turn Citroen CX 1985 1.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1985, Model line: CX, Model: Citroen CX 1985 1.GPages: 394

Page 189 of 394

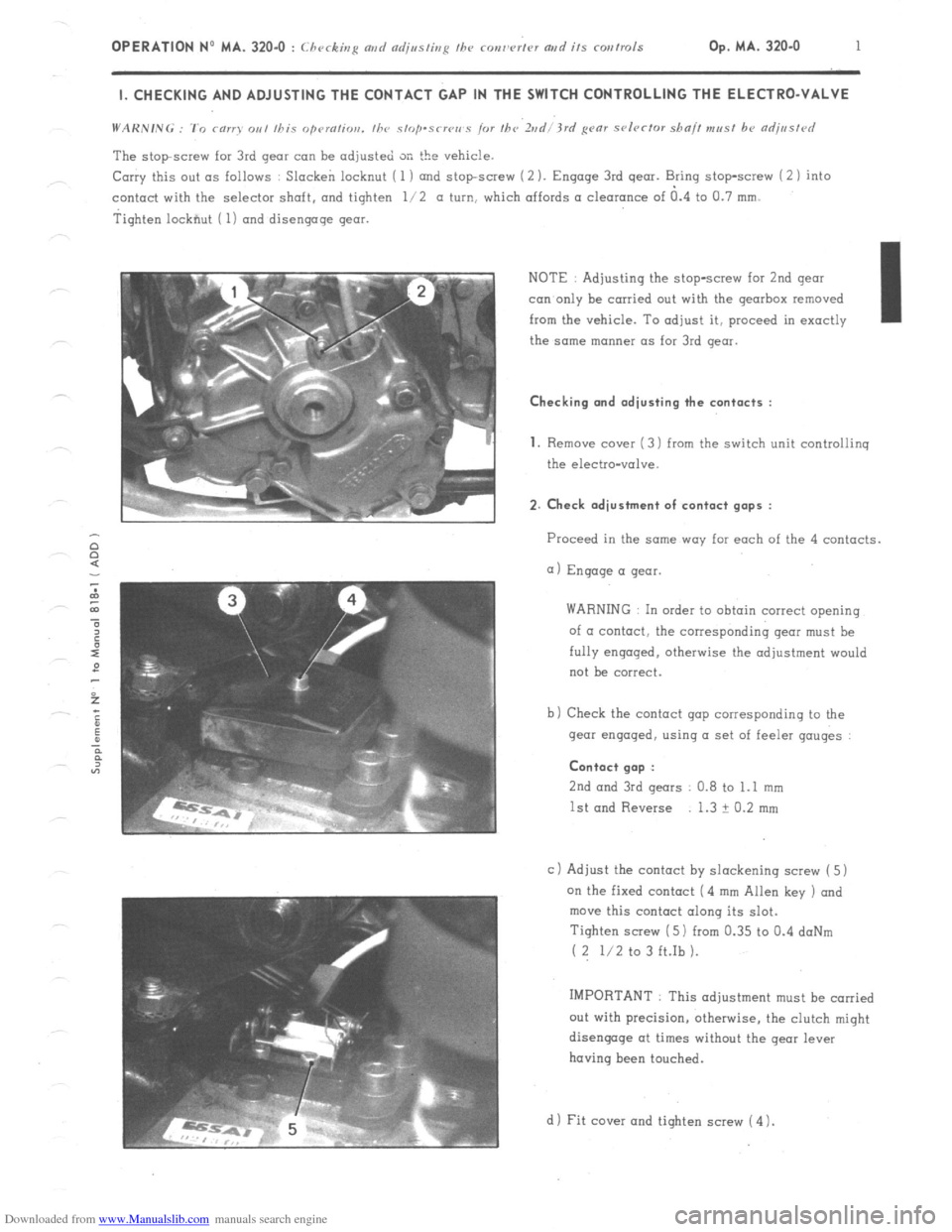

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 320-O : Checking md czdjssting fhe ronw’rtcv artd its corrtrols Op. MA. 320.0 1 I. CHECKING AND ADJUSTING THE CONTACT GAP IN THE SWITCH CONTROLLING THE ELECTRO-VALVE

The stopscrew for 3rd gear can be adjusted SK the vehicle.

Carry this out as follows : Slacken locknut ( 1 ) and stopscrew (2 ). Engage 3rd gear. Bring stop-screw i 2 1 into

contact with the selector shaft. and tighten l/2 a turn, which affords a clearance of a.4 to Cl.7 mm.

Tighten lockfiut ( 1) and disengage gear.

NOTE : Adjusting the stop-screw for 2nd gear

con only be carried out with the gearbox removed

from the vehicle. To adjust it, proceed in exactly I

the same manner as for 3rd gear. Checking and adjusting the contacts :

1.

Remove cover ( 3) from the switch unit controliinq

the electro-valve. 2. Check adjustment of contact gaps :

Proceed in the same way far each of the 4 contacts.

a) Engage a gear.

WARNING In order to obtain correct opening

of a contact, the corresponding gear must be

fully engaged. otherwise the adjustment would

not be correct.

b) Check the contact gap corresponding to the

gear engaged, using a set of feeler gauges : Contact gap :

2nd

and 3rd gears 0.8 to 1.1 mm

1st and Reverse 1.3 ? 0.2 mm

c 1 Adjust the contact by slackening screw ( 5)

on the fixed contact (4 mm Allen key ) and

move this contact along its slot.

Tighten screw ( 5) from 0.35 to 0.4 doNm

( 2 l/2 to 3 ft.Ib ).

IMPORTANT : This adjustment must be carried

out with precision, otherwise, the clutch might

disengage at times without the gear lever

having been touched.

d 1 Fit cover and tighten screw ( 4 1.

Page 191 of 394

Downloaded from www.Manualslib.com manuals search engine 2. Lubrication :

- Type of oil

- Capacity

- Difference between min and mox on dipstick TOTAL EP 80

1600 litres (2.8pts)

C.150 litres (0.26pts)

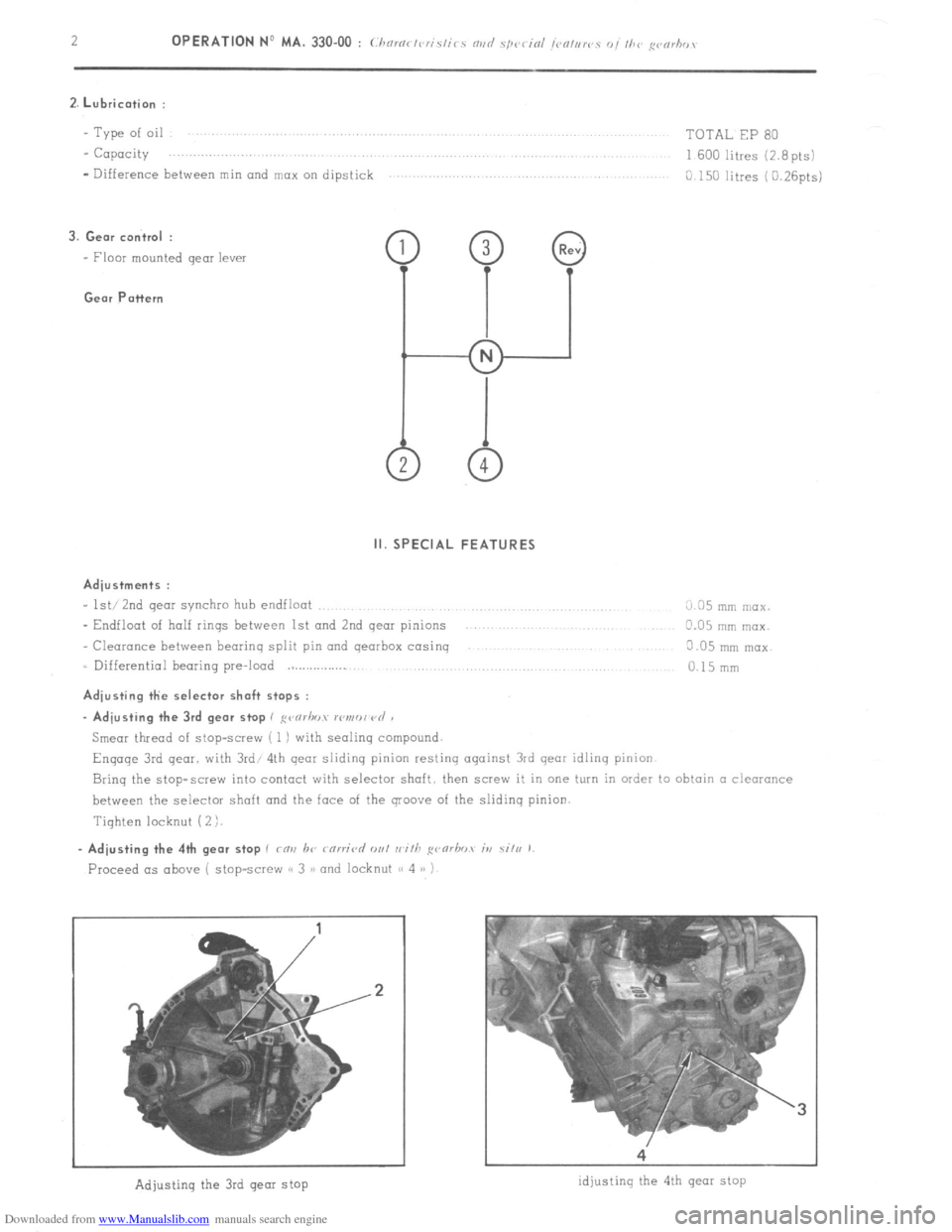

3. Gem control :

- Floor mounted gear lever Gear Pattern

Il. SPECIAL FEATURES

Adjustments :

- lst/ 2nd gear synchro hub endfloot

_ Endfloot of half rinqs between 1st and 2nd qear pinions

- Clearance between beorinq split pin and qearbox cosinq

= Differential bearing pre-loud Adjusting the selector shaft stops : L/35 mln rnclx.

0.05 mm max.

3.05 mnl mox

c.15 mm

- Adjusting the 3rd gear stop I ,

Engage 3rd qear. with 3rd/ 4th qear slidinq pinion restinq aqainst 3rd qear idlinq pinion

Brinq the stop-screw into contact with selector shaft then screw it in one turn in order to obtain CI clearonce

between the selector shaft and the face of the groove of the slidinq pinion.

Tiqhten locknut ( 2 ).

Proceed as above ( stop-screw a< 3 > and locknut ,< 4 /> )

.2

Adjusting the 3rd gear stop idjustinq the 4th gear stop

Page 196 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 330.00 : ( l~nmrtvrisfirs

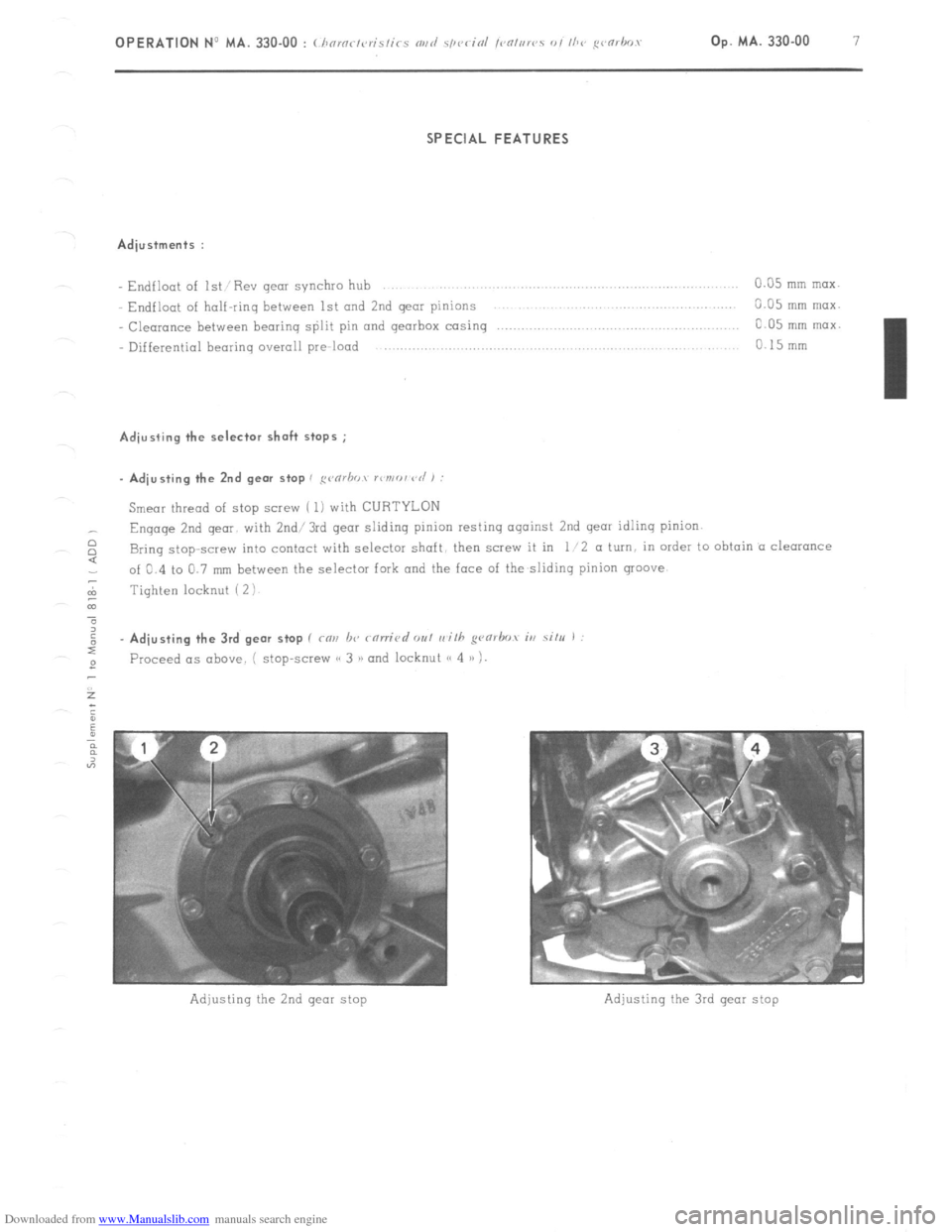

Adiustments :

Endflaot of 1st: Rev gear sjnchro hub 0.35 mm max.

Endfloat of half-ring between

1st and 2nd gear pinions 3.05 nlm nlax.

Clearance between beorinq split pin and gearbox casing c.05 mm nlax.

Differential bearing overoll pre-load 0 15mm Adiusting the selector shaft stops ;

Smear thread of stop screw ( 1) with CURTYLON

Engage 2nd qear. with 2nd/3rd gear sliding pinion resiinq against 2nd gear idling pinion.

$ Bring stop-screw into contaci with selector shaft, then screw it in 1 ‘2 a turn. in order to obtain o clearance

of 0.4 io 0.7 mm between the selector fork and the face of the slidinq pinion groove

7

m Tighten locknut ( 2 ! - Adjusting the 3rd gear stop ( cm lx

rorric,d out rrith pnrbov iu situ I

Proceed ~1s above. j stop-screw (< 3 >) and locknut e 4 1) !.

Page 198 of 394

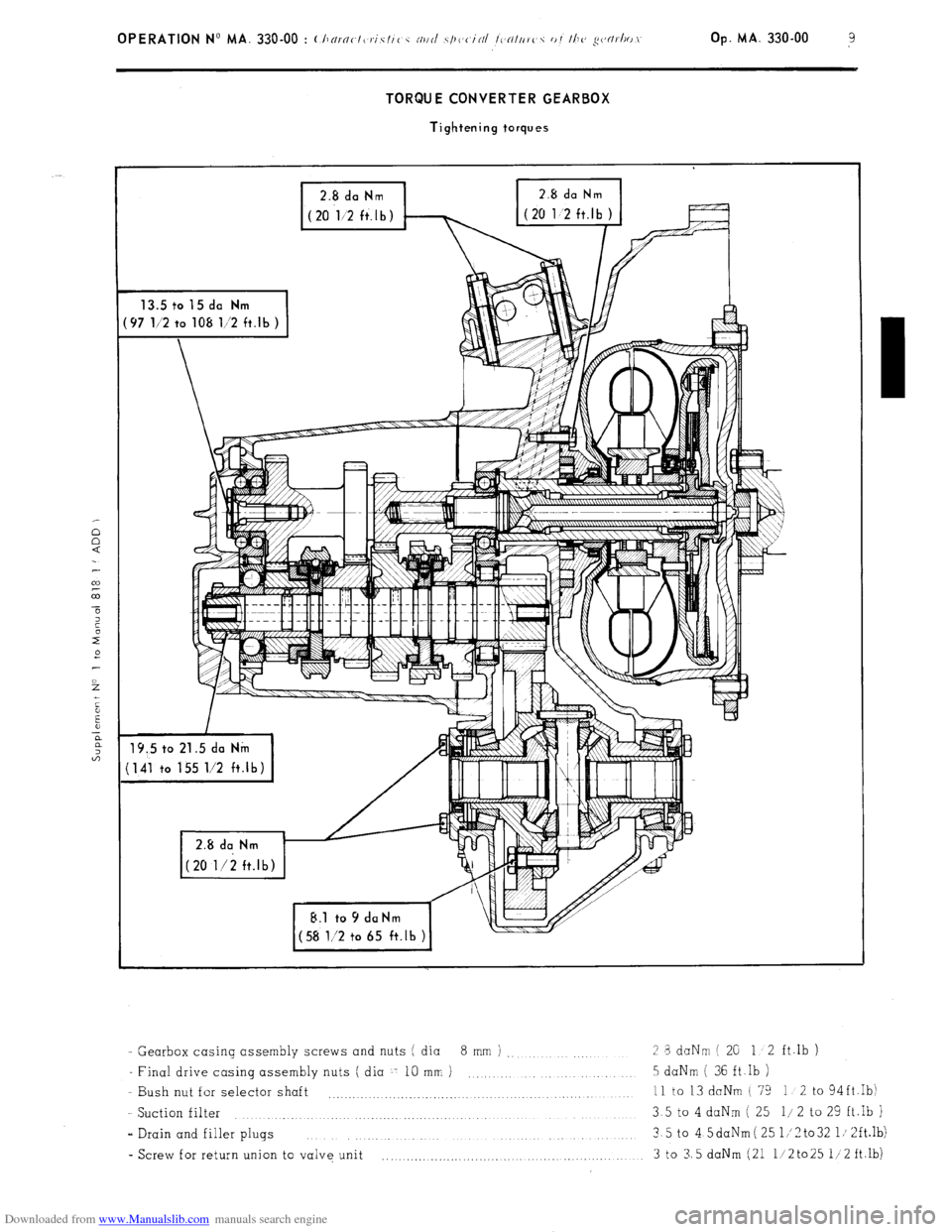

Downloaded from www.Manualslib.com manuals search engine TORQUE CONVERTER GEARBOX

Tightening torques

1 2.b da Nm 1

19.5 to 21.5 da Nm

141 to 155 l/2 ft.lb)

I

- Gearbox casing assembly screws and nuts ( dia 8 mm 1 ? 3 daNm ( 20 1 / 2 ft.Ib )

Final drive casing assembly nuts ( dia ~- 10 mm i

5 daNm ( 36 ft.Ib )

Bush nut for selector shaft

.._.. _..._.. 11 to 13 daNm ( 7” 1 2 to 94ft.Ib)

Suction filter 3 5 to 4 daNm ( 25 l/ 2 to 29 ft.Ib )

.._..,.

- Drain and filler plugs

3 5 to 4 5daNmJ 25 1,‘2to32 1; 2ft.Ib)

- Screw for return union to valve unit

.,... 3 to 3.5 daNm (21 1/2to25 l/2 ft.lb)

Page 203 of 394

Downloaded from www.Manualslib.com manuals search engine ii. SPECIAL FEATURES

Adjustments :

- Endfloat of lW2nd gear synchio nuts

0.05 mm max.

- Endfloot of half-ring between 2nd and 3rd gear pinions GO5 mm mox

- Clearance between bearing split pin and gearbox casing

0.05 mm nlax.

- Overall prelood on differential bearinq

0.15 mnl Adjusting the selector shaft stops :

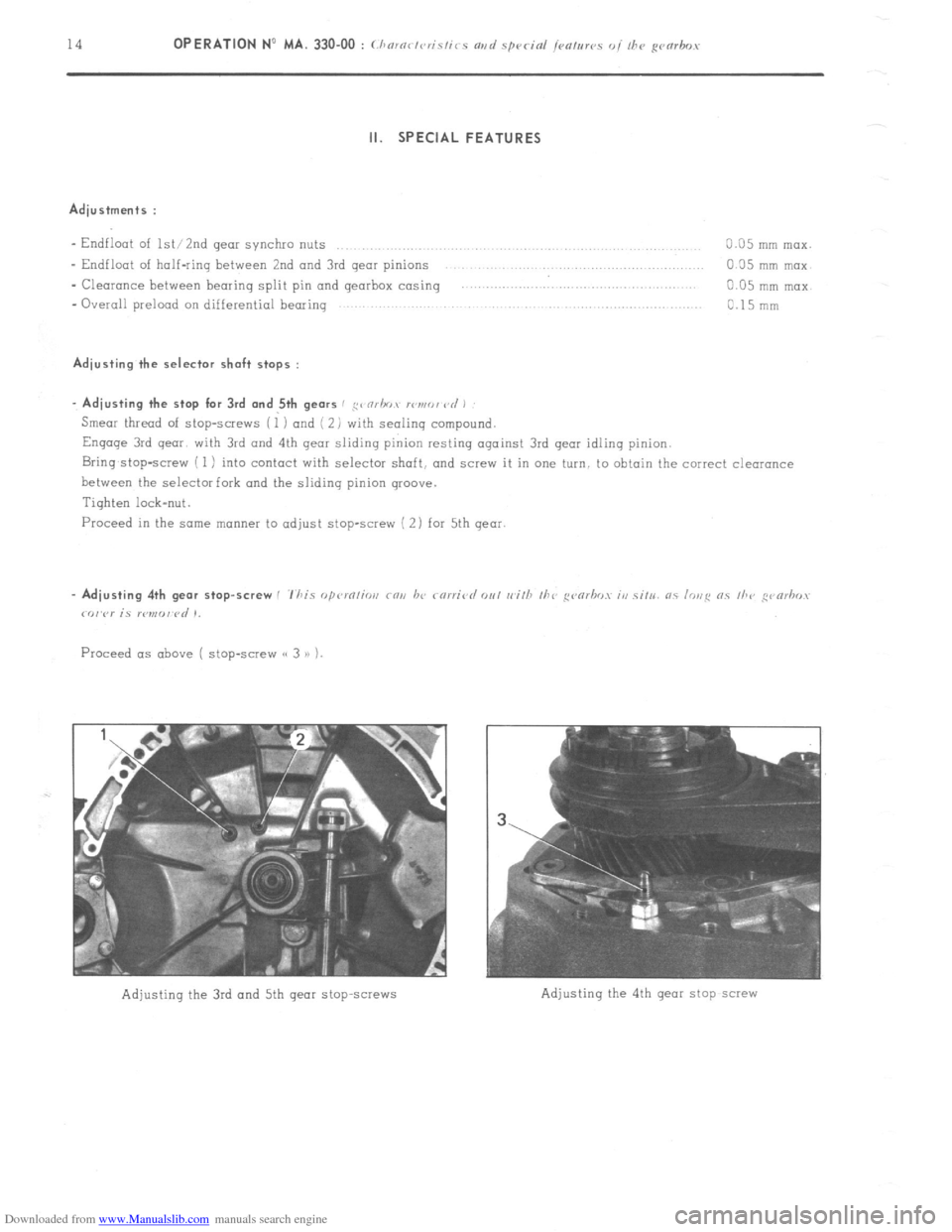

. Adjusting the stop for 3rd and 5th gears / ,g< nrhov lI~n,r,, vd ,

Smear thread of stop-screws (1 ) and ( 2) with sealing compound.

Engage 3rd qear with 3rd and 4th qeor sliding pinion resting against 3rd gear idling pinion.

Bring,stop-screw ( 1) into contact with selector shaft, and scw.v it in one turn, to obtain the correct clearance

between the selector fork and the sliding pinion groove.

Tighten lock-nut.

Proceed in the some manner to adjust stop-screw ( 2) for 5th qear.

Adjusting the 3rd and 5th gear stop~screws

Page 209 of 394

Downloaded from www.Manualslib.com manuals search engine Supplement NC 1 to Manual 818-l f CORR )

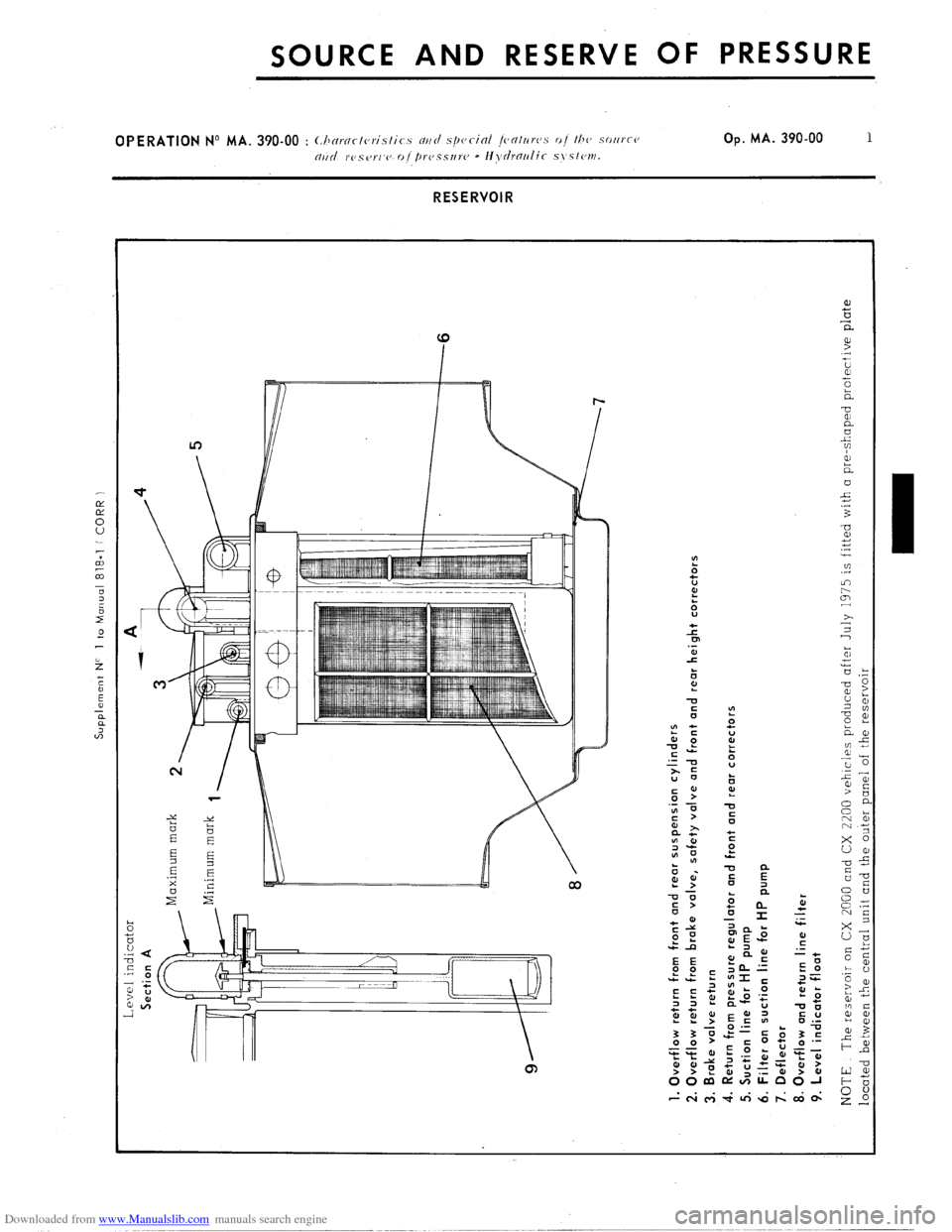

Level indicator

Section A

Maximum mark

Minimum mark

1. Overflow return from front and rear suspension cylinders

2. Overflow return from brake valve, safety valve and front and rear height correctors

3. Brake valve return

4. Return from pressure regulator and front and rear correctors

5. Suction line for HP pump

6. Filter on suction line for HP pump

7. Deflector

8. Overflow and return line filter

9. Level indicator float

NOTE The reservoir on CX 2000 and CX 2200 vehicles produced after July 1375 is fitted with a pre-shaped protective plate

located between the central unit and the outer uanel of the reservoir

Page 217 of 394

Downloaded from www.Manualslib.com manuals search engine Op. MA. 390.00 9

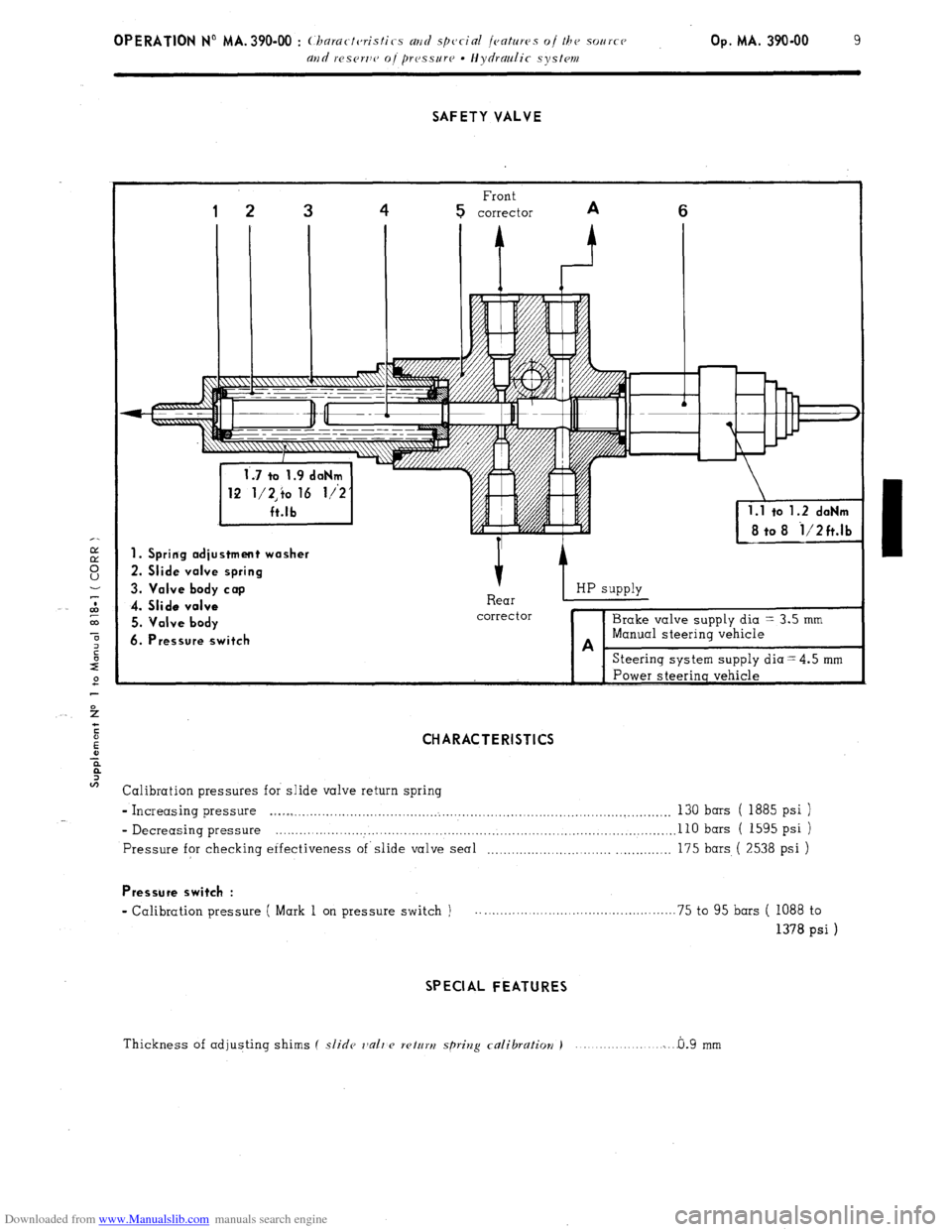

SAFETY VALVE

Front

1 2 3 4 5 corrector A 6

i 8 to 8 i/2ft.lb

1. Spring adjustment washer

2. Slide valve spring

3. Valve body cap

4. Slide valve

5. Valve body

6. Pressure switch 1 HP SWP~Y I-

corrector

Steering system supply diaz4.5 mm

CHARACTERISTICS

Calibration pressures for slide valve return spring

- Increasing pressure .l~lOs _._..........__...._,..__._....,..__..__.__.,...___........._...._...,__..._.._.,,.._.,...,.... 130 bars ( 1885 psi )

- Decreasing pressure . . . . . . . . . .._.. I ~...~~~....~.~.....~.~.~.~.~.~~~.~.~....~.~~~~.....~~~..~..~....~~.~~...~.~.. 110 bars ( 1595 psi )

Pressure for checking erfectiveness of’slide valve seal .,_._._.,__._._...,._._.,....__ _,..,..,_.___. 175 bars ( 2538 psi )

Pressure switch :

- Calibration pressure ( Mark 1 on pressure switch ) .._.............._.............._............. 75 to 95 bars ( 1088 to

1378 psi )

SPECIAL FEATURES

Thickness of adjusting shims ( slide rlalrzc wturtj spriv2g calibration i 0.9 mm ...._.__..._....,..._.i___

Page 229 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 390-O : Checkin

P the hydraulic componm~s on the ucbicle Op. MA. 390-O 3

f Mama sleeting wbi&s I

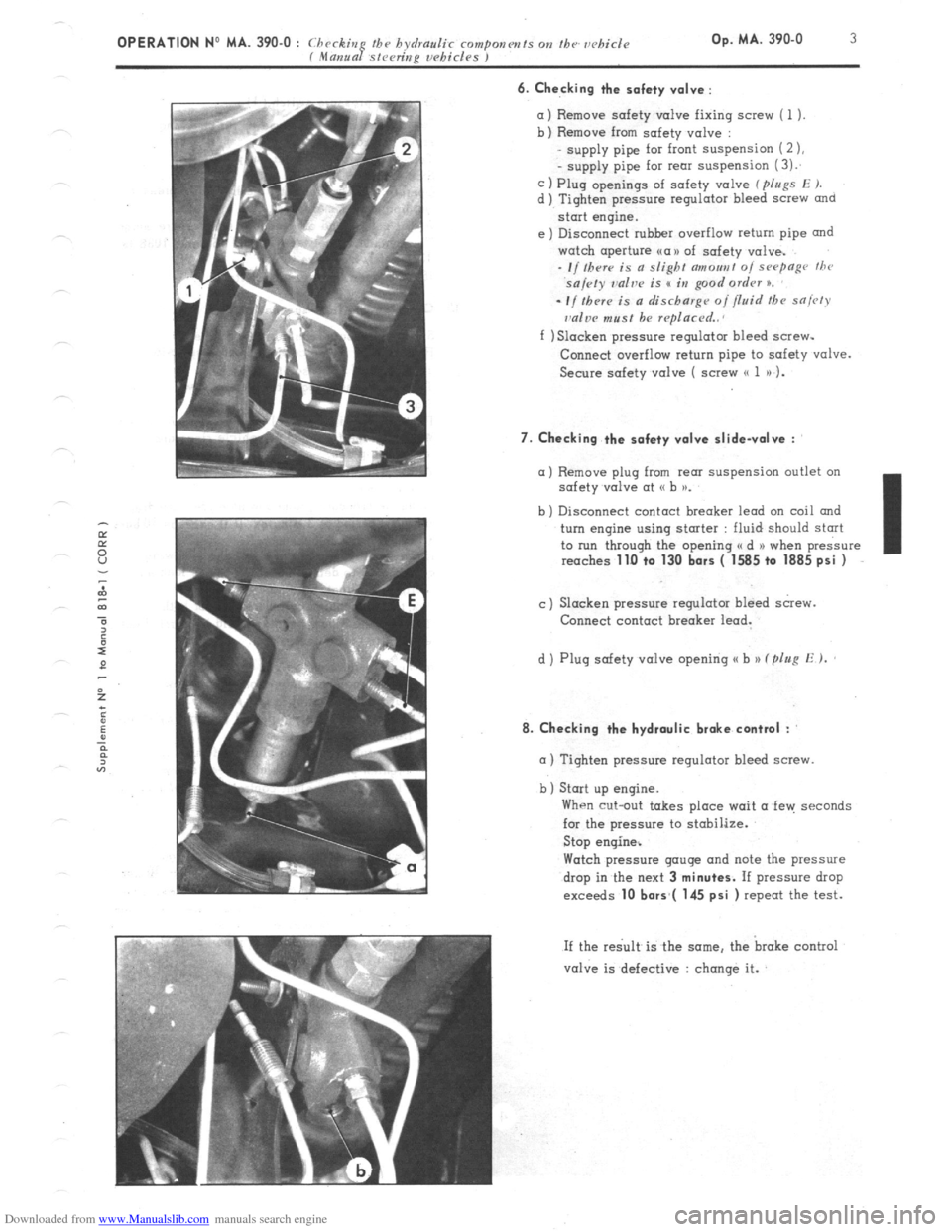

6. Checking the safety valve :

=I

bl

Cl

dl

Remove safety v&e fixing screw ( 1 ).

Remove from safety valve :

supply pipe for front suspension (2 ),

- supply pipe for rem suspension (3):

Plug openings of safety valve ( pIugs E J.

Tighten pressure regulator bleed screw

and

start engine.

Disconnect rubher overflow return pipe and

watch aperture ~a>> of safety valve.

- I/ Iherr is a slight c7moa,,t 0, sHymge thr

sa/cty ~dve is s in good ordrv n.

el

-If thrr~ is a discharge of fluid the sniw

dw must be rqlacrd..

f ) Slacken pressure regulator bleed screw-

Conned overflow return pipe to safety valve.

Secure safety valve ( screw (( 1 a) 1.

7. Checking the safety valve slidevolve :

a) Remove plug from rem suspension outlet on

safety v&e at G b >a.

b ) Disconnect contact breaker lead on coil and

turn engine using stmter : fluid should start

to run through the opening a d N when pressure

reaches

1lLl +o 130 bars ( 1585 to 1885 psi )

c) Slacken pressure regulator bleed screw.

Connect contact breaker lead.

d ) Plug safety valve opening u b )) (plug E ).

8. Checking the hydraulic brake contml :

m ) Tighten pressure regulator bleed screw.

b) Start up engine.

When cut-out takes place wait a fen: seconds

for the pressure to stobilize.

Stop engine%

Watch pressure gauge and note the pressure

drop in the next 3

minutes. If pressure drop

exceeds 10 bors*( 145 psi ) repeat the test.

If the re< is the same. the broke control

valve is defective : change it.

Page 230 of 394

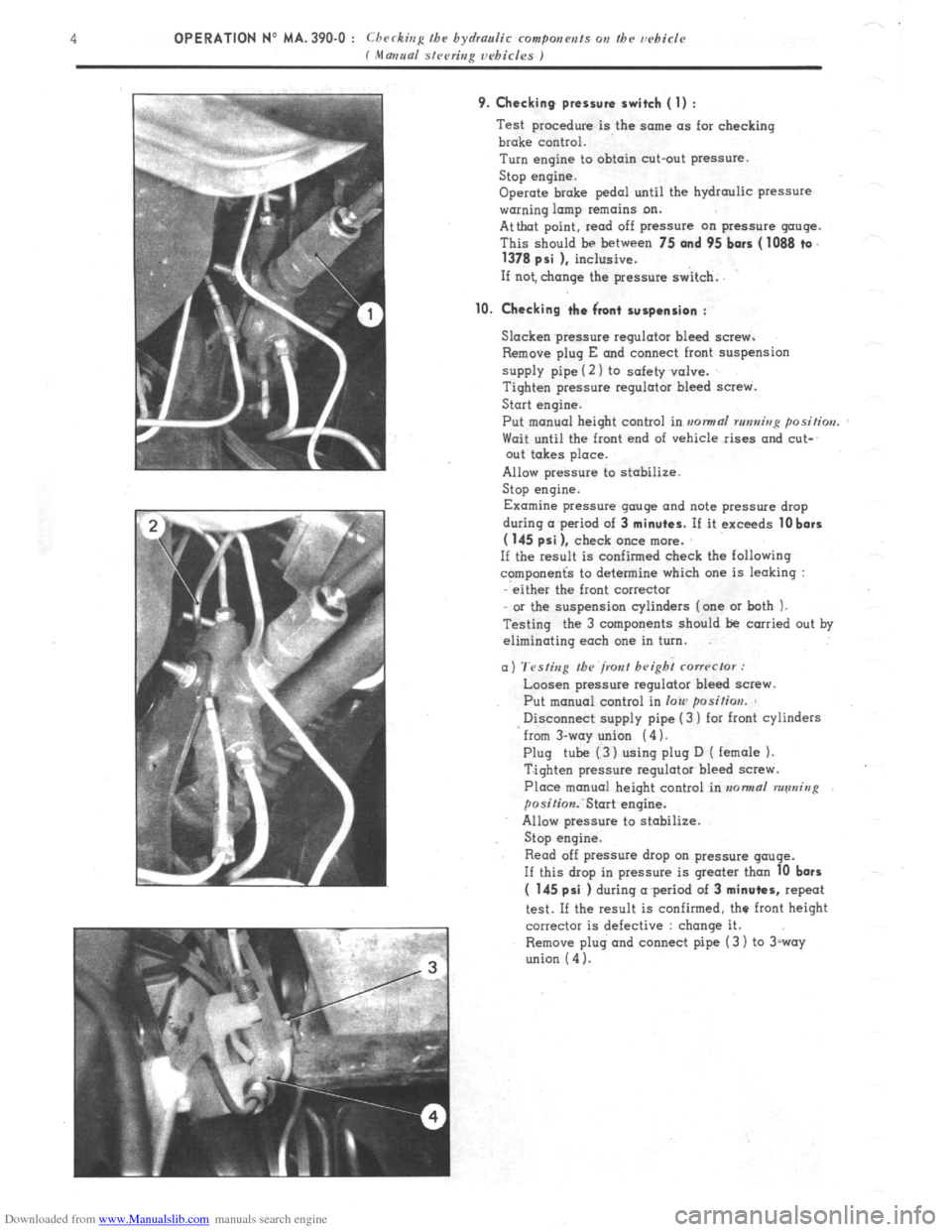

Downloaded from www.Manualslib.com manuals search engine 9. Checking pressure switch (1) : Test procedure is the sctme as for checking

broke control.

Turn engine to obtain cut-out pressure.

Stop engine.

Operate brake pedal until the hydraulic pressure

warning lamp remains on.

Attbat point, read off pressure on pressure gauge.

This should be between 75

and 95 bars ( 1088 ta.

1378 psi 1, inclusive.

If not, change the pressure switch.

10. Checking the Front suspension : Slacken.pressure regulator bleed screw.

Remove plug E and connect front suspension

supply pipe (2 ) to safety valve.

Tighten pressure regulator bleed screw.

Start engine.

Put manual height control in

rronnaf rtmni>rp positim. Wait until the front end of vehicle rises and cut-

out takes place.

Allow pressure to stabilize.

Stop engine.

Examine pressure gauge and note pressure drop

during wperiod of 3

minutes. If it exceeds 10 bars

( 145 psi 1, check once more.

If the result is confirmed check the following

c?mponenG to determine which one is leaking :

either the front corrector

or the suspension cylinders (one or both ).

Testing the 3 components should be carried out by

eliminating each one in turn.

(I) Testing the front height cmwclor : Loosen pressure regulator bleed saew.

Put manual control in

loin position. Disconnect supply pipe (3 ) for front cylinders

from 3-way union (4 ).

Plug tube (3 ) using plug D ( female 1.

Tighten pressure regulator bleed scwe.

Place manual height control in normal running

posiGon:Start engine.

Allow pressure to stabilize.

Stop engine.

Read off pressure drop on pressure qtruqe.

If this drop in pressure is greater than

10 bars (

145 psi ) during a period of 3 minutes, repeat

test. If the result is confirmed, the front height

corrector is defective : change it.

Remove plug and connect pipe (3 ) to 3roy

union

(4 ).

Page 236 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 410-O : ( /,c

1

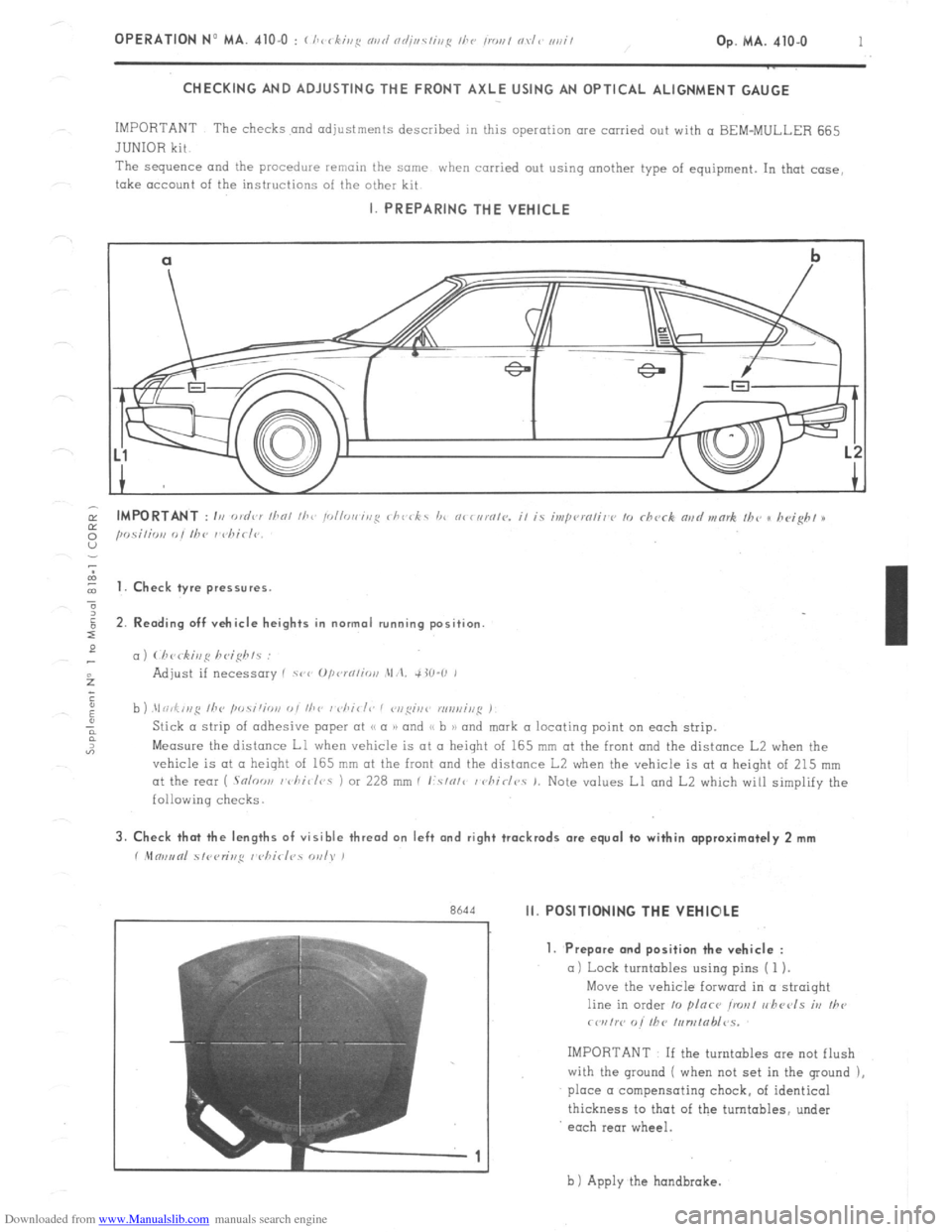

CHECKING AND ADJUSTING THE FRONT AXLE USING AN OPTICAL ALIGNMENT GAUGE

IMPORTANT The checks and adjustments described in this operation are carried out with a BEM-MULLER 665

JUNIOR kit

The sequence and

the procedure remain the same when carried out using another type of equipment. In that case,

take account of the instructions of the other kit I. PREPARING THE VEHICLE

cl

b

-.

I t 1. Check tyre pressures.

2. Rending off vehicle heights in normal running position

c,)

b ) .\I ri,f,,,g /he ,w.s;‘;o,,

Measure the distance Ll when vehicle is at II height of 165 mm at the front and the distance L2 when the

vehicle is at CL height of 165 mm at the front and the distance L2 when the vehicle is at a height of 215 mm

at the rear ( .Snloo,, I vhi~/r,s 1 or 228 mm I I:.s/o/c / chirlr,. 1. Note values Ll and L2 which will simplify the

following checks. 3. Check that the lengths of visible thread on left and right trackrods are equal to within approximately 2 mm

r .Mm,,tnl 51<,<,r;r,,q I <,hirl?s WI). )

r

Rh‘td Ii. POSITIONING THE VEHIOLE

7

-1 1. Prepare and position the vehicle :

a) Lock turntables using pins ( 1 ).

Move the vehicle forward in a straight

line in order 10 plnce ironl r,hccls iv

Ihe

rwrtw o/’ fhC /,,n,tab/~s.

IMPORTANT If the turntables ore not flush

with the ground ( when not set in the ground ),

place a compensating chock, of identical

thickness to that of the turntables, under

each rear wheel.

b 1 Apply the hondbrake.