Turn Citroen XSARA PICASSO 2005 1.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: XSARA PICASSO, Model: Citroen XSARA PICASSO 2005 1.GPages: 462, PDF Size: 10.48 MB

Page 183 of 462

Downloaded from www.Manualslib.com manuals search engine 177

ENGINE

XSARA - XSARA PICASSO AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

Without air conditioning (continued)

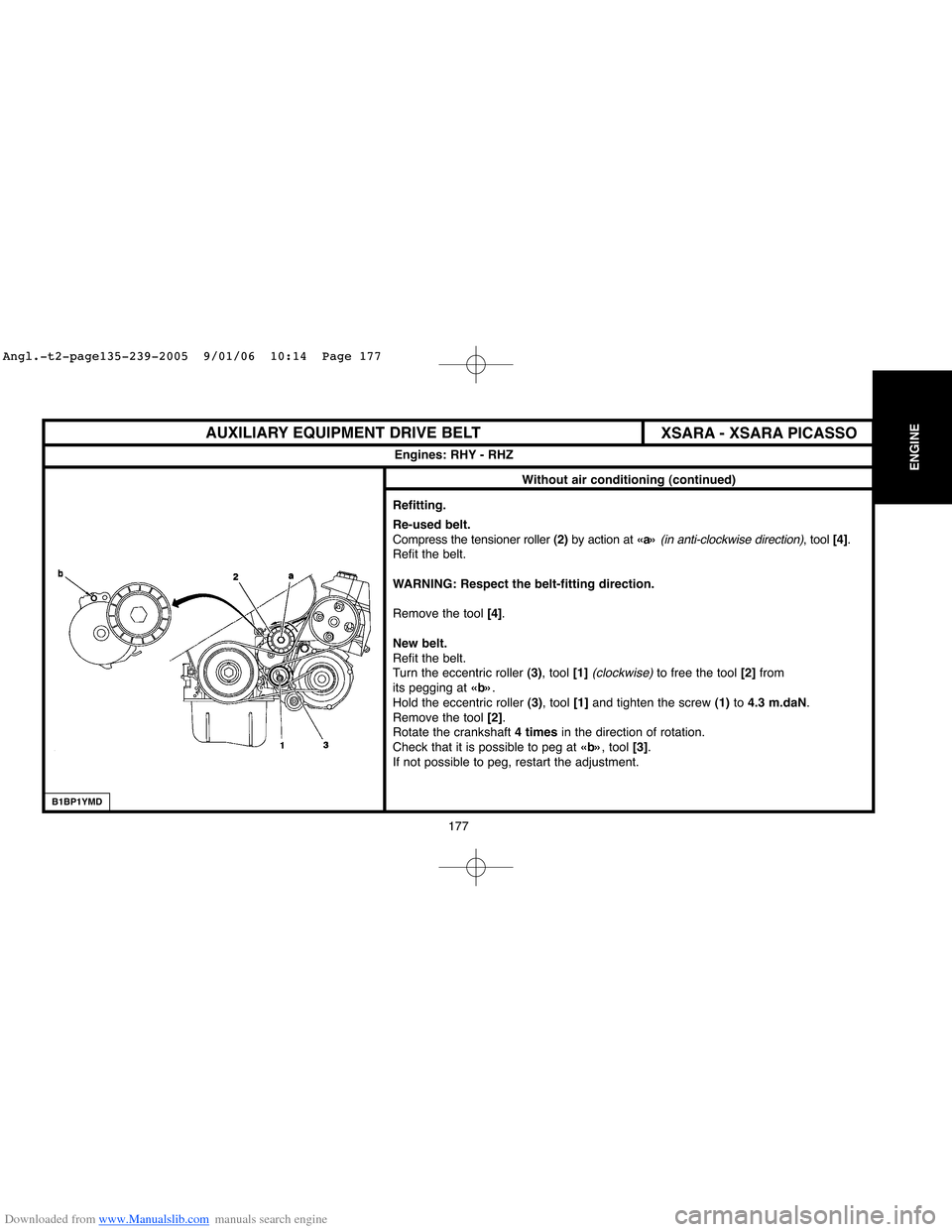

Refitting.

Re-used belt.

Compress the tensioner roller (2)by action at «a»

(in anti-clockwise direction), tool [4].

Refit the belt.

WARNING: Respect the belt-fitting direction.

Remove the tool [4].

New belt.

Refit the belt.

Turn the eccentric roller (3), tool [1]

(clockwise)to free the tool [2]from

its pegging at «b».

Hold the eccentric roller (3), tool [1]and tighten the screw (1)to 4.3 m.daN.

Remove the tool [2].

Rotate the crankshaft 4 timesin the direction of rotation.

Check that it is possible to peg at «b», tool [3].

If not possible to peg, restart the adjustment.

B1BP1YMD

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 177

Page 185 of 462

Downloaded from www.Manualslib.com manuals search engine 179

ENGINE

XSARA - XSARA PICASSO

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

With air conditioning (continued)

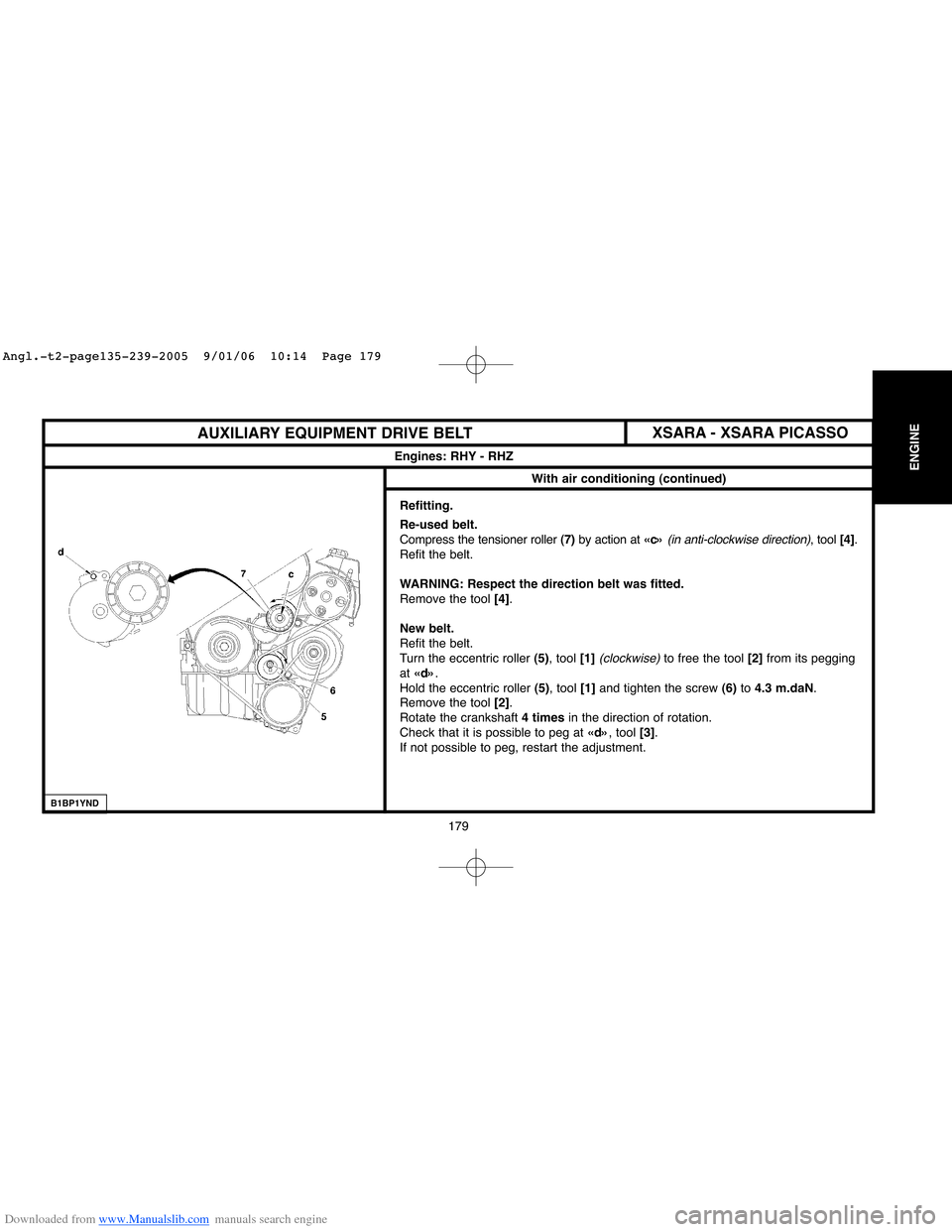

Refitting.

Re-used belt.

Compress the tensioner roller (7)by action at «c»

(in anti-clockwise direction), tool [4].

Refit the belt.

WARNING: Respect the direction belt was fitted.

Remove the tool [4].

New belt.

Refit the belt.

Turn the eccentric roller (5), tool[1]

(clockwise)to free the tool [2]from its pegging

at «d».

Hold the eccentric roller (5), tool [1]and tighten the screw (6)to 4.3 m.daN.

Remove the tool [2].

Rotate the crankshaft 4 timesin the direction of rotation.

Check that it is possible to peg at «d», tool [3].

If not possible to peg, restart the adjustment.

B1BP1YND

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 179

Page 186 of 462

![Citroen XSARA PICASSO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 180

ENGINE

B1BP2J5D

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHV - 4HY

Tools.

[1]Dynamic tensioner compression lever: (-).0188.Z.

[2]Dynamic ten Citroen XSARA PICASSO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 180

ENGINE

B1BP2J5D

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHV - 4HY

Tools.

[1]Dynamic tensioner compression lever: (-).0188.Z.

[2]Dynamic ten](/img/9/4138/w960_4138-185.png)

Downloaded from www.Manualslib.com manuals search engine 180

ENGINE

B1BP2J5D

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHV - 4HY

Tools.

[1]Dynamic tensioner compression lever: (-).0188.Z.

[2]Dynamic tensioner roller retaining peg Ø 4 mm : (-).0188.Q1

Removing.

Remove the splash-shield, under-engine sound-deadening, front RH wheel.

WARNING: Mark the direction of fitting of the auxiliaries drive belt in the case of

re-use of the belt.

Compress the dynamic tensioner roller (1)by acting at «b»

(anti-clockwise), using tool [1].

Peg using tool [2]at «a».

IMPERATIVE : Check that the roller (1) turns freely

(without play and without tight

spots).

Refitting.

Refit the auxiliaries drive belt.

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly positioned in

the grooves of the various pulleys.

Compress the dynamic tensioner roller (1)by acting at «b», using tool [1].

Remove tool [2] at «a».

Complete the refitting.

JUMPER

Without air conditioning

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 180

Page 191 of 462

![Citroen XSARA PICASSO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 185

ENGINE

Tools.

[1]Flywheel peg: 4507-T.A

[2] Camshaft pulley peg: 4507-T.B Toolkit 4507-T

[3]Square: 4507-T.J

[4] Belt tension measuri Citroen XSARA PICASSO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 185

ENGINE

Tools.

[1]Flywheel peg: 4507-T.A

[2] Camshaft pulley peg: 4507-T.B Toolkit 4507-T

[3]Square: 4507-T.J

[4] Belt tension measuri](/img/9/4138/w960_4138-190.png)

Downloaded from www.Manualslib.com manuals search engine 185

ENGINE

Tools.

[1]Flywheel peg: 4507-T.A

[2] Camshaft pulley peg: 4507-T.B Toolkit 4507-T

[3]Square: 4507-T.J

[4] Belt tension measuring instrument: 4122-T

[5] Valve rocker thrust plate: 4533-T.Z

Checking the timing.

Peg the flywheel, using tool [1].

Peg the camshaft pulley, using tool [2].

Setting the timing.

NOTE:Remove the sparking plugs, to ease rotation of the crankshaft.

Rotate the engine by means of the crankshaft screw (1).

Peg the camshaft pinion.

Peg the flywheel

Slacken the nut (2).

Fullt detension the belt by acting on the tensioner roller.

Remove the belt.

IMPERATIVE: Check that the tensioner roller turns freely

(no tight spot).

CHECKING AND SETTING THE VALVE TIMING

Engines: KFW - NFV

B1EP067CB1EP066CB1EP068C

XSARA - XSARA PICASSO

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 185

Page 192 of 462

![Citroen XSARA PICASSO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 186

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: KFW - NFV

Refitting the timing belt.

NOTE :Check that the pegs [1]and [2]are in place. Citroen XSARA PICASSO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 186

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: KFW - NFV

Refitting the timing belt.

NOTE :Check that the pegs [1]and [2]are in place.](/img/9/4138/w960_4138-191.png)

Downloaded from www.Manualslib.com manuals search engine 186

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: KFW - NFV

Refitting the timing belt.

NOTE :Check that the pegs [1]and [2]are in place.

WARNING: Respect the direction of fitting of the belt: The arrows "a" indicate the direction of rotation of

the crankshaft.

Position:

-The timing belt, belt "b"well-tensioned in the following order: Crankshaft pinion, camshaft pulley, coolant pump

pulley, tensioner roller.

- Tool [5]

(respect the direction of fitting relative to the valve timing).

- Put the tensioner roller in contact with the belt.

- Tighten the nut (2).

Pre-tensioning the belt.

Place tool [4] on the tensioned part "b"of the belt.

Slacken the screw (2).

Turn the roller (3)in the anti-clockwise direction using the drive square, to obtain a value of: 44 SEEMunits.

Tighten the nut (2) to 2 m.daN.

Remove tools [1], [2] and [4].

Rotate the crankshaft 4 turnsin the normal direction of rotation.

IMPERATIVE: Never turn the crankshaft backwards.

B1EP06AC

B1EP069C

XSARA - XSARA PICASSO

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 186

Page 193 of 462

Downloaded from www.Manualslib.com manuals search engine 187

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engines: KFW - NFV

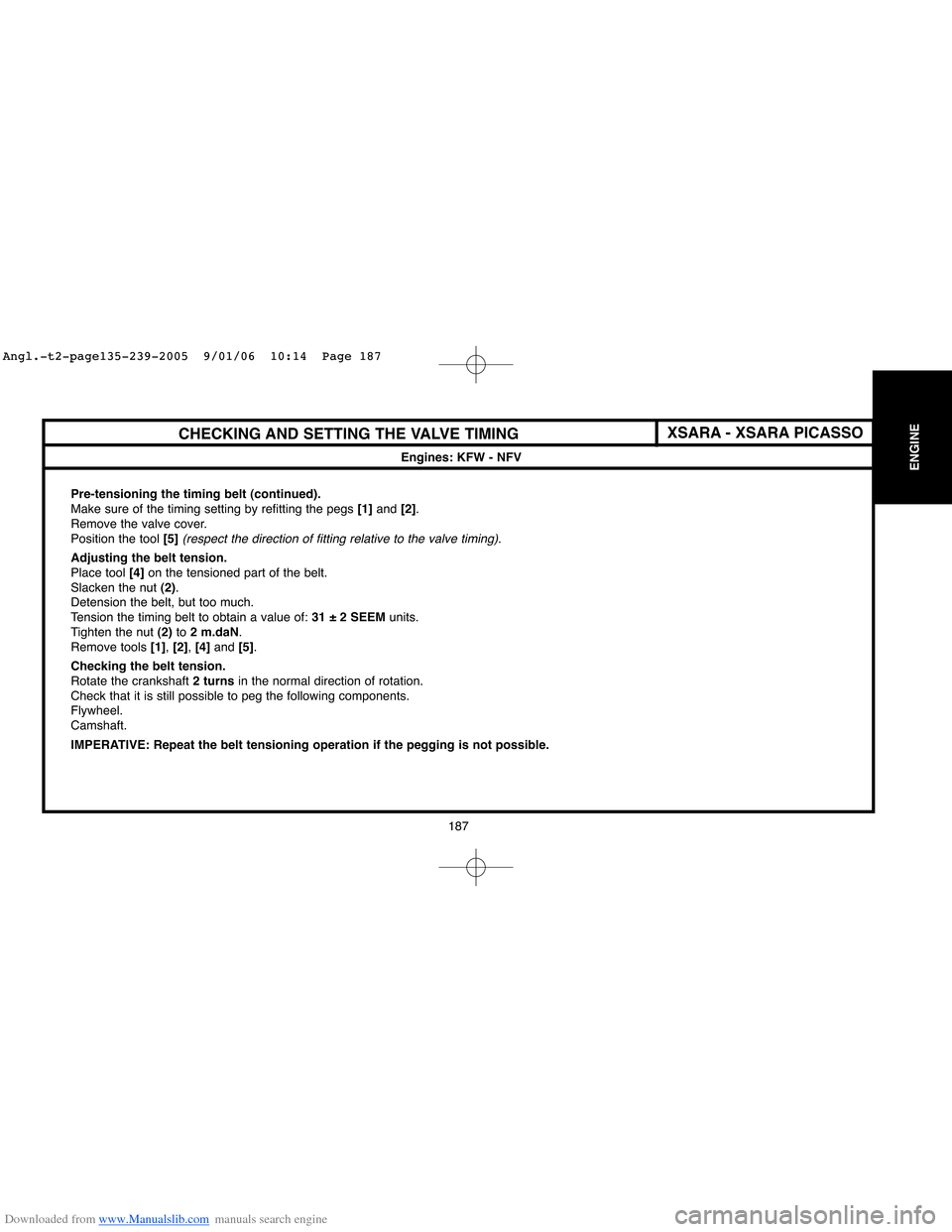

Pre-tensioning the timing belt (continued).

Make sure of the timing setting by refitting the pegs [1]and [2].

Remove the valve cover.

Position the tool [5]

(respect the direction of fitting relative to the valve timing).

Adjusting the belt tension.

Place tool [4]on the tensioned part of the belt.

Slacken the nut (2).

Detension the belt, but too much.

Tension the timing belt to obtain a value of: 31 ± 2 SEEMunits.

Tighten the nut (2)to 2 m.daN.

Remove tools [1], [2], [4] and [5].

Checking the belt tension.

Rotate the crankshaft 2 turnsin the normal direction of rotation.

Check that it is still possible to peg the following components.

Flywheel.

Camshaft.

IMPERATIVE: Repeat the belt tensioning operation if the pegging is not possible.

XSARA - XSARA PICASSO

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 187

Page 194 of 462

![Citroen XSARA PICASSO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 188

ENGINECHECKING THE VALVE TIMING

Engine: KFU

Tools.

[1] Flywheel setting peg: 4507-TA. Toolkit 4507-T

[2] Camshaft setting peg: 4533-TA.C1

[ Citroen XSARA PICASSO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 188

ENGINECHECKING THE VALVE TIMING

Engine: KFU

Tools.

[1] Flywheel setting peg: 4507-TA. Toolkit 4507-T

[2] Camshaft setting peg: 4533-TA.C1

[](/img/9/4138/w960_4138-193.png)

Downloaded from www.Manualslib.com manuals search engine 188

ENGINECHECKING THE VALVE TIMING

Engine: KFU

Tools.

[1] Flywheel setting peg: 4507-TA. Toolkit 4507-T

[2] Camshaft setting peg: 4533-TA.C1

[3] Camshaft setting peg: (-).0194.A

IMPERATIVE: Respect the safety and cleanliness requirements.

Checking.

Deconnect the battery.

Remove:

- The engine cover.

- The upper timing cover (1).

- The oil filter (2).

Remove the sparking plugs to facilitate rotation of the engine.

Turn the engine by means of the crankshaft screw.

IMPERATIVE: Never turn the engine backwards.

Suspend the engine.

Remove:

- The screws (3), the upper RH engine support (4)and the screws (5).

B1BP37JC

B1BP37KC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 188

Page 197 of 462

Downloaded from www.Manualslib.com manuals search engine 191

ENGINE

191

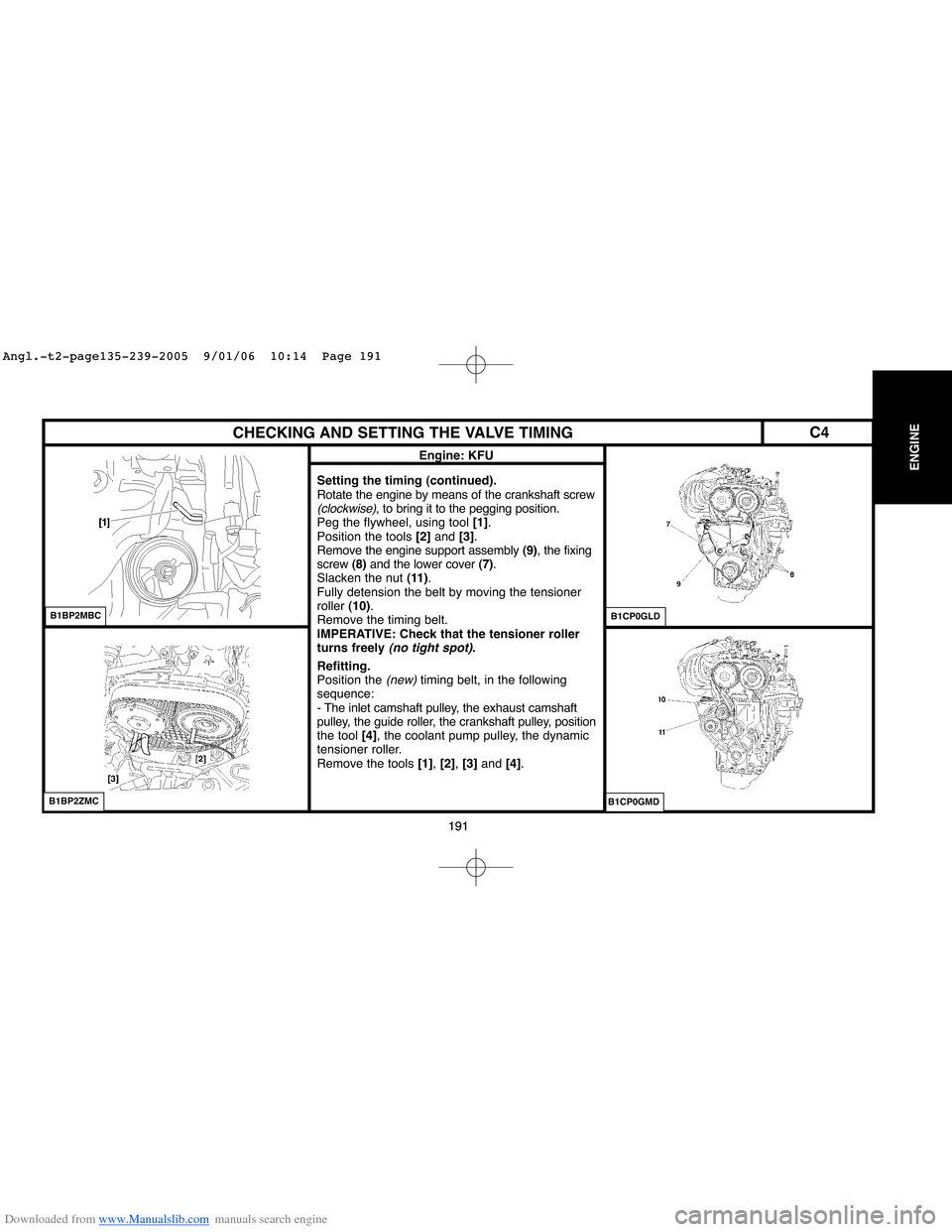

CHECKING AND SETTING THE VALVE TIMING

Engine: KFU

Setting the timing (continued).

Rotate the engine by means of the crankshaft screw

(clockwise), to bring it to the pegging position.

Peg the flywheel, using tool [1].

Position the tools [2]and [3].

Remove the engine support assembly (9), the fixing

screw (8)and the lower cover (7).

Slacken the nut (11).

Fully detension the belt by moving the tensioner

roller (10).

Remove the timing belt.

IMPERATIVE: Check that the tensioner roller

turns freely

(no tight spot).

Refitting.

Position the

(new)timing belt, in the following

sequence:

- The inlet camshaft pulley, the exhaust camshaft

pulley, the guide roller, the crankshaft pulley, position

the tool [4], the coolant pump pulley, the dynamic

tensioner roller.

Remove the tools [1], [2], [3]and [4].

B1BP2MBC

B1BP2ZMC

B1CP0GLD

B1CP0GMD

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 191

Page 198 of 462

Downloaded from www.Manualslib.com manuals search engine 192

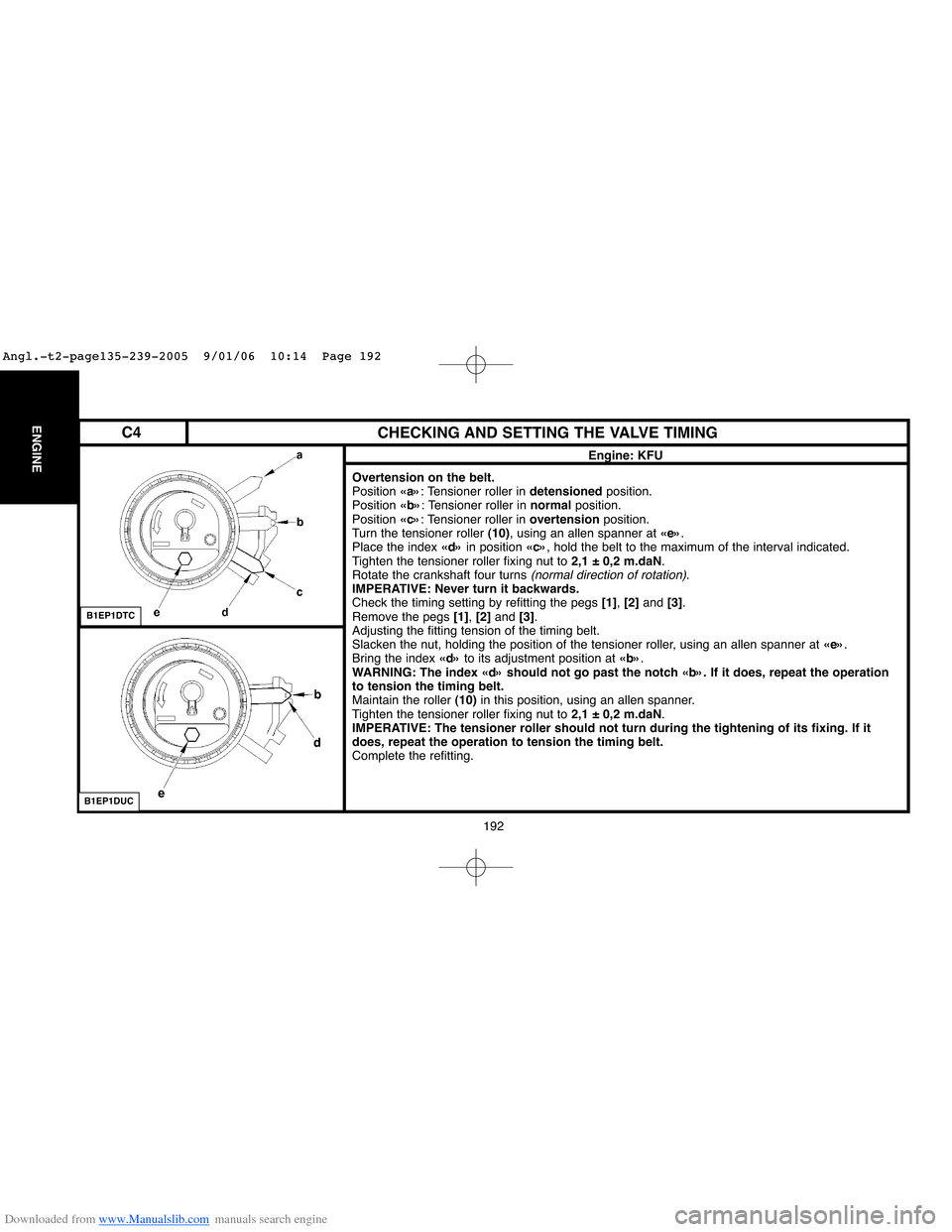

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: KFU

Overtension on the belt.

Position «a»: Tensioner roller in detensionedposition.

Position «b»: Tensioner roller in normalposition.

Position «c»: Tensioner roller in overtensionposition.

Turn the tensioner roller (10), using an allen spanner at «e».

Place the index «d»in position «c», hold the belt to the maximum of the interval indicated.

Tighten the tensioner roller fixing nut to 2,1 ± 0,2 m.daN.

Rotate the crankshaft four turns

(normal direction of rotation).

IMPERATIVE: Never turn it backwards.

Check the timing setting by refitting the pegs [1], [2] and [3].

Remove the pegs [1], [2]and [3].

Adjusting the fitting tension of the timing belt.

Slacken the nut, holding the position of the tensioner roller, using an allen spanner at «e».

Bring the index «d»to its adjustment position at «b».

WARNING: The index «d» should not go past the notch «b». If it does, repeat the operation

to tension the timing belt.

Maintain the roller (10)in this position, using an allen spanner.

Tighten the tensioner roller fixing nut to 2,1 ± 0,2 m.daN.

IMPERATIVE: The tensioner roller should not turn during the tightening of its fixing. If it

does, repeat the operation to tension the timing belt.

Complete the refitting.

B1EP1DTC

B1EP1DUC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 192

Page 201 of 462

Downloaded from www.Manualslib.com manuals search engine 195

ENGINE

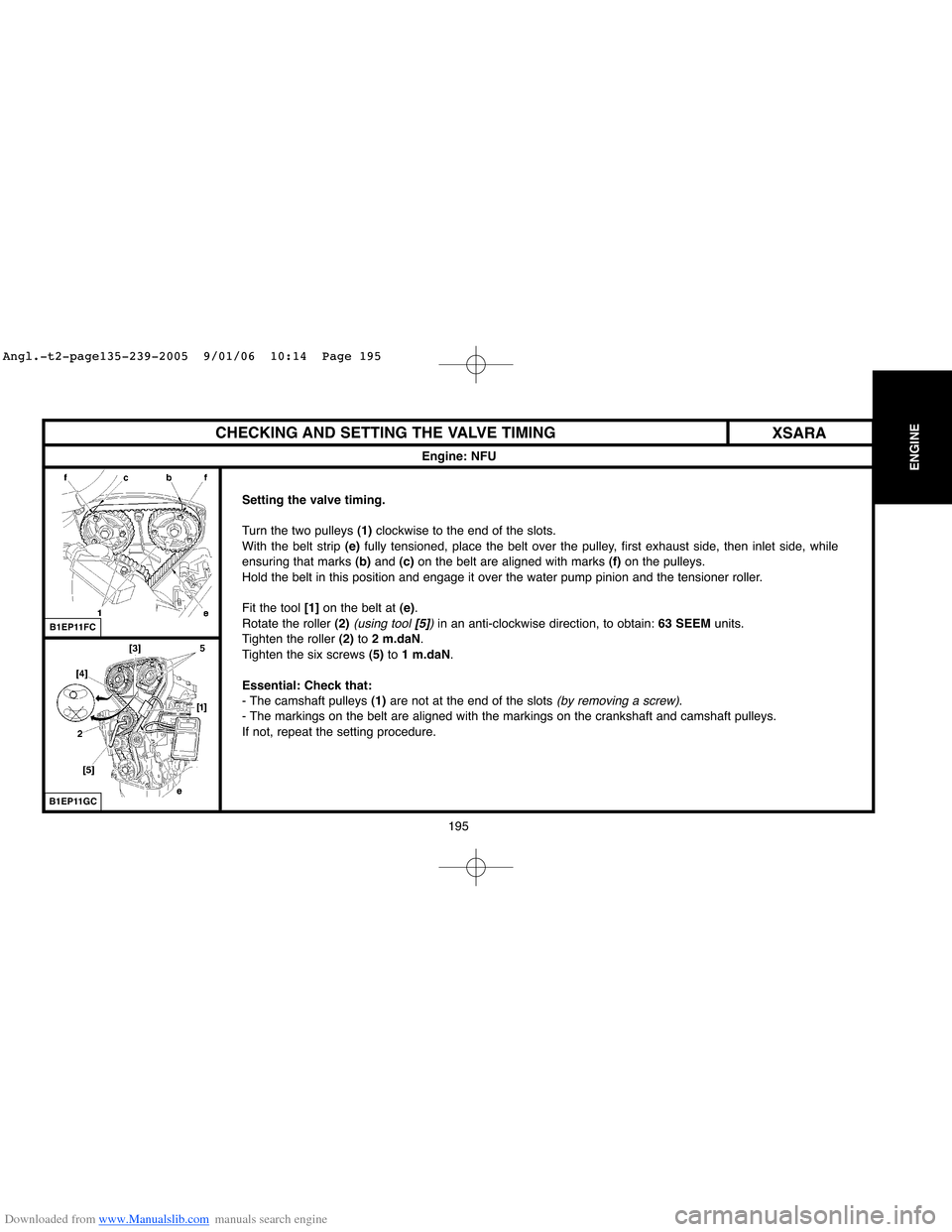

CHECKING AND SETTING THE VALVE TIMING

Engine: NFU

Setting the valve timing.

Turn the two pulleys (1)clockwise to the end of the slots.

With the belt strip (e)fully tensioned, place the belt over the pulley, first exhaust side, then inlet side, while

ensuring that marks (b)and (c)on the belt are aligned with marks (f)on the pulleys.

Hold the belt in this position and engage it over the water pump pinion and the tensioner roller.

Fit the tool [1] on the belt at (e).

Rotate the roller (2)

(using tool [5])in an anti-clockwise direction, to obtain: 63 SEEMunits.

Tighten the roller (2)to 2 m.daN.

Tighten the six screws (5)to 1 m.daN.

Essential: Check that:

- The camshaft pulleys (1)are not at the end of the slots

(by removing a screw).

- The markings on the belt are aligned with the markings on the crankshaft and camshaft pulleys.

If not, repeat the setting procedure.

B1EP11GC

B1EP11FC

XSARA

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 195