Turn Citroen XSARA PICASSO 2005 1.G Service Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: XSARA PICASSO, Model: Citroen XSARA PICASSO 2005 1.GPages: 462, PDF Size: 10.48 MB

Page 234 of 462

Downloaded from www.Manualslib.com manuals search engine 228

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Checking and setting the timing (continued).

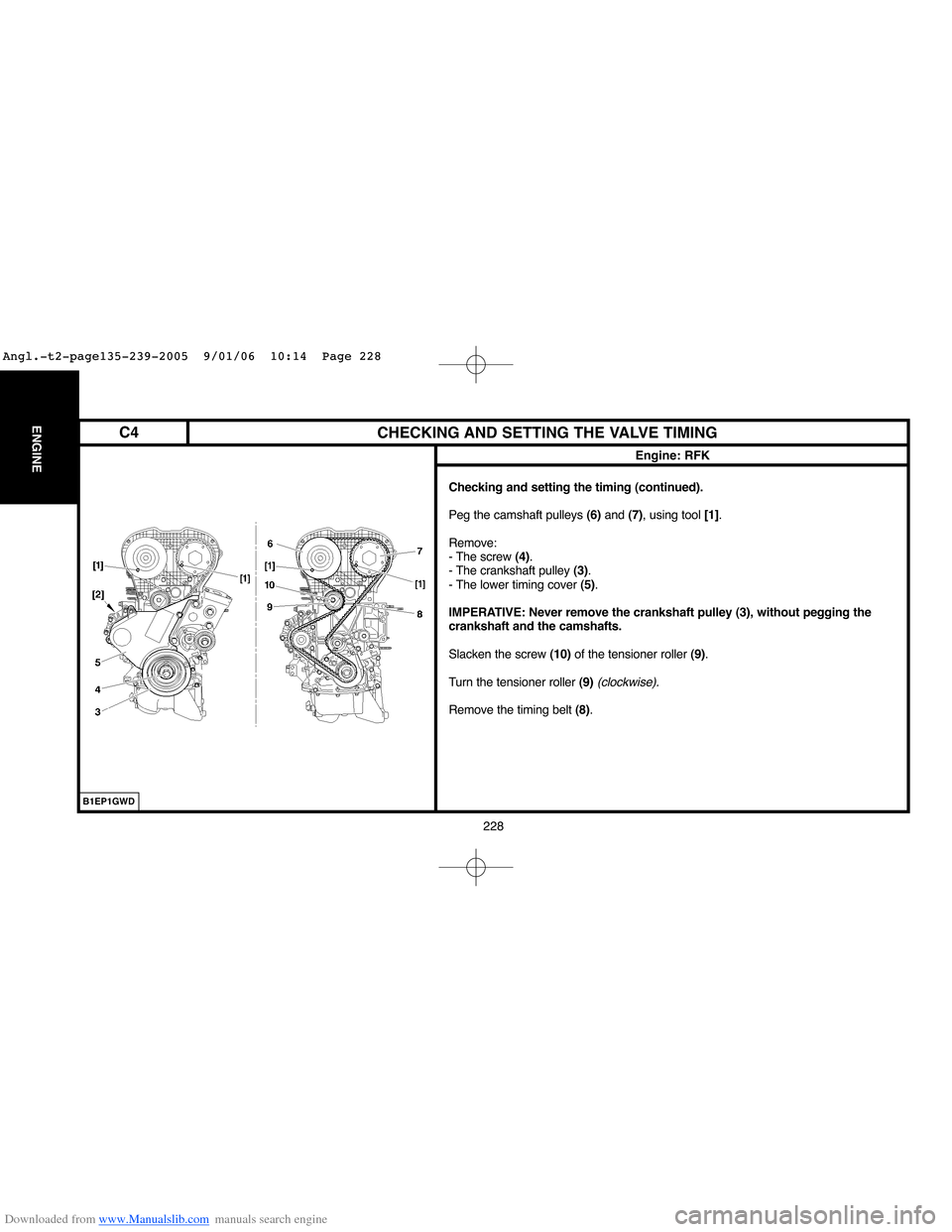

Peg the camshaft pulleys (6)and (7), using tool [1].

Remove:

- The screw (4).

- The crankshaft pulley (3).

- The lower timing cover (5).

IMPERATIVE: Never remove the crankshaft pulley (3), without pegging the

crankshaft and the camshafts.

Slacken the screw (10)of the tensioner roller (9).

Turn the tensioner roller (9)

(clockwise).

Remove the timing belt (8).

B1EP1GWD

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 228

Page 235 of 462

Downloaded from www.Manualslib.com manuals search engine 229

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Checking and setting the timing (continued).

Refitting.

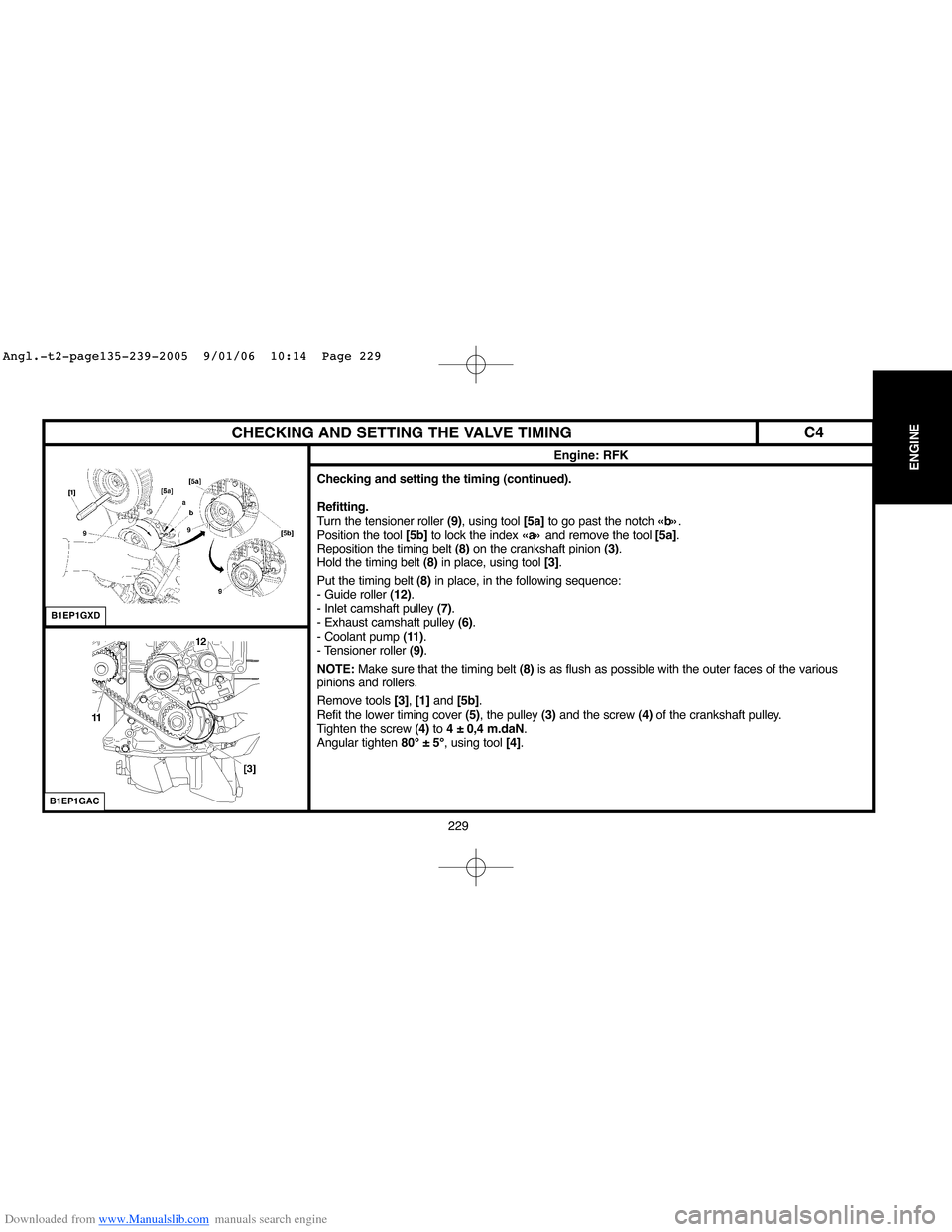

Turn the tensioner roller (9), using tool [5a]to go past the notch «b».

Position the tool [5b]to lock the index «a»and remove the tool [5a].

Reposition the timing belt (8)on the crankshaft pinion (3).

Hold the timing belt (8)in place, using tool [3].

Put the timing belt (8)in place, in the following sequence:

- Guide roller (12).

- Inlet camshaft pulley (7).

- Exhaust camshaft pulley (6).

- Coolant pump (11).

- Tensioner roller (9).

NOTE:Make sure that the timing belt (8)is as flush as possible with the outer faces of the various

pinions and rollers.

Remove tools [3], [1]and [5b].

Refit the lower timing cover (5), the pulley (3)and the screw (4)of the crankshaft pulley.

Tighten the screw (4)to 4 ± 0,4 m.daN.

Angular tighten 80° ± 5°, using tool [4].

B1EP1GXD

B1EP1GAC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 229

Page 236 of 462

Downloaded from www.Manualslib.com manuals search engine 230

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RFK

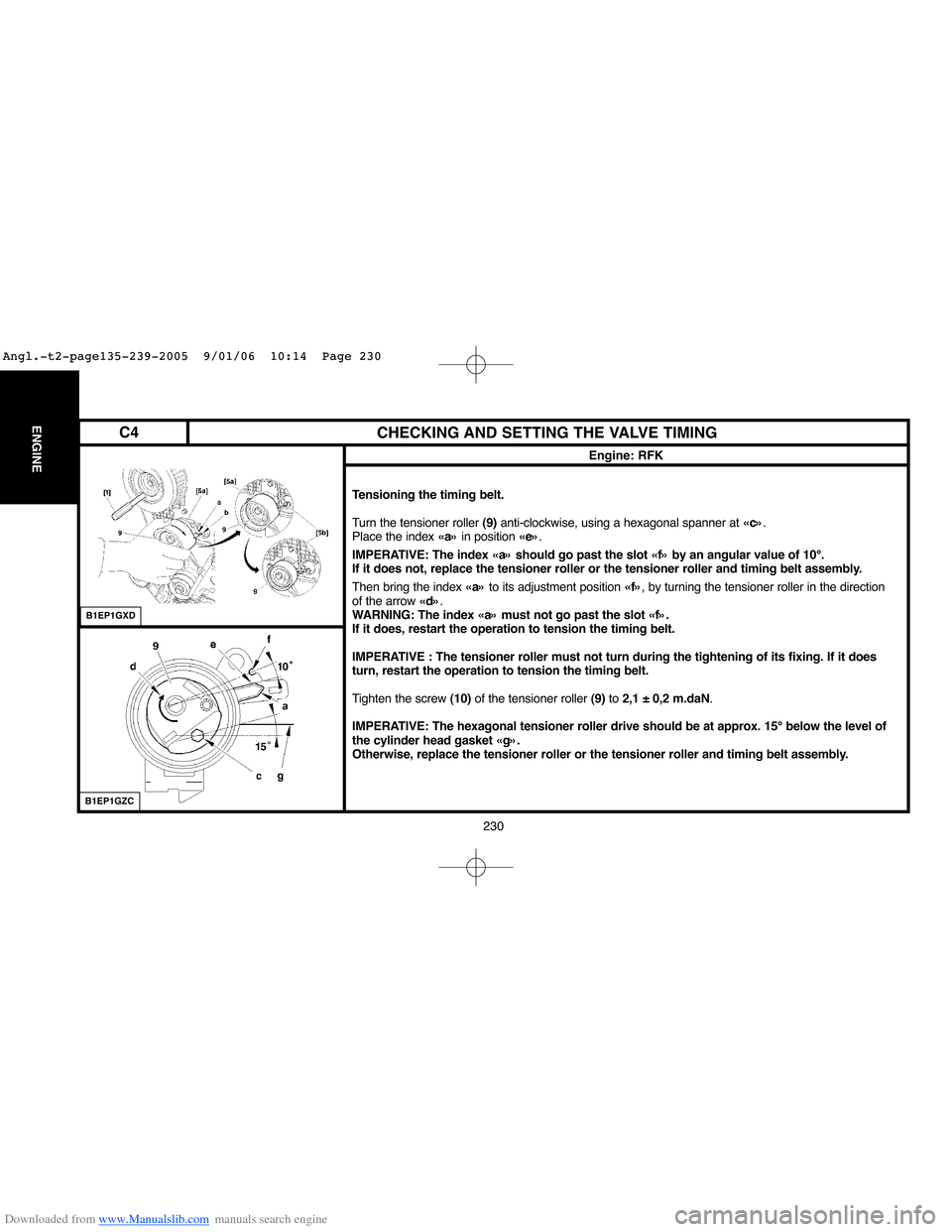

Tensioning the timing belt.

Turn the tensioner roller (9)anti-clockwise, using a hexagonal spanner at «c».

Place the index «a»in position «e».

IMPERATIVE: The index «a» should go past the slot «f» by an angular value of 10°.

If it does not, replace the tensioner roller or the tensioner roller and timing belt assembly.

Then bring the index «a»to its adjustment position «f», by turning the tensioner roller in the direction

of the arrow «d».

WARNING: The index «a» must not go past the slot «f».

If it does, restart the operation to tension the timing belt.

IMPERATIVE : The tensioner roller must not turn during the tightening of its fixing. If it does

turn, restart the operation to tension the timing belt.

Tighten the screw (10)of the tensioner roller (9)to 2,1 ± 0,2 m.daN.

IMPERATIVE: The hexagonal tensioner roller drive should be at approx. 15° below the level of

the cylinder head gasket «g».

Otherwise, replace the tensioner roller or the tensioner roller and timing belt assembly.

B1EP1GXD

B1EP1GZC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 230

Page 242 of 462

Downloaded from www.Manualslib.com manuals search engine 236

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 8HX - 8HZ

B1EP18HC

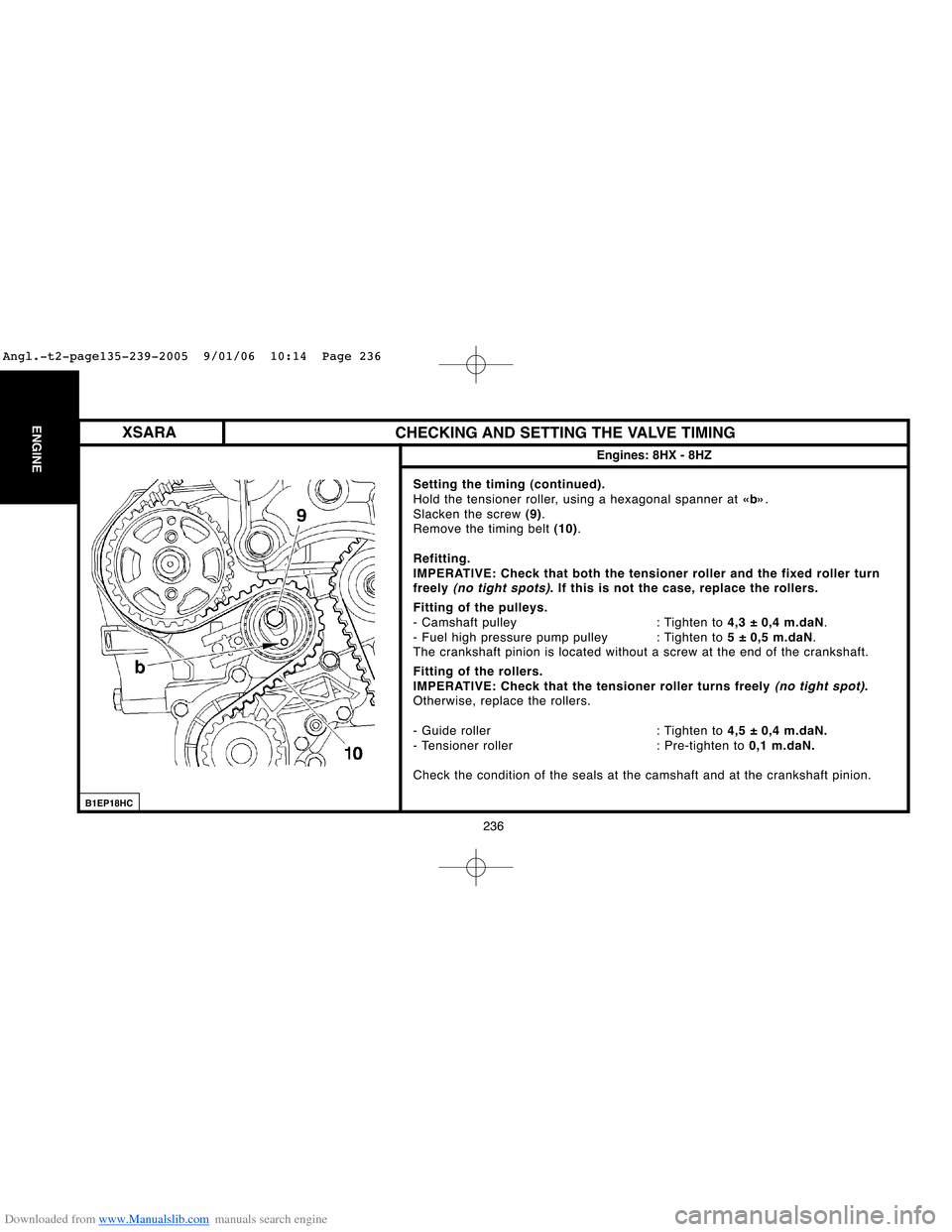

Setting the timing (continued).

Hold the tensioner roller, using a hexagonal spanner at «b».

Slacken the screw (9).

Remove the timing belt (10).

Refitting.

IMPERATIVE: Check that both the tensioner roller and the fixed roller turn

freely

(no tight spots). If this is not the case, replace the rollers.

Fitting of the pulleys.

- Camshaft pulley : Tighten to 4,3 ± 0,4 m.daN.

- Fuel high pressure pump pulley : Tighten to 5 ± 0,5 m.daN.

The crankshaft pinion is located without a screw at the end of the crankshaft.

Fitting of the rollers.

IMPERATIVE: Check that the tensioner roller turns freely

(no tight spot).

Otherwise, replace the rollers.

- Guide roller : Tighten to 4,5 ± 0,4 m.daN.

- Tensioner roller : Pre-tighten to 0,1 m.daN.

Check the condition of the seals at the camshaft and at the crankshaft pinion.

XSARA

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 236

Page 244 of 462

Downloaded from www.Manualslib.com manuals search engine 238

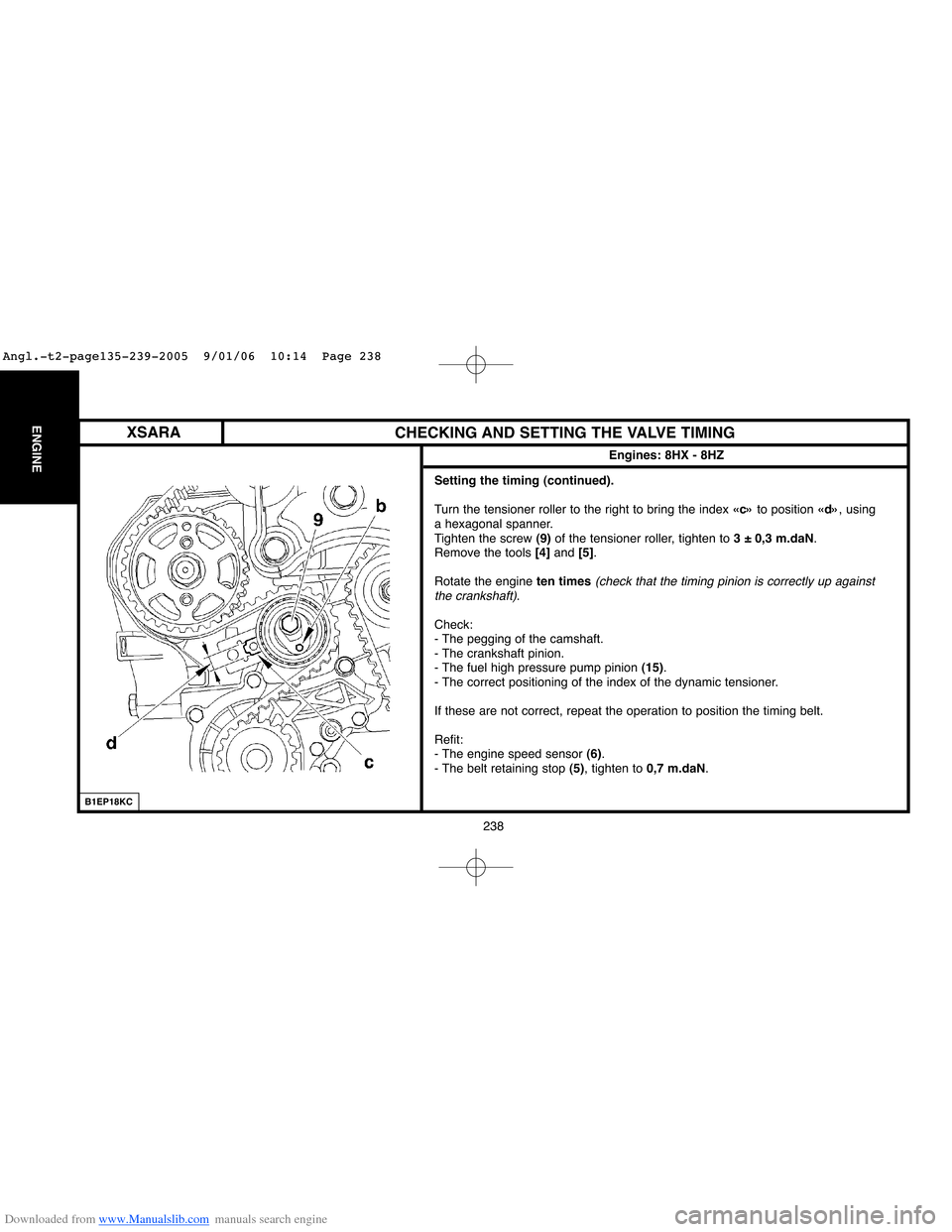

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 8HX - 8HZ

B1EP18KC

Setting the timing (continued).

Turn the tensioner roller to the right to bring the index «c»to position «d», using

a hexagonal spanner.

Tighten the screw (9)of the tensioner roller, tighten to 3 ± 0,3 m.daN.

Remove the tools [4]and [5].

Rotate the engine ten times

(check that the timing pinion is correctly up against

the crankshaft).

Check:

- The pegging of the camshaft.

- The crankshaft pinion.

- The fuel high pressure pump pinion (15).

- The correct positioning of the index of the dynamic tensioner.

If these are not correct, repeat the operation to position the timing belt.

Refit:

- The engine speed sensor (6).

- The belt retaining stop (5), tighten to 0,7 m.daN.

XSARA

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 238

Page 247 of 462

![Citroen XSARA PICASSO 2005 1.G Service Manual Downloaded from www.Manualslib.com manuals search engine 241

ENGINE

CHECKING THE VALVE TIMING

Engines: 9HX - 9HY - 9HZ

Turn the engine in the normal direction of rotation until the peg [1]engages in t Citroen XSARA PICASSO 2005 1.G Service Manual Downloaded from www.Manualslib.com manuals search engine 241

ENGINE

CHECKING THE VALVE TIMING

Engines: 9HX - 9HY - 9HZ

Turn the engine in the normal direction of rotation until the peg [1]engages in t](/img/9/4138/w960_4138-246.png)

Downloaded from www.Manualslib.com manuals search engine 241

ENGINE

CHECKING THE VALVE TIMING

Engines: 9HX - 9HY - 9HZ

Turn the engine in the normal direction of rotation until the peg [1]engages in the setting hole.

Peg the flywheel at «b», using tool [1].

Move aside the electrical harness (6).

Remove:

- The engine support (7).

- The screw (8).

- The accessories drive pulley (9).

- The lower timing cover (10).

- The upper timing cover (11).

- The tool [1].

Refit the screw (8).

Rotate the crankshaft six times

(clockwise).

IMPERATIVE: Never turn it backwards.

B1BP305C

B1EP1HJD

C4

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 241

Page 250 of 462

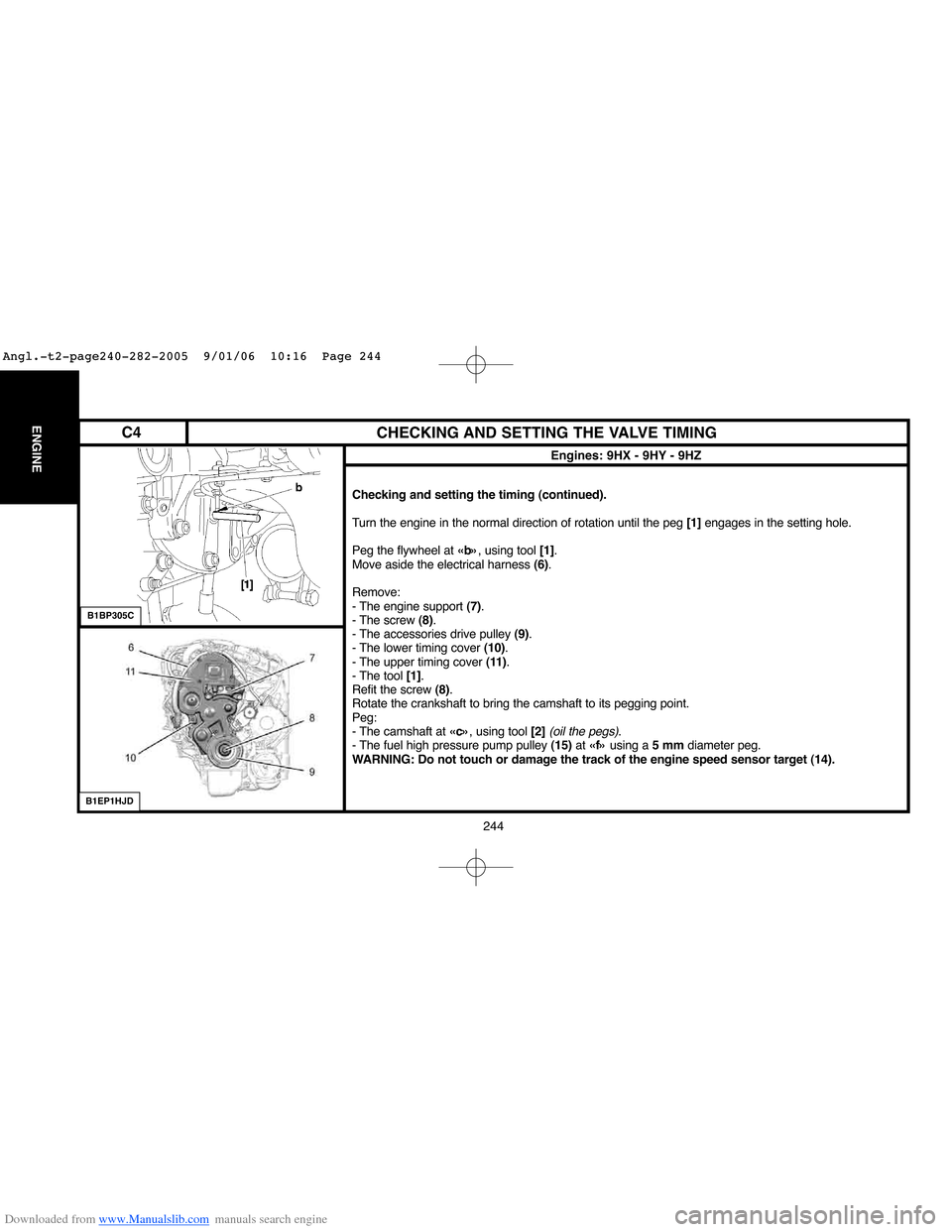

Downloaded from www.Manualslib.com manuals search engine 244

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 9HX - 9HY - 9HZ

Checking and setting the timing (continued).

Turn the engine in the normal direction of rotation until the peg [1]engages in the setting hole.

Peg the flywheel at «b», using tool [1].

Move aside the electrical harness (6).

Remove:

- The engine support (7).

- The screw (8).

- The accessories drive pulley (9).

- The lower timing cover (10).

- The upper timing cover (11).

- The tool [1].

Refit the screw (8).

Rotate the crankshaft to bring the camshaft to its pegging point.

Peg:

- The camshaft at «c», using tool [2]

(oil the pegs).

- The fuel high pressure pump pulley (15)at «f»using a 5 mmdiameter peg.

WARNING: Do not touch or damage the track of the engine speed sensor target (14).

B1BP305C

B1EP1HJD

C4

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 244

Page 251 of 462

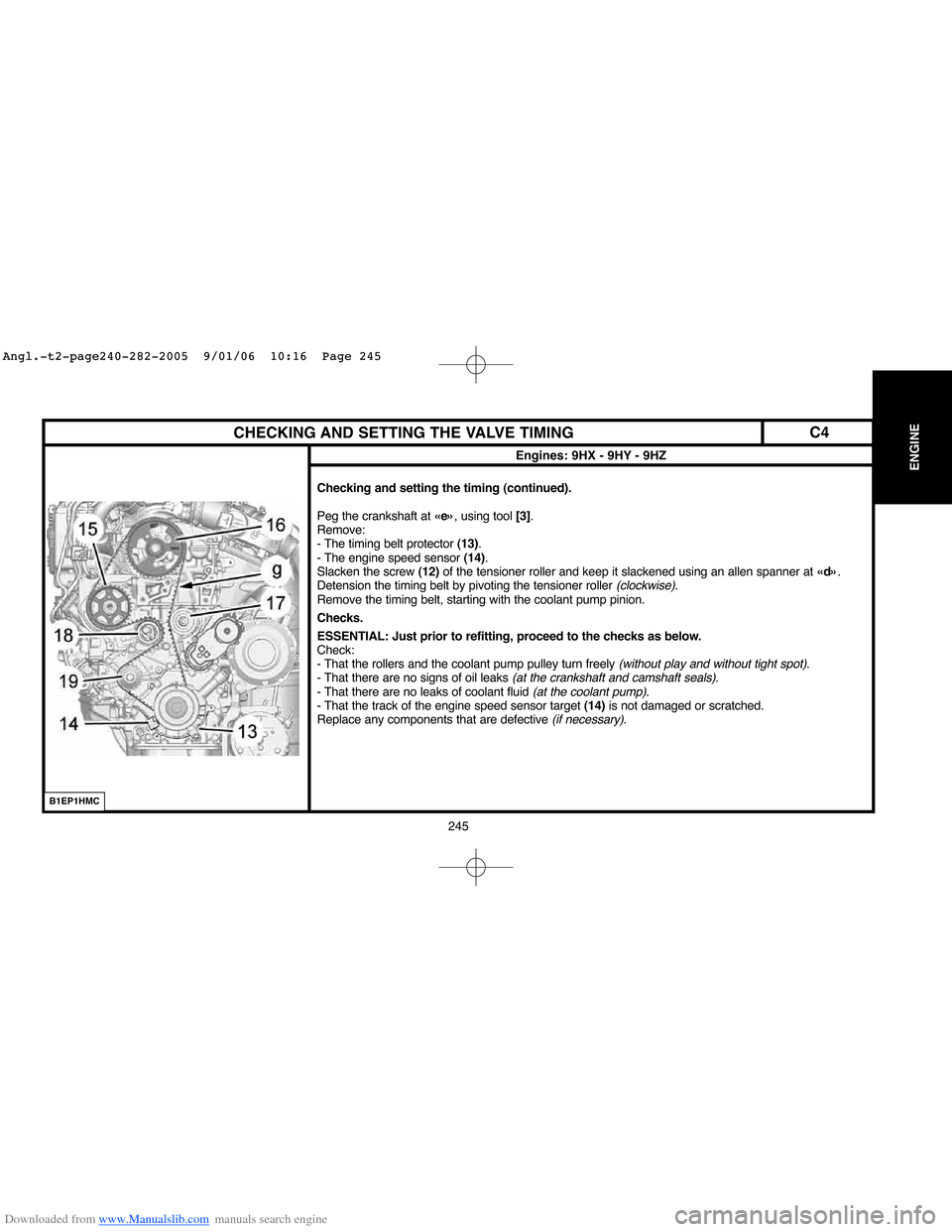

Downloaded from www.Manualslib.com manuals search engine 245

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engines: 9HX - 9HY - 9HZ

Checking and setting the timing (continued).

Peg the crankshaft at «e», using tool [3].

Remove:

- The timing belt protector (13).

- The engine speed sensor (14).

Slacken the screw (12)of the tensioner roller and keep it slackened using an allen spanner at «d».

Detension the timing belt by pivoting the tensioner roller

(clockwise).

Remove the timing belt, starting with the coolant pump pinion.

Checks.

ESSENTIAL: Just prior to refitting, proceed to the checks as below.

Check:

- That the rollers and the coolant pump pulley turn freely

(without play and without tight spot).

- That there are no signs of oil leaks (at the crankshaft and camshaft seals).

- That there are no leaks of coolant fluid (at the coolant pump).

- That the track of the engine speed sensor target (14)is not damaged or scratched.

Replace any components that are defective

(if necessary).

B1EP1HMC

C4

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 245

Page 257 of 462

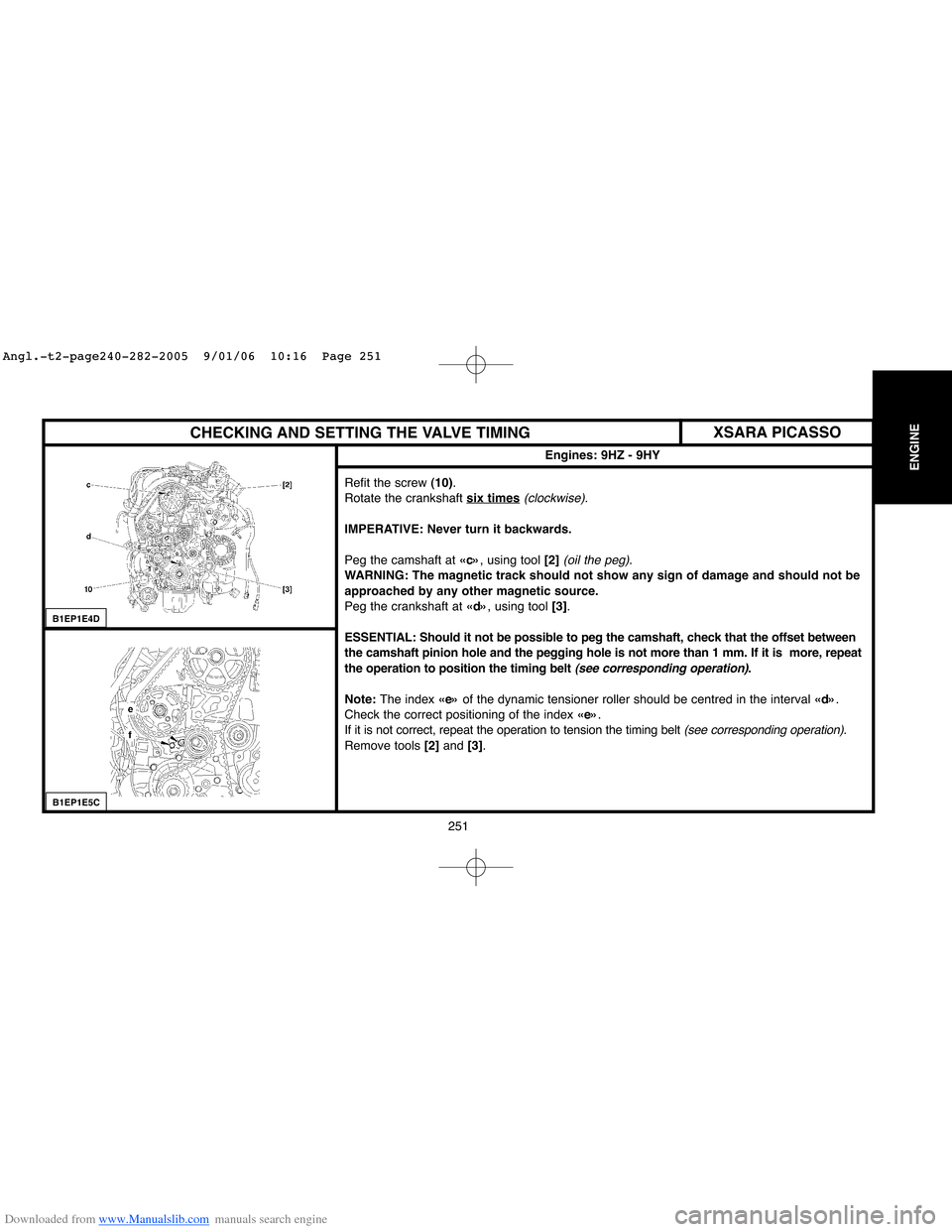

Downloaded from www.Manualslib.com manuals search engine 251

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

Refit the screw (10).

Rotate the crankshaft six times

(clockwise).

IMPERATIVE: Never turn it backwards.

Peg the camshaft at «c», using tool [2]

(oil the peg).

WARNING: The magnetic track should not show any sign of damage and should not be

approached by any other magnetic source.

Peg the crankshaft at «d», using tool [3].

ESSENTIAL: Should it not be possible to peg the camshaft, check that the offset between

the camshaft pinion hole and the pegging hole is not more than 1 mm. If it is more, repeat

the operation to position the timing belt

(see corresponding operation).

Note: The index «e»of the dynamic tensioner roller should be centred in the interval «d».

Check the correct positioning of the index «e».

If it is not correct, repeat the operation to tension the timing belt

(see corresponding operation).

Remove tools [2] and [3].

B1EP1E4D

B1EP1E5C

XSARA PICASSO

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 251

Page 261 of 462

Downloaded from www.Manualslib.com manuals search engine 255

ENGINE

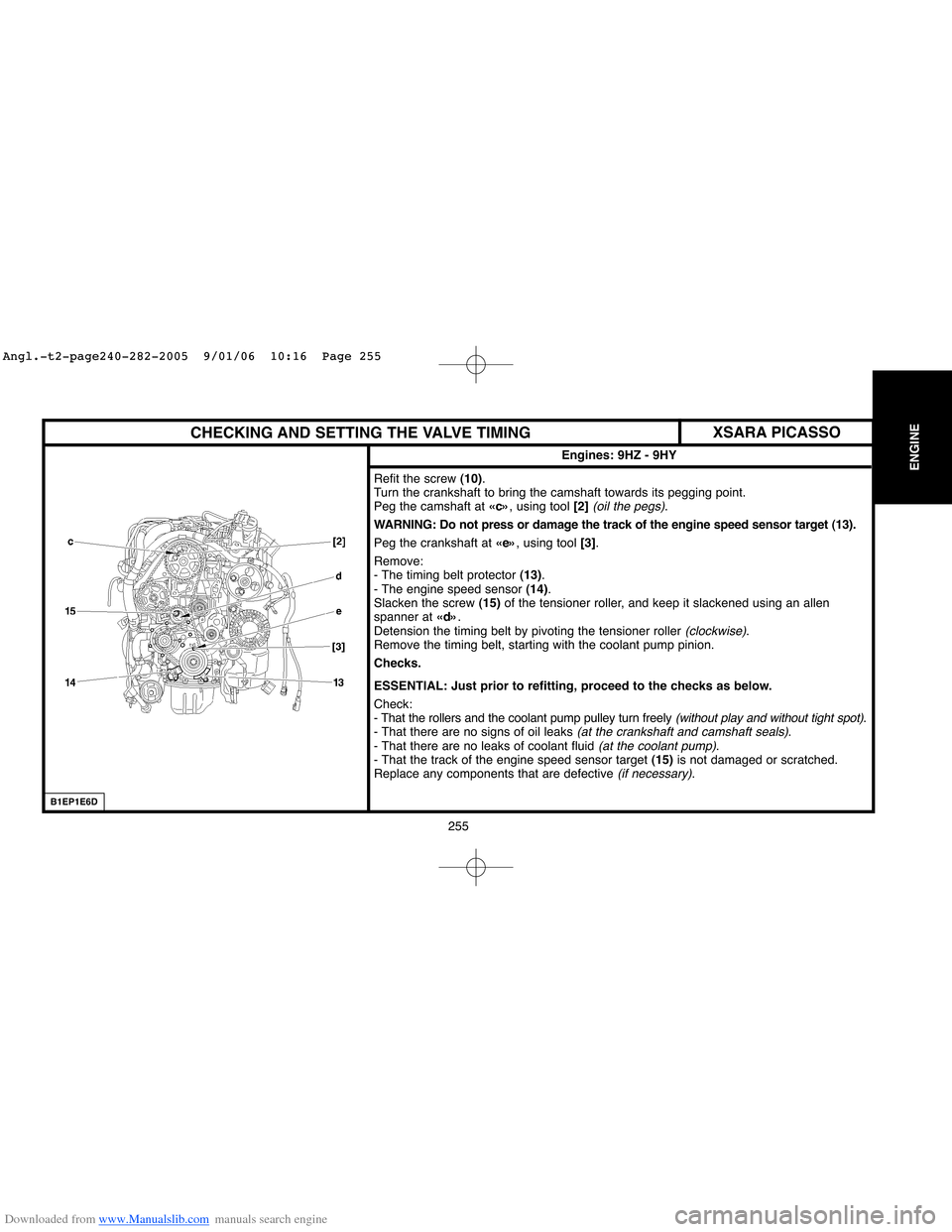

CHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

B1EP1E6D

Refit the screw (10).

Turn the crankshaft to bring the camshaft towards its pegging point.

Peg the camshaft at «c», using tool [2]

(oil the pegs).

WARNING: Do not press or damage the track of the engine speed sensor target (13).

Peg the crankshaft at «e», using tool [3].

Remove:

- The timing belt protector (13).

- The engine speed sensor (14).

Slacken the screw (15)of the tensioner roller, and keep it slackened using an allen

spanner at «d».

Detension the timing belt by pivoting the tensioner roller

(clockwise).

Remove the timing belt, starting with the coolant pump pinion.

Checks.

ESSENTIAL: Just prior to refitting, proceed to the checks as below.

Check:

- That the rollers and the coolant pump pulley turn freely

(without play and without tight spot).

- That there are no signs of oil leaks (at the crankshaft and camshaft seals).

- That there are no leaks of coolant fluid (at the coolant pump).

- That the track of the engine speed sensor target (15)is not damaged or scratched.

Replace any components that are defective

(if necessary).

XSARA PICASSO

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 255