ECU CITROEN DS3 CABRIO 2018 Handbook (in English)

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2018, Model line: DS3 CABRIO, Model: CITROEN DS3 CABRIO 2018Pages: 248, PDF Size: 8.79 MB

Page 125 of 248

123

You can change mode at any time by

moving the gear selector from A to M or

vice-versa.

Never select neutral N when the vehicle

is moving.

Temporary control of gear changing

You can temporarily take over control of gear

changes using the steering mounted + and -

control paddles: if the engine speed allows, the

gear change is carried out.

This function allows you to anticipate certain

situations, such as overtaking another vehicle

or approaching a bend in the road.

Following a

few moments with no action on

the control paddles, the gearbox returns to

automatic operation.

Manual mode

F Select position M .

Reverse

To engage reverse gear, the vehicle must be

stationary with your foot on the brake pedal.

F

Sel

ect position R .

Stopping the vehicle

Before switching off the engine, you can:

-

c hange to position N to be in neutral, or

-

l

eave the vehicle in gear; in this case the

vehicle cannot be moved.

For all parking situations, you must apply

the parking brake to immobilise the

vehicle.

The gears engaged appear in turn in

the instrument panel. The gear change requests are only executed if

the engine speed permits.

It is not necessary to release the accelerator

when changing gear.

When braking or slowing down, the gearbox

changes down automatically to allow the

vehicle to accelerate in the correct gear.

Under full acceleration, the change up will

not take place unless the driver operates the

gear selector or the steering mounted paddles

(except if the engine is close to its maximum

speed).

You can change mode at any time by

moving the gear selector from A to M or

vice-versa.

Never select neutral N when the vehicle

is moving. There is an audible signal upon

engagement of reverse.

At low speed, if reverse gear is requested, the

N warning lamp flashes and the gearbox goes

into neutral automatically.

To engage reverse, put the gear selector into

position N , then to position R .

When immobilising the vehicle with the

engine running, you must put the gear

selector into neutral (position N ).

06

Driving

Page 140 of 248

138

Exceeding programmed

speed

F Press firmly on the accelerator pedal,

going beyond the point of resistance, to

exceed the programmed speed limit.

The speed limiter is deactivated temporarily

and the programmed speed, which is still

displayed, flashes.

Return to the programmed speed, by means of

intentional or unintentional deceleration of the

vehicle, automatically cancels the flashing of

the speed.

Exiting speed limiter mode

F Turn thumb wheel 1 to the 0 position: the

speed limiter mode is deselected. The

display returns to the total mileage recorder.

Malfunction

In the event of a speed limiter fault, the speed

i s cleared resulting in flashing of the dashes. On sharp acceleration, as when

descending a

steep hill, the speed limiter

will not be able to prevent the vehicle from

exceeding the programmed speed.

To avoid any risk of jamming of the pedals:

-

e

nsure that mats are secured correctly,

-

n

ever place one mat on top of another.

Have it checked in the dealer network or by

a

qualified workshop.

Cruise control

System which automatically

maintains the speed of the vehicle

at the value programmed by the

driver, without any action on the

accelerator pedal.

Cruise control is switched off

manually or

by pressing the brake or clutch pedal or on

triggering of the trajectory control systems for

safety reasons.

It is possible to exceed the programmed speed

temporarily by depressing the accelerator

pedal.

To return to the programmed speed, simply

release the accelerator pedal.

Switching off the ignition cancels any

programmed speed setting.

Cruise control cannot, in any circumstances, replace

the need to respect speed limits, nor can it replace

the need for vigilance on the part of the driver.

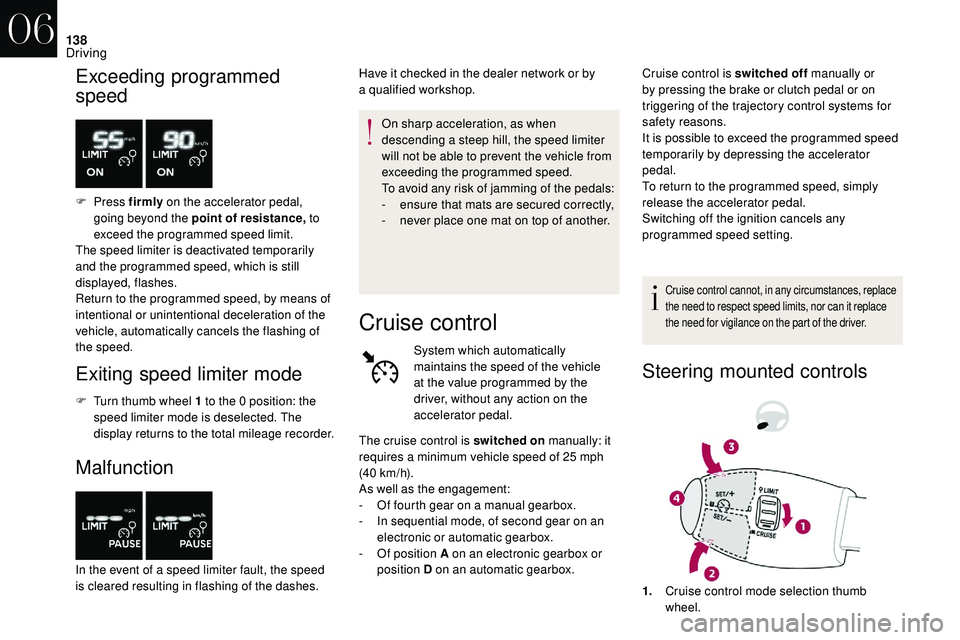

Steering mounted controls

The cruise control is switched on manually: it

requires a minimum vehicle speed of 25 mph

(40

km/h).

As well as the engagement:

-

O

f fourth gear on a manual gearbox.

-

I

n sequential mode, of second gear on an

electronic or automatic gearbox.

-

O

f position A on an electronic gearbox or

position D on an automatic gearbox.

1.Cruise control mode selection thumb

wheel.

06

Driving

Page 142 of 248

140

Malfunction

In the event of a cruise control fault, the speed

i s cleared resulting in flashing of the dashes.

Have it checked by an authorised dealer or by

a

qualified workshop. When cruise control is active, be careful

when holding one of the speed setting

buttons: this may result in a

very rapid

change in the speed of your vehicle.

Do not use the cruise control on slippery

roads or in heavy traffic.

When descending a

steep hill, the cruise

control system cannot prevent the vehicle

from exceeding the programmed speed.

To avoid any risk of jamming the pedals:

-

E

nsure that mats are secured correctly.

-

D

o not fit one mat on top of another.

Active City Brake

Active City Brake is a driving assistance

s ystem that aims to avoid a frontal collision

or reduce the speed of an impact if the driver

does not react sufficiently (inadequate brake

application).

This system has been designed to

improve driving safety.

The driver must always check the traffic

and assess the distances and relative

speeds of other vehicles.

Active City Brake cannot in any

circumstances replace the need for

vigilance on the part of the driver.

Never look at the laser sensor through

an optical instrument (magnifying glass,

microscope, etc.) at a

distance of less

than 10

centimetres: risk of eye injury!

Principle

Using a laser sensor located at the top of the

w indscreen, this system detects a vehicle

running in the same direction or stationary

ahead of your vehicle.

When necessary, the vehicle's braking system

is operated automatically to avoid a

collision

with the vehicle ahead.

Automatic braking occurs later than if

done by the driver, so as to inter vene only

when there is a

high risk of collision.

Conditions of activation

Active City Brake functions if the following

conditions are met:

-

ig

nition on,

-

t

he vehicle is moving for ward,

-

t

he speed is between about 3 and 19 mph

(5

and 30 km/h),

06

Driving

Page 168 of 248

166

Access to the kit

This kit is installed in the under floor storage,

under the boot floor.

Composition of the kit

1.12 V compressor, with built-in pressure

gauge.

2. Bottle of sealant, with built-in hose.

3. Speed limit sticker.

Repair procedure

F Park the vehicle without obstructing any

traffic and apply the parking brake.

F

F

ollow the safety instructions (hazard

warning lamps, warning triangle, wearing

high visibility vest, etc.) according to the

legislation in force in the country where you

are driving.

F

S

witch off the ignition.

F

U

ncoil the pipe stowed under the

compressor.

Avoid removing any foreign bodies which

have penetrated the tyre. F

R

emove the valve cap from the tyre to be

repaired and keep it in a

clean place.

F

C

onnect the pipe from the compressor to

the bottle of sealant. F

T

urn over the sealant bottle and secure it in

the cut-out provided on the compressor.

F

C

onnect the hose from the bottle of sealant

to the valve of the tyre to be repaired and

tighten firmly.

08

In the event of a breakdown

Page 169 of 248

167

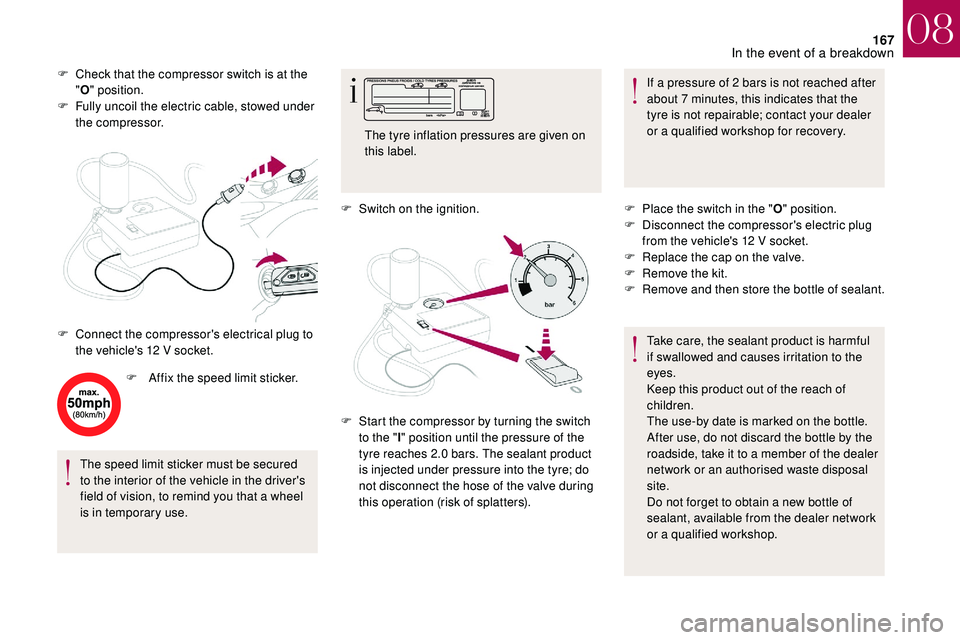

F Check that the compressor switch is at the "O " position.

F

F

ully uncoil the electric cable, stowed under

the compressor.

F

A

ffix the speed limit sticker.

The speed limit sticker must be secured

to the interior of the vehicle in the driver's

field of vision, to remind you that a

wheel

is in temporary use. F

S

witch on the ignition.If a

pressure of 2 bars is not reached after

about 7

minutes, this indicates that the

tyre is not repairable; contact your dealer

or a

qualified workshop for recovery.

F

C

onnect the compressor's electrical plug to

the vehicle's 12

V socket. The tyre inflation pressures are given on

this label.

F

S

tart the compressor by turning the switch

to the " l" position until the pressure of the

tyre reaches 2.0

bars. The sealant product

is injected under pressure into the tyre; do

not disconnect the hose of the valve during

this operation (risk of splatters). F

P

lace the switch in the "O" position.

F

D

isconnect the compressor's electric plug

from the vehicle's 12

V socket.

F

R

eplace the cap on the valve.

F

R

emove the kit.

F

R

emove and then store the bottle of sealant.

Take care, the sealant product is harmful

if swallowed and causes irritation to the

eyes.

Keep this product out of the reach of

children.

The use-by date is marked on the bottle.

After use, do not discard the bottle by the

roadside, take it to a

member of the dealer

network or an authorised waste disposal

site.

Do not forget to obtain a

new bottle of

sealant, available from the dealer network

or a

qualified workshop.

08

In the event of a breakdown

Page 171 of 248

169

If a pressure of 2 bars is not reached after

7 minutes, this indicates that the tyre is

not repairable; contact your dealer or

a

qualified workshop for recovery.

F

O

nce the correct pressure is reached, put

the switch to the " O" position.

F

R

emove the kit then stow it.

Do not drive more than 120

miles (200 km)

with a

temporarily repaired tyre; see your

dealer or a

qualified workshop to change

the tyre.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Under-inflation

detection , refer to the corresponding

section.

Spare wheel

Scan the QR code on page 3 to view

e xplanatory videos.

Procedure for changing a

damaged wheel with

the spare wheel using the tools provided with

the vehicle.

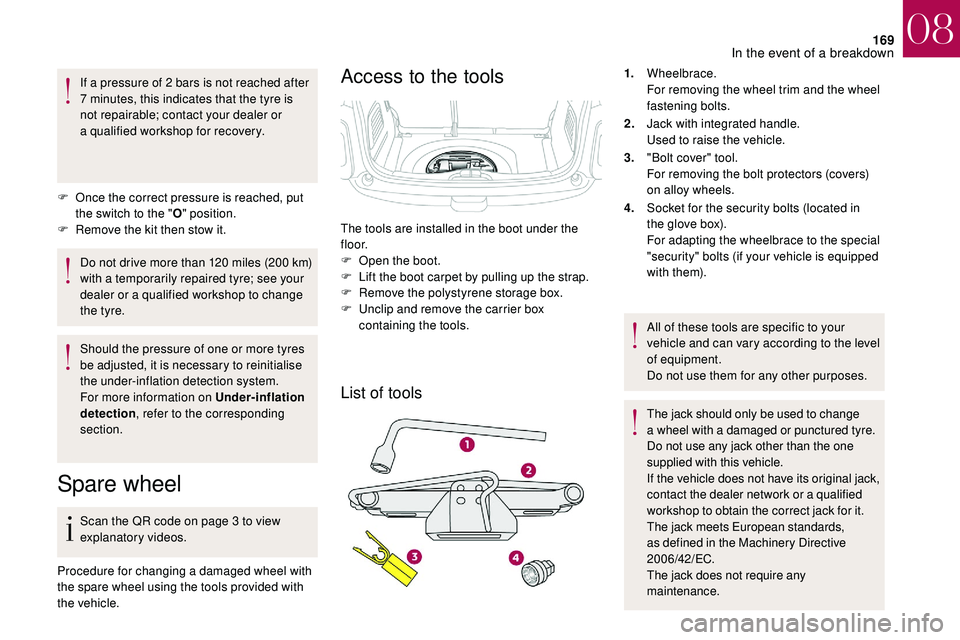

Access to the tools

List of tools

1. Wheelbrace.

For removing the wheel trim and the wheel

fastening bolts.

2. Jack with integrated handle.

Used to raise the vehicle.

3. "Bolt cover" tool.

For removing the bolt protectors (covers)

on alloy wheels.

4. Socket for the security bolts (located in

the glove box).

For adapting the wheelbrace to the special

"security" bolts (if your vehicle is equipped

with them).

All of these tools are specific to your

vehicle and can vary according to the level

of equipment.

Do not use them for any other purposes.

The jack should only be used to change

a

wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with this vehicle.

If the vehicle does not have its original jack,

contact the dealer network or a

qualified

workshop to obtain the correct jack for it.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/EC.

The jack does not require any

maintenance.

The tools are installed in the boot under the

f l o o r.

F

O

pen the boot.

F

L

ift the boot carpet by pulling up the strap.

F

R

emove the polystyrene storage box.

F

U

nclip and remove the carrier box

containing the tools.

08

In the event of a breakdown

Page 173 of 248

171

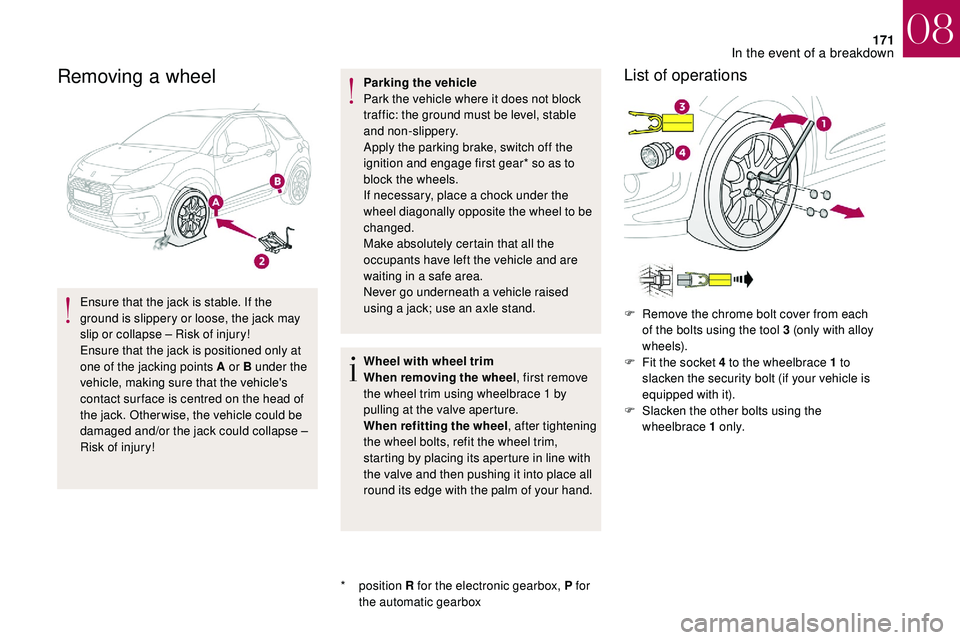

Removing a wheel

Ensure that the jack is stable. If the

ground is slippery or loose, the jack may

slip or collapse – Risk of injury!

Ensure that the jack is positioned only at

one of the jacking points A or B under the

vehicle, making sure that the vehicle's

contact sur face is centred on the head of

the jack. Otherwise, the vehicle could be

damaged and/or the jack could collapse –

Risk of injury!

*

position R for the electronic gearbox, P for

the automatic gearbox Parking the vehicle

Park the vehicle where it does not block

traffic: the ground must be level, stable

and non-slippery.

Apply the parking brake, switch off the

ignition and engage first gear* so as to

block the wheels.

If necessary, place a

chock under the

wheel diagonally opposite the wheel to be

changed.

Make absolutely certain that all the

occupants have left the vehicle and are

waiting in a safe area.

Never go underneath a vehicle raised

using a jack; use an axle stand.

Wheel with wheel trim

When removing the wheel , first remove

the wheel trim using wheelbrace 1

by

pulling at the valve aperture.

When refitting the wheel , after tightening

the wheel bolts, refit the wheel trim,

starting by placing its aperture in line with

the valve and then pushing it into place all

round its edge with the palm of your hand.

List of operations

F Remove the chrome bolt cover from each of the bolts using the tool 3 (only with alloy

w h e e l s).

F

F

it the socket 4 to the wheelbrace 1 to

slacken the security bolt (if your vehicle is

equipped with it).

F

S

lacken the other bolts using the

wheelbrace 1

o n l y.

08

In the event of a breakdown

Page 175 of 248

173

Fitting the "space-saver " spare wheel

If your vehicle is fitted with alloy wheels,

when tightening the bolts on fitting, it is

normal to notice that the washers do not

come into contact with the "space-saver"

spare wheel. The wheel is secured by the

conical contact of each bolt.

After changing a

wheel

Do not exceed 50

mph (80 km/h) when

driving with the "space-saver" type spare

wheel fitted.

Visit the dealer network or a

qualified

workshop as soon as possible to have the

tightness of the bolts and the pressure of

the spare wheel checked.

Have the punctured wheel checked. After

inspection, the technician will let you know

if the tyre can be repaired or if it must be

replaced.List of operations

F Put the wheel in place on the hub.

F S crew in the bolts by hand to the stop.

F

P

re-tighten the security bolt (if your vehicle

is so equipped) using the wheelbrace

1

fitted with the security socket 4 .

F

P

re-tighten the other bolts using the

wheelbrace 1

o n l y.

F

N

ow lower the vehicle fully.

F

F

old the jack 2 and detach it. F

T

ighten fully the security bolt (if your vehicle

is so equipped) using the wheelbrace

1 fitted with the security socket 4

.

F T ighten the other bolts using the

wheelbrace 1 o n l y.

F

P

ut the chrome bolt covers back on each of

the bolts (only with alloy wheels).

F

S

tore the tools in the box.

08

In the event of a breakdown

Page 183 of 248

181

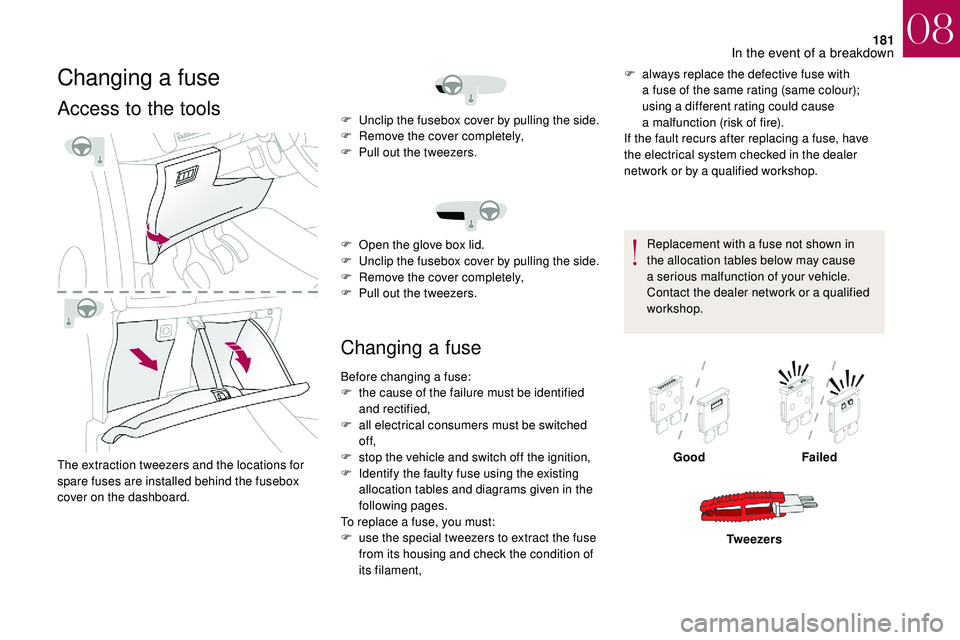

Changing a fuse

Access to the tools

The extraction tweezers and the locations for

spare fuses are installed behind the fusebox

cover on the dashboard.

Changing a fuse

F always replace the defective fuse with

a fuse of the same rating (same colour);

using a

different rating could cause

a

malfunction (risk of fire).

If the fault recurs after replacing a

fuse, have

the electrical system checked in the dealer

network or by a

qualified workshop.

Replacement with a

fuse not shown in

the allocation tables below may cause

a

serious malfunction of your vehicle.

Contact the dealer network or a

qualified

workshop.

F

U

nclip the fusebox cover by pulling the side.

F

R

emove the cover completely,

F

P

ull out the tweezers.

F

O

pen the glove box lid.

F

U

nclip the fusebox cover by pulling the side.

F

R

emove the cover completely,

F

P

ull out the tweezers.

Before changing a

fuse:

F

t

he cause of the failure must be identified

and rectified,

F

a

ll electrical consumers must be switched

of f,

F

s

top the vehicle and switch off the ignition,

F

I

dentify the faulty fuse using the existing

allocation tables and diagrams given in the

following pages.

To replace a

fuse, you must:

F

u

se the special tweezers to extract the fuse

from its housing and check the condition of

its filament, Good

Failed

Tw e e z e r s

08

In the event of a breakdown

Page 191 of 248

189

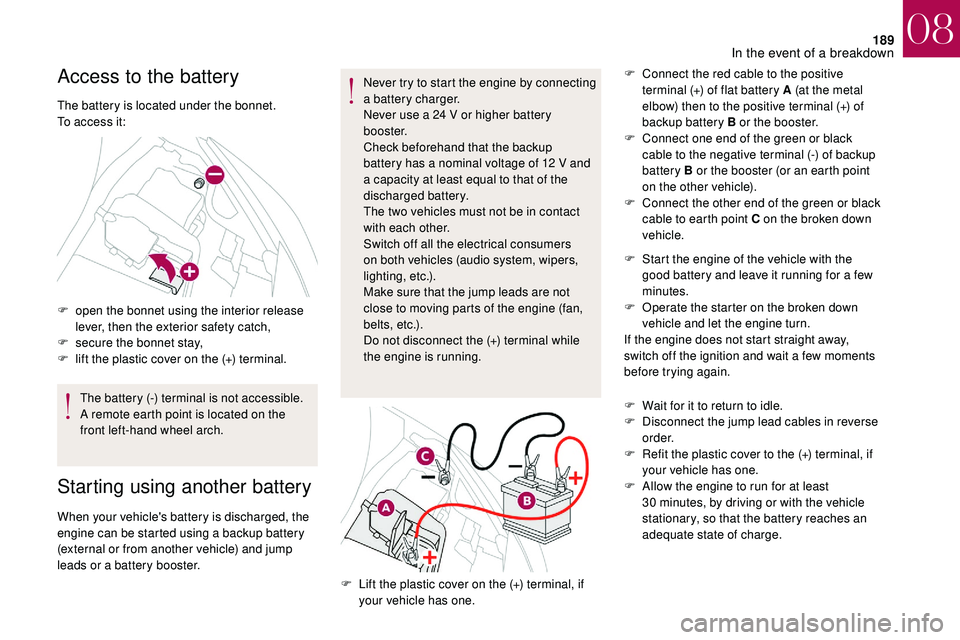

Access to the battery

The battery is located under the bonnet.

To access it:

F

o

pen the bonnet using the interior release

lever, then the exterior safety catch,

F

s

ecure the bonnet stay,

F

l

ift the plastic cover on the (+) terminal.The battery (-) terminal is not accessible.

A remote earth point is located on the

front left-hand wheel arch.

Starting using another battery

When your vehicle's battery is discharged, the

engine can be started using a backup battery

(external or from another vehicle) and jump

leads or a

battery booster. Never try to start the engine by connecting

a

battery charger.

Never use a 24 V or higher battery

b o o s t e r.

Check beforehand that the backup

battery has a nominal voltage of 12 V and

a capacity at least equal to that of the

discharged battery.

The two vehicles must not be in contact

with each other.

Switch off all the electrical consumers

on both vehicles (audio system, wipers,

lighting, etc.).

Make sure that the jump leads are not

close to moving parts of the engine (fan,

belts, etc.).

Do not disconnect the (+) terminal while

the engine is running. F

C

onnect the red cable to the positive

terminal (+) of flat battery A (at the metal

elbow) then to the positive terminal (+) of

backup battery B or the booster.

F

C

onnect one end of the green or black

cable to the negative terminal (-) of backup

battery B or the booster (or an earth point

on the other vehicle).

F

C

onnect the other end of the green or black

cable to earth point C on the broken down

vehicle.

F

L

ift the plastic cover on the (+) terminal, if

your vehicle has one. F

S

tart the engine of the vehicle with the

good battery and leave it running for a few

minutes.

F

O

perate the starter on the broken down

vehicle and let the engine turn.

If the engine does not start straight away,

switch off the ignition and wait a few moments

before trying again.

F

W

ait for it to return to idle.

F

D

isconnect the jump lead cables in reverse

o r d e r.

F

R

efit the plastic cover to the (+) terminal, if

your vehicle has one.

F

A

llow the engine to run for at least

30 minutes, by driving or with the vehicle

stationary, so that the battery reaches an

adequate state of charge.

08

In the event of a breakdown