weight Citroen CX 1982 1.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1982, Model line: CX, Model: Citroen CX 1982 1.GPages: 394

Page 62 of 394

Downloaded from www.Manualslib.com manuals search engine Op. MA. 100-00

BARRELS AND PISTONS (2350 cc 1

-I

-I

The. Replacement Parts Department only supplies barrel, piston, gudgeon pin and piston ring assemblies in

sets of 4.

. Thickness of barrel base gasket ( uncompressed ) : . . . . . . . . . . . . . .._.._....................................................... 0.1 2 JO.O1O mm

protrusion of barrel ( with gasket uncompressed ) : _..._,_,...,._,............................................................ 0.045 to 0.115 mm

- Variation in weight (pistons, gudgeon pins, and gudgeon pin circlips ) on the same engine : . . . 5 g max.

Page 79 of 394

Downloaded from www.Manualslib.com manuals search engine CARBURATION

OPERATION No MA. 142.00 : Cl~nroricrirtir-s mid .sprrinl ,cnhrcs oi /he cnrh,,wt/or Op. MA. 142.00 1

ENGINE M20/616

I

WEBER CARBURETTORS

34 DMTR 25/200 IDENTIFICATION MARK W 55.00 c:?( 2000 -71 1976

34 DMTR 25/250 IDENTIFICATION MARK W 55-50 cx

2000 7, Id76 -

34 DMTR 25/100 IDENTIFICATION MARK W 54.00 * (.Y X,0(? ;\I/< CO.VIl. - 7 ,976

34 DMTR 25/150 IDENTIFICATION MARK W 54-50 * c-i 2000 /t/K LO\‘,). 7 ,976 -

DESCRIPTION

- Dual choke ,, compound /) type, anti-pollution carburettor with mechonicaliy controlled second choke butterfly

- Mechanically controlled acceleration pump ( cam ) on 1st choke

- Choke on 1st body vacuum assisted cold

start strangler flap

- Fitted damper on idling speed system.

* with incorporated fast idle device

ADJUSTMENTS

DESCRIPTION Primary choke

Venturi bore

Main jets ( removable )

Air corrrction jets

Emulsion tubes

Idling jets [removable ) .._..

Air-bleed idling jets

Acceleration pump injector -high type ( weighted )

Econostot petrol jet ( in cover )

Econostat delaying orifice ( in cover .I

Ball-operated needle valve

Double float : Weights

Positive butterfly opening - Strangler flap fully closed

22 26

115 135

AD 1 ( 195 ) AD 2 ( 180 )

F 30 F 25

50 70

110 70

40

110

100

1 75 “It”

13 1 0.5 g

1.25 i 0.05 mm I

Secondary choke

Page 84 of 394

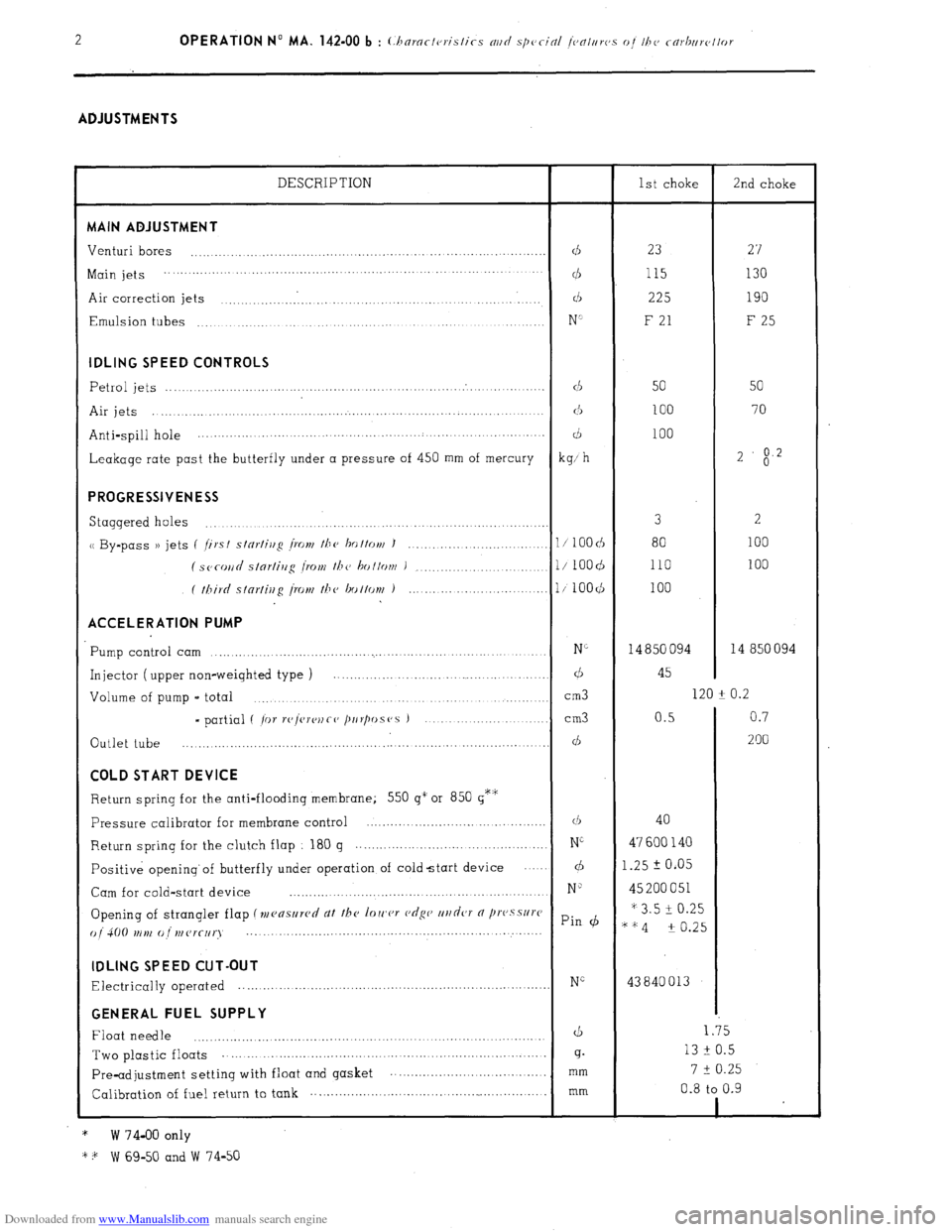

Downloaded from www.Manualslib.com manuals search engine ADJUSTMENTS

DESCRIPTION

1st choke

2nd choke MAIN ADJUSTMENT

Venturi bores

...................................................................................

d 23

27

Main jets ................. ...........................

... ................. ... ....... ...............

cl5 115 130

Air correction jets ..............................................................

d 225 190

Emulsion tubes

...............................................................

......

N’ F 21

F 25 IDLING SPEED CONTROLS

Petrol jets

.......................................................................................

d

50 50

Air jets .....................................................................................

(3

100 70

Anti-spill hole ............... ..............................................

....... ........

d 100

Leakage rate past the butterfly under a pressure of 450 mm of mercury

kg; h 2

$2 PROGRESSIVENESS

Staggered holes 3

2 ...............................................................................

u By-pass )) jets (

/irst stnrtiug /row the ho ttott/ J

100 ............................ 1 / 100 cb 80

( SC~COII~ slnrlirrg I.0Nf the bottom )

...................... l/ 1OOd 110 100

( third stnrfiug [row the bottov~ )

........................... l/100($

100 ACCELERATION PUMP

Pump control cam N”

14 850 094 14 850 094 ...............................................................................

Injector ( upper non-weighted type ) ............................................

d 45

Volume of pump - total

cm3 120 -t 0.2

.......................................................................

- partial ( /or r(‘/vre)~Co /~IIr/wS(‘S ) ................... ...........

cm3 0.5 0.7

Outlet tube

200 ................................................. ....... ...........

............... ... d COLD START DEVICE

Return spring for the anti-flooding membrane; 550 g” or 850 g*‘i;

Pressure calibrator for membrane control ...........................................

(1, 40

Return

spring for the clutch flap

180 g ...............................................

Ni 47 600 140

Positive opening’of butterfly under operation of coldstart device

.... d 1.25 2 0.05

Cam for cold-start device

N” 45 200 051

..............................................................

Opening of strangler flap (mensllrcd dt the loIc,cr c,dgc’ ur/dcJT 0 /lI’(‘.sSlI)‘C * 3.5 i 0.25

() j 4(j(J tr ,),, (J ,,, (Jr(-[,q Pin (b

““4 -t 0.25

..... ... .....................................................

... ...... IDLING SPEED CUT-OUT

Electrically operated NG 43840013 ............................................................................. GENERAL FUEL SUPPLY

Float needle

d 1.35

..................................................................................

Two plastic floats 13 F 0.5 ...................................

............... .............................

g.

7 t 0.25

Pre-adjustment setting with float and gasket ...............................

....... mm

Calibration of fuel return to tank .................................

......................... mm 0.8 to 0.9

1

*

W 74-00 only

* + W 69-50 and W 74-50 .

Page 158 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 210-O : (.h(~~-ki/lg n~lc/ c~tlj~~s/irtg the igrlitiorl Op. MA. 210-O 3

1. Checking the condition of the contacts :

Check the voltage drop across the contacts ( contacts closed ) under a voltage of 12 volts. using a test-bench.

The voltage drop should be 0.2 volts max.

I

2. Checking the centrifugal advance curve :

a) Note the advance in stages for steadily increasing engine speeds from 0 to 3000 rpm. and for steadily

decreasing engine speeds from 3000 rpm to 0, t~/~kjj/$ SII~L’

the irirwasc, or d~,rrc~as~’ is c-o~~ti~ootl.5.

These points must fall within the shaded area of the curve.

b) To a certain extent. it is possible to correct the advance curve, by altering the tension of the springs for

the centrifugal weights To obtain this condition, slightly bend (

iv t/1(, np1)ro/)riotc, ciirectioll J the securing

brackets for the springs, or replace them.

IY NOTE : If luminous spots are produced outside the four normal positions at speeds under 3000 rpm. make

5 sure the contact points are clean and if necessary make sure the test-bench battery is fully charged. before

U replacing the contact-breaker unit. the spring of which may have weakened.

7

co

m

r 3. Checking the spark regularity :

2

Whatever the speed of rotation, the angular difference of the four opening positions of the points must n.ot

3 exceed lo I 21n.xint~lm r/In/ oj distributor : 3250 I./)NI. c,.vcc,pt I)l’(.lit,t.tt~K 525 06X A : 2750

r/m 1,

c

E

!i

a

z 4. Ch k’ ec rng and adjusting the dwell angle :

Run the distributor at a steady speed, and check that the dwell angle is equal ;o 55’ ? 2”30’. If this is not the

case, adjust the contact breaker to obtain this condition.

5. Checking the ignition condenser :

With the contact points open. measure the capacity of the condenser; This value must be 0.30 i 0.03 wF.

If this is not the case. replace the condenser.

6. Check the vacuum advance curve :

This check is carried out at a constant rpm of 200, with no centrifugal advance.

Check the points of the increasing curve. and the decreasing curve. If the vacuum capsule has n hathcr.

it will be necessary to blank it off during this check.

Page 163 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 210-O Q : C.‘/)c,r&iug nnrt nrljtlsliug I110 c~t~~clro~~ic igrliliorl sj’slvnv. Op. MA. 210-O a 3

1. Adiust star-point gop : 0.3 to 0.5

mm

2. Check the centrifugal advance curve :

a) Note the advance in stages for steadily increasing engine speeds from 0 to 3000 rpm and for steadily decreasing

engine speeds from 3000 rpm to 0. making sure the increase or decrease is continuous. These points must fall

within the shaded area of the curve.

b ) To a certain extent. it is possible to correct the advance curve. by altering the tension of the springs for the

z centrifugal weights To obtain this condition slightly bend (

irr I~V nppropriate clirvcliou ) the securing brackets

6 for the springs. or replace them.

ot,

43

a

3

E

E 3. Checking the symmetry of the star-points :

-z

0

IFi

The angular positioning of the 4- star-points must be the same to within 1”. whatever the speed of the engine.

4. Checking the vacuum advance curve :

This check is carried out at a constant 200 rpm. with no centrifugal advance.

Check the points for the increasing curve, then the decreasing curve.

If the vacuum capsule has a breather, it will be necessary to blank it off during the’test.

Page 243 of 394

Downloaded from www.Manualslib.com manuals search engine a OPERATION N’ MA. 410-O : (./~rrkiq N,,I/

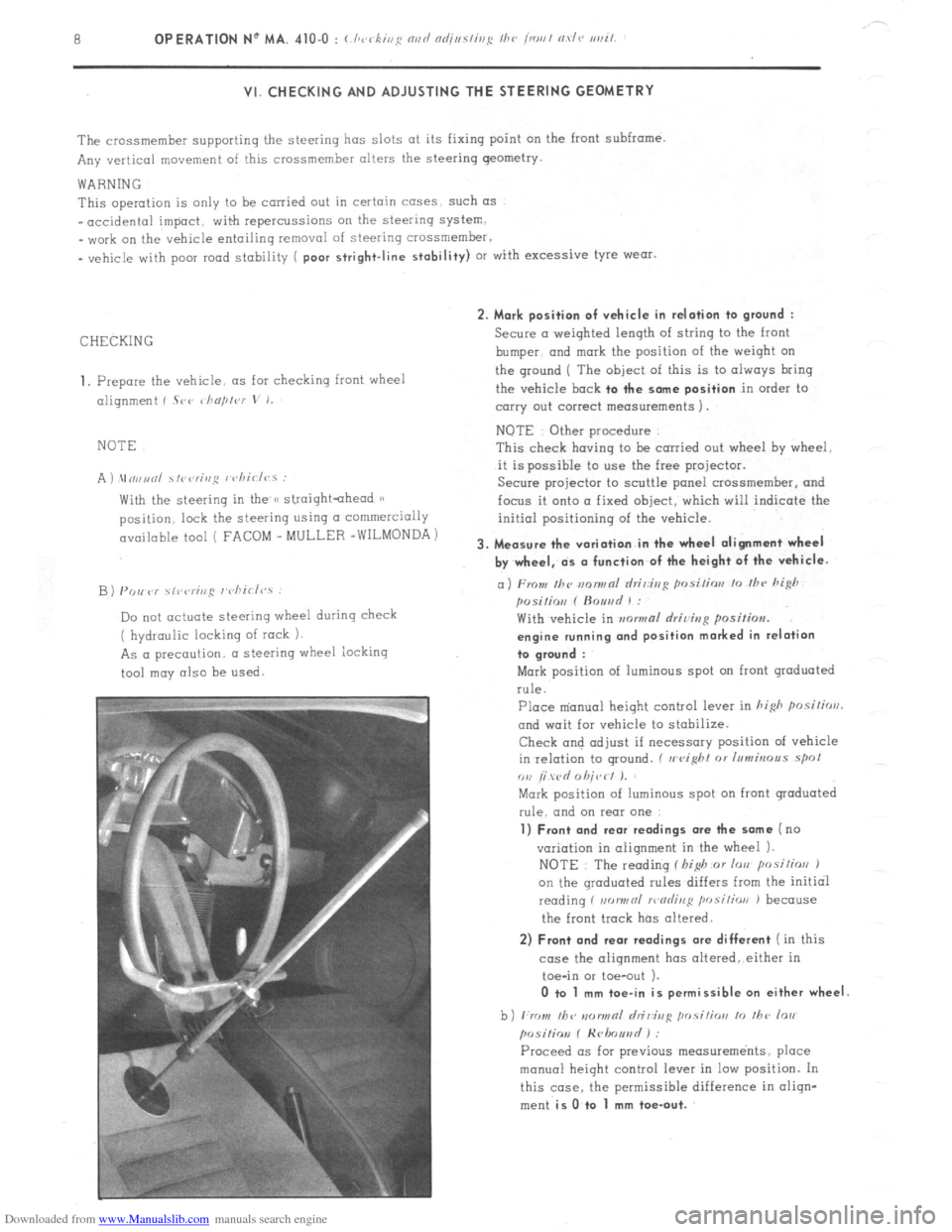

VI. CHECKING AND ADJUSTING THE STEERING GEOMETRY

The crossmember supporting the steering has slots at its fixing point on the front subframe.

Any vertical movement of this crossmember alters the steering geometry.

WARNING

This operation is only to

be carried out in certain ccxses such as

-accidental impact, with repercussions on the steering system.

-work on the vehicle entoiling removal of steering crossmember.

- vehicle with poor

road stability ( p oar stright-line stability) 01 with excessive tyre weor.

CHECKING

1, Prepare the vehicle. as for checking front wheel

alignment ( Srr ~ho/,lvr

V I.

NOTE

A ) \In,,unl ~fi~<,r;,,~ I chiclvs :

With the steering in the /< straightahead 1)

position. lock the steering using CI commercially

available tool ( FACOM _ MULLER -WILMONDA)

B) PO,, P)’ \,r,rr;ng r’cliirl<,.s :

Do not actuate steering wheel during check

( hydraulic locking of rock 1.

As a precaution. a steering wheel iocking

tool may also be

used. 2. Mark position of vehicle in relation to

ground :

Secure a weighted length of string to the front

bumper. and

mark the position of the weiqht on

the ground ( The

object of this is to always bring

the vehicle

bock to the some position in order to

carry out correct measurements 1.

NOTE Other procedure

This check having to be carried out wheel hy wheel.

it is possible to use the free projector.

Secure projector to scuttle panel crossmemher, and

focus it onto a fixed object, which will indicate the

initial positioning of the vehicle.

3. Measure the variation in the wheel alignment wheel

by wheel, ds o function of the height of the vehicle.

a) From Ihc m~nwnl rlri,:ir,g posi/ior, lo /hc hi@

posilio,, f ftouad 1 :

With vehicle in mwmal rlriving position.

engine running ond position marked in relation

to groond :

Mark position of luminous spot on front graduated

rule.

Place m’anual height control lever in hi&

posilirrrl.

and wait for vehicle to stabilize.

Check and adjust if necessary position of vehicle

in relation to ground. ( II

eight 01 Inmbrous spol

ou /i wd 0 hit,< I J.

Mark position of luminous spot on front graduated

rule. and on rear one

1) Front and rear readings ore the some (no

variation in alignment in the wheel 1.

NOTE : The reading f I,i$ or lorr posilios J

on the qroduated rules differs from the initial

reading f non,,nl >r,nrlinl:

position J because

the front track has altered.

2) Front and rear readings ore different ( in this

case the alignment has oltered,.either in

toe-in or toe-out ).

0 to 1 mm toe-in is permissible on either wheel

b) ,:rr ,,I, /bv IIDIINRI hi&g ,,osi,;orr lo ,I,<, lo,,

posiliov f Hrlmuad ) :

Proceed OS for previous measurements, place

manual height control lever in low position. In

this case. the permissible difference in oliqn-

ment

is O.to 1 mm toe-out.

Page 258 of 394

Downloaded from www.Manualslib.com manuals search engine 2 OPERATION No MA. 430-O : ~hwki~zg nrtd nrijustittg the suspwrsiott ntd its cotttrol

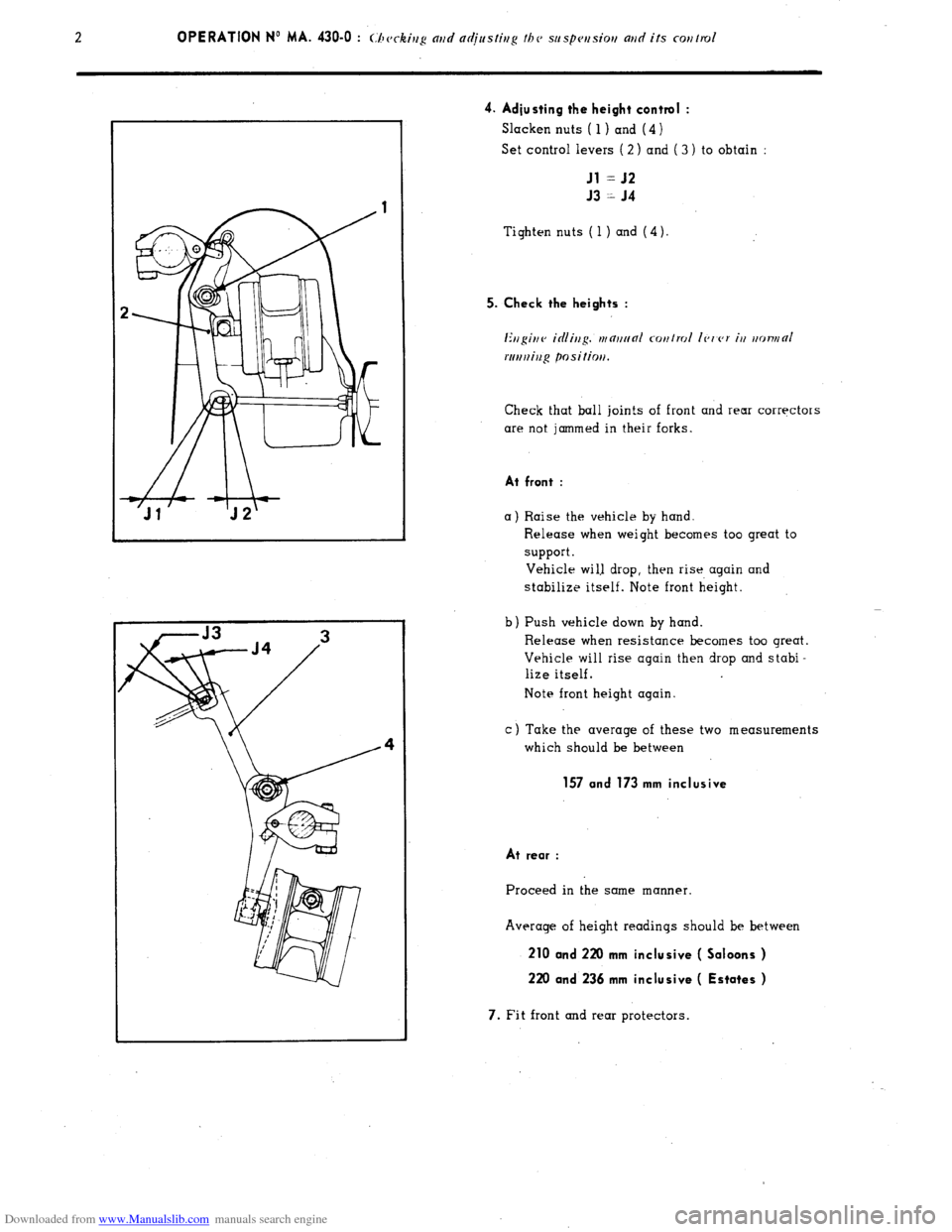

4. Adjusting the height control :

Slacken nuts ( 1) and (4 )

Set control levers ( 2 ) and ( 3 ) to obtain :

Jl = J2

J3 = J4

Tighten nuts ( 1 ) and (4).

5. Check the heights :

Ertgittv icilittg. tttnttt~nl cotttrol Ic,t’c,r itt ttotvttO/

rtrrtttiug positiott.

Check that ball join!s of front and rear corrqctors

are not jammed in their forks.

At front :

a) Raise the vehicle by hand.

b Release when weight becomes too great to

support.

Vehicle wi1.l drop, then rise again and

stabilize itself. Note front height.

Push vehicle down by hand

Release when resistance becomes too great.

Vehicle will rise again then drop and stabi-

lize itself.

Note front height again.

c) Take the average of these two measurements

which should be between

157 and 173 mm inclusive

At rear :

Proceed in the same manner.

Average of height readings should be between

210 and 220 mm inclusive ( Saloons )

220 and 236 mm inclusive ( Estates )

7. Fit front and rear protectors.

Page 268 of 394

Downloaded from www.Manualslib.com manuals search engine d

m

.-

0

2

f Op. MA. 440-00

7 -

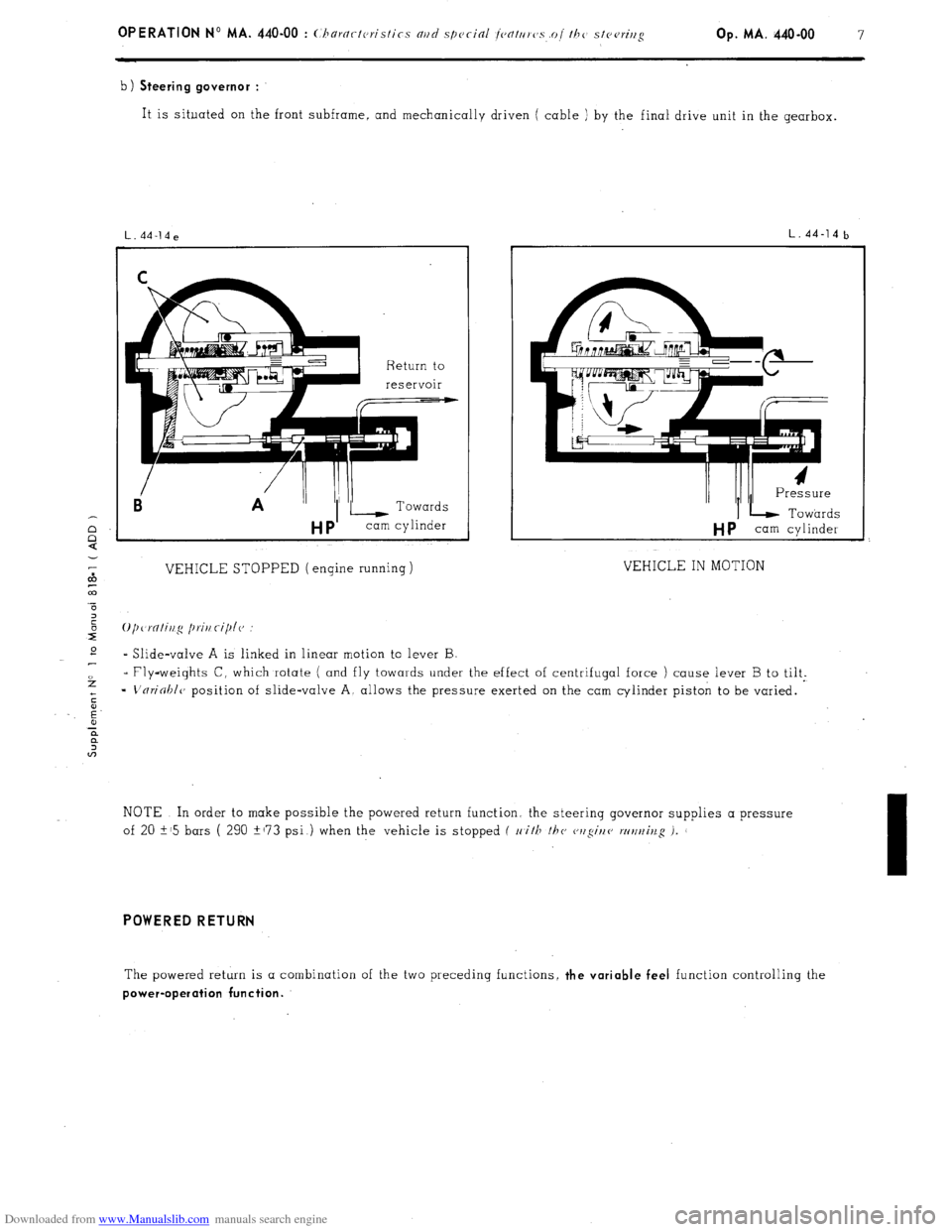

b) Steering governor :

It is situated on the front subframe, and mechanically driven ( cable ) by the final drive unit in the gearbox.

Ei A ”

VEHICLE STOPPED (engine running)

L.44-14b

I/ /II I Pressure

IL Towards

HP cam cylinder

VEHICLE IN MOTION

* Slide-valve A is linked in linear motion to lever B

- Fly-weights C, which rotate ( and fly towards under the effect of centrifugal force ) cause lever B to tilt.

=

L'nrioblc, position of slide-valve A, allows the pressure exerted on the cam cylinder piston to be varied.

NOTE In order to make possible the powered return function. the steerinq governor supplies a pressure

of 20 i-15 bars ( 290 +173 psi ) when the vehicle is stopped f 11

i/F /hc cwgir/e wt/t~iv.g i.

I

POWERED RETURN

The powered return is a combination of the two preceding functions, the variable feel function controlling the

power-operation function.

Page 361 of 394

Downloaded from www.Manualslib.com manuals search engine AIR-CONDITIONING

CHARACTERISTICS AND SPECIAL FEATURES OF THE AIR-CONDITIONING SYSTEM

The air-conditioning system includes the refrigeration and the heating of the air drawn into the passenger compart-

ment. REFRIGERATION

This allows the air in the passenger compartment to be cooled, while at the same time reducing its dampness (and

therefore the misting up of the glass ) HEATING

It is of the (( FROID - 15)) or (( FROID - 20 )) type

1 The air is blown around the channels of a radiator supplied by water from the engine cooling system.

&

co

5

3

t

E REFRIGERATION

E I. CHARACTERISTICS

ASPERA FRIGO type HG 700 or

Compressor

1 .

SANKYO * type SD 508

De-watering tank . SINGER

Condenser _.. ._..: _._...... . . . . . . . . . . . CHAUSSON

Evaporator-blower , SOFICA

Flexible hoses ..,_.,....,............................................................................... STRATOFLEX and RANCO

Refrigerating fluid . R. 12 Weight

of refrigerating fluid _..._.._._._..,_..__.................................................... 1 kg ( 2.2 lbs )

Oil for lubricating compressor TOTAL LUNARIA 25 or SUNISO No. 5

or TEXACO CAPELLA (( E )) grade 500

Quantity of oil for lubricating compressor ,

280 g i.e. a height of 21 to 29 mm

f

CJSCC,~~ ior SANKYO UIVI~WSSO~ J

* Only fitted on vehicles fitted with converter and air-conditioning option.

Page 387 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 852-O : Adius/ir,y I/><, bo,,r,r/ Op. MA. 852-O 1

~.

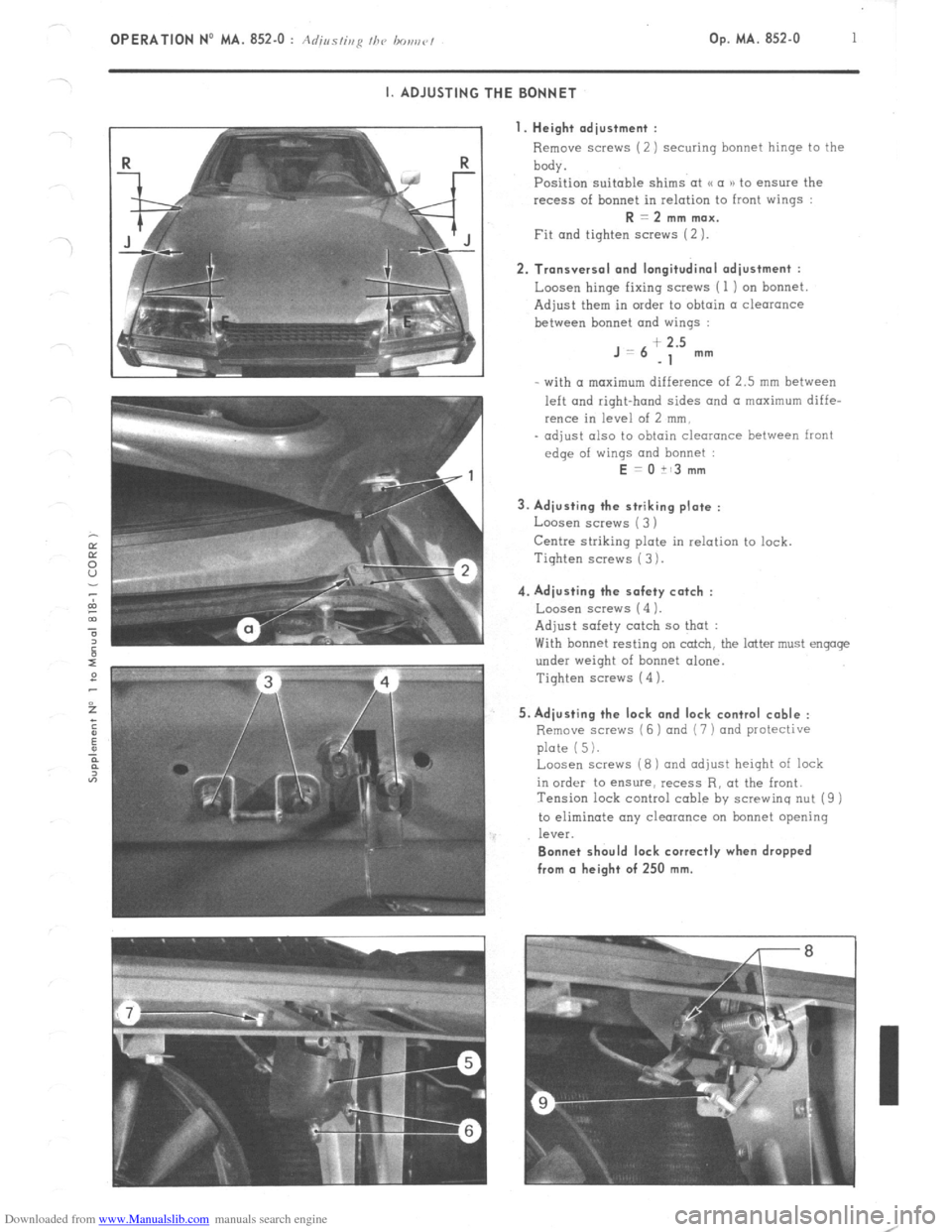

I. ADJUSTING THE BONNET

I. Height adjustment :

Remove screws (2) securing bonnet hinge to the

body.

Position suitable shims at u a )) to ensure the

recess of bonnet in relation to front wings : R = 2 mm max.

Fit and tighten screws (2 ). 2. Transversal and longitudinal adjustment :

Loosen hinge fixing screws ( 1 ) on bonnet

Adjust them in order to obtain a clearance

between bonnet and wings : J=6

+ 2.5

-1 mm

- with (I maximum difference of 2.5 mm between

left and right-hand sides and a maximum diffe-

rence in level of 2 mm,

- adjust also to obtain clearance between front

edge of wings and bonnet : E = 0 it3 mm

3. Adjusting the striking plate :

Loosen screws ( 3 )

Centre striking plate in relation to lock.

Tiqhten screws ( 3 ). 4. Adjusting the safety catch :

Loosen screw5 (4 1.

Adjust safety catch so that :

With bonnet resting on catch, the latter must engage

under weight of bonnet alone.

Tighten screws (4 ). 5. Adjusting the lock and lock control cable :

Remove scravs (6 ) and (7 ) and protective

plate (5).

Loosen screws (8) and adjust height of lock

in order to ensure, recess R, at the front.

Tension lock control cable by screwing nut (9 )

to eliminate any clearance on bonnet opening

leV%. Bonnet should lock correctly when dropped

from (I height of 250 mm.