ECU Citroen JUMPY 2016 2.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2016, Model line: JUMPY, Model: Citroen JUMPY 2016 2.GPages: 595, PDF Size: 12.47 MB

Page 275 of 595

273

Jumpy _en_Chap07_info-pratiques_ed01-2016

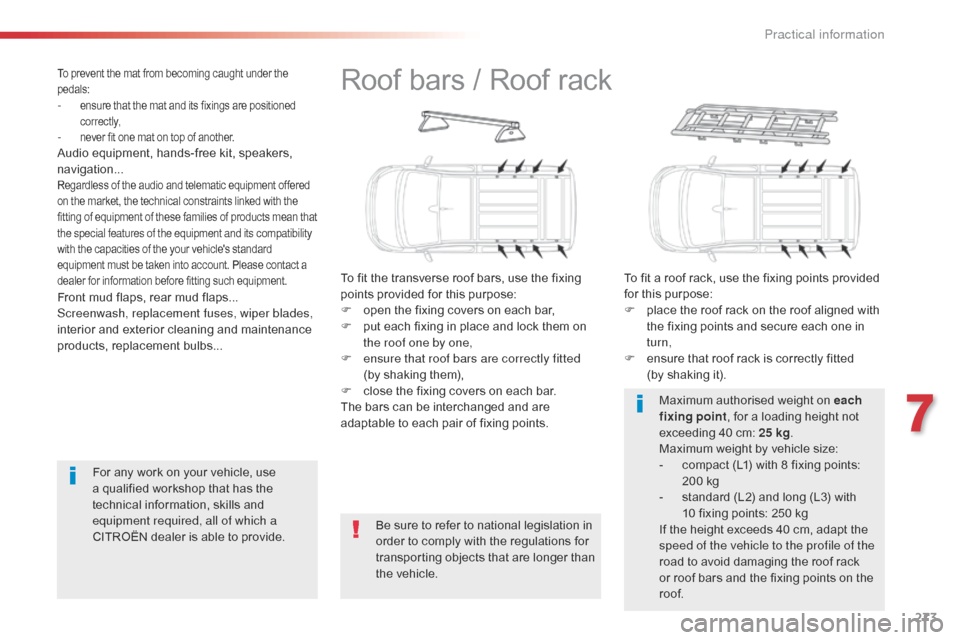

Roof bars / Roof rack

To fit the transverse roof bars, use the fixing

points provided for this purpose:

F

o

pen the fixing covers on each bar,

F

p

ut each fixing in place and lock them on

the roof one by one,

F

e

nsure that roof bars are correctly fitted

(by shaking them),

F

c

lose the fixing covers on each bar.

The bars can be interchanged and are

adaptable to each pair of fixing points. To fit a roof rack, use the fixing points provided

for this purpose:

F

p

lace the roof rack on the roof aligned with

the fixing points and secure each one in

turn,

F

e

nsure that roof rack is correctly fitted

(by shaking it).

Be sure to refer to national legislation in

order to comply with the regulations for

transporting objects that are longer than

the vehicle. Maximum authorised weight on each

fixing point

, for a loading height not

exceeding 40 cm: 25 kg.

Maximum weight by vehicle size:

-

c

ompact (L1) with 8 fixing points:

200 kg

-

s

tandard (L2) and long (L3) with

10 fixing points: 250 kg

If the height exceeds 40 cm, adapt the

speed of the vehicle to the profile of the

road to avoid damaging the roof rack

or roof bars and the fixing points on the

roof.

Front mud flaps, rear mud flaps...

Screenwash, replacement fuses, wiper blades,

interior and exterior cleaning and maintenance

products, replacement bulbs...

To prevent the mat from becoming caught under the

pedals:

- ensure that the mat and its fixings are positioned

c o r r e c t l y,

- never fit one mat on top of another.Audio equipment, hands-free kit, speakers,

navigation...

Regardless of the audio and telematic equipment offered

on the market, the technical constraints linked with the

fitting of equipment of these families of products mean that

the special features of the equipment and its compatibility

with the capacities of the your vehicle's standard

equipment must be taken into account. Please contact a

dealer for information before fitting such equipment.

For any work on your vehicle, use

a qualified workshop that has the

technical information, skills and

equipment required, all of which a

CITROËN dealer is able to provide.

7

Practical information

Page 289 of 595

287

Jumpy _en_Chap08_En-cas-de-panne_ed01-2016

Warning triangle (stowing)

Before leaving your vehicle to set up

and install the triangle, switch on the

hazard warning lamps and put on your

high visibility vest.

This safety equipment should be used in

addition to the hazard warning lamps.

Its presence in the vehicle is mandatory.

Placing the triangle in the

road

Refer to the manufacturer's instructions on

unfolding and assembly supplied with the

triangle. F

P

lace the triangle behind the vehicle, as

required by the legislation in force in your

c o unt r y.

The triangle is available as an

accessory; contact a CITROËN dealer

or a qualified workshop.

Tool box

Access

The tool box is located under the left-hand front

seat.

As a safety measure, the bars 1 and

2

prevent the box escaping from its

housing, if it is not correctly secured.

8

In the event of a breakdown

Page 290 of 595

288

Jumpy _en_Chap08_En-cas-de-panne_ed01-2016

Stowing

F Press the latches A and slide them inwards to release the box.

F

L

ift the box slightly then pull it as far as it

will go to take it past bar 1 .

F

T

hen, lift the box upwards to take it past

bar 2 . F

U nclip the fixings B on the cover, then

open it for access to the tools.

OpeningRemoving

Pull on the box to check that it is secure

in its housing.

F

O

ffer up the box with the front inclined

upwards.

F

T

o take it past bar 2 , push the box in and

down. F

T

o take it past bar 1

, raise the box slightly

then push it fully in.

F

R

efit the cover on the box and clip the

fixings B. F

O

nce the box is fully home

in its housing,

push it against the floor carpet then slide

the latches A outwards to secure it.

In the event of a breakdown

Page 291 of 595

289

Jumpy _en_Chap08_En-cas-de-panne_ed01-2016

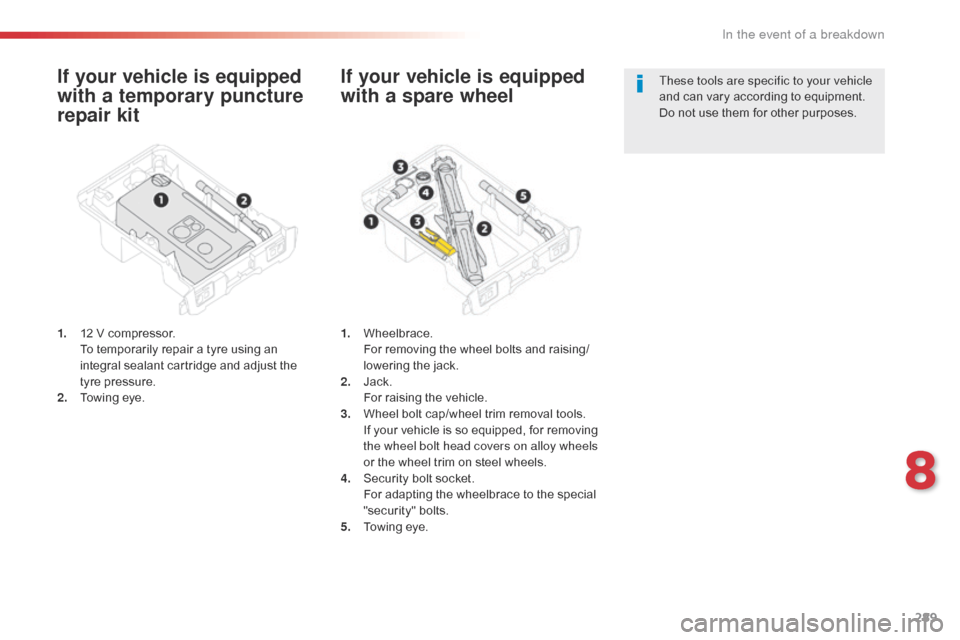

If your vehicle is equipped

with a temporary puncture

repair kit

1. 12 V compressor. To temporarily repair a tyre using an

integral sealant cartridge and adjust the

tyre pressure.

2.

T

owing eye.

If your vehicle is equipped

with a spare wheel

1. Wheelbrace. F or removing the wheel bolts and raising/

lowering the jack.

2.

J

ack.

F

or raising the vehicle.

3.

W

heel bolt cap/wheel trim removal tools.

I

f your vehicle is so equipped, for removing

the wheel bolt head covers on alloy wheels

or the wheel trim on steel wheels.

4.

S

ecurity bolt socket.

F

or adapting the wheelbrace to the special

"security" bolts.

5.

T

owing eye. These tools are specific to your vehicle

and can vary according to equipment.

Do not use them for other purposes.

8

In the event of a breakdown

Page 298 of 595

296

Jumpy _en_Chap08_En-cas-de-panne_ed01-2016

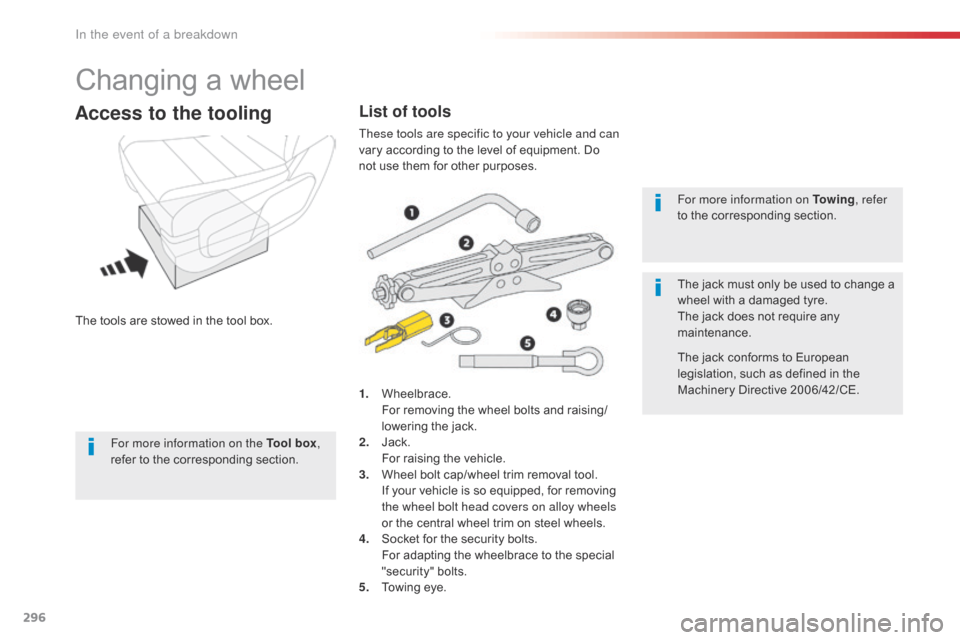

Changing a wheel

The tools are stowed in the tool box.

Access to the tooling

1. Wheelbrace. For removing the wheel bolts and raising/

lowering the jack.

2.

J

ack.

F

or raising the vehicle.

3.

W

heel bolt cap/wheel trim removal tool.

I

f your vehicle is so equipped, for removing

the wheel bolt head covers on alloy wheels

or the central wheel trim on steel wheels.

4.

S

ocket for the security bolts.

F

or adapting the wheelbrace to the special

"security" bolts.

5.

T

owing eye. For more information on To w i n g

, refer

to the corresponding section.

The jack must only be used to change a

wheel with a damaged tyre.

The jack does not require any

maintenance.

The jack conforms to European

legislation, such as defined in the

Machinery Directive 2006/42/CE.

List of tools

These tools are specific to your vehicle and can

vary according to the level of equipment. Do

not use them for other purposes.

For more information on the Tool box ,

refer to the corresponding section.

In the event of a breakdown

Page 301 of 595

299

Jumpy _en_Chap08_En-cas-de-panne_ed01-2016

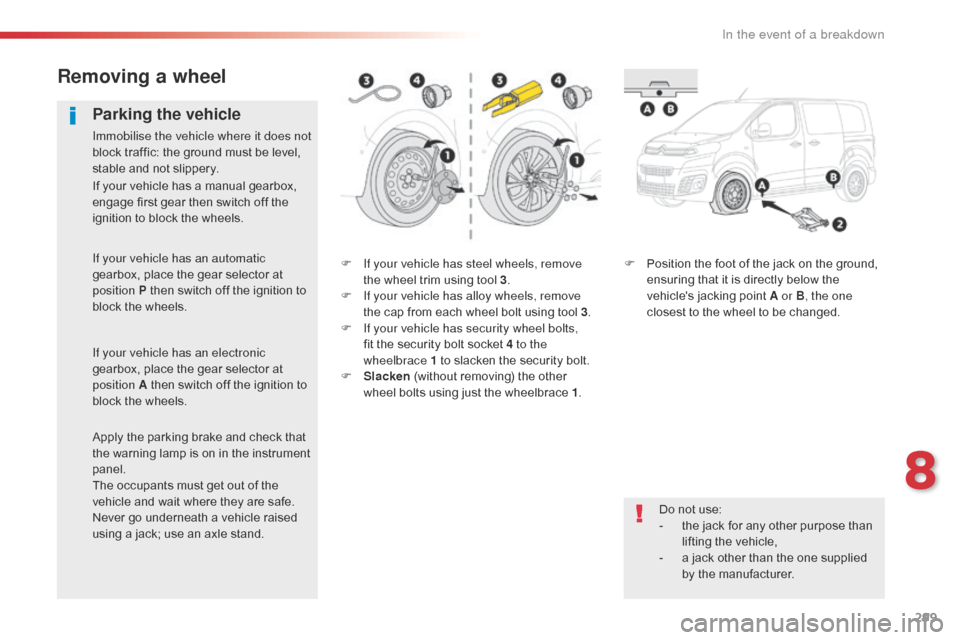

F If your vehicle has steel wheels, remove the wheel trim using tool 3 .

F

I

f your vehicle has alloy wheels, remove

the cap from each wheel bolt using tool 3 .

F

I

f your vehicle has security wheel bolts,

fit the security bolt socket 4 to the

wheelbrace

1 to slacken the security bolt.

F

S

lacken (without removing) the other

wheel bolts using just the wheelbrace 1 .F

P osition the foot of the jack on the ground,

ensuring that it is directly below the

vehicle's jacking point A or B , the one

closest to the wheel to be changed.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not

block traffic: the ground must be level,

stable and not slippery.

Do not use:

-

t

he jack for any other purpose than

lifting the vehicle,

-

a j

ack other than the one supplied

by the manufacturer.

If your vehicle has a manual gearbox,

engage first gear then switch off the

ignition to block the wheels.

If your vehicle has an automatic

gearbox, place the gear selector at

position P then switch off the ignition to

block the wheels.

If your vehicle has an electronic

gearbox, place the gear selector at

position A then switch off the ignition to

block the wheels.

Apply the parking brake and check that

the warning lamp is on in the instrument

panel.

The occupants must get out of the

vehicle and wait where they are safe.

Never go underneath a vehicle raised

using a jack; use an axle stand.

8

In the event of a breakdown

Page 303 of 595

301

Jumpy _en_Chap08_En-cas-de-panne_ed01-2016

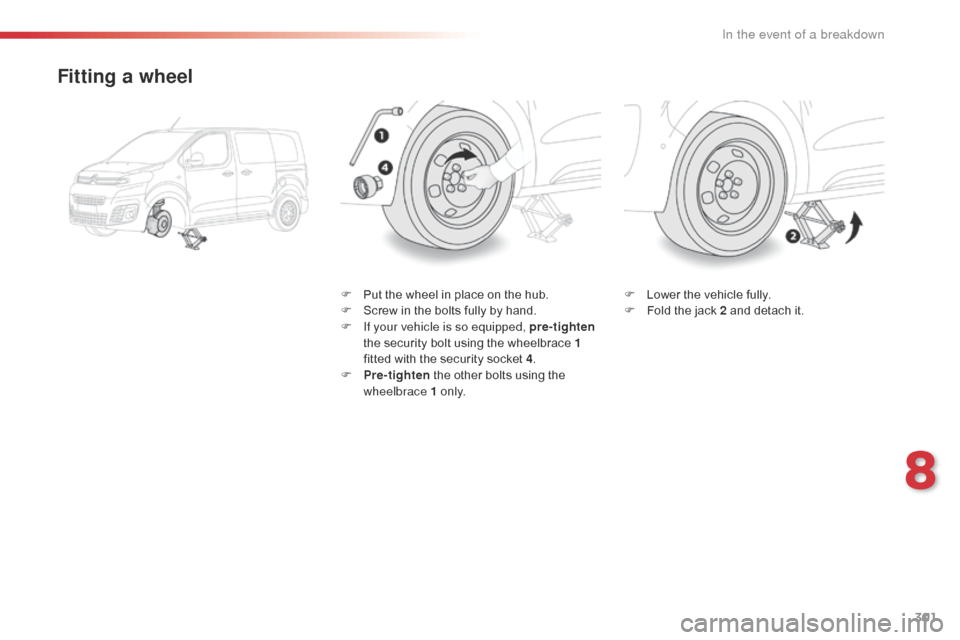

Fitting a wheel

F Put the wheel in place on the hub.

F S crew in the bolts fully by hand.

F

I

f your vehicle is so equipped, pre- tighten

the security bolt using the wheelbrace 1

fitted with the security socket 4 .

F

P

re-tighten the other bolts using the

wheelbrace 1 o n l y. F

L ower the vehicle fully.

F F old the jack 2 and detach it.

8

In the event of a breakdown

Page 304 of 595

302

Jumpy _en_Chap08_En-cas-de-panne_ed01-2016

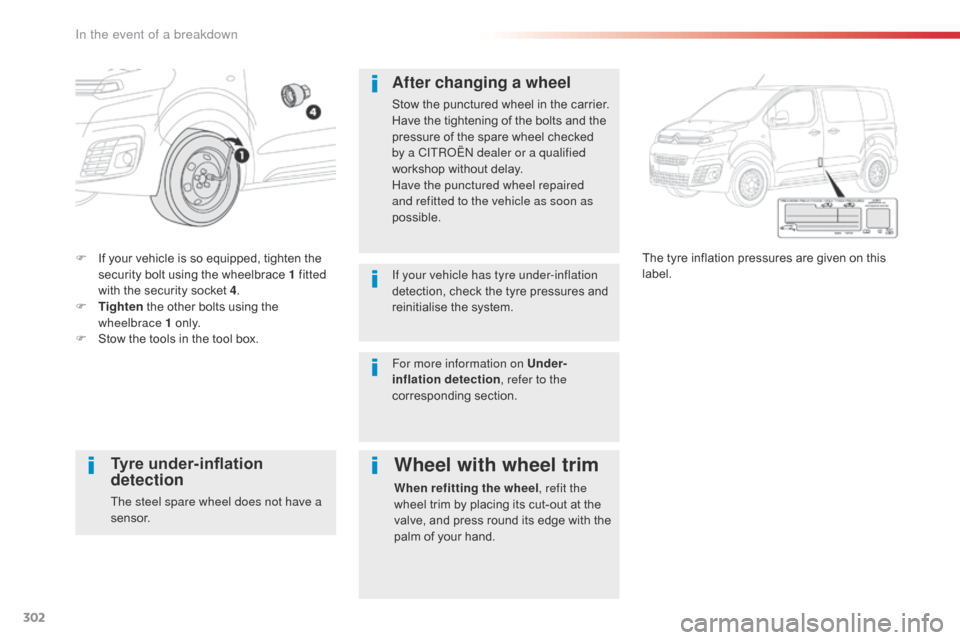

F If your vehicle is so equipped, tighten the security bolt using the wheelbrace 1 fitted

with the security socket 4 .

F

T

ighten the other bolts using the

wheelbrace 1 o n l y.

F

S

tow the tools in the tool box. The tyre inflation pressures are given on this

label.

After changing a wheel

Stow the punctured wheel in the carrier.

Have the tightening of the bolts and the

pressure of the spare wheel checked

by a CITROËN dealer or a qualified

workshop without delay.

Have the punctured wheel repaired

and refitted to the vehicle as soon as

possible.

If your vehicle has tyre under-inflation

detection, check the tyre pressures and

reinitialise the system.

Tyre under-inflation

detection

The steel spare wheel does not have a

sensor.

Wheel with wheel trim

When refitting the wheel

, refit the

wheel trim by placing its cut-out at the

valve, and press round its edge with the

palm of your hand.

For more information on Under-

inflation detection

, refer to the

corresponding section.

In the event of a breakdown

Page 314 of 595

312

Jumpy _en_Chap08_En-cas-de-panne_ed01-2016

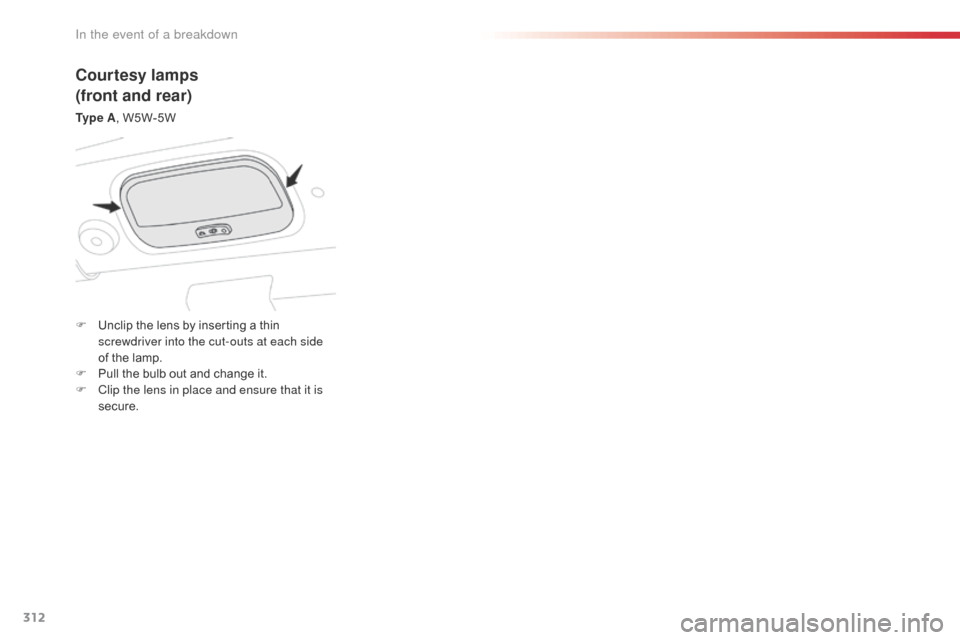

Courtesy lamps

(front and rear)

Ty p e A, W5W-5W

F

U

nclip the lens by inserting a thin

screwdriver into the cut-outs at each side

of the lamp.

F

P

ull the bulb out and change it.

F

C

lip the lens in place and ensure that it is

secure.

In the event of a breakdown

Page 317 of 595

315

Jumpy _en_Chap08_En-cas-de-panne_ed01-2016

Courtesy lamps

(front and rear)

For the replacement of this type of LED lamp

and light guide, contact a CITROËN dealer or a

qualified workshop.

A replacement kit for the LEDs is available from

CITROËN dealers.Rear lamps

For more information on Changing a bulb and

in particular, the types of bulbs, refer to the

corresponding section.

Platform cab

F Identify the failed bulb.

F R emove the four screws securing the lens.

F

P

ull the lens towards you.

F

R

emove the failed bulb by pressing lightly

on it and then turning it a quarter turn

clockwise.

F

C

hange the bulb.

1.

D

irection indicators.

Ty

p e B , P21W-21W

2.

B

rake lamps.

Ty

p e B , P21W-21W

3.

S

idelamps.

Ty

p e B , R10W-10W

4.

R

eversing lamps.

Ty

p e B , P21W-21W

5.

F

oglamps.

Ty

p e B , P21W-21W To reassemble, carry out these operations in

reverse order.

8

In the event of a breakdown