CITROEN DISPATCH SPACETOURER DAG 2020 Handbook (in English)

Manufacturer: CITROEN, Model Year: 2020, Model line: DISPATCH SPACETOURER DAG, Model: CITROEN DISPATCH SPACETOURER DAG 2020Pages: 324, PDF Size: 10.89 MB

Page 201 of 324

199

If your vehicle's AdBlue® tank is

completely empty – which is confirmed

by the message "Top up AdBlue: Starting

impossible", you must top up with at least

5

litres.

Important: in the event of a top-up after

a breakdown because of a lack of

AdBlue, you must wait around 5

minutes

before switching on the ignition, without

opening the driver’s door, locking

the vehicle, introducing the key into

the ignition switch, or introducing

the key of the Keyless Entr y and

Star ting system into the passenger

compartment .

Switch on the ignition, then wait for

10

seconds before starting the engine.

Advice on care

General recommendations on the care and

maintenance of your vehicle are given in the

warranty and maintenance record. Observe the following recommendations to avoid damaging your vehicle:

-

D

o not clean your headlamps with a dry or abrasive cloth, nor with detergent or solvent

products. Use a sponge and soapy water or a pH neutral product.

-

W

hen using a high-pressure washer on stubborn dirt, avoid prolonged use on the

headlamps, the lamps and their edges to avoid damaging their lacquer finish and seals.

-

N

ever use an abrasive sponge to clean persistent dirt, as this may scratch the paint

sur face. Use a soft cloth with soapy water instead.

-

W

hen washing your vehicle, never clean the interior with a water jet.

-

W

hen washing your vehicle in an automatic roller-brush car wash, be sure to lock your

doors and, depending on version, remove the key and deactivate the " Hands-Free

Access " system.

-

N

ever use high-pressure washing to clean the engine compartment, in order to avoid

damaging the electrical units.

-

L

iquids carried in an open vessel (e.g. a cup or mug) could be spilt, presenting a risk of

damage on contact with the controls in the dashboard and centre console. Be careful.

Depending on version, in order to avoid damaging or unpeeling the stickers on the bodywork,

you are strongly advised against using high-pressure cleaners to wash your vehicle. It is

recommended that you wash it using a high-flow water jet and rinse the vehicle down using

demineralised water.

Only a microfibre cloth is recommended for wiping your vehicle ; it must be clean and used

g e nt l y.

It is always preferable to have paint repairs carried out by a CITROËN dealer or a qualified

workshop.

7

Practical information

Page 202 of 324

200

Warning triangle

This safety equipment should be used in

addition to the hazard warning lamps.

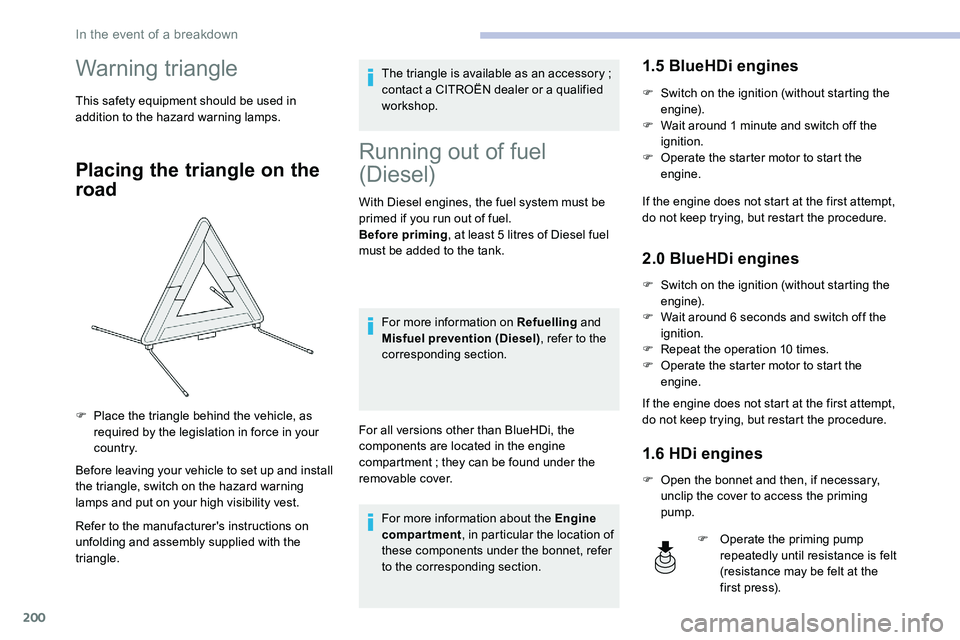

Placing the triangle on the

road

Before leaving your vehicle to set up and install

the triangle, switch on the hazard warning

lamps and put on your high visibility vest.

Refer to the manufacturer's instructions on

unfolding and assembly supplied with the

triangle.The triangle is available as an accessory

;

contact a CITROËN dealer or a qualified

workshop.

Running out of fuel

(Diesel)

With Diesel engines, the fuel system must be

primed if you run out of fuel.

Before priming , at least 5

litres of Diesel fuel

must be added to the tank.

For more information on Refuelling and

Misfuel prevention (Diesel) , refer to the

corresponding section.

For all versions other than BlueHDi, the

components are located in the engine

compartment

; they can be found under the

removable cover.

For more information about the Engine

compartment , in particular the location of

these components under the bonnet, refer

to the corresponding section.

1.5 BlueHDi engines

F Switch on the ignition (without starting the engine).

F

W

ait around 1 minute and switch off the

ignition.

F

O

perate the starter motor to start the

engine.

If the engine does not start at the first attempt,

do not keep trying, but restart the procedure.

2.0 BlueHDi engines

F Switch on the ignition (without starting the engine).

F

W

ait around 6 seconds and switch off the

ignition.

F

R

epeat the operation 10

times.

F

O

perate the starter motor to start the

engine.

If the engine does not start at the first attempt,

do not keep trying, but restart the procedure.

1.6 HDi engines

F Open the bonnet and then, if necessary, unclip the cover to access the priming

pump.

F

P

lace the triangle behind the vehicle, as

required by the legislation in force in your

c o u nt r y.

F

O

perate the priming pump

repeatedly until resistance is felt

(resistance may be felt at the

f i r st p r e s s).

In the event of a breakdown

Page 203 of 324

201

F Operate the starter motor to start the engine (if the engine does not start at the first

attempt, wait around 15 seconds before

trying again).

F

I

f the engine does not start after a few

attempts, operate the priming pump again,

then the starter motor.

F

P

ut the cover back in place and clip it in,

then close the bonnet.

2.0 HDi engines

F Open the bonnet and then, if necessary, unclip the cover to access the priming

pump.

F

L

oosen the degassing bolt. F

O

perate the priming pump until

fuel appears in the transparent

tube.

F

R

etighten the degassing bolt.

F

O

perate the starter motor until the engine

starts (if the engine does not start at the

first attempt, wait around 15

seconds before

trying again).

F

I

f the engine does not start after a few

attempts, operate the priming pump again,

then the starter motor.

F

P

ut the cover back in place and clip it in,

then close the bonnet.

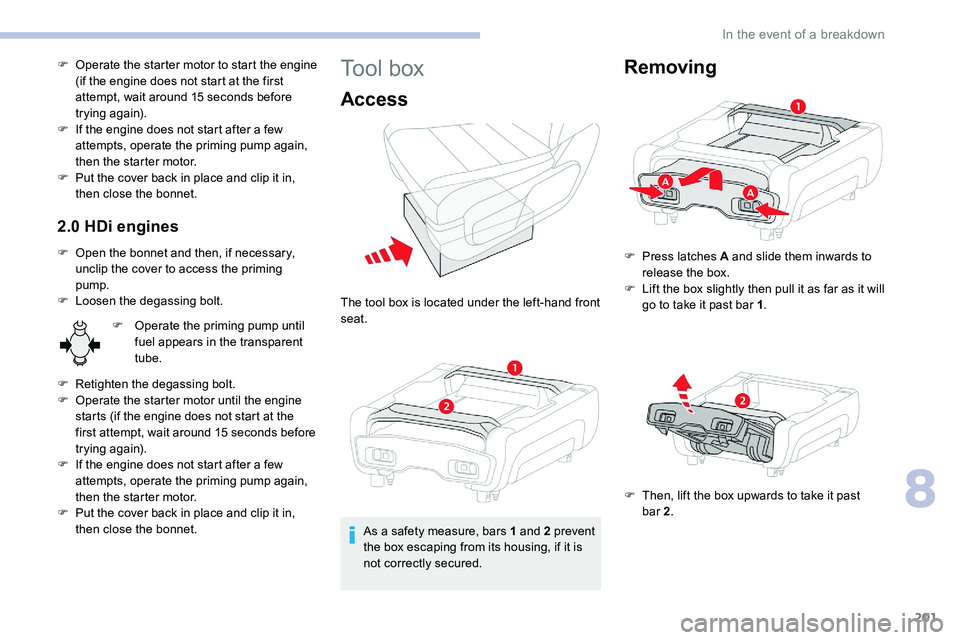

Tool box

Access

The tool box is located under the left-hand front

seat.

As a safety measure, bars 1 and 2 prevent

the box escaping from its housing, if it is

not correctly secured.

Removing

F Press latches A and slide them inwards to release the box.

F

L

ift the box slightly then pull it as far as it will

go to take it past bar 1 .

F

T

hen, lift the box upwards to take it past

bar

2.

8

In the event of a breakdown

Page 204 of 324

202

Opening

Storage

F Refit the cover on the box and clip fixings B.

F

P

osition the box with the front inclined

upwards.

F

T

o take it past bar 2 , push the box in and

down.

F

T

o take it past bar 1 , raise the box slightly

then push it fully in. F

O

nce the box is fully home

in its housing,

push it against the floor carpet then slide

latches A outwards to secure it.

Pull on the box to check that it is secure in

its housing.

Temporary puncture

repair kit

Scan the QR code on page 3 to view

explanatory videos.

Comprising a compressor and a sealant

cartridge, it allows the temporary repair of

a tyre so that you can drive to the nearest

garage. It is designed to repair most punctures

which could affect the tyre, located on the

tyre tread or shoulder.

Its compressor can be used to check and

adjust the pressure of the tyre.

Access to the kit

This kit is stowed in a tool box.

For more information on the Tool box ,

refer to the corresponding section.

List of tools

These tools are specific to the vehicle and may

vary according to the level of equipment. Do

not use them for any other purpose.

F

U

nclip fixings B on the cover, then open it

for access to the tools.

In the event of a breakdown

Page 205 of 324

203

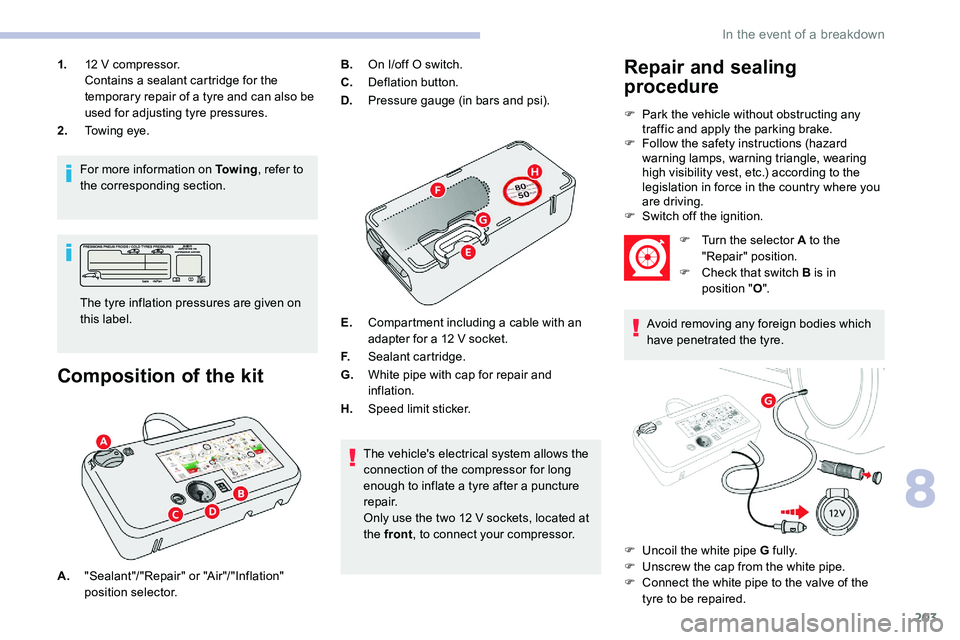

1.12 V compressor.

Contains a sealant cartridge for the

temporary repair of a tyre and can also be

used for adjusting tyre pressures.

2. Towing eye.

For more information on To w i n g , refer to

the corresponding section.

Composition of the kit

The tyre inflation pressures are given on

this label. B.

On I/off O switch.

C. Deflation button.

D. Pressure gauge (in bars and psi).

E. Compartment including a cable with an

adapter for a 12

V socket.

F. Sealant cartridge.

G. White pipe with cap for repair and

inflation.

H. Speed limit sticker.

The vehicle's electrical system allows the

connection of the compressor for long

enough to inflate a tyre after a puncture

repair.

Only use the two 12

V sockets, located at

the front , to connect your compressor.

Repair and sealing

procedure

F Park the vehicle without obstructing any

traffic and apply the parking brake.

F

F

ollow the safety instructions (hazard

warning lamps, warning triangle, wearing

high visibility vest, etc.) according to the

legislation in force in the country where you

are driving.

F

S

witch off the ignition.

A. "Sealant"/"Repair" or "Air"/"Inflation"

position selector. F

T

urn the selector A to the

"Repair" position.

F

C

heck that switch B is in

position " O".

Avoid removing any foreign bodies which

have penetrated the tyre.

F

U

ncoil the white pipe G fully.

F

U

nscrew the cap from the white pipe.

F

C

onnect the white pipe to the valve of the

tyre to be repaired.

8

In the event of a breakdown

Page 206 of 324

204

F Connect the compressor's electrical plug to the vehicle's 12 V socket.

F

A

ffix the speed limit sticker.

The speed limit sticker must be secured

to the interior of the vehicle in the driver's

field of vision, to remind you that a wheel

is in temporary use.

F

S

tart the vehicle and leave the engine

running.

Do not start the compressor before

connecting the white pipe to the tyre valve:

the sealant product would be expelled

through the pipe.

F

S

witch on the compressor by moving

switch B to position I until the tyre pressure

reaches 2.0 bars. The sealant product is

injected under pressure into the tyre

; do not

disconnect the pipe from the valve during

this operation (risk of blowback). If after approximately seven

minutes this

pressure is not reached, this indicates

that the tyre is not repairable

; contact a

CITROËN dealer or a qualified workshop

for assistance.

F

R

emove the kit and screw the cap back

on the white pipe. Take care to avoid

contaminating the vehicle with traces of

fluid. Keep the kit to hand.

Take care, the sealant product is harmful

if swallowed and causes irritation to the

eyes.

Keep this product out of the reach of

children.

The use-by date of the fluid is marked on

the bottle.

After use, do not discard the bottle in

standard waste, take it to a CITROËN

dealer or an authorised waste disposal

site.

Do not forget to obtain a new bottle of

sealant, available from a CITROËN dealer

or a qualified workshop.

Inflation, occasional

inflation and checking

pressure

F Drive immediately for approximately three miles (five kilometres), at reduced

speed (between 12 and 37

mph (20 and

60

km/h)), to plug the puncture.

F

S

top to check the repair and measure the

tyre pressure using the kit.

In the event of a breakdown

Page 207 of 324

205

F Turn selector A to the "Inflation" position.

F

U

ncoil the white pipe G fully.

F

C

onnect the white pipe to the

valve of the repaired wheel.

F

C

onnect the compressor's electrical plug to

the vehicle's 12

V socket again.

F

S

tart the vehicle and leave the engine

running.

As soon as possible, go to a CITROËN

dealer or a qualified workshop.

You must inform the technician that this kit

was used. After inspection, the technician

will tell you whether the tyre can be

repaired or if it must be replaced.

F

A

djust the pressure using the compressor

(to inflate: switch B in position " I"

; to

deflate: switch B

in position " O" and press

button

C ), in accordance with the vehicle's

tyre pressure label, located on the driver’s

door aperture.

A significant loss of pressure indicates that

the puncture has not been fully plugged

;

contact a CITROËN dealer or a qualified

workshop for assistance.

F

R

emove the kit and stow it. F

D rive at reduced speed (50 mph

(80

km/h) max.) limiting the distance

travelled to approximately 125

miles

(2 0 0

k m).

It is also possible to use the compressor,

without injecting sealant, to check and, if

necessary, adjust the tyre pressures.

If after 7

minutes this pressure is not

reached, this indicates that the tyre is not

repairable

; contact a CITROËN dealer or

a qualified workshop for assistance.

Do not drive more than 125

miles (200 km)

with a repaired tyre

; contact a CITROËN

dealer or a qualified workshop to change

the tyre.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Tyre under-

inflation detection , refer to the

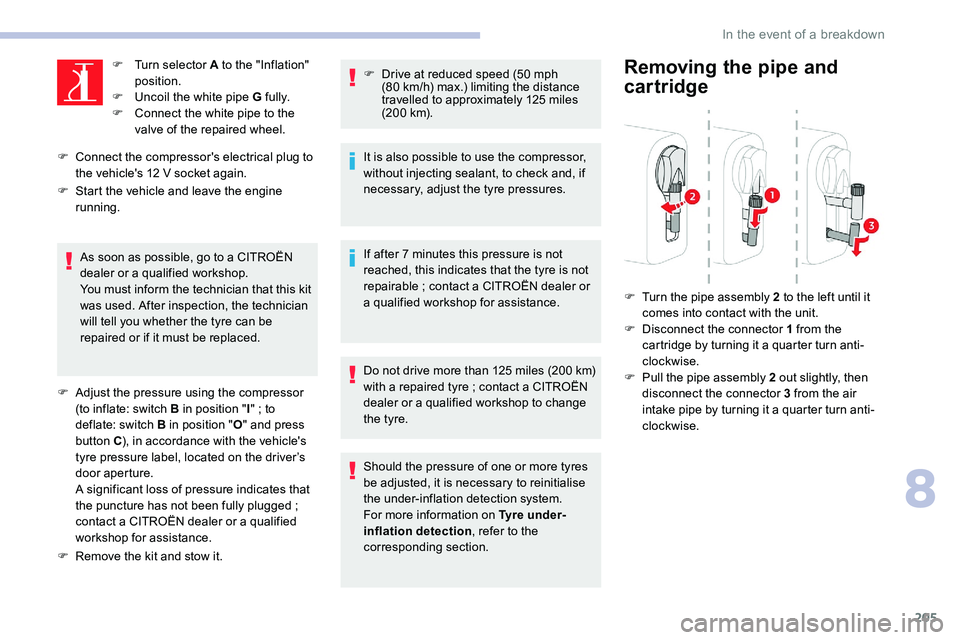

corresponding section.Removing the pipe and

cartridge

F Turn the pipe assembly 2 to the left until it comes into contact with the unit.

F

D

isconnect the connector 1 from the

cartridge by turning it a quarter turn anti-

clockwise.

F

P

ull the pipe assembly 2 out slightly, then

disconnect the connector 3 from the air

intake pipe by turning it a quarter turn anti-

clockwise.

8

In the event of a breakdown

Page 208 of 324

206

Be careful of fluid discharge.

The expiry date of the fluid is indicated on

the cartridge.

The sealant cartridge is designed for

single use ; it must be replaced even if

only partly used.

After use, do not discard the cartridge into

the environment, take it to an authorised

waste disposal site or a CITROËN dealer.

Do not forget to obtain a new sealant

cartridge, available from CITROËN

dealers or from a qualified workshop.

Spare wheel

Scan the QR code on page 3 to view

explanatory videos.

Procedure for changing a damaged wheel with

the spare wheel using the tools provided with

the vehicle.

Access to the tools

The tools are stowed in a tool box. For more information on the Tool box ,

refer to the corresponding section.

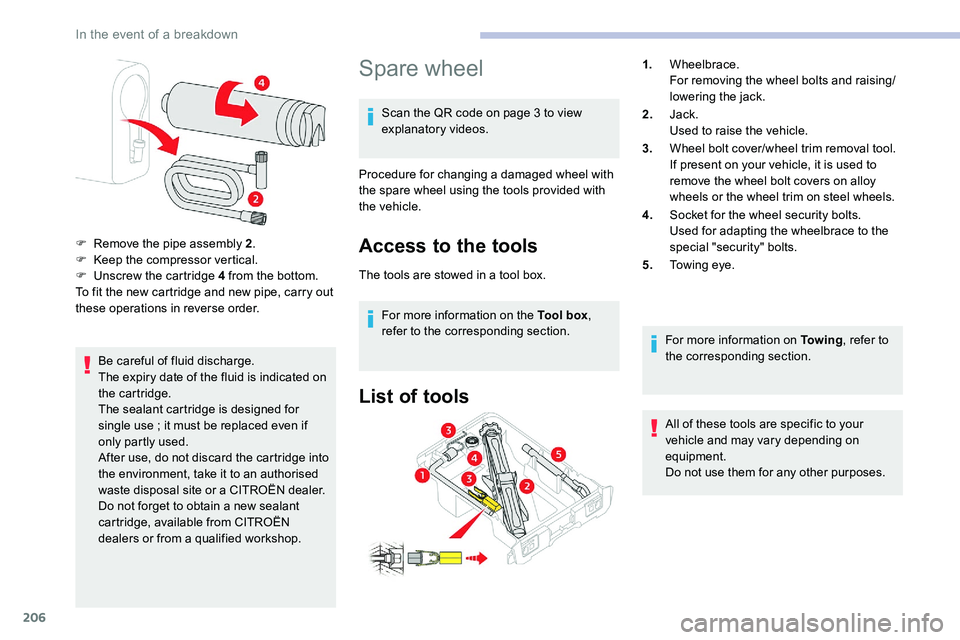

List of tools

For more information on To w i n g , refer to

the corresponding section.

All of these tools are specific to your

vehicle and may vary depending on

equipment.

Do not use them for any other purposes.

F

R

emove the pipe assembly 2

.

F

K

eep the compressor vertical.

F

U

nscrew the cartridge 4 from the bottom.

To fit the new cartridge and new pipe, carry out

these operations in reverse order. 1.

Wheelbrace.

For removing the wheel bolts and raising/

lowering the jack.

2. Jack.

Used to raise the vehicle.

3. Wheel bolt cover/wheel trim removal tool.

If present on your vehicle, it is used to

remove the wheel bolt covers on alloy

wheels or the wheel trim on steel wheels.

4. Socket for the wheel security bolts.

Used for adapting the wheelbrace to the

special "security" bolts.

5. Towing eye.

In the event of a breakdown

Page 209 of 324

207

The jack must only be used to change

a wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with this vehicle.

If the vehicle does not have its original

jack, contact a CITROËN dealer or a

qualified workshop to obtain the correct

jack for it.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/CE.

The jack does not require any

maintenance.

Access to the spare wheel

F Access to the spare wheel is from the rear.

F D epending on version, open the side-

hinged doors or the tailgate.

To avoid any unwanted opening of the

electric side door(s), deactivate the

Hands-Free Access function in the vehicle

configuration menu.

For more information on the Hands-

Free Sliding Side Door , refer to the

corresponding section. F

I

f the vehicle is fitted with a towing device,

raise the rear of the vehicle using the

jack (must be at jacking point B ) to allow

sufficient space to remove the spare wheel.

Remove the spare wheel from the

carrier

F Access the carrier bolt, located on the rear door sill.

F

S

lacken the bolt using the wheelbrace

(about 14 turns) until the carrier is low

enough to allow the carrier hook to be

disengaged. F

R

elease the carrier from the hook, take the

spare wheel and place it next to the wheel

to be changed.

Refit the spare wheel in the

carrier

F Position the wheel facing the carrier.

F P rogressively return the wheel to the carrier

by pushing alternately at the left and right

until it is clear of the hook fixing area.

8

In the event of a breakdown

Page 210 of 324

208

Tyre in the carrier

If you want to change the size of the tyre on the

spare wheel, follow the instructions below.A punctured tyre of size 215 or 225 can be

placed in the carrier.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not

block traffic: the ground must be level,

stable and non-slippery.

With a manual gearbox, engage first gear

then switch off the ignition to block the

wheels.

With an automatic gearbox, place the gear

selector in position

P then switch off the

ignition to block the wheels.

With an electronic gearbox, place the gear

selector in position

A then switch off the

ignition to block the wheels.

Apply the parking brake and check that

the warning lamp is on in the instrument

panel.

The occupants must get out of the vehicle

and wait where they are safe.

Never go underneath a vehicle raised

using a jack

; use an axle stand.

F

E

ngage the carrier on the hook, then tighten

the bolt using the wheelbrace until the bolt

is fully tightened.

Original tyre size XS - M XL

215/65 R16 Placing a

225 wheel in the carrier is prohibited.

There is no restriction.

215/60 R17

215/60 R17 M&S

2 2 5 / 5 5 R17

Placing a

215 wheel

in the

carrier is not

recommended (risk of noise).

F With a steel wheel, remove the bolt cover using tool 3 or the trim by hand.

F

W

ith an alloy wheel, remove the cap from

each of the bolts using tool

3.

F

I

f the vehicle is so equipped, fit security

bolt socket

4 to wheelbrace 1 to slacken the

security bolt.

F

S

lacken (without removing) the other wheel

bolts using just wheelbrace

1.

F

P

lace the foot of the jack on the ground

and ensure that it is directly below jacking

point

A or B provided on the underbody,

whichever is closest to the wheel to be

changed.

In the event of a breakdown