diagram Citroen CX 1983 1.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1983, Model line: CX, Model: Citroen CX 1983 1.GPages: 394

Page 4 of 394

Downloaded from www.Manualslib.com manuals search engine Operation

number

VIA. 000

VIA. 00

VIA. 00-600

vlA. 00-655

VIA. 01

WA. 02

MA. 03

MA. 100-00

MA. 112-O

MA. 120-O

MA. 142-000

MA. 142-00

MA. 142-00 a

MA. 142-00 b

MA. 142-00 SI

MA. 142-O

MA. 142-O SD

MA. 144-00

MA. 144-O

MA. 173-O

MA. 210-00

MA. 210-00 a

MA. 210-O

MA. 210-O a

MA. 220-O

MA. 221-O

MA. 230-00

MA. 230-O

MA. 236-O

MA. 312-00

MA. 314-O

MA. 320-00

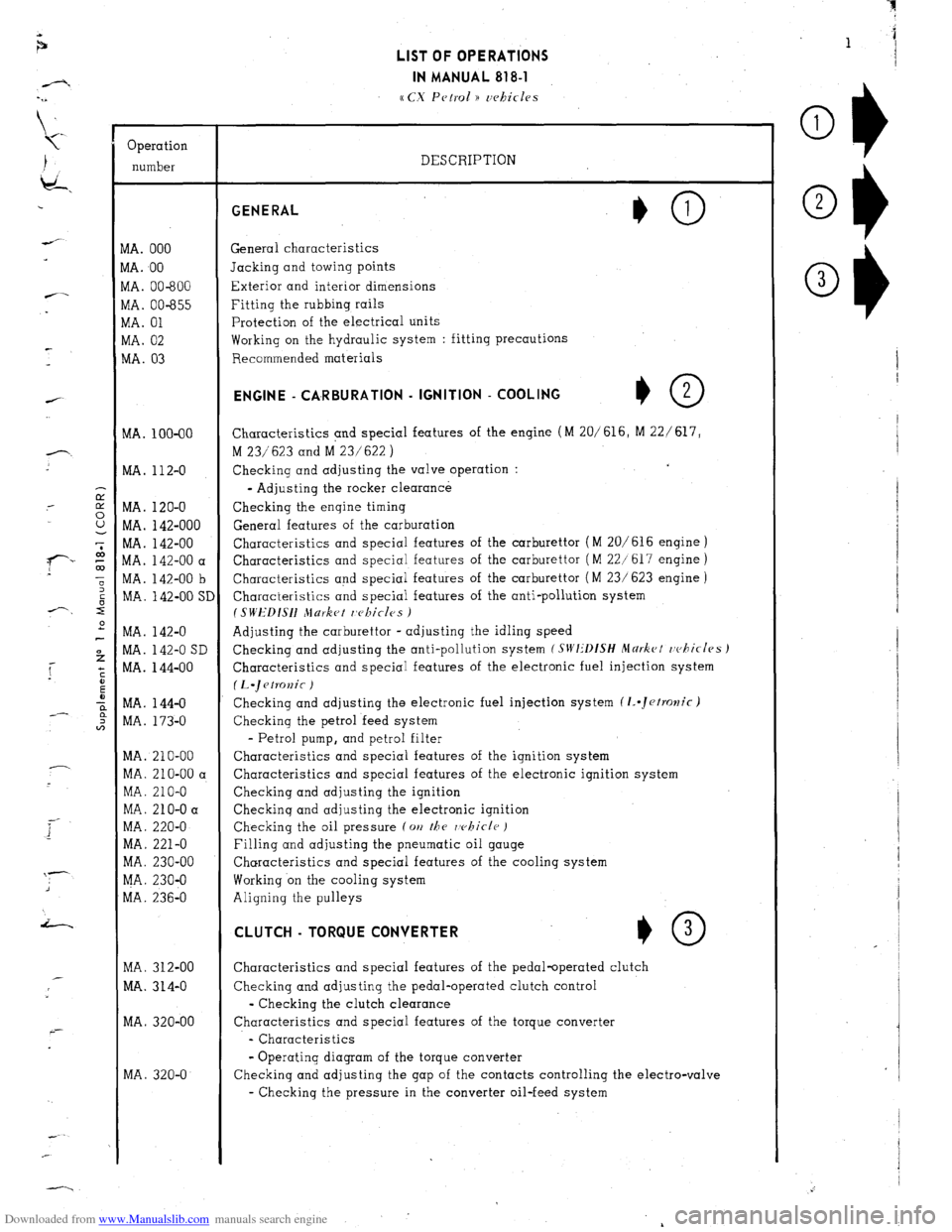

MA. 320-O LIST OF OPERATIONS

IN MANUAL 818-l

cc CX Petrol )) uehicles

DESCRIPTION GENERAL

General characteristics

Jacking and towing points

Exterior and interior dimensions

Fitting the rubbing rails

Protection of the electrical units

Working on the hydraulic system : fitting precautions

Recommended materials ENGINE - CA,RBURATlON - IGNITION - COOLING

+O 2

Characteristics and special features of the engine (M 20/616, M 22/ 617,

M 23/623 and M 23/622 )

Checking and adjusting the valve operation :

- Adjusting the rocker clearance

Checking the engine timing

General features of the carburation

Characteristics and special features of the carburettor (M 20/616 engine )

Characteristics and special features of the carburettor ( M 22/617 engine )

Characteristics and special features of the carburettor ( M 23/ 623 engine )

Characteristics and special features of the anti-pollution system

I SWEDISH Jlurket r,c~kicles )

Adjusting the carburettor - adjusting the idling speed

Checking and adjusting the anti-pollution system

(SIVI:‘DfSH Mdrkct rvhicles J

Characteristics and special features of the electronic fuel injection system

(L.~etKJnic )

Checking and adjusting the electronic fuel injection system (1..Jetrolzic)

Checking the petrol feed system

- Petrol pump, and petrol filter

Characteristics and special features of the ignition system

Characteristics and special features of the electronic ignition system

Checking and adjusting the ignition

Checkinq and adjusting the electronic ignition

Checking the oil pressure (on

the rvhicle )

Filling and adjusting the pneumatic oil gauge

Characteristics and special features of the cooling system

Working on the cooling system

Aligning the pulleys CLUTCH - TORQUE CONVERTER

*O 3

Characteristics and special features of the pedal-operated clutch

Checking and adjusting the pedal-operated clutch control

- Checking the clutch clearance

Characteristics and special features of the torque converter

- Characteristics

- Operating diagram of the torque converter

Checking and adjusting the gap of the contacts controlling the electro-valve

- Checking the pressure in the converter oil-feed system

Page 6 of 394

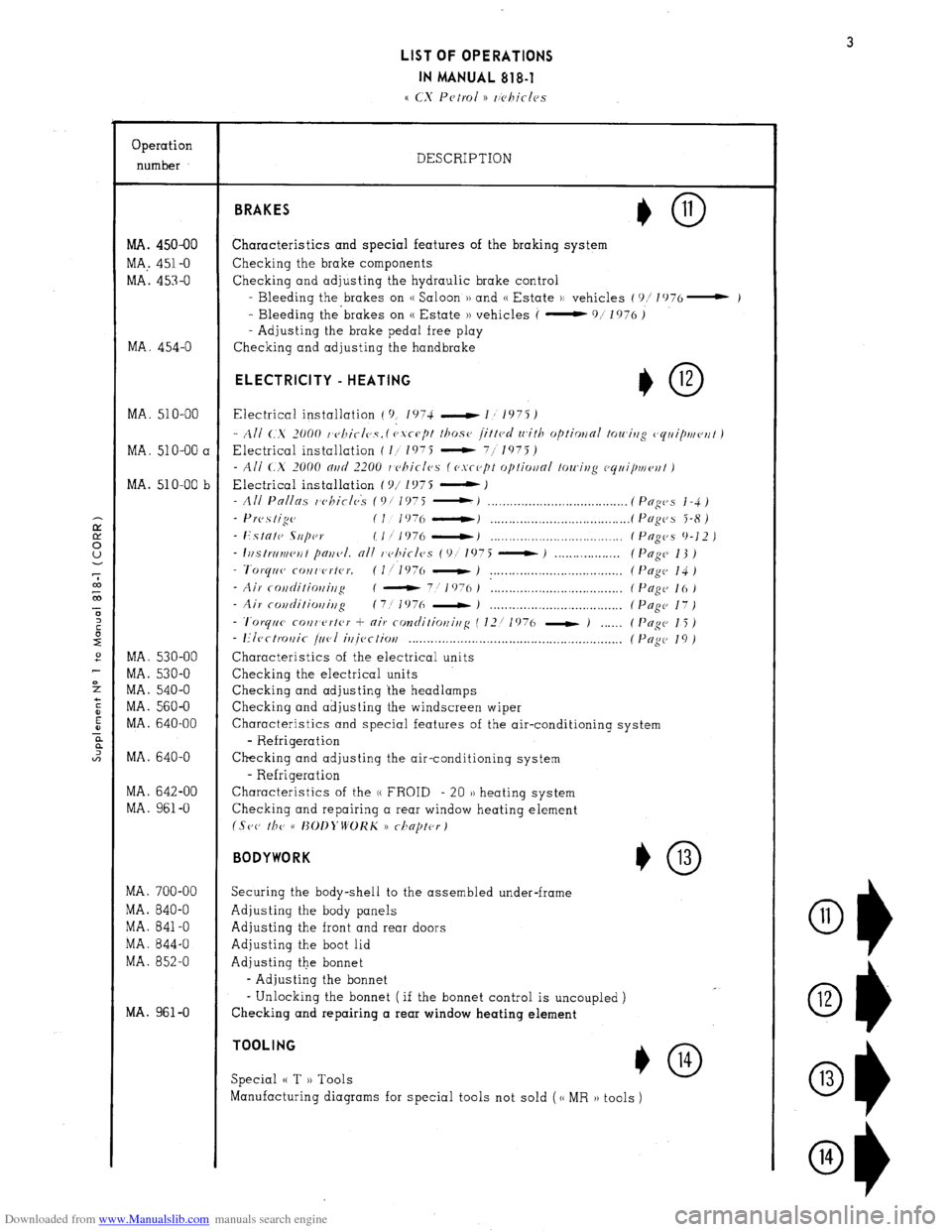

Downloaded from www.Manualslib.com manuals search engine LIST OF OPERATIONS

IN MANUAL 818-l

Operation

number

MA. 450-00

MA,. 451-O

MA. 453-O

MA. 454-O

MA. 510-00

MA. 51 O-00 a

MA. 510-00 b

MA. 530-00

MA. 530-O

MA. 540-O

MA. 560-O

MA. 640-00

MA. 640-O

MA. 642-00

MA. 961-O

MA. 700-00

MA. 840-O

MA. 841-O

MA. 844-O

MA. 852-O

MA. 961-O DESCRIPTION BRAKES

Characteristics and special features of the braking system

Checking the brake components

Checking and adjusting the hydraulic brake control

- Bleeding the brakes on (( Saloon )) and (( Estate H vehicles (‘)/ lO76- )

- Bleeding the’brakes on (( Estate )) vehicles (

-911976)

- Adjusting the brake pedal free play

Checking and adjusting the handbrake ELECTRICITY - HEATING

I,0 12

Electrical installation ( 9, 1074 -1,1975)

- All C..X 2000 t’cJllicl0.Y. ( cJ.vc-u[)t those 1.ittcd with optimnl towitzg (,rjriiptueflt )

Electrical installation ( I/ 1975 - 711975)

- All <.X 2000 nrtcl 2200 I c>hiclcs (esrept optiwnl towing ccjrli/mv~~t )

Electrical installation ( c)/ 1 !J7 5 - J

- All Pnllas whirlck (Of 1975 :.I __._._.___............................ (Pfiges j-4)

- Prc,.s tige (I 1976 ----tJ . . . . . . . . . . . . . . . . .._.................. (Pngc~s 5-8)

- Estntc SIIpw IIf 1976 -1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (Pugc,s 9-12 )

- I~~strriv~cut pajf~,I. nil r~c~hicles (9!’ 1975 - ) . ( Page 13 )

- Tvrqrl~~ COIlI erter. (l/l976 - ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ( I’ogc, 14 )

- Air rotiditioffir~g ( - 7:

1076 ) : . . . (PcIgc- 16)

- Air covditiorli,lg (7! 1976 - J . . . .

- ‘l’orytrc~ coilr’f’rter + air contlitiotfirfg ( 12/ 1976 - )

- I?Iect~~r~ic j&l

if~iectiov . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics of the electrical units

Checking the electrical units

Checking and adjusting the headlamps

Checking and adjusting the windscreen wiper

Pngc 17)

Pogc 15 )

Pup 19)

Characteristics and special features of the air-conditioning system

- Refrigeration

Checking and adjusting the air-conditioning system

- Refrigeration

Characteristics of the (( FROID - 20 )) heating system

Checking and repairing a rear window heating element

(Set, r/JP cc I~OI~~‘WOKK 1) rilnptc~rj

BODYWORK

*0 13

Securing the body-shell to the assembled under-frame

Adjusting the body panels

Adjusting the front and rear doors

Adjusting the boot lid

Adjusting the bonnet

- Adjusting the bonnet

- Unlocking the bonnet ( if the bonnet control is uncoupled )

Checking and repairing a rear window heating element TOOLING

Special (( T )) Tools *O 14

Manufacturing diagrams for special tools not sold (cc MR )) tools )

O1)

11

Ol) 12

Ok 13

O1) 14

Page 40 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 00-855 : Fitting the side finishing strips. Op. MA. 00-855 3

1. Fitting the upper door finishing strips (1 ) :

/

Mark the following : I

- on the front door, the point u a 1 1) at a distance of 23 mm from the front upper corner of the door and 10 mm from I

. the window surround embellishers,

- on the rear door, the point (( a 7 )) 31 mm from the front edge of the door, and 10 mm from the window surround

embellisher,

- on the rear wing the point u a 13 1) 35 mm from the front edge of the wing, and 6 mm from the upper edge of the

wing.

Using a piece of string, draw a line passing through each point, and draw the axis of the strips.

Mark the axis of the strip fixing holes (see diagram page 2 ), as well as the holes at (( a 17 )) and CC a 18 )).

Drill the holes ( 5 mm diameter ).

Fit the plastic clips.

Position the strips on the clips.

2 2. Fitting the rubbing roils (2) ot the centre of the doors :

0

2 Mark the front and rear points at a distance of 260 mm at the front and 208 mm at the rear from the waistline of

2 the vehicle.

2

Mark the central axis of the rubbing rail using a length of string.

2 Draw a line linking the holes as per diagram on page 2.

Drill all the holes (diameter = 8 mm).

s

5 Fit the plastic clips, and secure them.

a Position and fit the rubbing rails onto the clips.

a

2

Page 65 of 394

Downloaded from www.Manualslib.com manuals search engine d) Valve springs :

The inlet and exhaust valve springs are identical.

Characteristics :

- Diameter of wire : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6 + 0.02 mm

Interior diameter : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 2 0.2 mm

- Length of spring under load : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 39mm(load=m40t2,8kg)

30.6 mm ( load = 84 ~‘1.8 kg )

Coating : ._._................................................................................................ Red or blue varnish

e) Upper spring cups : Identical inlet and exhaust.

f ) Retaining clips : Identical inlet and exhaust

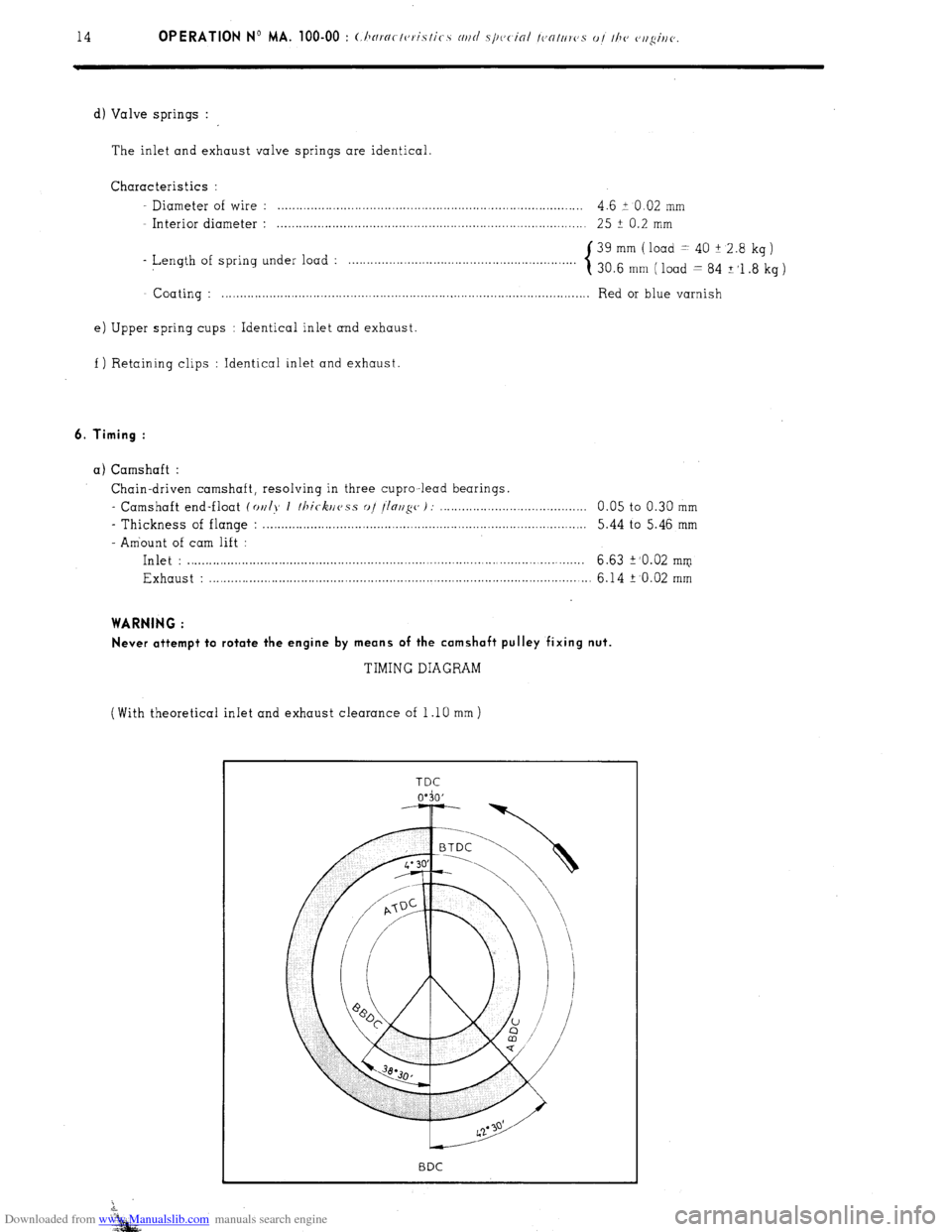

6. Timing :

a) Camshaft :

Chain-driven camshaft, resolving in three cupro -lead bearings.

- Camshaft end-float (a,//>~ I /hi<-krlc~ss a,/ !/o,/s(, I: 0.05 to 0.30 mm

- Thickness of flange : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.44 to 5.46 mm

- Amount of cam lift :

Inlet : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..__.._..._ _.;._.; .._...._ ..__.___.., 6.63

2’0.02 mm

Exhaust : ___._._..._.........................................................................................,... 6.14 + ‘0.02 mm

WARNING :

Never attempt to rotate the engine by means of the camshaft pulley fixing nut.

TIMING DIAGRAM

(With theoretical inlet and exhaust clearance of 1 .lO mm )

Page 76 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION N” MA. 142.000 : c ,, P)C rni ,t n i,,, <‘ 0, I/?< < rirheri,/irin.

Op. MA. 142.000

5

2

:

m

2

-

b E

*

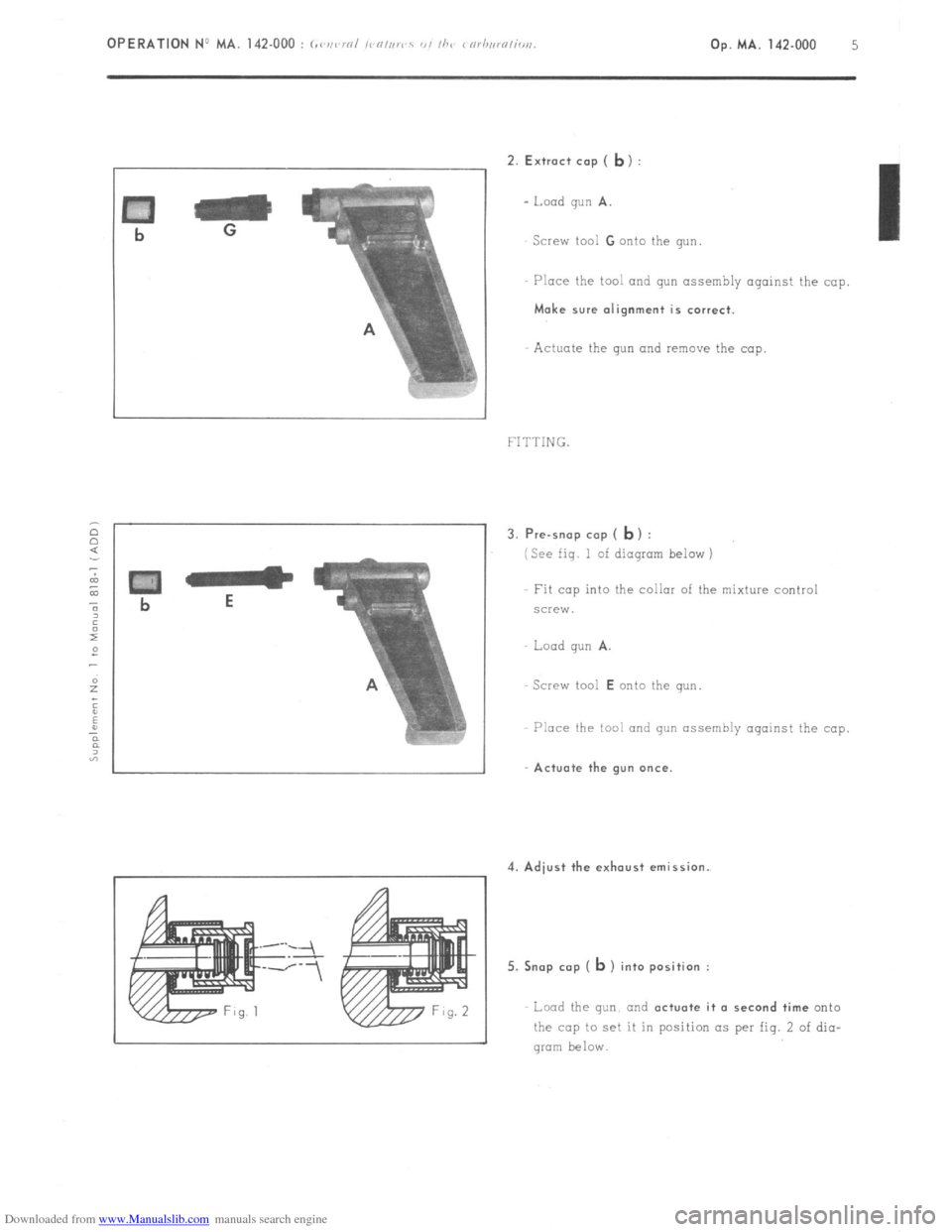

2. Extract cop ( ly) :

- Load gun A.

Screw tool G onto the gun.

Place the tool and gun assembly against the cop

Make sure alignment is correct.

Actuate the gun and remove the cop.

FITTING.

3.

~re-rno~ cap ( b) :

(See fig. I of diagram below )

Fit cap into the collar of the mixture control

screw.

Load qun

A.

Screw tool E onto the wn

Place the tool and gun assembly against the cop

’ 1 1 Actuate the gun once.

4. Adjust the exhaust emission.

I

5. ~nop cop (

b ) into position :

Load the gun. and (~ctuote it o second time onto

the cop to set it in position as per fig. 2 of dio-

gram below.

Page 87 of 394

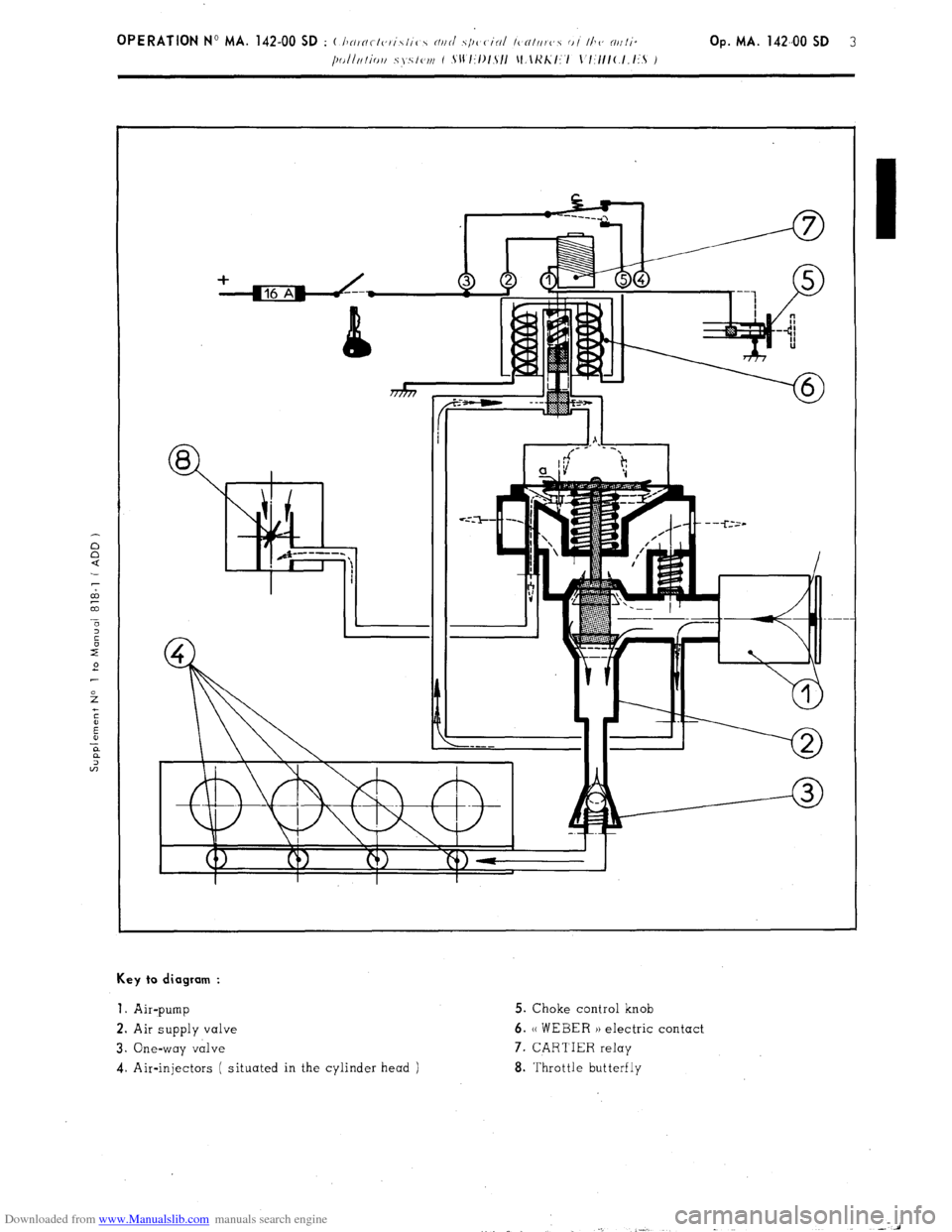

Downloaded from www.Manualslib.com manuals search engine Key to diagram :

1.

Air-pump 5. Choke control knob

2. Air supply valve 6. (( WEBER )) electric contact

3. One-way valve 7. CARTIER relay

4. Air-injectors ( situated in the cylinder head ) 8. Throttle butterfly

Page 115 of 394

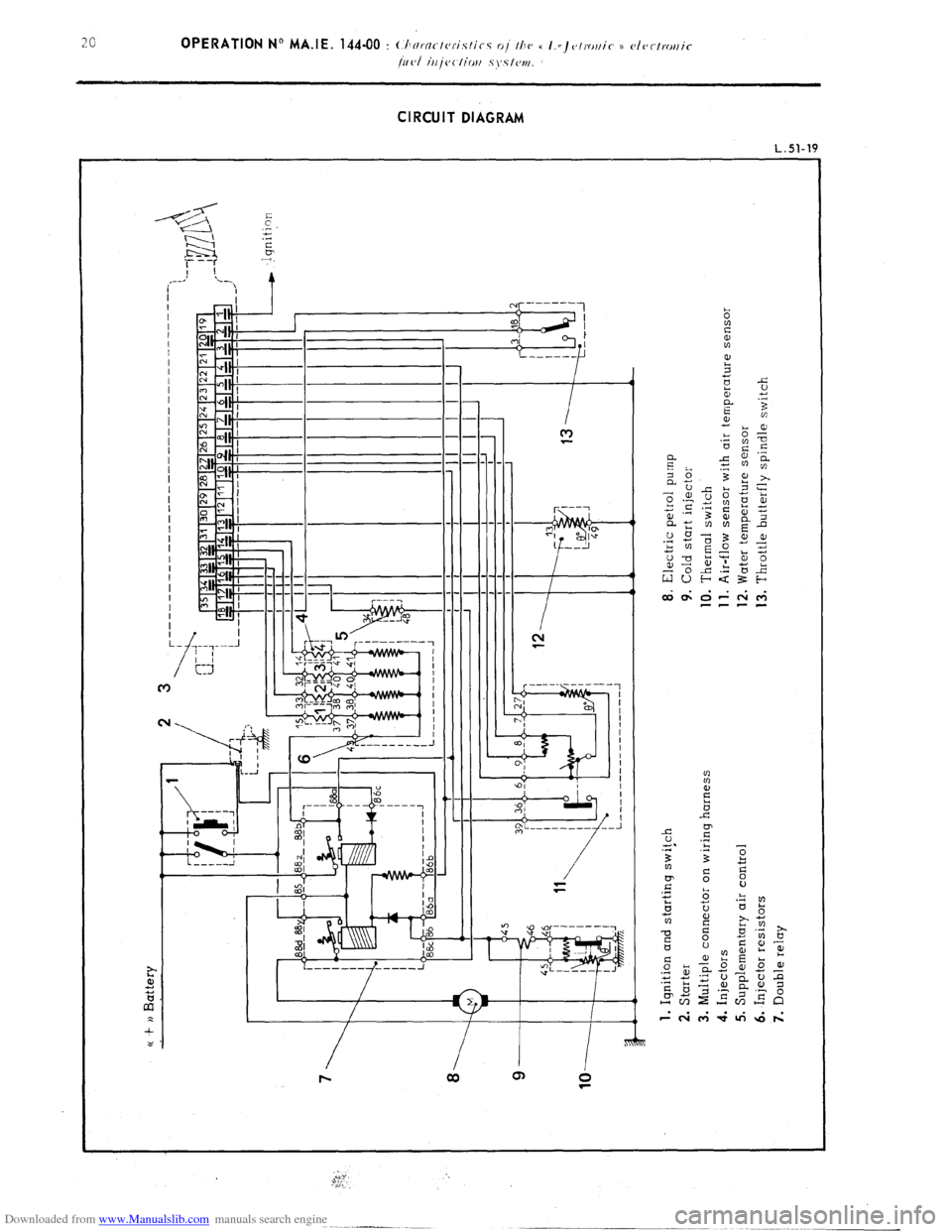

Downloaded from www.Manualslib.com manuals search engine CIRCUIT DIAGRAM

L.Sl-19

I III I

I

--_

------

-- ---- 1 r---7

2, 0 ;,”

1 ---J

::- ----

---- r---~

“‘i

Page 131 of 394

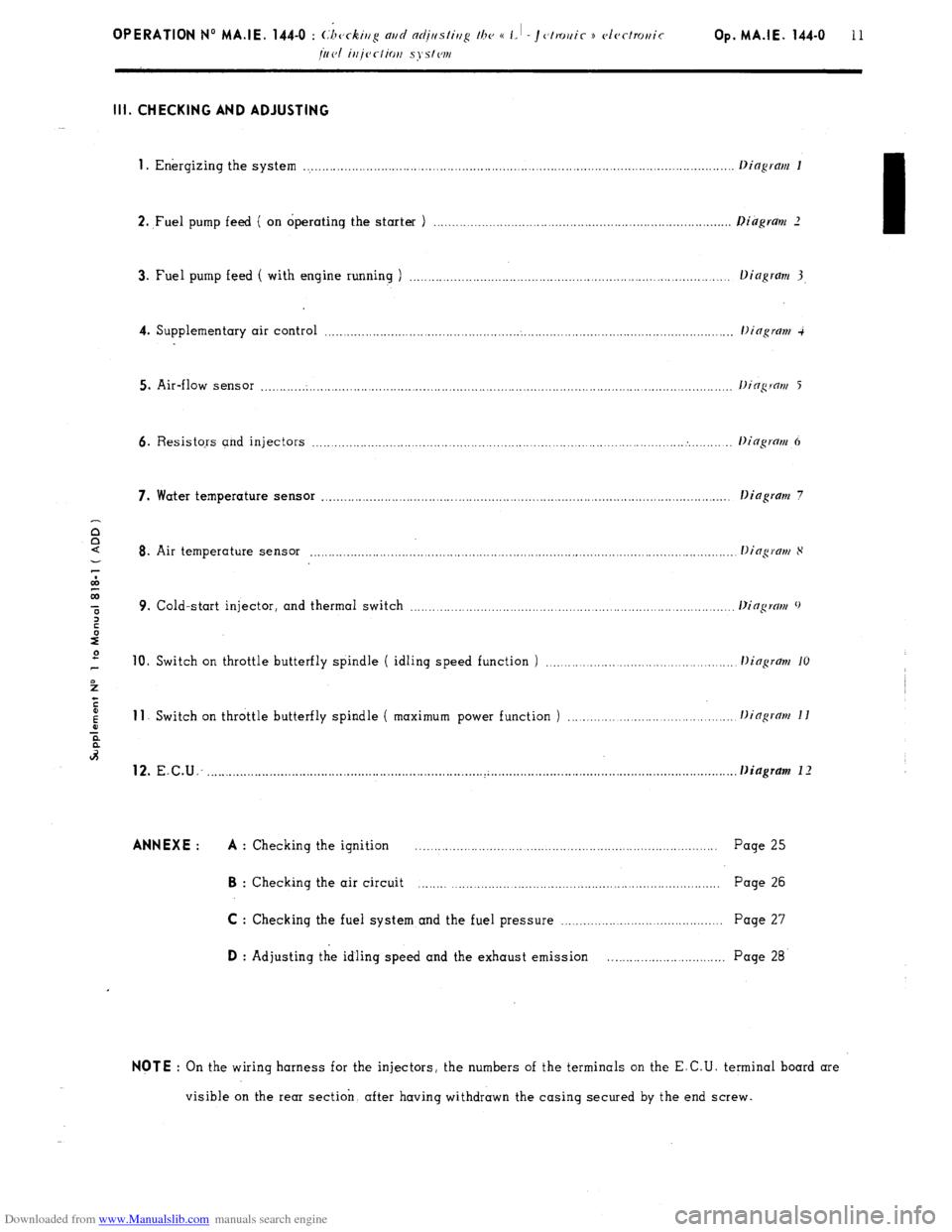

Downloaded from www.Manualslib.com manuals search engine Ill. CHECKING AND ADJUSTING

1

. Energizing the system ..................................................................................................................

2. ,Fuel pump feed ( on operating the starter ) .............................................................................

3. Fuel pump feed ( with engine running ) ...................................................................................

4. Supplementary air control ...........................................................................................................

5. Air-flow sensor ............................................................................................................................

6. Resistors and injectors ................................................................................................... . ........

7. Water temperature sensor ............................................................................................................ .

Dingram 7

8. Air temperature sensor ...............................................................................................................

9. Cold-start injector, and thermal switch ...................................................................................

10. Switch on throttle butterfly spindle ( idling speed function ) ............................................ 11

Switch on throttle butterfly spindle ( maximum power function ) ...................................... 12.

E.C.U: ......................................................................... ..~ ............................................................... . . Diagram 1 I ANNEXE : A

: Checking the ignition .................................................................................. Page 25 B

: Checking the air circuit ................................................................................ Page 26

C : Checking the fuel system and the fuel pressure ........................................... Page 27 D

: Adjusting the idling speed and the exhaust emission .............................. Page 28 NOTE

: On the wiring harness for the injectors, the numbers of the terminals on the E.C.U. terminal board are

visible on the rear section. after having withdrawn the casing secured by the end screw.

Page 132 of 394

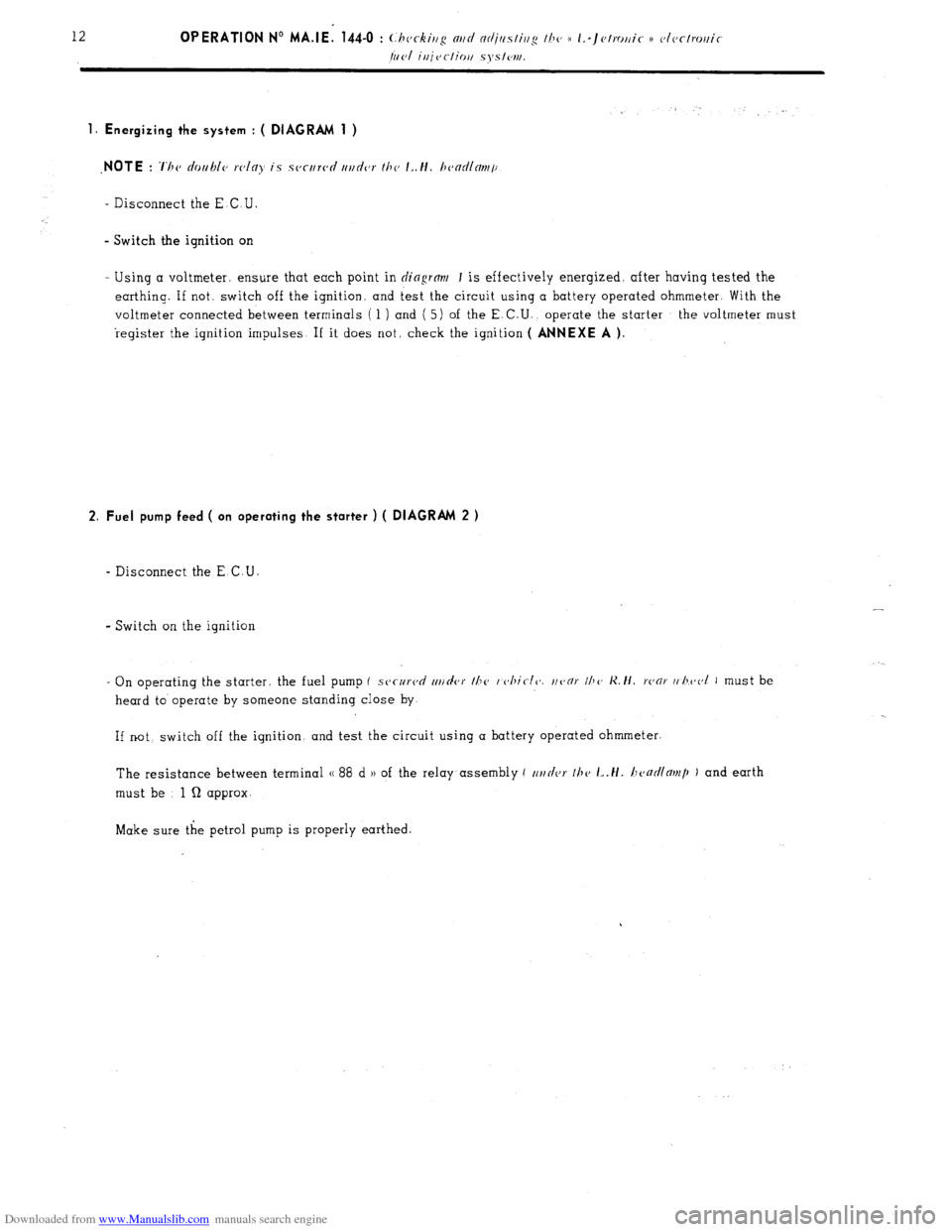

Downloaded from www.Manualslib.com manuals search engine 1. Energizing the system : ( DIAGRAM 1 )

_ Disconnect the E.C U

- Switch the ignition on

Using a voltmeter. ensure that each point in

dingrm 1 is effectively energised. after having tested the

earthing. If not, switch off the ignition. and test the circuit using a battery operated ohmmeter. With the

voltmeter connected between terminals ( 1 ) and ( 5) of the E. C.U., operate the starter the voltmeter must

register the ignition impulses If it does not. check the ignition

( ANNEXE A ).

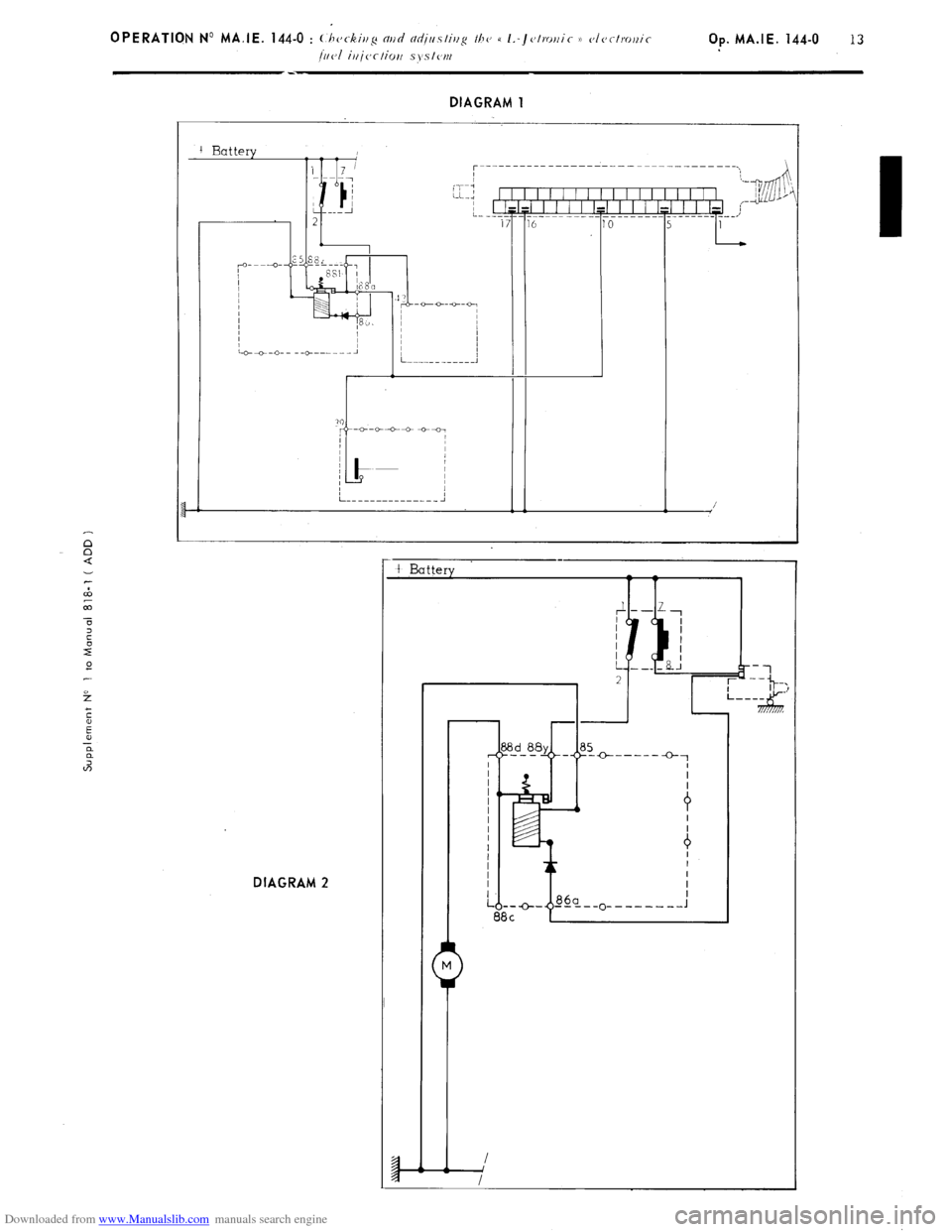

2. Fuel pump feed ( on operating the starter ) ( DIAGRAM 2 )

- Disconnect the E C.U.

- Switch on the ignition

- On operating the starter. the fuel pump (

secureri rrt/rler the I c~hiclc’. uoor IIJO K. ti. ronr (, l~eol I must be

heard to operate by someone standing close by

If not switch off the ignition, and test the circuit using a battery operated ohmmeter.

The resistance between terminal (( 88 d H of the relay assembly ( c~r~tler 111~

L,H. honr/llor)~p ) and earth

must be 1 Q approx-

Make sure the petrol pump is properly earthed.

Page 133 of 394

Downloaded from www.Manualslib.com manuals search engine f

E

E

a

a

2 DIAGRAM 1

I t

5 E 0

t-

DIAGRAM 2 /

-

t Battery +-----

0-1