Castor Citroen CX 1981 1.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1981, Model line: CX, Model: Citroen CX 1981 1.GPages: 394

Page 5 of 394

Downloaded from www.Manualslib.com manuals search engine .r.

-/1

LIST OF OPERATIONS

IN MANUAL 818-1

a CX Petrol )) 7,rhifles

--

-

f-7

i---- _--

-

Operation

number

MA. 330-00

MA . . 344-O

MA. 372-00

MA. 390-00

MA. 390-O

MA. 410-00

MA. 410-O

MA. 420-00

MA. 420-O

MA. 430-00

MA. 430-O

MA. 434-O

MA. ,440-00

MA. 440-O DESCRIPTION GEARBOX and GEARBOX CQNTROL

*O 4

Characteristics and special features of the gearbox

- Four-speed gearbox with pedal-operated clutch

- Gearbox.with torque converter

- Draining and refilling the gearbox and the torque converter

- Five-speed gearbox with pedal-operated clutch

Adjusting the gearbox control mechanism DRIVE SttiFTS

Characteristics and special features of the drive-shafts SOURCE AND RESERVE OF PRESSURE

Characteristics and special features of the source and reserve of pressure -

hydraulic system

Checking the hydraulic components on the vehicle FRONT AXLE

+O 7

Characteristics and special features of the front axle

Checking and adjusting the front axle :

- Checking the camber

- Checking and adjusting the castor angle

- Checking and adjusting the wheel alignment

- Checking and adjusting the steering geometry

- Checking the steering for straight line deviation (

whirfes cjq77ippcJrl with REAR AXLE

*O 8

Characteristics and special features of the rear axle

Checking and adjusting the rear axle SUSPENSION SYSTEM

I,0 9

Characteristics and special features of the suspension system

Checking and adjusting the suspension and its controls

Adjusting the anti-roll bar STEERING SYSTEM

*@

Characteristics and special features of the steering system

- Manual steering

- Power steering with powered return

Checking and adjusting the steering (see Op. MA. 410-O )

Ob

4

Ob 5

Ok 6

Ok 7

O+ 8

O1) 9

Page 232 of 394

Downloaded from www.Manualslib.com manuals search engine FRONT AXLE

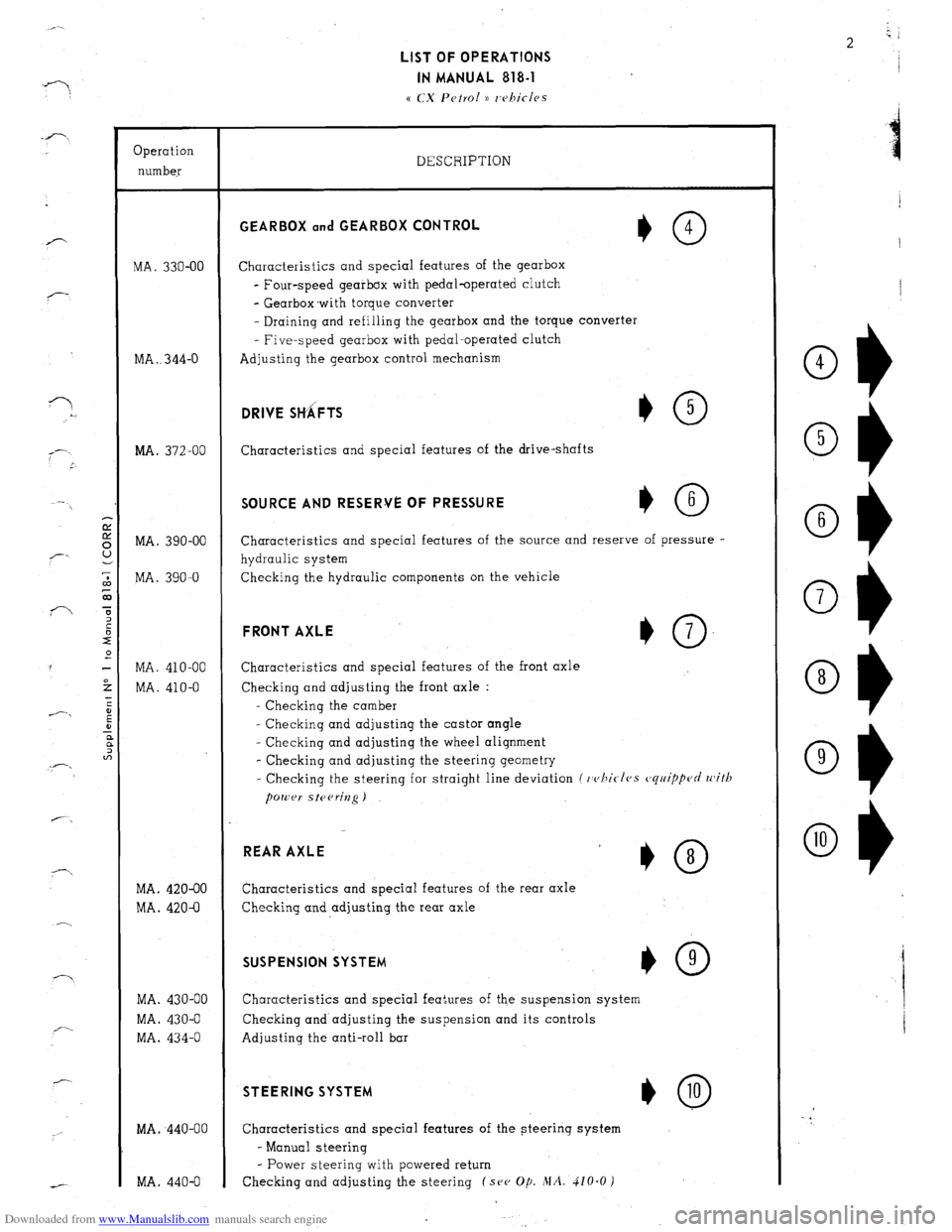

OPERATION No MA. 410-00 : Charnctvristics arid S(ICJCI’O~ /‘rattrres o,i the front as/e unit Op. MA. 410-00 1

t

SWIVEL

L. 41-l

2.7 daNm

19 1/2ft.lb

‘* Fixing screw for lower ball joint on swivel 2.7 daNm (19 l/2 ft.lb )

I. DESCRIPTION

‘Castor

( adjustable by displacirlg 1011’er am ) :

Castor angle ( for optical appliatjce readings ) : _.,,....._..._,......,,,,,,.......,.,........,,,.,......,,............ - 0’40’

to - lo

Camber ( ttot adiastable ) :

Camber angle ,,.,,,.,,,..._,,,__.....,...,,.........,,.,.......................................................................... . . . . . 00 + 13’

- 29’

Alignment :

Toe-in ,.........._.__...,.,..,.,,.,,,,,.........,,,,.,......................,....................................................................... 1 to 4

mm

IMPORTANT : Checking of readings given above should be made :

- with vehicle empty, engine running and in normal running position with heights maintained at 165 mm at the

front and 215 mm at rear ( Saloons ) or 228.mm ( Estates ) ( See

Op. MA. 410-O ) ~

NOTE : Castor allgle at the ball joint cau be checked aud adjusted ic’itb equipmcwt 6309.7‘ f class- 2 tools J,

see page 3.

Page 234 of 394

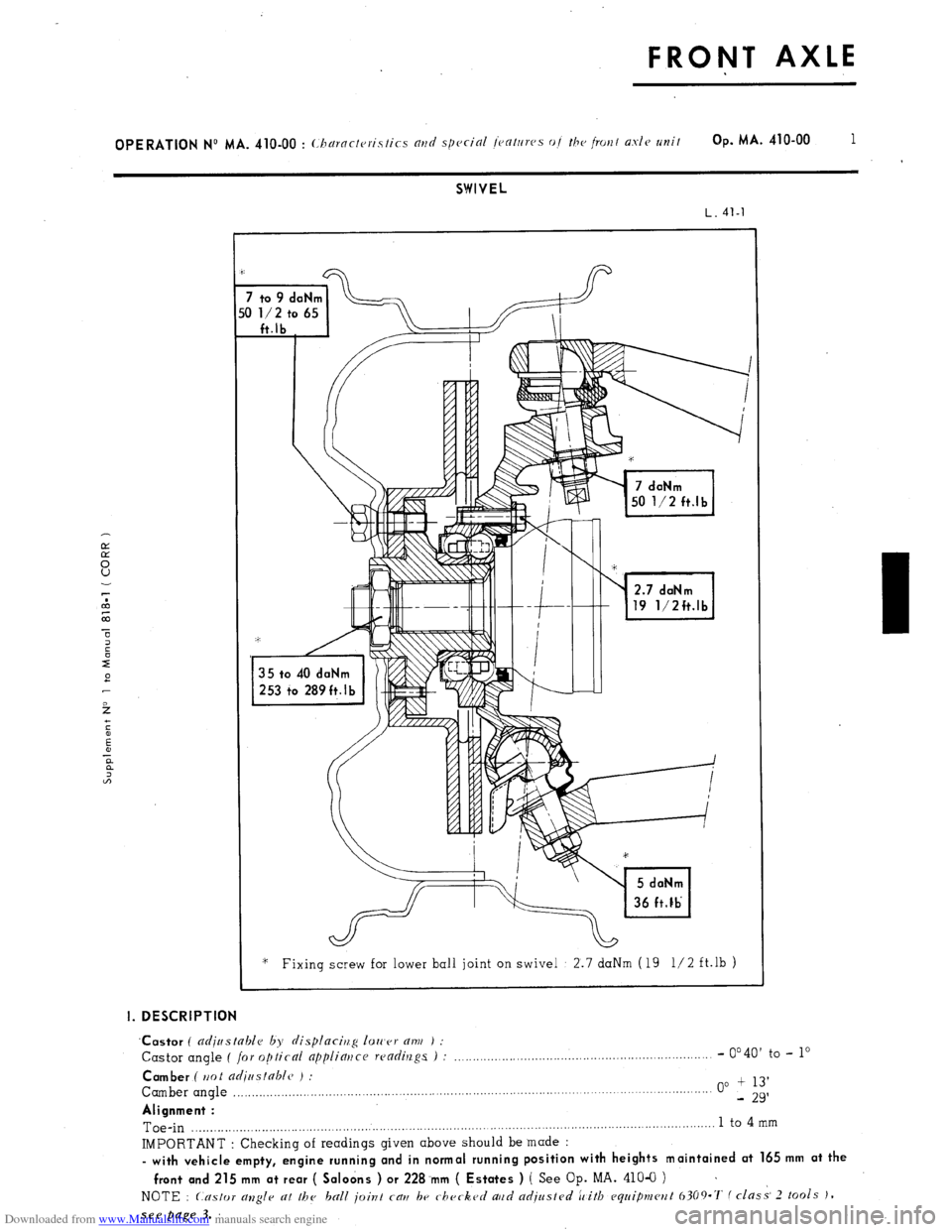

Downloaded from www.Manualslib.com manuals search engine Shims for adjusting castor angle

Thickness from 0.5 to 6 mm ,

in steps of 0.5mm (- - Lower wheelorms :

E Lateral cleoronce of wheelarm. before tightening nut (3 1

z ( fbmugh rhoicr o/ wnshr~r I I u I ,..................,.,............................,..,..,.,........................,....,...... 0 to 0.9 mm

2 NOTE To carry out this measurement, it is necessary to use tool 6312-T. class 2. in order to ovoid any mistakes

t due to the expanding of the G fluid-bloc n bushes. g Checking and adjusting the castor angle, using tool 6309-T :

s Assemble the components of tool 6309-T and place checking pin A in the groove of pod C.

2 Slacken screw D,

and tilt pad C so that bush B is squarely in contact with it, over its entire contact face. and

f tighten screw D.

; Measure distance L. It must be between 49 and 50.5 mm.

: NOTE A I mm rhaug~~ ia the Ihirknrss o//he adjr~s/mw/ shims produc-~s a Imm r~ariatim oi rlislmc~ L.

Remove the wheelarms, and determine the distribution of shims ( 1) and ( 2 ) in order to obtain distance L.

FRONT FRON T

Page 239 of 394

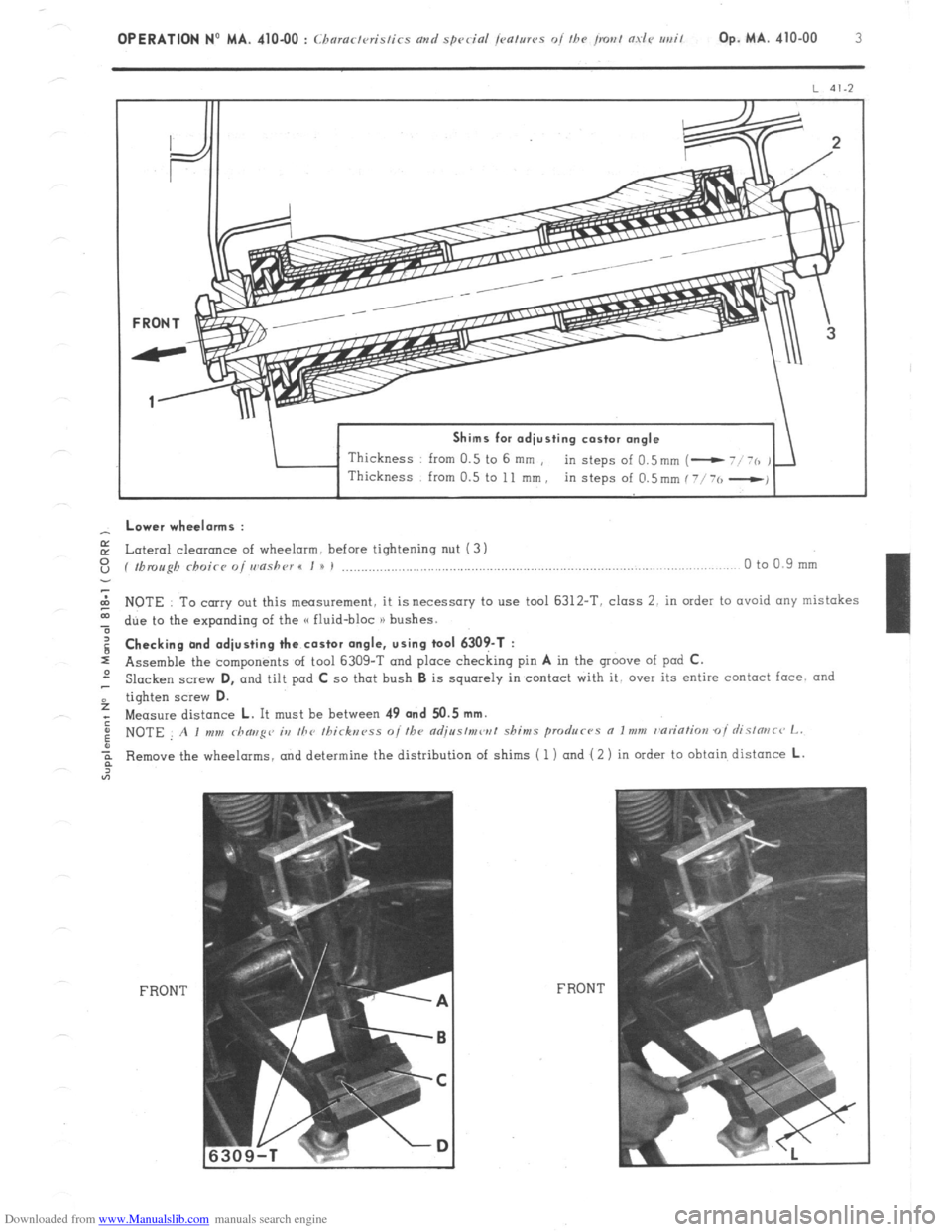

Downloaded from www.Manualslib.com manuals search engine III. CHECKING THE CAMBER ANGLE

NOTE : The camber angle is not adjustable.

1. Prepare vehicle and set in position f src chapfrrs

I and 2 ).

2. Setting up checking apparatus :

Place the apparatus on the magnetic support of the

wheel to be checked.

Use the axis corresponding to the blue mmu A..

Keep the level in a horizontal position. Tighten

locking screw ( 1).

3. Checking the comber angle :

IMPORTANT : Check that the reading Ll has not

changed ( SC<’ rhnprcr I ).

a) Turn the disc (2 ) until the fixed spirit-level

bubble (3 1 is centred.

b) Note in blur scnle (at o a n ) the reading of the

comber rmqle.

c ) Carry out the same operation on the other

wheel.

Comber angle must be between 0’ + 13’ - 29’

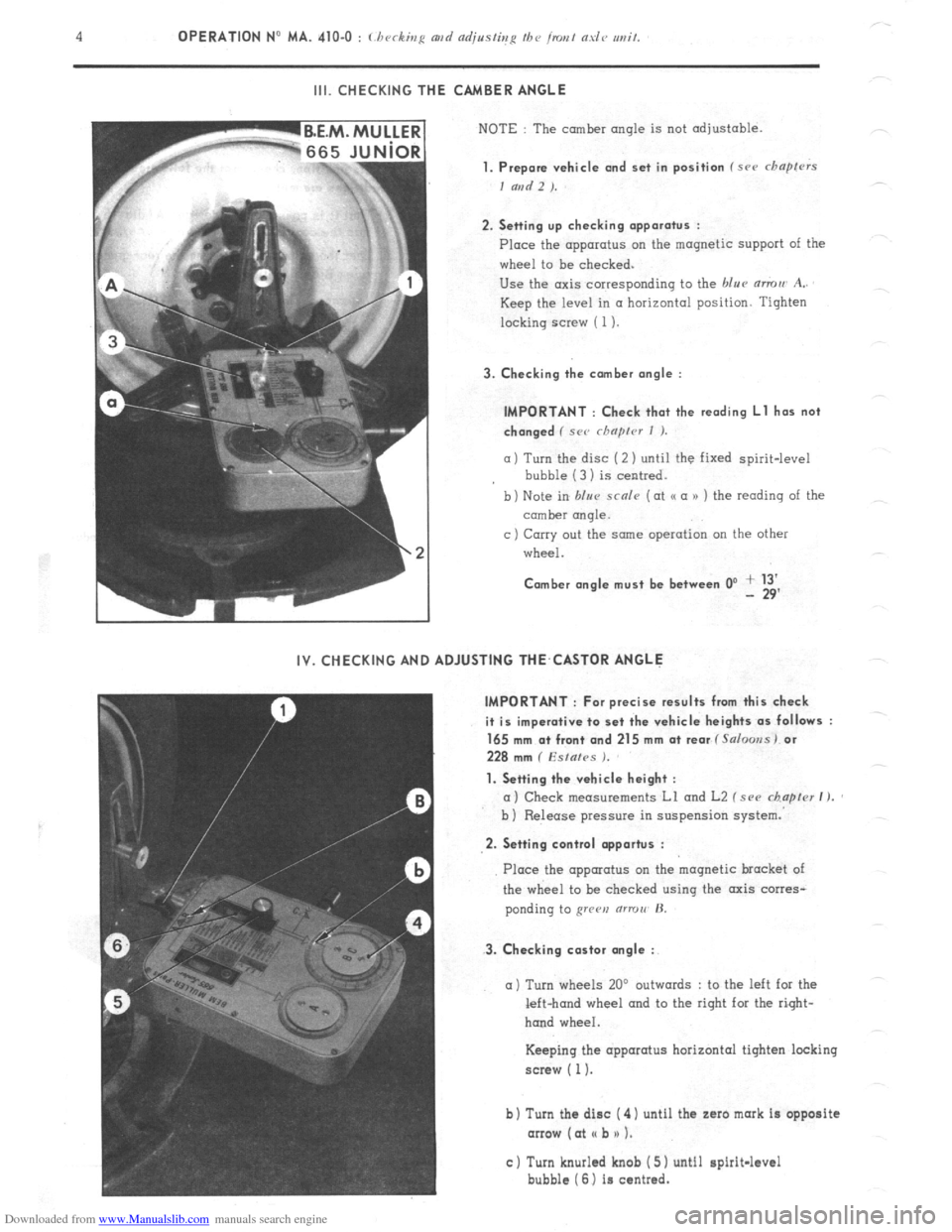

IV. CHECKING AND ADJUSTING THE,CASTOR ANGLE

IMPORTANT : For precise results from this check

it is imperative to set the vehicle heights as follows :

165 mm a+ front and 215 mm at rear f Salooss) or

228 mm ( Esfafes ).

1. Setting the vehicle height :

a) Check measurements Ll and L2 f see chapter I ).

b ) Release pressure in suspension system.

2. Setting control opportus :

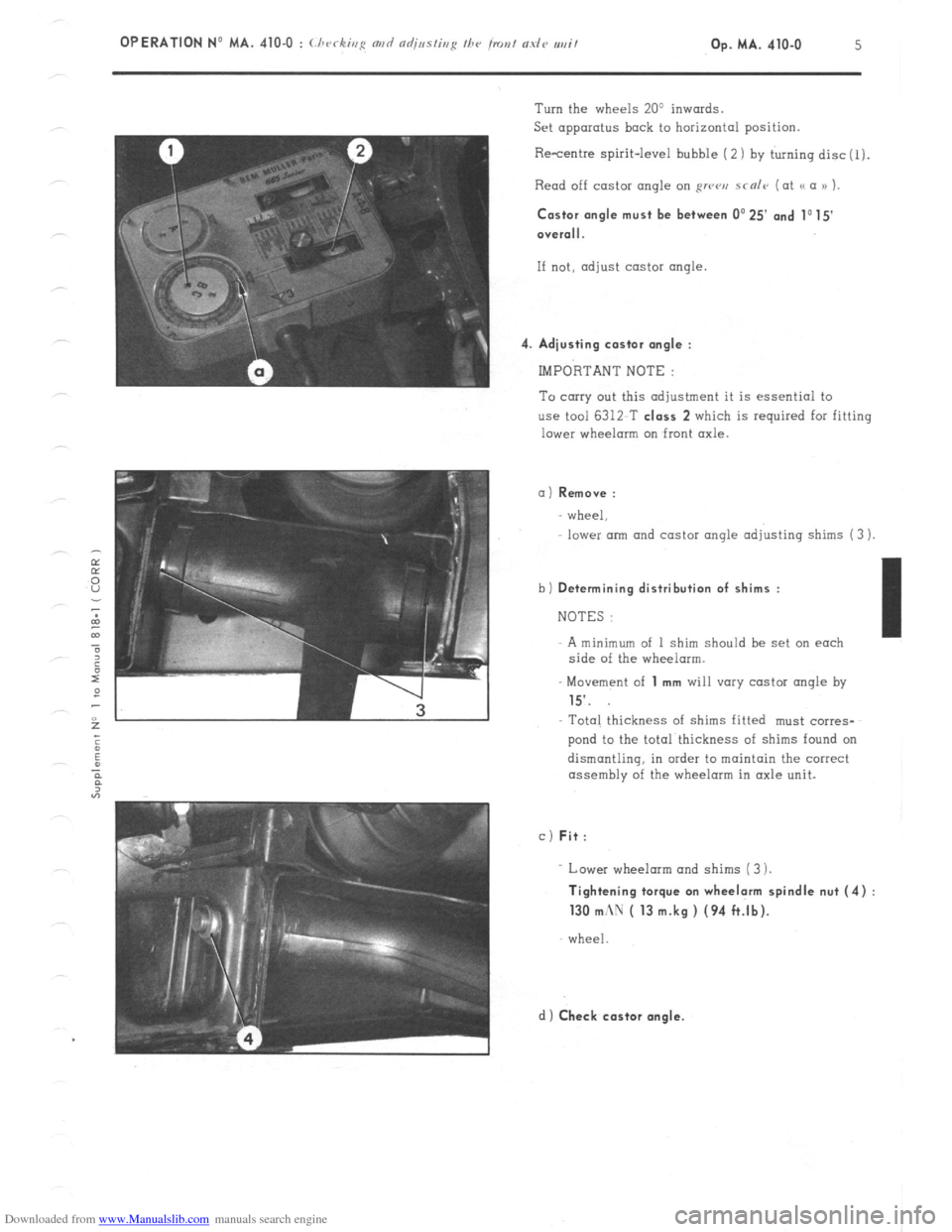

3. Checking castor angle :

Place the apparatus on the magnetic bracket of

the wheel to be checked using the axis corres-

ponding to grren (ITTOII’ H.

a) Turn wheels 20’ outwards : to the left for the

left-hand wheel and to the right for the right-

hand wheel.

Keeping the apparatus horizontal tighten locking

screw ( 1).

b) Turn the disc ( 4) until the zaro mark is opposite

arrow (at I( b n 1.

c) Turn knurled knob ( 5) until spirit-level

bubble (6) is centred.

Page 240 of 394

Downloaded from www.Manualslib.com manuals search engine 4 Turn the wheels 20’ inwards.

Set apparatus back to horizontal position.

Resentre spirit-level bubble ( 2) by turning disc(l).

Read off castor angle on RWCJ,J scnlr (at a a )) ).

Castor angle must be

between 0’25’ and 1015

O”erall.

If not, adjust castor angle

Adiusting castor angle :

IMPORTANT NOTE :

To carry out this adjustment it is essential to

use tool 6312 T class 2 which is required for fitting

lower wheelorm on front axle.

a) Remove :

wheel,

lower arm and castor angle adjusting shims (3 )

b)

Determining distribution of shims :

NOTES :

A minimum of 1 shim should be set on each

side of the wheelarm.

- Movement of

1 mm will vary castor angle by

15’.

Total thickness of shims fitted must corres-

pond to the total thickness of shims found on

dismantling, in order to maintain the correct

assembly of the wheelarm in axle unit.

c) Fit:

Lower wheelarm and shims (3 ).

Tightening torque on wheelarm spindle nut (4)

130 mc\U ( 13 m.kg ) (94 ft.lb).

wheel

d) Check castor angle.