Citroen JUMPY MULTISPACE DAG 2010 2.G Owner's Manual

Manufacturer: CITROEN, Model Year: 2010, Model line: JUMPY MULTISPACE DAG, Model: Citroen JUMPY MULTISPACE DAG 2010 2.GPages: 235, PDF Size: 11.17 MB

Page 121 of 235

DIESEL

115

Fuel

CHECKS

6

FUEL CIRCUIT DISARMED

In a serious collision, a mechanism

automatically prevents fuel from reaching

the engine.

DIESEL REPRIMING PUMP

If you should run out of fuel, it is necessary

to re-prime the circuit:

- fill the fuel tank with at least five litres of

diesel,

- squeeze and release the manual re-priming pump, under the bonnet

under the protective cover, until fuel

appears in the transparent pipe,

- operate the starter until the engine starts. The flashing of this warning light

is accompanied by a message on

the display.

Check that there is no odour or leakage of

fuel outside the vehicle and re-establish the

fuel supply:

- switch off the ignition (STOP position),

- remove the key,

- put the key back in the ignition,

- switch on the ignition and start.

Quality of the fuel used for Diesel engines Quality of the fuel used for petrol engines

The Diesel engines are perfectly compatible

with biofuels which conform to current

and future European standards (Diesel

fuel which complies with standard EN 590

mixed with a biofuel which complies with

standard EN 14214) available at the pumps

(containing up to 7 % Fatty Acid Methyl

Ester).

The B30 biofuel can be used in certain

Diesel engines; however, this use is subject

to strict application of the special servicing

conditions. Consult a CITROËN dealer.

The use of any other type of (bio)fuel

(vegetable or animal oils, pure or diluted,

domestic fuel...) is strictly prohibited (risk of

damage to the engine and fuel system). The petrol engines are perfectly compatible

with E10 type petrol biofuels (containing

10 % ethanol), conforming to European

standards EN 228 and EN 15376.

E85 type fuels (containing up to 85 %

ethanol) are reserved exclusively for

vehicles marketed for the use of this type

of fuel (BioFlex vehicles). The quality of

the ethanol must comply with European

standard EN 15293.

For Brazil only, special vehicles are

marketed to run on fuels containing up to

100 % ethanol (E100 type).

Page 122 of 235

DIESEL

115

Fuel

CHECKS

6

FUEL CIRCUIT DISARMED

In a serious collision, a mechanism

automatically prevents fuel from reaching

the engine.

DIESEL REPRIMING PUMP

If you should run out of fuel, it is necessary

to re-prime the circuit:

- fill the fuel tank with at least five litres of

diesel,

- squeeze and release the manual re-priming pump, under the bonnet

under the protective cover, until fuel

appears in the transparent pipe,

- operate the starter until the engine starts. The flashing of this warning light

is accompanied by a message on

the display.

Check that there is no odour or leakage of

fuel outside the vehicle and re-establish the

fuel supply:

- switch off the ignition (STOP position),

- remove the key,

- put the key back in the ignition,

- switch on the ignition and start.

Quality of the fuel used for Diesel engines Quality of the fuel used for petrol engines

The Diesel engines are perfectly compatible

with biofuels which conform to current

and future European standards (Diesel

fuel which complies with standard EN 590

mixed with a biofuel which complies with

standard EN 14214) available at the pumps

(containing up to 7 % Fatty Acid Methyl

Ester).

The B30 biofuel can be used in certain

Diesel engines; however, this use is subject

to strict application of the special servicing

conditions. Consult a CITROËN dealer.

The use of any other type of (bio)fuel

(vegetable or animal oils, pure or diluted,

domestic fuel...) is strictly prohibited (risk of

damage to the engine and fuel system). The petrol engines are perfectly compatible

with E10 type petrol biofuels (containing

10 % ethanol), conforming to European

standards EN 228 and EN 15376.

E85 type fuels (containing up to 85 %

ethanol) are reserved exclusively for

vehicles marketed for the use of this type

of fuel (BioFlex vehicles). The quality of

the ethanol must comply with European

standard EN 15293.

For Brazil only, special vehicles are

marketed to run on fuels containing up to

100 % ethanol (E100 type).

Page 123 of 235

116

Battery

BATTERY

This is housed in a compartment located

underneath the floor, in front of the front

right seat. Before disconnecting the battery, you must

wait for 2 minutes after switching off the

ignition.

Never disconnect a terminal when the

engine is running.

Never charge a battery without first

disconnecting the terminals.

After every reconnection of the battery,

switch on the ignition and wait 1 minute

before starting to allow the electronic

systems to be initialised. If slight difficulties

are experienced after this, please contact a

CITROËN dealer. It is advisable to disconnect the battery

if the vehicle is not to be used for a

period of more than one month. After the engine has stopped, with the key

in the ignition position, certain functions

(windscreen wiper, electric windows, courtesy

lights, audio equipment, etc.) can only be

used for a cumulative duration of thirty

minutes, to prevent discharging of the battery.

To charge the battery using a battery charger

- Disconnect the battery,

- Follow the instructions for use given by

the battery charger manufacturer,

- Reconnect starting with the negative (-) terminal,

- Check that the terminals and connectors are clean. If they are covered with

sulphate (white or greenish deposit),

disconnect them and clean them.

To start the vehicle from another battery

- Connect the red cable to the positive (+) terminals of the two batteries,

- Connect one end of the green or black cable to the negative (-) terminal of the

slave battery,

- Connect the other end of the green or black cable to an earth point on the

broken down vehicle as far as possible

from the battery,

- Operate the starter, let the engine run,

- Wait for the engine to return to idle, then disconnect the cables. Once the thirty minutes are over, the active

functions are put on standby and the battery

warning light flashes accompanied by a

message on the display.

To resume the use of these functions

immediately, start the engine and let it run

for a few minutes.

The time available will then be double the

time for which the engine was left running.

However, this time will always be between

five and thirty minutes.

A flat battery will prevent the engine from

starting.

Page 124 of 235

117

Repairing a wheel

QUICK HELP

7

PUNCTURE REPAIR KIT

The kit is located at the rear left of the

vehicle.

The temporary tyre repair kit consists of

a compressor and a bottle (containing a

sealant).

Using the kit

- Switch off the ignition,

- affix the speed limitation sticker to the vehicle's steering wheel to remind you

that a wheel is in temporary use,

- check that the switch A is at position " 0 ",

- connect the pipe of the bottle 1 to the

valve of the tyre to be repaired,

- connect the compressor's electrical plug to the vehicle's 12 V socket,

- start the vehicle and let the engine run,

- switch on the compressor by pressing the switch A to position " 1 " until the tyre

pressure reaches 2.0 bars,

Vehicles supplied with a temporary

puncture repair kit do not have a spare

wheel or tooling (jack, wheelbrace, ...). - remove the compressor, unclip and

store the bottle in a sealed bag to avoid

staining your vehicle with traces of fluid,

- drive immediately, for approximately two miles (three kilometres), at reduced

speed (between 12 and 37 mph (20 and

60 km/h)), to seal the puncture,

- stop to check the repair and the pressure,

If, after approximately five to ten

minutes, you are not able to obtain

this pressure, the tyre cannot be repaired;

contact a CITROËN dealer for roadside

assistance.

Page 125 of 235

118

Repairing a wheel

- connect the compressor pipe directly to the valve of the repaired wheel.

- connect the compressor's electrical plug to the vehicle's 12 V socket again,

- start the vehicle again and let the engine run, Warning, the bottle of fluid contains

ethylene-glycol, this product is harmful

if swallowed and causes irritation to

the eyes. Keep this product out of reach of

children.

The expiry date of the fluid is indicated

under the bottle.

The bottle is intended for a single use; once

opened, it must be replaced.

After use, do not discard the bottle into the

environment, take it to a CITROËN dealer or

to a specialised waste disposal site.

Do not forget to obtain a new bottle of

sealant available from CITROËN dealers.

- adjust the pressure using the

compressor (to inflate: switch A in

position " 1 "; to deflate: switch A in

position " 0 " and press button B ), in

accordance with the vehicle's tyre

pressure label (located on the door

aperture, on the driver's side), then

remember to check that the leak has

been sealed correctly (no further

loss of pressure after several miles

(kilometres)),

- remove the compressor, then stow the complete kit,

- drive at reduced speed (50 mph (80 km/h) max) limiting the distance travelled to

approximately 125 miles (200 km),

- visit a CITROËN dealer as soon as possible to have the tyre repaired or

replaced by a technician.

Page 126 of 235

119

Changing a wheel

QUICK HELP

7

CHANGING A WHEEL

If your vehicle is equipped with a spare

wheel located underneath the vehicle, follow

these instructions.

1. PARKING THE VEHICLE

- It is imperative that you ensure that the occupants get out of the vehicle and

wait in a safe location.

- If possible, park the vehicle on level, stable and non-slippery ground.

- Apply the handbrake, switch off the ignition and engage first or reverse gear.

- If available, place a chock under the wheel diagonally opposite the one to be

changed.

On certain types of ground and/or if

considerable loads are being transported,

the vehicle must be raised in order to

disengage the spare wheel from the carrier.

Call a CITROËN dealer. If your vehicle is fitted with suspension

with pneumatic compensation, please

deactivate the system. Refer to the "Rear

suspension" section of chapter 3.

- If fitted on your vehicle, open the plastic flap located at the rear left of the

vehicle.

- Unscrew the nut then take out the jack and the wheelbrace.

1. Wheelbrace.

2. Jack.

3. Alloy wheel embellisher remover.

The jack and the tool kit are specific to

your vehicle. Do not use them for other

purposes.

Page 127 of 235

120

Changing a wheel

- Open the cover, located on the sill, to access the carrier bolt.

- Unscrew the bolt using the wheelbrace until the carrier is lowered fully. - Detach the carrier from the hook and

place the spare wheel near the wheel to

be changed. 3. SPARE WHEEL

- Gain access to the spare wheel from the rear.

- Open the rear doors. You can switch on the courtesy light to

increase the light.

Page 128 of 235

Changing a wheel

QUICK HELP

7

4. OPERATING PROCEDURE

Do not extend the jack until you have started

unscrewing the bolts on the wheel to be

changed and have placed the chock under

the wheel diagonally opposite.

- Remove the trim pulling it using the

embellisher remover.

- Loosen the wheel bolts and start unscrewing them.

- Place the jack in contact with the locating point provided, the one which is

closest to the wheel to be changed.

Ensure that the jack is straight and that the base of the jack is fully in contact

with the ground.

- Extend the jack to lift the wheel clear of the ground.

- Resume and complete the unscrewing of the wheel bolts.

- Remove the bolts and remove the wheel. Special tools for vehicles fitted with alloy

wheels

If your vehicle has wheels with alloy rims:

- The embellisher is removed using the

alloy wheel embellisher remover.

- Each wheel is fitted with an anti-theft bolt.

- These bolts can be loosened using your anti-theft socket (given to you

on delivery of your vehicle) and the

wheelbrace.

Page 129 of 235

122

Changing a wheel

- Lower the vehicle completely by folding the jack, then remove the jack.

- Tighten the bolts again using the wheelbrace, tighten them fully without

forcing them.

- Place the wheel to be repaired in the carrier. - Secure the carrier on the hook then

raise the carrier using the bolt and the

wheel brace. Check that the wheel and

the carrier are flush against the floor of

the vehicle.

- Remember to close the flap, located on the sill.

- Store the trim in the vehicle.

Never go underneath the vehicle when

it is supported only by the jack.

Never use a screwdriver in place of the

wheelbrace. - Position the wheel on the hub and start tightening the wheel bolts by hand.

- Carry out an initial tightening of the bolts using the wheelbrace.

Page 130 of 235

123

Snow screen

QUICK HELP

7

6. REFITTING THE REPAIRED WHEEL

The wheel is refitted as described in step 5,

not forgetting to refit the wheel trim. The spare wheel is not designed to be

used over long distances. Have the

tightening of the bolts and the tyre pressure

checked by a CITROËN dealer as soon

as possible. Also, have the original wheel

repaired and refitted by a CITROËN dealer

as soon as possible. Refer to the "Identification features"

section of chapter 8 to locate the tyre

label.

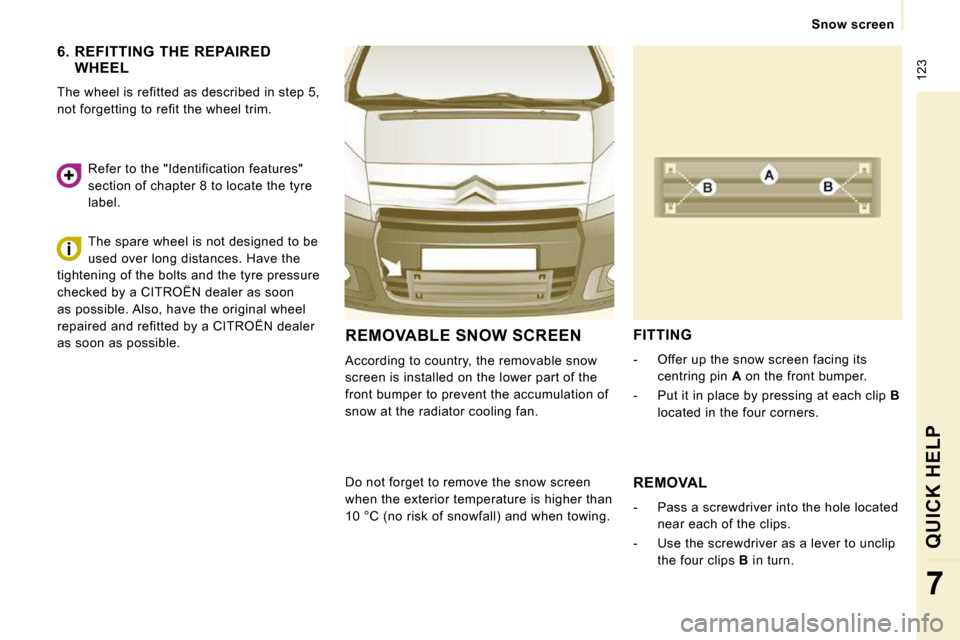

REMOVABLE SNOW SCREEN

According to country, the removable snow

screen is installed on the lower part of the

front bumper to prevent the accumulation of

snow at the radiator cooling fan.

FITTING

- Offer up the snow screen facing its

centring pin A on the front bumper.

- Put it in place by pressing at each clip B

located in the four corners.

Do not forget to remove the snow screen

when the exterior temperature is higher than

10 °C (no risk of snowfall) and when towing.

REMOVAL

- Pass a screwdriver into the hole located

near each of the clips.

- Use the screwdriver as a lever to unclip the four clips B in turn.