turn Citroen CX 1985 1.G Repair Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1985, Model line: CX, Model: Citroen CX 1985 1.GPages: 394

Page 371 of 394

Downloaded from www.Manualslib.com manuals search engine II. PRECAUTIONS TO BE TAKEN WHEN WORKING ON THE AIR-CONDITIONING SYSTEM

a) It is imperative to wear goggles

b ) Do not smoke R 12 fluid,in the presence of a flame turns into a toxic gas.

c) Never heat any section of the refrigerating system.

d) Never switch on the refrigerating system if both electric cooling fans are not connected

e ) Never check the compressor oil level without first having drained the refrigerating circuit.

f ) Never use any oil other than TOTAL (( LUNARIA 25 H, SUNISO No 5 or TEXACO CAPELLA (( E 1) grade 500

g ) Never use refrigerating fluid other than R.12.

NOTE Refrigerating fluid may- be sold under different names : FORANE (( 12 )), FLUGENE (( 12 ))! FREON ((12 ))

( the most important feature is the number (( 12 H which defines the fluid’s properties ).

IMPORTANT NOTES

A. The compressor

MUST NEVER b e switched on when the circuit has been drained of its refrigerating fluid.

during work ‘being carried out in the workshop. for example,. Indeed, in these conditions,

the compressor

would be functioning in air, and would deteriorate rapidly.

‘Consequently, in case of an exchange of compressor necessitating draining the system of its refrigerating

fluid, in a workshop not equipped with the necessary equipment for refilling ( SOGEV equipment )

IT IS

IMPERATIVE,

before driving the vehicle to another workshop equipped with the special equipment. to carry

out the following

- To leave the blanking plugs on the compressor. in order to avoid ingress of air ( the new compressor contains

refrigerating fluid ).

- To blank the intake and outlet hoses and to fix them tempororily.

- Todisconnect the supply lead to the electro-magnetic compressor clutch

( lead with white sleeve ).

NOTE : We remind you that if the circuit has been in contact with the atmosphere, it is necessary to replace

the de-watering tank, and the compressor oil.

B. Slight oil seepage is permissible at the front bearing of the air-conditioning compressor.

Compressors showing such a seepage, and being replaced OS a result, will not be accepted under warranty.

Ill. TIGHTENING TORQUES FOR THE UNIONS IN THE CIRCUIT :

( Oil the union threads with TOTAL LUNARIA 25 before fitting )

On the compressor Intake union : 5/8” 3.45 to 4.3,daNm ( 25 to 31 ft.lb )

Outlet union l/2”’ 2.9 to 3.75 daNm ( 21 to 27 ft.lb )

On the condenser Input union l/2” 4.85 to 5.5 daNm ( 35 to 39 3/4 ft.lb )

Output union : 3/ 8” 2.7 to 3.3 daNm ( 19 l/2 to 23 3/4 ft.lb )

On-de-watering tank : Unions : 3/8” 2.1 to 2.5daNm ( 15 l/4 to 18 ft.lb )

On : Input union evaporator : 3/8” 2.1 to 2.5 daNm ( 15 l/4 to 18 ft.lb )

Output union 5/8” 3.45 to 4.3 daNm ( 25 to 31 ft.lb )

Page 372 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 640.0 : ( h<,ck;ux n,,d od;es/ieg /he nir-~o,,di/io,,iri,~ Z\.SI<:IN Op. MA. 640-O

3

IV. FILLING THE REFRIGERATING CIRCUIT

using SOGEV equipment and a

PRESTOGAZ refill of R. 12

A. VEHICLES FITTED WITH A << ASPERA-FRIGO ,) COMPRESSOR

NOTE Equipment used for this operation :

a) SO(.I.,’ rori/<~iio,l Manufacturer Ets S.0.G.E.V

Avenue de 1 Atlantique Z.I. 91401 ORSAY -Tel. 907-64-00

b) I’Kli$ IoL:\/ ,v/i// o/ I?. II

1 kg refill supplied by the Replacement Parts Department under

ref. No.ZC 9 857 108 U.

IMPORTANT Precautions to be taken during this operation :

a) It is IMPERATIVE to wear goqqles.

b) Never smoke during the operation

R. 12 fluid turns into a toxic gas in the presence of LI flame

c) Never heat any port of the refriqerotinq circuit.

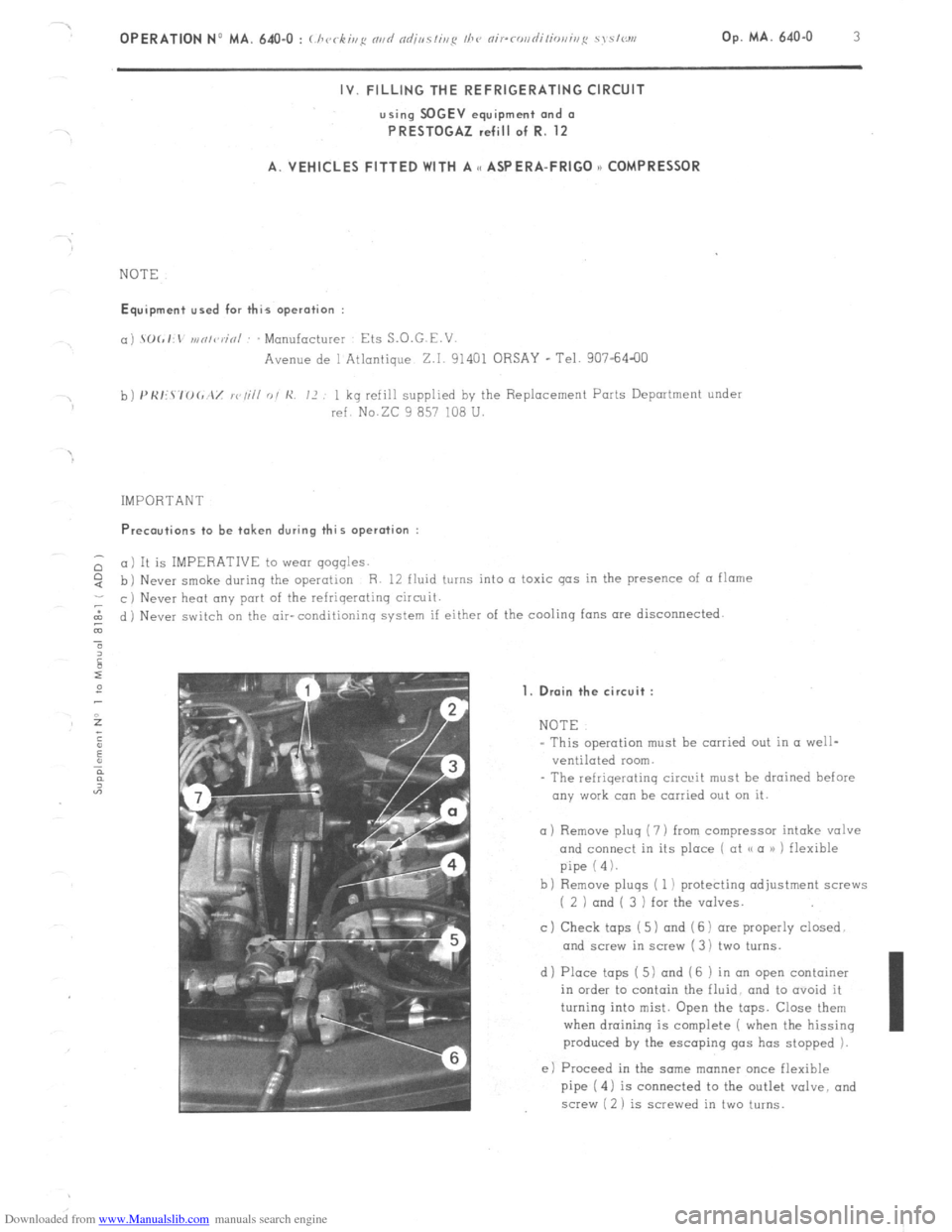

d) Never switch on the air-conditioninq system if either of the cooling fans are disconnected. 1. Drain the circuit :

NOTE

- This operation must be carried out in a well-

ventilated room.

- The refriqerating circcit must be drained before

any work can be carried out on it.

a) Remove pluq (7 ) from compressor intake valve

and connect in its place ( at (/ a /) ) flexible

pipe (4).

b) Remove pluqs ( 1 ) protecting adjustment screws

( 2 ) and ( 3 ) for the valves.

c ) Check tops ( 5) and (6 1 are properly closed

and screw in screw ( 3 1 two turns.

d) Place taps ( 5) and (6 ) in an open container

in order to contain the fluid, and to ovoid it

turning into mist. Open the taps. Close them

when draininq is complete ( when the hissing

produced by the escaping gas has stopped 1.

e) Proceed in the same tn(mner once flexible

pipe ( 4) is connected to the outlet valve, and

screw ( 2 ) is screwed in two turns.

Page 373 of 394

Downloaded from www.Manualslib.com manuals search engine 4 OPERATION No MA. 640.0 : ( ht.< k;nS our/ ndj,,~/ir,~ I/><, ni~.rr,r,r/i/ior,i,,F sm,<,,,,.

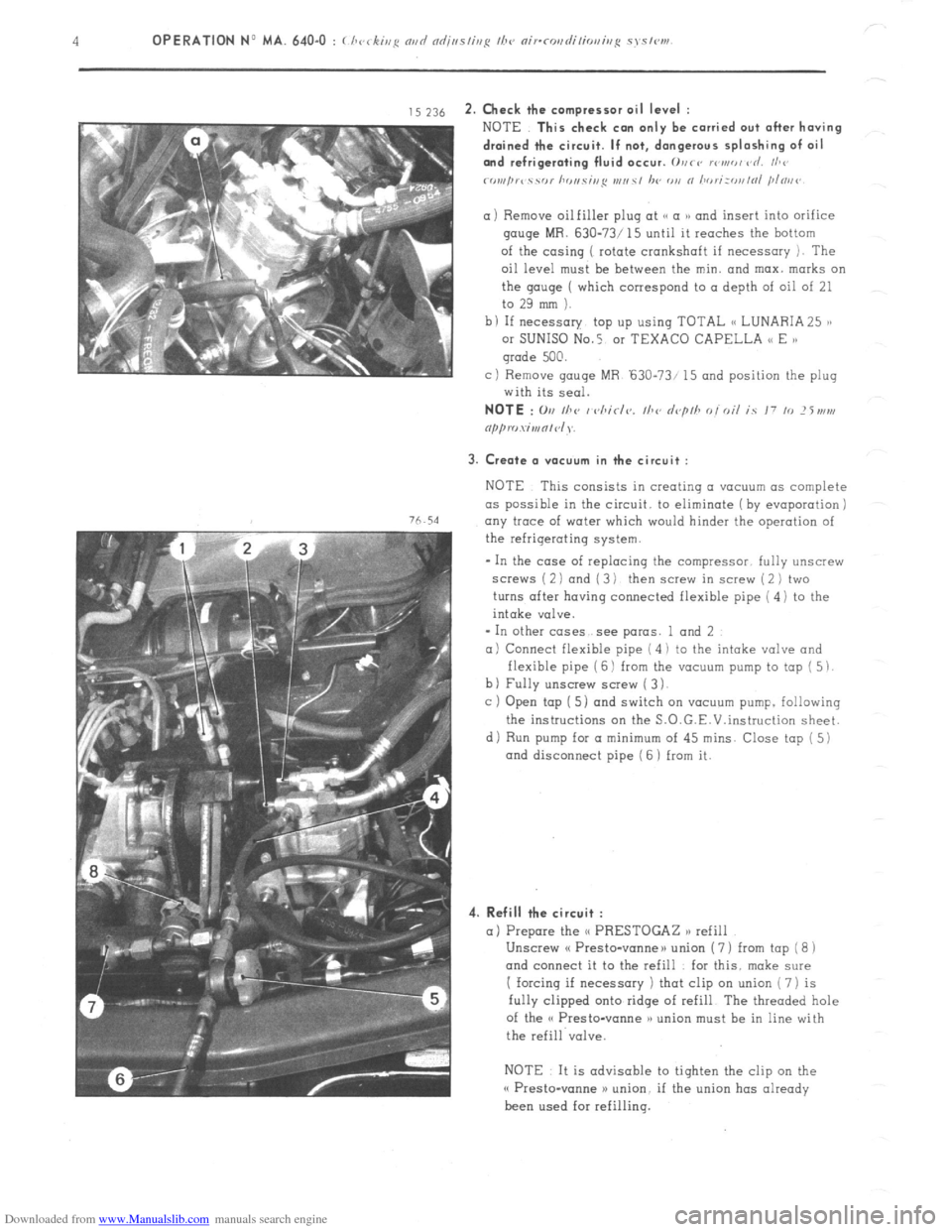

,s ~16 2. Check the ccmpress~r oil level :

76.54

NOTE This check con only be carried out after having

drained the circuit. If not, dangerous splashing of oil

and refrigerating fluid occur. 0vrs rowed vd. I/,<’

rornprc ‘i YC,l hr ,I,. Yi,,S I,,,, s, /w

gauge MR. 630-73/ 15 until it reaches the hottam

of the casing ( rotate crankshaft if necessary 1. The

oil level must be between the min. and max. marks on

the qauqe ( which correspond to a depth of oil of 21

to 29 mm ).

b I If necessary top up using TOTAL (< LUNARIA 25 ),

or SUNISO No.5 01 TEXACO CAPELLA << E )a

grade 500.

c) Remove gouge MR ‘630-73/ 15 and position the plug

with its seal.

3. Create a V(IEYU~ in the circuit :

NOTE This consists in creotinq a vacuum as complete

as possible in the circuit. to eliminate (by evaporation j

any trace of water which

would hinder the operation of

the refrigerating system.

- In the case of replacing the compressor. fully unscrew

screws ( 2 1 and ( 3 1 then screw in screw ( 2 ) two

turns after having connected flexible pipe ( 4) to the

intake valve.

* In other cases see paras. 1 and 2

a) Connect flexible pipe ( 4 i to the intake valve and

flexible pipe ( 6 1 from the vacuum pump to top ( 5 1.

b) Fully unscrew screw ( 3 1.

c ) Open tap [ 5) and switch on vacuum pump. following

the instructions on the S.O.G.E.V.instruction sheet.

di Run pump for a minimum

of 45 mins. Close tap ( 5)

and disconnect pipe ( 6 1 from it.

4. Refill the circuit :

a) Prepare the <( PRESTOGAZ n refill

Unscrew cf Presto-vanneu union ( 7 ) from tap ( 8 1

and connect it to the refill for this. make sure

I forcing if necessary ) that clip on union ( 7) is

fully clipped onto ridge of refill The threaded hole

of the o Presto-vanne )a union must be in line with

the refill valve.

NOTE It is advisable to tighten the clip on the

o Presto-wane >) union. if the union has already

been used for refilling.

Page 378 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 642-W : ~Thnracteristics o/ thy, e I:Ko/I) - -70 3 hc,nriug s, stew Op. MA. 642-00 3

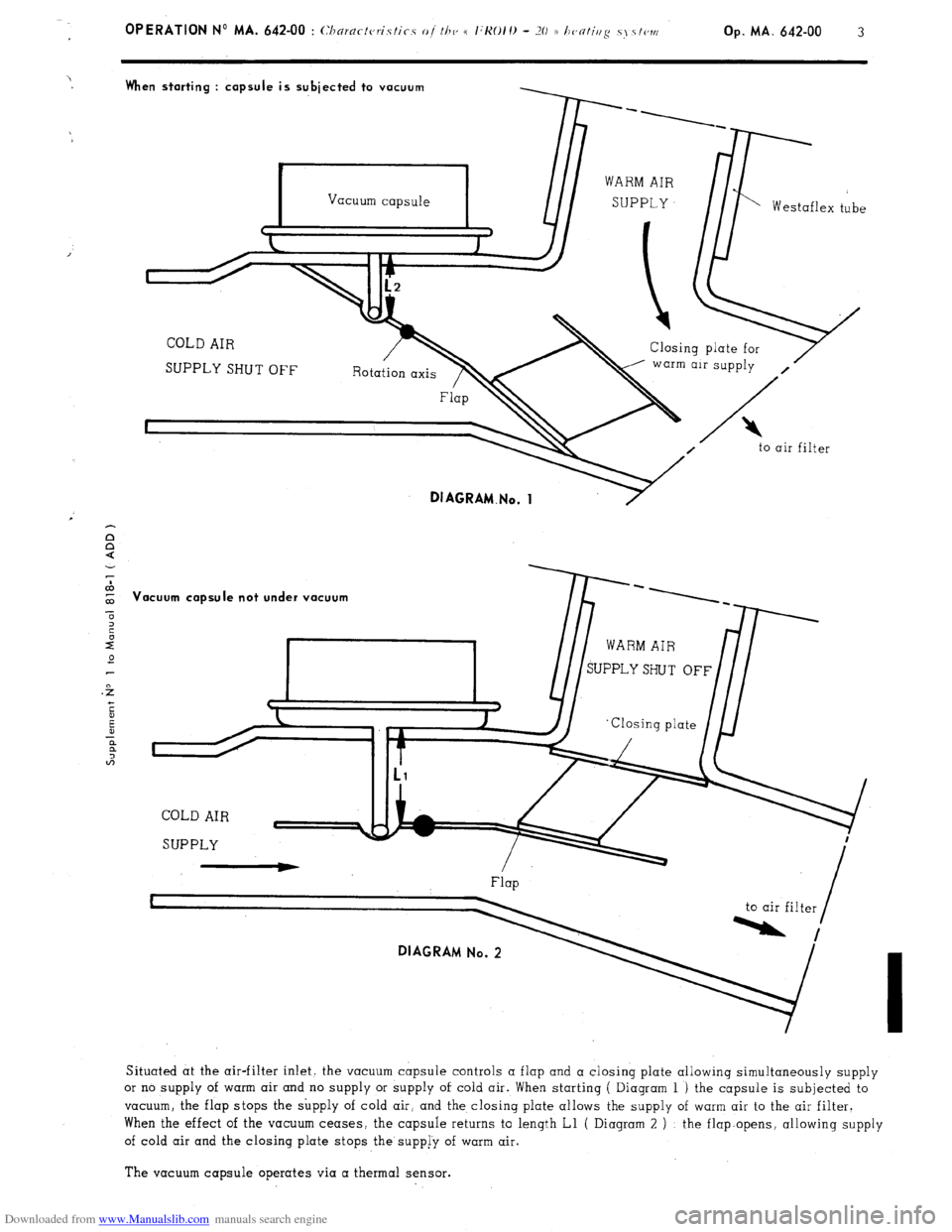

When starting : capsule is subjected to vacuum

Vacuum capsule

Westaflex tube

c J

J

COLD AIR

Closing plate for

SUPPLY SHUT OFF warm air supply

,

Flap B

I

to air filter

DIAGRAM.No. 1

‘acuum capsule not under vacuum

Flap

DIAGRAM No. 2

to air filter

Situated at the air-filter inlet. the vacuum capsule controls a flap and a closing plate allowing simultaneously supply

or no supply of warm air and no supply or supply of cold air. When starting ( Diagram 1 ) the capsule is subjected to

vacuum, the flap stops the supply of cold air, and the closing plate allows the supply of warm air to the air filter.

When the effect of the vacuum ceases, the capsule returns to length Ll ( Diagram 2 ) : the flap.opens, allowing supply

of cold air and the closing plate stops the supp[y of warm air.

The vacuum capsule operates via a thermal sensor.

Page 389 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 961-O : C/ 3fc ztzg and repairing a war winabzc’ hrating elcmcnt k’ Op. MA. 961-O 1

I. CHECKING

Power of heating resistance :

S&Ions ., 140 to 160 watts at 13.5 1: 0.2 volts

Estates .,.,............: . . . . . . . .._.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ~.. 130 to 150 watts at 13.5 t 0.2 volts

To check :he heating resistance of a rear window. measure

Either the current flowing in the resistance, using an ammeter connected in series to the supply lead of

the element. The current should be :

Saloons ,..., ., ,. ,. ,..,. ,,., ,,,., _, ,. .,., ..l_. 9.2 to 10.6 amps at 12 volts

Estates . . .., ,,..._.__.. .:_._ ._ . ..8 5 to 9.8 amps at 12 volts

Or the resistance using an ohmmeter. Resistance should be :

Saloons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . j _..__.._....,. 1.1 to 1.3Q

Estates . .._...........,.,.,...,.....,..,..................................,,..,.,.,.,........,. 1 .2 to 1.4 !J

II. REPAIRING

1. Replacement of terminals : Tin that part of the terminal to be soldered. Solder it in the required location ( soldering iron ).

2. Repairing a section of the heating element : a) Obtain from the Replacement Parts Department :

- 1 Repair kit .,,..,,..,,.,.,.,.,,,.,.,,....,................,,,,,...,., ZC. 9 855 128 U

This M SECURIGLACE ))‘outfit includes :

- 1 Bottle of abrasive cleaning powder

- 1 Small bottle of conductive enamel

- 1 Tube of adhesive

- 1 Tube of hardener for adhesive

- 1 Small bottle of metallic powder

- 1 Roll of thick self-adhesive tape

- 1 Warning lamp for detecting cuts

- 1 Roll of self-adhesive tape for detecting cuts ( thermopaper )

- 1 Plastic spatula

- 1 Small glass plate ( for preparation of mixtures )

b)

Locating the cut : With the resistance fed as normal :

- Locate the defective resistance wire by sticking the adhesive detection tape at the centre of the rear

window ( interior side ) and on all resistance wires so that the tape is perpendicular to the latter.

The unbroken wires will turn the thermo-paper blue when they increase in temperature.

- Slide the two pointed probes of the warning lamp support on the cut wire. When the lamp lights up,

the pointed probes are on both sides of the break in the wire.

By slightly moving the probes along the length of the wire, the exact extent of the cut can be determined.