DAEWOO LACETTI 2004 Service Repair Manual

LACETTI 2004

DAEWOO

DAEWOO

https://www.carmanualsonline.info/img/54/56877/w960_56877-0.png

DAEWOO LACETTI 2004 Service Repair Manual

Trending: checking oil, seat, Ect, p0420, speedometer, engine controls, jump start terminals

Page 1571 of 2643

5A1 – 222IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

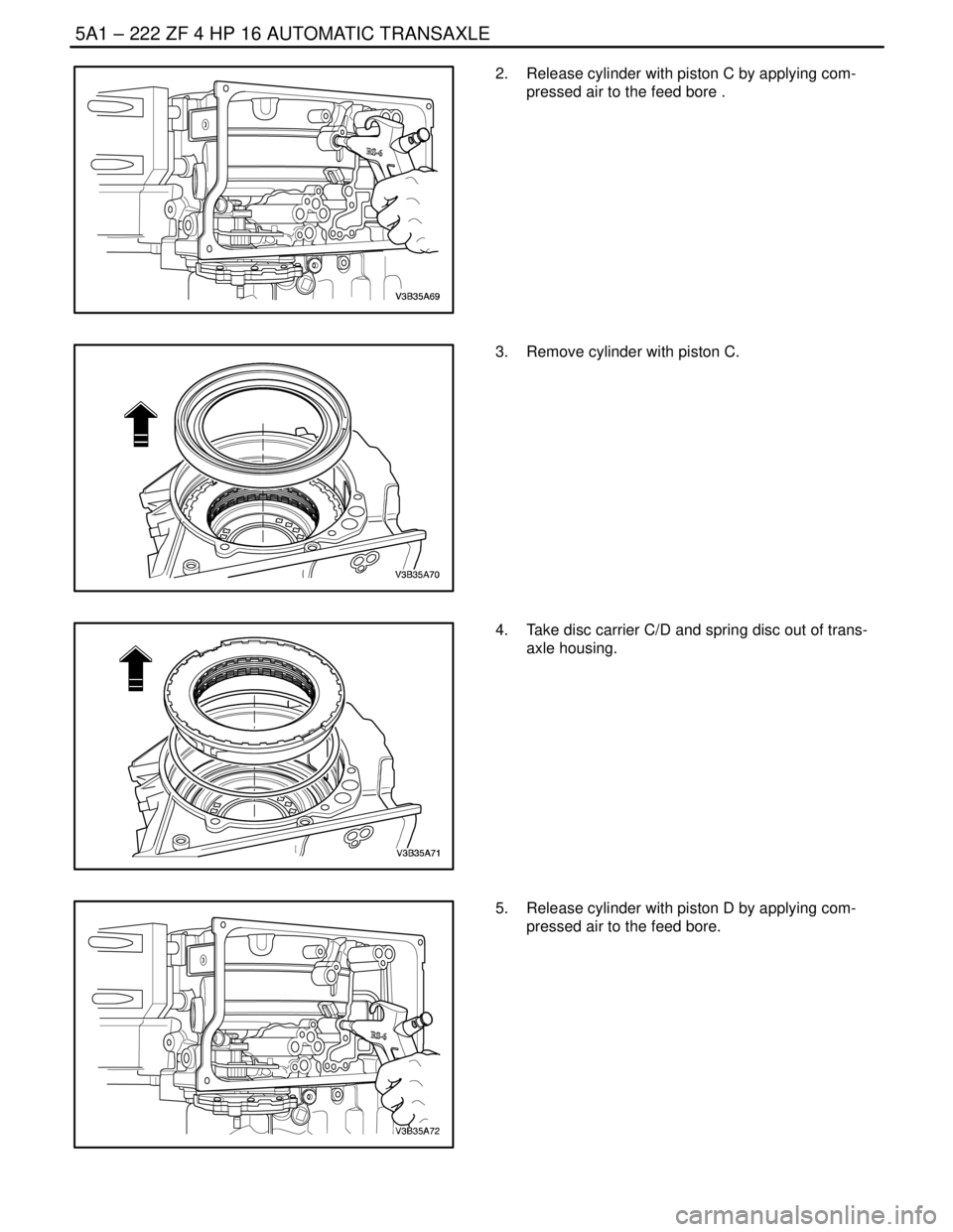

2. Release cylinder with piston C by applying com-

pressed air to the feed bore .

3. Remove cylinder with piston C.

4. Take disc carrier C/D and spring disc out of trans-

axle housing.

5. Release cylinder with piston D by applying com-

pressed air to the feed bore.

Page 1572 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 223

DAEWOO V–121 BL4

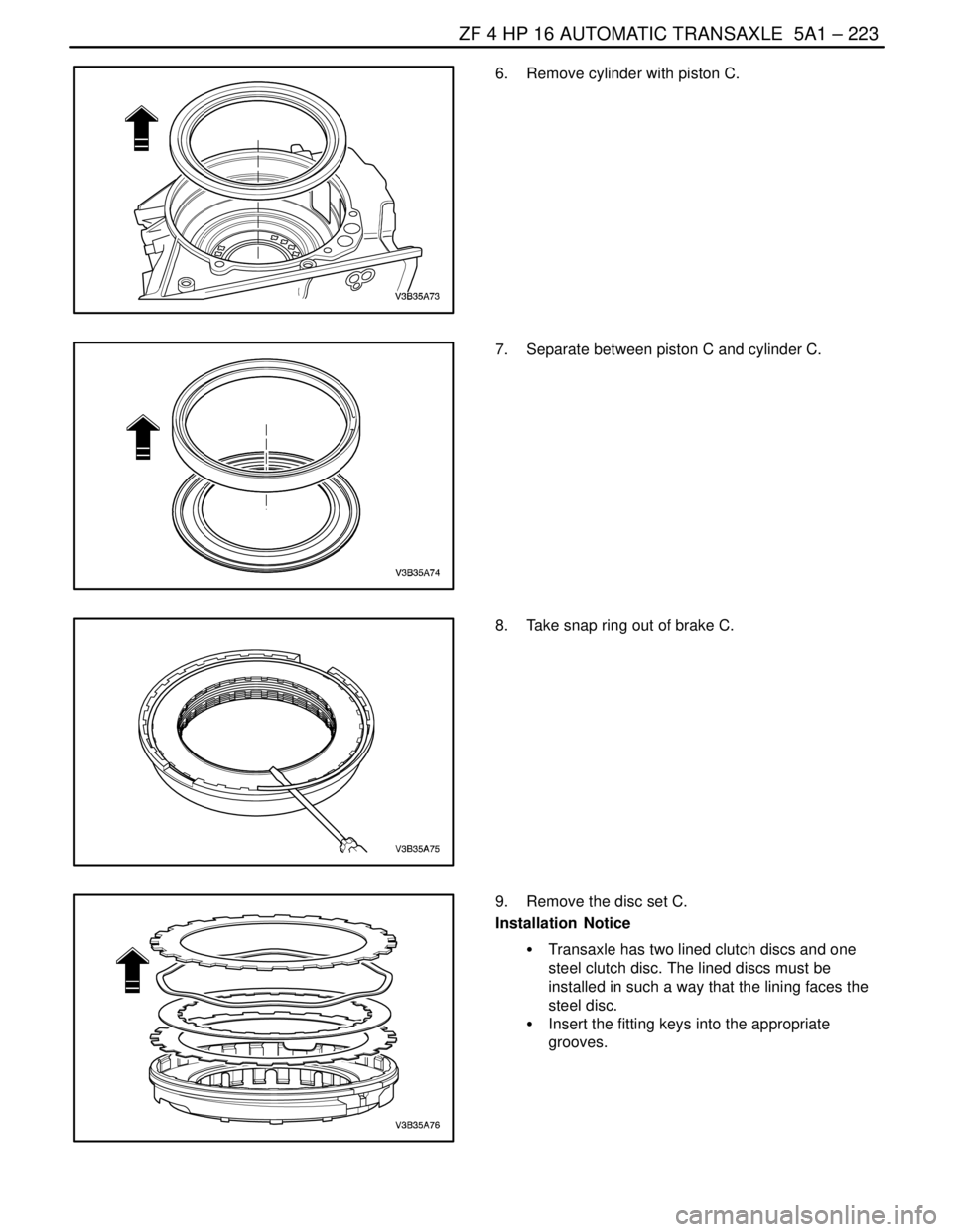

6. Remove cylinder with piston C.

7. Separate between piston C and cylinder C.

8. Take snap ring out of brake C.

9. Remove the disc set C.

Installation Notice

S Transaxle has two lined clutch discs and one

steel clutch disc. The lined discs must be

installed in such a way that the lining faces the

steel disc.

S Insert the fitting keys into the appropriate

grooves.

Page 1573 of 2643

5A1 – 224IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

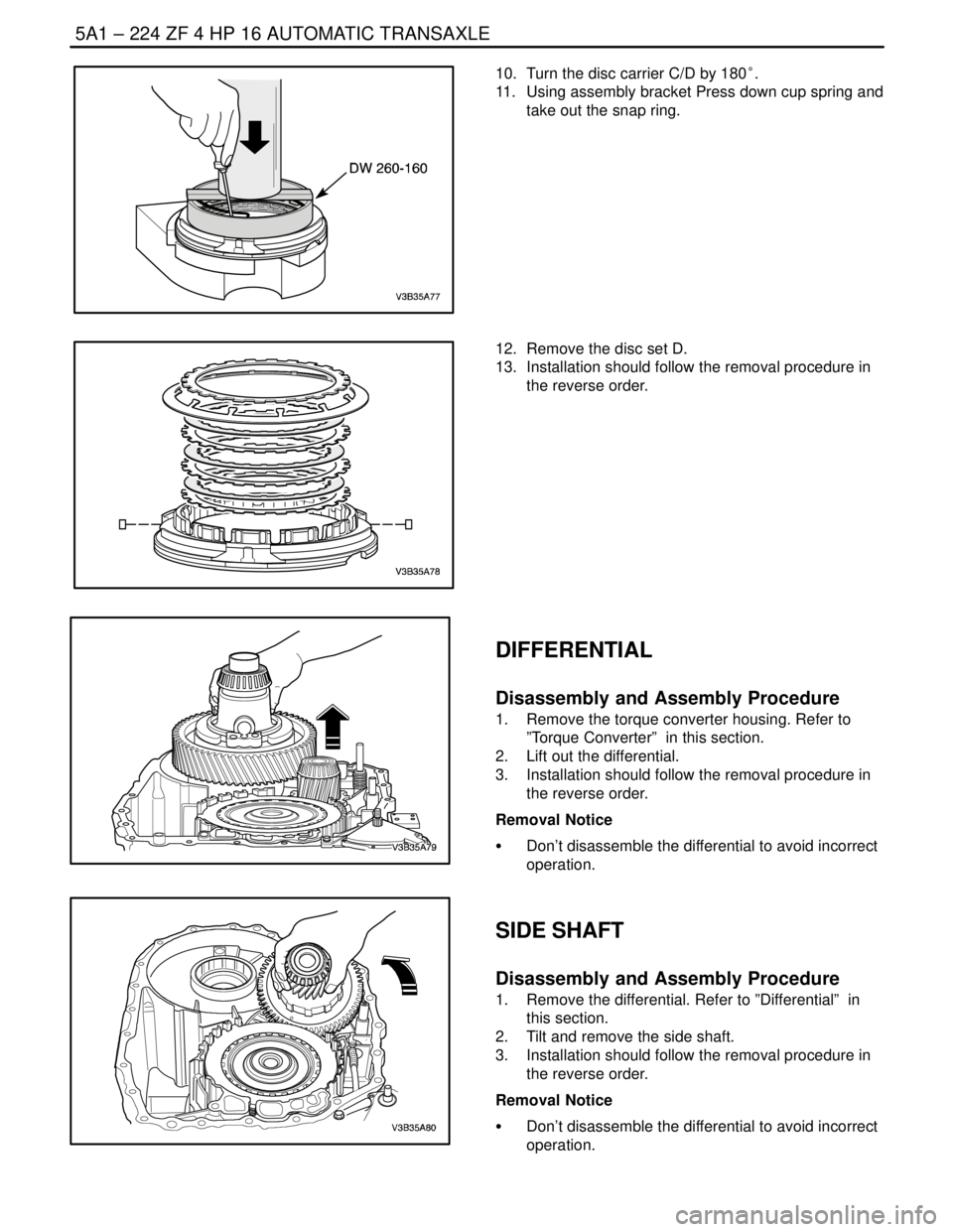

10. Turn the disc carrier C/D by 180°.

11. Using assembly bracket Press down cup spring and

take out the snap ring.

12. Remove the disc set D.

13. Installation should follow the removal procedure in

the reverse order.

DIFFERENTIAL

Disassembly and Assembly Procedure

1. Remove the torque converter housing. Refer to

”Torque Converter” in this section.

2. Lift out the differential.

3. Installation should follow the removal procedure in

the reverse order.

Removal Notice

S Don’t disassemble the differential to avoid incorrect

operation.

SIDE SHAFT

Disassembly and Assembly Procedure

1. Remove the differential. Refer to ”Differential” in

this section.

2. Tilt and remove the side shaft.

3. Installation should follow the removal procedure in

the reverse order.

Removal Notice

S Don’t disassemble the differential to avoid incorrect

operation.

Page 1574 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 225

DAEWOO V–121 BL4

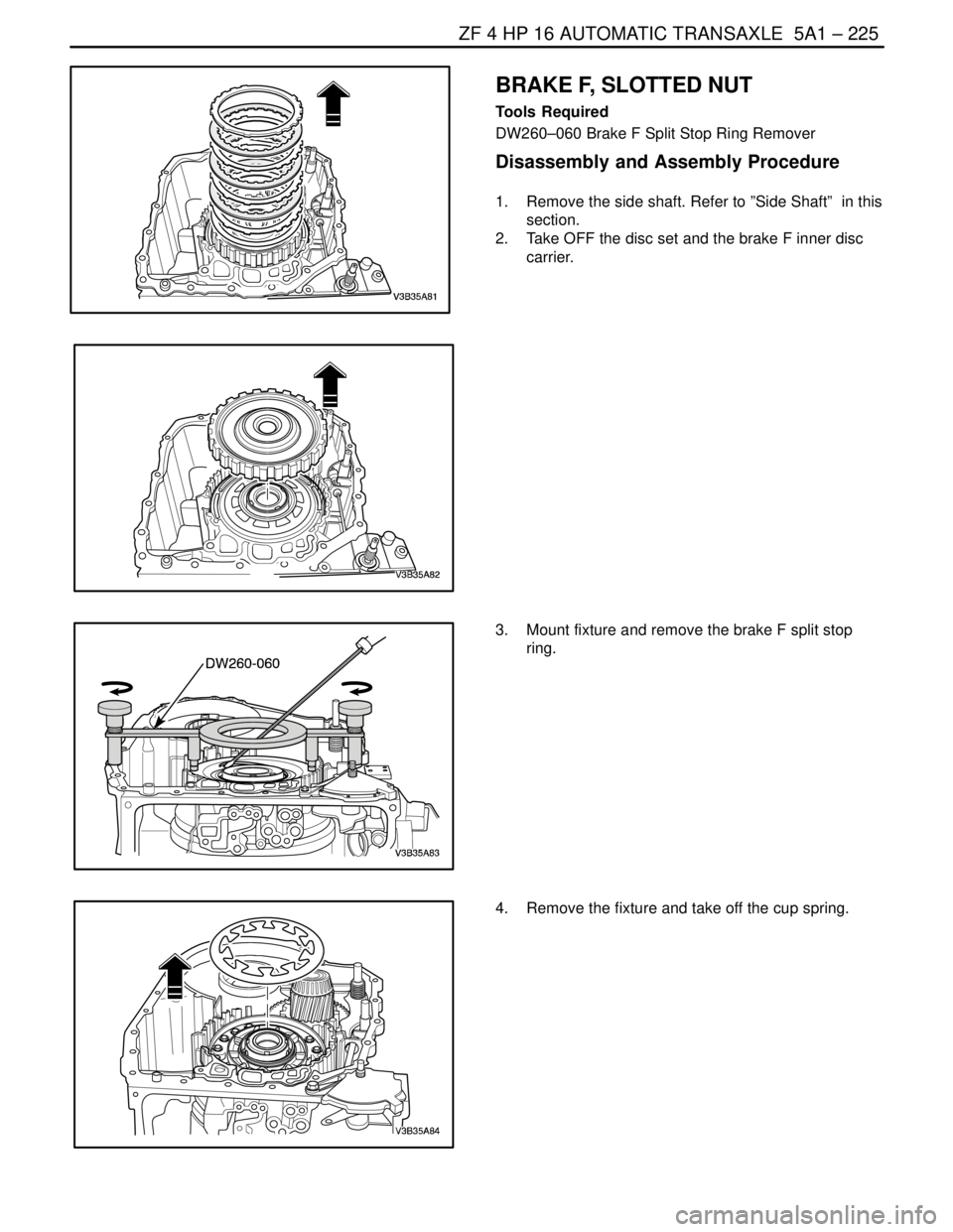

BRAKE F, SLOTTED NUT

Tools Required

DW260–060 Brake F Split Stop Ring Remover

Disassembly and Assembly Procedure

1. Remove the side shaft. Refer to ”Side Shaft” in this

section.

2. Take OFF the disc set and the brake F inner disc

carrier.

3. Mount fixture and remove the brake F split stop

ring.

4. Remove the fixture and take off the cup spring.

Page 1575 of 2643

5A1 – 226IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

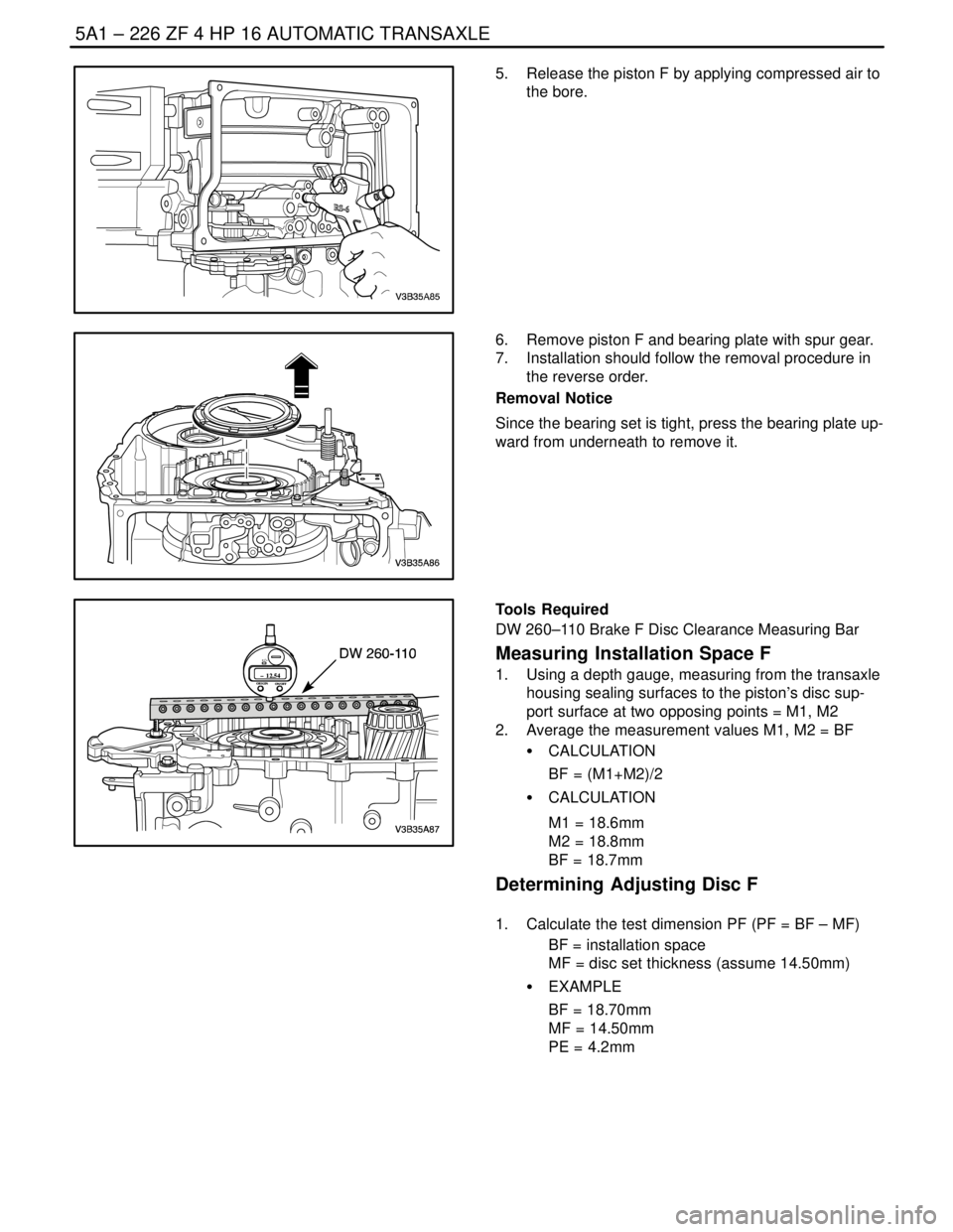

5. Release the piston F by applying compressed air to

the bore.

6. Remove piston F and bearing plate with spur gear.

7. Installation should follow the removal procedure in

the reverse order.

Removal Notice

Since the bearing set is tight, press the bearing plate up-

ward from underneath to remove it.

ORIGIN

ON/OFF– 12.54

+ / –

ORIGIN

ON/OFF– 12.54

+ / –

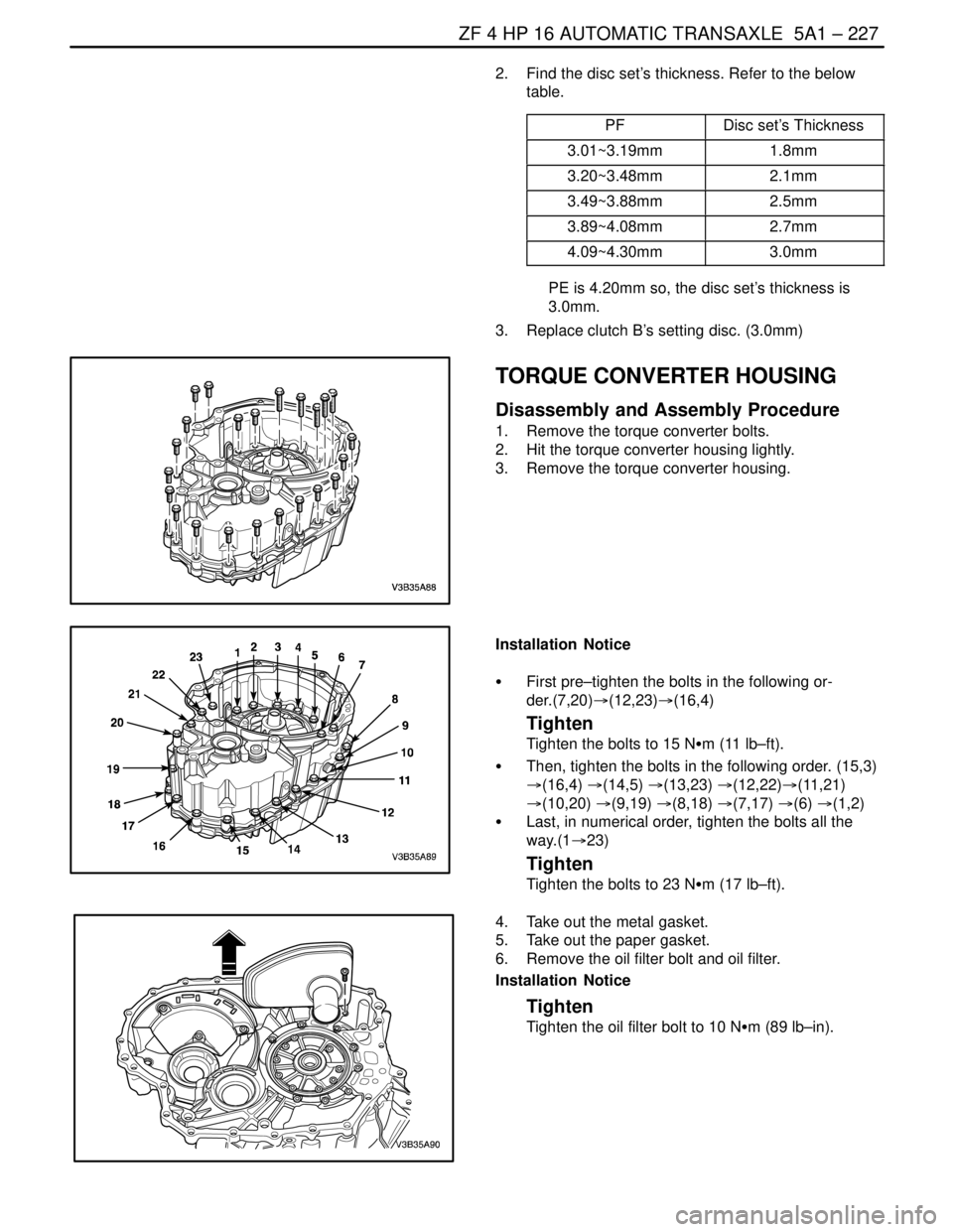

Tools Required

DW 260–110 Brake F Disc Clearance Measuring Bar

Measuring Installation Space F

1. Using a depth gauge, measuring from the transaxle

housing sealing surfaces to the piston’s disc sup-

port surface at two opposing points = M1, M2

2. Average the measurement values M1, M2 = BF

S CALCULATION

BF = (M1+M2)/2

S CALCULATION

M1 = 18.6mm

M2 = 18.8mm

BF = 18.7mm

Determining Adjusting Disc F

1. Calculate the test dimension PF (PF = BF – MF)

BF = installation space

MF = disc set thickness (assume 14.50mm)

S EXAMPLE

BF = 18.70mm

MF = 14.50mm

PE = 4.2mm

Page 1576 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 227

DAEWOO V–121 BL4

2. Find the disc set’s thickness. Refer to the below

table.

PF

Disc set’s Thickness

3.01~3.19mm1.8mm

3.20~3.48mm2.1mm

3.49~3.88mm2.5mm

3.89~4.08mm2.7mm

4.09~4.30mm3.0mm

PE is 4.20mm so, the disc set’s thickness is

3.0mm.

3. Replace clutch B’s setting disc. (3.0mm)

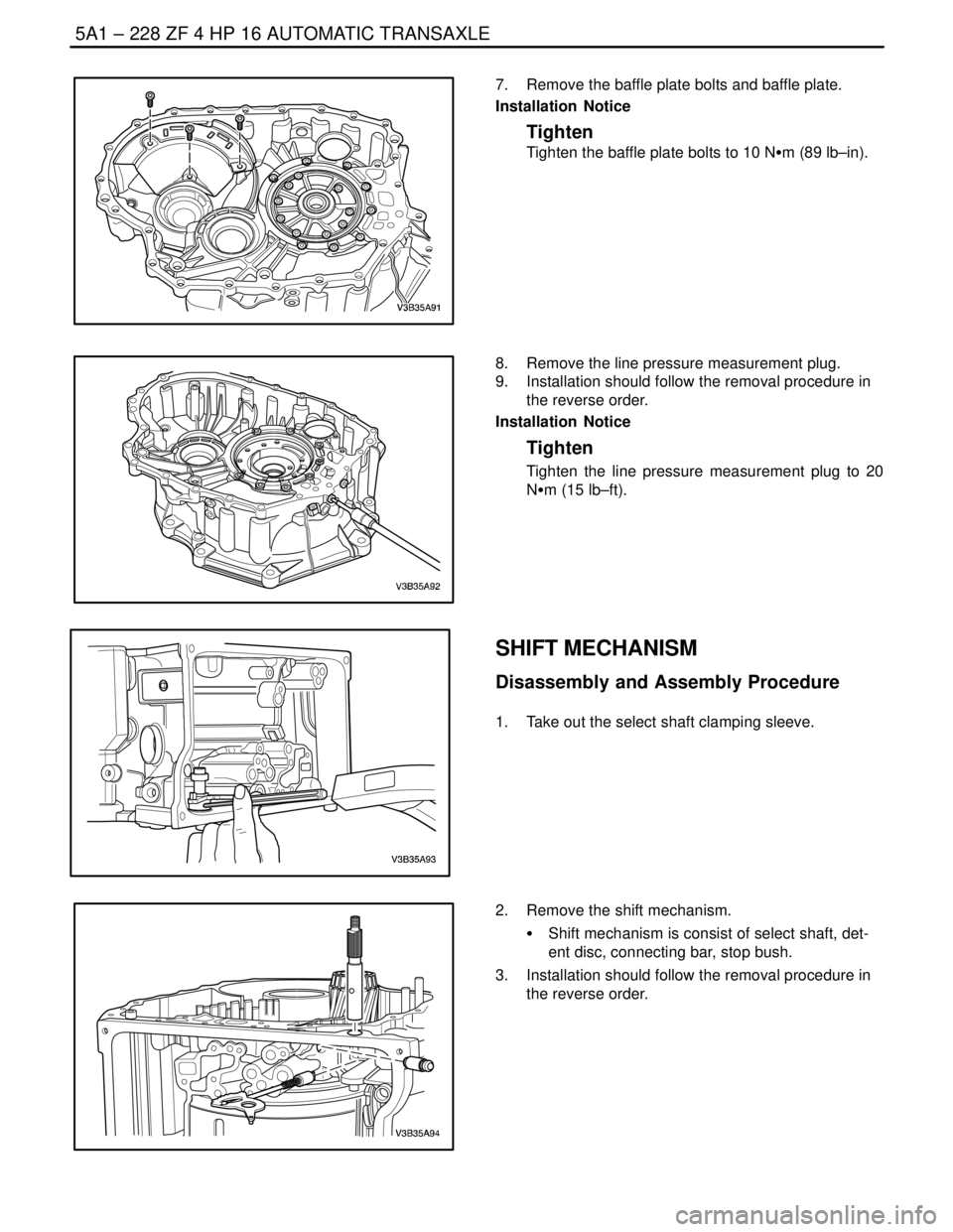

TORQUE CONVERTER HOUSING

Disassembly and Assembly Procedure

1. Remove the torque converter bolts.

2. Hit the torque converter housing lightly.

3. Remove the torque converter housing.

Installation Notice

S First pre–tighten the bolts in the following or-

der.(7,20)�(12,23)�(16,4)

Tighten

Tighten the bolts to 15 NSm (11 lb–ft).

S Then, tighten the bolts in the following order. (15,3)

�(16,4) �(14,5) �(13,23) �(12,22)�(11,21)

�(10,20) �(9,19) �(8,18) �(7,17) �(6) �(1,2)

S Last, in numerical order, tighten the bolts all the

way.(1�23)

Tighten

Tighten the bolts to 23 NSm (17 lb–ft).

4. Take out the metal gasket.

5. Take out the paper gasket.

6. Remove the oil filter bolt and oil filter.

Installation Notice

Tighten

Tighten the oil filter bolt to 10 NSm (89 lb–in).

Page 1577 of 2643

5A1 – 228IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

7. Remove the baffle plate bolts and baffle plate.

Installation Notice

Tighten

Tighten the baffle plate bolts to 10 NSm (89 lb–in).

8. Remove the line pressure measurement plug.

9. Installation should follow the removal procedure in

the reverse order.

Installation Notice

Tighten

Tighten the line pressure measurement plug to 20

NSm (15 lb–ft).

SHIFT MECHANISM

Disassembly and Assembly Procedure

1. Take out the select shaft clamping sleeve.

2. Remove the shift mechanism.

S Shift mechanism is consist of select shaft, det-

ent disc, connecting bar, stop bush.

3. Installation should follow the removal procedure in

the reverse order.

Page 1578 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 229

DAEWOO V–121 BL4

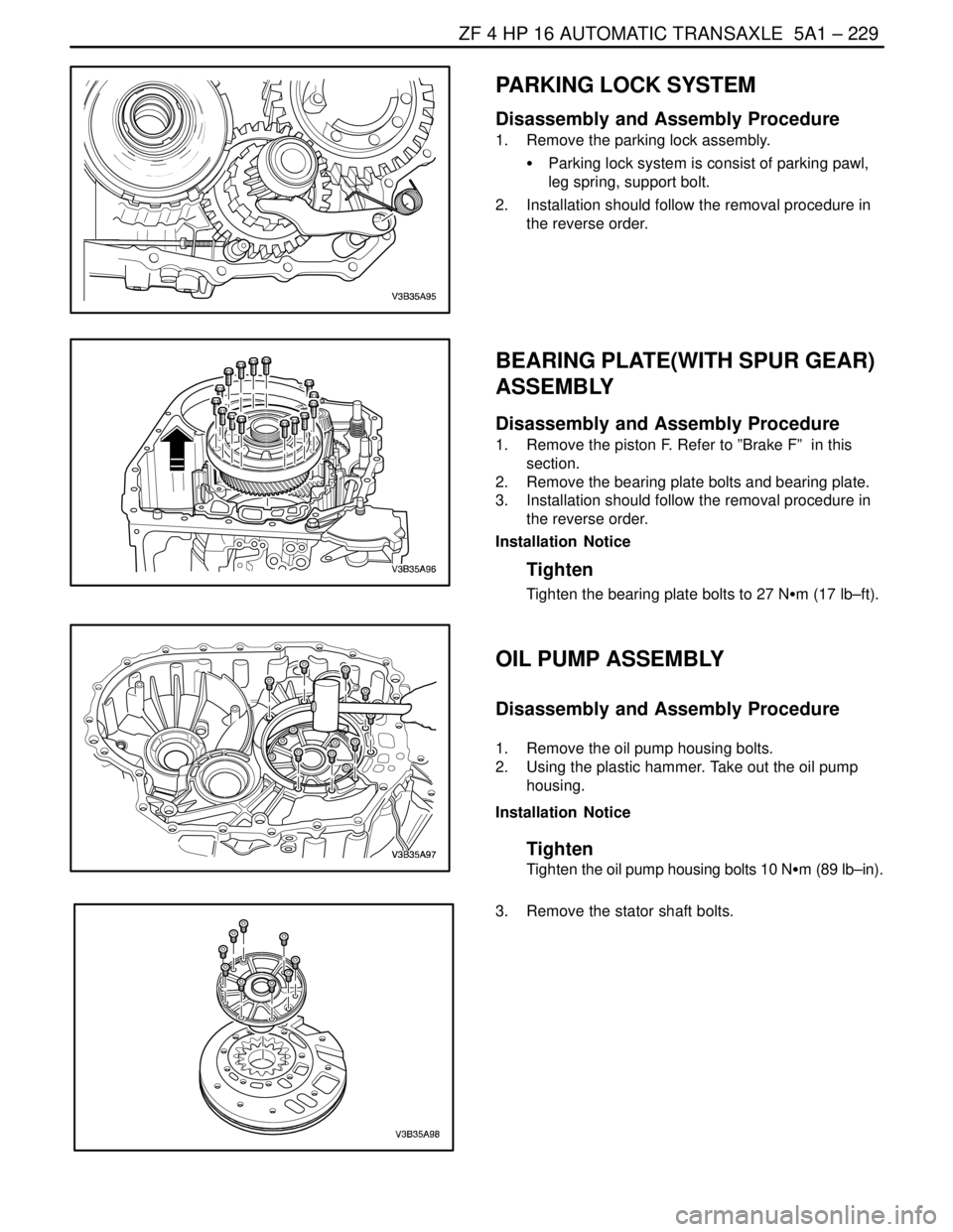

PARKING LOCK SYSTEM

Disassembly and Assembly Procedure

1. Remove the parking lock assembly.

S Parking lock system is consist of parking pawl,

leg spring, support bolt.

2. Installation should follow the removal procedure in

the reverse order.

BEARING PLATE(WITH SPUR GEAR)

ASSEMBLY

Disassembly and Assembly Procedure

1. Remove the piston F. Refer to ”Brake F” in this

section.

2. Remove the bearing plate bolts and bearing plate.

3. Installation should follow the removal procedure in

the reverse order.

Installation Notice

Tighten

Tighten the bearing plate bolts to 27 NSm (17 lb–ft).

OIL PUMP ASSEMBLY

Disassembly and Assembly Procedure

1. Remove the oil pump housing bolts.

2. Using the plastic hammer. Take out the oil pump

housing.

Installation Notice

Tighten

Tighten the oil pump housing bolts 10 NSm (89 lb–in).

3. Remove the stator shaft bolts.

Page 1579 of 2643

5A1 – 230IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

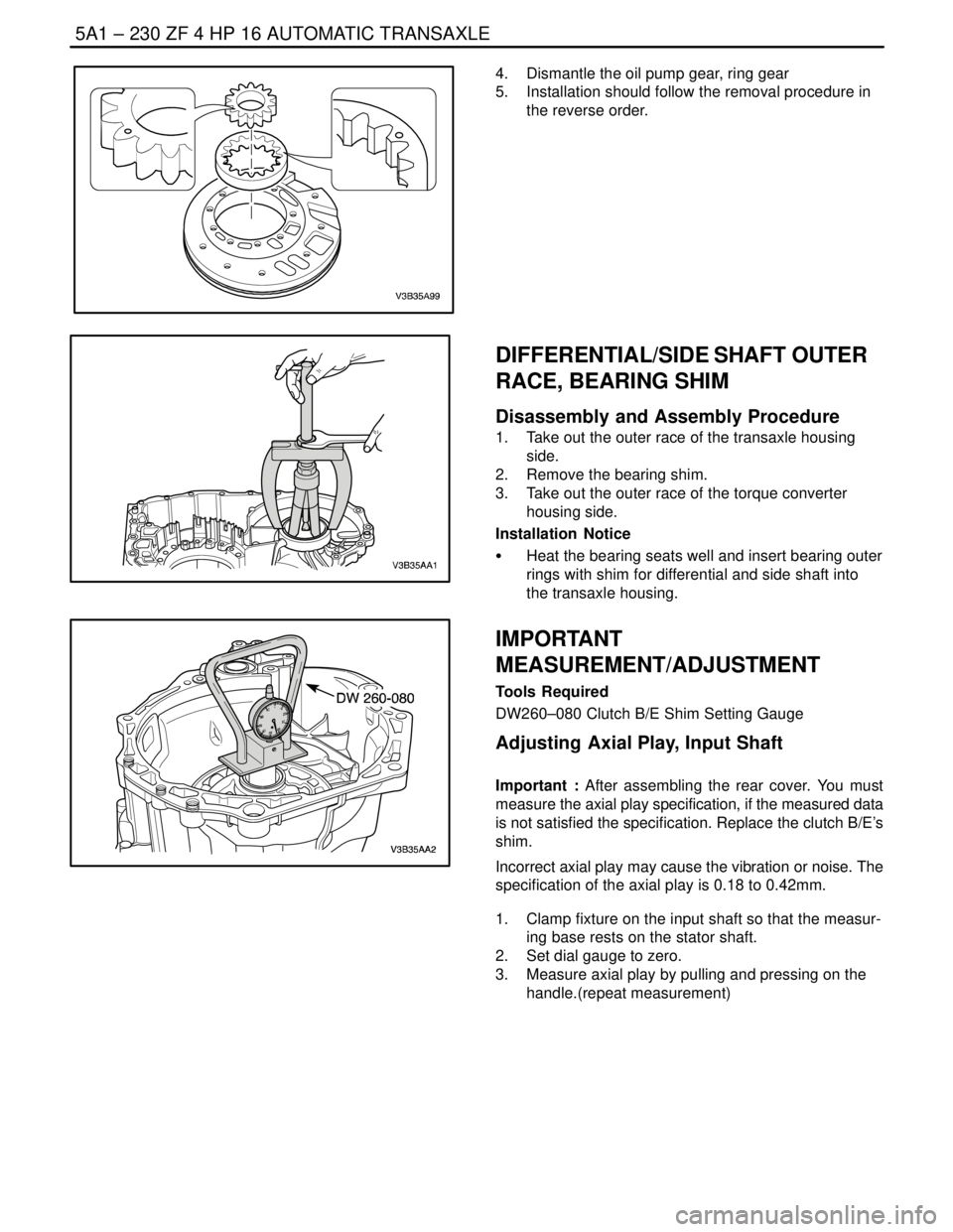

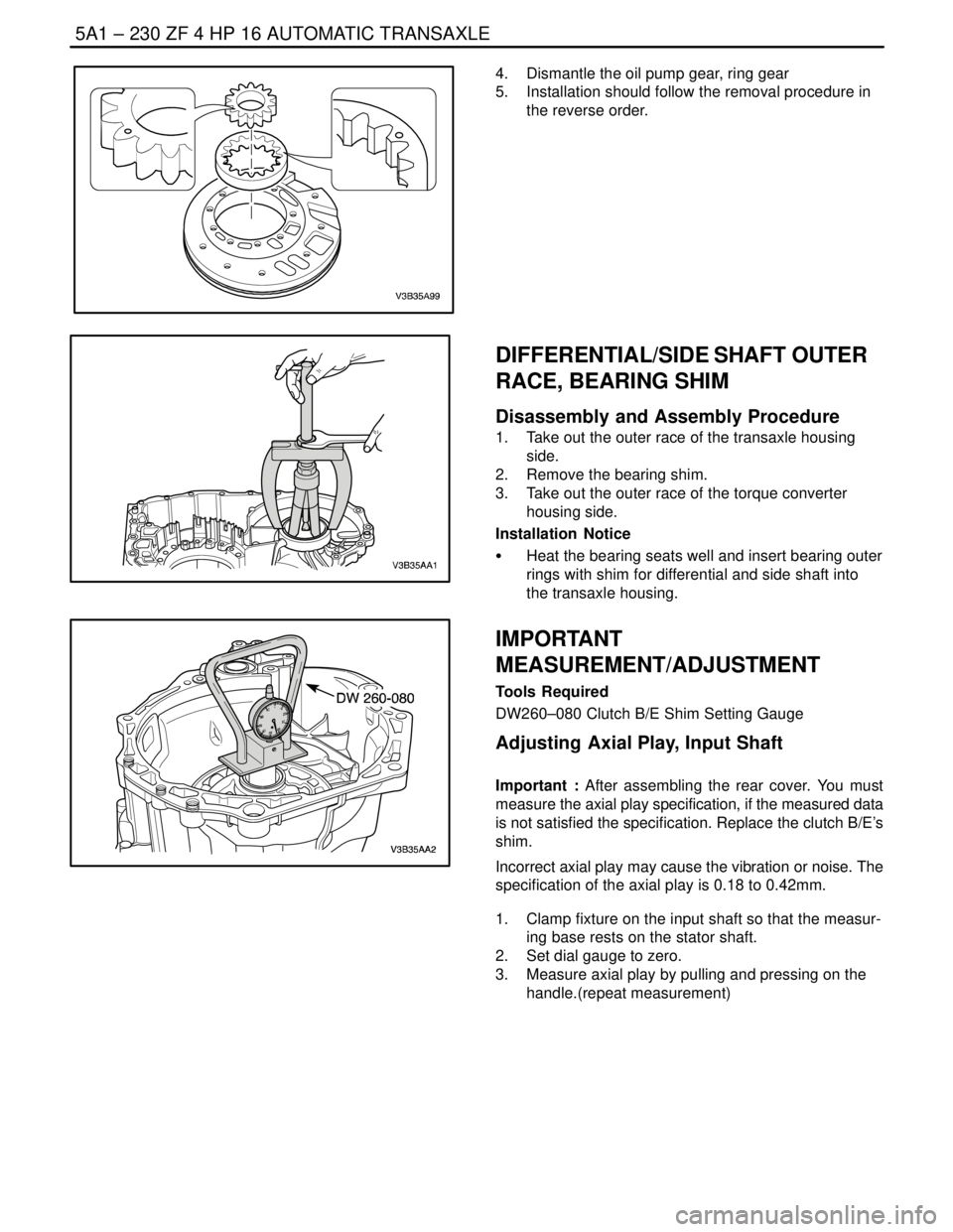

4. Dismantle the oil pump gear, ring gear

5. Installation should follow the removal procedure in

the reverse order.

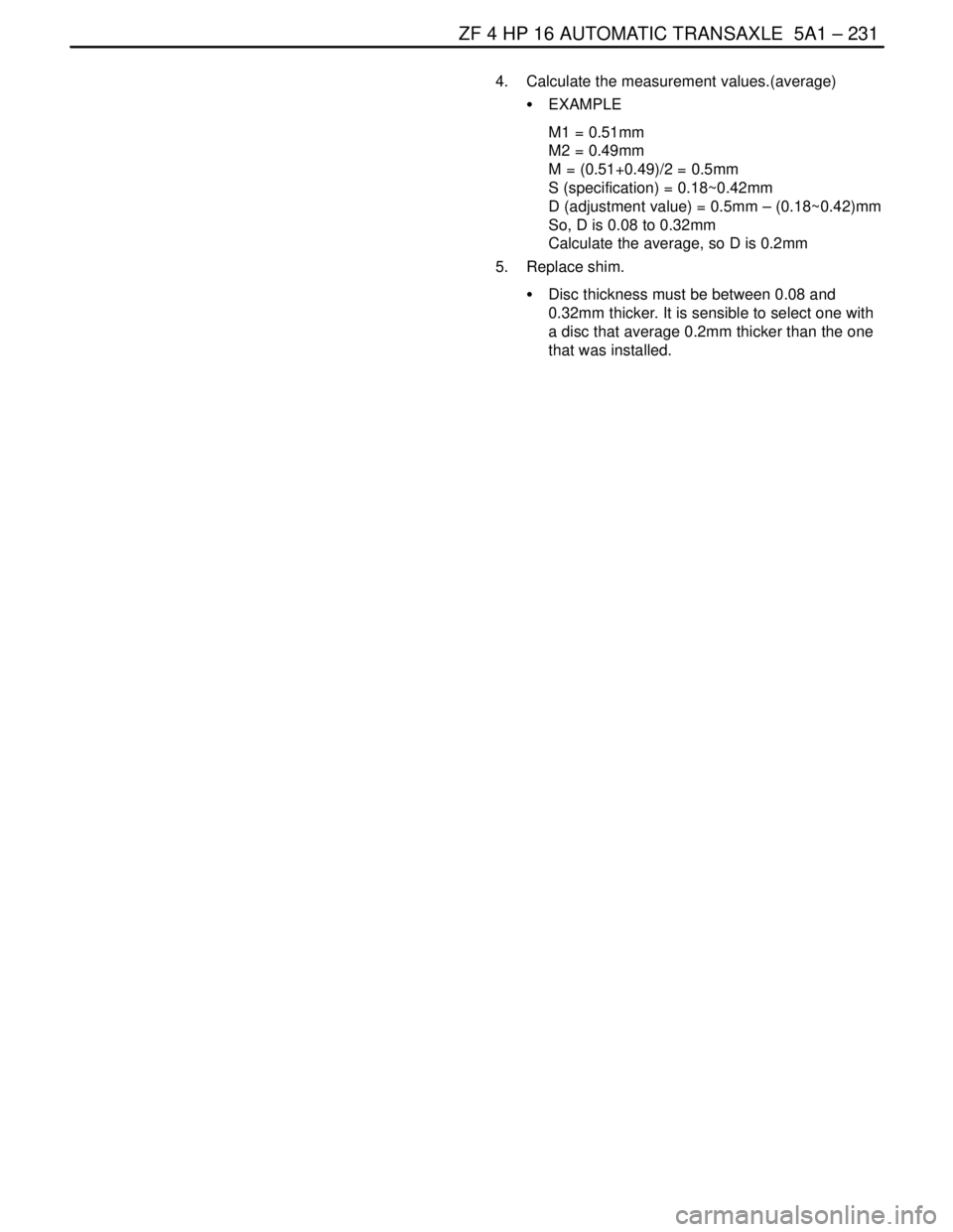

DIFFERENTIAL/SIDE SHAFT OUTER

RACE, BEARING SHIM

Disassembly and Assembly Procedure

1. Take out the outer race of the transaxle housing

side.

2. Remove the bearing shim.

3. Take out the outer race of the torque converter

housing side.

Installation Notice

S Heat the bearing seats well and insert bearing outer

rings with shim for differential and side shaft into

the transaxle housing.

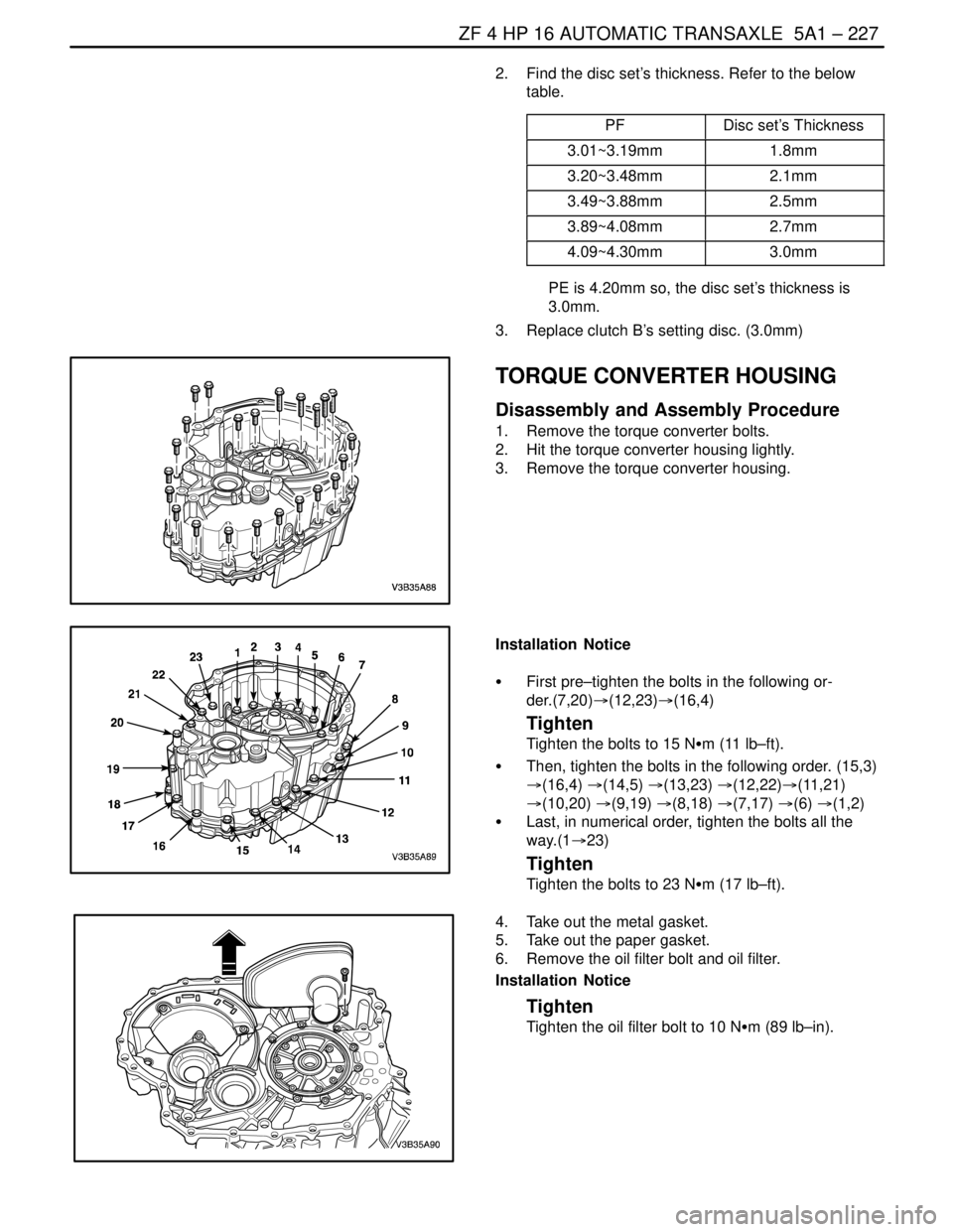

IMPORTANT

MEASUREMENT/ADJUSTMENT

Tools Required

DW260–080 Clutch B/E Shim Setting Gauge

Adjusting Axial Play, Input Shaft

Important : After assembling the rear cover. You must

measure the axial play specification, if the measured data

is not satisfied the specification. Replace the clutch B/E’s

shim.

Incorrect axial play may cause the vibration or noise. The

specification of the axial play is 0.18 to 0.42mm.

1. Clamp fixture on the input shaft so that the measur-

ing base rests on the stator shaft.

2. Set dial gauge to zero.

3. Measure axial play by pulling and pressing on the

handle.(repeat measurement)

Page 1580 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 231

DAEWOO V–121 BL4

4. Calculate the measurement values.(average)

S EXAMPLE

M1 = 0.51mm

M2 = 0.49mm

M = (0.51+0.49)/2 = 0.5mm

S (specification) = 0.18~0.42mm

D (adjustment value) = 0.5mm – (0.18~0.42)mm

So, D is 0.08 to 0.32mm

Calculate the average, so D is 0.2mm

5. Replace shim.

S Disc thickness must be between 0.08 and

0.32mm thicker. It is sensible to select one with

a disc that average 0.2mm thicker than the one

that was installed.

Trending: AUX, hood release cable, hood cable, coolant reservoir, spark plugs replace, spark, ACC