ground DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 525 of 2643

ENGINE CONTROLS 1F – 279

DAEWOO V–121 BL4

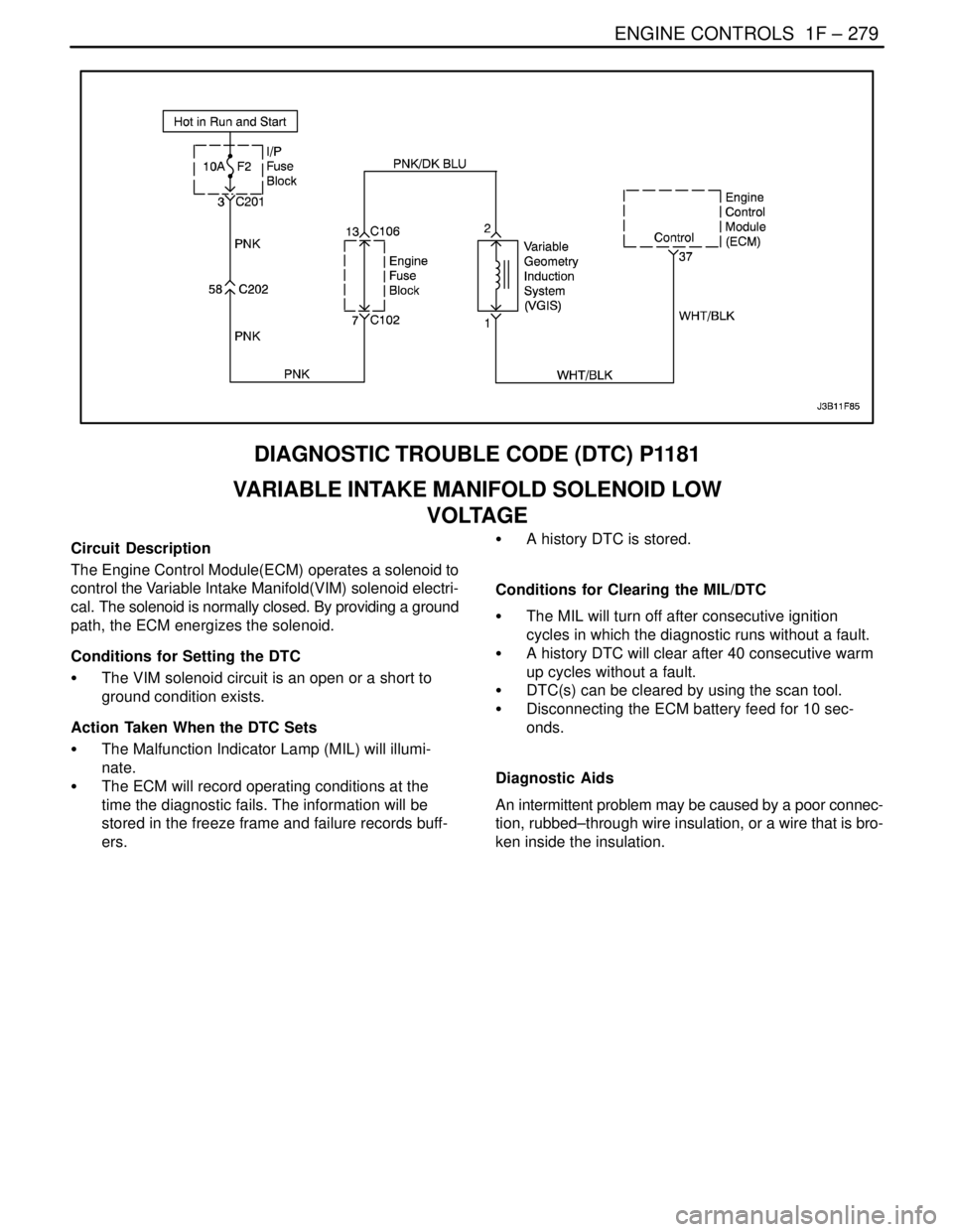

DIAGNOSTIC TROUBLE CODE (DTC) P1181

VARIABLE INTAKE MANIFOLD SOLENOID LOW

VOLTAGE

Circuit Description

The Engine Control Module(ECM) operates a solenoid to

control the Variable Intake Manifold(VIM) solenoid electri-

cal. The solenoid is normally closed. By providing a ground

path, the ECM energizes the solenoid.

Conditions for Setting the DTC

S The VIM solenoid circuit is an open or a short to

ground condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. The information will be

stored in the freeze frame and failure records buff-

ers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An intermittent problem may be caused by a poor connec-

tion, rubbed–through wire insulation, or a wire that is bro-

ken inside the insulation.

Page 526 of 2643

1F – 280IENGINE CONTROLS

DAEWOO V–121 BL4

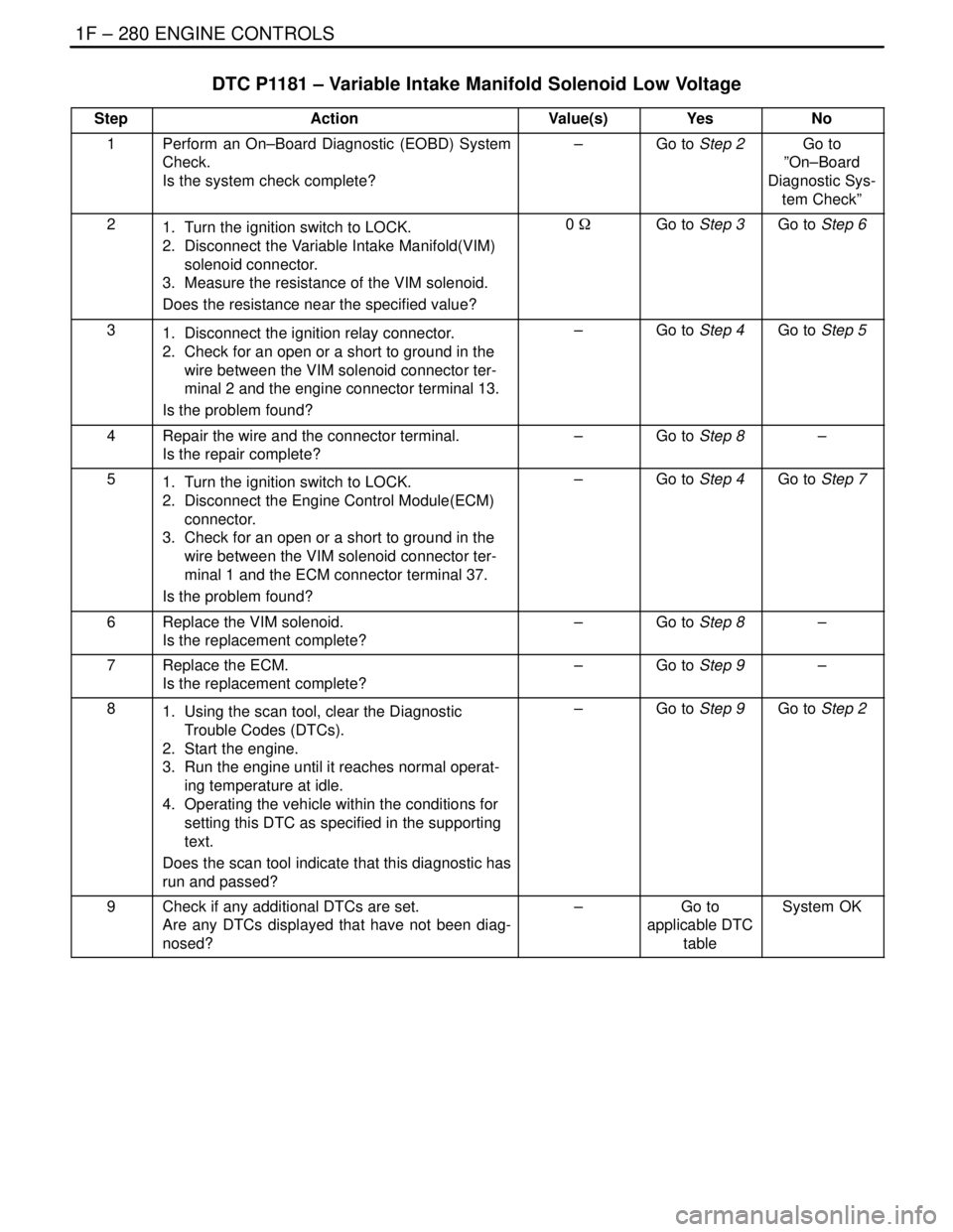

DTC P1181 – Variable Intake Manifold Solenoid Low Voltage

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch to LOCK.

2. Disconnect the Variable Intake Manifold(VIM)

solenoid connector.

3. Measure the resistance of the VIM solenoid.

Does the resistance near the specified value?0 WGo to Step 3Go to Step 6

31. Disconnect the ignition relay connector.

2. Check for an open or a short to ground in the

wire between the VIM solenoid connector ter-

minal 2 and the engine connector terminal 13.

Is the problem found?–Go to Step 4Go to Step 5

4Repair the wire and the connector terminal.

Is the repair complete?–Go to Step 8–

51. Turn the ignition switch to LOCK.

2. Disconnect the Engine Control Module(ECM)

connector.

3. Check for an open or a short to ground in the

wire between the VIM solenoid connector ter-

minal 1 and the ECM connector terminal 37.

Is the problem found?–Go to Step 4Go to Step 7

6Replace the VIM solenoid.

Is the replacement complete?–Go to Step 8–

7Replace the ECM.

Is the replacement complete?–Go to Step 9–

81. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine.

3. Run the engine until it reaches normal operat-

ing temperature at idle.

4. Operating the vehicle within the conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 9Go to Step 2

9Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

applicable DTC

tableSystem OK

Page 527 of 2643

ENGINE CONTROLS 1F – 281

DAEWOO V–121 BL4

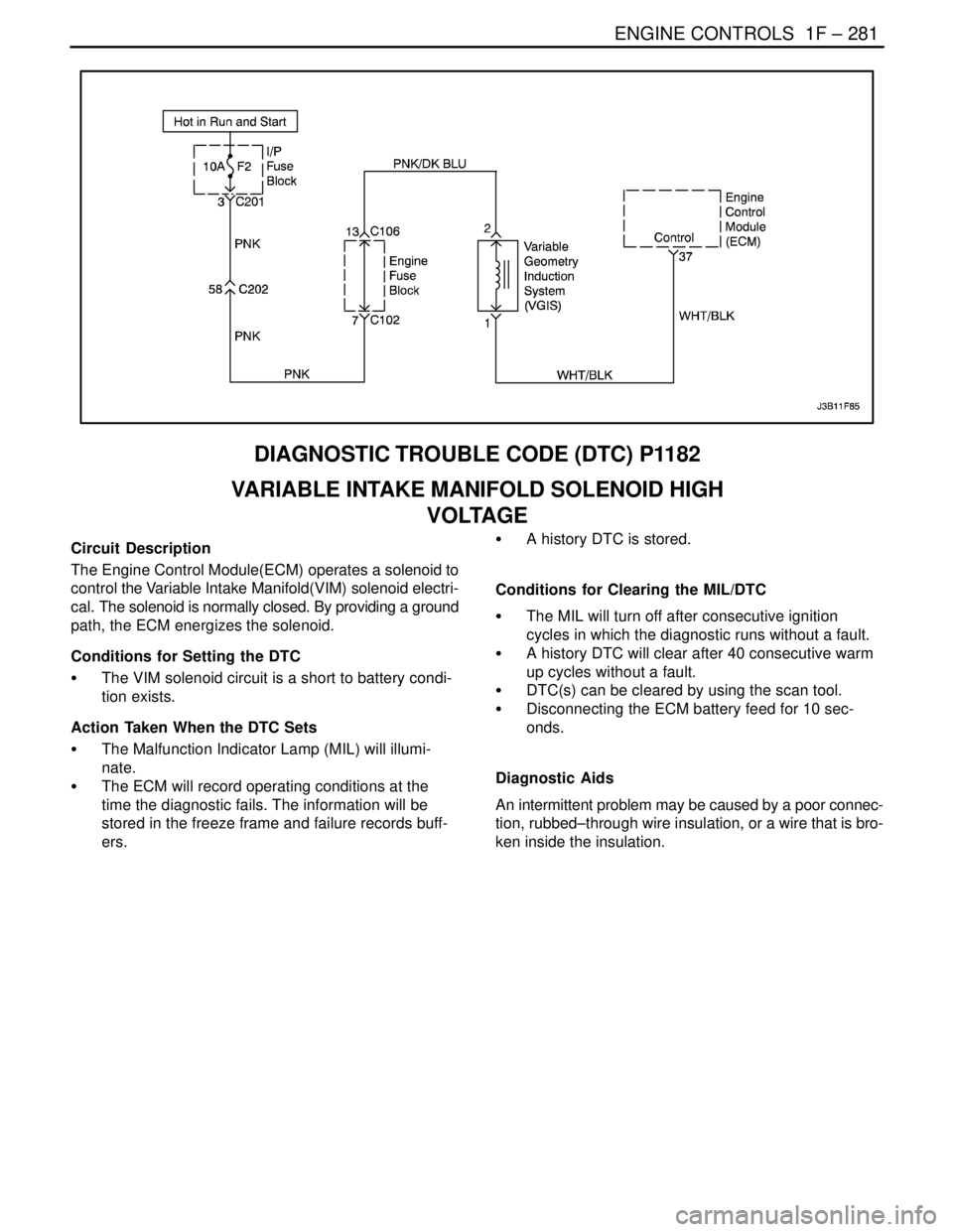

DIAGNOSTIC TROUBLE CODE (DTC) P1182

VARIABLE INTAKE MANIFOLD SOLENOID HIGH

VOLTAGE

Circuit Description

The Engine Control Module(ECM) operates a solenoid to

control the Variable Intake Manifold(VIM) solenoid electri-

cal. The solenoid is normally closed. By providing a ground

path, the ECM energizes the solenoid.

Conditions for Setting the DTC

S The VIM solenoid circuit is a short to battery condi-

tion exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. The information will be

stored in the freeze frame and failure records buff-

ers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An intermittent problem may be caused by a poor connec-

tion, rubbed–through wire insulation, or a wire that is bro-

ken inside the insulation.

Page 530 of 2643

1F – 284IENGINE CONTROLS

DAEWOO V–121 BL4

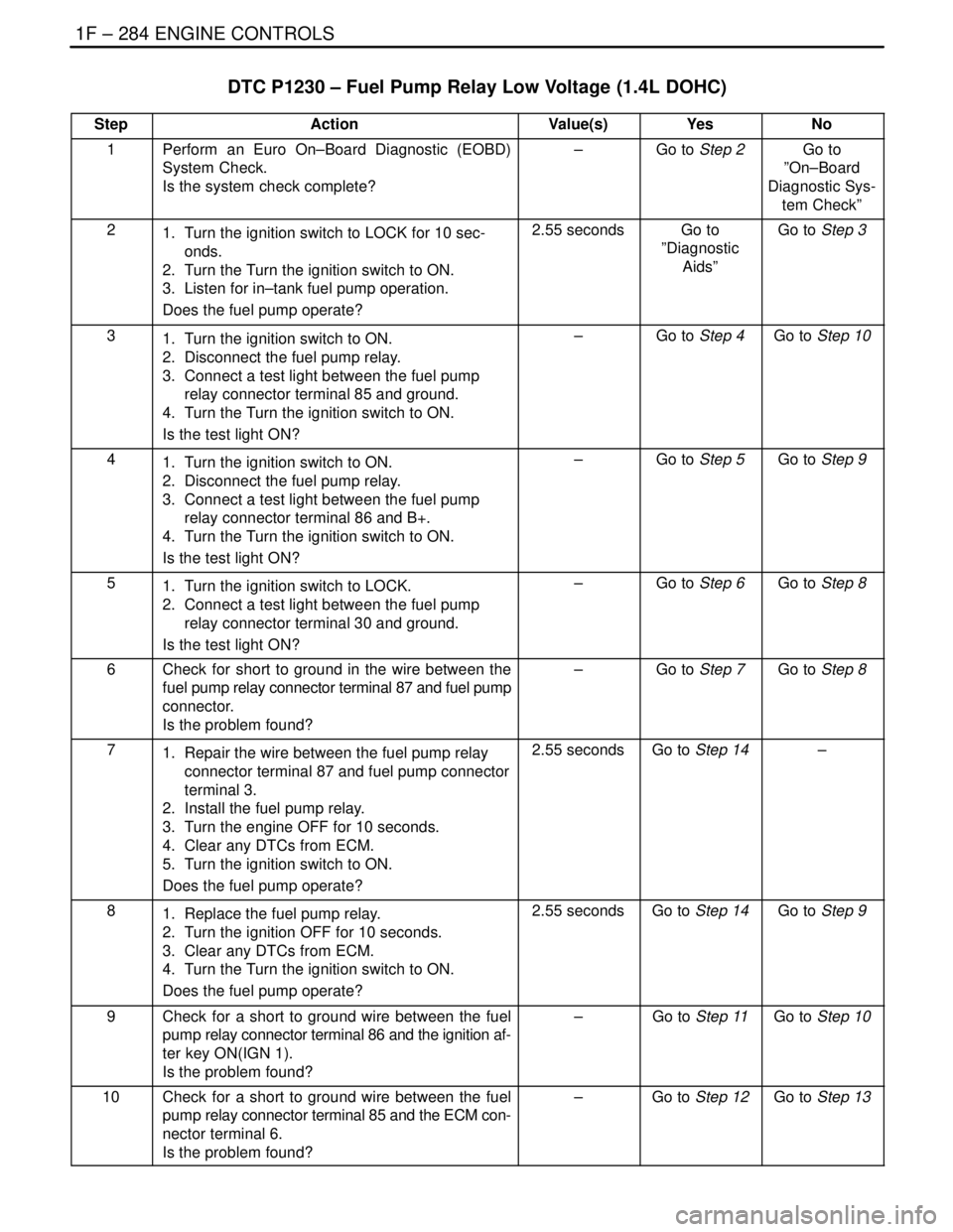

DTC P1230 – Fuel Pump Relay Low Voltage (1.4L DOHC)

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch to LOCK for 10 sec-

onds.

2. Turn the Turn the ignition switch to ON.

3. Listen for in–tank fuel pump operation.

Does the fuel pump operate?2.55 secondsGo to

”Diagnostic

Aids”Go to Step 3

31. Turn the ignition switch to ON.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 85 and ground.

4. Turn the Turn the ignition switch to ON.

Is the test light ON?–Go to Step 4Go to Step 10

41. Turn the ignition switch to ON.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 86 and B+.

4. Turn the Turn the ignition switch to ON.

Is the test light ON?–Go to Step 5Go to Step 9

51. Turn the ignition switch to LOCK.

2. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Is the test light ON?–Go to Step 6Go to Step 8

6Check for short to ground in the wire between the

fuel pump relay connector terminal 87 and fuel pump

connector.

Is the problem found?–Go to Step 7Go to Step 8

71. Repair the wire between the fuel pump relay

connector terminal 87 and fuel pump connector

terminal 3.

2. Install the fuel pump relay.

3. Turn the engine OFF for 10 seconds.

4. Clear any DTCs from ECM.

5. Turn the ignition switch to ON.

Does the fuel pump operate?2.55 secondsGo to Step 14–

81. Replace the fuel pump relay.

2. Turn the ignition OFF for 10 seconds.

3. Clear any DTCs from ECM.

4. Turn the Turn the ignition switch to ON.

Does the fuel pump operate?2.55 secondsGo to Step 14Go to Step 9

9Check for a short to ground wire between the fuel

pump relay connector terminal 86 and the ignition af-

ter key ON(IGN 1).

Is the problem found?–Go to Step 11Go to Step 10

10Check for a short to ground wire between the fuel

pump relay connector terminal 85 and the ECM con-

nector terminal 6.

Is the problem found?–Go to Step 12Go to Step 13

Page 533 of 2643

ENGINE CONTROLS 1F – 287

DAEWOO V–121 BL4

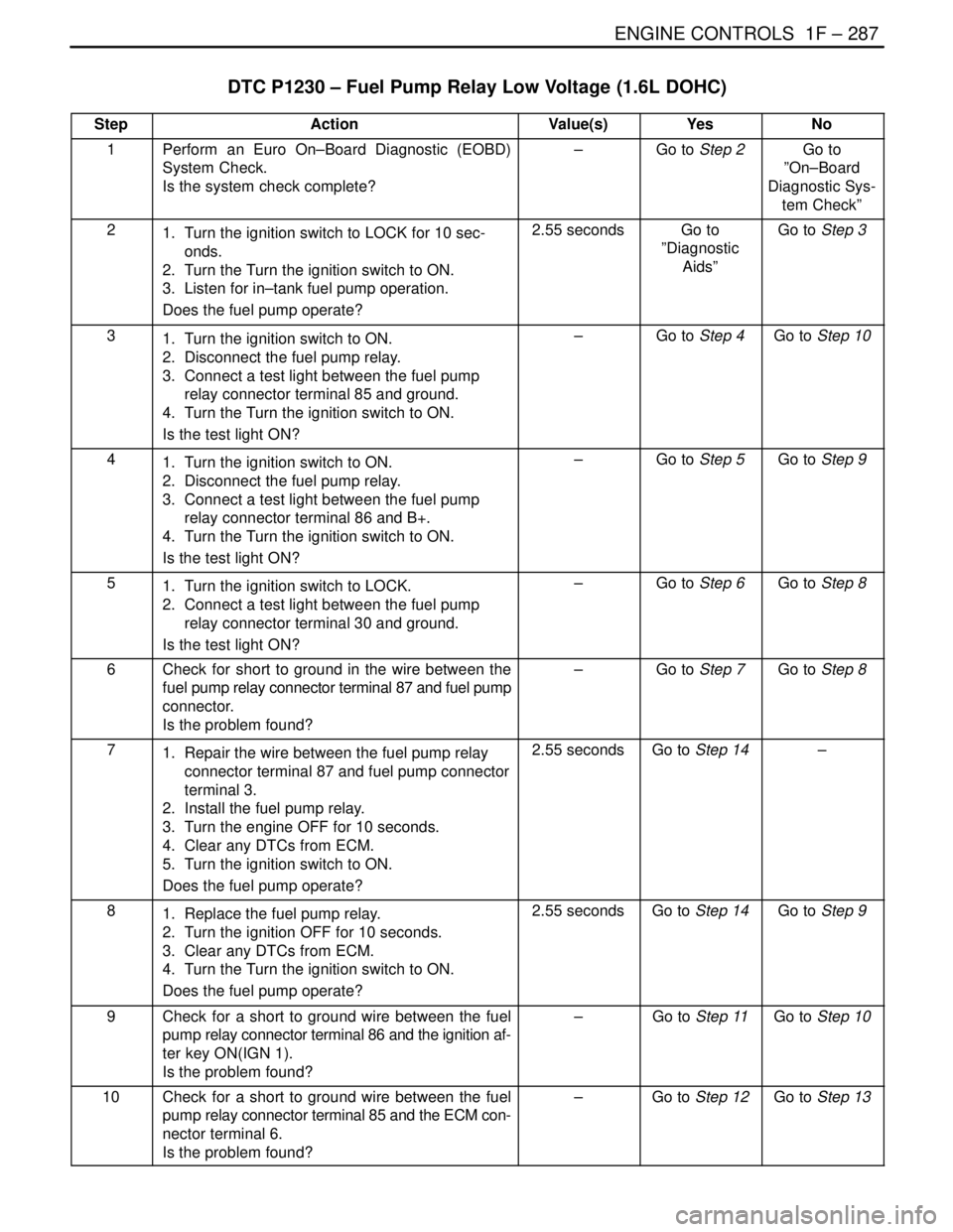

DTC P1230 – Fuel Pump Relay Low Voltage (1.6L DOHC)

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch to LOCK for 10 sec-

onds.

2. Turn the Turn the ignition switch to ON.

3. Listen for in–tank fuel pump operation.

Does the fuel pump operate?2.55 secondsGo to

”Diagnostic

Aids”Go to Step 3

31. Turn the ignition switch to ON.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 85 and ground.

4. Turn the Turn the ignition switch to ON.

Is the test light ON?–Go to Step 4Go to Step 10

41. Turn the ignition switch to ON.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 86 and B+.

4. Turn the Turn the ignition switch to ON.

Is the test light ON?–Go to Step 5Go to Step 9

51. Turn the ignition switch to LOCK.

2. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Is the test light ON?–Go to Step 6Go to Step 8

6Check for short to ground in the wire between the

fuel pump relay connector terminal 87 and fuel pump

connector.

Is the problem found?–Go to Step 7Go to Step 8

71. Repair the wire between the fuel pump relay

connector terminal 87 and fuel pump connector

terminal 3.

2. Install the fuel pump relay.

3. Turn the engine OFF for 10 seconds.

4. Clear any DTCs from ECM.

5. Turn the ignition switch to ON.

Does the fuel pump operate?2.55 secondsGo to Step 14–

81. Replace the fuel pump relay.

2. Turn the ignition OFF for 10 seconds.

3. Clear any DTCs from ECM.

4. Turn the Turn the ignition switch to ON.

Does the fuel pump operate?2.55 secondsGo to Step 14Go to Step 9

9Check for a short to ground wire between the fuel

pump relay connector terminal 86 and the ignition af-

ter key ON(IGN 1).

Is the problem found?–Go to Step 11Go to Step 10

10Check for a short to ground wire between the fuel

pump relay connector terminal 85 and the ECM con-

nector terminal 6.

Is the problem found?–Go to Step 12Go to Step 13

Page 546 of 2643

1F – 300IENGINE CONTROLS

DAEWOO V–121 BL4

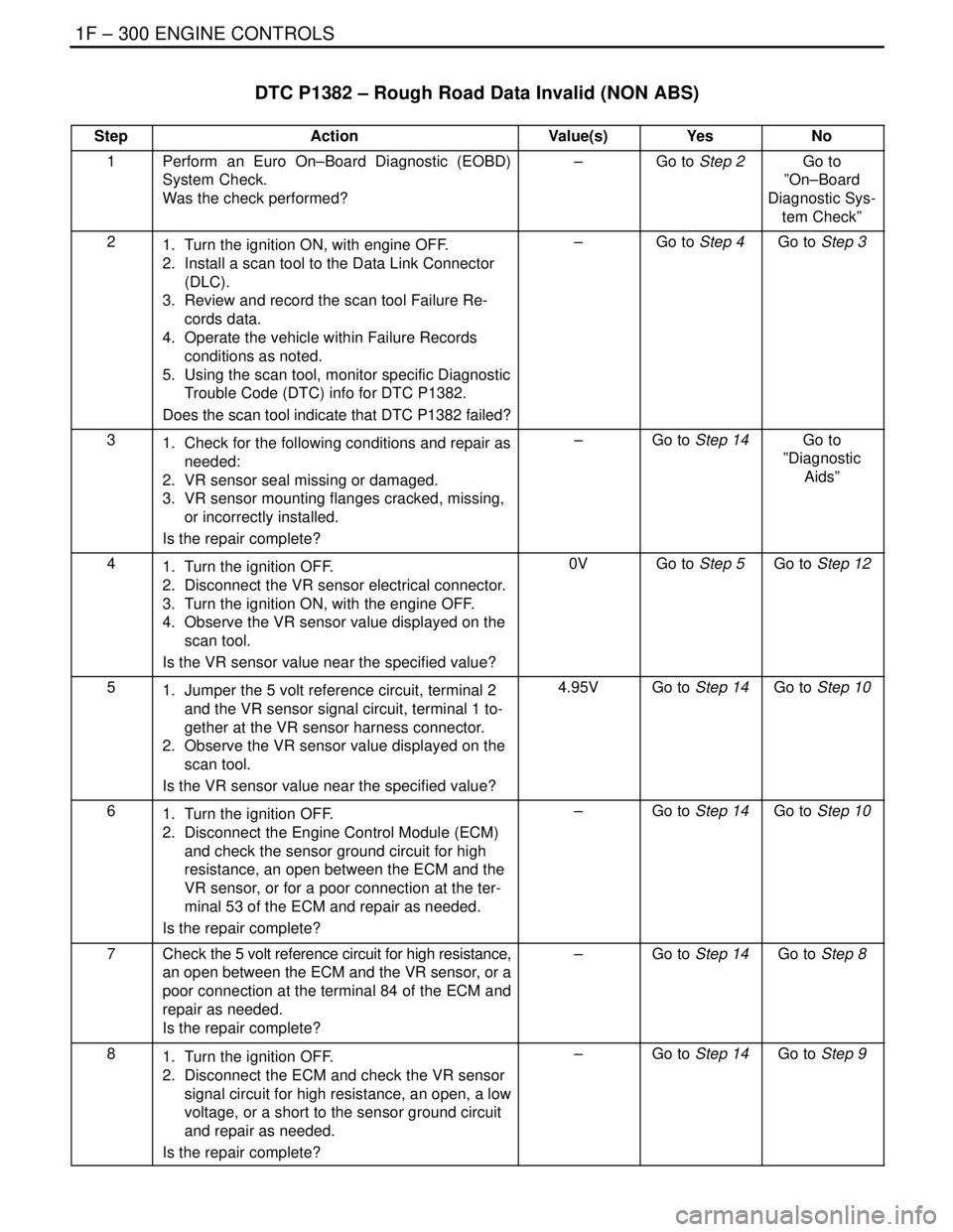

DTC P1382 – Rough Road Data Invalid (NON ABS)

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition ON, with engine OFF.

2. Install a scan tool to the Data Link Connector

(DLC).

3. Review and record the scan tool Failure Re-

cords data.

4. Operate the vehicle within Failure Records

conditions as noted.

5. Using the scan tool, monitor specific Diagnostic

Trouble Code (DTC) info for DTC P1382.

Does the scan tool indicate that DTC P1382 failed?–Go to Step 4Go to Step 3

31. Check for the following conditions and repair as

needed:

2. VR sensor seal missing or damaged.

3. VR sensor mounting flanges cracked, missing,

or incorrectly installed.

Is the repair complete?–Go to Step 14Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Disconnect the VR sensor electrical connector.

3. Turn the ignition ON, with the engine OFF.

4. Observe the VR sensor value displayed on the

scan tool.

Is the VR sensor value near the specified value?0VGo to Step 5Go to Step 12

51. Jumper the 5 volt reference circuit, terminal 2

and the VR sensor signal circuit, terminal 1 to-

gether at the VR sensor harness connector.

2. Observe the VR sensor value displayed on the

scan tool.

Is the VR sensor value near the specified value?4.95VGo to Step 14Go to Step 10

61. Turn the ignition OFF.

2. Disconnect the Engine Control Module (ECM)

and check the sensor ground circuit for high

resistance, an open between the ECM and the

VR sensor, or for a poor connection at the ter-

minal 53 of the ECM and repair as needed.

Is the repair complete?–Go to Step 14Go to Step 10

7Check the 5 volt reference circuit for high resistance,

an open between the ECM and the VR sensor, or a

poor connection at the terminal 84 of the ECM and

repair as needed.

Is the repair complete?–Go to Step 14Go to Step 8

81. Turn the ignition OFF.

2. Disconnect the ECM and check the VR sensor

signal circuit for high resistance, an open, a low

voltage, or a short to the sensor ground circuit

and repair as needed.

Is the repair complete?–Go to Step 14Go to Step 9

Page 549 of 2643

ENGINE CONTROLS 1F – 303

DAEWOO V–121 BL4

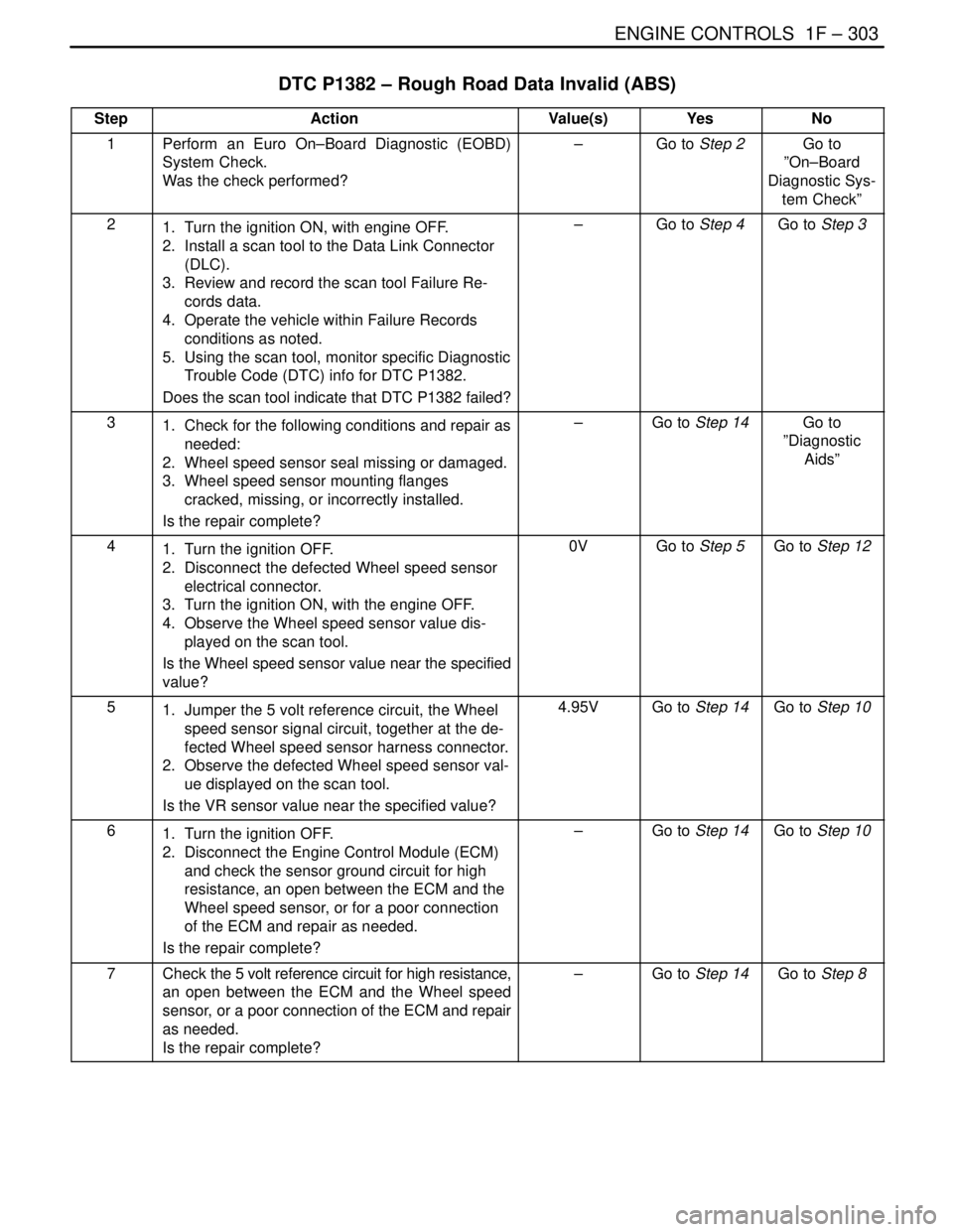

DTC P1382 – Rough Road Data Invalid (ABS)

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition ON, with engine OFF.

2. Install a scan tool to the Data Link Connector

(DLC).

3. Review and record the scan tool Failure Re-

cords data.

4. Operate the vehicle within Failure Records

conditions as noted.

5. Using the scan tool, monitor specific Diagnostic

Trouble Code (DTC) info for DTC P1382.

Does the scan tool indicate that DTC P1382 failed?–Go to Step 4Go to Step 3

31. Check for the following conditions and repair as

needed:

2. Wheel speed sensor seal missing or damaged.

3. Wheel speed sensor mounting flanges

cracked, missing, or incorrectly installed.

Is the repair complete?–Go to Step 14Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Disconnect the defected Wheel speed sensor

electrical connector.

3. Turn the ignition ON, with the engine OFF.

4. Observe the Wheel speed sensor value dis-

played on the scan tool.

Is the Wheel speed sensor value near the specified

value?0VGo to Step 5Go to Step 12

51. Jumper the 5 volt reference circuit, the Wheel

speed sensor signal circuit, together at the de-

fected Wheel speed sensor harness connector.

2. Observe the defected Wheel speed sensor val-

ue displayed on the scan tool.

Is the VR sensor value near the specified value?4.95VGo to Step 14Go to Step 10

61. Turn the ignition OFF.

2. Disconnect the Engine Control Module (ECM)

and check the sensor ground circuit for high

resistance, an open between the ECM and the

Wheel speed sensor, or for a poor connection

of the ECM and repair as needed.

Is the repair complete?–Go to Step 14Go to Step 10

7Check the 5 volt reference circuit for high resistance,

an open between the ECM and the Wheel speed

sensor, or a poor connection of the ECM and repair

as needed.

Is the repair complete?–Go to Step 14Go to Step 8

Page 550 of 2643

1F – 304IENGINE CONTROLS

DAEWOO V–121 BL4

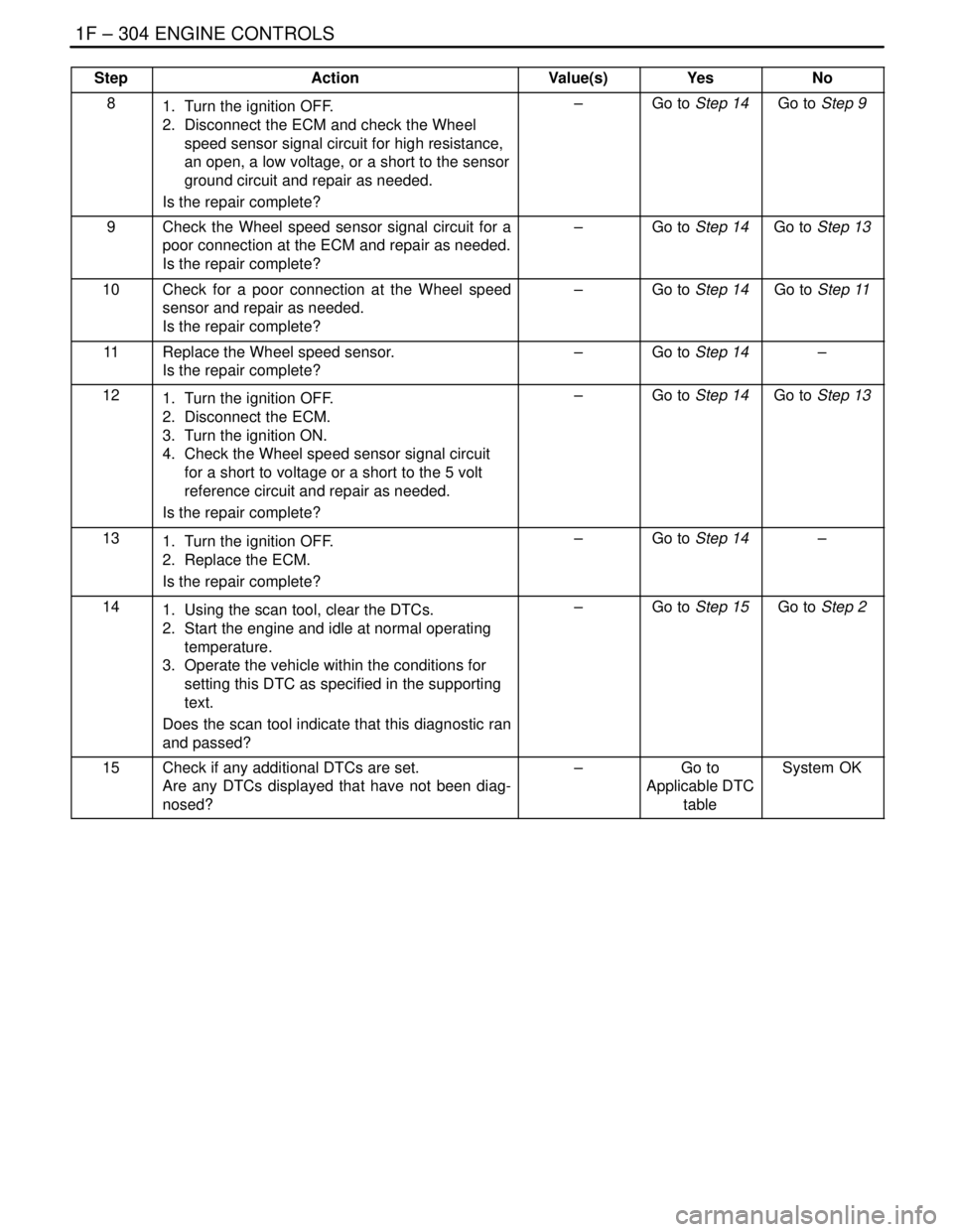

StepNo Yes Value(s) Action

81. Turn the ignition OFF.

2. Disconnect the ECM and check the Wheel

speed sensor signal circuit for high resistance,

an open, a low voltage, or a short to the sensor

ground circuit and repair as needed.

Is the repair complete?–Go to Step 14Go to Step 9

9Check the Wheel speed sensor signal circuit for a

poor connection at the ECM and repair as needed.

Is the repair complete?–Go to Step 14Go to Step 13

10Check for a poor connection at the Wheel speed

sensor and repair as needed.

Is the repair complete?–Go to Step 14Go to Step 11

11Replace the Wheel speed sensor.

Is the repair complete?–Go to Step 14–

121. Turn the ignition OFF.

2. Disconnect the ECM.

3. Turn the ignition ON.

4. Check the Wheel speed sensor signal circuit

for a short to voltage or a short to the 5 volt

reference circuit and repair as needed.

Is the repair complete?–Go to Step 14Go to Step 13

131. Turn the ignition OFF.

2. Replace the ECM.

Is the repair complete?–Go to Step 14–

141. Using the scan tool, clear the DTCs.

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic ran

and passed?–Go to Step 15Go to Step 2

15Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 552 of 2643

1F – 306IENGINE CONTROLS

DAEWOO V–121 BL4

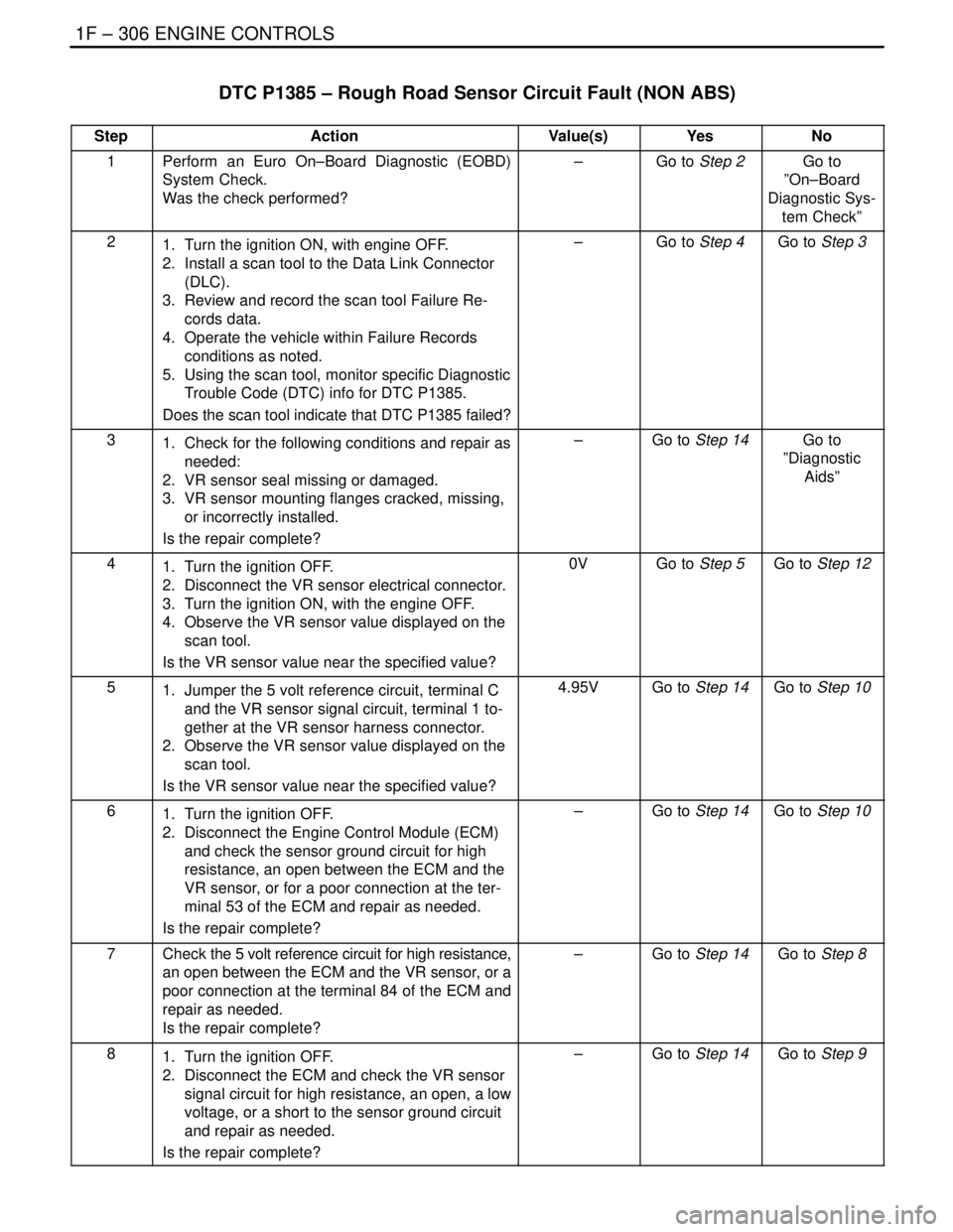

DTC P1385 – Rough Road Sensor Circuit Fault (NON ABS)

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition ON, with engine OFF.

2. Install a scan tool to the Data Link Connector

(DLC).

3. Review and record the scan tool Failure Re-

cords data.

4. Operate the vehicle within Failure Records

conditions as noted.

5. Using the scan tool, monitor specific Diagnostic

Trouble Code (DTC) info for DTC P1385.

Does the scan tool indicate that DTC P1385 failed?–Go to Step 4Go to Step 3

31. Check for the following conditions and repair as

needed:

2. VR sensor seal missing or damaged.

3. VR sensor mounting flanges cracked, missing,

or incorrectly installed.

Is the repair complete?–Go to Step 14Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Disconnect the VR sensor electrical connector.

3. Turn the ignition ON, with the engine OFF.

4. Observe the VR sensor value displayed on the

scan tool.

Is the VR sensor value near the specified value?0VGo to Step 5Go to Step 12

51. Jumper the 5 volt reference circuit, terminal C

and the VR sensor signal circuit, terminal 1 to-

gether at the VR sensor harness connector.

2. Observe the VR sensor value displayed on the

scan tool.

Is the VR sensor value near the specified value?4.95VGo to Step 14Go to Step 10

61. Turn the ignition OFF.

2. Disconnect the Engine Control Module (ECM)

and check the sensor ground circuit for high

resistance, an open between the ECM and the

VR sensor, or for a poor connection at the ter-

minal 53 of the ECM and repair as needed.

Is the repair complete?–Go to Step 14Go to Step 10

7Check the 5 volt reference circuit for high resistance,

an open between the ECM and the VR sensor, or a

poor connection at the terminal 84 of the ECM and

repair as needed.

Is the repair complete?–Go to Step 14Go to Step 8

81. Turn the ignition OFF.

2. Disconnect the ECM and check the VR sensor

signal circuit for high resistance, an open, a low

voltage, or a short to the sensor ground circuit

and repair as needed.

Is the repair complete?–Go to Step 14Go to Step 9

Page 554 of 2643

1F – 308IENGINE CONTROLS

DAEWOO V–121 BL4

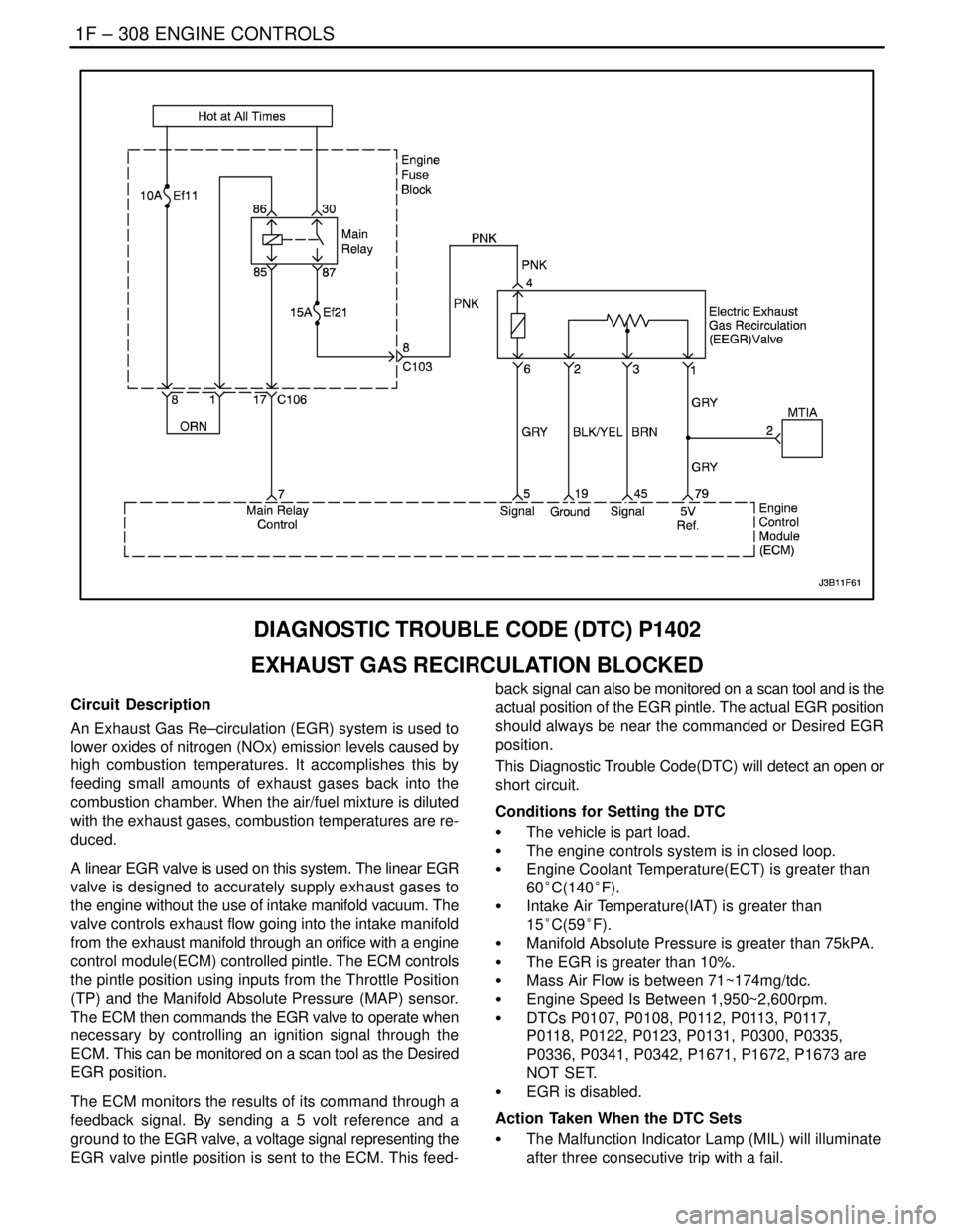

DIAGNOSTIC TROUBLE CODE (DTC) P1402

EXHAUST GAS RECIRCULATION BLOCKED

Circuit Description

An Exhaust Gas Re–circulation (EGR) system is used to

lower oxides of nitrogen (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced.

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with a engine

control module(ECM) controlled pintle. The ECM controls

the pintle position using inputs from the Throttle Position

(TP) and the Manifold Absolute Pressure (MAP) sensor.

The ECM then commands the EGR valve to operate when

necessary by controlling an ignition signal through the

ECM. This can be monitored on a scan tool as the Desired

EGR position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The actual EGR position

should always be near the commanded or Desired EGR

position.

This Diagnostic Trouble Code(DTC) will detect an open or

short circuit.

Conditions for Setting the DTC

S The vehicle is part load.

S The engine controls system is in closed loop.

S Engine Coolant Temperature(ECT) is greater than

60°C(140°F).

S Intake Air Temperature(IAT) is greater than

15°C(59°F).

S Manifold Absolute Pressure is greater than 75kPA.

S The EGR is greater than 10%.

S Mass Air Flow is between 71~174mg/tdc.

S Engine Speed Is Between 1,950~2,600rpm.

S DTCs P0107, P0108, P0112, P0113, P0117,

P0118, P0122, P0123, P0131, P0300, P0335,

P0336, P0341, P0342, P1671, P1672, P1673 are

NOT SET.

S EGR is disabled.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.