SPARE WHEEL CITROEN RELAY 2020 Handbook (in English)

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2020, Model line: RELAY, Model: CITROEN RELAY 2020Pages: 196, PDF Size: 34.07 MB

Page 109 of 196

107

In the event of a breakdown

8

► Install extended socket A, wheelbrace D and

wheel bar B on the retaining bolt.

► Turn the assembly anti-clockwise to lower the

wheel.

► Turn to the locking point of the winch,

indicated by the hardening of the manoeuvre and

notch G not visible.

► After unrolling the cable completely, take the

spare wheel out.

With steel wheels:

► Unscrew handle H. ►

Remove caliper I from the outer part of the

steel wheel.

With alloy wheels:

► Unscrew the three fixing bolts K.

► Unscrew handle H.

► Remove bracket J from caliper I.

► Remove the spare wheel and place it near

the wheel to be replaced.

► If possible, place a chock under the wheel

diagonally opposite the wheel to be changed.

3 - Position the jack

Ensure that the jack is stable.

If the ground is slippery or loose, the jack

may collapse - Risk of injury!

Take care to place the jack strictly at jacking point 1 or 2 under the vehicle,

making sure that the jack head is centred at

the contact point on the vehicle. Otherwise,

there is a risk of damage to the vehicle and/or

the jack collapsing.

Make sure that any passengers are safe

(removed, away from the vehicle).

Never put your hands or your head in the

wheel arch.

Page 111 of 196

109

In the event of a breakdown

84 - Replacing the wheel to

be repaired

► Remove the wheel trim (depending on

version) by levering with screwdriver E.

► Unlock the bolts using wheelbrace D and

wheel bar B.

For more information on Positioning the

jack, refer to the corresponding section.

► Make sure that the jack is stable and

correctly positioned on the underbody.

► Using wheelbrace D and wheel bar B, extend

the jack sufficiently to release the wheel.

To clear the wheel easily, a space of about 2 to 3 cm is needed between the

ground and the tyre.

If the wheel is badly punctured/crushed,

increase the space but do not operate the

jack to its maximum lifting position.

► Unscrew the bolts completely and remove the

wheel to be repaired.

► Make sure that the spare wheel contact

surfaces, the bolts and bolt housings are clean

and free of impurities that could cause loosening

of the fixing bolts.

Do not grease the bolts before screwing

them on: they could unscrew themselves

spontaneously.

► Fit the spare wheel by aligning the 2

holes M with the 2 corresponding shafts N.

► Start screwing the bolts by hand.

Screw the bolts in this order.

Page 112 of 196

11 0

In the event of a breakdown

► Lightly tighten using wheelbrace D and wheel

bar B.

► Lower the vehicle using wheelbrace D and

wheel bar B, and then remove the jack.

► Tighten the bolts again using wheelbrace D

and wheel bar B.

Have the tightening of the bolts and the

pressure of the spare wheel checked by

the Manufacturer's dealer network or a

qualified workshop without delay.

Have the punctured wheel repaired and

refitted on the vehicle as soon as possible.

If your vehicle has tyre under-inflation

detection, check the tyre pressures and

reinitialise the system.

5 - Storing the wheel to be

repaired

You must reposition the wheel to be repaired or

the spare wheel under the vehicle to lock the

winch system.

Check that it is securely fastened in its

compartment under the floor.

Improper wheel positioning can compromise

safety.

► Reposition the wheel at the rear of the

vehicle.

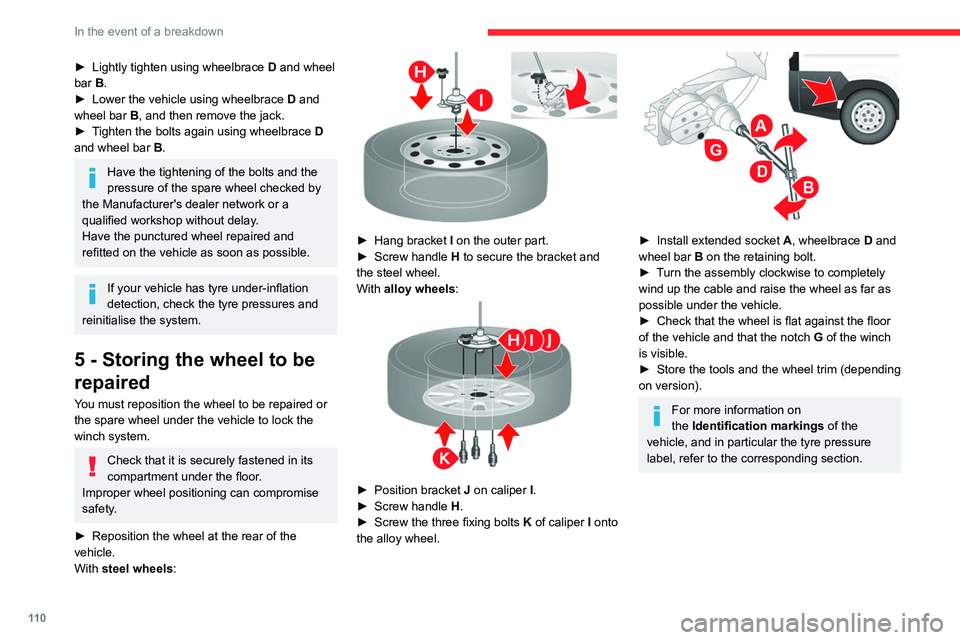

With steel wheels:

► Hang bracket I on the outer part.

► Screw handle H to secure the bracket and

the steel wheel.

With alloy wheels:

► Position bracket J on caliper I.

► Screw handle H.

► Screw the three fixing bolts K of caliper I onto

the alloy wheel.

► Install extended socket A, wheelbrace D and

wheel bar B on the retaining bolt.

► Turn the assembly clockwise to completely

wind up the cable and raise the wheel as far as

possible under the vehicle.

► Check that the wheel is flat against the floor

of the vehicle and that the notch G of the winch

is visible.

► Store the tools and the wheel trim (depending

on version).

For more information on

the Identification markings of the

vehicle, and in particular the tyre pressure

label, refer to the corresponding section.

Changing a bulb

The headlamps have polycarbonate lenses with a protective coating:

► do not clean them using a dry or

abrasive cloth, nor with a detergent or

solvent product,

► use a sponge and soapy water or a pH

neutral product,

► when using a high pressure washer on

persistent marks, do not keep the lance

directed towards the lamps or their edges for

too long, so as not to damage their protective

coating and seals.

Changing a bulb must only be done with

the ignition off and after the lamp has

been switched off for several minutes - Risk

of serious burns!

► Do not touch the bulb directly with your

fingers, use a lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a failed bulb with a new bulb

with the same type and specification.

In some weather conditions (e.g. low

temperature or humidity), the presence

of misting on the internal surface of the glass

of the headlamps and rear lamps is normal; it

Page 181 of 196

179

Alphabetical index

Tools 105–110

Topping-up AdBlue® 102

Touch screen 158, 173

Touch screen audio-telematic system 158, 173

Towball, quickly detachable 92–94

Towbar with quickly detachable towball 92–94

Towed loads 124

Towing another vehicle 122

Traction control (ASR) 52–53

Traffic information (TA) 152

Trip computer 19

Type of bulbs 111

Tyres 100

Tyre under-inflation detection 71–72

U

Under-inflation (detection) 71–72

USB 152–153, 161–162

V

Ventilation 31–33

Voice commands 155–157, 169–171

W

Warning and indicator lamps 6–7

Warning lamps 7

Warning lamp, seat belts 55

Warnings and indicators 6–7

Washing 74

Weights 124

Wheel, spare 100, 105–110

Window controls 25

Wipers 49

Wipers, automatic rain sensitive 49