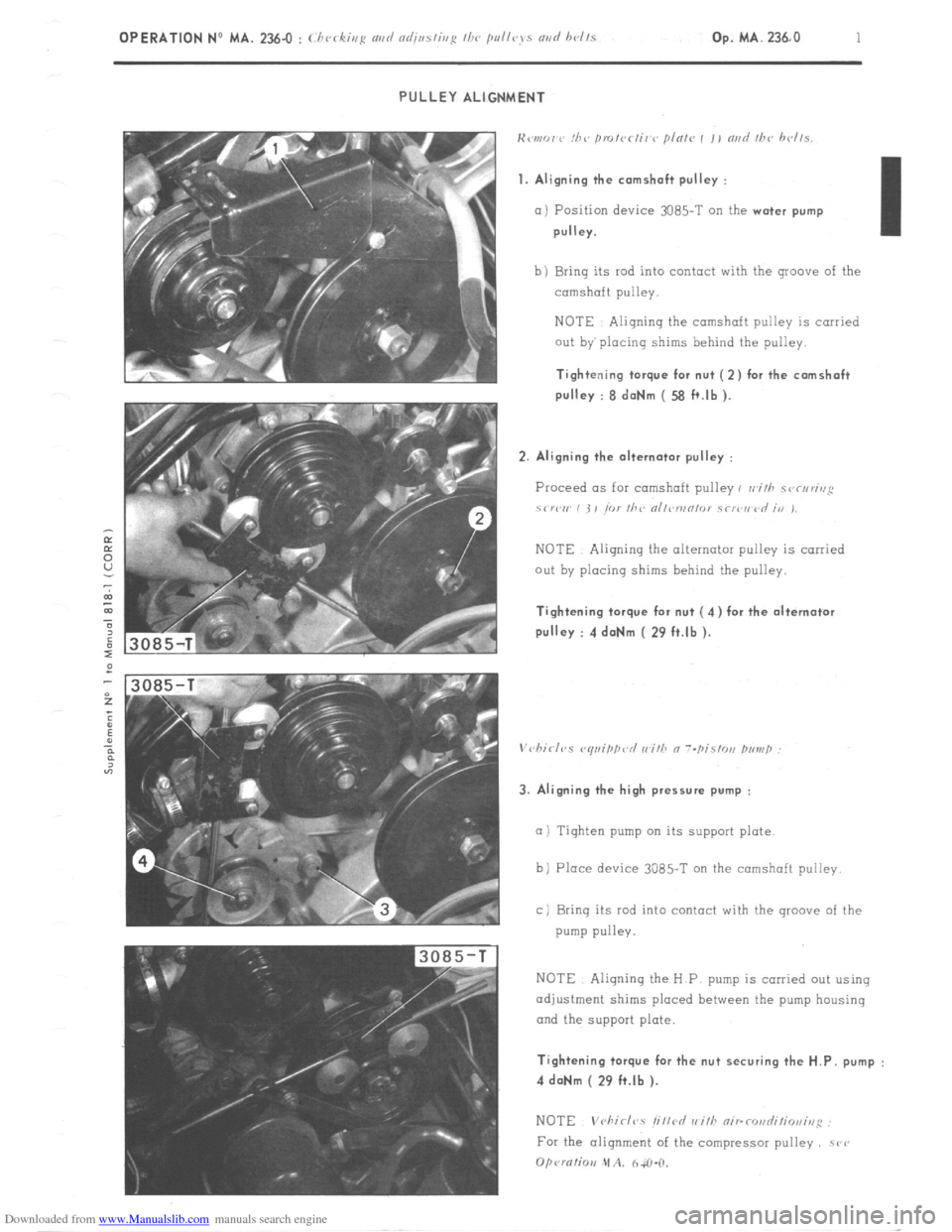

PULLEY ALIGN& IENT

1. Aligning the camshaft pulley :

a) Position device 3085-T on the water pump

pulley.

b) Bring its rod into contact with the groove of the

camshaft pulley.

NOTE Aligning the camshaft pulley is carried

out by’plocing shims behind the pulley.

Tightening torque for nut (2) for the comshoft

pulley : 8 daNm ( 58 h.lb ).

2. Aligning the alternator pulley :

Proceed as for camshaft pulley / ,,,;/I> s

NOTE Aligning the alternator pulley is carried

out by plocinq shims behind the pulley.

Tightening torque for nut (4) for the olternatov

pulley : 4 daNm ( 29 ft.lb ).

3. Aligning the high pressure pump :

a ) Tighten pump on its support plate

b) Place device 3085-T on the camshaft pulley.

c) Brinq its rod into contact with the groove of the

pump pulley.

NOTE Aliqninq the H P pump is curried out using

adjustment shims placed between the pump housing

and the support plate.

Tightening torque for the nut securing the H.P. pump :

4 doNm ( 29 ft.lb ).

NOTE Vchirlc,s filled ,,~;//I oirrrii,rli/iriniii,~

For the alignment of the compressor pulley, SLO

Opr~mrio~, MA, ~,40.,-(,.

Page 232 of 394

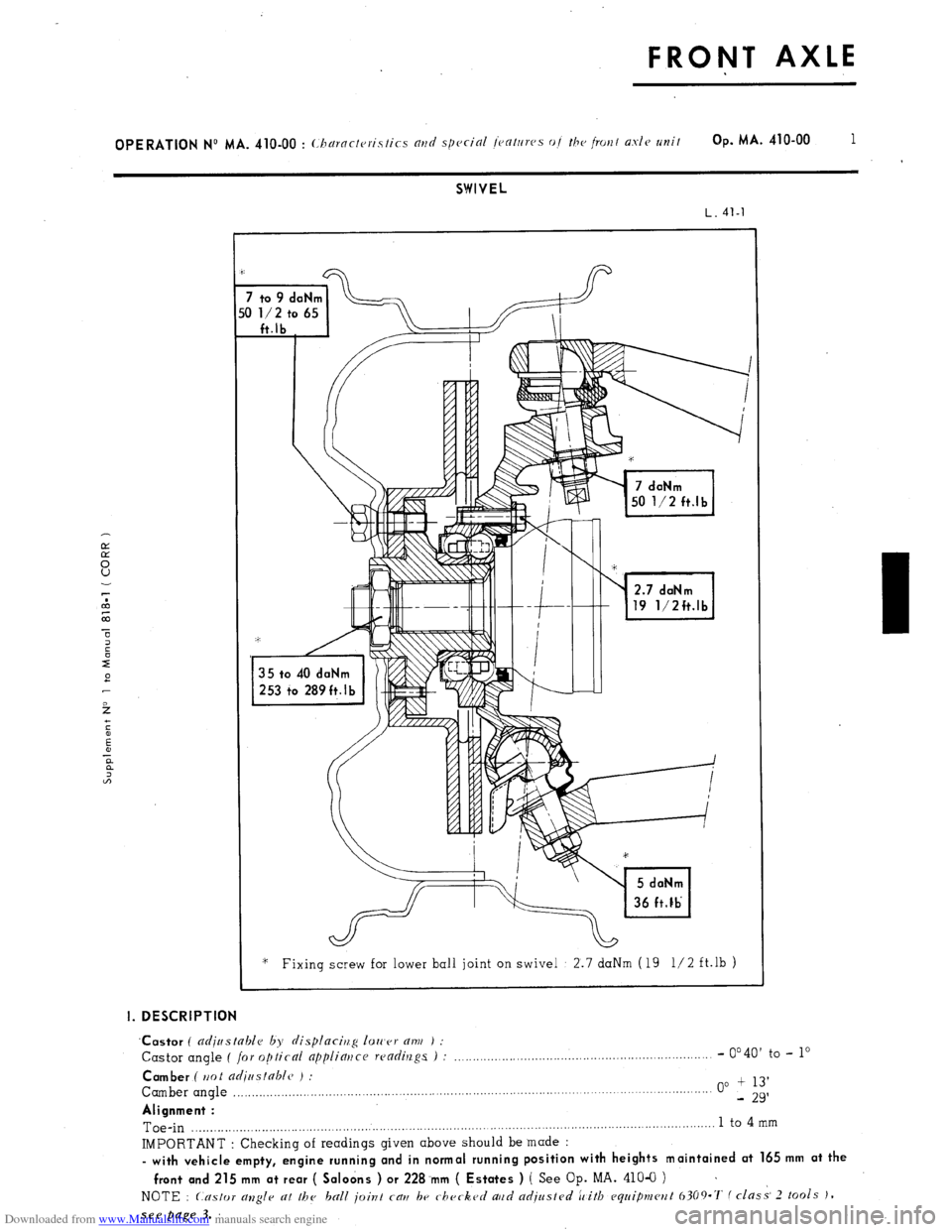

Downloaded from www.Manualslib.com manuals search engine FRONT AXLE

OPERATION No MA. 410-00 : Charnctvristics arid S(ICJCI’O~ /‘rattrres o,i the front as/e unit Op. MA. 410-00 1

t

SWIVEL

L. 41-l

2.7 daNm

19 1/2ft.lb

‘* Fixing screw for lower ball joint on swivel 2.7 daNm (19 l/2 ft.lb )

I. DESCRIPTION

‘Castor

( adjustable by displacirlg 1011’er am ) :

Castor angle ( for optical appliatjce readings ) : _.,,....._..._,......,,,,,,.......,.,........,,,.,......,,............ - 0’40’

to - lo

Camber ( ttot adiastable ) :

Camber angle ,,.,,,.,,,..._,,,__.....,...,,.........,,.,.......................................................................... . . . . . 00 + 13’

- 29’

Alignment :

Toe-in ,.........._.__...,.,..,.,,.,,,,,.........,,,,.,......................,....................................................................... 1 to 4

mm

IMPORTANT : Checking of readings given above should be made :

- with vehicle empty, engine running and in normal running position with heights maintained at 165 mm at the

front and 215 mm at rear ( Saloons ) or 228.mm ( Estates ) ( See

Op. MA. 410-O ) ~

NOTE : Castor allgle at the ball joint cau be checked aud adjusted ic’itb equipmcwt 6309.7‘ f class- 2 tools J,

see page 3.

Page 236 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 410-O : ( /,c

1

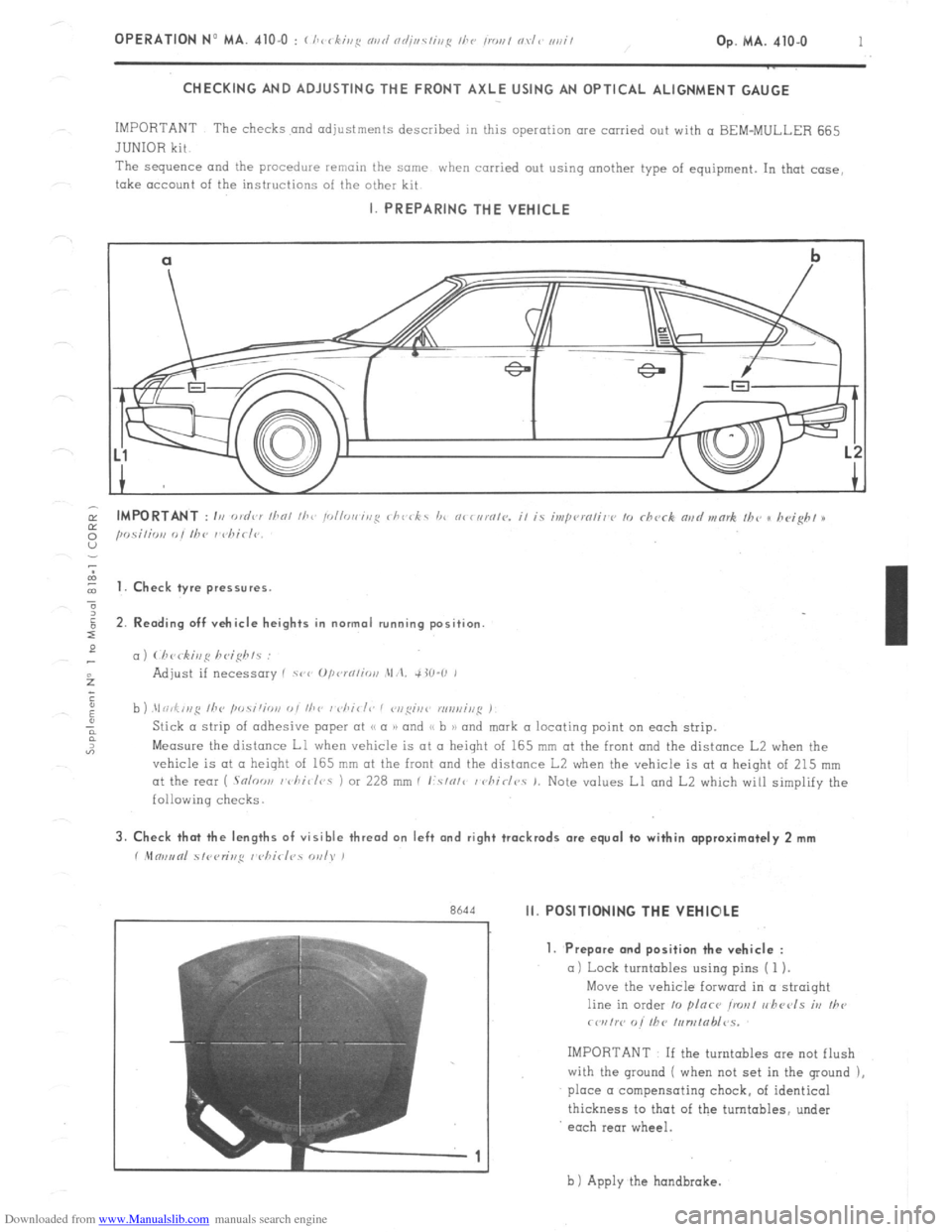

CHECKING AND ADJUSTING THE FRONT AXLE USING AN OPTICAL ALIGNMENT GAUGE

IMPORTANT The checks and adjustments described in this operation are carried out with a BEM-MULLER 665

JUNIOR kit

The sequence and

the procedure remain the same when carried out using another type of equipment. In that case,

take account of the instructions of the other kit I. PREPARING THE VEHICLE

cl

b

-.

I t 1. Check tyre pressures.

2. Rending off vehicle heights in normal running position

c,)

b ) .\I ri,f,,,g /he ,w.s;‘;o,,

Measure the distance Ll when vehicle is at II height of 165 mm at the front and the distance L2 when the

vehicle is at CL height of 165 mm at the front and the distance L2 when the vehicle is at a height of 215 mm

at the rear ( .Snloo,, I vhi~/r,s 1 or 228 mm I I:.s/o/c / chirlr,. 1. Note values Ll and L2 which will simplify the

following checks. 3. Check that the lengths of visible thread on left and right trackrods are equal to within approximately 2 mm

r .Mm,,tnl 51<,<,r;r,,q I <,hirl?s WI). )

r

Rh‘td Ii. POSITIONING THE VEHIOLE

7

-1 1. Prepare and position the vehicle :

a) Lock turntables using pins ( 1 ).

Move the vehicle forward in a straight

line in order 10 plnce ironl r,hccls iv

Ihe

rwrtw o/’ fhC /,,n,tab/~s.

IMPORTANT If the turntables ore not flush

with the ground ( when not set in the ground ),

place a compensating chock, of identical

thickness to that of the turntables, under

each rear wheel.

b 1 Apply the hondbrake.

Page 237 of 394

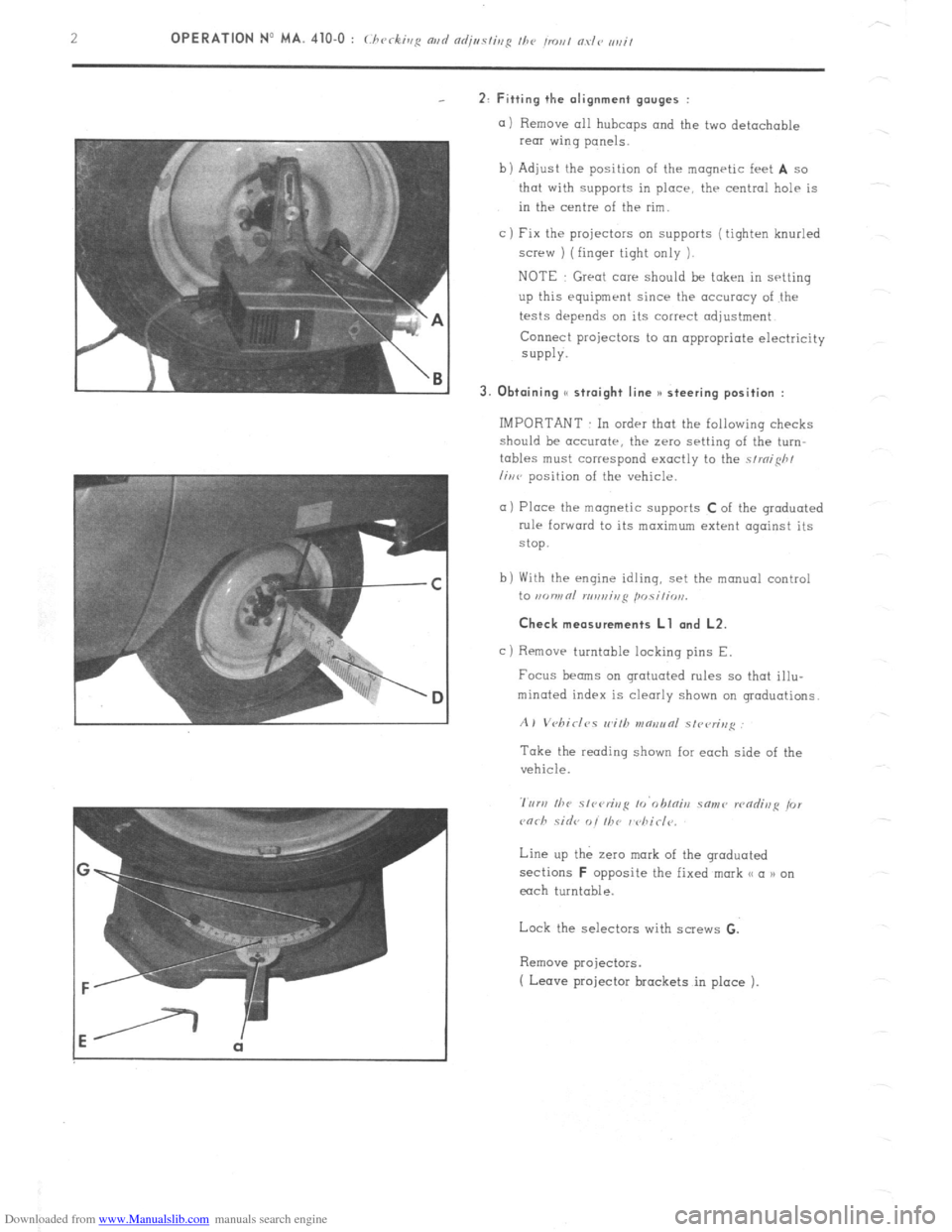

Downloaded from www.Manualslib.com manuals search engine 2: Fitting the alignment gauges :

a) Remove all hubcaps and the two detachable

rear wing panels.

b) Adjust the position of the magnetic feet

A so

that with supports in place, thr central help is

in the centre of the rim.

c ) Fix the projectors on supports ( tighten knurled

screw ) (finger tight only 1.

NOTE Great care should be taken in setting

up this equipment since the accuracy of the

tests depends on its correct adjustment

Connect projectors to on appropriate electricity

SUPPlY.

3. Obtaining S( straight line )I steering position :

IMPORTANT In order that the following checks

should be accurate, the zero setting of the turn-

tables must correspond exactly to the strnifih/

liwv position of the vehicle.

a) Place the magnetic supports C of the graduated

rule forward to its maximum extent against its

stop.

b) With the engine idling, set the manual control

to ,KJWRl n,n,,ir,ji posili, ,,,.

Check measurements Ll and L2.

c)

Removr turntable locking pins E.

Focus beams on grotuoted rules so that illu-

minated index is clearly shown on graduations.

A) Vebirlc,s wilh v~aeunl slvvrin,~

Take the reading shown for each side of the

vehicle.

Line up the zero mark of the graduated

sections

F opposite the fixed mark << a n on

each turntable.

Lock the selectors with screws G.

Remove projectors.

( Leave projector brackets in place ).

Page 241 of 394

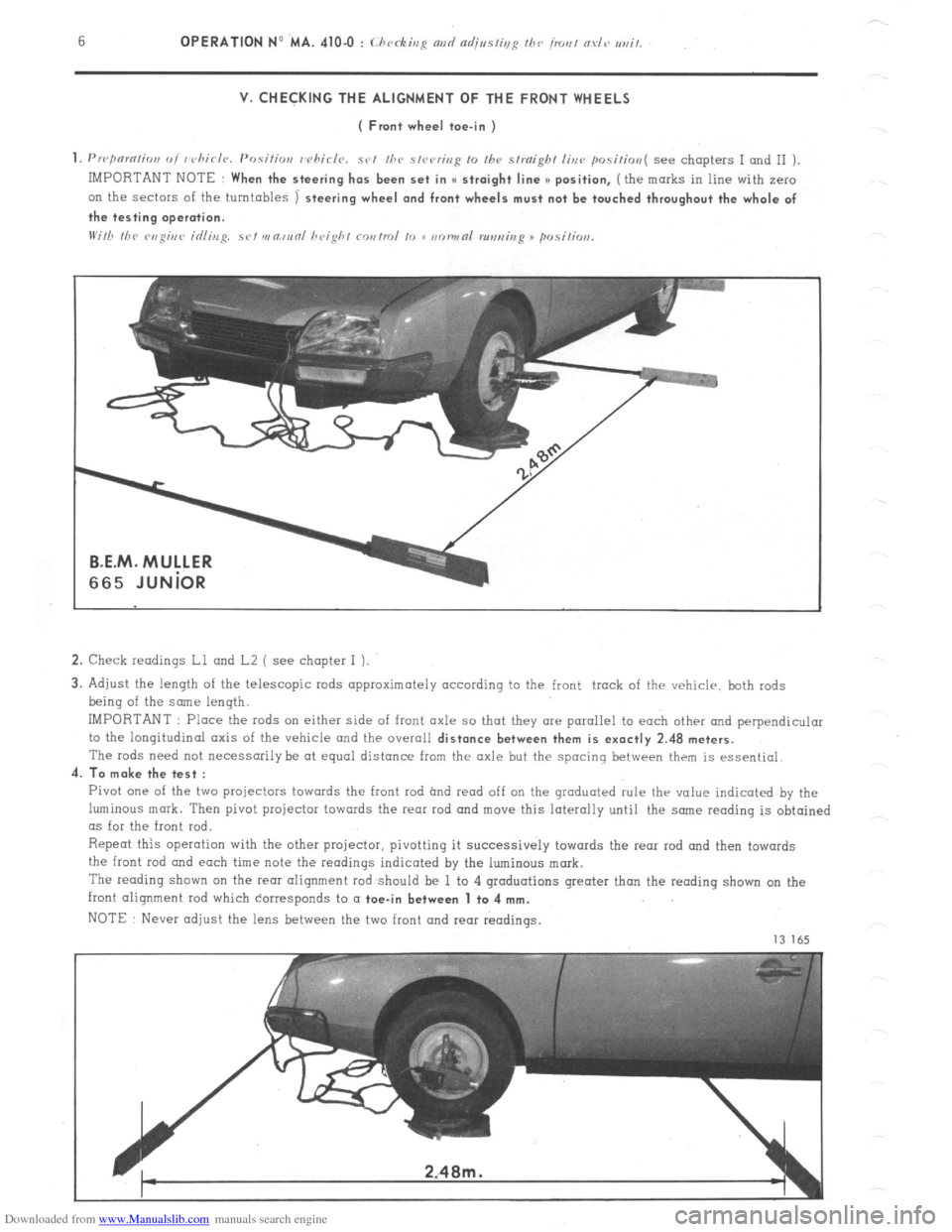

Downloaded from www.Manualslib.com manuals search engine V. CHECKING THE ALIGNMENT OF THE FRONT WHEELS

( Front wheel toe-in )

1. Prrpnmtion oi whirlr~. Positior,

whirls. set /he s,rering 10 Ihv straight line positim~( see chapters I and II )

IMPORTANT NOTE

When the steering has been set in I( straight line >) position, (the marks in line with zero

on the sectors of the turntables

1 steering wheel and front wheels must not be touched throughout the whole of

the testing operation.

2. Check readings Ll and L2 ( see chapter I ).

3. Adjust the length of the telescopic rods approximately according to the front track of the vehicle, both rods

being of the some length.

IMPORTANT : Place the rods on either side of front axle so that they are parallel to each other and perpendicular

to the longitudinal axis of the vehicle and the overall

distance between them is exactly 2.48 meters.

The rods need not necessarily be at equal distance from the axle but the spacing between them is essential.

4.

To make the test :

Pivot one of the two projectors towards the front rod hnd read off on the graduated rule thr value indicated by the

luminous mark. Then pivot projector towards the rear rod and move this laterally until the snne reading is obtained

as for the front rod.

Repeat this operation with the other projector, pivotting it successively towards the rear rod and then towards

the front

rod and each time note the readings indicated by the luminous mark.

The reading shown on the rem alignment rod should be 1 to 4 graduations greater than the reading shown on the

front alignment rod which corresponds to a

toe-in between 1 to 4 mm.

NOTE Never adjust the lens between the two front and rear readings.

13 165

Page 242 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 410-O : I hvr-6iq n,,d od;n.s/isg /hc /~,a, nrle uei/ Op. MA. 410-O 7

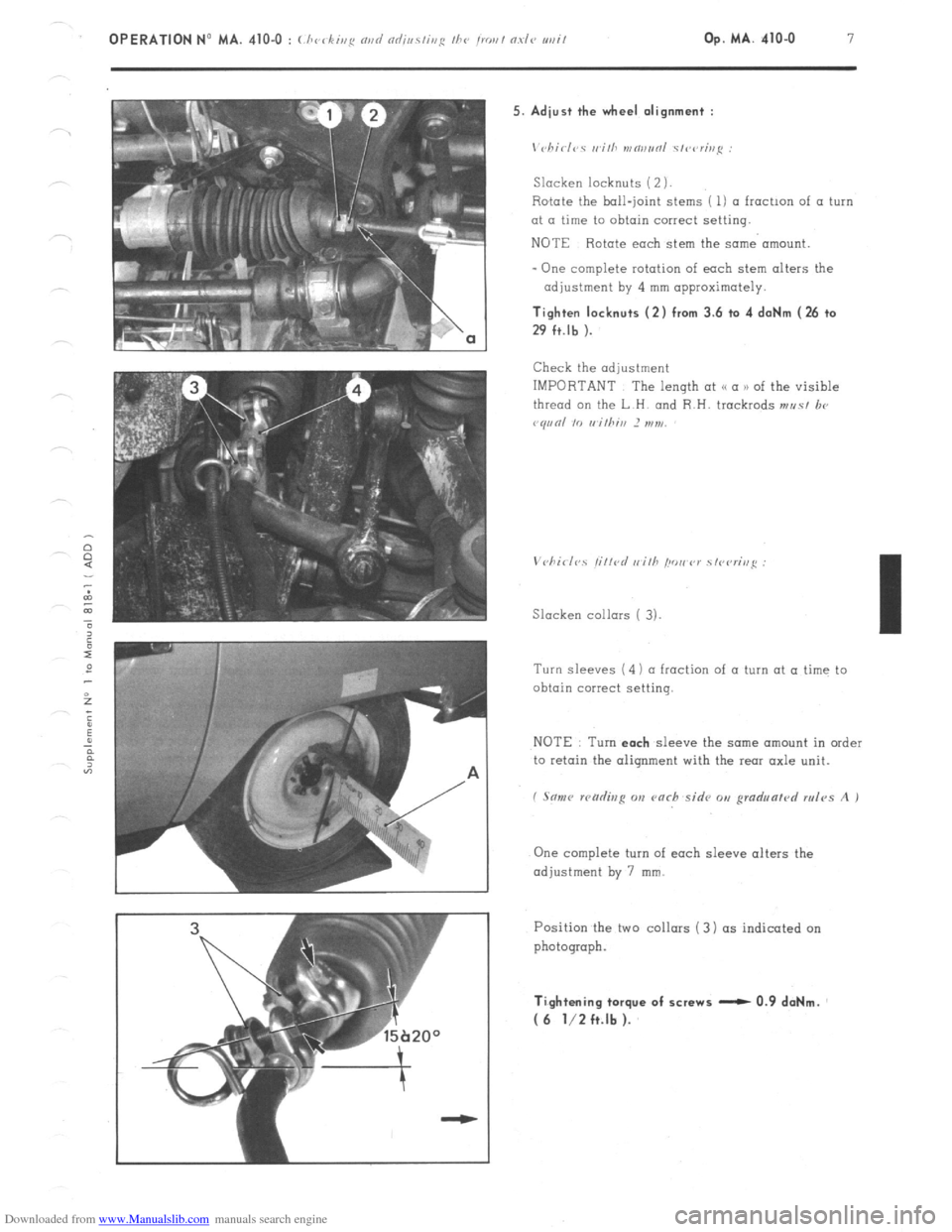

’ 15b20° 5. Adiust the wheel alignment :

\‘chirl‘,s II ilh mw,r,ol s/wrh,i: :

Slacken locknuts (2 ).

Rotate the ball-joint stems ( 1) a froctmn of a turn

at a time to obtain correct setting.

NOTE Rotate each stem the same’ amount.

- One complete rotation of each stem alters the

adjustment by 4 mm approximately. Tighten locknuts (2) from 3.6 to 4 daNm (26 to

29 ft.lb ).

Check the adjustment

IMPORTANT The length at (< a n of the visible

thread on the L.H. and R.H. trackrods ,,,r,s/ lx,

vq,,nl IO rrithin 2 ,,,7,,,

Slacken collars ( 3).

Turn sleeves (4) ~1 fraction of a turn at a time to

obtain correct setting.

NOTE Turn each

sleeve the same amount in order

to retain the oiiqnment with the rear axle unit.

I Son<, wcidisp on varh sidv o,, gmd,,lrrn/r,d rules A I

One complete turn of each sleeve alters the

adjustment by 7 mm.

Position the two collars ( 3) (IS indicated on

photograph. Ti.ghtening torque of screws - 0.9 daNm.

( 6 l/2 ft.lb ).

Page 243 of 394

Downloaded from www.Manualslib.com manuals search engine a OPERATION N’ MA. 410-O : (./~rrkiq N,,I/

VI. CHECKING AND ADJUSTING THE STEERING GEOMETRY

The crossmember supporting the steering has slots at its fixing point on the front subframe.

Any vertical movement of this crossmember alters the steering geometry.

WARNING

This operation is only to

be carried out in certain ccxses such as

-accidental impact, with repercussions on the steering system.

-work on the vehicle entoiling removal of steering crossmember.

- vehicle with poor

road stability ( p oar stright-line stability) 01 with excessive tyre weor.

CHECKING

1, Prepare the vehicle. as for checking front wheel

alignment ( Srr ~ho/,lvr

V I.

NOTE

A ) \In,,unl ~fi~<,r;,,~ I chiclvs :

With the steering in the /< straightahead 1)

position. lock the steering using CI commercially

available tool ( FACOM _ MULLER -WILMONDA)

B) PO,, P)’ \,r,rr;ng r’cliirl<,.s :

Do not actuate steering wheel during check

( hydraulic locking of rock 1.

As a precaution. a steering wheel iocking

tool may also be

used. 2. Mark position of vehicle in relation to

ground :

Secure a weighted length of string to the front

bumper. and

mark the position of the weiqht on

the ground ( The

object of this is to always bring

the vehicle

bock to the some position in order to

carry out correct measurements 1.

NOTE Other procedure

This check having to be carried out wheel hy wheel.

it is possible to use the free projector.

Secure projector to scuttle panel crossmemher, and

focus it onto a fixed object, which will indicate the

initial positioning of the vehicle.

3. Measure the variation in the wheel alignment wheel

by wheel, ds o function of the height of the vehicle.

a) From Ihc m~nwnl rlri,:ir,g posi/ior, lo /hc hi@

posilio,, f ftouad 1 :

With vehicle in mwmal rlriving position.

engine running ond position marked in relation

to groond :

Mark position of luminous spot on front graduated

rule.

Place m’anual height control lever in hi&

posilirrrl.

and wait for vehicle to stabilize.

Check and adjust if necessary position of vehicle

in relation to ground. ( II

eight 01 Inmbrous spol

ou /i wd 0 hit,< I J.

Mark position of luminous spot on front graduated

rule. and on rear one

1) Front and rear readings ore the some (no

variation in alignment in the wheel 1.

NOTE : The reading f I,i$ or lorr posilios J

on the qroduated rules differs from the initial

reading f non,,nl >r,nrlinl:

position J because

the front track has altered.

2) Front and rear readings ore different ( in this

case the alignment has oltered,.either in

toe-in or toe-out ).

0 to 1 mm toe-in is permissible on either wheel

b) ,:rr ,,I, /bv IIDIINRI hi&g ,,osi,;orr lo ,I,<, lo,,

posiliov f Hrlmuad ) :

Proceed OS for previous measurements, place

manual height control lever in low position. In

this case. the permissible difference in oliqn-

ment

is O.to 1 mm toe-out.

Page 246 of 394

Downloaded from www.Manualslib.com manuals search engine REAR AXLE

OPERATION No MA. &!O-OO : (.;haracteristics mtd special l~alur~s 01 rho war O.Y/C wit Op. MA. 420-00 1

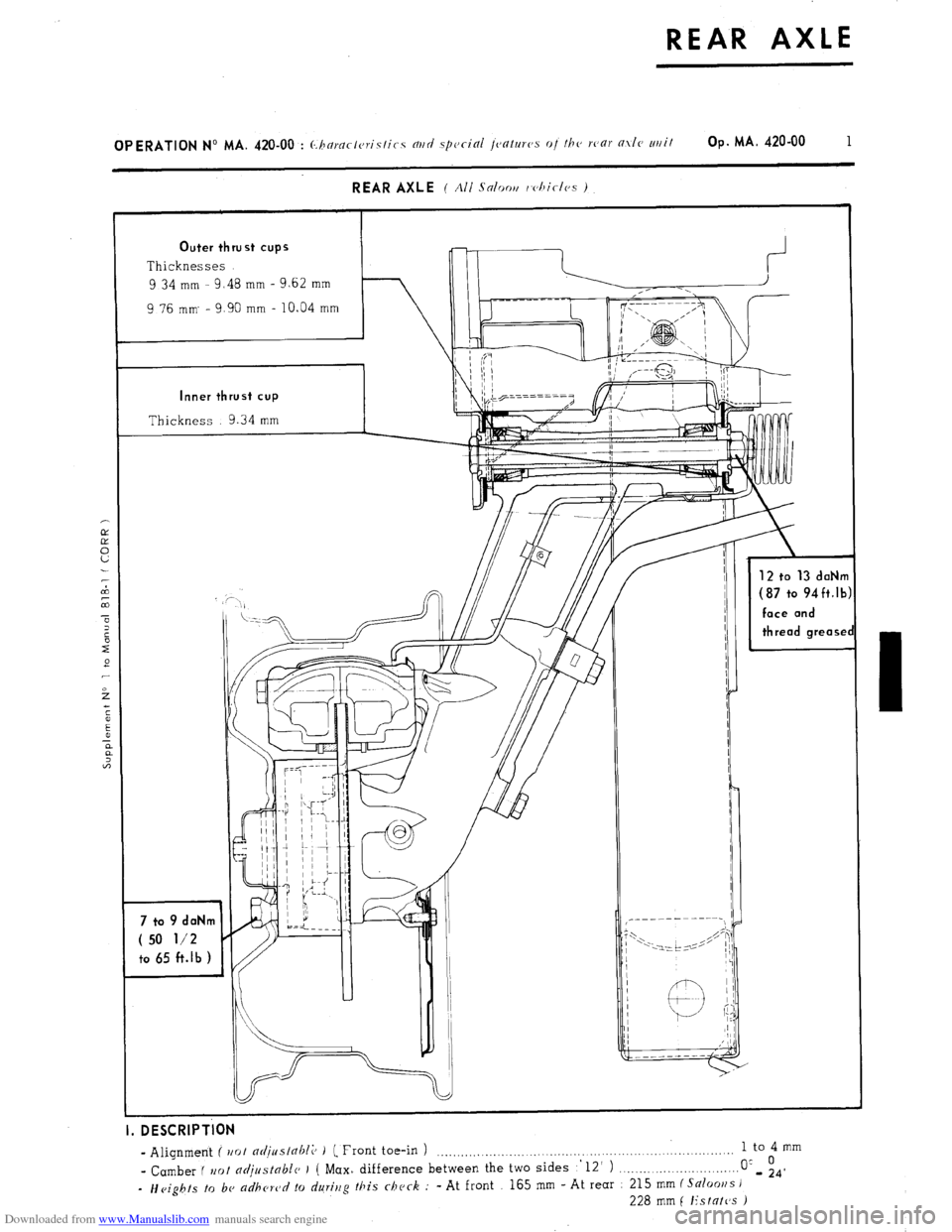

I Outer thrust cups

Thicknesses 9 34

mm -

9.48 mm - 9.62 mm 9 76

mm’ -

9.90 mm - 10.04 mm 12 to 13 daNn

DESCRIPTION

-

Alignment ( trot nr/juslabl;J ) (. Front toe-in ) ._....,.,.,....,,._........._._._....._..._........ ..,............__._... 1 to 04 mm

- Camber I uot adjustable

J ( Max. difference between the two sides .’ 12’ ) ,,.__._..._...._,......._._... O”- 24,

- Heights to bc a&crc,d to durirrg this chvck : - At front 165 mm - At rear 215 mm I Saloons )

228

mm [ /?stntvs )