Citroen CX 1982 1.G Workshop Manual

Manufacturer: CITROEN, Model Year: 1982, Model line: CX, Model: Citroen CX 1982 1.GPages: 394

Page 361 of 394

Downloaded from www.Manualslib.com manuals search engine AIR-CONDITIONING

CHARACTERISTICS AND SPECIAL FEATURES OF THE AIR-CONDITIONING SYSTEM

The air-conditioning system includes the refrigeration and the heating of the air drawn into the passenger compart-

ment. REFRIGERATION

This allows the air in the passenger compartment to be cooled, while at the same time reducing its dampness (and

therefore the misting up of the glass ) HEATING

It is of the (( FROID - 15)) or (( FROID - 20 )) type

1 The air is blown around the channels of a radiator supplied by water from the engine cooling system.

&

co

5

3

t

E REFRIGERATION

E I. CHARACTERISTICS

ASPERA FRIGO type HG 700 or

Compressor

1 .

SANKYO * type SD 508

De-watering tank . SINGER

Condenser _.. ._..: _._...... . . . . . . . . . . . CHAUSSON

Evaporator-blower , SOFICA

Flexible hoses ..,_.,....,............................................................................... STRATOFLEX and RANCO

Refrigerating fluid . R. 12 Weight

of refrigerating fluid _..._.._._._..,_..__.................................................... 1 kg ( 2.2 lbs )

Oil for lubricating compressor TOTAL LUNARIA 25 or SUNISO No. 5

or TEXACO CAPELLA (( E )) grade 500

Quantity of oil for lubricating compressor ,

280 g i.e. a height of 21 to 29 mm

f

CJSCC,~~ ior SANKYO UIVI~WSSO~ J

* Only fitted on vehicles fitted with converter and air-conditioning option.

Page 362 of 394

Downloaded from www.Manualslib.com manuals search engine II. OPERATING PRINCIPLE

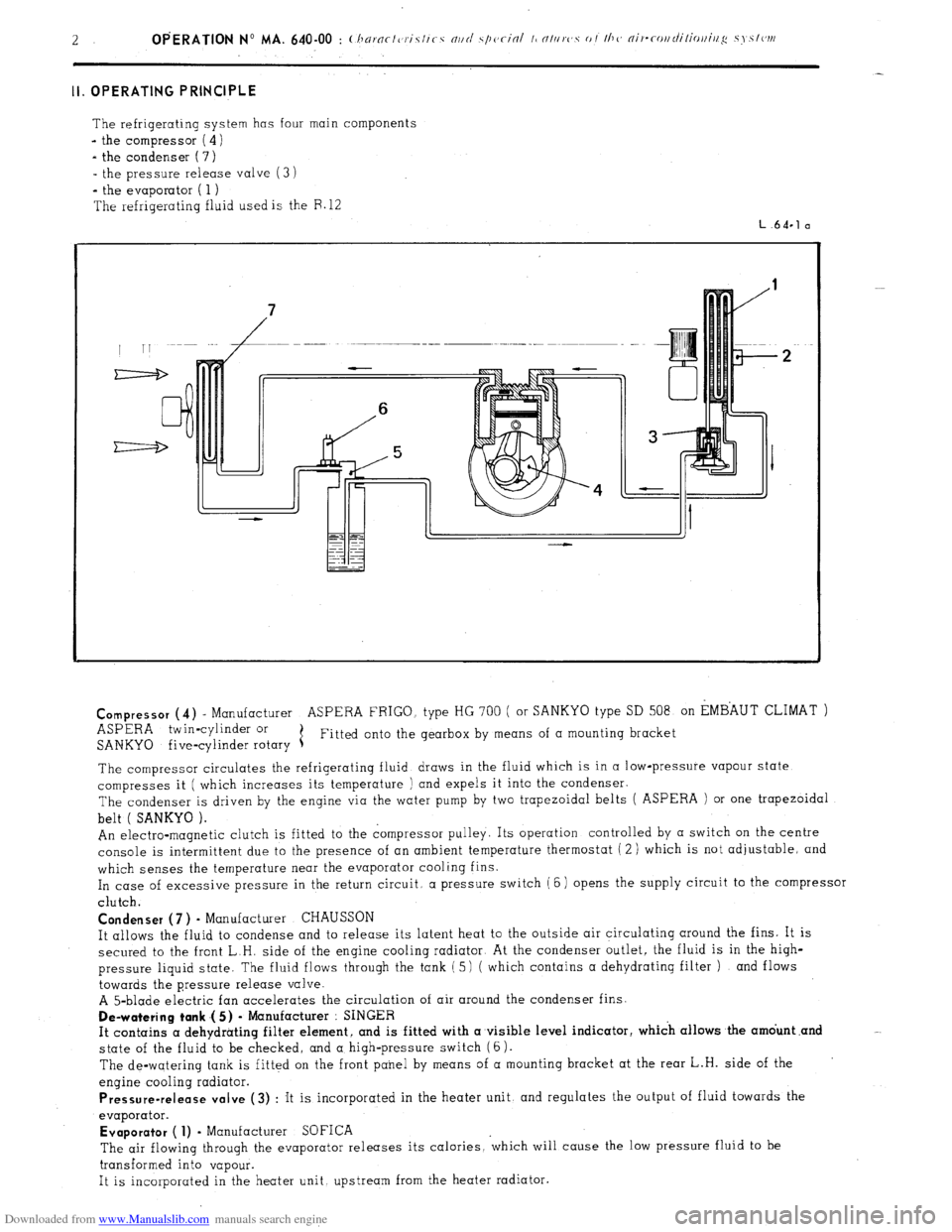

The refrigerating system has four main components

- the compressor ( 4)

- the condenser ( 7)

- the pressure release valve (3 i

*

the evaporator ( 1 )

The refrigerating fluid used is the F. 12

L.64.1 a

Compressor

(4) - Manufacturer ASPERA FRIGO. type HG 700 ( or SANKYO type SD 508 on EMBAUT CLIMAT )

ASPERA twin-cylinder or

SANKYO five-cylinder rotary 1 Fitted onto the gearbox by means of a mounting bracket

The compressor circulates the refrigerating fluid draws in the fluid which is in a low-pressure vapour state

compresses it ( which increases its temperature ) and expels it into the condenser.

The condenser is driven by the engine via the water pump by two trapezoidal belts ( ASPERA ) or one trapezoidal

belt ( SANKYO ).

An electro-magnetic clutch is fitted to the compressor pulley. Its operation controlled by a switch on the centre

console is intermittent due to the presence of an ambient temperature thermostat ( 2 ) which is not adjustable, and

which senses the temperature near the evaporator cooling fins.

In case of excessive pressure in the return circuit, a pressure switch (6) opens the supply circuit to the compressor

clutch.

Condenser (7 ) - Manufacturer CHAUSSON

It allows the fluid to condense and to release its latent heat to the outside air circulating around the fins. It is

secured to the front L.H. side of the engine cooling radiator At the condenser outlet, the fluid is in the high-

pressure liquid state. The fluid flows through the tank ( 5) ( which contains a dehydrating filter ) and flows

towards the pressure release valve.

A 5-blade electric fan accelerates the circulation of air around the condenser fins.

De-watering tank .( 5) - Manufacturer : SINGER

It contains a dehydrating filter element, and is fitted with a visible level indicator, which allows the amdunt .and

state of the fluid to be checked, and a high-pressure switch (6).

The de-watering tank is fitted on the front panel by means of a mounting bracket at the rear L.H. side of the

engine cooling radiator.

Pressure-release valve (3) : It is incorporated in the heater unit, and regulates the output of fluid towards the

evaporator.

Evaporator ( 1) - Manufacturer SOFICA

The air flowing through the evaporator releases its calories, ‘which will cause the low pressure fluid to be

transformed into vapour.

It is incorporated in the heater unit upstream from the heater radiator.

Page 363 of 394

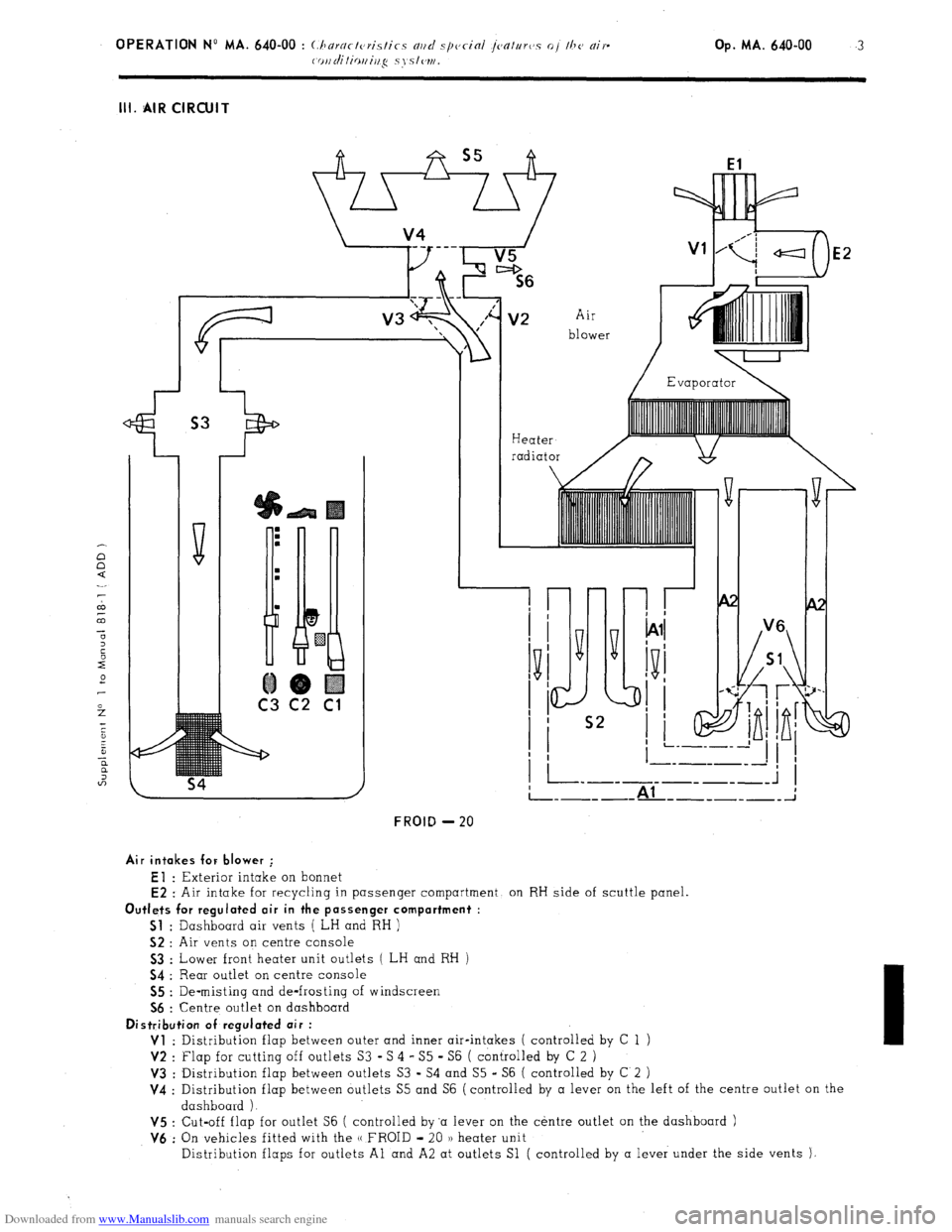

Downloaded from www.Manualslib.com manuals search engine III. AIR CIRCUIT

Heater

radiator

El

E2

Air

blower

I-

FROID - 20

__------- ----- _; Al

E2 : Air intake for recycling in passenger compartment, on RH side of scuttle panel.

Outlets for regulated air in the passenger compartment :

Sl

: Dashboard air vents ( LH and RH )

52 : Air vents on centre console

Air intakes for blower ;

El : Exterior intake on bonnet

53 : Lower front heater unit outlets ( LH and RH )

54 : Rear outlet on centre console

55 : De-misting and de-frosting of windscreen

56 : Centre outlet on dashboard

Distribution of regulated air :

Vl

: Distribution flap between outer and inner air-intakes ( controlled by C 1

V2 : Flap for cutting off outlets S3 -S 4 - S5 - S6 ( controlled by C 2 )

V3 : Distribution flap between outlets S3 - S4 and S5 - S6 ( controlled by C 2

V4 : Distribution flap between outlets S5 and S6 (controlled by a lever on the left of the centre outlet on the

dashboard ).

V5 : Cut-off flap for outlet S6 ( controlled by ‘a lever on the centre outlet on the dashboard )

V6 : On vehicles fitted with the u FROID - 20 )I heater unit

Distribution flaps for outlets Al and A2 at outlets Sl ( controlled by a lever under the side vents ),

Page 364 of 394

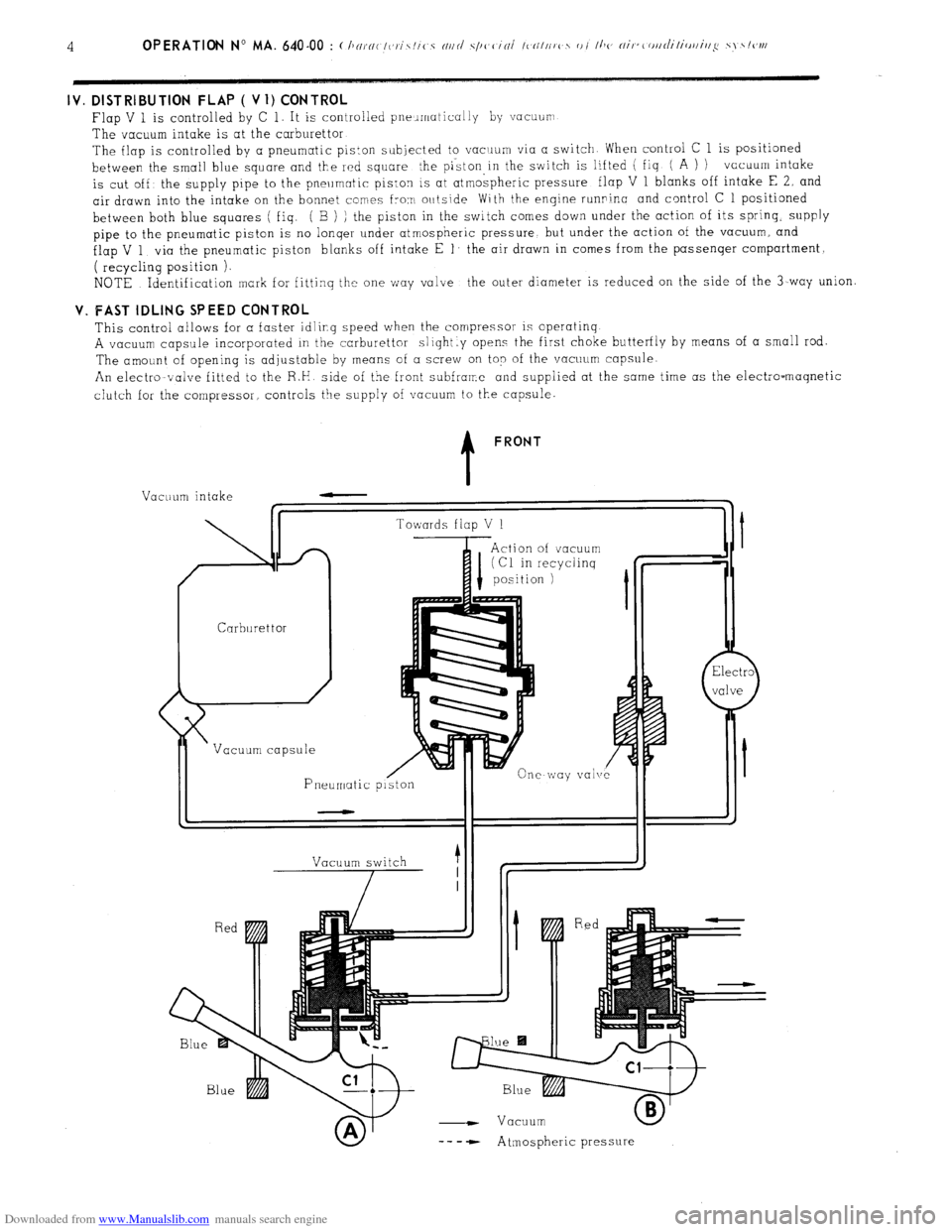

Downloaded from www.Manualslib.com manuals search engine IV. DISTRIBUTION FLAP ( Vl) CONTROL

Flap V 1 is controlled by C 1. It is controlled pneumatically by vacuurr

The vacuum intake is at the carburettor

The flap is controlled by a pneumatic piston subjected to vacrrum via a switch When control C 1 is positioned

between the small blue square and the red square the piston,in the switch is lifted ( fiq ( A ) ) vacuum intake

is cut off’ the supply pipe to the pneumatic piston is at atmospheric pressure flap V 1 blanks off intake E 2, and

air drawn into the intake on the bonnet comes from outside With the engine runninc and control C 1 positioned

between both blue squares ( fiq. ( B ) ) the piston in the switch comes down under the action of its spring.

supply

pipe to the pneumatic piston is no lonqer under atmospheric pressure but under the action of the vacuum, and

flap V 1 via the pneumatic piston blanks off intake E 1’ the air drawn in comes from the passenqer compartment,

( recycling position ).

NOTE Identification mark for fittinq the one way valve the outer diameter is reduced on the side of the 3-way union V. FAST IDLING SPEED CONTROL

This control allows for a faster idling speed when the compressor is operatinq

A vacuum capsule incorporated in the carburettor slightly opens the first choke butterfly by means of a small rod.

The amount of opening is adjustable by means of a screw on top of the vacuum capsule.

An electromvalve fitted to the R.H side of the front subframe and supplied at the same time as the electro-maqnetic

clutch for the compressor controls the supply of vacuum to the capsule. t FRONT

Vacuum intake

Carburettor /

Vacuum capsule

Pneumatic p Towards flap V 1

Action of vacuum

I (Cl in recyclinq

position 1

vale

Vacuum switch

7 1

- Vacuum

-- - - Atmospheric pressure

Page 365 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 640-00 : (:hnrnc-/eris/ics nrtd s.pcc-in/ ~bntttrcs of I/T<< nir- Op. ihA. 640-00 5

c-ottdiliottittg systc~ttt

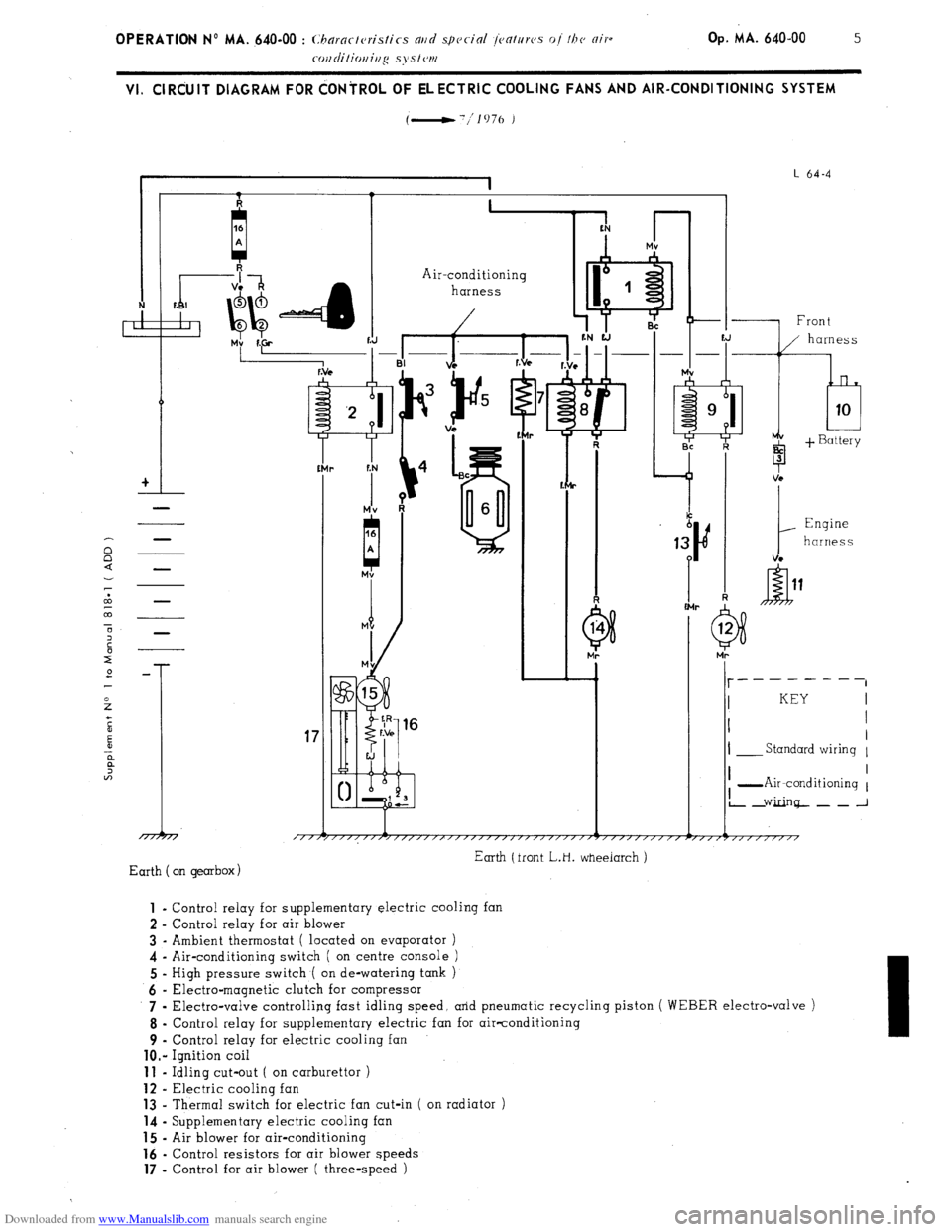

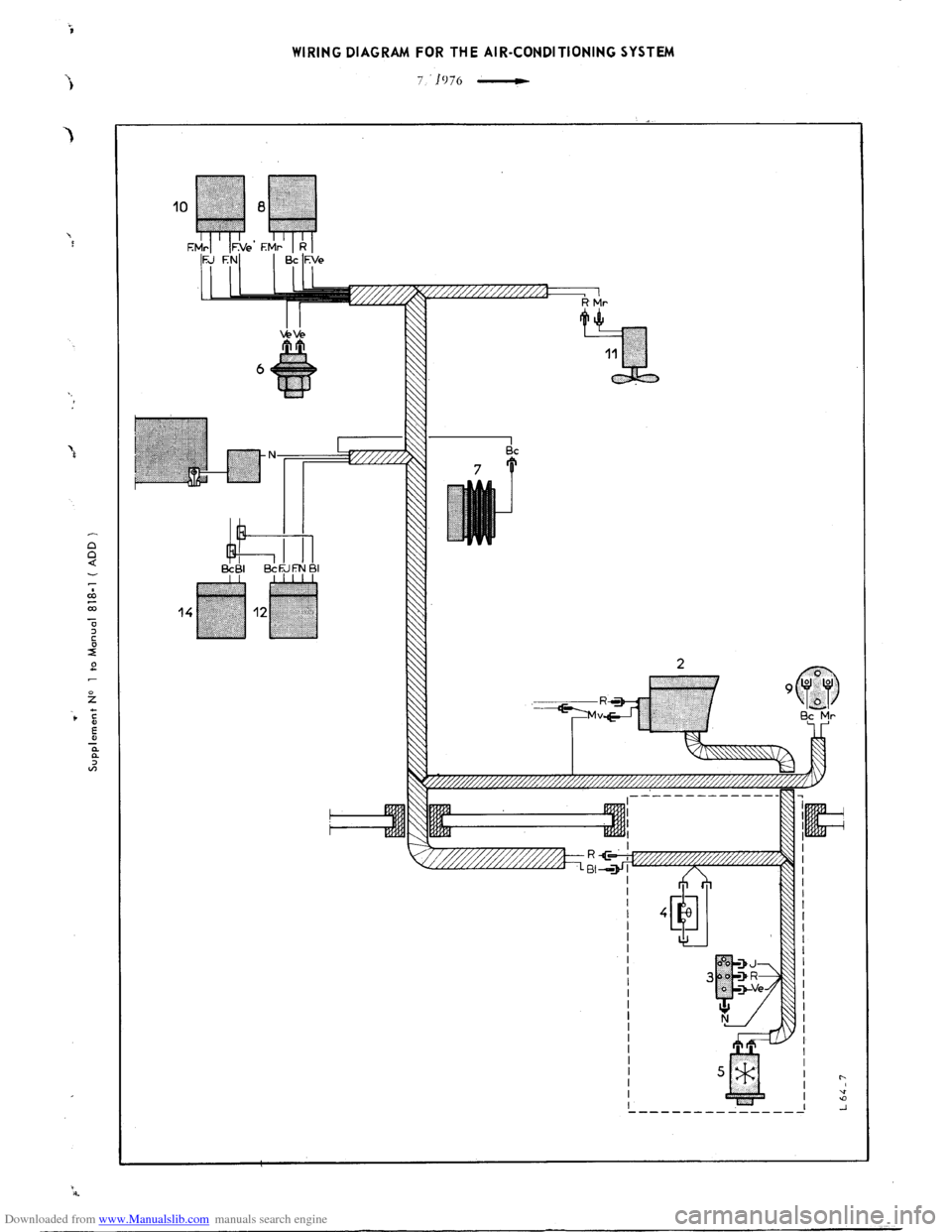

VI. ClRdUlT DIAGRAM FOR dONiROL OF ELECTRIC COOLING FANS AND AIR-CONDITIONING SYSTEM

(-'/lo76 )

I

I L 64-4

I 1. I

+I

-

Air-conditioning

harness

r

-I% ii.+

f:N

r

Mv

A

-1 Front

b 3

1

Engine

harness

VC -

I- __------

I KEY

I I

I

I- Standard wiring 1

17

/TTj I I

I -Air-conditioning 1

L2Ginq--~_J

Earth (front L.H. wheeiarch )

Earth on gearbox) 1

- Control relay for supplementary electric cooling fan

2 - Control relay for air blower

3 - Ambient thermostat ( located on evaporator )

4 - Air-conditioning switch ( on centre console )

5 - High pressure switch ( on de-watering tank )

6 - Electra-magnetic clutch for compressor

7 .

Electra-valve controlling fast idling speed, arid pneumatic recycling piston ( WEBER electro-valve )

8 - Control relay for supplementary electric fan for air-conditioning

9 - Control relay for electric cooling fan

lo.- Ignition coil 11

- Idling cut-out ( on carburettor ) 12

- Electric cooling fan 13

- Thermal switch for electric fan cut-in ( on radiator ) 14

- Supplementary electric cooling fan 15

- Air blower for air-conditioning 16

- Control resistors for air blower speeds 17

- Control for air blower ( three-speed )

Page 366 of 394

Downloaded from www.Manualslib.com manuals search engine Operating principle :

Both electric fans ( 12) and ( 14) cool the engine coolant in the radiator. Electric fan ( 14) cools the condenser

when the compressor expels the air-conditioning cooling fluid under pressure.

Simultaneous supply to fans (12) and (14) :

This is carried out by means of contacts in relays ( 1 ) and ( 9). The fl ow of current in the energizinq winding of

relays ( 1 ) and ( 9) therefore operates both electric fans simultaneously.

The relay windings are supplied when

- ignition is switched on

*

thermal switch ( 13) controlled by the coolant temperature in the radiator is off. _-

Supply to supplementary electric fan ( 14) alone :

This is carried out by contacts in relay ( 8) when its energizing winding is supplied

The relay winding is supplied when

- ignition is on

- air-conditioning switch ( 4) is off

a

contact on the ambient temperature thermostat ( 3) is closed.

Supply to the electro-magnetic clutch for the compressor :

The clutch supply is a function of the following

- Air-conditioning switch (4)

- Ambient temperature thermostat ( 3 )

-

High pressure switch ( 5).

Supply to the blower ( 15) :

This is carried out by resistors ( 16) of the rheostat. This rheostat controls the speed of the blower ( 3-speed )

and consequently, the volume of displaced air.

Page 367 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 640-00 : (hnrnct~~tis~ics md special jenttrrvs of the nir-

coi~ditiouing systcw. 1 Op. MA. 640-00

7

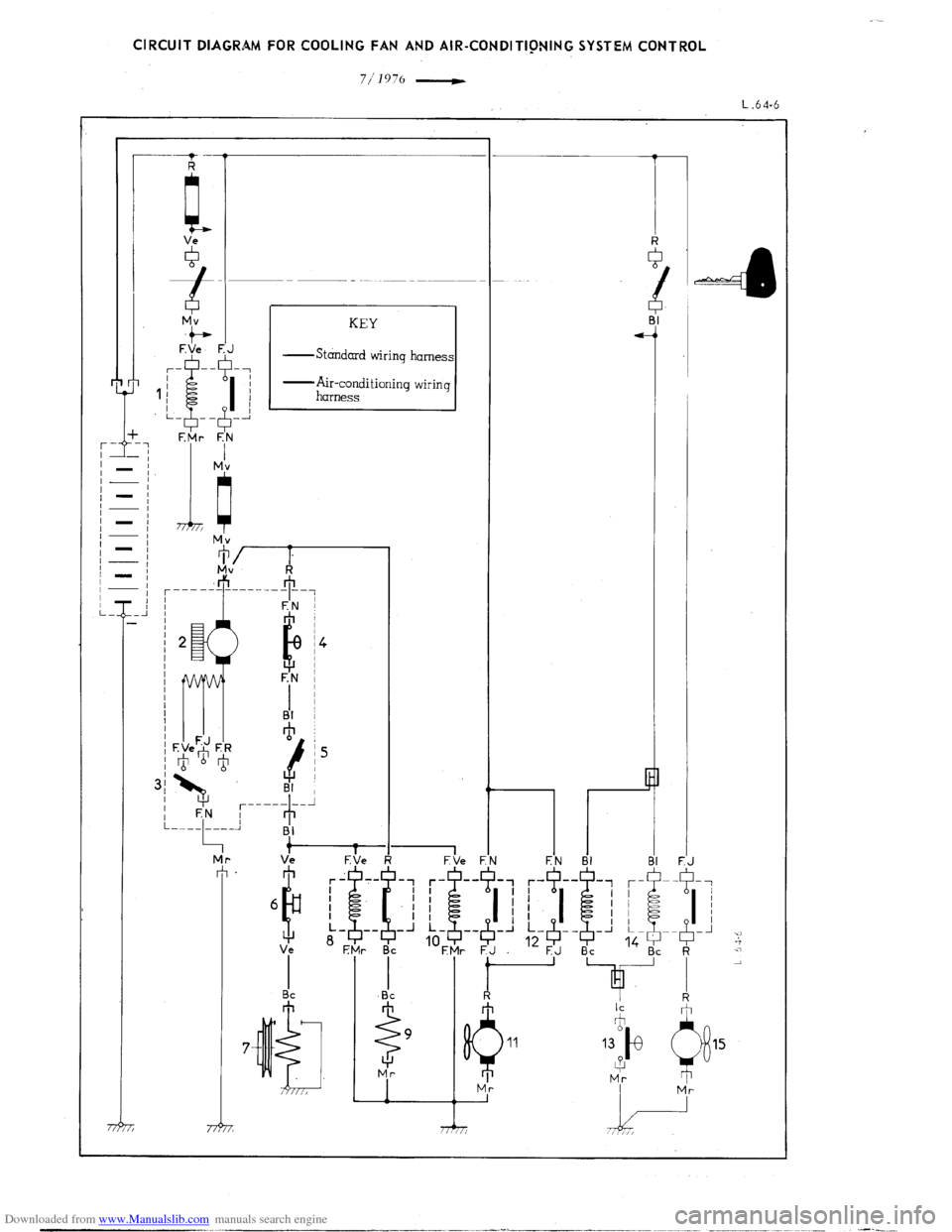

VII. WIRING DIAGRAMS FOR COOLING FAN AND AIR-CONDITIONING SYSTEM CONTROLS

7.; 1976 - Special features :

From 1977 models, the fast-idle electro-valve ( 9) is manufactured by (( PIERBLJRG )).

When it is not energized. the electro-valve lets low pressure through to.wards the carburettor capsule (fast-

idle ) I contrary to the (( WEBER )) electro-valve fitted previously.

Fitting the (( PIERBURG )) electro-valve necessitates fitting a relay (8) which is energized when the air-

conditioning system is operating. This relay with its N open )) contact cuts off supply to electro-valve ( 9)

which therefore produces fast-idle.

The rest of the operation is identical to the preceding diagram. DESCRIPTION OF COMPONENTS :

1

- Heater relay ( standard )

2 - Air blower ( Stmdnrd )

3 - Speed control for blower f Stnudnrd )

4 - Regulating thermostat

5 - Air-conditioning switch

6 - Pressure switch ( on dc-wnkrivg t~rrk ,)

7 - Compressor cl.utch

8 - Control relay for fast-idle electro-valve

9 - Fast-idle electro-valve

10 - Relay f0r’L.H. supplementary electric fan ( air-rorzditio)litlg J 11

i Supplementary L.H. electric fan ( cooliug )

12 - Relay for L.H. supplementary electric fan ( cooling ) 13

- Control thermostat ( on radiator ) for electric fans ( Standard ) 14

- Relay for R.H. electric fan ( Stmzdurd 1

15 - Electric cooling fan ( Stnrrdurd )

e

P.T.O.

Page 368 of 394

Downloaded from www.Manualslib.com manuals search engine

Page 369 of 394

Downloaded from www.Manualslib.com manuals search engine

Page 370 of 394

Downloaded from www.Manualslib.com manuals search engine Op. MA. 640-O 1 II CHECKING AND ADJUSTING :

1. Checking the operation of the air-conditioning :

Faulty operation may be due to the following

Insufficient quantity of R.12 fluid, caused by

improper filling 01 a leak.

Water in the system.

Insufficient quantity of fluid may be detected by examining the transparent index mark of the de-watering tank.

This lack of fluid would be shown up by the appearance of air-bubbles during operation.

The presence of water is shown up by the formation of a small quantity of ice near the pressure release valve

which causes irregular functioning of the system.

In both cases. the system must be drained. the circuits niust be put under vwzuum (to eliminate any trace of

water ). and refilled with R.12 fluid. 2. Corburation

: Adjusting the idling speeds (as soon as electric coolinq fans cut out )

a) Vc,hirlcs wi/hou/ loryue con wrtcr :

Engine idling speed 850 to 900 rpm ( compressor switched off )

Fast idling speed 1000 to 1050 rpm ( compressor in operation )

b) Vrhirles with torque co~twrt~~r

Engine idling speed 700 to 750 rpm ( compressor switched off )

Fast idling speed 725 to 775 rpm ( handbrake on, vehicle immobilised. one gear engaged, and compressor

switched off 1

The fast idling speed is adjustable by means of adjusting screw located on top of the vacuum capsule on the

cmburettor. NOTE

: In case the fast idle is impossible to obtain, the vacuum capsule may be moved ( slacken both fixing

screws on carburettor ). in order to reduce the clearance at the fixing point of the rod controlling the first

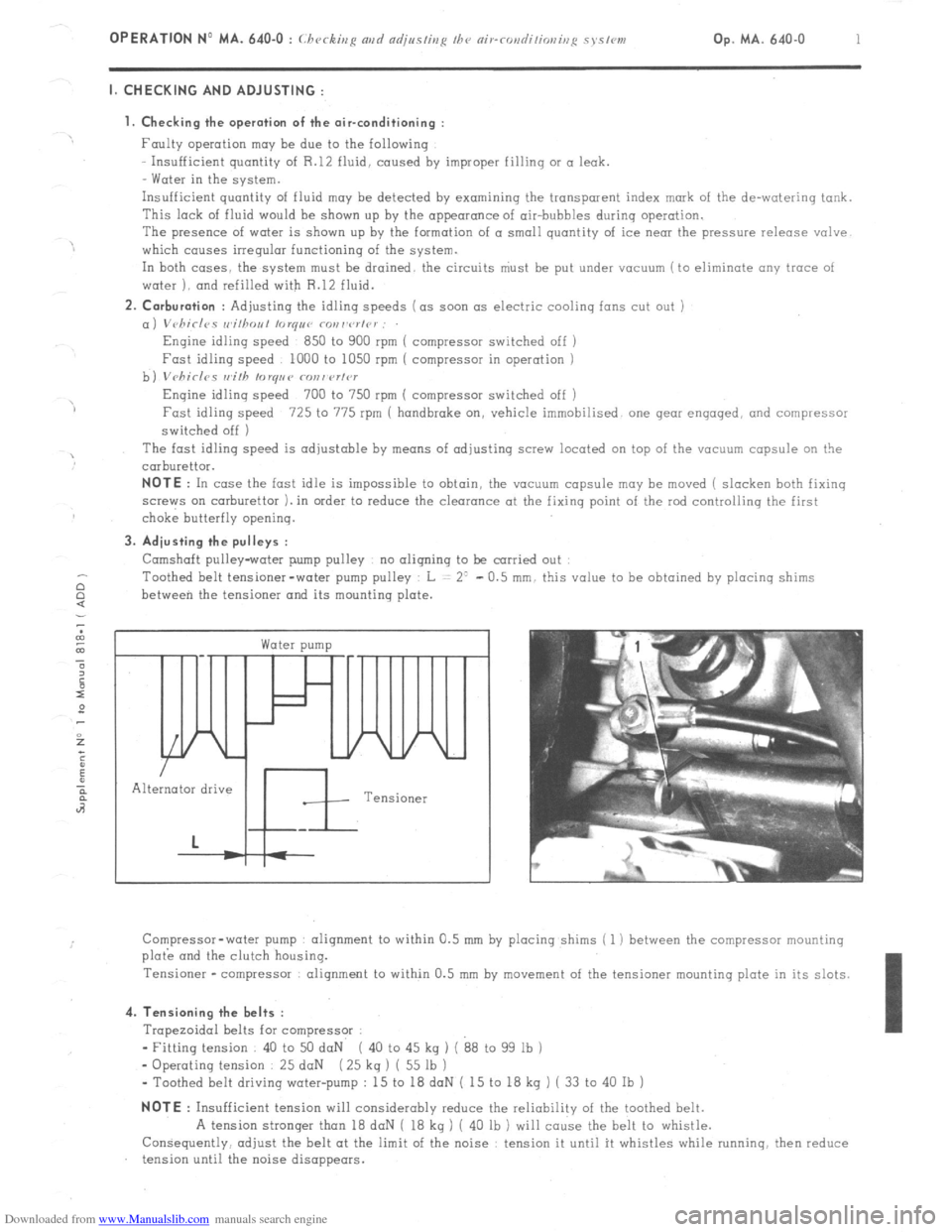

choke butterfly opening. 3. Adjusting the pulleys :

Camshaft pulley-water pump pulley no aligning to be carried out

Toothed belt tensioner-water pump pulley L = 2’ - 0.5 mm. this value to be obtained by placing shims

between the tensioner and its mounting plate. c

Water pump /

In

Alternator drive

Tensioner

Compressor-water pump alignment to within 0.5 mm by placing shims ( 1 ) between the compressor mounting

plo& and the clutch housing.

Tensioner -compressor alignment to within 0.5 mm by

movement of the tensioner mounting plate in its slots. 4. Tensioning the belts :

Trapezoidal belts for compressor :

- Fitting tension 40 to 50 daN ( 40 to 45 kg ) ( 88 to 99 lb )

- Operating tension 25 daN ( 25 kq ) ( 55 lb )

- Toothed belt driving water-pump : 15 to 18 doN ( 15 to 18 kg ) ( 33 to 40 Ib ) NOTE

: Insufficient tension will considerably reduce the reliability of the toothed belt.

A tension stronger than 18 daN ( 18 kg ) ( 40 lb ) will cause the belt to whistle.

Consequently, adjust the belt at the limit of the noise : tension it until it whistles while running. then reduce

tension until the noise disappears.