length Citroen CX 1983 1.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1983, Model line: CX, Model: Citroen CX 1983 1.GPages: 394

Page 242 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 410-O : I hvr-6iq n,,d od;n.s/isg /hc /~,a, nrle uei/ Op. MA. 410-O 7

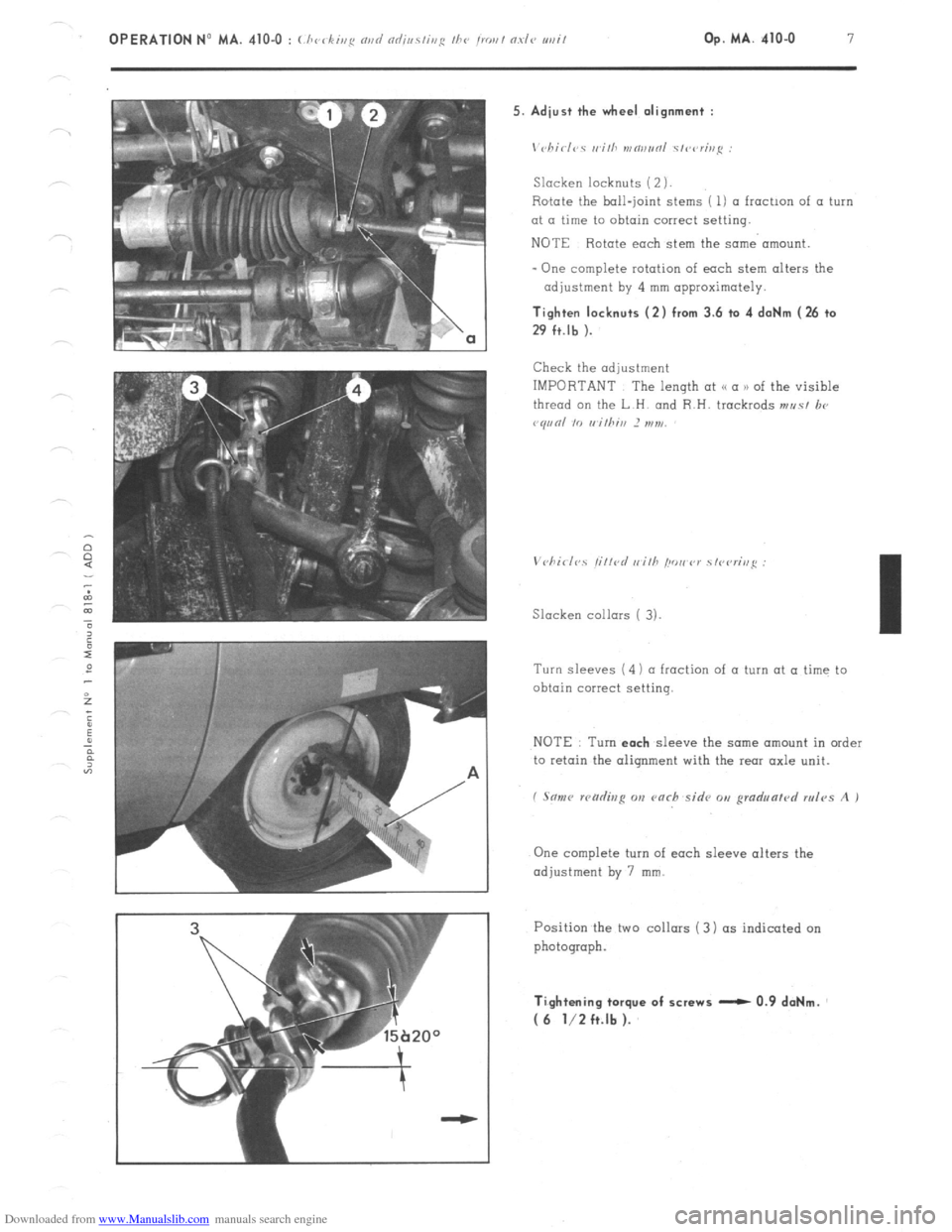

’ 15b20° 5. Adiust the wheel alignment :

\‘chirl‘,s II ilh mw,r,ol s/wrh,i: :

Slacken locknuts (2 ).

Rotate the ball-joint stems ( 1) a froctmn of a turn

at a time to obtain correct setting.

NOTE Rotate each stem the same’ amount.

- One complete rotation of each stem alters the

adjustment by 4 mm approximately. Tighten locknuts (2) from 3.6 to 4 daNm (26 to

29 ft.lb ).

Check the adjustment

IMPORTANT The length at (< a n of the visible

thread on the L.H. and R.H. trackrods ,,,r,s/ lx,

vq,,nl IO rrithin 2 ,,,7,,,

Slacken collars ( 3).

Turn sleeves (4) ~1 fraction of a turn at a time to

obtain correct setting.

NOTE Turn each

sleeve the same amount in order

to retain the oiiqnment with the rear axle unit.

I Son<, wcidisp on varh sidv o,, gmd,,lrrn/r,d rules A I

One complete turn of each sleeve alters the

adjustment by 7 mm.

Position the two collars ( 3) (IS indicated on

photograph. Ti.ghtening torque of screws - 0.9 daNm.

( 6 l/2 ft.lb ).

Page 243 of 394

Downloaded from www.Manualslib.com manuals search engine a OPERATION N’ MA. 410-O : (./~rrkiq N,,I/

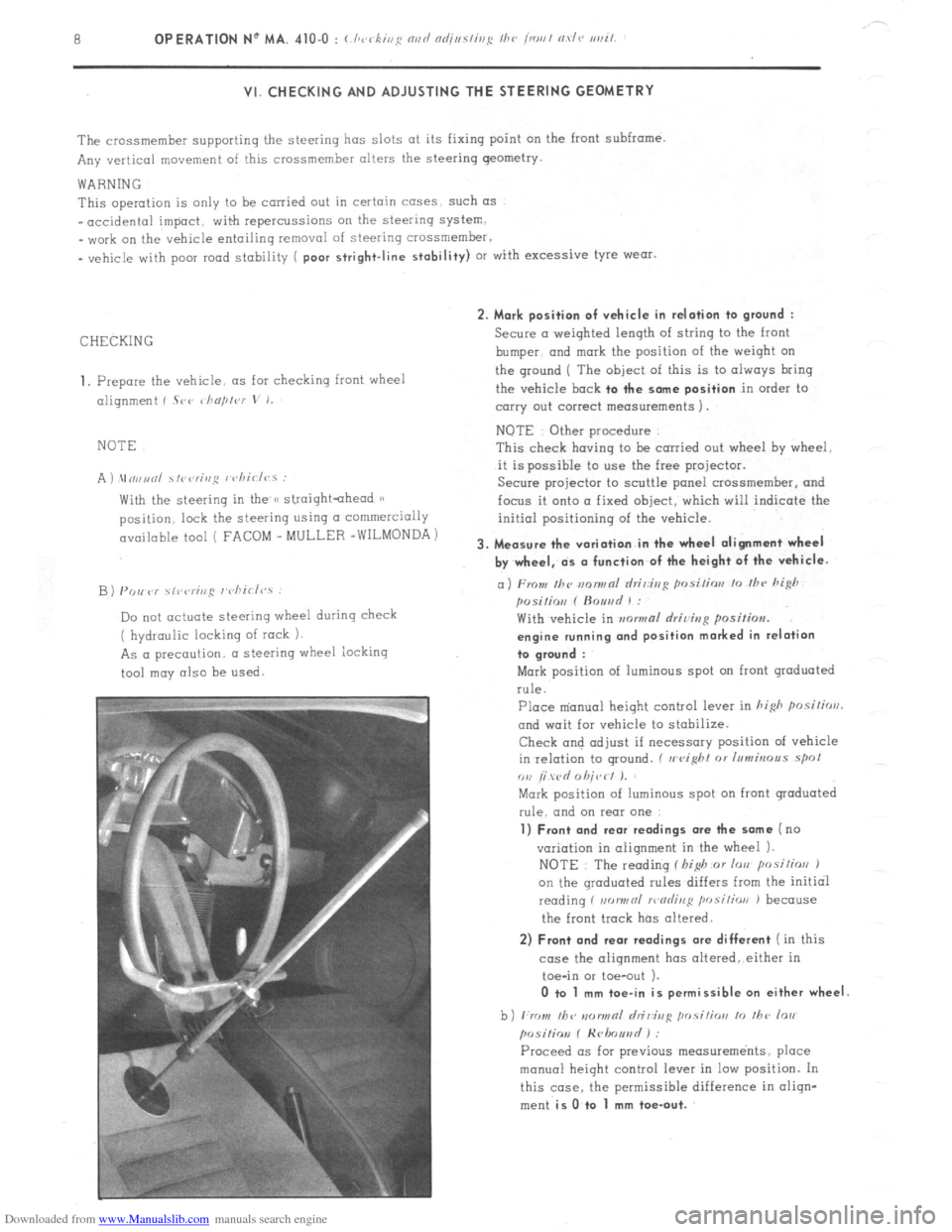

VI. CHECKING AND ADJUSTING THE STEERING GEOMETRY

The crossmember supporting the steering has slots at its fixing point on the front subframe.

Any vertical movement of this crossmember alters the steering geometry.

WARNING

This operation is only to

be carried out in certain ccxses such as

-accidental impact, with repercussions on the steering system.

-work on the vehicle entoiling removal of steering crossmember.

- vehicle with poor

road stability ( p oar stright-line stability) 01 with excessive tyre weor.

CHECKING

1, Prepare the vehicle. as for checking front wheel

alignment ( Srr ~ho/,lvr

V I.

NOTE

A ) \In,,unl ~fi~<,r;,,~ I chiclvs :

With the steering in the /< straightahead 1)

position. lock the steering using CI commercially

available tool ( FACOM _ MULLER -WILMONDA)

B) PO,, P)’ \,r,rr;ng r’cliirl<,.s :

Do not actuate steering wheel during check

( hydraulic locking of rock 1.

As a precaution. a steering wheel iocking

tool may also be

used. 2. Mark position of vehicle in relation to

ground :

Secure a weighted length of string to the front

bumper. and

mark the position of the weiqht on

the ground ( The

object of this is to always bring

the vehicle

bock to the some position in order to

carry out correct measurements 1.

NOTE Other procedure

This check having to be carried out wheel hy wheel.

it is possible to use the free projector.

Secure projector to scuttle panel crossmemher, and

focus it onto a fixed object, which will indicate the

initial positioning of the vehicle.

3. Measure the variation in the wheel alignment wheel

by wheel, ds o function of the height of the vehicle.

a) From Ihc m~nwnl rlri,:ir,g posi/ior, lo /hc hi@

posilio,, f ftouad 1 :

With vehicle in mwmal rlriving position.

engine running ond position marked in relation

to groond :

Mark position of luminous spot on front graduated

rule.

Place m’anual height control lever in hi&

posilirrrl.

and wait for vehicle to stabilize.

Check and adjust if necessary position of vehicle

in relation to ground. ( II

eight 01 Inmbrous spol

ou /i wd 0 hit,< I J.

Mark position of luminous spot on front graduated

rule. and on rear one

1) Front and rear readings ore the some (no

variation in alignment in the wheel 1.

NOTE : The reading f I,i$ or lorr posilios J

on the qroduated rules differs from the initial

reading f non,,nl >r,nrlinl:

position J because

the front track has altered.

2) Front and rear readings ore different ( in this

case the alignment has oltered,.either in

toe-in or toe-out ).

0 to 1 mm toe-in is permissible on either wheel

b) ,:rr ,,I, /bv IIDIINRI hi&g ,,osi,;orr lo ,I,<, lo,,

posiliov f Hrlmuad ) :

Proceed OS for previous measurements, place

manual height control lever in low position. In

this case. the permissible difference in oliqn-

ment

is O.to 1 mm toe-out.

Page 282 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 451-O : Uwckirrg the hrflkv rov,~o,rrnts Op. MA. 451.0 1

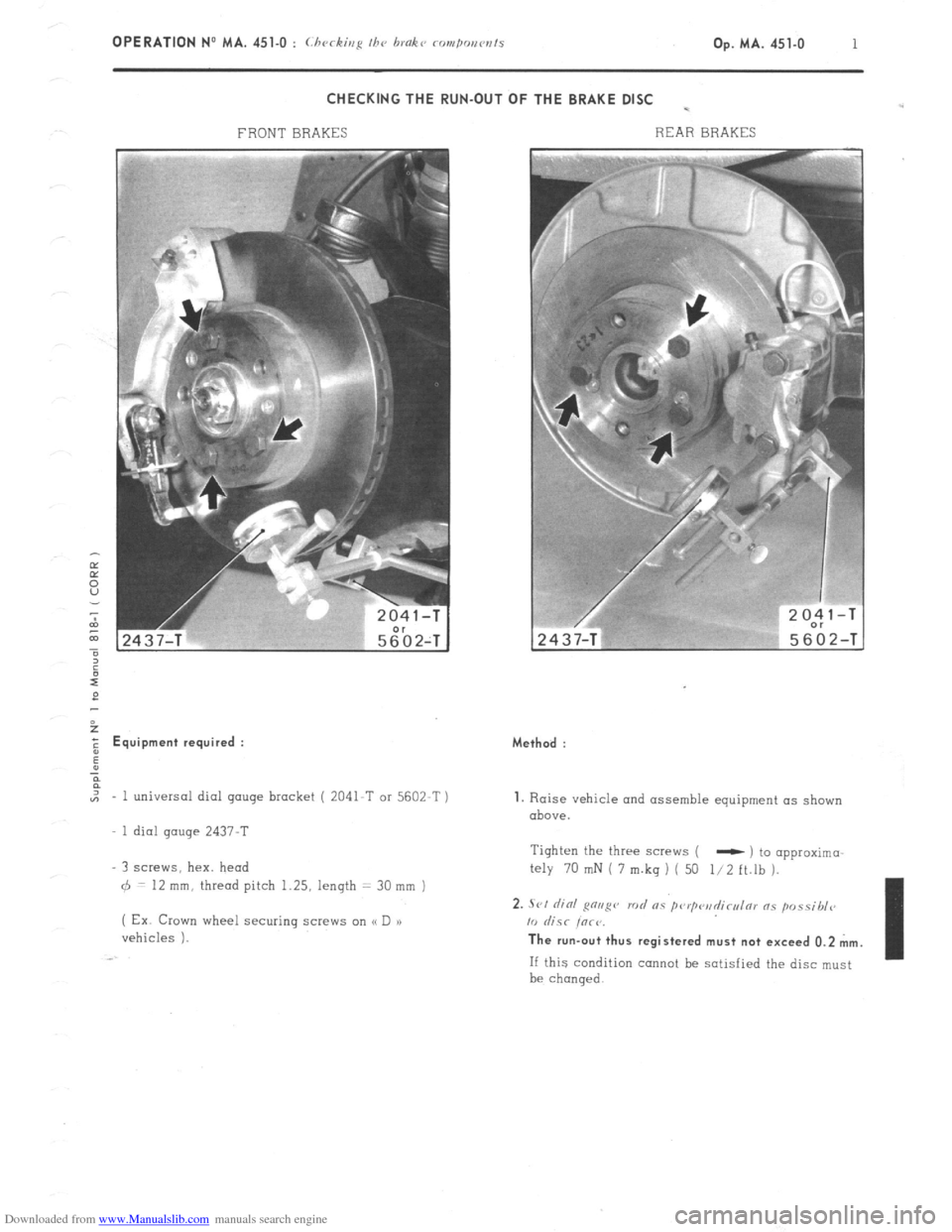

CHECKING THE RUN-OUT OF THE BRAKE DISC -

FRONT BRAKES REAR BRAKES 2

E Equipment required :

,,, - 1 universal dial gauge bracket ( 2041-T or 5602-T )

1 dial gauge 2437-T

3 screws, hex. head

6 = 12 mm, thread pitch 1.25, length = 30 mm )

( Ex Crown wheel securing screw on (< D a)

vehicles ). Method :

1. Raise vehicle and assemble equipment as shown

above.

Tighten the three screws (

- ) to opproximo

My 70 mN i 7 m.kq ) ( 50 l/2 ft.lh ).

2. .Sl,l did g”“g” rod RS pwp<‘il~cl,l171 ns p”ssibl<~

10 &SC iorr. The run-out thus registered must not exceed 0.2 mm.

If this condition cannot be satisfied the disc must

be chanqed.

Page 286 of 394

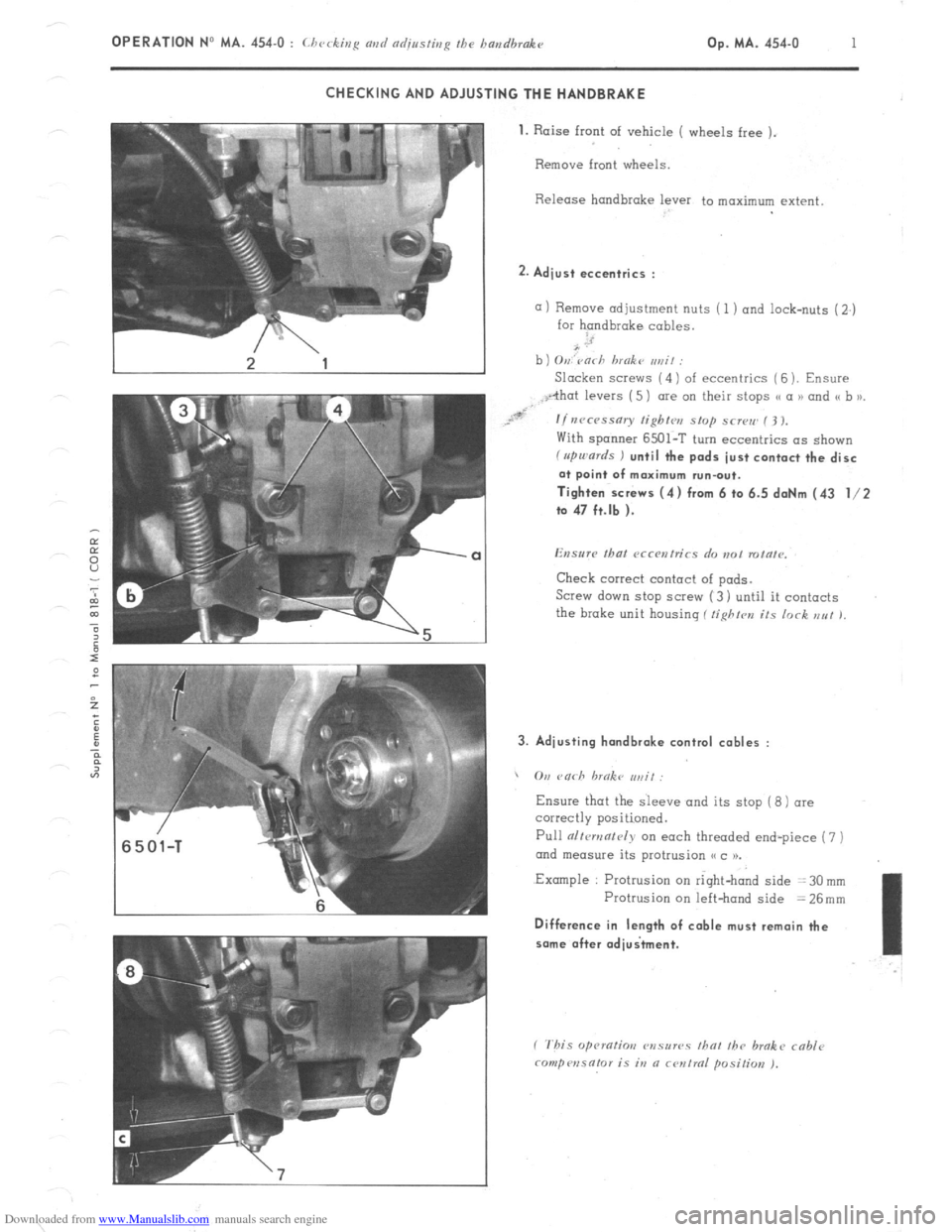

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 454-O : Lhcckiu~ avd adjnsfbrR fhe bandbrake op. MA. 454-u I CHECKING AND ADJUSTING THE HANDBRAKE

1.

Raise front of vehicle ( wheels free ).

Remove front wheels.

Release handbrake lever to maximum extent 2. Adjust eccentrics :

a) Remove adjustment nuts ( 1 ) and lock-nuts (2.)

for handbrake cables.

b ) O,,,‘varh hmokt~ ,,rzit :

Slacken SCI~WS (4) of eccentrics ( 6 ). Ensure

With spanner 6501-T turn eccentrics as shown f rrpu,ards ) until the pads just contact the disc

at point of maximum run-out.

Tighten screws (4) from 6 to 6.5 daNm (43 l/2

to 47 ft.lb ).

Check correct contact of pads.

Screw down stop SCI~W (3) until it contacts

the brake unit housing ( tighfrn its lock EN! 1, 3. Adjusting hondbrake control cables :

, On rnrh hrnkc ,,,, if:

Ensure

Pull alfcmnf~~iy on each threaded end-piece (7 )

ond measure its protrusion (< c 1).

.Example : Protrusion on right-hand side = 30 mm

Protrusion on left-hand side = 26mm Difference in length of cable must remain the

some after adiuitment.

Page 348 of 394

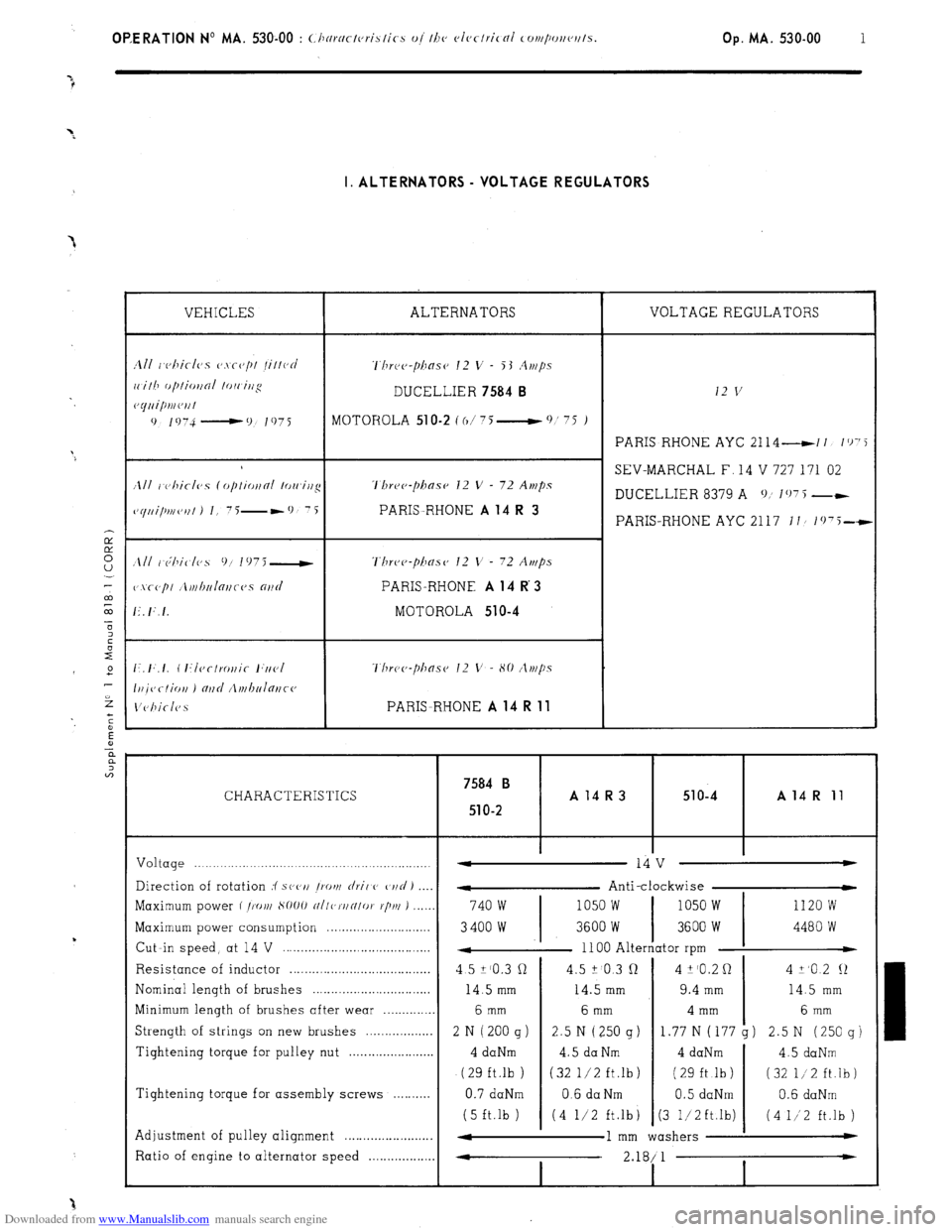

Downloaded from www.Manualslib.com manuals search engine OP,ERATlON No MA. 530-00 : <.Ilnrnctc,rislics oj I/IV cJlec/rical cor~~/~~r~c~~t/s. Op. MA. 530-00 1 I. ALTERNATORS - VOLTAGE REGULATORS

VEHICLES ALTERNATORS VOLTAGE REGULATORS

1111 r~c,hicl(~s CJ.\~(J/)/ /il/ocJ ‘l’hrc~c~-pilasc~ 12 v - 53 .4r,/ps

ri.ilh f~/~IioI~oI lo/i irjg DUCELLIER 7584 B 12 v c~yuipmc~ril

0 1 !, 74 - 0 I 97 i

MOTOHOLA 51 O-2 C o/ 75 __t 0 ’ ‘5 )

PARIS RHONE AYC 2114 -11 I’)‘5

SEV-MARCHAL F, 14 V 727 171 02

/Ill I c)hiclvs (opliotfni lowirtg ‘l’hre~~-phase 12 V - 72 Amps

DUCELLIER 8379 A 0; 107 5 --

~~yui/mc,,fl J I, 7i-*9 7i PARIS-RHONE A 14 R 3 PARIS-RHONE AYC 2117 II/ 1(j75-t

Three-phase’ 12 V - 72 Amps

PARIS-RHONE A 14 R 3

MOTOROLA 510-4

Thr~~~~-pha.s~~ 12 V - 80 /lt)t/?s

PARISRHONE A 14 R 11

7584 B CHARACTERISTICS A14R3 51 o-4 A 14 R 11

51

O-2

Voltage .._._._.._._.._____.......................,...................,. -

14 v w

Direction of rotation :f s(‘(‘I/ /rot)/

rlril C’ C,I/C/ J

- Anti-clockwise

Maximum power f /X),/I S1)OO

~/I/c,~/IN/oI. r/j/u ) ..,__, 740 w 1050 w 1050 w 1120 w

Maximum power consumption . . . . . .._..__.______........

3400 w 3600 W 3600 W 4480 W

Cut -in speed, at 14 V . .

4 1100 Alternator rpm t

Resistance of inductor . .

4 5 Z’O.3 cl 4.5 ? 0.3 Q 4 k’O.2 0 4 +,o 2 12

Nominal length of brushes .

14.5 mm 14.5 mm 9.4 mm 14.5 mm

Minimum length of brushes after wear . . 6 mm 6 mm 4 mm 6 mm

Strength of strings on new brushes . . . . . . . . . . . . . . . . . 2 N ( 200 g ) 2.5 N (250 g)

1.77 N (177 g) 2.5 N (250 g)

Tightening torque for pulley nut . . 4 daNm 4.5 da Nm 4 daNm

4.5 daNm

(29 ft.lb ) (32 l/2 ft.lb) ( 29 ft .lb ) (32 l/2 ft.lb)

Tightening torque for assembly screws .

0.7 daNm 0.6 da Nm 0.5 daNm 0.6 daNm

(5 ft.lb ) (4 l/2 ft.lb

j (3 1,‘2ft.lb) (4 1/‘2 ft.lb )

Adjustment of pulley alignment . . . . . . . . . . . . . . . . . . . . . . . . 4

1 mm washers w

Ratio of engine to alternator speed . . . 4

2.18/ 1 *

I I

Page 351 of 394

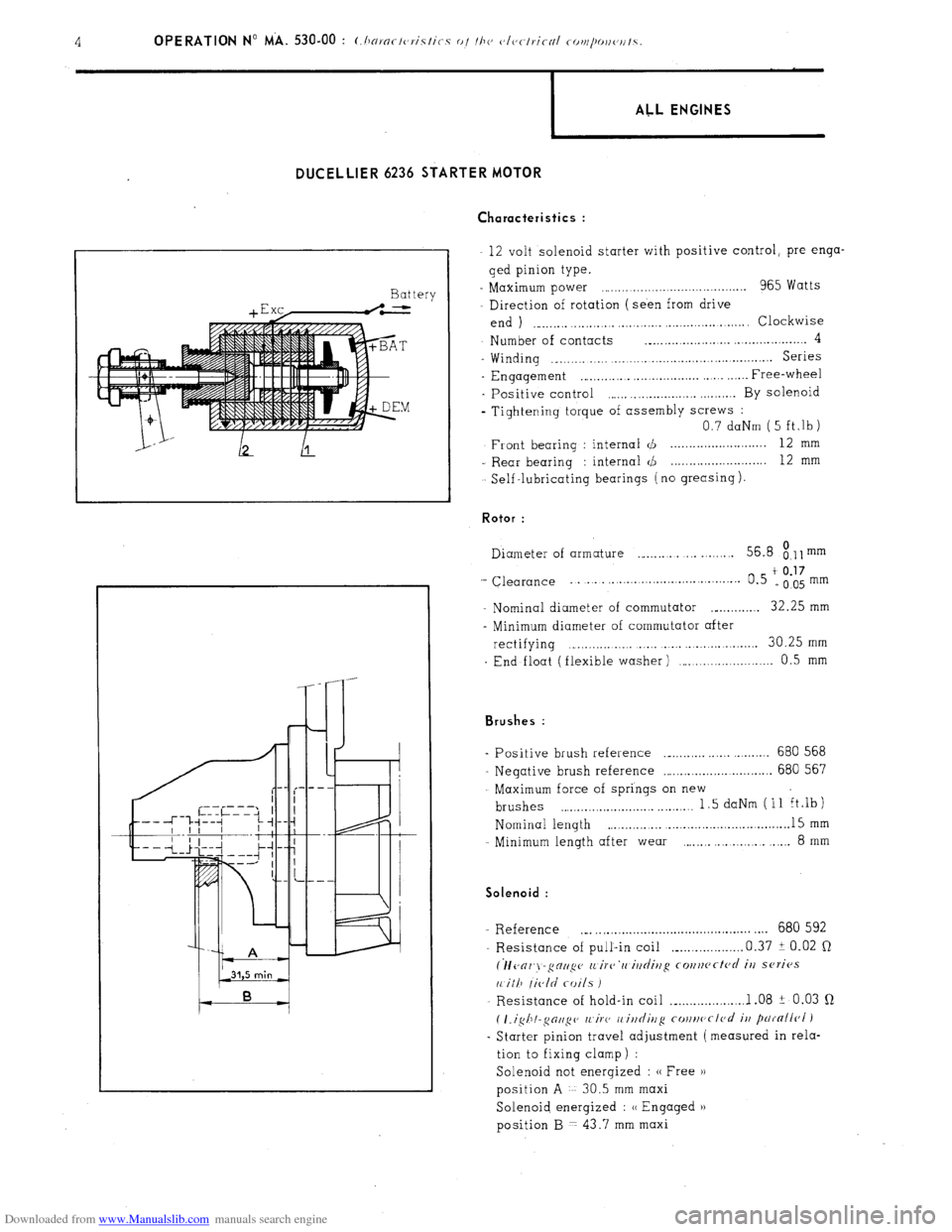

Downloaded from www.Manualslib.com manuals search engine DIJCELLIER 6236 STARTER MOTOR

Ch aracteristics :

Battery

+ E xc,-.L

I ALL ENGINES

12 volt solenoid starter with positive control, pre-enga-

ged pinion type.

- Maximum power ,.,..................................... 965 Watts

Direction of rotation (seen from drive

end ) ,.,_,.,.,. ..,.,...,.,. ,.,.,.,...._ . . . . .._...... .,.,. Clockwise

Number of contacts ._.,.,.,.,.,.,_........ ..,.,.,............. 4

- Winding ._.,.,......... ,.,.,.,_......,.,.....,.,...............~... Series

- Engagement ,~.,.,...,... ,.,............... . Free-wheel

- Positive control ,.,.,. . . . . . . . . . . ..,.,.,... By solenoid

- Tightening torque of assembly screws :

0.7 daNm ( 5 ft,lb)

Front bearing : internal d . . . 12 mm

- Rear bearing : internal <,!J 12

mm

Self -lubricating bearings ( no greasing ). Rotor :

Diameter of armature ,_,.,.,. .,. _..._.... 56.8

8.11 mm

‘- Clearance ... . . . . . . . . . . . .

t 0.17 0.5 e005mm

- Nominal diameter of commutator ._._...,.,.,. 32.25 mm

- Minimum diameter of commutator after

rectifying . . . . . . . . . . . . . . . . . . . . . 30.25 mm

End float (flexible washer) ,.........,.,.,..._.....,. 0.5 mm Brushes :

Positive brush reference ._._.,.,... ,..... . . . . . 680 568

Negative brush reference ..,.,.,.,.,.,.,............... 680 567

Maximum force of springs on new

brushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 daNm (11 ft.lb)

Nominal length . . . . ._.............,...............~. 15 mm

Minimum length after wear ., . . . . . . . . 8

mm Solenoid :

- Reference ._. ,.,..............~........................ .,.. 680 592

Resistance of pull-in coil ,_...,.,.........,. 0.37 i 0.02 Q

(lfc~or~j-gctup (L irc~‘rc iltdittg co~~rtcftc~d it/ series

11 ill7 /ic,ld coils I

Resistance of hold-in coil ,_...,...,.......... 1 .08 ? 0.03 Q

( I.igh!-~oll~c~ /l~iF(, I, ittditlg cottrtc~cl<~d

it/ parnllr~l )

- Starter pinion travel adjustment (measured in rela-

tion to fixing clamp) :

Solenoid not energized : (( Free H

position A 30.5 mm maxi

Solenoid energized : u Engaged u

position B 7 43.7 mm maxi

Page 352 of 394

Downloaded from www.Manualslib.com manuals search engine 1 ALL ENGINES

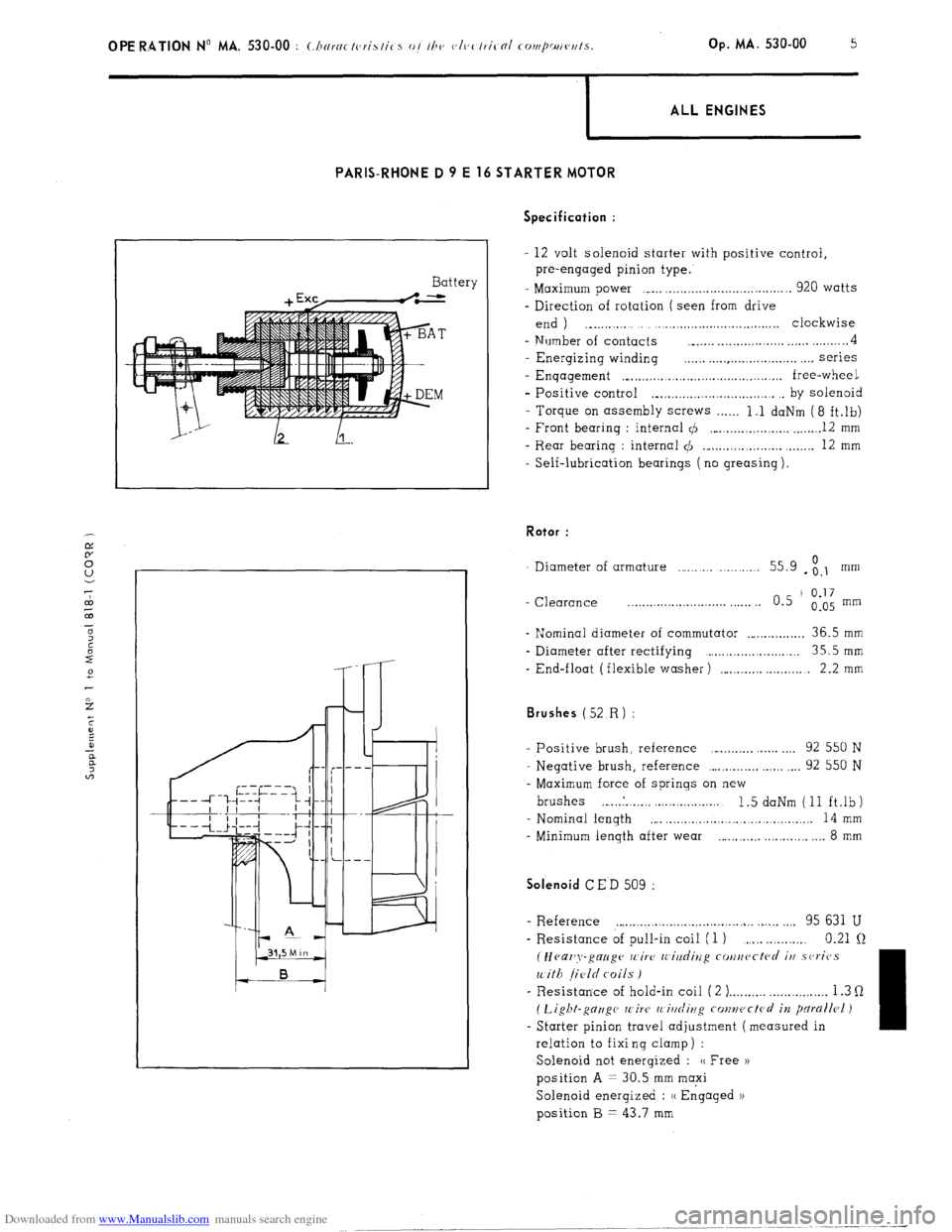

PARIS-RHONE D 9 E 16 STARTER MOTOR

Battery Specification :

- 12 volt solenoid starter with positive control,

pre-engaged pinion type.

- Maximum power ,..... ,................................. 920 watts

- Direction of rotation ( seen from drive

end ) ., . . . ._..,.,...,.,..................... clockwise

- Number of contacts __..... . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

- Energizing winding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . series

- Enqagement ,“...,.,.........,.,.............,......... free-wheel

- Positive control ._.,.,.,.,.,.,.......,.,.,....... . by solenoid

- Torque on assembly screws . . . . . . 1.1 daNm (8 ft.lb)

- Front bearing : internal 4 ,..._.,.....,...,.,.,. _....._. 12 mm

- Rear bearing : internal $I ._...,...,...,.,.,.,. ,.....,. 12 mm

- Self-lubrication bearings ( no greasing ). Rotor :

Diameter of armature . . . . . . . . . . . . . . . 55.9 - ;.I mm

- Clearance _.......................... . . . . . . 0.5 ’

0.17

0.05 mm

- “Jominal diameter of commutator . . . . . . . . . . . . . . . . 36.5 mm

- Diameter after rectifying ,.....,................... 35.5mm

- End-float (flexible washer) ,....._.,... . . . 2.2 mm Brushes (52

R) :

- Positive brush, reference . . . . . . . . . . . . . . 92 550 N

- Negative brush, reference ,...,.,.,.,.,. ,.,.,. . . . 92 550 N

- Maximum force of springs on new

brushes ,... ..I. . ,. ,. . . . ..,......... 1.5 daNm (11 ft.lb)

- Nominal length

,... . . . . . . .., . . . . . . . .,......... 14 mm

- Minimum length after wear . . . . . . . ..,......... 8 mm Solenoid

CED 509 :

- R.eference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ,.,. 95 631 U

- Resistance of pull-in coil (1 ) . . . . . 0.21 Q

(Heaz’y-gauge wire IL’i?/dirzg cotlucctcd iu .sc,ricJs

with field coils )

- Resistance of hold-in coil ( 2 ) . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3 Q

( Light-gc7zigc wire’ 11 itlrliug conwctcrl in pdrallrl )

- Starter pinion travel adjustment (measured in

relation to fixi ng clamp ) :

Solenoid not energized : (( Free ))

position A = 30.5 mm maxi

Solenoid energized : (( Engaged 1)

position B = 43.7 mm

Page 359 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 560.0 : ~hrrkin~ o,,d oc/@s/i,,g I/><, wiurisrrrr,, wip’r. Op. MA. 560.0

1

Fi

m

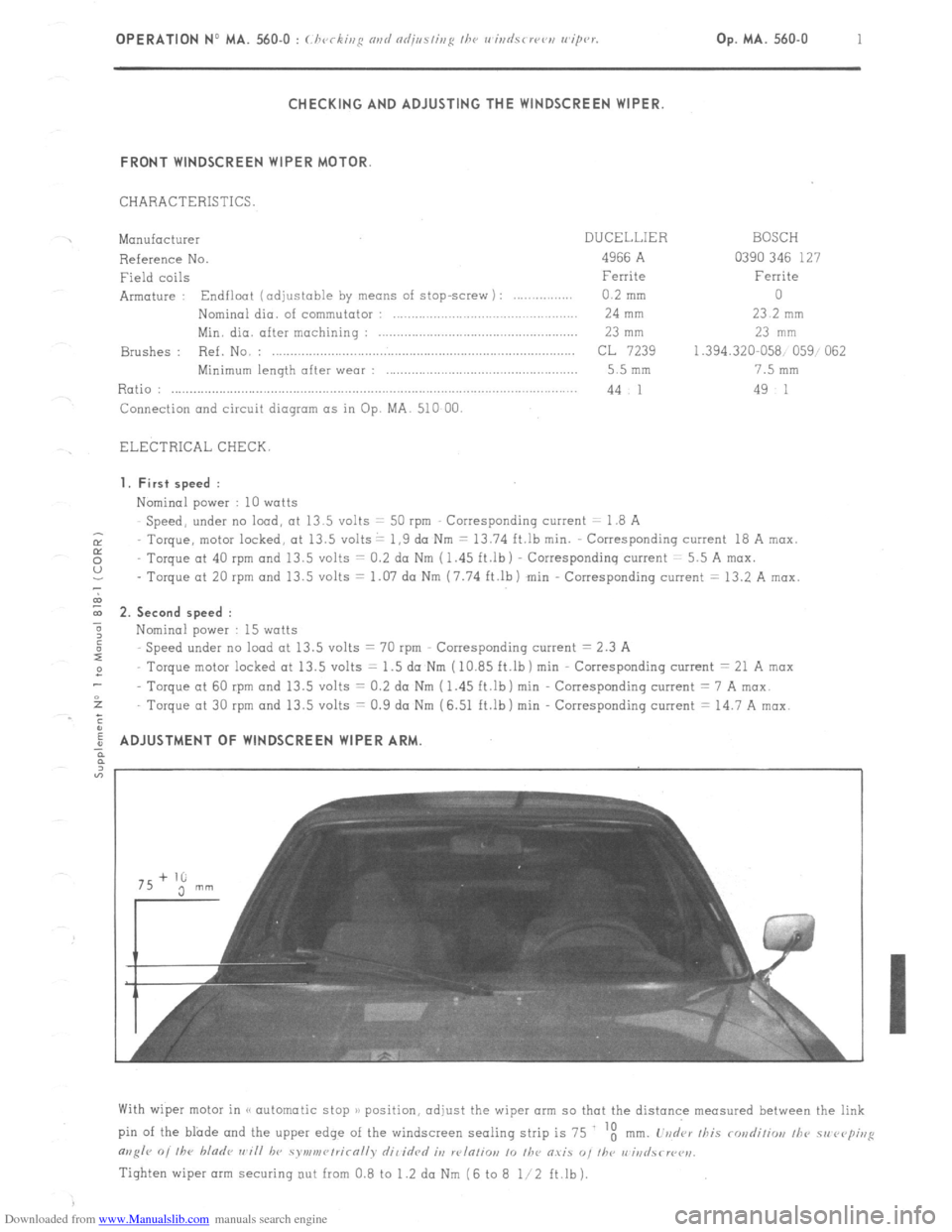

0 CHECKING AND ADJUSTING THE WINDSCREEN WIPER.

FRONT WINDSCREEN WIPER MOTOR

CHARACTERISTICS.

Manufacturer DUCELLIER

Reference No. 4966 A

Field coils Ferrite

Armature : Endfloot (adjustable by means of stop-screw) : 0.2 mm

Nominal dia. of commutator :

24 mm

Min. dia. after machining : 23 mm

Brushes : Ref. No. :

CL 7239

Minimum length after wear : 5.5 mm

Ratio : .._...................................................................................................

44 1

Connection and circuit diagram as in Op. MA. 510 00.

ELECTRICAL CHECK. BOSCH

0390 346 127

Ferrite

0

23.2 mm

23 mm

1.394.320-058 059, 062

7.5 mm

49 1

1. First speed :

Nominal power : IO watts

Speed, under no load, at 13.5 volts = 50 rpm Corresponding current = I.8 A

Torque, motor locked, at 13.5 volts = 1.9 da Nm 7 13.74 ft.lb min. Corresponding current 18 A max.

Torque at 40 rpm and 13.5 volts = 0.2 do Nm (1.45 ft.lb) Correspondinq current = 5.5 A max.

- Torque ot 20 rpm and 13.5 volts = 1.07 da Nm (7.74 ft.lb) min Corresponding current = 13.2 A max.

2. Second speed :

Nominal power : 15 watts

Speed under no load at 13.5 volts = 70 rpm Corresponding current = 2.3 A

Torque motor locked at 13.5 volts = 1.5 do Nm (IO.85 ft.lb) min Corresponding current = 21 A max

Torque at 60 rpm and 13.5 volts = 0.2 da Nm (1.45 ft.lb) min Corresponding current = 7 A max

Torque ot 30 rpm and 13.5 volts = 0.9 da Nm (6.51 ft.lb) min Corresponding current = 14.7 A mrx.

ADJUSTMENT OF WINDSCREEN WIPER ARM

With wiper motor in (< automatic stop )/ position, adjust the wiper arm so that the distance measured between the link

pin of the blade and the upper edge of the windscreen sealing strip is 75 ‘t

mm. L’vd‘ar /his rondiliw, /he 51, rvp;,,g

m,g/r 0, /he bladr ,,~i// hv symv,r~/rirn//v dil idrd it, w/n/io,, 10 /he O.YiS “, I/w r,‘iri

Tighten wiper arm securing out from 0.8 to 1.2 da Nm (6 to 8 l/2 ft.lb).

Page 360 of 394

Downloaded from www.Manualslib.com manuals search engine 2 OPERATION No MA. 560-O : (:/ ivc ,,,* our/ nd;,,s/ii,~ ,,w I, ,,i

k’

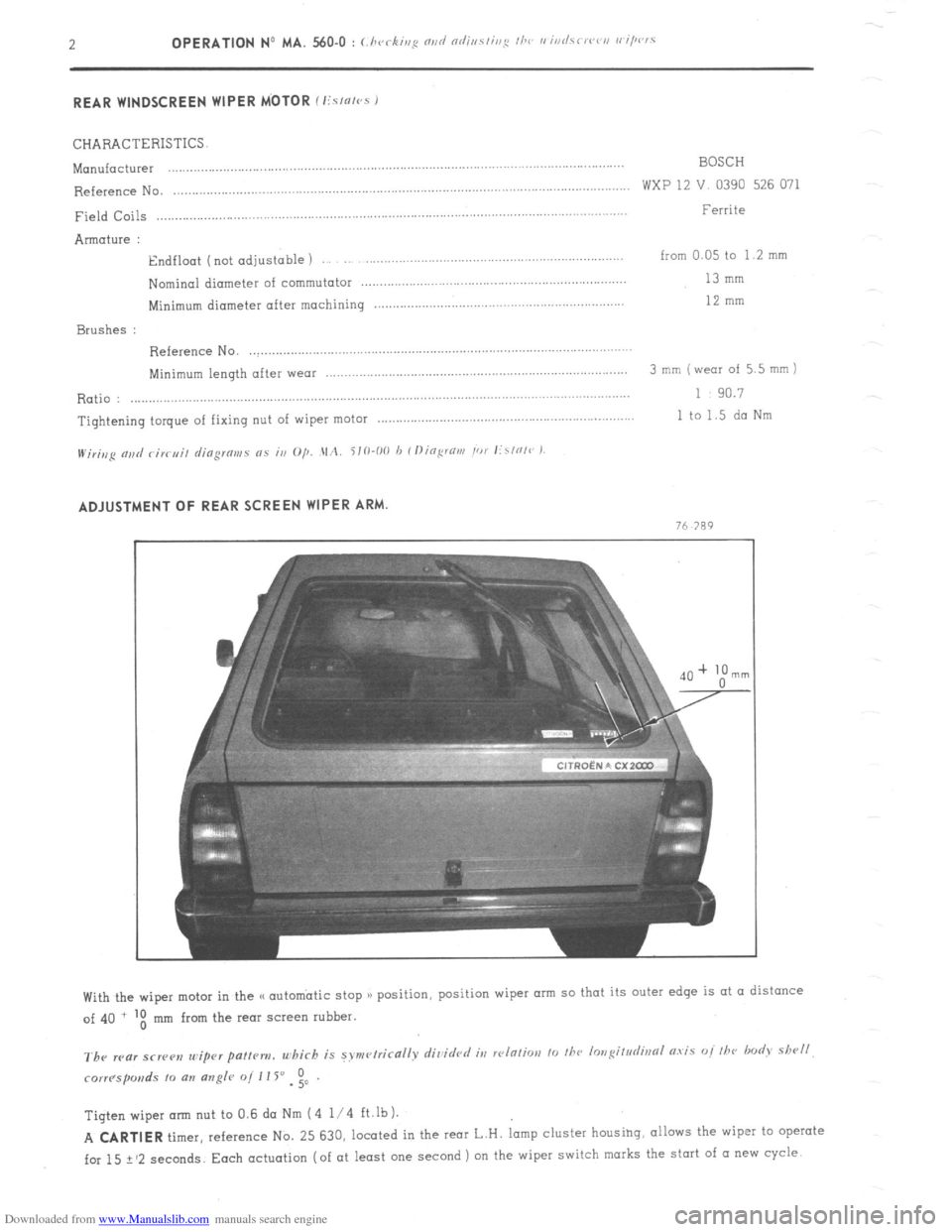

REAR WINDSCREEN WIPER MOTOR (lislnlvs J

CHARACTERISTICS.

Mon”facturer ..,..._....,...........,.................................................................................................... BOSCH

~ef,yence

~0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... WXP

12 V 0390

526 071

Field Coils

. . . . . . . . . . . . . . . . . .._............................................................................................................ Ferrite

Armature :

Endfloat ( “ot adj”stable ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . from 0.05 to 1 2 mm

Nominal diameter of commutator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 mm

Minimum diameter after machining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 mm

Brushes :

&ference

No. ,.: . . . . . . . . . . . . . . . . . .._.................................................................................

Minimum length after wear ,.,......._................,...................................................... 3 mm ( wear of 5.5 mm )

Ratio :

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ................ 1 90.7

Tightening torque of fixing nut of wiper motor .,.....,..,................................................~.......... 1 to 1.5 da Nm

H/;r;,,p nj,d c;K,J;, djogmms 0.5 in O/j. .\1,2. i10-00 h Il)ing:rtirn Ior lirl0l~~ ) ADJUSTMENT OF REAR SCREEN WIPER ARM.

n

Tigtenwiperarm nut to0.6daNm (4 l/4 ft.lb).

A CARTIER

timer, reference No. 25 630, located in the IMT L.H. lamp cluster housihg, allows the wiper to operate

for 15 ? ‘2 seconds. Each actuation (of at least one second ) on the wiper switch marks the start of (I new cycle

Page 378 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 642-W : ~Thnracteristics o/ thy, e I:Ko/I) - -70 3 hc,nriug s, stew Op. MA. 642-00 3

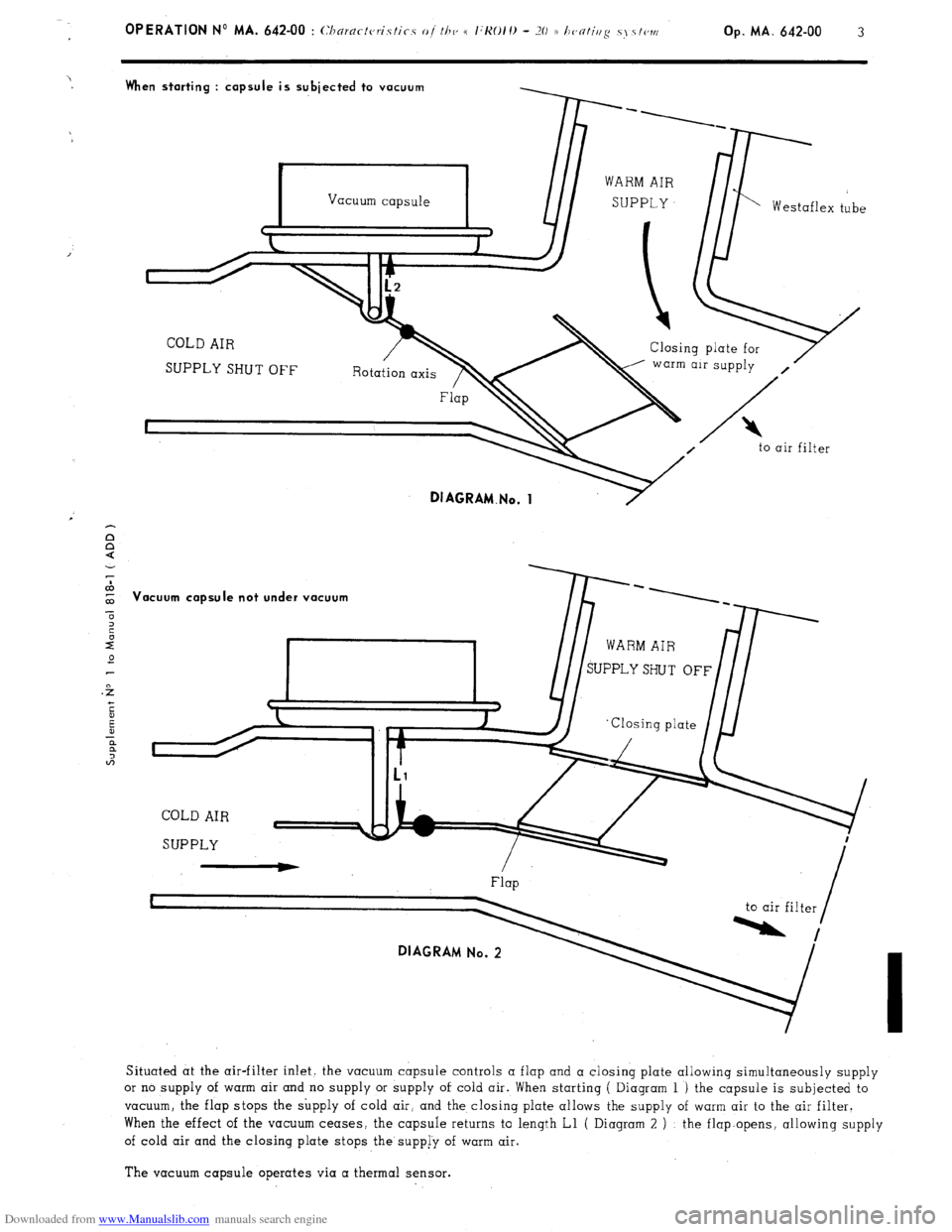

When starting : capsule is subjected to vacuum

Vacuum capsule

Westaflex tube

c J

J

COLD AIR

Closing plate for

SUPPLY SHUT OFF warm air supply

,

Flap B

I

to air filter

DIAGRAM.No. 1

‘acuum capsule not under vacuum

Flap

DIAGRAM No. 2

to air filter

Situated at the air-filter inlet. the vacuum capsule controls a flap and a closing plate allowing simultaneously supply

or no supply of warm air and no supply or supply of cold air. When starting ( Diagram 1 ) the capsule is subjected to

vacuum, the flap stops the supply of cold air, and the closing plate allows the supply of warm air to the air filter.

When the effect of the vacuum ceases, the capsule returns to length Ll ( Diagram 2 ) : the flap.opens, allowing supply

of cold air and the closing plate stops the supp[y of warm air.

The vacuum capsule operates via a thermal sensor.