plug Citroen XSARA PICASSO 2005 1.G Service Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: XSARA PICASSO, Model: Citroen XSARA PICASSO 2005 1.GPages: 462, PDF Size: 10.48 MB

Page 353 of 462

Downloaded from www.Manualslib.com manuals search engine 347

CLUTCH

GEARBOX

TRANSMISSION

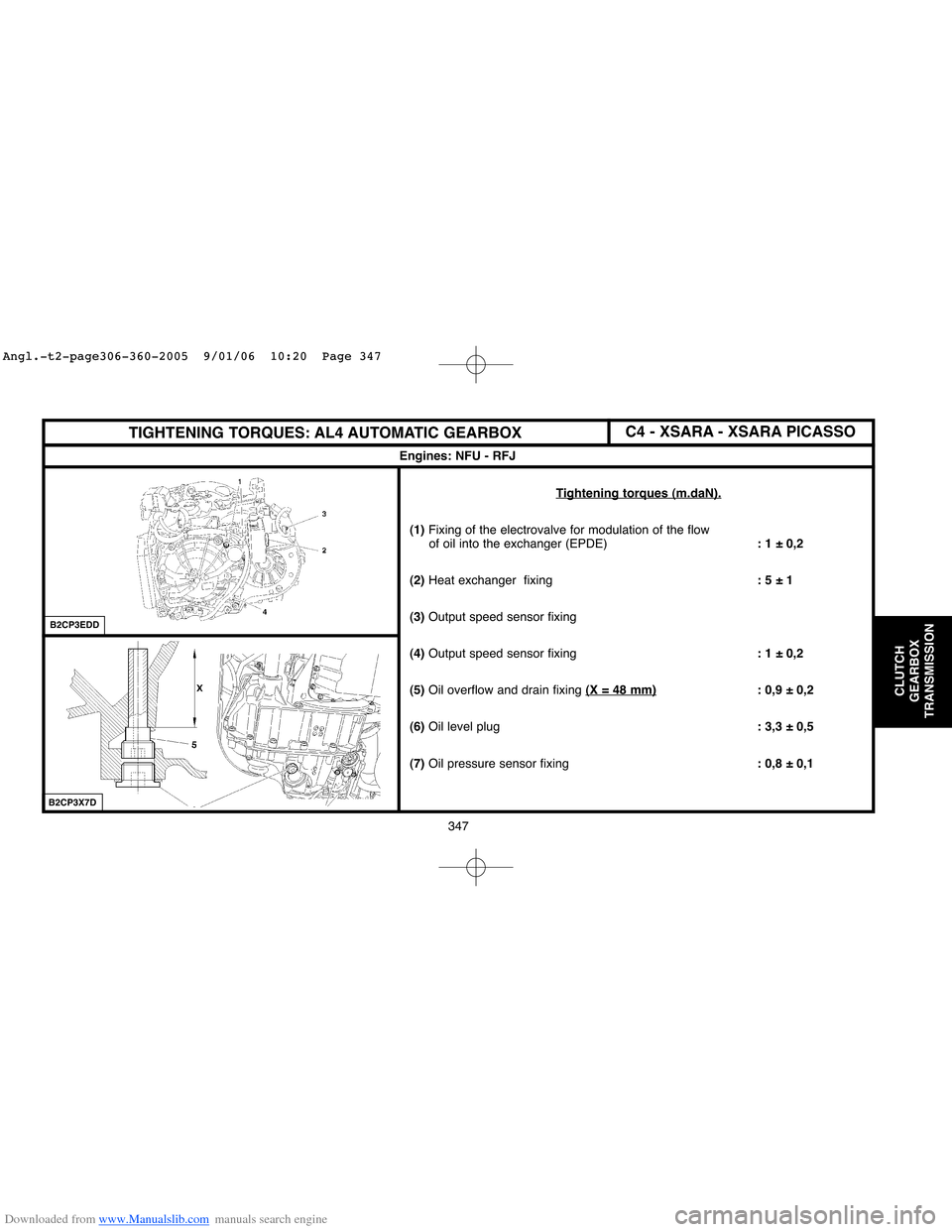

TIGHTENING TORQUES: AL4 AUTOMATIC GEARBOX

Engines: NFU - RFJ

B2CP3EDD

B2CP3X7D

Tightening torques (m.daN).

(1) Fixing of the electrovalve for modulation of the flow

of oil into the exchanger (EPDE): 1 ± 0,2

(2)Heat exchanger fixing: 5 ± 1

(3) Output speed sensor fixing

(4)Output speed sensor fixing: 1 ± 0,2

(5)Oil overflow and drain fixing(X = 48 mm)

: 0,9 ± 0,2

(6)Oil level plug: 3,3 ± 0,5

(7)Oil pressure sensor fixing: 0,8 ± 0,1

C4 - XSARA - XSARA PICASSO

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 347

Page 354 of 462

Downloaded from www.Manualslib.com manuals search engine 348

CLUTCH

GEARBOX

TRANSMISSION

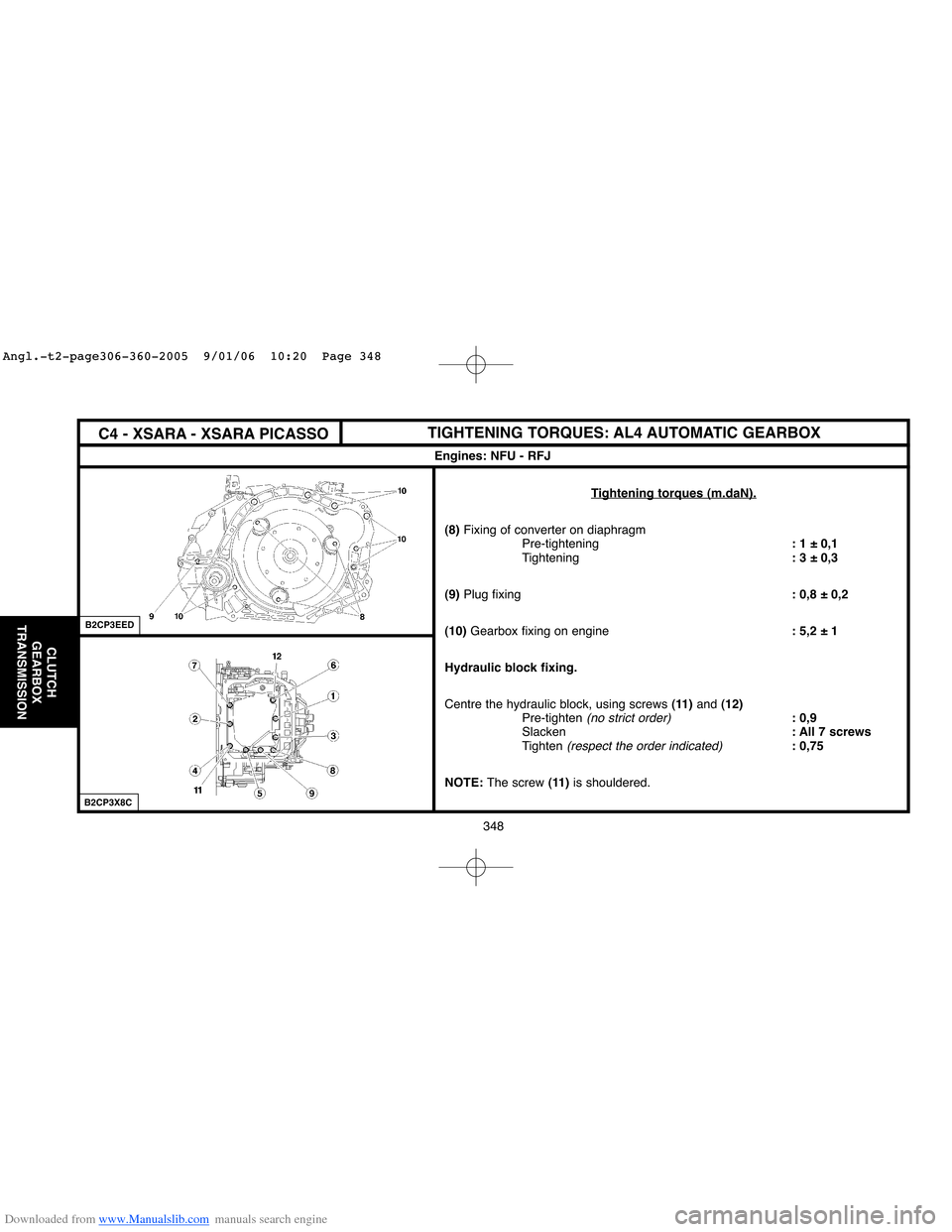

C4 - XSARA - XSARA PICASSOTIGHTENING TORQUES: AL4 AUTOMATIC GEARBOX

Engines: NFU - RFJ

B2CP3EED

B2CP3X8C

Tightening torques (m.daN).

(8) Fixing of converter on diaphragm

Pre-tightening: 1 ± 0,1

Tightening: 3 ± 0,3

(9)Plug fixing: 0,8 ± 0,2

(10)Gearbox fixing on engine: 5,2 ± 1

Hydraulic block fixing.

Centre the hydraulic block, using screws (11) and (12)

Pre-tighten

(no strict order): 0,9

Slacken: All 7 screws

Tighten

(respect the order indicated): 0,75

NOTE: The screw (11)is shouldered.

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 348

Page 355 of 462

Downloaded from www.Manualslib.com manuals search engine 349

CLUTCH

GEARBOX

TRANSMISSION

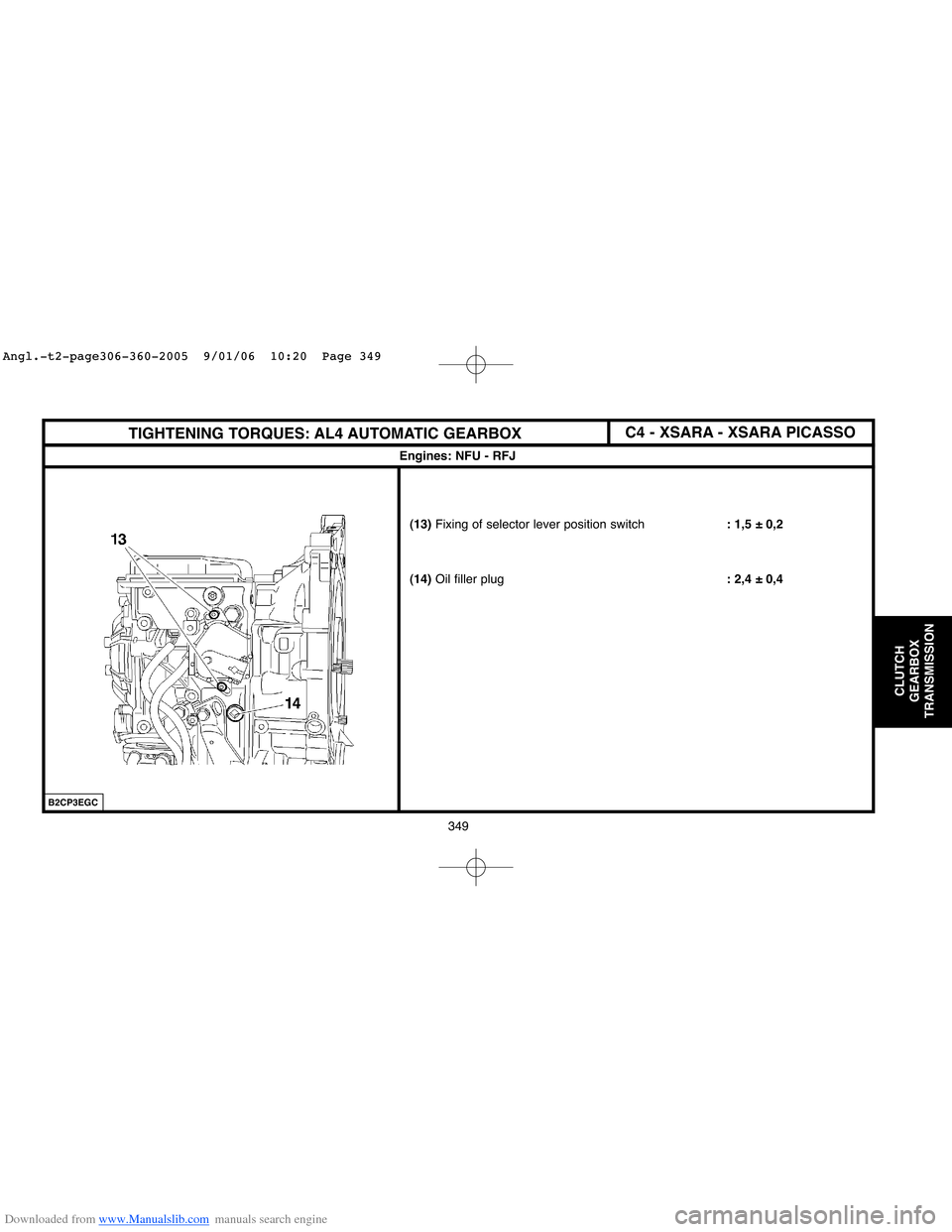

Engines: NFU - RFJ

B2CP3EGC

(13)Fixing of selector lever position switch: 1,5 ± 0,2

(14)Oil filler plug: 2,4 ± 0,4

TIGHTENING TORQUES: AL4 AUTOMATIC GEARBOXC4 - XSARA - XSARA PICASSO

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 349

Page 377 of 462

![Citroen XSARA PICASSO 2005 1.G Service Manual Downloaded from www.Manualslib.com manuals search engine 371

AXLES

SUSPENSION

STEERING

C4CHECKING THE POWER STEERING ASSISTANCE PRESSURE

Tools.

[1]Pressure gauge: (-).0710.AZ

[2]Checking tube: press Citroen XSARA PICASSO 2005 1.G Service Manual Downloaded from www.Manualslib.com manuals search engine 371

AXLES

SUSPENSION

STEERING

C4CHECKING THE POWER STEERING ASSISTANCE PRESSURE

Tools.

[1]Pressure gauge: (-).0710.AZ

[2]Checking tube: press](/img/9/4138/w960_4138-376.png)

Downloaded from www.Manualslib.com manuals search engine 371

AXLES

SUSPENSION

STEERING

C4CHECKING THE POWER STEERING ASSISTANCE PRESSURE

Tools.

[1]Pressure gauge: (-).0710.AZ

[2]Checking tube: pressure gauge to tap: (-).0710.B1

[3]Checking tube: high pressure pipe to tap: (-).0710.B2

[4]Checking tube: high pressure pump to tap: (-).0710.B3

[5]3-way tap: (-).0710.C

[6]Union: (-).0710.J

[7]Union: (-).0710.K

[8] Plugs for checking valve sealing: (-).0710.H

Precautions to be taken.

Work with care to avoid entry of polluting particles into the circuit.

NOTE:The correct operation of the system requires perfect cleanliness of the fluid and of the

hydraulic components.

Check:

- The level of the power steering fluid.

- The condition of the piping and unions.

Using the tools.

Prepare the checking assembly [1], [2], [3], [4], [5], [6]and [7].

Attach the tool [1].

Remove the front RH wheel, the splash-shield and the screen wash reservoir.

B3EP16CC

B3EP16DC

Angl.-t2-page361-397-2005 9/01/06 10:22 Page 371

Page 379 of 462

Downloaded from www.Manualslib.com manuals search engine 373

AXLES

SUSPENSION

STEERING

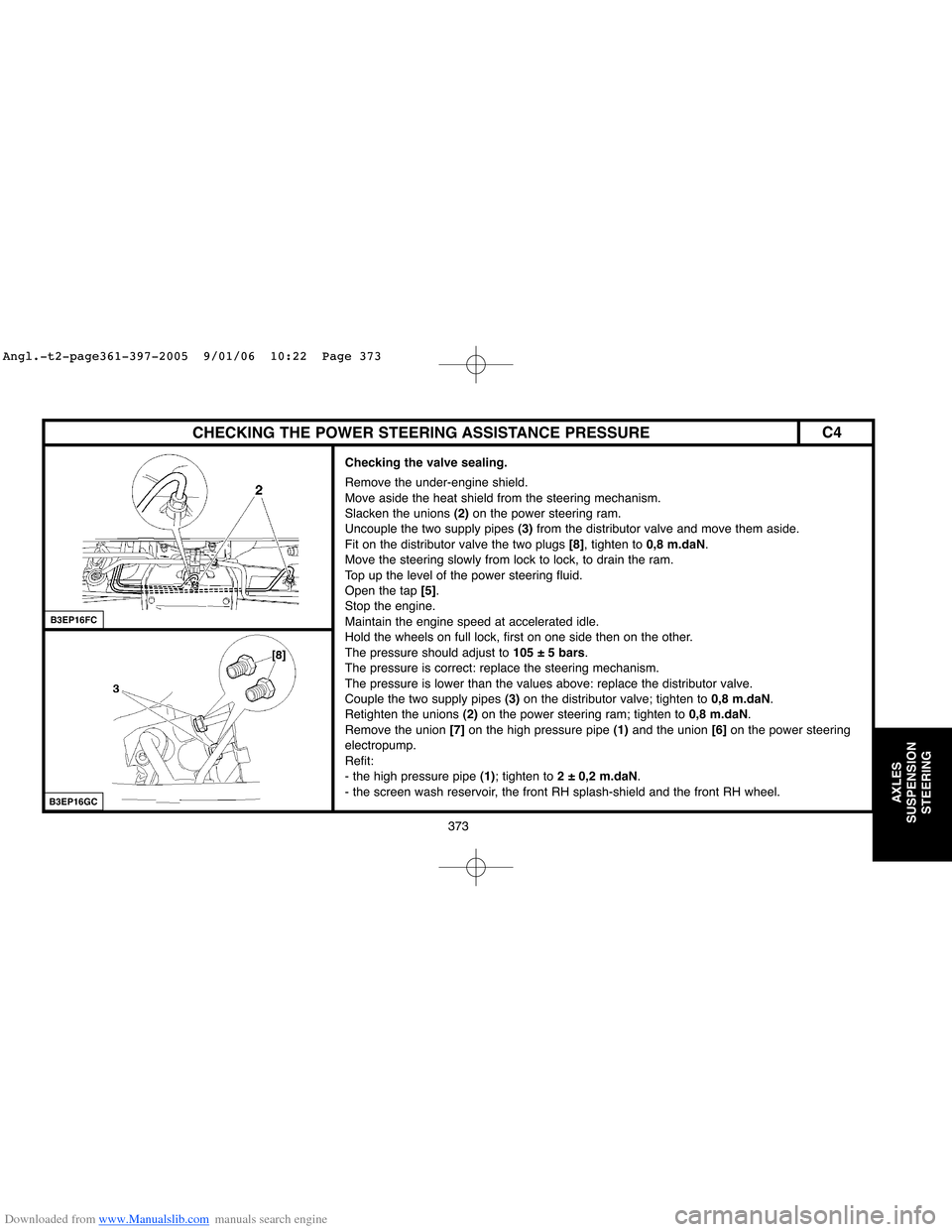

CHECKING THE POWER STEERING ASSISTANCE PRESSURE

Checking the valve sealing.

Remove the under-engine shield.

Move aside the heat shield from the steering mechanism.

Slacken the unions (2)on the power steering ram.

Uncouple the two supply pipes (3)from the distributor valve and move them aside.

Fit on the distributor valve the two plugs [8], tighten to 0,8 m.daN.

Move the steering slowly from lock to lock, to drain the ram.

Top up the level of the power steering fluid.

Open the tap [5].

Stop the engine.

Maintain the engine speed at accelerated idle.

Hold the wheels on full lock, first on one side then on the other.

The pressure should adjust to 105 ± 5 bars.

The pressure is correct: replace the steering mechanism.

The pressure is lower than the values above: replace the distributor valve.

Couple the two supply pipes (3)on the distributor valve; tighten to 0,8 m.daN.

Retighten the unions (2)on the power steering ram; tighten to 0,8 m.daN.

Remove the union [7]on the high pressure pipe (1)and the union [6]on the power steering

electropump.

Refit:

- the high pressure pipe (1); tighten to 2 ± 0,2 m.daN.

- the screen wash reservoir, the front RH splash-shield and the front RH wheel.

B3EP16FC

B3EP16GC

C4

Angl.-t2-page361-397-2005 9/01/06 10:22 Page 373

Page 442 of 462

Downloaded from www.Manualslib.com manuals search engine 436

AIR

CONDITIONING

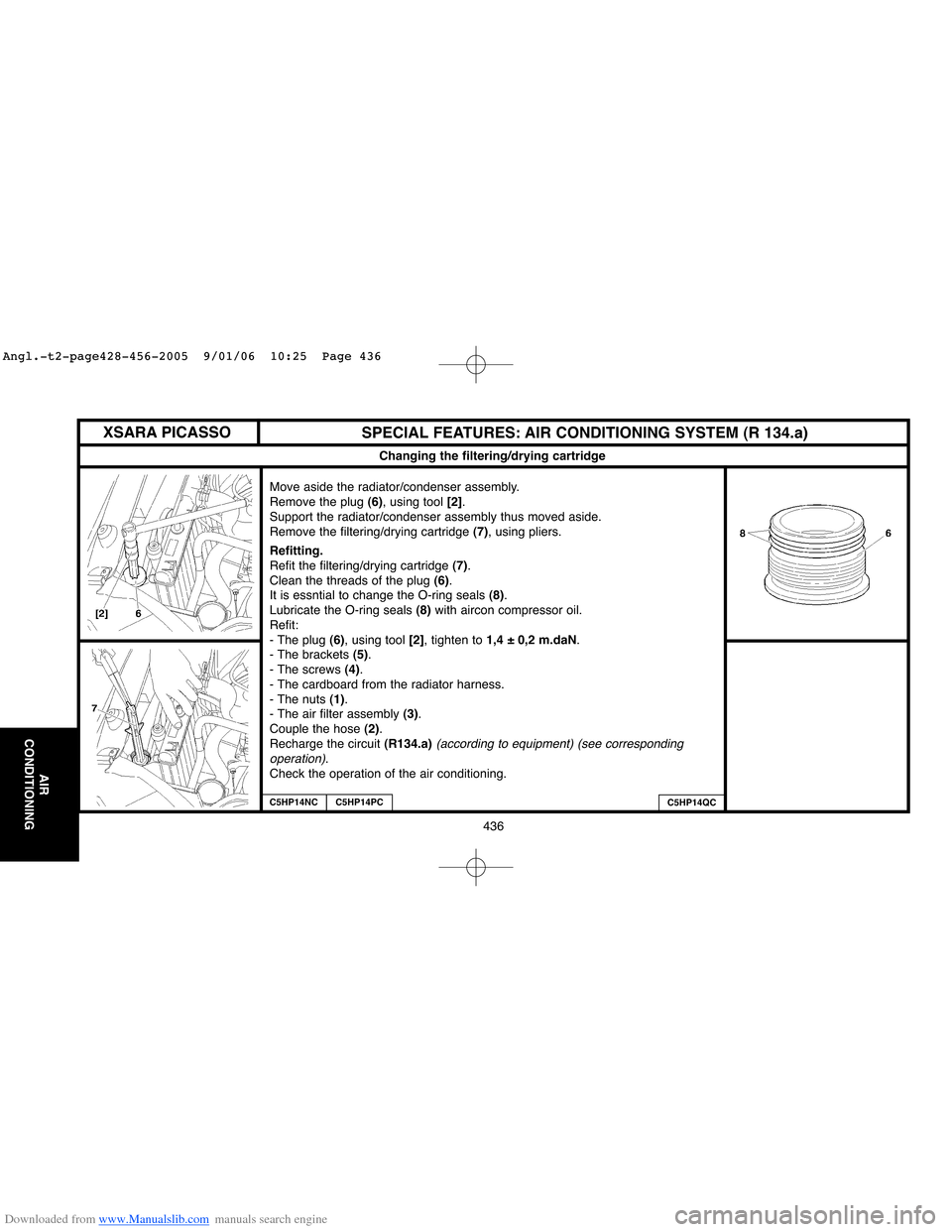

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Changing the filtering/drying cartridge

Move aside the radiator/condenser assembly.

Remove the plug (6), using tool [2].

Support the radiator/condenser assembly thus moved aside.

Remove the filtering/drying cartridge (7), using pliers.

Refitting.

Refit the filtering/drying cartridge (7).

Clean the threads of the plug (6).

It is essntial to change the O-ring seals (8).

Lubricate the O-ring seals (8)with aircon compressor oil.

Refit:

- The plug (6), using tool [2], tighten to 1,4 ± 0,2 m.daN.

- The brackets (5).

- The screws (4).

- The cardboard from the radiator harness.

- The nuts (1).

- The air filter assembly (3).

Couple the hose (2).

Recharge the circuit (R134.a)

(according to equipment) (see corresponding

operation).

Check the operation of the air conditioning.

C5HP14NCC5HP14PCC5HP14QC

XSARA PICASSO

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 436

Page 459 of 462

Downloaded from www.Manualslib.com manuals search engine 453

AIR

CONDITIONING

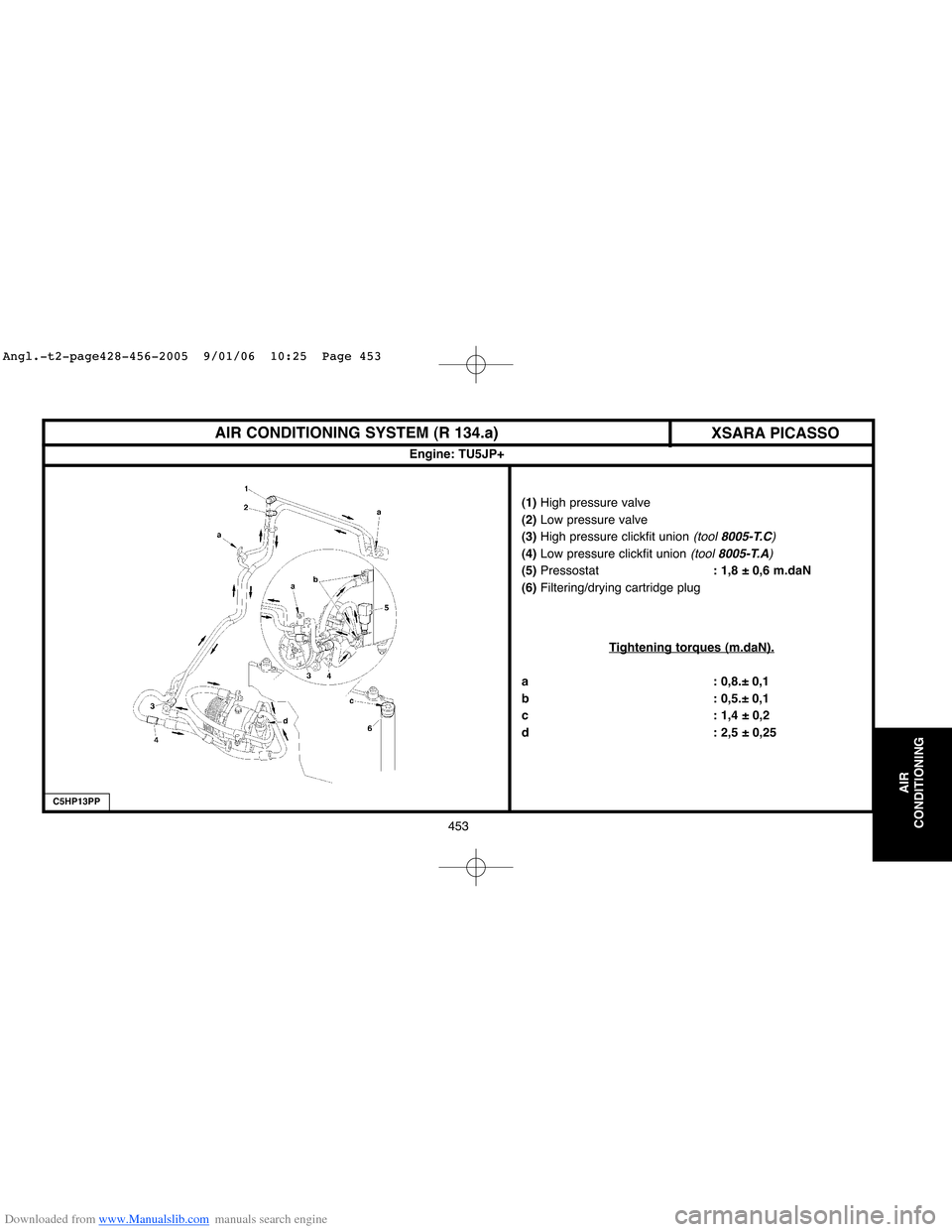

(1)High pressure valve

(2)Low pressure valve

(3)High pressure clickfit union

(tool 8005-T.C)

(4) Low pressure clickfit union (tool 8005-T.A)

(5)Pressostat: 1,8 ± 0,6 m.daN

(6)Filtering/drying cartridge plug

T

ightening torques (m.daN).

a : 0,8.± 0,1

b : 0,5.± 0,1

c : 1,4 ± 0,2

d : 2,5 ± 0,25

XSARA PICASSO AIR CONDITIONING SYSTEM (R 134.a)

C5HP13PP

Engine: TU5JP+

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 453

Page 460 of 462

Downloaded from www.Manualslib.com manuals search engine 454

AIR

CONDITIONING

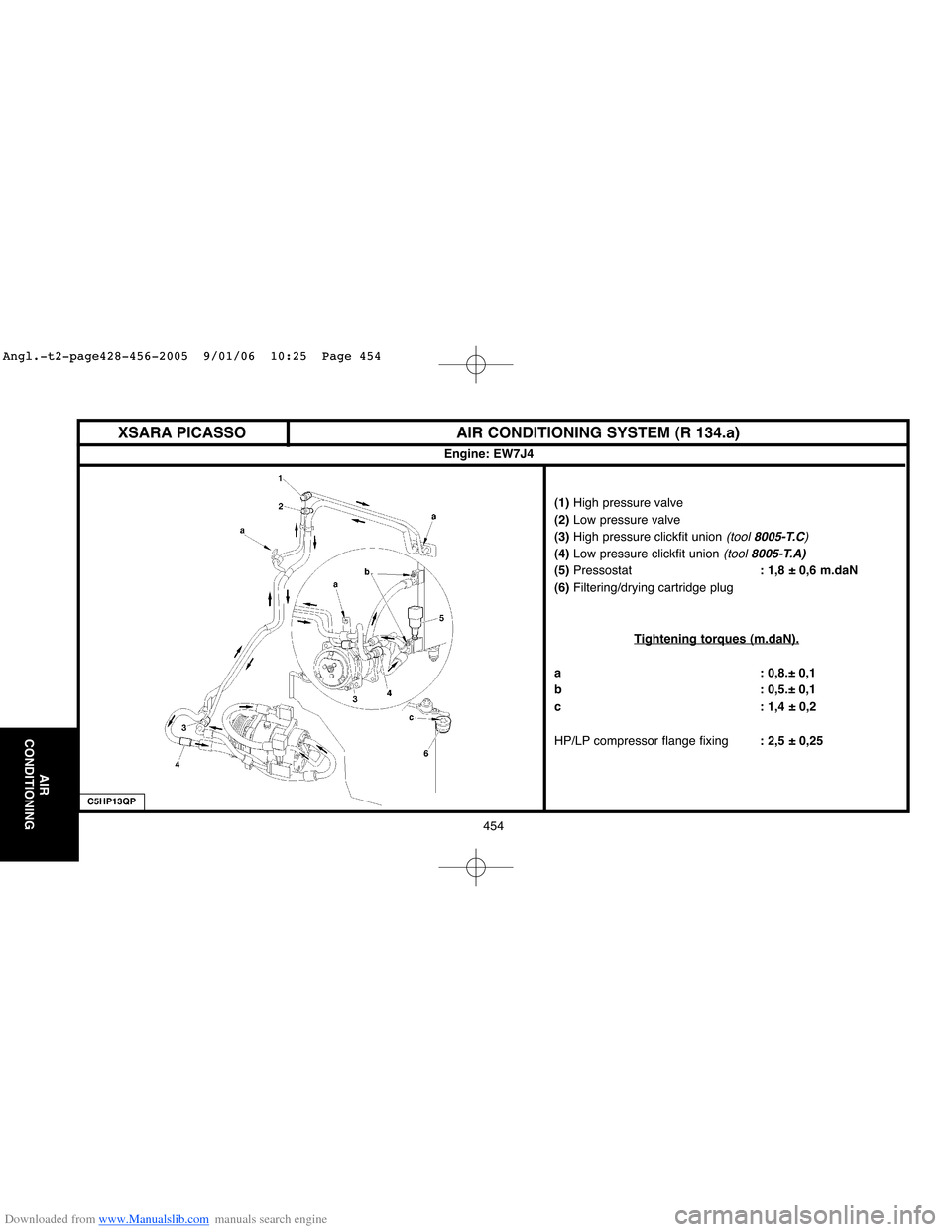

(1)High pressure valve

(2)Low pressure valve

(3)High pressure clickfit union

(tool 8005-T.C)

(4)Low pressure clickfit union(tool 8005-T.A)

(5)Pressostat: 1,8 ± 0,6 m.daN

(6)Filtering/drying cartridge plug

T

ightening torques (m.daN).

a : 0,8.± 0,1

b : 0,5.± 0,1

c : 1,4 ± 0,2

HP/LP compressor flange fixing: 2,5 ± 0,25

XSARA PICASSO

AIR CONDITIONING SYSTEM (R 134.a)

C5HP13QP

Engine: EW7J4

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 454

Page 462 of 462

Downloaded from www.Manualslib.com manuals search engine 456

AIR

CONDITIONING

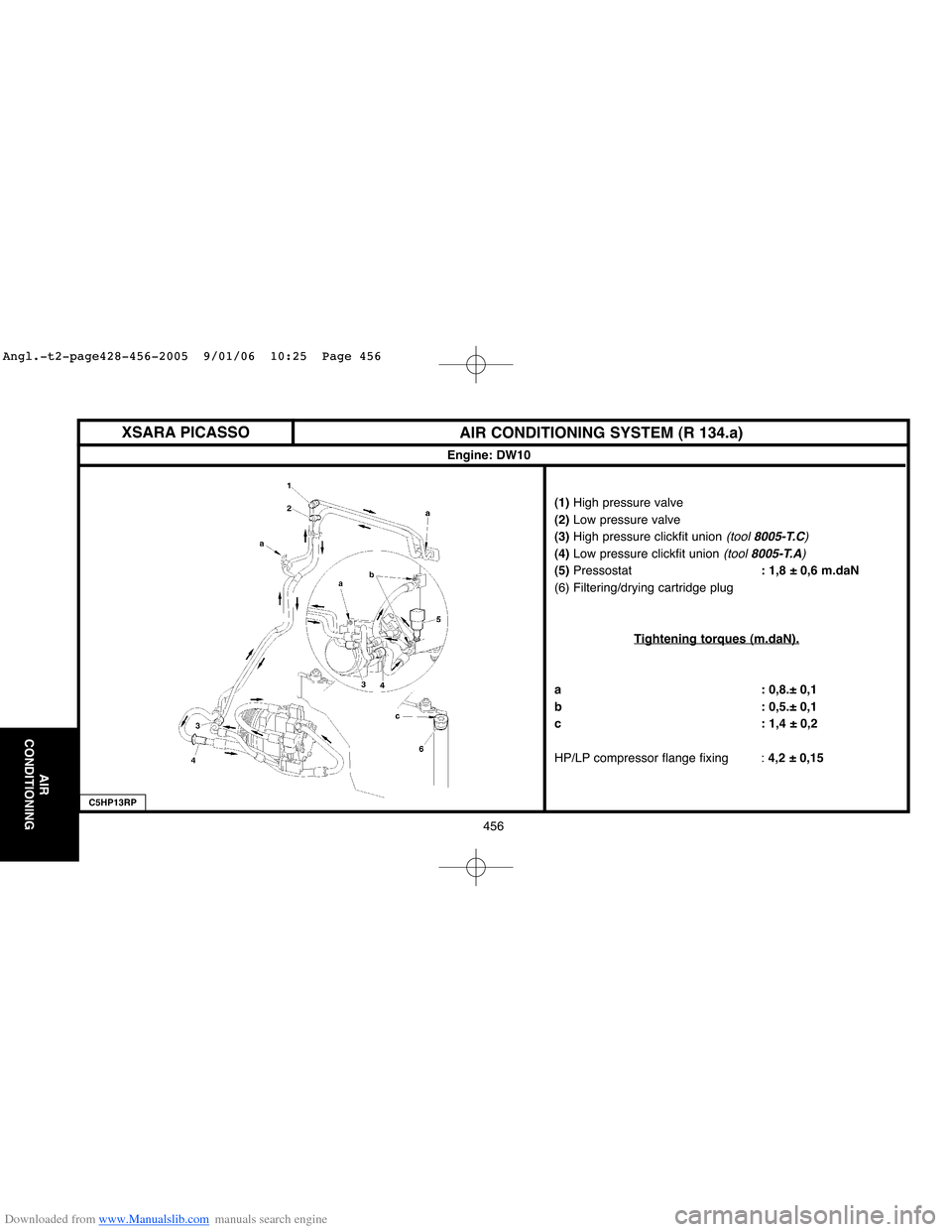

(1) High pressure valve

(2)Low pressure valve

(3)High pressure clickfit union

(tool 8005-T.C)

(4)Low pressure clickfit union (tool 8005-T.A)

(5)Pressostat: 1,8 ± 0,6 m.daN

(6) Filtering/drying cartridge plug

T

ightening torques (m.daN).

a : 0,8.± 0,1

b : 0,5.± 0,1

c : 1,4 ± 0,2

HP/LP compressor flange fixing : 4,2 ± 0,15

XSARA PICASSO

AIR CONDITIONING SYSTEM (R 134.a)

C5HP13RP

Engine: DW10

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 456