CITROEN DS7 CROSSBACK 2022 Owners Manual

Manufacturer: CITROEN, Model Year: 2022, Model line: DS7 CROSSBACK, Model: CITROEN DS7 CROSSBACK 2022Pages: 244, PDF Size: 6.87 MB

Page 171 of 244

169

Practical information07

Remove dust from the Alcantara® parts

regularly with a dry cloth, soft brush or

vacuum cleaner.

Clean the Alcantara

®, without rubbing too

vigorously, with a white cotton cloth which is

slightly damp.

To find out which products and procedures to use

on different types of stains, refer to the "Textile -

Stain removal" section.

For more information, go to the Alcantara

®

trademark website: www.alcantara.com.

Leather

Leather is a natural product. Appropriate regular

care is essential for its durability.

It must be protected and nourished using a

specific leather product, to keep it supple and

preserve its original appearance.

Do not use maintenance products which

are not suitable for cleaning leather

(e.g. solvent, detergent, petrol, pure alcohol).

Do not use bleaching or colour-removal

products (e.g. perchloroethylene).

When cleaning items partly made from leather,

take care not to damage the other materials

with the specific leather product.

Before cleaning greasy stains or liquids,

quickly mop up any surplus.

Before cleaning, wipe off any residues liable

to scuff the leather, using a cloth that has

been dampened with demineralised water and

thoroughly wrung out.

Clean the leather, without rubbing too

vigorously, using a soft cloth moistened with

soapy water or a pH-neutral product.

Dry with a soft, dry cloth.

Page 172 of 244

170In the event of a breakdown08

Warning triangle

This reflective and dismantlable device is to be

installed on the side of the road when a vehicle is

broken down or damaged.

Before getting out of the vehicle

Turn on the hazard warning lamps, then

put on the safety vest to assemble and install

the triangle.

Storage compartment

There is a compartment in the interior trim of the

tailgate to store a warning triangle.

► After opening the tailgate, release the cover by

turning the screw a quarter turn to the left.

Assembling and placing the

triangle

For versions supplied with a triangle as original

equipment, refer to the illustration above.

For other versions, refer to the assembly

instructions provided with the triangle.

► Put the triangle in place behind the vehicle, as

required by local legislation.

Running out of fuel

(Diesel)

With Diesel engines, the fuel system must be

primed if you run out of fuel.

Before starting to prime the system, it is essential

to put at least 5 litres of Diesel into the fuel tank.

For more information on Refuelling and on

Misfuel prevention (Diesel), refer to the

corresponding section. ►

Switch on the ignition (without starting the

engine).

► Wait around 1 minute and switch off the

ignition.

► Operate the starter motor to start the engine.

If the engine does not start at the first attempt,

do not keep trying, but restart the procedure.

Tool kit

Set of tools supplied with the vehicle.

Its content depends on your vehicle's equipment:

–

T

emporary puncture repair kit.

–

Spare wheel.

Page 173 of 244

171In the event of a breakdown08

Accessing the tools

The tool kit is stored in the boot, under the floor.

Versions with rigid boot floor:

► Open the boot.

► Lift the rigid boot floor.

► Attach the floor hook to the upper boot seal.

Versions with 2-position boot floor:

► Open the boot.

► Place the adjustable boot floor in the high

position. ►

Lift the boot floor past the two retractable

stops.

► Place the boot floor onto these two stops to

hold it up.

Versions with articulated boot mat

(Rechargeable hybrid):

► Open the boot.

► Unfold the articulated boot mat by pulling its

handle until it is fully opened.

With temporary puncture repair kit

With spare wheel

These tools are specific to the vehicle and

may vary according to the level of

equipment.

Do not use them for any other purpose.

The jack must only be used to change a

wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with the vehicle.

If the vehicle does not have its original jack,

contact a dealer or a qualified workshop

to obtain the one that was intended by the

manufacturer.

The jack meets European standards, as

defined in the Machinery Directive 2006/42/

CE.

The jack does not require any maintenance.

Page 174 of 244

172In the event of a breakdown08

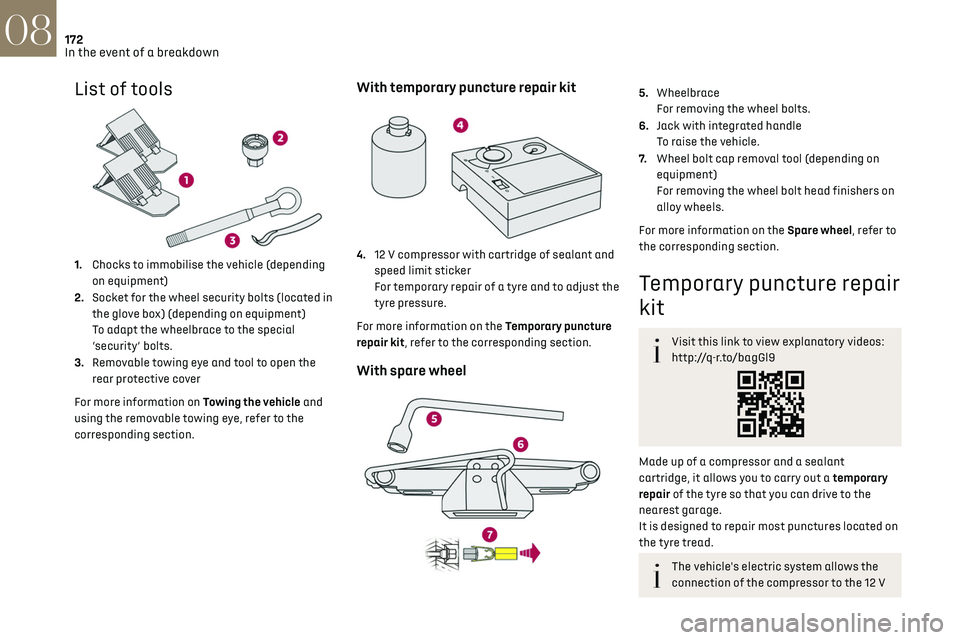

List of tools

1.Chocks to immobilise the vehicle (depending

on equipment)

2. Socket for the wheel security bolts (located in

the glove box) (depending on equipment)

To adapt the wheelbrace to the special

‘security’ bolts.

3. Removable towing eye and tool to open the

rear protective cover

For more information on Towing the vehicle and

using the removable towing eye, refer to the

corresponding section.

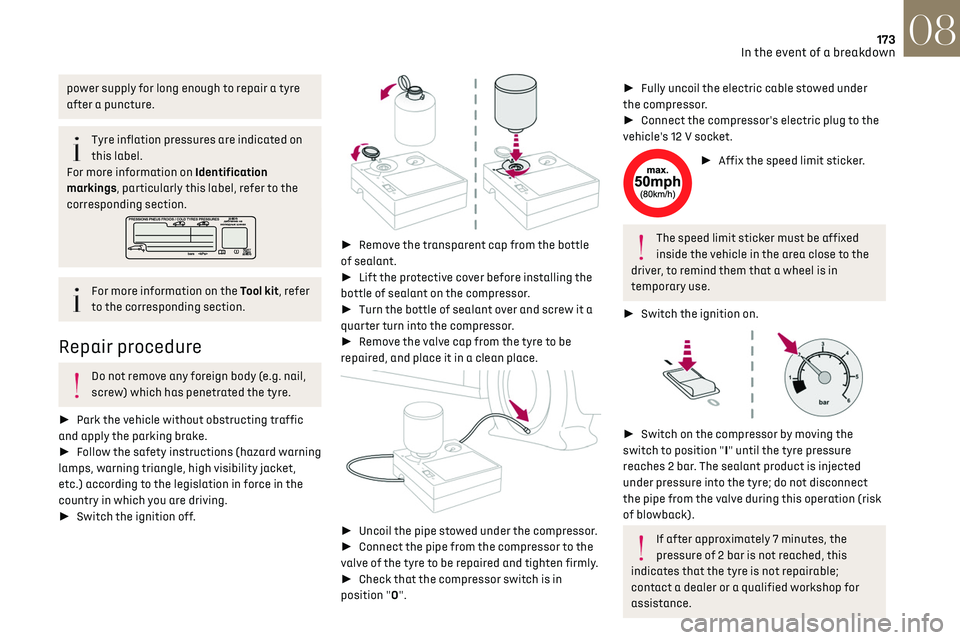

With temporary puncture repair kit

4. 12 V compressor with cartridge of sealant and

speed limit sticker

For temporary repair of a tyre and to adjust the

tyre pressure.

For more information on the Temporary puncture

repair kit, refer to the corresponding section.

With spare wheel

5. Wheelbrace

For removing the wheel bolts.

6. Jack with integrated handle

To raise the vehicle.

7. Wheel bolt cap removal tool (depending on

equipment)

For removing the wheel bolt head finishers on

alloy wheels.

For more information on the Spare wheel, refer to

the corresponding section.

Temporary puncture repair

kit

Visit this link to view explanatory videos:

http://q-r.to/bagGl9

Made up of a compressor and a sealant

cartridge, it allows you to carry out a temporary

repair of the tyre so that you can drive to the

nearest garage.

It is designed to repair most punctures located on

the tyre tread.

The vehicle's electric system allows the

connection of the compressor to the 12 V

Page 175 of 244

173In the event of a breakdown08

power supply for long enough to repair a tyre

after a puncture.

Tyre inflation pressures are indicated on

this label.

For more information on Identification

markings, particularly this label, refer to the

corresponding section.

For more information on the Tool kit, refer

to the corresponding section.

Repair procedure

Do not remove any foreign body (e.g. nail,

screw) which has penetrated the tyre.

► Park the vehicle without obstructing traffic

and apply the parking brake.

► Follow the safety instructions (hazard warning

lamps, warning triangle, high visibility jacket,

etc.) according to the legislation in force in the

country in which you are driving.

► Switch the ignition off.

► Remove the transparent cap from the bottle

of sealant.

► Lift the protective cover before installing the

bottle of sealant on the compressor.

► Turn the bottle of sealant over and screw it a

quarter turn into the compressor.

► Remove the valve cap from the tyre to be

repaired, and place it in a clean place.

► Uncoil the pipe stowed under the compressor.

► Connect the pipe from the compressor to the

valve of the tyre to be repaired and tighten firmly.

► Check that the compressor switch is in

position "O".

► Fully uncoil the electric cable stowed under

the compressor.

► Connect the compressor's electric plug to the

vehicle's 12 V socket.

► Affix the speed limit sticker.

The speed limit sticker must be affixed

inside the vehicle in the area close to the

driver, to remind them that a wheel is in

temporary use.

► Switch the ignition on.

► Switch on the compressor by moving the

switch to position "I" until the tyre pressure

reaches 2 bar. The sealant product is injected

under pressure into the tyre; do not disconnect

the pipe from the valve during this operation (risk

of blowback).

If after approximately 7 minutes, the

pressure of 2 bar is not reached, this

indicates that the tyre is not repairable;

contact a dealer or a qualified workshop for

assistance.

Page 176 of 244

174In the event of a breakdown08

► Move the switch to position "O".

► Disconnect the compressor's electric plug

from the vehicle's 12 V socket.

► Remove the kit.

► Refit the cap on the valve.

► Remove and store the bottle of sealant.

The sealant product is harmful if

swallowed and causes irritation to the

eyes.

Keep this product out of the reach of children.

The use-by date of the fluid is marked on the

bottle.

After use, do not discard the bottle into

the environment; take it to a dealer or an

authorised waste disposal site.

Do not forget to obtain a new bottle of

sealant, available from a dealer or a qualified

workshop.

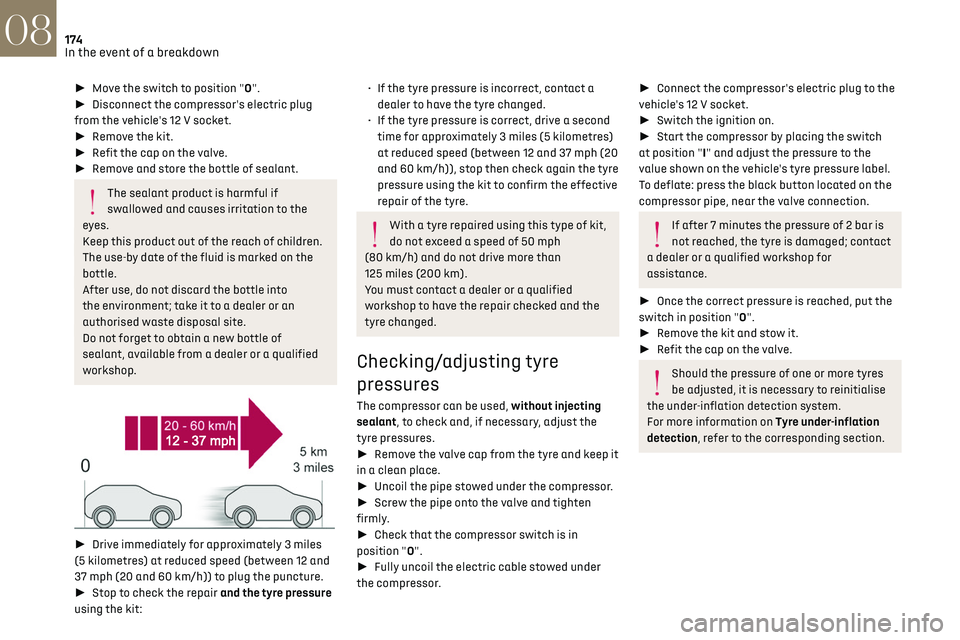

► Drive immediately for approximately 3 miles

(5 kilometres) at reduced speed (between 12 and

37 mph (20 and 60 km/h)) to plug the puncture.

► Stop to check the repair and the tyre pressure

using the kit:

• If the tyre pre ssure is incorrect, contact a

dealer to have the tyre changed.

•

If the tyre pre

ssure is correct, drive a second

time for approximately 3 miles (5 kilometres)

at reduced speed (between 12 and 37 mph (20

and 60 km/h)), stop then check again the tyre

pressure using the kit to confirm the effective

repair of the tyre.

With a tyre repaired using this type of kit,

do not exceed a speed of 50 mph

(80 km/h) and do not drive more than

125 miles (200 km).

You must contact a dealer or a qualified

workshop to have the repair checked and the

tyre changed.

Checking/adjusting tyre

pressures

The compressor can be used, without injecting

sealant, to check and, if necessary, adjust the

tyre pressures.

► Remove the valve cap from the tyre and keep it

in a clean place.

► Uncoil the pipe stowed under the compressor.

► Screw the pipe onto the valve and tighten

firmly.

► Check that the compressor switch is in

position "O".

► Fully uncoil the electric cable stowed under

the compressor.

► Connect the compressor's electric plug to the

vehicle's 12 V socket.

► Switch the ignition on.

► Start the compressor by placing the switch

at position "I" and adjust the pressure to the

value shown on the vehicle's tyre pressure label.

To deflate: press the black button located on the

compressor pipe, near the valve connection.

If after 7 minutes the pressure of 2 bar is

not reached, the tyre is damaged; contact

a dealer or a qualified workshop for

assistance.

► Once the correct pressure is reached, put the

switch in position "O".

► Remove the kit and stow it.

► Refit the cap on the valve.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Tyre under-inflation

detection, refer to the corresponding section.

Page 177 of 244

175

In the event of a breakdown08

Spare wheel

Visit this link to view explanatory videos:

http://q-r.to/bagGl9

For more information on the Tool kit, refer

to the corresponding section.

Accessing the spare wheel

The spare wheel is stored in the boot, under the

floor.

To access the spare wheel, first refer to the Tool

kit section.

Depending on version, the spare wheel

may be a standard size steel or alloy

wheel.

In some countries, it is a ‘space saver’ wheel.

Removing the spare wheel

► Slacken the central nut.

► Remove the fastening device (nut and bolt).

► Lift the spare wheel towards the back of the

boot.

► Take the wheel out of the boot.

Putting the spare wheel back in place

► Put the spare wheel back in place in its

housing.

► Slacken the nut on the bolt by a few turns.

► Position the fastening device (nut and bolt) in

the middle of the wheel.

► Tighten the central nut sufficiently to retain

the wheel correctly.

► Put the tool box back in place in the middle of

the wheel and clip it in place.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not

obstruct traffic: the ground must be level,

stable and non-slippery.

Select mode P on the automatic gearbox to

lock the wheels, apply the parking brake,

unless it is set to automatic mode, and switch

off the ignition.

Page 178 of 244

176

In the event of a breakdown08

Check that the parking brake indicator lamps

on the instrument panel are on fixed.

The occupants must get out of the vehicle and

wait where they are safe.

If necessary, place a chock under the wheel

diagonally opposite the wheel to be changed.

Never go underneath a vehicle raised using a

jack; use an axle stand.

Wheel with wheel trim

When removing the wheel, first remove

the wheel trim by pulling at the valve aperture

using the wheelbrace.

When refitting the wheel, refit the wheel trim,

starting by placing its aperture in line with the

valve and then pushing it into place all round

its edge with the palm of your hand.

► To remove the wheel bolt cover on each of the

bolts, use tool 7 (alloy wheels).

► Fit security socket 2 on wheelbrace 5 to

slacken the security bolt.

► Slacken the other bolts using the

wheelbrace 5 only.

Never use an impact wrench on the

security bolt socket.

► Place the foot of jack 6 on the ground and

ensure that it is directly below the front A or

rear B jacking point on the underbody, whichever

is closest to the wheel to be changed.

► Extend jack 6 until its head comes into contact

with jacking point A or B; contact area A or B on

the vehicle must be properly inserted into the

central part of the head of the jack.

► Raise the vehicle until there is sufficient space

between the wheel and the ground to easily admit

the spare (not punctured) wheel.

Ensure that the jack is stable. If the

ground is slippery or loose, the jack may

slip or collapse - risk of injury!

Take care to position the jack strictly at

one of the jacking points A or B under the

vehicle, ensuring that the head of the jack is

centred under the contact area on the vehicle.

Otherwise, there is a risk of damage to the

vehicle and/or of the jack collapsing - risk of

injury!

Page 179 of 244

177

In the event of a breakdown08

► Remove the bolts and store them in a clean

place.

► Remove the wheel.

Fitting a wheel

Fitting a steel or "space-saver" type spare

wheel

If the vehicle is fitted with alloy wheels, the

washers A do not make contact with the steel

or "space-saver" type spare wheel. The wheel

is held in place by the conical contact surface

B of each bolt.

► Fit the wheel on the hub.

► Screw in the bolts by hand as far as possible.

► Pre-tighten the security bolt using the

wheelbrace 5 equipped with a security socket 2.

► Pre-tighten the other bolts using the

wheelbrace 5 only.

► Lower the vehicle again fully.

► Fold jack 6 and remove it.

► Tighten the security bolt using the

wheelbrace 5 equipped with a security socket 2.

► Tighten the other bolts using the wheelbrace 5

only.

► Refit the bolt covers to each of the bolts

(depending on equipment).

► Store the tools.

After changing a wheel

Store the punctured wheel in the boot or,

depending on version, remove the central cover

first to store it beneath the floor in place of the

spare wheel.

With a "space-saver" type spare wheel

Deactivate certain driving aid functions (Active

Safety Brake, Adaptive cruise control, etc.).

Page 180 of 244

178

In the event of a breakdown08

Do not exceed the maximum authorised speed

of 50 mph (80 km/h) or the maximum distance

of 50 miles (80 km).

Driving with more than one "space-saver" type

spare wheel is prohibited.

Visit a dealer or a qualified workshop.

Have the tightening of the spare wheel's

bolts and its tyre pressure checked.

Have the punctured tyre examined. After

inspection, the technician will advise you on

whether the tyre can be repaired or if it must

be replaced.

Changing a bulb

In some weather conditions (e.g. low

temperature or humidity), misting on the

internal surface of the glass of the headlamps

and rear lamps is normal, and will disappear

after the lamps have been on for a few

minutes.

Never look too closely at the light beam of

LED technology lamps - risk of serious eye

injury!

The headlamps have polycarbonate

lenses with a protective coating:

–

Do not clean them with a dry or abrasiv

e

cloth, nor with detergent or solvent products.

–

U

se a sponge and soapy water or a pH

neutral product.

–

When using a high-pre

ssure washer on

persistent marks, do not keep the lance

directed towards the headlamps, lamps or

their edges for too long, so as not to damage

their protective coating and seals.

Changing a bulb must only be done with

the ignition off and after the headlamp /

lamp has been switched off for several

minutes - risk of serious burns!

Do not touch the bulb directly with your

fingers; use a lint-free cloth.

It is essential only to use anti-ultraviolet (UV)

type bulbs, so as not to damage the headlamp.

Always replace a failed bulb with a new bulb

of the same type and specification. To avoid

lighting imbalance, replace the bulbs in pairs.

After changing a bulb

To refit, carry out the operations in

reverse order to removal.

Close the protective cover very carefully to

guarantee the sealing of the lamps.

Light-emitting diode (LED)

headlamps and lamps

Depending on version, the affected types of

headlamps/lamps are:

–

LED t

echnology headlamps.

–

DS PIXEL LED VISION 3

.0 headlamps.

–

Offset da

ytime running lamps/sidelamps/

direction indicators.

–

Direction indic

ator side repeaters.

–

Side spo

tlamps.

–

B

rake lamps.

–

T

ailgate rear lamps.

–

Third brak

e lamp.

–

Number pla

te lamps.

If you need to replace this type of bulb,

you must contact a dealer or a qualified

workshop.

Do not touch the LED technology bulbs - risk of

electrocution!