length Citroen CX 1983 1.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1983, Model line: CX, Model: Citroen CX 1983 1.GPages: 394

Page 66 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 100-00 : Characteristics and special features of the engine. Op. MA. 100.00 15

b) Timing chain :

- Clearance between the chain and the chain guide : . . . . . . . . . . . . . . . . . . . . . . . . . . 0.10 to 0.50 mm

c) Rockers :

- Length of push rods :

- Inlet : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189.10 ‘, Og’Q5 mm

- Exhaust : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213.35 + 0.3

- 0.75 mm

- Maximum out of true of pushrods : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 mm

- Rocker clearance (engine cold) :

-Inlet : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.15mm

- Exhaust : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 mm

7. Flywheel :

2 - Distance between the clutch mechanism thrust face, and the 0 u clutch disc thrust face : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 -is mm

7

co

G NOTE : It is essential to fit the diaphragm or flywheel mounting screws with LOCTITE FRENETANCH.

x

z - Correct fitting of starter ring : non machined face of the ring facing the flywheel shouldering.

s

2

E 8. Lubrication system :

5

z

6%

- Grade of oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TOTAL ALTIGRADE GTS 20/W 50

2

- Capacity of sump :

- after dismantling : . . . . . . . .._................................................................. 5.800 litres ( IO.2 pts )

- after draining and changing the filter : : . . . . . . . . . . . . . . . l......................... 5.306 litres ( 9.3 pts )

- after draining : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.650 litres ( 8.2 pts )

- Oil pressure :

(At a temperature of 100 +‘S’ C)

- at 2000 rpm : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 .bar min. ( 43.5 psi )

- at 4000 rpm : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 to 5 bar ( 58 to 72 l/2 psi )

- Calibration of pressure switch : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475 to 675 mbar ( 7 to 9.8 psi )

(warning lamp goes oat)

- Calibration of temperature switch (CX 2000 e Jan. 1975) : . . . . 1... 147’ to 150’ C

(warning lamp goes comes on)

(All CX vehicles Jan. 1975 -) : 135” to 138’ C

(warning lamp comes on )

- Calibration of relief valve spring :

- length of spring fully compressed : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 mm

- length of spring under load of 10.9 kg : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 mm

- Filter cartridge :

- calibration of (( by-pass )) valve : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 550 mbar ( 8 psi )

NOTE : When changing the filter cartridge, check the cleanliness of the seal and’the contact area on the filter

housing.

- For removing and fitting the cartridge : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Use Tool 6002-T

Page 95 of 394

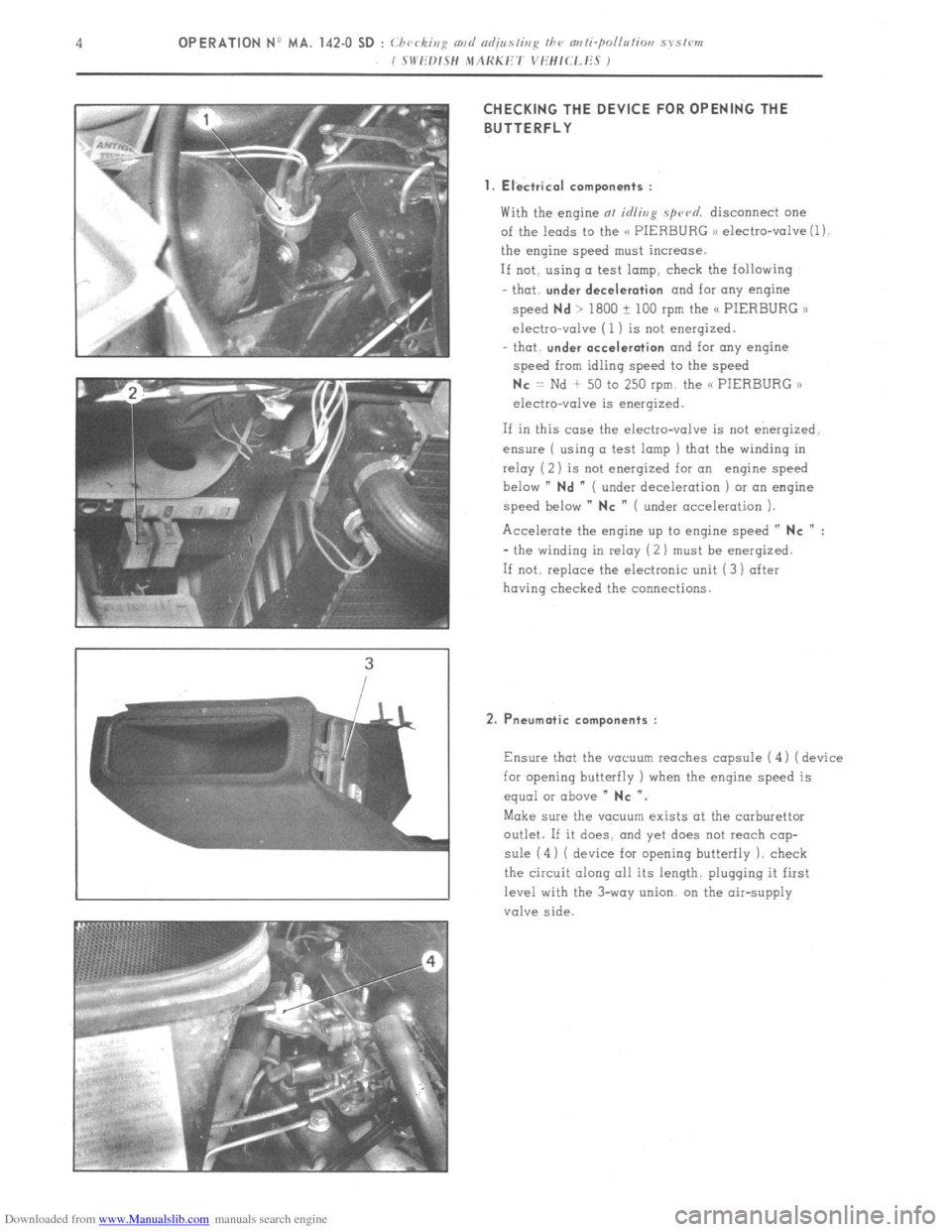

Downloaded from www.Manualslib.com manuals search engine CHECKING THE DEVICE FOR OPENING THE

BUTTERFLY

1. Electrical components :

With the engine at idling spu~d. disconnect one

of the leads to the C< PIERBURG ,) electro-valve (1).

the engine speed must increase.

If not. using a test lamp, check the following

that.

under deceleration and for any engine

speed

Nd > 1800 ? 100 rpm the /C PIERBURG >l

electro-valve (1 ) is not energized.

- that.

under acceleration and for any engine

speed from idling speed to the speed

Nc = Nd + 50 to 250 rpm. the C< PIERBURG ,,

electro-valve is energized.

If in this case the electro-valve is not energized.

ensure ( using a test lamp ) that the winding in

relay ( 2) is not enerqized for an engine speed

below ”

Nd ” ( under deceleration ) or an engine

speed below ”

NC ” ( under acceleration ).

Accelerate the engine up to engine speed ”

NC n :

- the winding in relay (2 ) must be enerqized.

If not. replace the electronic unit (3) after

having checked the connections.

2. Pneumatic components :

Ensure that the vacuum reaches capsule ( 4 1 ( device

for opening butterfly ) when the engine speed is

equal or above ”

NC “.

Make sure the vacuum exists at the carburettor

outlet. If it does. and yet does not reach cap-

sule (4) ( device for opening butterfly 1. check

the circuit along all its length. plugging it first

level with the 3-way union. on the air-supply

valve side.

Page 150 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 173-O : Chrrkivp fhr prmd s,,pp/> Op. MA. 173.0 1

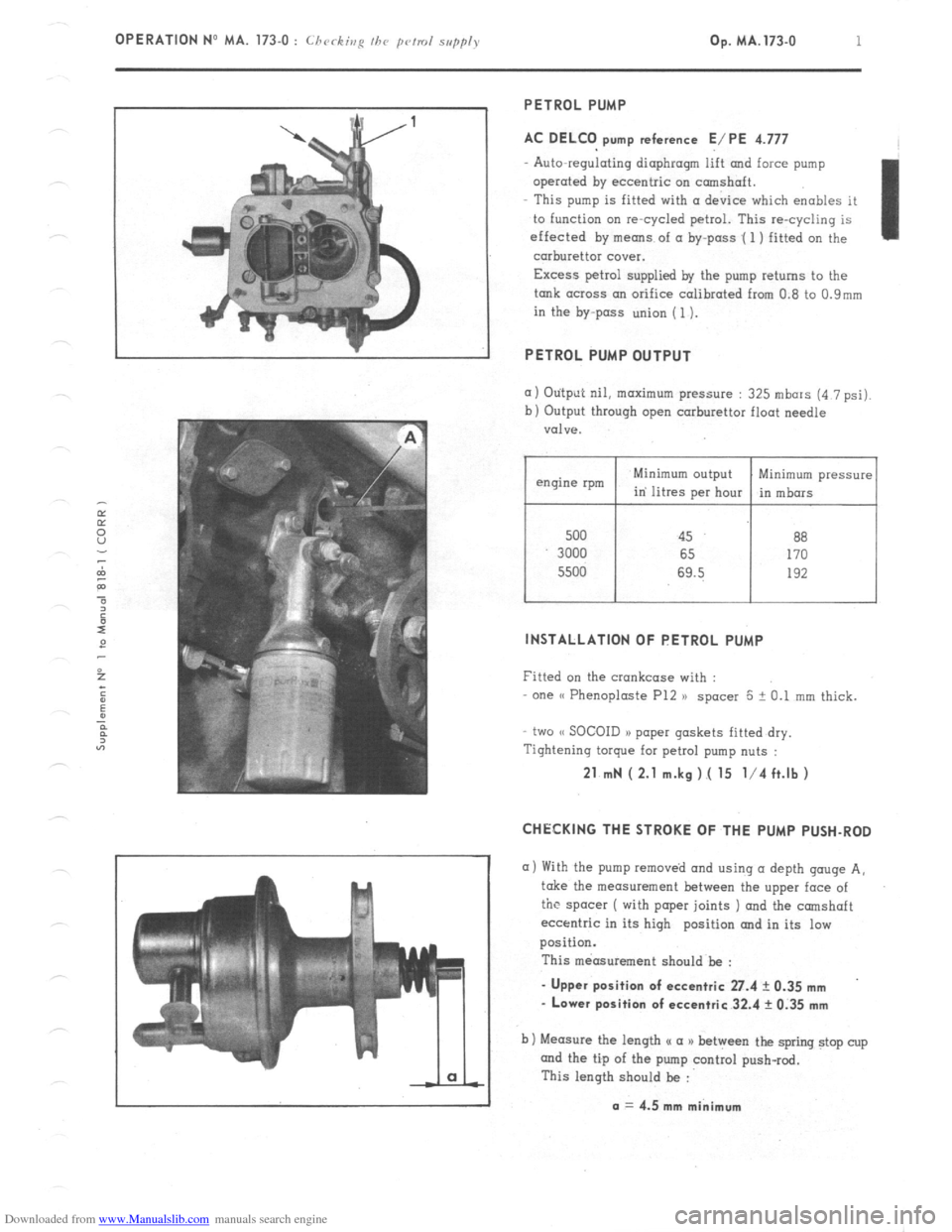

PETROL PUMP

AC DELCO pump reference E/PE 4.777

Auto-regulating diaphragm lift and force pump

operated by eccentric on camshaft.

This pump is fitted with (I device which enables it

to function on re-cycled petrol. This re-cycling is

effected by means of a by-pass .( 1 ) fitted on the

carburettor cover.

Excess petrol supplied by the pump returns to the

tank across an orifice calibrated from 0.8 to 0.9mm

in the by-pass union (1).

PETROL PUMP OUTPUT

(I) Otitput nil, maximum pressure : 325 mbars (4 7 psi).

b) Output through open carburettor float needle

valve.

500 45 88

3000 65 170

5500 69.5 192

I I

Minimum pressure

in mbors

INSTALLATION OF PETROL PUMP

Fitted on the crankcase with :

one (( Phenoploste P12 )) spacer 5 + 0.1 mm thick.

two (< SOCOID a> paper gaskets fitted dry.

Tightening torque for petrol pump nuts :

21 mN ( 2.1 m.kg ).( 15 l/4 ft.lb )

CHECKING THE STROKE OF THE PUMP PUSH-ROD

a) With the pump removed and using (I depth gouge A,

take the measurement between the upper face of

the spacer ( with paper joints ) and the camshaft

eccentric in its high position and in its low

position.

This measurement should be :

- Upper position of eccentric 27.4 ? 0.35 mm

- Lower position of eccentric 32.4 rk 0.35 mm

b) Measure the length u a a) between the spring stop cup

and the tip of the pump control push-rod.

This length should be :

a = 4.5 mm minimum

Page 153 of 394

Downloaded from www.Manualslib.com manuals search engine 2 OPERATION No MA. 210-00 :~~‘hornc:cris:ics mri special /~~nttrrc,.s o,/ /he ig/litiorl Spark plug gap .,...._.......,...,. ,..._. ,...... ., ,, ,,

Q.6 to 0.7 mm

1 iqhtenrng torque ( cylinder head cold ) .._..._._........._.......... .20 to 25 mN ( 2 to 2.5 m.kg)

f Smear the thread with e NO-BIND n ) - ( 14 l/2 to 18 ft.Ib ) IGNITION COIL

External resistor type

I Manufacturer

I DUCELLIER

I SEV MARCHAL

I MARELLI

Reference N” 2777 C E 44 910 312 BZR 206 A

Primary circuit resistance ( at 20” C ) 0.68 i 0.02 n 1.1 to 1.2 Q 0.8+ 10 .: ,R

Resistance of outer resistor (at 20” C ) 1.32 + 5 ‘; R 1.5 to 1.6 R 1.35 i 4 . . R

Secondary circuit resistance (at 20” C ) 7500 2 1000 n

6000 -!I 5 Cl 7500 + 10 !’ Q H.T. LEADS

Length in mm Resistance of leads ( at 20” C )

Manufacturer. .................. .......................................................... ..................................................... ELECTRIFIL

Reference ..................... ............. ........... ....... ....... ... ........................ ............ ......... Bougicord 400 RTF 33

All rY?biclas ( - I/’ 1975 1

Description of leads

Coil to distributor ............................ ...........

Distributor to No 1 cylinder ... . ..................

Distributor to No 2 cylinder .......................

Distributor to N” 3 cylinder ........................

Distributor to N” 4 cylinder ........................ 570 to 580 625 to 1025 !J

400 to 410 420 to 645 11

520 to 530 555 to 850 11

540 to 550 580 to 880 Q

710 to 720 770 to 1165 Q

I I I

Description of leads Length in mm

I Resistance of leads ( at 20” C )

Coil to distributor ......................................... 820 to83O- 10 1 75 -859 to 860

Distributor to No 1 cylinder ..................... 360 to 370

Distributor to N” 2 cylinder ........................ 520 to 530

Distributor to NC 3 cylinder ....................... 540 to 550

Distributor to N” 4 cylinder

...................... 710 to 720 920 to 1400 - 10 175 -93.3 to 1450

400 to 570 n

555 to 850 R

580 to 880 Q

770 to 1165 Q

I I 1

Page 155 of 394

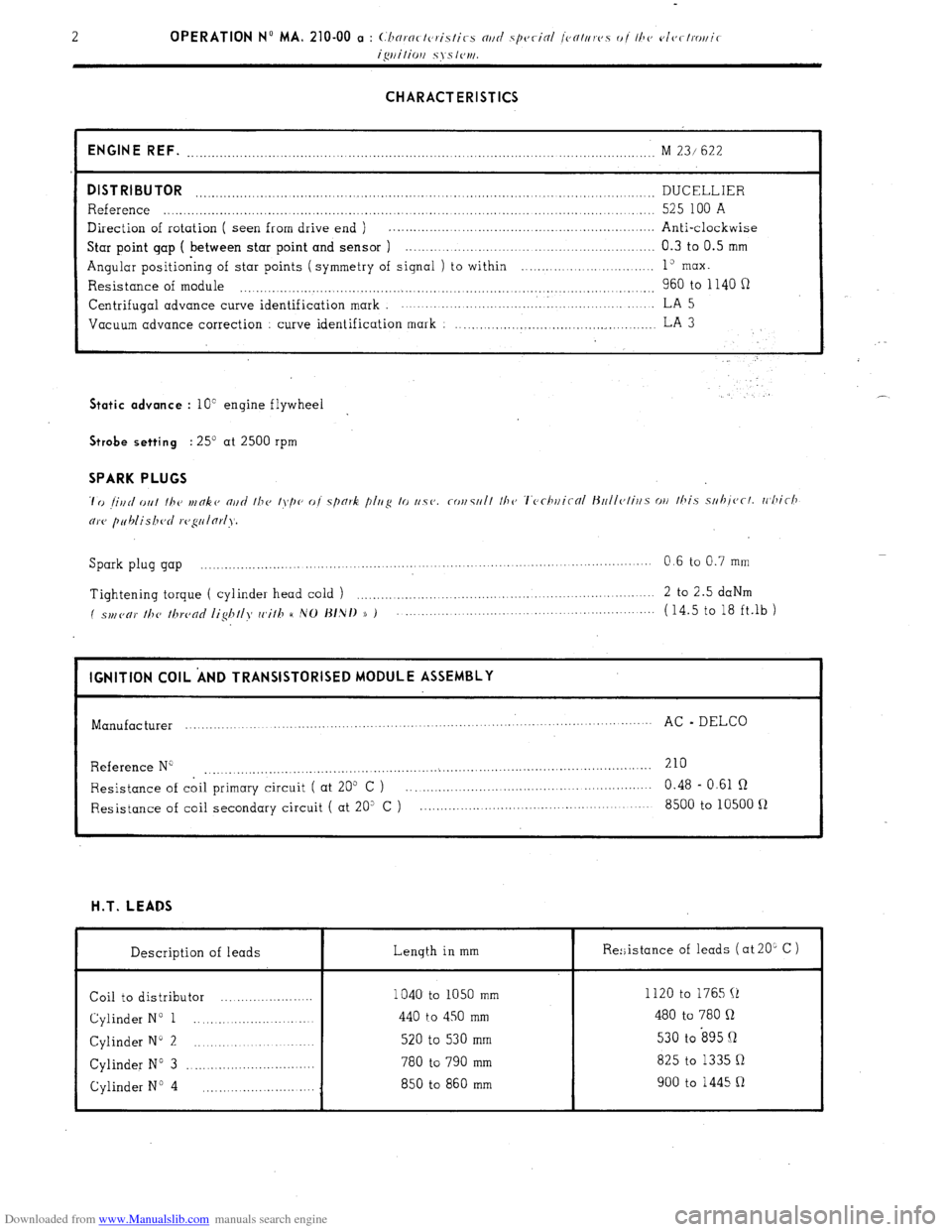

Downloaded from www.Manualslib.com manuals search engine CHARACTERISTICS

ENGINE REF.

........................................................................................... ........................ M 23/ 622

DISTRIBUTOR DUCELLIER ..................................................................................................................

Reference ..................................................................................................................... 525 100 A

Direction of rotation ( seen from drive end ) . .................................................................

Anti-clockwise

Star point gap ( between star point and sensor ) .............................................................. 0.3 to 0.5 mm

Angular positioning of star points ( symmetry of signal ) to within ........... ... ... ....... ..... 1” max.

Resistance of module 960 to 1140 fi .................................................................................................. Centrifugal

advance curve identification mark ................................. . ..................... LA 5

Vacuum advance correction

curve identification mark : ..................................................

LA 3 Static advance

: 10” engine flywheel . .’ Strobe setting

: 25’ at 2500 rpm SPARK PLUGS

Spark plug gap ................. ....

.................... ................... ....... 0.6 to 0.7 mm

......................... .........

Tightening torque ( cylinder head cold ) ....................................................................

2 to 2.5 daNm

( spl,(,c,)’ //T(, /hrc,nc/ /ig/T//>f cc,i//T H ,VO J~/,N/) )) ) ...................................................... (14.5 to 18 ft.lb )

I IGNITION COIL ‘AND TRANSISTORISED MODULE ASSEMBLY

I

Manufacturer ...............

................... ........ .............. .............. .......

AC - DELCO

...........................

Reference N” 210

....................................................... ...

....................................................

Resistance of coil primary circuit ( at 205 C ) ............................................................ 0.48 - 0.61 R

Resistance of coil secondary circuit ( at 20” C ) ......................................................... 8500 to 10500 fl H.T. LEADS

Description of leads Length in mm

Coil to distributor ....................... 1040 to 1050 mm

Cylinder N” 1 ............................ 440 to 450 mm

Cylinder N” 2 ............................. 520 to 530 mm

Cylinder N” 3 ................................ 780 to 790 mm

Cylinder No 4 850 to 860 mm

............................ Re:;istance of leads ( at 20L C )

I

1120 to 1765 (1

480 to 780 Q

530 to s95 Q

825 to 1335 Q

900 to 1445 R

Page 178 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 230.0 : M k

08 ,ri,y r,i, //I<’ roo/i,ip c, s,w,,.

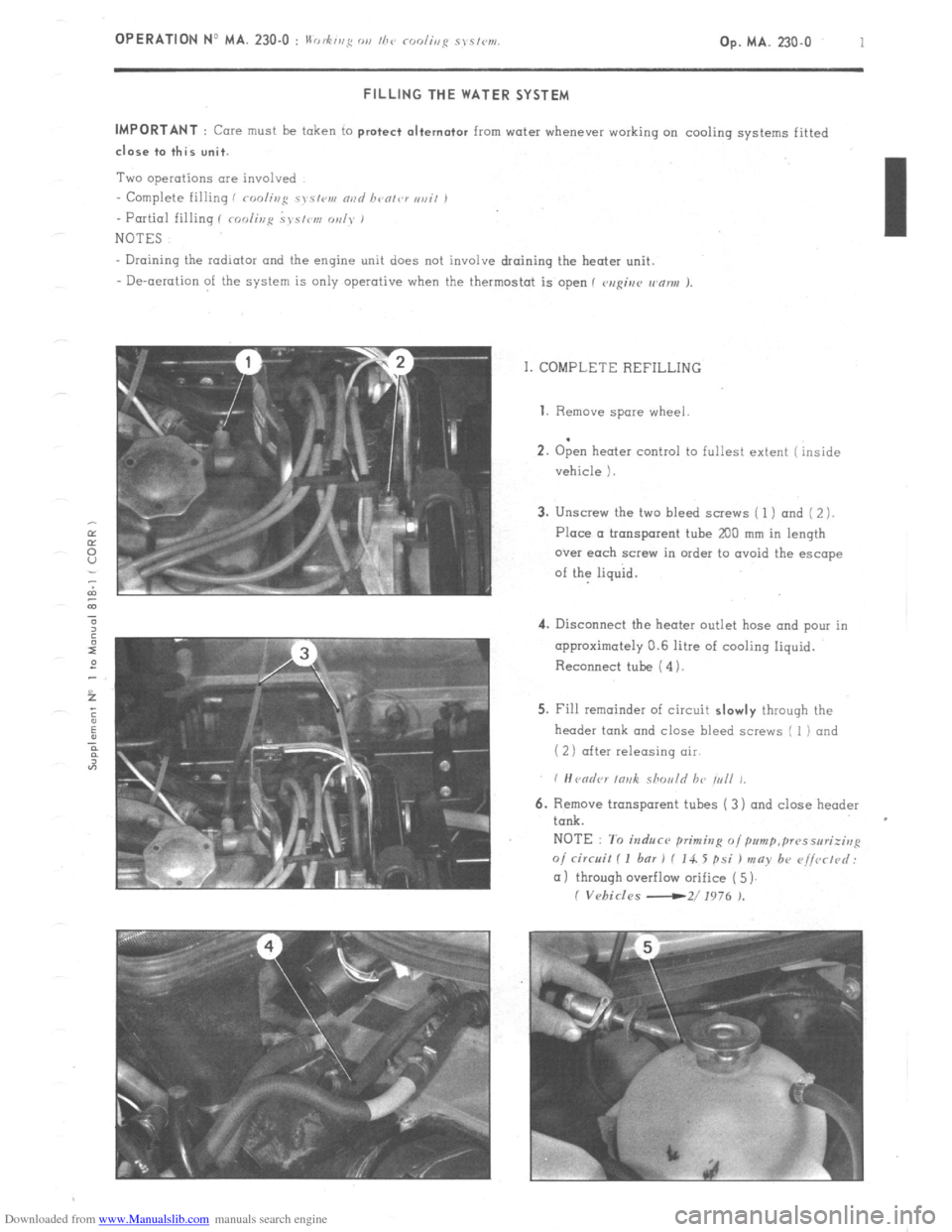

Op. MA. 230.0 1 FILLING THE WATER SYSTEM

IMPORTANT

: Core must be token to protect alternator from water whenever working on cooling systems fitted close to this unit.

Two operations are involved

- Complete filling i roolir~g c~s~<,v, nvd bvolvr ,,ail ,

- Partial filling I roolir,p ~J~S/IW, oul~* 1

NOTES

Draining the radiator and the engine unit does not involve draining the heater unit.

- De-aeration of the system is only operative when the thermostat is open 1 v,rgiur wnnu J.

I. COMPLETE REFILLING 1. Remove

spare wheel

.

2. Open heater control to fullest extent ( inside

vehicle 1.

3. Unscrew the two bleed screws ( 1 ) and ( 2 ).

Place a tronsporent tube

200 mm in length

over each screw in order to ovoid the escape

of the liquid.

4. Disconnect the heater outlet hose and pour in

approximately 0.6 litre of cooling liquid.

Reconnect tube ( 4).

5. Fill remainder of circuit slowly through the

header tank and close bleed screws I 1) and

( 2) after releasing air

6. Remove transparent tubes ( 3) and close header

tank.

NOTE : To induce primitzg o/pum~,~~~sseri;irrp

o/ circuit I I bar 1 f 14. 5 psi ) may b+ r~i/vrtd:

(11 through overflow orifice ( 5)

I Vehicles -2/ 1976 ).

Page 213 of 394

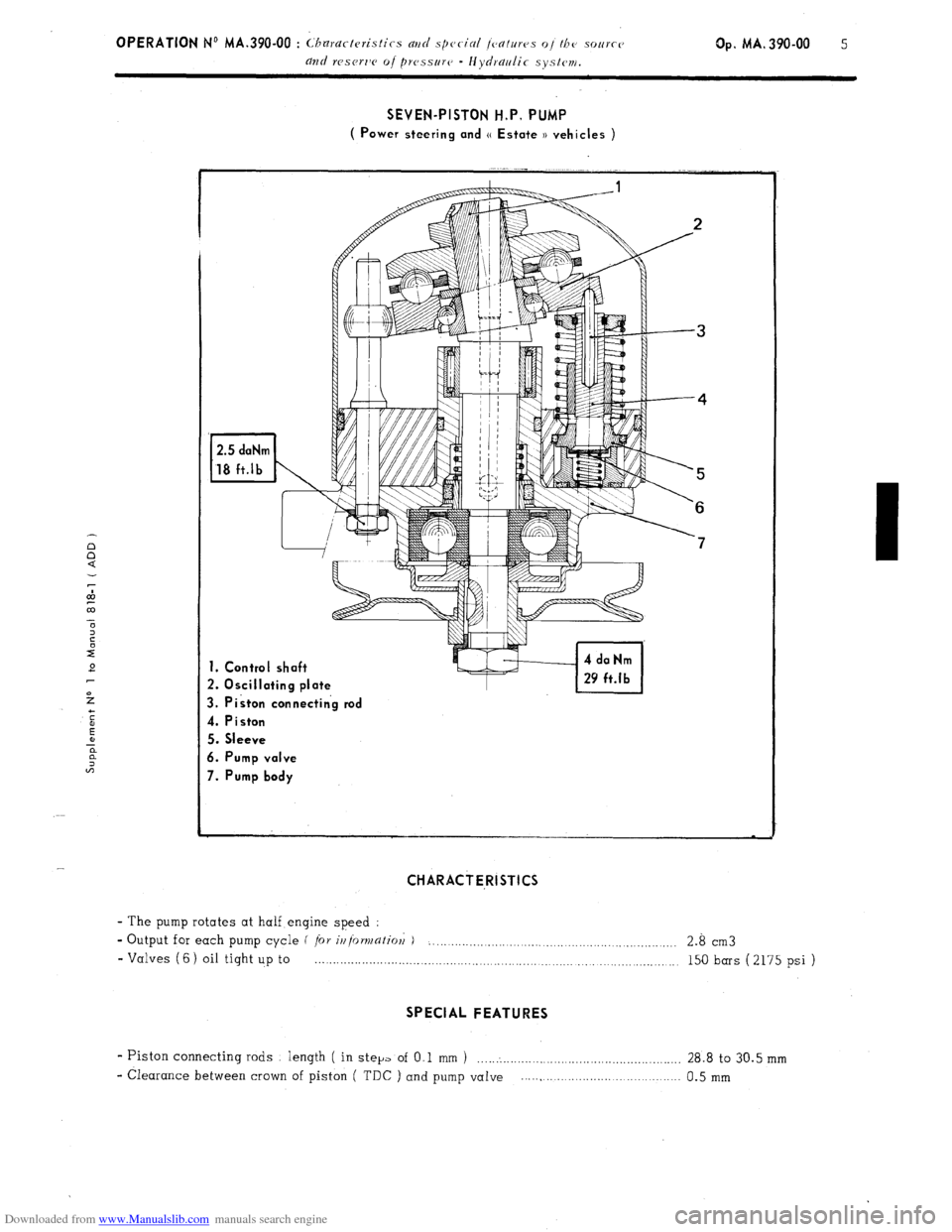

Downloaded from www.Manualslib.com manuals search engine SEVEN-PISTON H.P, PUMP

( Power steering and (( Estate )) vehicles )

1. Control shaft

2. Oscillating plate

3. Piston connectin’g rod

4. Piston

5. Sleeve

6. Pump valve

7. Pump body

CHARACTE,RISTICS

- The pump rotates at half engine speed :

- Output for each pump cycle f

/or ir/{orv/afiol; ) . . . . . . . . . . .._.._........._.........._.........._............. 2.8 cm3

- Valves (6) oil tight up to . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._._....... 150 bars (2175 psi )

SPECIAL FEATURES

- Piston connecting rods length ( in step of O,l mm 1 ......................................................... 28.8 to 30.5 mm

- Clearance between crown of piston ( TDC ) and pump vaIve ..... , ...................................... 0.5 mm

Page 235 of 394

Downloaded from www.Manualslib.com manuals search engine 4 OPERATION No MA. 410-00 : (haractvristirs avd special jmtms oi the irout aslc urrit REPAIRS :

- Old type (( fluid-bloc )) bushes ( length : 79.5 mm ) must not be fitted with the later wheelarms.. and vice-versa.

- It is possible, on any vehicle, to fit one, or both sides with the later wheelarms, providing the appropriate shims

are used.

Page 236 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 410-O : ( /,c

1

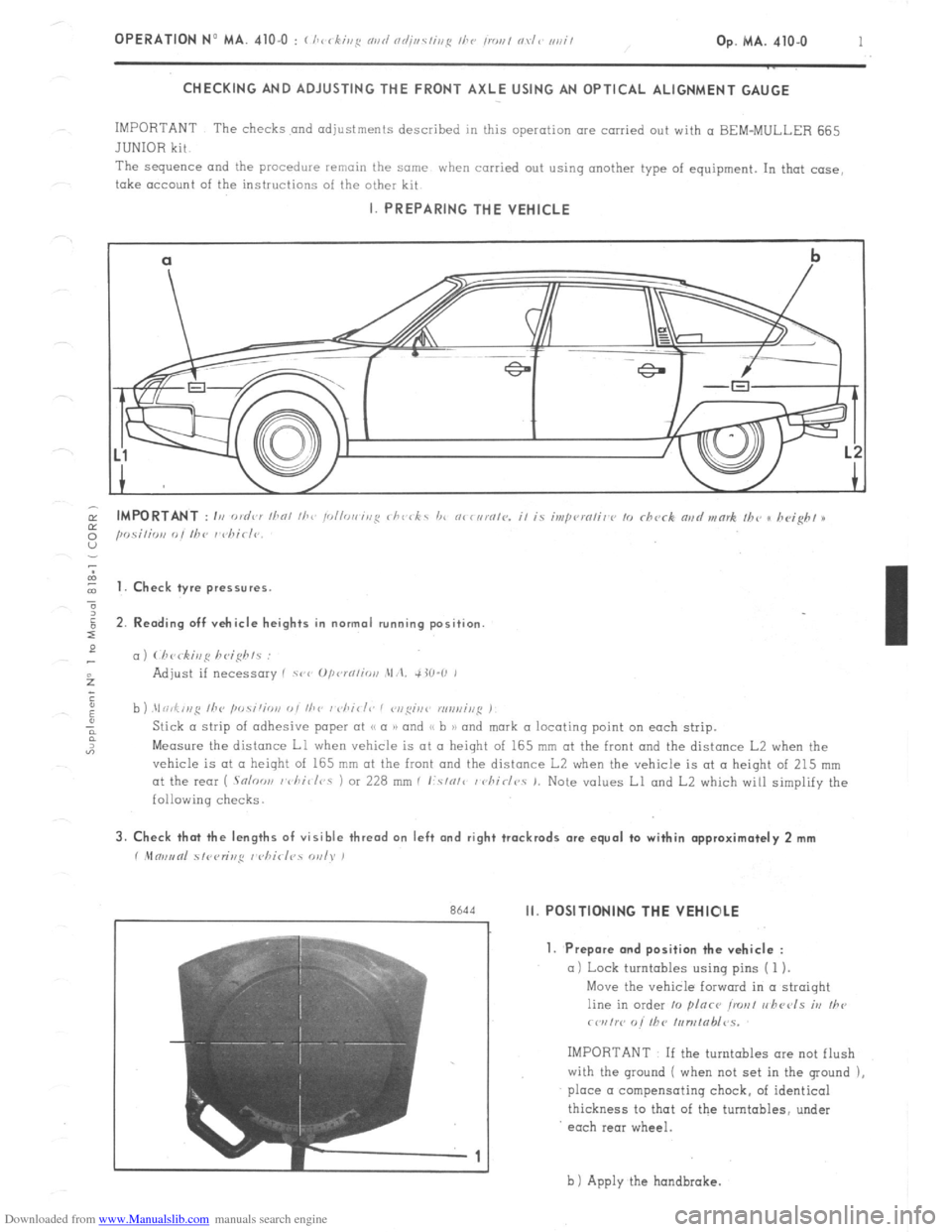

CHECKING AND ADJUSTING THE FRONT AXLE USING AN OPTICAL ALIGNMENT GAUGE

IMPORTANT The checks and adjustments described in this operation are carried out with a BEM-MULLER 665

JUNIOR kit

The sequence and

the procedure remain the same when carried out using another type of equipment. In that case,

take account of the instructions of the other kit I. PREPARING THE VEHICLE

cl

b

-.

I t 1. Check tyre pressures.

2. Rending off vehicle heights in normal running position

c,)

b ) .\I ri,f,,,g /he ,w.s;‘;o,,

Measure the distance Ll when vehicle is at II height of 165 mm at the front and the distance L2 when the

vehicle is at CL height of 165 mm at the front and the distance L2 when the vehicle is at a height of 215 mm

at the rear ( .Snloo,, I vhi~/r,s 1 or 228 mm I I:.s/o/c / chirlr,. 1. Note values Ll and L2 which will simplify the

following checks. 3. Check that the lengths of visible thread on left and right trackrods are equal to within approximately 2 mm

r .Mm,,tnl 51<,<,r;r,,q I <,hirl?s WI). )

r

Rh‘td Ii. POSITIONING THE VEHIOLE

7

-1 1. Prepare and position the vehicle :

a) Lock turntables using pins ( 1 ).

Move the vehicle forward in a straight

line in order 10 plnce ironl r,hccls iv

Ihe

rwrtw o/’ fhC /,,n,tab/~s.

IMPORTANT If the turntables ore not flush

with the ground ( when not set in the ground ),

place a compensating chock, of identical

thickness to that of the turntables, under

each rear wheel.

b 1 Apply the hondbrake.

Page 241 of 394

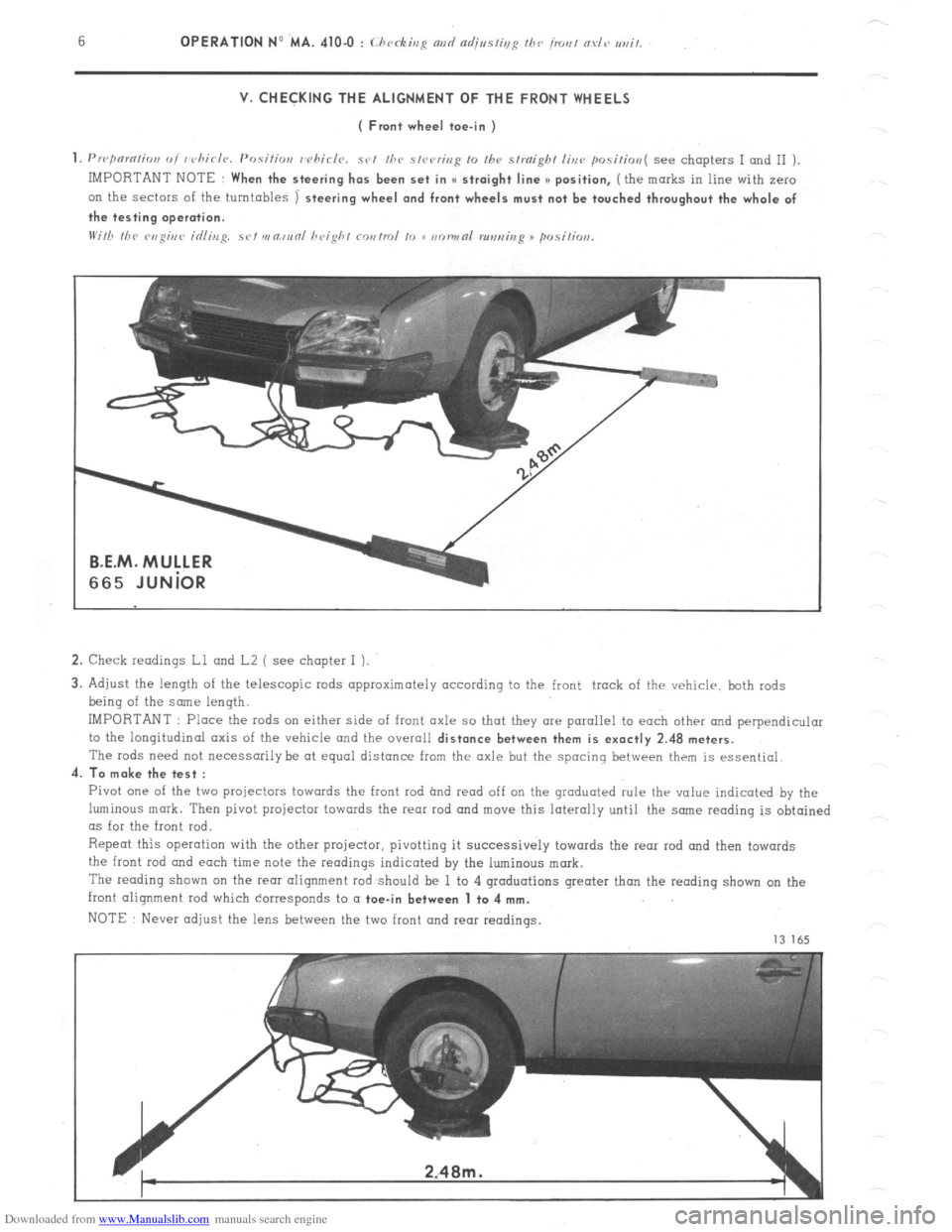

Downloaded from www.Manualslib.com manuals search engine V. CHECKING THE ALIGNMENT OF THE FRONT WHEELS

( Front wheel toe-in )

1. Prrpnmtion oi whirlr~. Positior,

whirls. set /he s,rering 10 Ihv straight line positim~( see chapters I and II )

IMPORTANT NOTE

When the steering has been set in I( straight line >) position, (the marks in line with zero

on the sectors of the turntables

1 steering wheel and front wheels must not be touched throughout the whole of

the testing operation.

2. Check readings Ll and L2 ( see chapter I ).

3. Adjust the length of the telescopic rods approximately according to the front track of the vehicle, both rods

being of the some length.

IMPORTANT : Place the rods on either side of front axle so that they are parallel to each other and perpendicular

to the longitudinal axis of the vehicle and the overall

distance between them is exactly 2.48 meters.

The rods need not necessarily be at equal distance from the axle but the spacing between them is essential.

4.

To make the test :

Pivot one of the two projectors towards the front rod hnd read off on the graduated rule thr value indicated by the

luminous mark. Then pivot projector towards the rear rod and move this laterally until the snne reading is obtained

as for the front rod.

Repeat this operation with the other projector, pivotting it successively towards the rear rod and then towards

the front

rod and each time note the readings indicated by the luminous mark.

The reading shown on the rem alignment rod should be 1 to 4 graduations greater than the reading shown on the

front alignment rod which corresponds to a

toe-in between 1 to 4 mm.

NOTE Never adjust the lens between the two front and rear readings.

13 165