Temperature Citroen CX 1984 1.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1984, Model line: CX, Model: Citroen CX 1984 1.GPages: 394

Page 139 of 394

Downloaded from www.Manualslib.com manuals search engine 7. Water temperature sensor : ( DIAGRAM 7 )

- Disconnecting ‘the water temperature sensor should cause the engine to stall. when hot.

- Disconnect the E.C U

Using the ohmmeter, test the continuity of the circuit. and measure directly the resisitance using the sensor

cc - 10’ C )) R = 7 to 12 kR

cc + 20” C )t R = 2 to 3 kQ

cc t 80” C H R -. 250 to 400 Q

e

2

ii 8. Air temperature sensor : ( DIAGRAM 8 )

E

-E

?

U-J

- Disconnect the E.C.U. -

Using an ohmmeter, test the continuity of the circuit. and measure the resistance of the sensor between

terminals (( 6 )) and (( 27 ))

(c-10’ CH. R-8toIlkQ

N t 20” C 1) R = 2 to 3 kQ

tt + 50” C n R x 750 to 900 !J

Page 140 of 394

Downloaded from www.Manualslib.com manuals search engine 9. Cold-start injector, and thermal switch : ( DIAGRAM 9 )

- Disconnect the E.C.U.

- Remove the cold-start injector, and place it above a graduated container.

- Disconnect the thermal switch, and connect terminal (( 46 )) to earth

- Switch the ignition on and actuate the starter motor. the quantity delivered must be approximately

135 cm3 /min ( 8 l/4 cuin’min 1.

- Disconnect the injector: its resistance must be 4.2 Q at 20” C

- Connect the injector to the thermal switch.

- If the water temperature is below 35” C, on operating the starter motor, the cold-start injector must supply

petrol for the followinq amounts of time

- 7.5 sets for a temperature of (( - 20” C ))

-5 ” ” (( - 10“ c N

-3

” cc 0: c ))

-1 ” ” (( 20” c >)

- On operating the starter. terminal (( 4 )) of the E.C.U. terminal board must be enerqized ( voltmeter between

terminals (( 4 )) and 0 5 )) 1.

10. Switch on throttle butterfly spindle ( Idling speed function ) : ( DIAGRAM 10 )

- Disconnect the E.C.U

- Using an ohmmeter, check that there is no resistance between terminals N 2 H and (( 18 H of the multiple

connector, without touching the accelerator pedal.

Page 149 of 394

Downloaded from www.Manualslib.com manuals search engine 28 OPERATION N” MA.IE. 144-O : Ch <,c ,ng n,,d nlfjusfiup Ihe u I.-~<~tro,,ir i) <~lrr/mr,ir k’

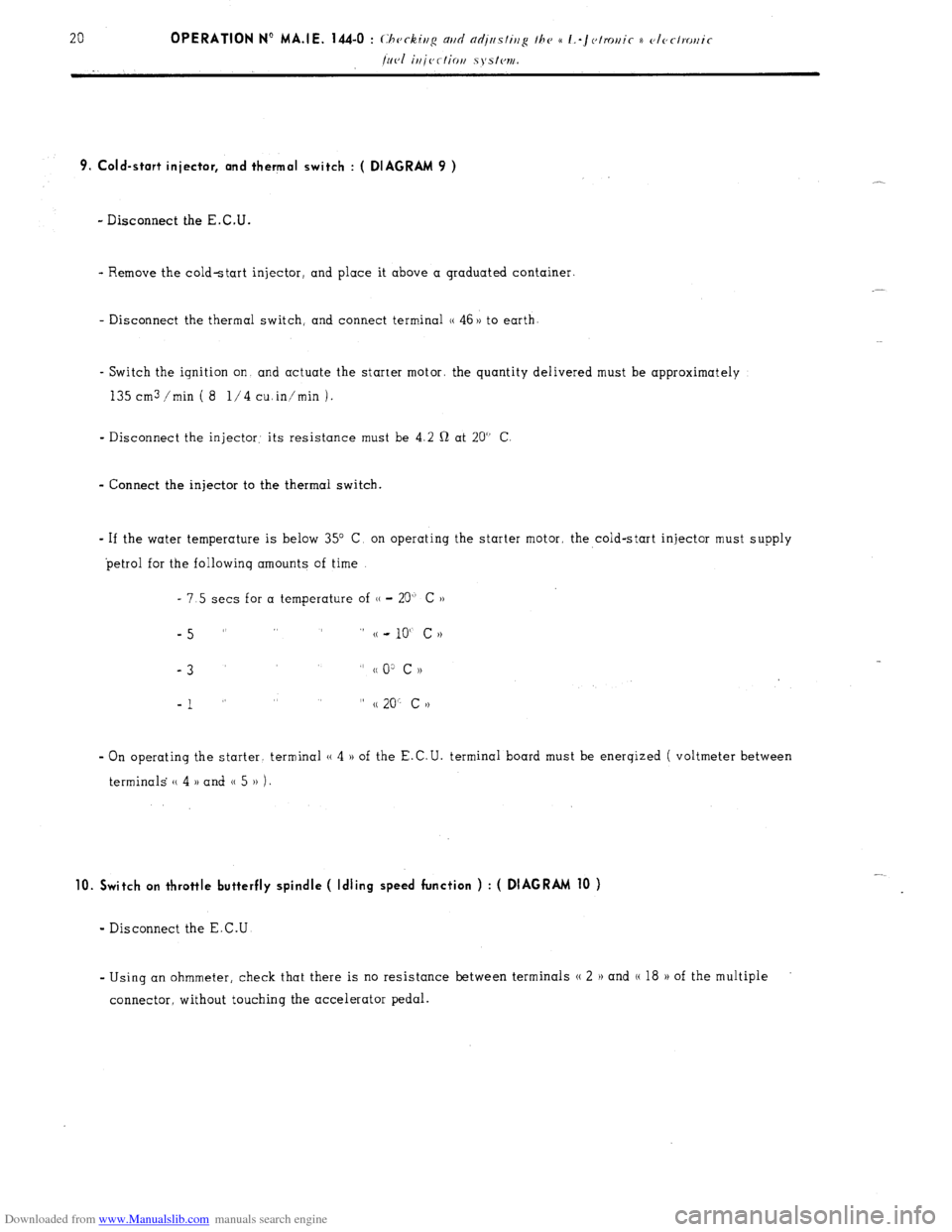

/,,,.I i,,jrr/io,, S~S,W1, ANNEXE : D - ADJUSTING THE IDLING SPEED AND THE EXHAUST EMISSION

CHECKING CONDITIONS

1.

Checking the idling speed must be carried out

on a clean engine on which the ignition and the

valve clearances are properly adjusted and

fitted with a clean air-filter.

2. Check that the throttle butterfly returns correctly

to its stop.

3. Do not load the alternator by switching an any

of the electrical components, except the iqnition

and the electric cooling fan (s) 4.

Run the engine to bring the oil temperature up

to 70 +o 80’ C ( wait for the electric cooling

fan is) to cut in ). IMPORTANT : Use exclusively (I high tension

tachometer ( do not damage the H.T. lead of

the ignition wiring harness ).

ADJUSTMENT

1. Check that the butterfly is not jammed in position

when it is resting against its stop.

2. Wait for the electric cooling fan (s) to cut in.

3. Use screw ( 1 ) to adjust the idling speed to 850

to 900 rpm.

4. Check the exhaust emission :

The resulting amount of CO - CO2 ( corrected CO

reading 1 must be beI& 4.5 %.

In case this reading cannot be obtained, check the

valve clearances, the ignition, the fuel pressure,

the air-tightness of the aircircuit, and the complete

fuel injection system.

5. On (I vehicle fitted with optional oirtonditioning

switch the compressor on, and adjust the idling

speed from 1000 to 1050

rpm, by adjusting the

screw on the auxiliary box located next to the

electro-vol”e.

Page 165 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 220-O : (.hrrkinfi Ih e oil pr~ssrrrc m the rehicle Op. MA. 220.0 1

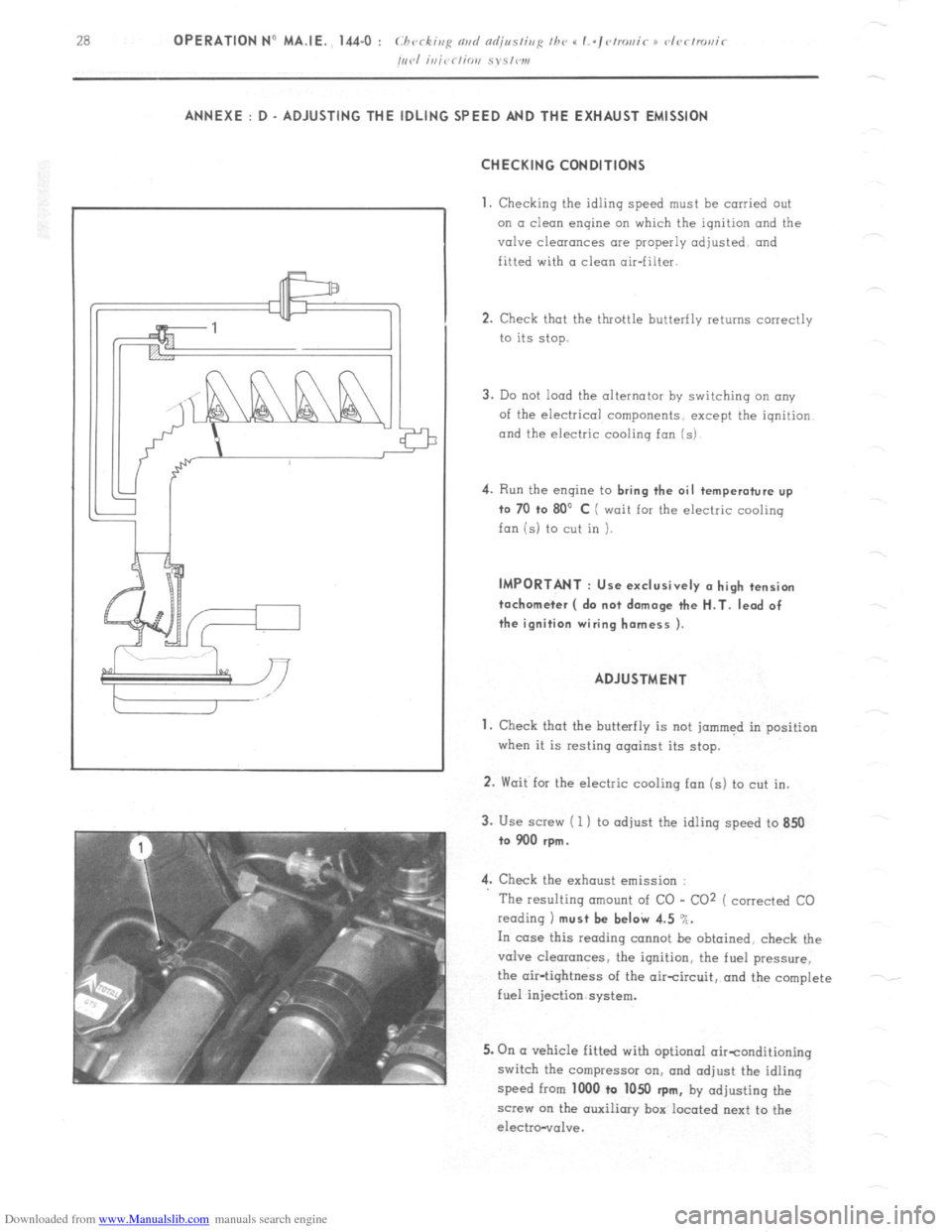

CHECKING THE OIL PRESSURE ON THE VEHICLE

79-T 1. Remove spare

wheel.

2. Check oil level if necessary.

4. Preparing pressure checking apparatus

Connect pressure gauge 2279-T ( ,wdun/r~l

imn 0 /o IO hnrs 1 to union 6004-T.

Tiqhten union screw ( 3 )

6. Start engine With oil temperature at 100’ C pressure should

be :

a+ 2000 rpm 3 bars mini43.5 psi ) o+ 4000 rpm 4 to 5 bars (58 to 72.5psi)

7. Rrmave union 6004-T and pressure qouqe. Tightening torque : 30 to 35 m \ ( 3 to 3.5 m.kg)

( 21 l/2 to 25 l/2 ft.lb )

Connect supply lead

Replace spare wheel

NOTE This operation con also be carried out

with the aid of CI MULLER kit,reference 451.

Page 170 of 394

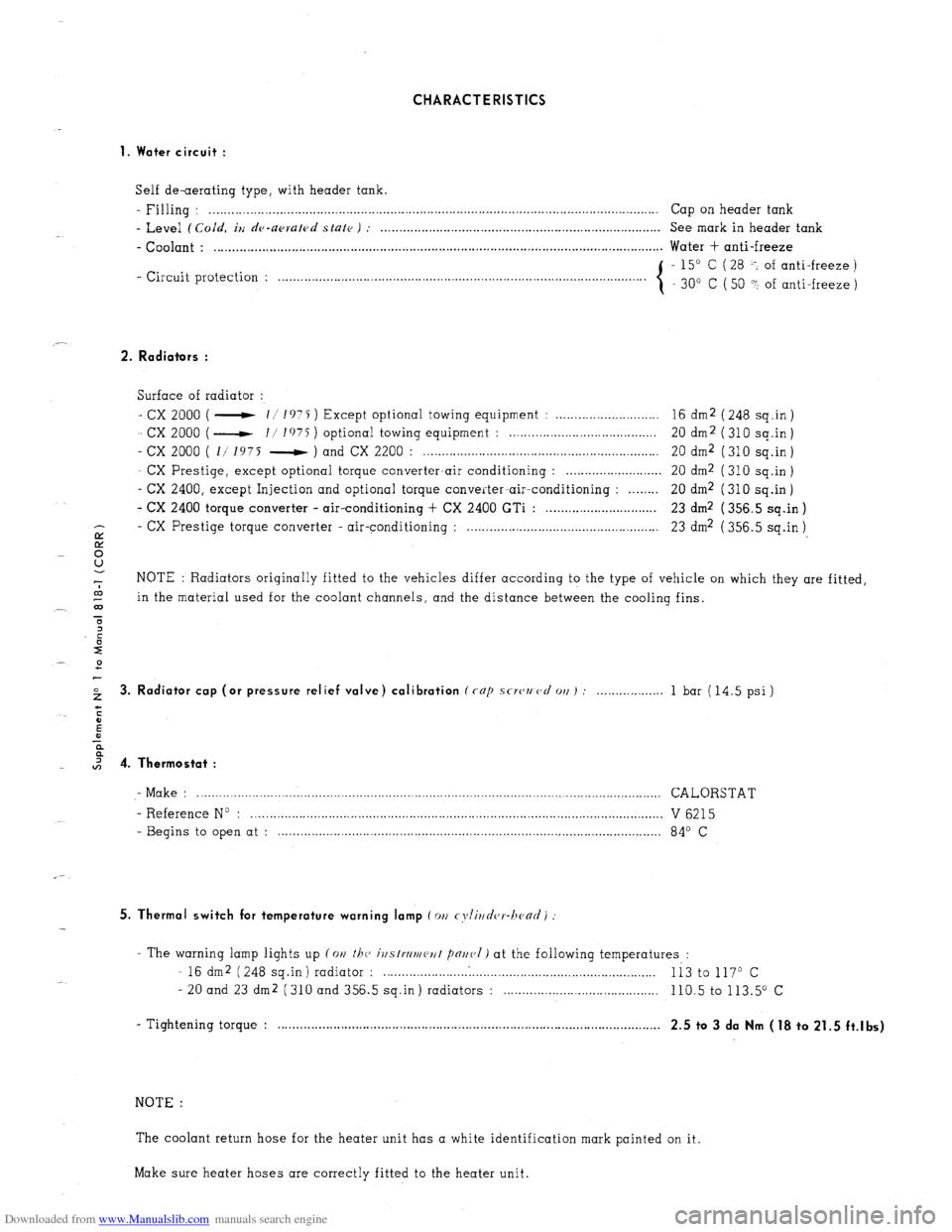

Downloaded from www.Manualslib.com manuals search engine CHARACTERISTICS

1. Water circuit :

Self de-aerating type, with header tank.

- Filling : . . . . . . . .._................................................................................................................ Cap on header tank

- Level (Cold, iu de-upruled state ) : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See mark in header tank

- Coolant : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. Water + anti-freeze

- Circuit protection : - 15” C ( 28 -: of anti-freeze )

. . . . . . . . . . . . . . . . . . . . .

30” C ( 50 ? of anti-freeze )

2. Radiators :

Surface of radiator :

- cx 2000 ( - 11 1975 ) Except optional towing equipment : . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 dm2 ( 248 sq.in )

- cx 2000 ( - I/ I’)75 ) optional towing equipment : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 dm2 (310 sq.in)

- cx 2000 ( 1/ 1975 - ) and CX 2200 : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 dm2 ( 310 sq.in )

- CX Prestige, except optional torque converter-air conditioning : . . . . . . . . . . . . . . . . . . . . . . . . . . 20 dm2 ( 310 sq.in )

- CX 2400, except Injection and optional torque converter-air-conditioning : . . . . . . . . 20 dm2 (310 sq.in)

- CX 2400 torque converter - air-conditioning + CX 2400 GTi : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 dm2 ( 356.5 sq.in )

- CX

E Prestige torque converter - air-conditioning : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 dm2 ( 356.5 sq.in )

8

-7 NOTE : Radiators originally fitted to the vehicles differ according to the type of vehicle on which they are fitted,

co

_- 03 in the material used for the coolant channels, and the distance between the cooling fins.

T

2 3. Radiator cap (or pressure relief valve) calibration (rap scwzmcl 011) : . . . 1 bar (14.5 psi)

I 4. Thermostat :

- Make : .............................................................................................................................. CALORSTAT

- Reference No : ................................................................................................................ V 6215

- Begins to open at : ........................................................................................................ 84’ C

5. Thermal switch for temperature warning lamp (011 cyli~~d(,r-hc~ad)

- The warning lamp lights up (on the, ivstrrlmeut pnr~(,I) at the following temperatures :

- 16 dm2 (248 sq.in) radiator : . . . . . . . . . . . . .

Ii3 to 117O c

- 20 and 23 dm2 (310 and 356.5 sq.in) radiators : . . . . 110.5 to 113.5” c

- Tightening torque : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . .

2.5 to 3 da Nm (18 to 21.5 ft.lbs)

NOTE :

The coolant return hose for the heater unit has a white identification mark painted on it.

Make sure heater hoses are correctly fitted to the heater unit.

Page 186 of 394

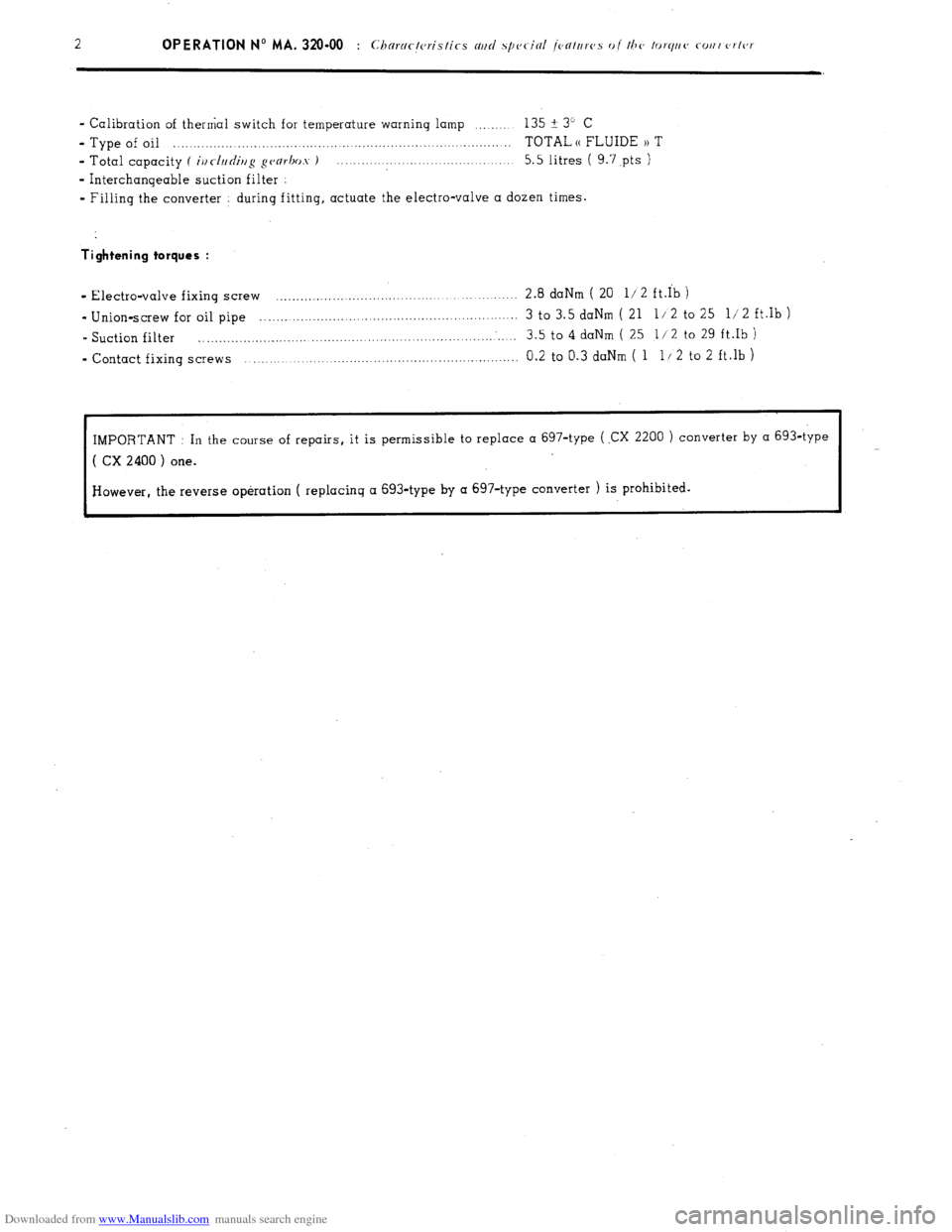

Downloaded from www.Manualslib.com manuals search engine - Calibration of thermal switch for temperature warning lamp .__._... 135 ? 3” C

- Type of oil . . .._..__.._._..___._._._._._.................,,.........._..._..._................. TOTAL (( FLUIDE 1) T

- Total capacity f

iur//rdiir/g ~~arhos ) .._._.._.......................... 5.5 litres ( 9.7,pts )

- Interchanqeable suction filter

- Filling the converter during fitting. actuate the electro-valve a dozen times.

Tightening torques :

- Electra-valve fixing screw ............................................................ 2.8 daNm ( 20 l/2 ft.Ib )

- Union-screw for oil pipe ............................................................... 3 to 3.5 daNm ( 21 l/ 2 to 25 l/ 2 ft.Ib )

- Suction filter .................................................... ........... ............. 3.5 to 4 daNm ( 25 l/2 to 29 ft.Ib )

- Contact fixing screws ................................................................... 0.2 to 0.3 daNm ( 1 11 2 to 2 ft.lb )

IMPORTANT : In the course of repairs, it is permissible to replace a 697-type ( .CX 2200 ) converter by a 693-type

( CX 2400 ) one.

However, the reverse operation ( replacing a 693-type by a 697-type converter ) is prohibited.

Page 292 of 394

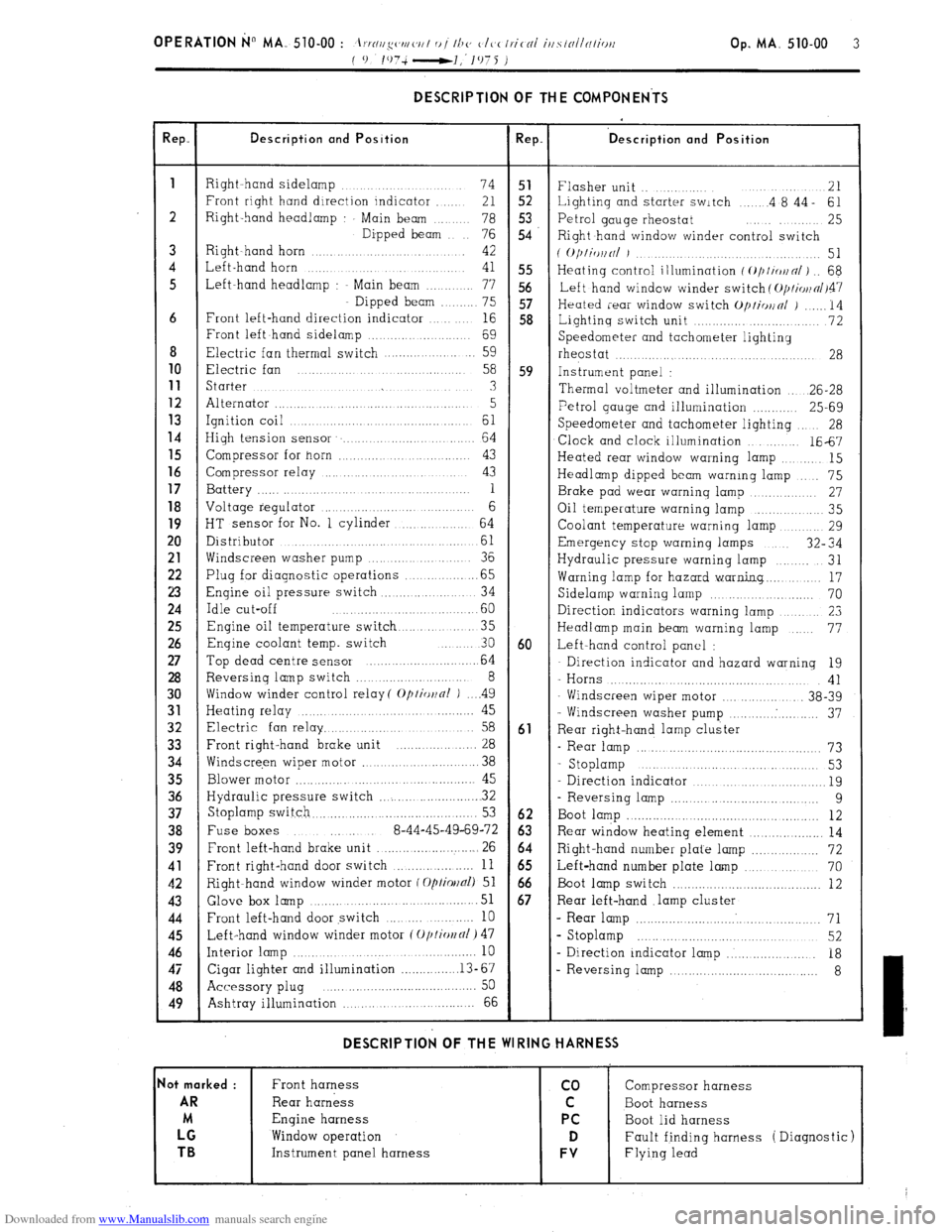

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 510-00 : \m//l‘!yc~tl/ <‘,/I 0 t Ih<’ <‘It,< Ir.itnl iusrtlllnliritt Op. MA. 510-00 3

f 0 lO7i-l,‘1975 )

DESCRIPTION OF THE COMPONENTS

!ep. Description and Position Rep. ‘D escription and Position

1

Right hand sidelamp ...... 74 51

Flasher unit .. ....... 21

Front right hand direction indicator ..... 21 52 Lighting and starter switch .... .4 8’44- 61

2 Right-hand headlamp Main beam .. 78 5.3

76 54 Petrol gauge rheostat ........ 25

Dipped beam

Right hand window winder control switch

3 Right~hand horn ............ 42

( O/)liWlNl J ................. 51

4 Left-hand horn ...

41 55 Heating control illumination f ~///io~n/) .. 68

5 Left-hand headlamp : Main beam ....... 77 56

Left hand window winder switch ( O/JI~OII~/~~~

Dipped beam ...... 75 57

Heated rear window switch Op/io~nl j ...... 14

6 Front left-hand direction indicator ... 16 58

Lightinq switch unit ............. ........... 72

Front left hand sidelamp ................. 69

Speedometer and tachometer lighting

8 Electric fan thermal switch .................. 59

rheostat ....... ...... .................... 28 10

Electric fan .......

58 59 Instrument panel : 11

Starter ...... ... .............. .......... 3

Thermal voltmeter and illumination .. 26-28 12

Alternator ............................ ........ 5 13 Petrol gauge and illumination ............ 25-69

Ignition coil ... ......... .............. 61 14

Speedometer and tachometer lighting 28

High tension sensor ....................... 64

Clock and clock illumination ....... 1667 15

Compressor for horn ............ ..... ...... 43

Heated rear window warning lamp ....... 15 16

Compressor relay ................... ..... 43

Headlamp dipped beam warning lamp ... 75 17

Battery ............. .... .. 1

Brake pad wear warning lamp .......... 27 18

Voltage regulator ......................... 6

Oil temperature warning lamp ............ 35

19

HT sensor for No. 1 cylinder ........... 64

Coolant temperature warning lamp ....... 29 20

Distributor ..................... ...........

61 Emergency stop warning lamps 32” 34

21

Windscreen washer pump ............. 36

Hydraulic pressure warning lamp ...... 31 22

Plug for diagnostic operations ............. .65

Warning lamp for hazard warning.. ...... 17 23

Engine oil pressure switch .............. .. 34

Sidelamp warning lamp ................... 70 24

Idle cut-off ....................... .60

Direction indicators warning lamp ........... 23 25

Engine oil temperature switch ........... 35

Headlamp main beam warning lamp ... 77 26

Enqine coolant temp. switch ... 30 60 Left-hand control panel : 27

Top dead centre sensor ........................ 64 Direction indicator and hazard warning 19 28

Reversing lamp switch ........................ 8

- Horns .................................... 41 30

Window winder control relay( Optior~nl ) .. ..4 9

Windscreen wiper motor ............... 38-39 31

Heating relay ............ ..................... 45

- Windscreen washer pump .......... . .......... 37 32

Electric fan relay ................................ 58 61

Rear right-hand lamp cluster 33

Front right-hand brake unit ................. 28

- Rear lamp ............................................... 73 34

Windscre,en wiper motor ........................ 38

- Stoplamp ............. .....

............ 53

35

Blower motor ............ .............................. 45

Direction indicator ................................... 19 36

Hydraulic pressure switch ...................... . 32

- Reversing lamp ..................................... 9 37

Stoplamp switch.. ......................................... 53 62

Boot lamp ................................................. 12 38

Fuse boxes ..... 8-44-45-49-69-72 63 Rear window heating element ................... 14 39

Front left-hand brake unit .......................... 26 64

Right-hand number plate lamp ................. 72 41

Front right-hand door switch ................... 11 65

Left-hand number plate lamp ................... 70 42

Right-hand window winder motor f Optiollal) 51 66

Boot lamp switch ........................................ 12 43 Glove box

lamp ...................................... 51 67 Rear left-hand .lamp cluster 44

Front left-hand door switch ........ .......... 10 - Rear lamp ................................................ 71 45

Left-hand window winder motor (Oplio~fll) 47 s Stoplamp ........................................... 52 46

Interior lamp ................................................. 10

- Direction indicator lamp ..................... 18 47

Cigar lighter and illumination ............... .13-67

- Reversing lamp .................................... 8 48

Accessory plug ..... ... .......................... .... 50

49

Ashtray illumination ,., ... ................ 66 DESCRIPTION OF THE WIRING HARNESS

lot marked :

Front harness co Compressor harness AR

Rear harness C Boot harness

M Engine harness PC

Boot lid harness LG

Window operation D Fault finding harness ( Diagnostic) TB

Instrument panel harness FV Flying lead

Page 300 of 394

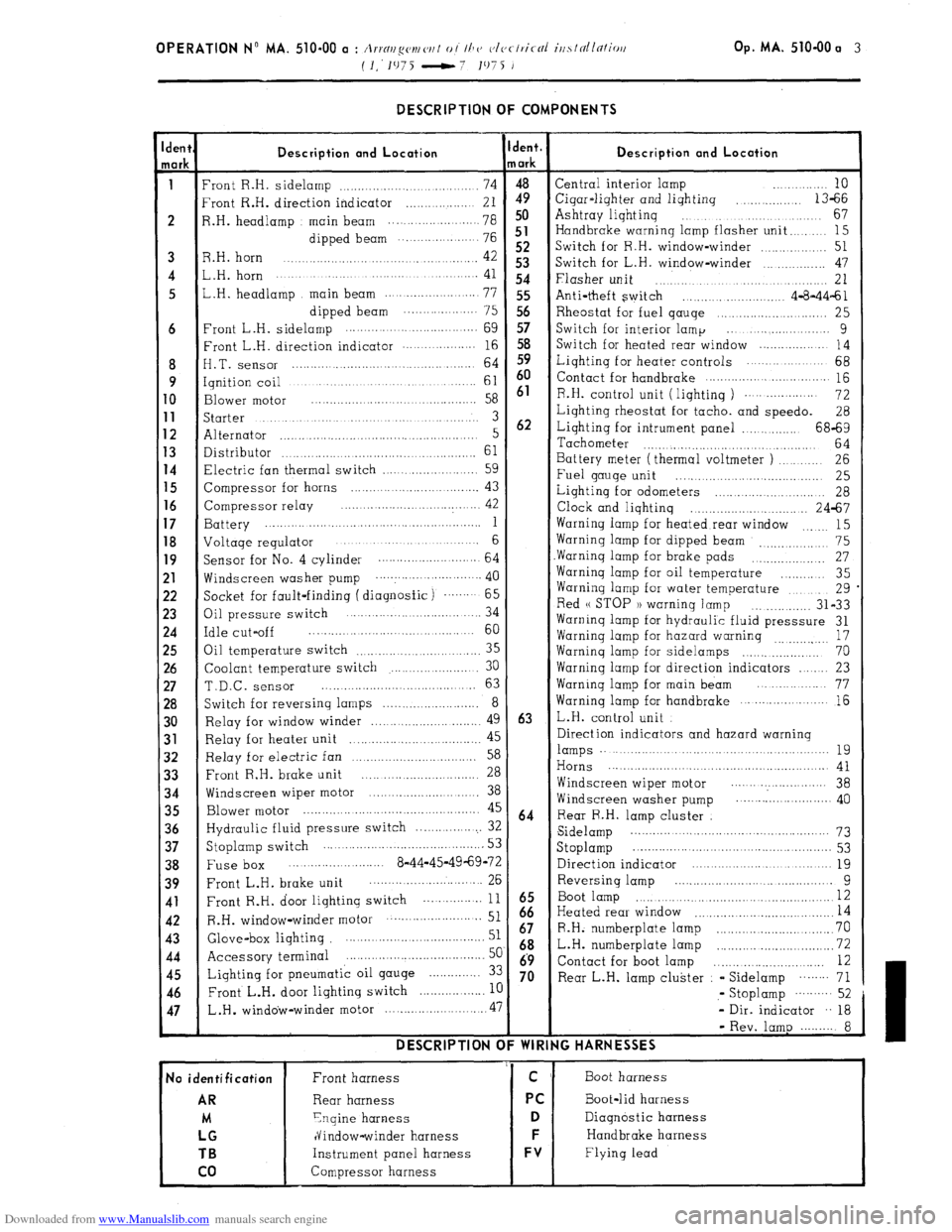

Downloaded from www.Manualslib.com manuals search engine OPERATION N” MA. 510-00 a : Arrnr~g(,v~ ('I, I 0 / Ih CJ c~lvclric-cil irtslnllc7liori Op. MA. 510-00 a 3

(I.‘1975 -7 1975 J

-

den{

lark

i

6

8

9

0

1

2

3

4

5

6

7

8

9

!l

!2

!3

!4

!5

!6

!7

!8

$0

)l

12

33

34

35

36

37

38

39

41

42

43

44

45

46

47

- DESCRIPTION OF COMPONENTS

Description and Location

‘ront R.H. sidelamp ................................... 74

‘rant R.H. direction indicator .................. 21

1.H. headlamp main beam ................. ..... 78

dipped beam ... .................. 76

3.H. horn 42 .............................................

,.H. horn ....................... ............. ............. 41

,.H. headlamp main beam .......................

77

dipped beam .................... 75

‘rant L.H. sidelamp .........

........................

69

:ront L.H. direction indicator .................. 16

I.T. sensor ............................................ 64

qnition coil ..............................................

61

3lower

motor .........................................

58

;tarter ...................................................... 3

Alternator ..................................................... 5

Xstributor 61 ...................................................

7lectric fan thermal switch .........................

59

Zompressor for horns ................................. 43

Compressor relay ..... .................

.............. 42

3attery ........... ...............................................

1

Joltaqe regulator ....................... ............. 6

jacket for fault-finding ( diagnosfic) ....... 65

3il pressure switch .... ....................... ... 34

:dle cut-off ........................................... 60

3il temperature switch

35 .............................

Coolant temperature switch ....................... 30

T.D.C. sensor ......................................... 63

Switch for reversing lamps .......................... 8

Relay for window winder ............................. 49

Relay for heater unit 45

................... ..............

Relay for electric fan 58 ..................................

Front R.H. brake unit 28 ...............................

Windscreen wiper motor .............................. 38

Blower motor ................................................ 45

Hydraulic fluid pressure switch ................... 32

Stoplamp switch ........................................... 53

Fuse box ..... .................... 8-44-45-49-69-72

Front L.H. brake unit ........................... ... 26

Front R.H. door lighting switch ... ............

11

R.H. window-winder motor .......................... 51

Glove-box lighting ....................................... 51

Accessory terminal ......................................

5c

Lighting for pneumatic oil gauge .............. 3:

Front L.H. door lighting switch

.................. I[ L.H .

window-winder motor ........................... .47 DESCRIPTION C

No identification

AR

M

LG

TB

co

Front harness

Rear harness

Ynqine harness

dindow-winder harness

Instrument panel harness

Compressor harness jent.

/ark

4”9 50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

iz

67

68

69

70 Description and Location Central interior lamp ............ 10

Cigar-liqhter and lighting

.............. 13-66

Ashtray liqhtinq ...................................

67

Handbrake warning lamp flasher unit

........ 15

Switch for R.H. window-winder

.............. 51

Switch for L.H. window-winder ................ 47

Flasher unit .............................................. 21

Anti-theft switch ......................... 4-8-44-61

Rheostat for fuel qauqe ............................ 25

Switch for interior lamp ... ....................

9

Switch for heated rear window ...................

14

Liqhting for heater controls ..................... 68

Contact for handbrake

............................... 115

R.H. control unit ( liqhtinq )

................... 72

Lighting rheostat for tacho. and speedo.

28

Lighting for intrument panel ................ 68-69

Tachometer

............................................ 64

Battery meter (thermal voltmeter )

.......... 26

Fuel gauge unit

..... ....... ....... ................ 25

Lighting for odometers

....... ......... .......... 28

Clock and lighting ................................ 24-67

Warning lamp for heated rear window

15 .......

Warning lamp for dipped beam 75

_, .................

Warninq lamp for brake pads ................... 27

Warninq lamp for oil temperature

............ 35

Warning lamp for water temperature

.......... 29

Red u STOP 1) warninq lamp

............... 31-33

Warninq lamp for hydraulic fluid presssure 31

Warninq lamp for hazard warning

17

...............

Warninq lamp for sidelamps .................... 70

Warning lamp for direction indicators ...... 23

Warninq lamp for main beam ................. 77

Warning lamp for handbrake

..................... 16

L.H. control unit

Direction indicators and hazard warning lamps .........................................................

19

Horns .......................................................... 41

Windscreen wiper motor ....... .................. 38

Windscreen washer pump .......................... 40

Rear R.H. lamp cluster

Sidelamp ...................................................

73

Stoplamp ....................... .............................. 53

Direction indicator ......................................

19

Reversing lamp ....................... .............

9

Boot lamp ................................................... I2

Heated rear window 14 .....................................

R.H. numberplate lamp ...............................

70

L.H. numberplate lamp ...........

.................... 72

Contact for boot lamp .............................

12

Rear L.H. lamp cluster - Sidelamp

........ 71

,- Stoplamp

.......... 52

- Dir. indicator .. 18

- Rev. lamp ......... 8

IG HARNESSES

Boot harness

Boot-lid harness

Diagnostic harness

Handbrake harness

Flying lead

Page 308 of 394

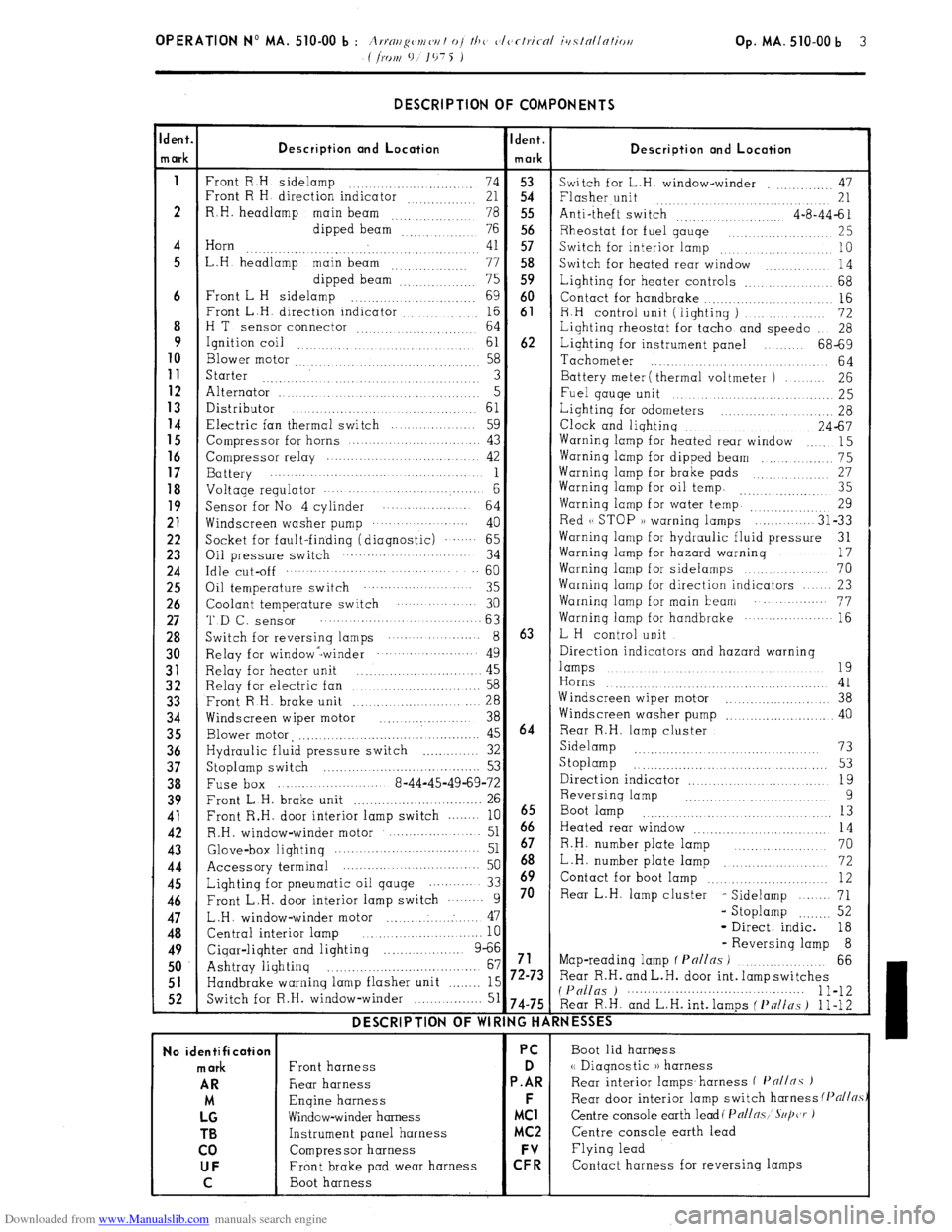

Downloaded from www.Manualslib.com manuals search engine DESCRIPTION OF COMPONENTS

dent.

Ident.

Description ond Location

n ark Description and Location

mark

1

Front R.H sidelamp

74 53

Switch for L.H. window-winder .,, 47

Front R H direction indicator

21 54 Flasher unit

.... 21

2 R.H. headlamp

main beam

78 55 Anti-theft switch

4-a-44-61

dipped beam

76 56 Rheostat for fuel gauqe

,.. 25

4 Horn

41 57

. Switch for interior lamp .,. 10

5 L.H headlamp main beam

.., .., ,.. 77 58

Switch for heated rear window

14

dipped beam”: 75 59 Lighting for heater controls _.. 68

6 Front L H sidelamp

.,. 69 60

Contact for handbrake .._....

16

Front L.H. direction indicator ,.... ._. _._.. 16 61

8 R.H control unit (lighting )

72

H T

sensor connector ,. 64

Lighting rheostat for tacho and speed0

28

9

Ignition coil ,.,

61 62 Lighting for instrument panel 68-69

10

Blower motor 58

Tachometer

.,.

64 11

Starter 3 Battery meter ( thermal voltmeter ) 26 12 Alternator ..I

5

Fuel gauqe unit 25 13

Distributor

61 14 Lighting for odometers _. 28 Electric fan thermal switch 59

Clock and lighting .._.. .,. 24-67

15

Compressor for horns 43 Warning lamp for heated rear window

15 16 Compressor relay 42 Warning lamp for dipped beam

_.. 75 17

Battery 1 Warninq lamp for brake pads 27 18 Voltage regulator . . . . . . . . . . 6 Warning lamp for oil temp. ,,_.. 35

19

Sensor for No 4 cylinder

64 Warning lamp for water temp. ..._.,,, ,,,,. 29 21

Windscreen washer pump ... .. ......

40 Red (( STOP )) warning lamps

31-33 22

Socket for fault-finding (diagnostic) .‘.‘.... 65 Warninq lamp for hydraulic fluid pressure

31 23

Oil pressure switch 34 Warning lamp for hazard warning

17 24 Idle cut-off .._........ 60

Warning lamp for sidelamps

70 25

Oil temperature switch 35 Warning lamp for direction indicators 23 26

Coolant temperature switch 30 Warninq lamp for main beam .‘..... 77 27 ‘I’D f-, SenSOr 63

Warning lamp for handbrake ... .‘........-.. 16 28

Switch for reversinq lamps ... ... ....... 8 63 L H control unit 30

Relay for window -winder ... ... .‘........ 49 Direction indicators and hazard warning 31

Relay for heater unit 45 lamps .,. .,...._ .,. .._ 19

.,. .._.......... 32

Relay for electric fan 58 Horns 41 33

Front R H. brake unit

.._.. 28 Windscreen wiper motor

..,.... 38 34

Windscreen wiper motor

_.............. 38 Windscreen washer pump

.._...... 40 35

Blower motor, ,._..._._....._._..._........ 45 64 Rear R.H. lamp cluster 36

Hydraulic fluid pressure switch _..._......... 32 Sidelamp .._...... 73

37

Stoplamp switch 53 S toplamp

_. _. _. _. _. _. _. 53

.._..............

38

Fuse box 8-44-45-49-69-72 Direction indicator

19

_.. _._.. 39

Front L.H. brake unit

. .._.._............... 26 Reversing lamp 9 41

Front R.H. door interior lamp switch 10

6665 Boot lamp .._. ._. 13

42

R.H. window-winder motor ..- 51 Heated rear window

14 43

Glove&or lightinq .._............ 51 67 R.H. number plate lamp 70

44

Accessory terminal 50 68 _..,......... L.H. number plate lamp

72 45

Lighting for pneumatic oil qauge 33 h9 Contact for boot lamp .._.. .._. .._........ 12 46

Front L.H. door interior lamp switch 9 70 Rear L.H. lamp cluster

- Sidelamp

71 47

L.H. window-winder motor ..: 47 - Stoplamp .._._... 52

48

Central interior lamp

10 - Direct. indic. 18 49

Cigar-lighter and lighting 9-66 - Reversing lamp 8

.._....

50 Ashtray lighting 67 71 Map-reading lamp f Pnl/ns ) .._..._....._.

66

_._......._...................... 51

Handbrake warning lamp flasher unit .._._.._ 15 72-73 Rear R.H. and L.H. door int. lamp switches 52

Switch for R.H. window-winder _..._.. 51 (P(/llgs ) 1 l-12 74-75 Rear R.H. and L.H. int. lamps ( f’nlins ) 1 l-12 DESCRIPTION OF WIRING HARNESSES

No identification PC

Boot lid harness mark

Front harness D <( Diagnostic )) harness AR

Rear harness P.AR Rear interior lamps.harness f I’n//nc )

M Engine harness F

Rear door interior lamp switch harness (Pflj/~.s LG

Window-winder harness MC1 Centre console earth lead( Pall~.~,’ S~/jczr ) TB

Instrument panel harness MC2 Centre console earth lead

co Compressor harness Flying lead UF

Front brake pad wear harness C: Contact harness for reversing lamps

C Boot harness

Page 313 of 394

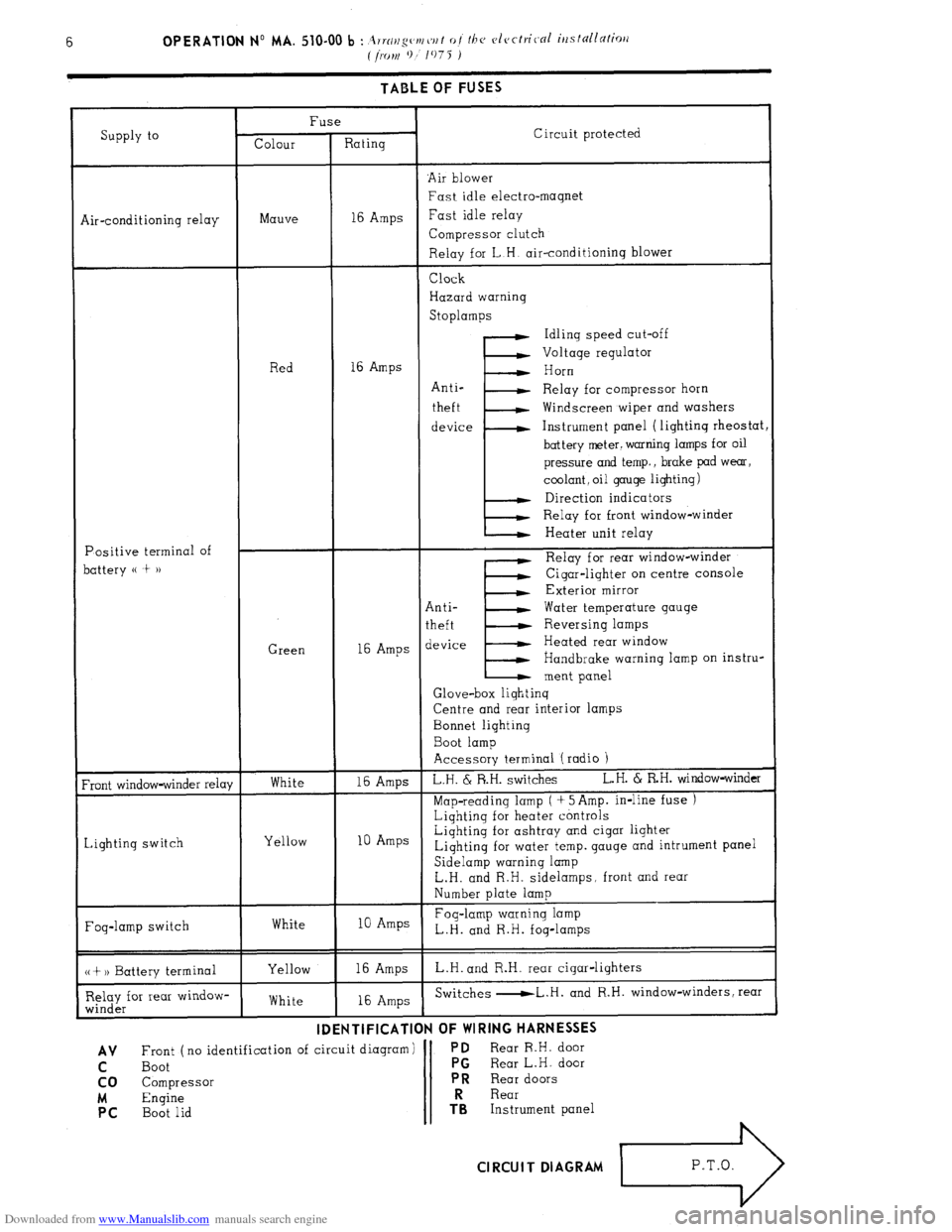

Downloaded from www.Manualslib.com manuals search engine TABLE OF FUSES

Supply to Fuse

Colour Rating Circuit protected

‘Air blower

Fast idle electro-magnet

Air-conditioning relay Mauve 16 Amps Fast idle relay

Compressor clutch

Relay for L.H. air-conditioning blower

Positive terminal of

battery (( t )) Red

Green Clock

Hazard warning

Stoplamps

Idling speed cut-off

Voltage regulator

16 Amps

I’ Horn

Anti-

Relay for compressor horn

theft Windscreen wiper and washers

device Instrument panel (lighting rheostat

battery meter. warning lamps for oil

pressure and temp., brake pad wear,

coolant, oil gauge lighting)

Direction indicators

Relay for front window-winder

Heater unit relay

E Relay for rear window-winder

Cigar-lighter on centre console

Exterior mirror

Anti- Water temperature gauge

theft Reversing lamps

16 Amps device Heated rear window

Handbrake warning lamp on instru-

ment panel

Glove-box lighting

Centre and rear interior lamps

Bonnet lighting

Boot lamp

Accessory terminal (radio 1

Front window-winder relay

Lighting switch White

Yellow 16 Amps L.H. & R.H. switches L.H. 6 RH. window-winder

Map-reading lamp ( + 5Amp. in-line fuse )

Lighting for heater controls

10 Amps Lighting for ashtray and cigar lighter

Lighting for water temp. gauge and intrument panel

Sidelamp warning lamp

L.H. and R.H. sidelamps. front and rear

Number plate lamp

Fog-lamp switch White 10 Amps Fog-lamp warning lamp

L.H. and R.H. fog-lamps

(( + 1) Battery terminal

Relay for rear window-

winder Yellow

White 16 Amps L.H. and R.H. rear cigar-lighters

16 Amps Switches -L.H. and R.H. window-winders, rear

-.. -- . ..-...- . . . -..---m-

IDENTIFICATION

OF WIRING HARNt33t3

AV Front ( no identification of circuit diagram) PD Rear R.H. door

C Boot PG

Rear L.H. door

co Compressor PR

Rear doors

M Engine Rear PC

Boot lid TRS Instrument panel Cl RCUI T DIAGRAM

L3

P.T.O.