CITROEN RELAY 2017 Handbook (in English)

Manufacturer: CITROEN, Model Year: 2017, Model line: RELAY, Model: CITROEN RELAY 2017Pages: 292, PDF Size: 9.04 MB

Page 171 of 292

169

cHAnGInG A WIPE r BLA d E

The steps, located in the front bumper,

enable you to reach the blades and the

screenwash jets.changing a front wiper blade

Raise the wiper arm.

Unclip the blade by pressing the button and

remove it by pulling it outwards.

Fit the new blade and ensure that it is

secured correctly.

Return the wiper arm to the normal position.

Check that the screenwash or

headlamp wash jets are not blocked.

QuIcK HELP

8

Worn wiper blade

Page 172 of 292

170

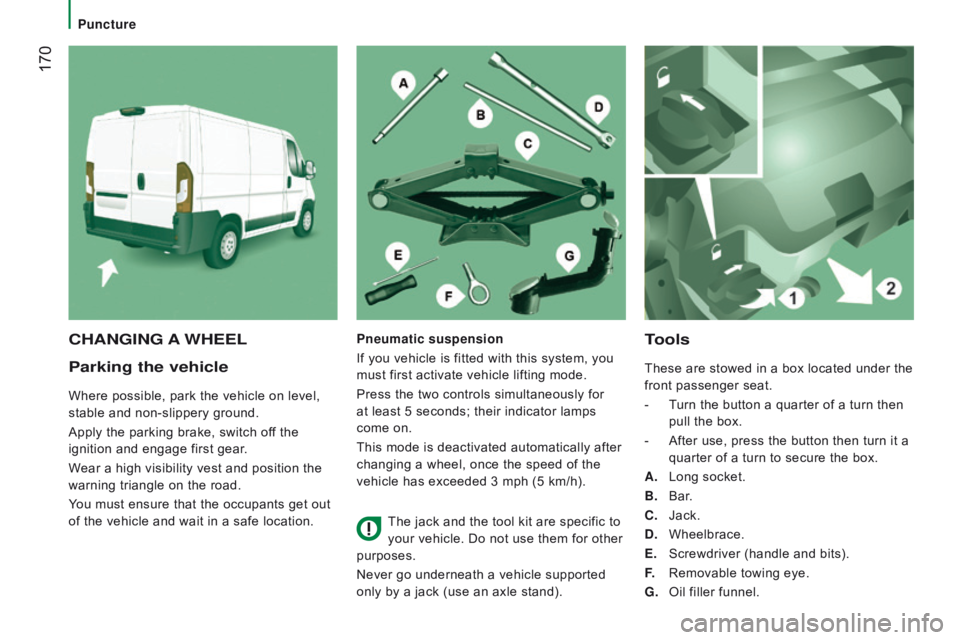

Parking the vehicle

Where possible, park the vehicle on level,

stable and non-slippery ground.

Apply the parking brake, switch off the

ignition and engage first gear.

Wear a high visibility vest and position the

warning triangle on the road.

You must ensure that the occupants get out

of the vehicle and wait in a safe location.

tools

These are stowed in a box located under the

front passenger seat.

-

T

urn the button a quarter of a turn then

pull the box.

-

After use, press the button then turn it a

quarter of a turn to secure the box.

A.

Long socket.

B.

Bar

.

c

.

Jack.

d

.

Wheelbrace.

E.

Screwdriver (handle and bits).

F.

Removable towing eye.

G.

Oil filler funnel.

cHAnGInG A WHEELPneumatic suspension

If you vehicle is fitted with this system, you

must first activate vehicle lifting mode.

Press the two controls simultaneously for

at least 5 seconds; their indicator lamps

come on.

This mode is deactivated automatically after

changing a wheel, once the speed of the

vehicle has exceeded 3 mph (5 km/h).

The jack and the tool kit are specific to

your vehicle. Do not use them for other

purposes.

Never go underneath a vehicle supported

only by a jack (use an axle stand).

Puncture

Page 173 of 292

171

● For versions with alloy wheels, remove

the three fixing screws j

from the

strap

K.

●

Remove the assembly from inside the

alloy wheel.

Spare wheel

The spare wheel retaining bolt is located

below the bumper on the right.

-

Install the long socket

A, the

wheelbrace

d

and the bar

B on the

retaining bolt.

-

T

urn the assembly anti-clockwise to

lower the wheel.

-

T

urn to the full extent, indicated by an

increase in the force required.

-

Having fully unwound the cable, take out

the spare wheel under the vehicle. ●

For versions with steel wheels, unscrew

the grip H .

●

Remove the carrier

I from the outer part

of the steel wheel.

-

Release the spare wheel and place it

near the wheel to be changed.

-

If possible, place a chock against the

wheel diagonally opposed to the wheel

to be changed.

QuIcK HELP

8

Puncture

Page 174 of 292

172

- Extend the jack using the wheelbrace d

and the bar B until the wheel is a few

centimetres off the ground.

-

Unscrew the bolts fully and remove the

wheel to be repaired.

-

Position the jack

c at one of the four

locations provided on the underbody

near the wheels.

If your vehicle has a folding foot board, the

jack must be positioned at 45°.

removing the wheel to be repaired

- Remove the trim (depending on version)

using the screwdriver E as a lever.

-

Release the bolts using the

wheelbrace

d

and the bar

B.

Puncture

Page 175 of 292

173

Fitting the spare wheelStowing the wheel

- Put the spare wheel in place on the hub

and fit the bolts by hand.

-

Pre-tighten the bolts using the

wheelbrace

d and the bar

B.

-

Lower the vehicle completely by folding

the jack

c

, then remove the jack.

-

T

ighten the bolts again using the

wheelbrace

d and the bar

B (tighten

them fully without forcing them). You must place the wheel to be repaired or

the spare wheel under the vehicle to secure

the carrier system.

-

Place the wheel at the rear of the vehicle.

●

For versions with

steel wheels, hook

the carrier I on the outside.

●

Screw in the grip

H to secure the carrier

and wheel. ●

For versions with alloy wheels, position

the strap K on the outside.

●

Fit the three strap fixing screws

j

to the

alloy wheel.

QuIcK HELP

8

Puncture

Page 176 of 292

174

Refer to the "Technical data -

Identification markings" section for the

location of the tyre pressure label.

-

Fit the long socket

A

, the wheelbrace

d

and bar B to the securing screw.

-

T

urn the assembly clockwise to fully

draw in the cable and raise the wheel

under the vehicle.

-

Check that the wheel is positioned

horizontally flat against the floor of

the vehicle and that the cut-out for the

carrier system is visible.

-

Stow the tools and the trim (depending

on version).

refitting the repaired wheel

Refitting the repaired wheel is the same as

fitting the spare wheel; don't forget to refit

the wheel trim.

The spare wheel is not designed to be used

over long distances. Have the tightening of

the bolts and pressure of the spare wheel

checked by a CITROËN dealer or a qualified

workshop without delay.

Also, have the original wheel repaired and

refitted by a CITROËN dealer or a qualified

workshop as soon as possible.

Puncture

Page 177 of 292

175

PuncturE rEPAIr KItrepairing the tyre

- Apply the parking brake.

-

Unscrew the tyre valve cap, remove the

filling hose B and screw the ring E onto

the valve. -

Start the engine.

-

Insert the connector G

into the nearest

power socket on the vehicle.

-

Switch on the compressor by placing the

switch F in position "I" (on),

-

Inflate the tyre to a pressure of 5 bar

.

To obtain a more accurate reading, you are

advised to check the pressure value on the

pressure gauge H , with the compressor off.

-

Check that the switch

F on the

compressor is in position "0" (off).

This temporary puncture repair kit stowed

in a bag located in one of the front door

pockets.

It consists of:

-

a cartridge

A , containing the sealant

fluid, equipped with:

●

a filling hose

B ,

●

a sticker

c

indicating "max. 80

km/h",

which the driver must affix in full

view

(on the dashboard) after

repairing the tyre,

-

a quick guide to use of the repair kit,

-

a compressor

d

equipped with a

pressure gauge and unions,

-

adaptors, for the inflation of various

items.

QuIcK HELP

8

Puncture

Page 178 of 292

176

- If a pressure of at least 3 bar is not

reached within 5 minutes, disconnect

the compressor from the valve and the

power socket, then move the vehicle

forward by approximately 10 metres

to

distribute the sealant fluid inside

the

tyre.

-

Then repeat the inflation operation:

●

if a pressure of at least

3 bar is not

reached within 10 minutes, switch off

your vehicle: the tyre has suffered

too much damage and repair has not

been possible. Contact a CITROËN

dealer or a qualified workshop.

●

if the tyre has been inflated to a

pressure of 5 bar, set off again

immediately.

After driving for approximately 10 minutes,

stop and check the pressure of the tyre

again.

Adjust the pressure to the value given on the

label on the driver's door pillar, and contact

a CITROËN dealer or a qualified workshop

as soon as possible.

checking and adjusting the

pressure

The compressor can only be used to check

and adjust the pressure.

-

Disconnect the hose

I and connect it to

the tyre valve directly; the cartridge will

then be connected to the compressor

and the filling fluid will not be injected.

If it is necessary to deflate the tyre, connect

the hose I to the tyre valve and press the

yellow button, placed in the centre of the

switch on the compressor.

replacing the cartridge

To replace the sealant cartridge, carry out

the following operations:

-

disconnect the hose

I,

-

turn the cartridge to be replaced

anticlockwise and lift it,

-

insert the new cartridge and turn it

clockwise,

-

reconnect the hose

I and connect the

hose B in its location.

The cartridge contains ethylene-glycol,

a product which is harmful if swallowed

and which causes irritation to the eyes.

Keep out of reach of children.

After use, do not discard the cartridge in the

environment, take it to a CITROËN

dealer or

an appropriate waste disposal organisation.

This puncture repair kit and

replacement cartridges are available

from CITROËN dealers.

Puncture

Page 179 of 292

177

tOWInG

t

owing the vehicle

The removable towing eye is located in the

tool box under the front passenger seat.

Unclip the cover using a flat tool.

Screw the removable towing eye in fully.

Attach the approved towing arm to to the

removable towing eye.

Place the gear lever in neutral.

towing another vehicle

The fixed towing eye is located on the right

below the bumper.

Attach the approved towing arm to the

fixed

eye.

Failure to observe this requirement

may result in damage to certain braking

components and the lack of some braking

assistance systems when the engine is

re-started.

General recommendations

Observe the legislation in force in your

country.

Ensure that the weight of the towing vehicle

is higher than that of the towed vehicle.

The driver must remain at the wheel of the

towed vehicle and must have a valid driving

licence.

When towing a vehicle with all four wheels

on the ground, always use an approved

towing arm; rope and straps are prohibited.

The towing vehicle must move off gently.

When towing a vehicle with the engine off,

there is no longer any power assistance for

braking or steering.

In the following cases, you must always call

on a professional recovery service:

-

vehicle broken down on a motorway or

fast road,

-

four-wheel drive vehicle,

-

when it is not possible to put the

gearbox into neutral, unlock the

steering, or release the parking brake,

-

towing with only two wheels on the

ground,

-

where there is no approved towing arm

available...

QuIcK HELP

8

Being towed or towing

Page 180 of 292

178

tOWBAr WItH QuIcKLY

d E t

A

c HABLE t

OWBALL

Presentation

This towball can be fitted and removed

quickly and easily without the use of tools. For information on the maximum

trailer weight and the recommended

nose weight, refer to the "Technical data -

Weights" section.

For information on safely towing a trailer,

refer to the "Accessories - Towing a trailer"

section.

1.

Carrier

2.

Connector socket.

3.

Safety eye.

4.

Detachable towball.

5.

Locking / unlocking wheel.

6.

Key lock.

7.

Key reference label. A.

Locked

position; the locking wheel is in

contact with towball (no gap).

B.

u

nlocked position; the locking wheel

and towball are no longer in contact

(gap of about 5 mm). Before each use

Check that the towball is correctly

locked and verify the following points:

- the green mark on the locking wheel

is in line with the green mark on the

towball,

-

the locking wheel is in contact with the

towball,

-

the key lock is on and the key removed;

the locking wheel can no longer be

operated,

-

the towball must no longer move at all in

its carrier; try to shake it by hand.

d

uring use

Never unlock the device when a trailer or

load carrier is fitted to the towball.

Never exceed the maximum authorised

weight for the vehicle (the Gross Vehicle

Weight - GVW), the trailer, or the sum of the

two (the Gross Train Weight - GTW).

Observe the legislation in force in the

country in which you are driving. After use

For journeys made without a trailer or load

carrier, the towball must be removed and

the blanking plug inserted in the carrier. This

measure applies particularly if the towball

could hinder visibility of the number plate or

lighting.

transport solutions