relay Citroen CX 1981 1.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1981, Model line: CX, Model: Citroen CX 1981 1.GPages: 394

Page 86 of 394

Downloaded from www.Manualslib.com manuals search engine ALL CX VEHICLES

ANTI-POLLUTION SYSTEM ( SWEDISH MARKET )

I - cx 2200 :

The object of the system is to reduce the amount of unburnt hydrocarbons and the amount of CO in the exhaust

( 2 to 3 Z. of CO ) by injecting air under pressure into the exhaust manifold OPERATION :

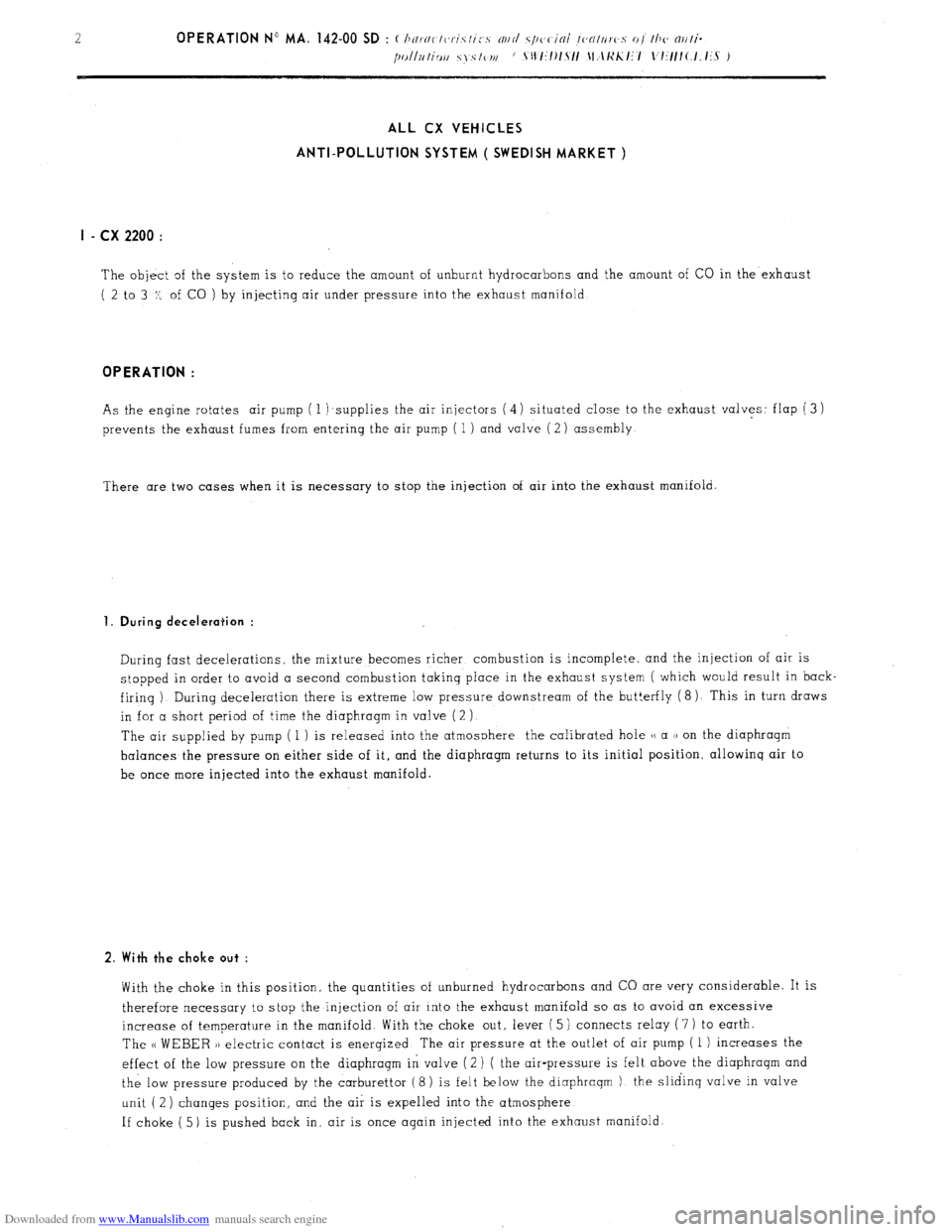

As the engine rotates air pump ( 1 )supplies the air injectors (4) situated close to the exhaust valves: flap (3)

prevents the exhaust fumes from entering the air pump ( 1 ) and valve ( 2) assembly

There are two cases when it is necessary to stop the injection of air into the exhaust manifold. 1. During deceleration :

During fast decelerations. the mixture becomes richer combustion is incomplete, and the injection of air is

stopped in order 1.0 avoid a second combustion taking place in the exhaust system ( which would result in back

firinq ). During deceleration there is extreme low pressure downstream of the but!erfly ( 8 ). This in turn draws

in for a short period of time the diaphragm in valve (2 )

The air supplied by pump ( 1 ) is released into the atmosphere the calibrated hole u a )) on the diaphraqm

balances the pressure on either side of it, and the diaphragm returns to its initial position, allowinq air to

be once more injected into the exhaust manifold. 2. With the choke out :

With the choke in this position, the quantities of unburned hydrocarbons and CO are very considerable. It is

therefore necessary to stop the injection of air into the exhaust manifold so as to avoid an excessive

increase of temperature in the manifold. With the choke out, lever ( 5 ) connects relay ( 7 ) to earth.

The u WEBER )) electric contact is enerqized The air pressure at the outlet of air pump ( 1 ) increases the

effect of the low pressure on the diaphragm in valve (2 ) ( the air-pressure is felt above the diaphragm and

the low pressure produced by the carburettor (8) is felt below the diaphraqm ) the sliding valve in valve

unit ( 2 ) changes position, and the air is expelled into the atmosphere

If choke ( 5) is pushed back in, air is once again injected into the exhaust manifold.

Page 87 of 394

Downloaded from www.Manualslib.com manuals search engine Key to diagram :

1.

Air-pump 5. Choke control knob

2. Air supply valve 6. (( WEBER )) electric contact

3. One-way valve 7. CARTIER relay

4. Air-injectors ( situated in the cylinder head ) 8. Throttle butterfly

Page 88 of 394

Downloaded from www.Manualslib.com manuals search engine II. cx 2000

The object of the system is t3 reduce the amount of unburnt hydrocarbons and the amount of CO in the exhaust

( approximately 2 to 3

of CO ) by injectinq air under pressure into the exhaust manifold

OPERATION :

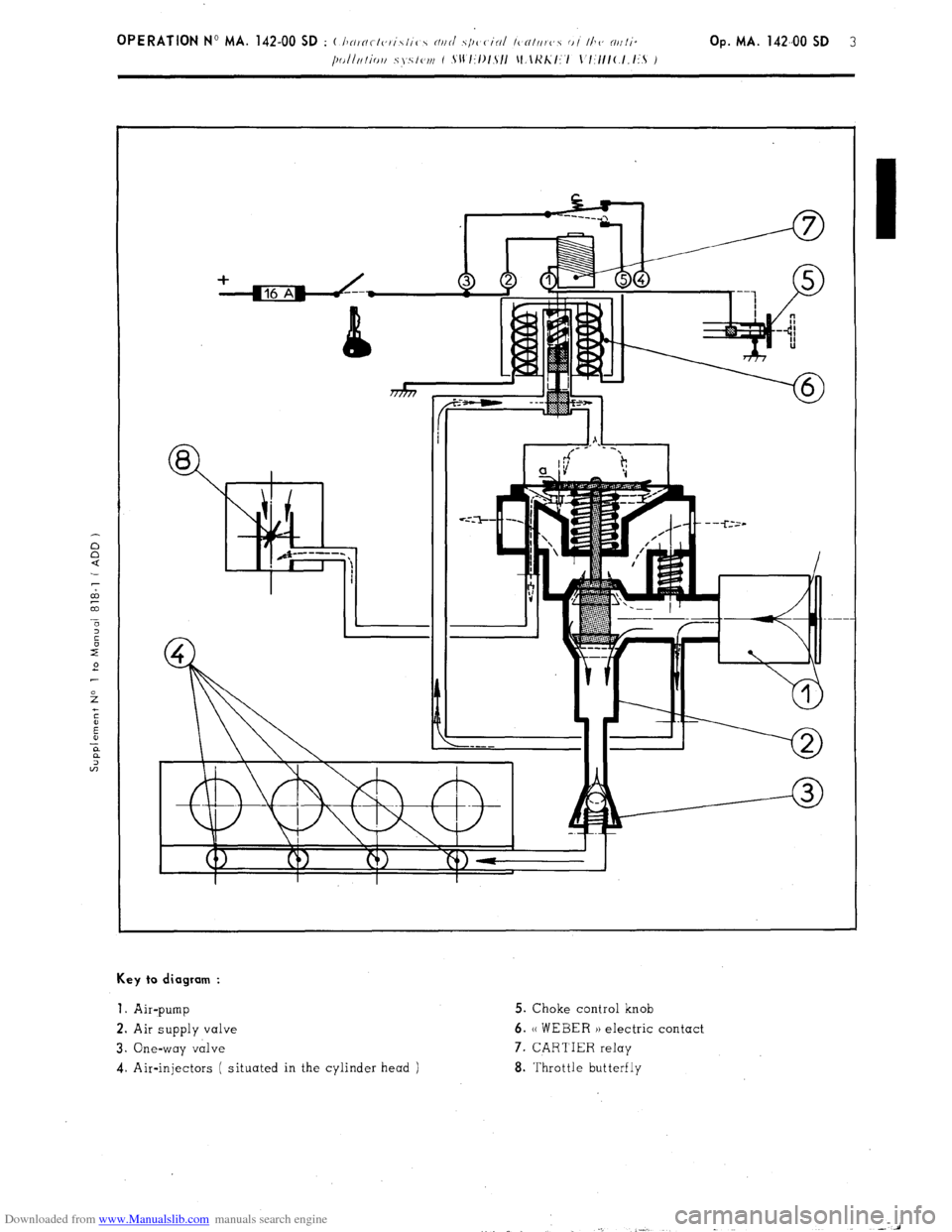

As the enqine rotates air pump ( 12) supplies the air injectors located near the exhaust valves: flap ( 13 )

prevents the exhaust fumes from entering the air pump and air supply duct assembly.

There are two cases where it is necessary to stop the injection of air into the exhaust manifold.

1. During deceleration :

Durinq fast deceleration. the mixture becomes richer combustion is incomplete and the injection of air is

stopped in order to avoid a second combustion takinq

place in the exhaust system ( which would result in

back-firinq ) Durinq deceleration there is extreme low pressure downstream of the butterfly ( 1 ). This in

turn draws in for a short period of time the diaphragm in valve ( 11 )

The air supplied by pump ( 12 ) is released into the atmosphere, the calibrated hole (( a 1) on the diaphragm

balances the pressure on either side of it and the diaphraqm returns to its initial position, allowinq air to

be once more injected into the exhaust manifold

2. With the choke out, for an engine coolant temperature of above 45’ + 3’ C, and whenever the coolant tempe-

rature remains above 35’ i “,I C.

In this situation the quantities of unburnt hydrocarbons and CO are very considerable It ‘is therefore necessary

to stop the injection of air into the exhaust manifold so as to avoid any excessive increase of temperature in

the manifold. On CX 2000 vehicles, injkction of air will be stopped when the enqine water temperature reaches

45” + 3- C Thermal switch ( 8 ) opens, relay ( 9 )

1s no lonqer enerqized. but electro-valve ( 7 ) remains live

( relay lead ). and is earthed via the choke control

The air pressure at the outlet of air-pump ( 12 )

increases the effect of the low pressure on the diaphraqm in

valve ( 11 ) ( the air pressure is felt above the diaphraq,m, and the low pressure produced by the carburettor (2)

is felt below the diaphraqm ). the slidinq valve in the duct chanqes position and the air is expelled into the

atmogphere If the choke ( 10) is pushed back in air is once again injected into the exhaust manifold

DEVICE FOR OPENING THE BUTTERFLY :

The object of the device is to maintain combustion during sudden deceleration up to an enqine speed

of

Nd 7 1800 + 100 rpm.

Durinq deceleration for any enqine speed above Nd, the electronic tachometer housinq ( 6 ) earths the

windinq of relay ( 5) Therefore the H PIERBURG 1) electro-valve ( 4) is no lonqer enerqized. Electro-

valve ( 4) is then under low-pressure, below the diaphragm of the device ( 3 ) for opening the butterfly

When the decreasinq enqine speed falls below

Nd, the electronic tachometer housing (6 ) cuts out the

earth of the winding in relay ( 5) Therefore the (( PIERBURG )) electro-valve ( 4) is enerqized The

electro-valve is no lonqer under low pressure below the diaphraqm of the device (3) for openinq the

butterfly the throttle butterfly returns to it s stop aqainst the idlinq speed adjustment screw. The dia-

phraqm of the device (3) for openinq the butterfly will once aqain be affected by low pressure ( under

the control of the electronic tachometer housing ) once the increasing engine speed reaches

NC ~ Nd t 50 to 250 rpm

Page 89 of 394

Downloaded from www.Manualslib.com manuals search engine 1 - Throttle butterfly

2 - Carburettor

3 - Butterfly openinq device 4-

N PIERBURG 1) 3-way electro-valve

5 - Control relay for butterfly opening device

6 - Electronic tachometer housing 7-

(( WEBER H electro-valve 8

- Engine coolant temperature switch 9.” Relay controlling exhaust manifold air injection 10

- Choke control

11 - Air supply valve 12

- Air pump 13 -

One way valve

14 - Cylinder head

15 - Jet ( calibrated to 0.40 )

Page 94 of 394

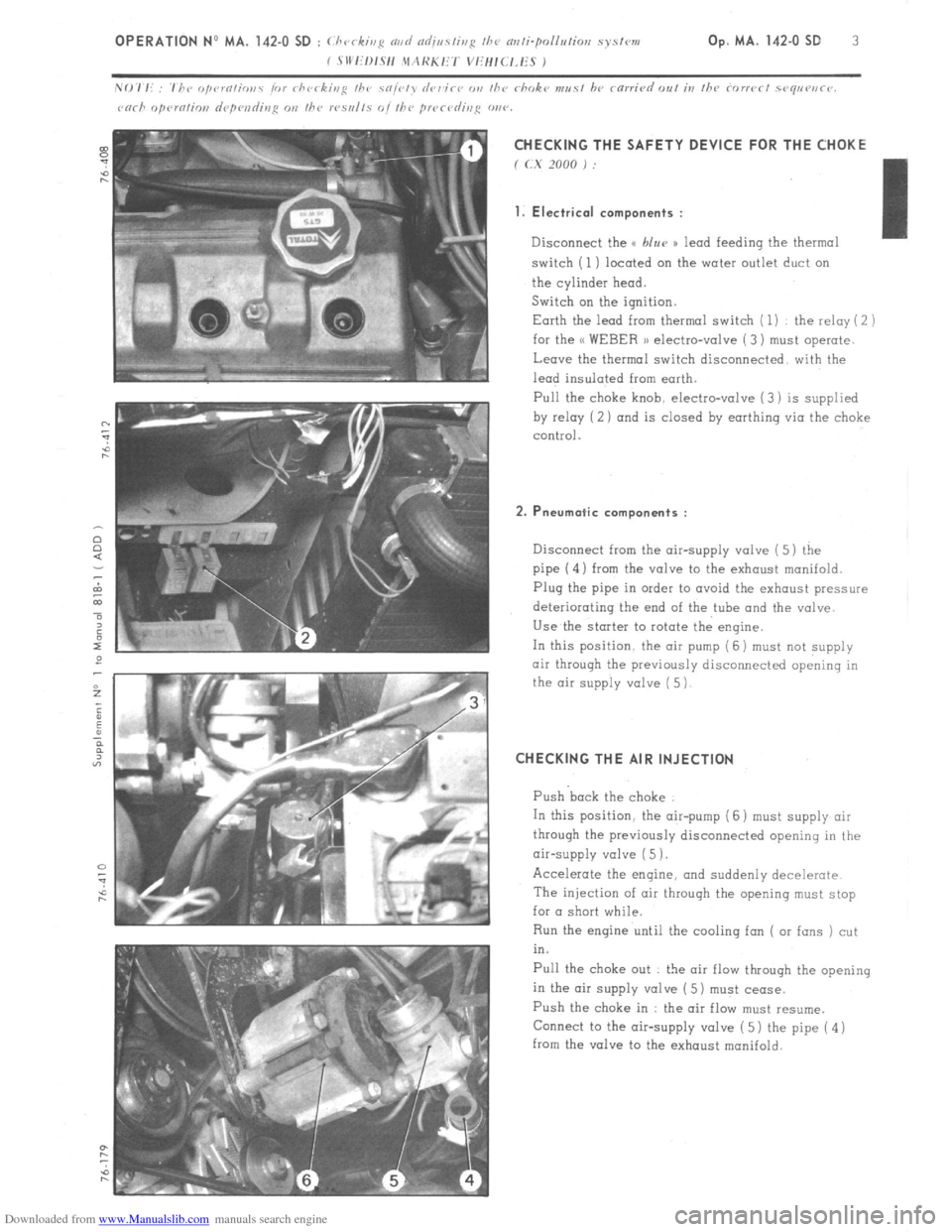

Downloaded from www.Manualslib.com manuals search engine CHECKING THE SAFETY DEVICE FOR THE CHOKE

f (.X 2000 j :

1. Electrical components :

Disconnect the u blur )) lead feeding the thermal

switch (1) located on the water outlet duct on

the cylinder head.

Switch on the ignition.

Earth the lead from thermal switch ( 1) the relay ( 2 )

for the << WEBER 1) electro-valve ( 3) must operate.

Leave the thermal switch disconnected with the

lead insulated from earth.

Pull the

choke knob. electro-valve (3) is supplied

by relay (2 ) and is closed by earthing via the choke

control.

2. Pneumatic components :

Disconnect from the air-supply valve ( 5) the

pipe (4) from the valve to the exhaust manifold.

Plug the pipe in order to avoid the exhaust pressure

deteriorating the end of the tube and the valve

Use the starter to rotate the engine.

In this position. the air pump (6 j must

not supply

air through the previously disconnected opening in

the air supply valve ( 5)

CHECKING THE AIR INJECTION

Push back the choke

In this position. the air-pump (6 ) must supply air

through the previously disconnected opening in the

air-supply valve ( 5 1.

Accelerate the engine, and suddenly decelerate

The injection of air throuqh the opening must stop

for a short while.

Run the engine until the cooling fan ( or fans ) cut

in.

Pull the choke out : the air flow through the opening

in the air supply valve ( 5) must cease.

Push the choke in : the air flow must resume.

Connect to the air-supply valve ( 5) the pipe ( 4 )

from the valve to the exhaust manifold.

Page 95 of 394

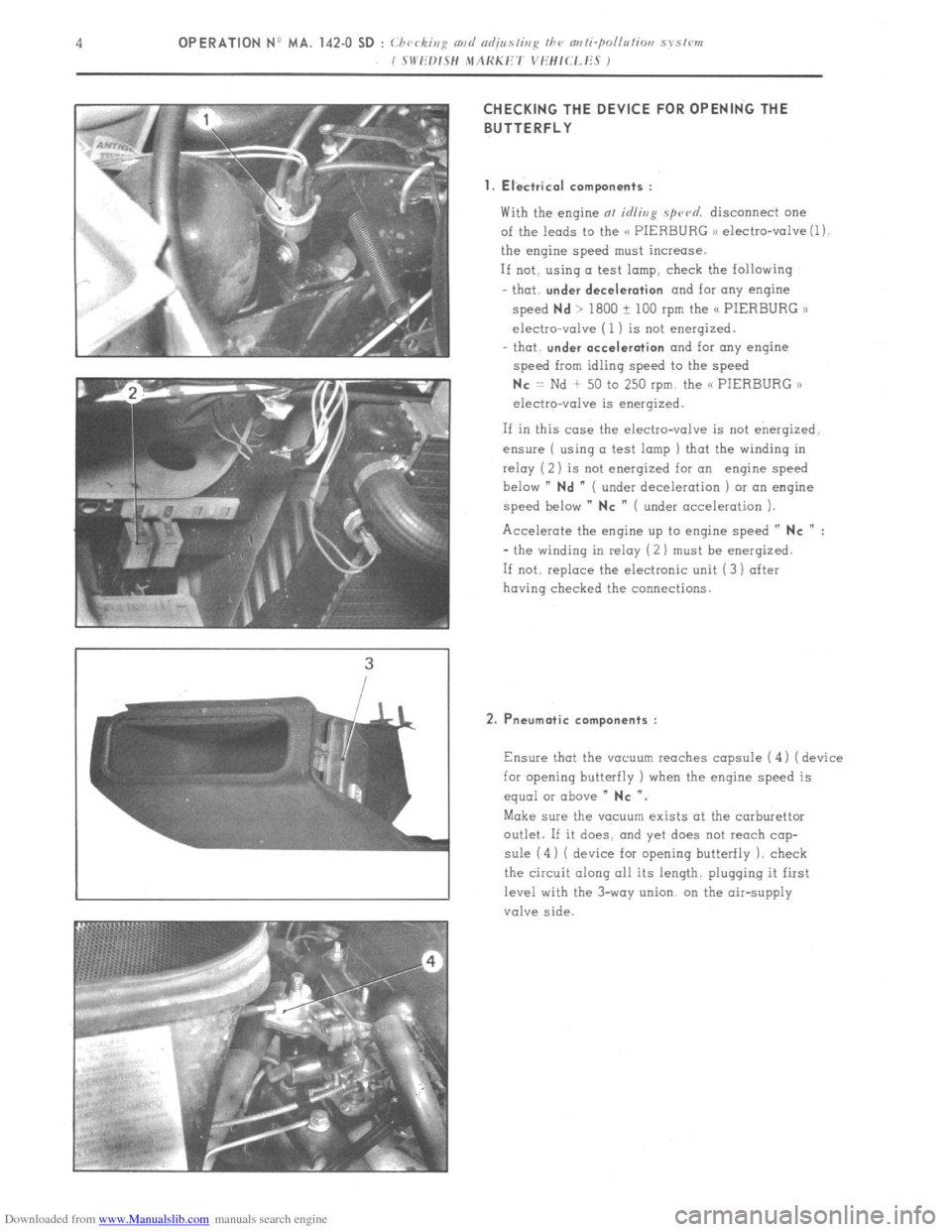

Downloaded from www.Manualslib.com manuals search engine CHECKING THE DEVICE FOR OPENING THE

BUTTERFLY

1. Electrical components :

With the engine at idling spu~d. disconnect one

of the leads to the C< PIERBURG ,) electro-valve (1).

the engine speed must increase.

If not. using a test lamp, check the following

that.

under deceleration and for any engine

speed

Nd > 1800 ? 100 rpm the /C PIERBURG >l

electro-valve (1 ) is not energized.

- that.

under acceleration and for any engine

speed from idling speed to the speed

Nc = Nd + 50 to 250 rpm. the C< PIERBURG ,,

electro-valve is energized.

If in this case the electro-valve is not energized.

ensure ( using a test lamp ) that the winding in

relay ( 2) is not enerqized for an engine speed

below ”

Nd ” ( under deceleration ) or an engine

speed below ”

NC ” ( under acceleration ).

Accelerate the engine up to engine speed ”

NC n :

- the winding in relay (2 ) must be enerqized.

If not. replace the electronic unit (3) after

having checked the connections.

2. Pneumatic components :

Ensure that the vacuum reaches capsule ( 4 1 ( device

for opening butterfly ) when the engine speed is

equal or above ”

NC “.

Make sure the vacuum exists at the carburettor

outlet. If it does. and yet does not reach cap-

sule (4) ( device for opening butterfly 1. check

the circuit along all its length. plugging it first

level with the 3-way union. on the air-supply

valve side.

Page 98 of 394

Downloaded from www.Manualslib.com manuals search engine 2

OPERATION No MA.IE. 144-00 : Chtiractcristics o/ the e 1,-Jc,tror,ic H clcctroltic

fire1 injc ctiwt systettt.

((L-JETRONIC,,

The H L-Jetronic 1) system is’an intermittent low-pressure injection system which injects petrol into the inlet

manifold.

The system measures the quantity of air drawn in by the engine. which is the main parameter for calculating

the amount of fuel. to be injected. The metering of the fuel is carried out by electro-magnetically triggered

injectors. These are under constant fuel pressure. The quantity of fuel injected is proportional to the duration

of injection. which in turn is optimally determined for any given engin& operating condition by an electronic

control unit ( E.C.U. ) from information supplied by several electric sensors.

One of the principal contributions of the H L-Jetronic H system is the reduction in the level of pollution of the

exhaust emissions.

The (( L-Jetronic v system is made up of the following components :

1

: Electric fuel pump

2 : Fuel filter

3 : Thermal switch

4 :, Double relay

5 : Electronic control unit ( E.C.U. )

6 : Supplementary air control

7 : Pressure regulator

8 : Injectors

9 : Cold-start injector

10. Idling speed adjustment screw

11 : Air-flow sensor ( with incorporated air temperature sensor )

12 : Switch on throttle butterfly spindle

13 : Additional resistors for the injectors (8)

Page 132 of 394

Downloaded from www.Manualslib.com manuals search engine 1. Energizing the system : ( DIAGRAM 1 )

_ Disconnect the E.C U

- Switch the ignition on

Using a voltmeter. ensure that each point in

dingrm 1 is effectively energised. after having tested the

earthing. If not, switch off the ignition. and test the circuit using a battery operated ohmmeter. With the

voltmeter connected between terminals ( 1 ) and ( 5) of the E. C.U., operate the starter the voltmeter must

register the ignition impulses If it does not. check the ignition

( ANNEXE A ).

2. Fuel pump feed ( on operating the starter ) ( DIAGRAM 2 )

- Disconnect the E C.U.

- Switch on the ignition

- On operating the starter. the fuel pump (

secureri rrt/rler the I c~hiclc’. uoor IIJO K. ti. ronr (, l~eol I must be

heard to operate by someone standing close by

If not switch off the ignition, and test the circuit using a battery operated ohmmeter.

The resistance between terminal (( 88 d H of the relay assembly ( c~r~tler 111~

L,H. honr/llor)~p ) and earth

must be 1 Q approx-

Make sure the petrol pump is properly earthed.

Page 135 of 394

Downloaded from www.Manualslib.com manuals search engine Op. MA.IE 444-O 15

3. Fuel pump feed ( with engine running ) : ( DIAGRAM 3 )

- Disconnect the E.C.U.

- Disconnect from the air-flow sensor the air hose to the butterfly housing

- Switch on the ignition:

- Actuate the air-flow sensor flap by hand’ when the petrol pump contact closes the pump should be heard

working.

If not, test the circuit using a

battery operated ohmmeter, without forgetting to test between terminal G 36 ))

on the air-flow sensor and terminal H 20 .)) on the E.C.U. for continuity ( The 2nd terminal is not connected

to the E.C.U. ).

- The resistance between terminals (( 86 b H and G 85 )) on the relay box f //j/nor thc~ I~./I. h<~ntllnr~tp ) must be

between 52 and 78 12.

P 4. Supplementary air control ( DIAGRAM 4 )

4

c

5

6

- Disconnect the E.C.U.

-E

? - Check that the supplementary air control is properly connected ( arrow on the casing )~

In

If it is fitted the wrong way round. the port may be blocked.

- The resistance between terminals (( 34 1, and (( 48 )) on the- supplementary air control must be 50 Q approx-

- Visual checking the port on the supplementary air control must be open when the engine is cold, and closed

when the engine temperature is above 60” C

- With the engine cold. if the air pipe to the supplementary air control is flattened the engine rpm must decrease.

With the engine warm, if the air pipe is disconnected, the engine must accelerate.

Page 289 of 394

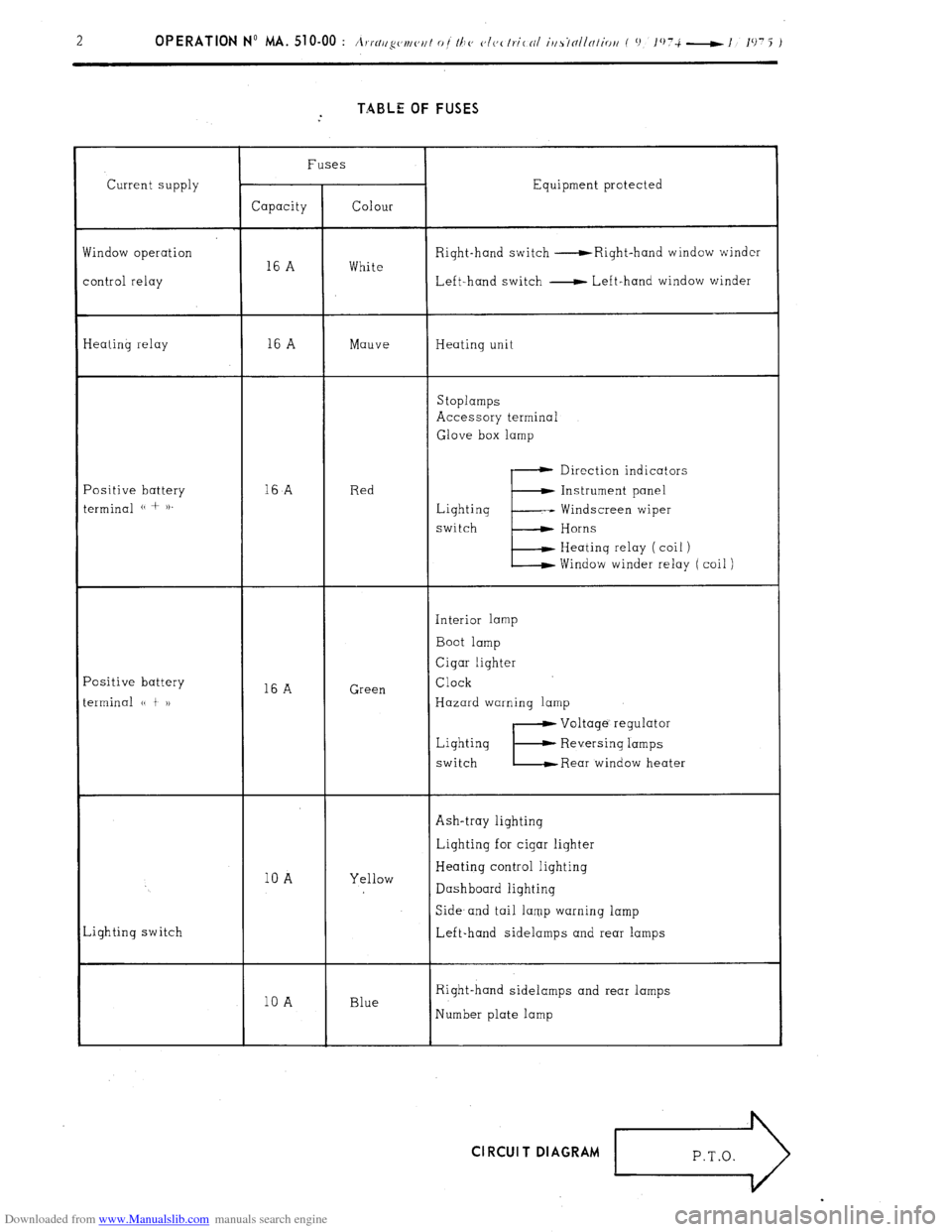

Downloaded from www.Manualslib.com manuals search engine TABLE OF FUSES

Current supply

findow operation

ontrol relay Fuses

Equipment protected

Capacity Colour

Right-hand switch -Right-hand window winder

16 A White

Left-hand switch - Left-hand window winder

Ieating relay 16 A Mauve Heating unit

Stoplamps

Accessory terminal

Glove box lamp

‘ositive battery

erminal (( + )). 16

A Red Direction indicators

E Instrument panel

Lighting -- Windscreen wiper

switch Horns

Heating relay ( coil )

Window winder relay ( coil )

‘ositive battery

erminal (( t 1) 16 A Green Interior lamp

Boot lamp

Cigar lighter

Clock

Hazard warning lamp

Lighting

switch

E

Voltage’ regulator

Reversing lamps

Rear window heater

Ash-tray lighting

10 A Yellow Lighting for cigar lighter

Heating control lighting

Dashboard lighting

,ighting switch Side- and tail lamp warning lamp

Left-hand sidelamps and rear lamps

10 A Blue Right-hand sidelamps and rear lamps

Number plate lamp Cl RCUI T DIAGRAM

r>