ground DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 610 of 2643

1F – 364IENGINE CONTROLS

DAEWOO V–121 BL4

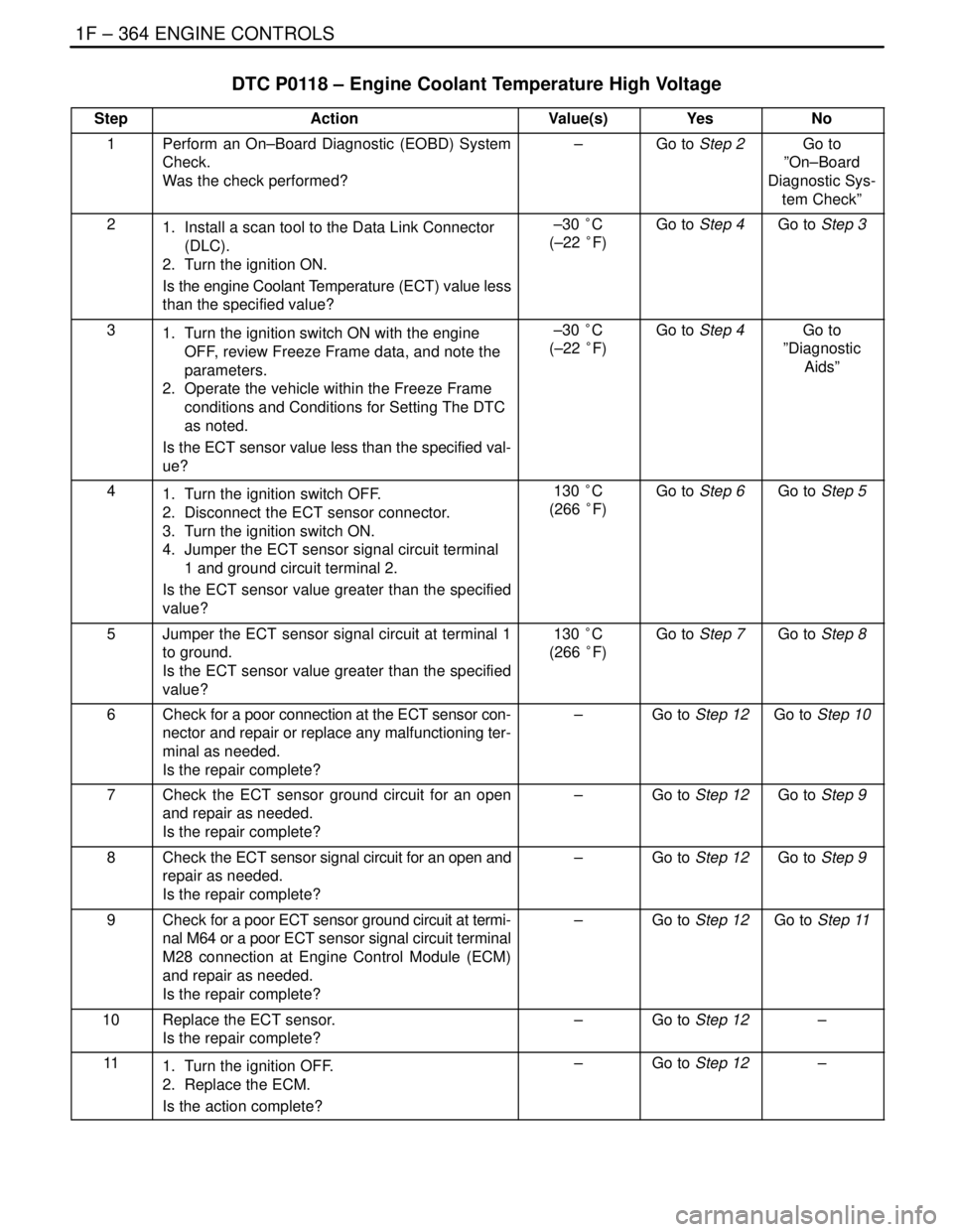

DTC P0118 – Engine Coolant Temperature High Voltage

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON.

Is the engine Coolant Temperature (ECT) value less

than the specified value?–30 °C

(–22 °F)Go to Step 4Go to Step 3

31. Turn the ignition switch ON with the engine

OFF, review Freeze Frame data, and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions and Conditions for Setting The DTC

as noted.

Is the ECT sensor value less than the specified val-

ue?–30 °C

(–22 °F)Go to Step 4Go to

”Diagnostic

Aids”

41. Turn the ignition switch OFF.

2. Disconnect the ECT sensor connector.

3. Turn the ignition switch ON.

4. Jumper the ECT sensor signal circuit terminal

1 and ground circuit terminal 2.

Is the ECT sensor value greater than the specified

value?130 °C

(266 °F)Go to Step 6Go to Step 5

5Jumper the ECT sensor signal circuit at terminal 1

to ground.

Is the ECT sensor value greater than the specified

value?130 °C

(266 °F)Go to Step 7Go to Step 8

6Check for a poor connection at the ECT sensor con-

nector and repair or replace any malfunctioning ter-

minal as needed.

Is the repair complete?–Go to Step 12Go to Step 10

7Check the ECT sensor ground circuit for an open

and repair as needed.

Is the repair complete?–Go to Step 12Go to Step 9

8Check the ECT sensor signal circuit for an open and

repair as needed.

Is the repair complete?–Go to Step 12Go to Step 9

9Check for a poor ECT sensor ground circuit at termi-

nal M64 or a poor ECT sensor signal circuit terminal

M28 connection at Engine Control Module (ECM)

and repair as needed.

Is the repair complete?–Go to Step 12Go to Step 11

10Replace the ECT sensor.

Is the repair complete?–Go to Step 12–

111. Turn the ignition OFF.

2. Replace the ECM.

Is the action complete?–Go to Step 12–

Page 612 of 2643

1F – 366IENGINE CONTROLS

DAEWOO V–121 BL4

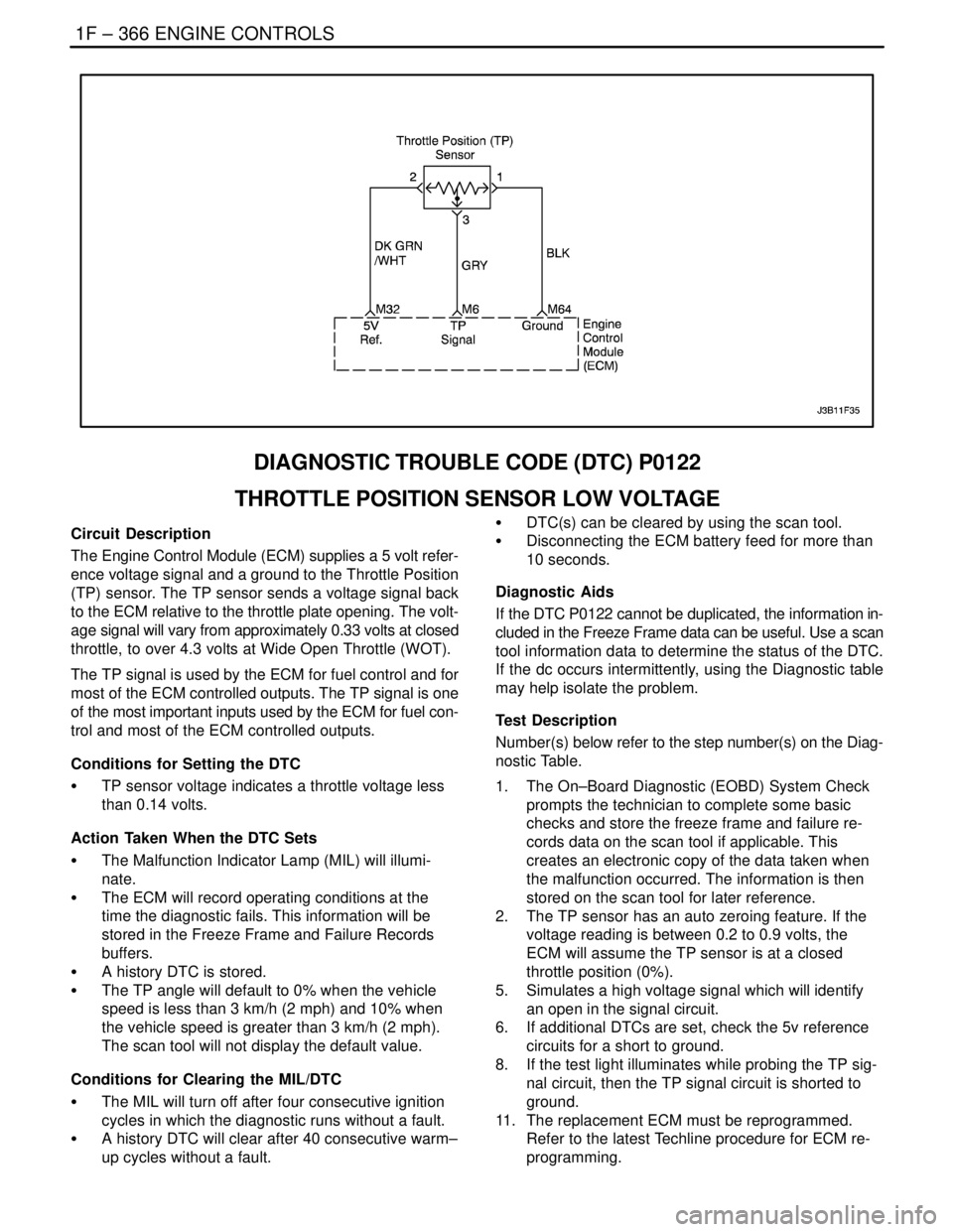

DIAGNOSTIC TROUBLE CODE (DTC) P0122

THROTTLE POSITION SENSOR LOW VOLTAGE

Circuit Description

The Engine Control Module (ECM) supplies a 5 volt refer-

ence voltage signal and a ground to the Throttle Position

(TP) sensor. The TP sensor sends a voltage signal back

to the ECM relative to the throttle plate opening. The volt-

age signal will vary from approximately 0.33 volts at closed

throttle, to over 4.3 volts at Wide Open Throttle (WOT).

The TP signal is used by the ECM for fuel control and for

most of the ECM controlled outputs. The TP signal is one

of the most important inputs used by the ECM for fuel con-

trol and most of the ECM controlled outputs.

Conditions for Setting the DTC

S TP sensor voltage indicates a throttle voltage less

than 0.14 volts.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S The TP angle will default to 0% when the vehicle

speed is less than 3 km/h (2 mph) and 10% when

the vehicle speed is greater than 3 km/h (2 mph).

The scan tool will not display the default value.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

If the DTC P0122 cannot be duplicated, the information in-

cluded in the Freeze Frame data can be useful. Use a scan

tool information data to determine the status of the DTC.

If the dc occurs intermittently, using the Diagnostic table

may help isolate the problem.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. The TP sensor has an auto zeroing feature. If the

voltage reading is between 0.2 to 0.9 volts, the

ECM will assume the TP sensor is at a closed

throttle position (0%).

5. Simulates a high voltage signal which will identify

an open in the signal circuit.

6. If additional DTCs are set, check the 5v reference

circuits for a short to ground.

8. If the test light illuminates while probing the TP sig-

nal circuit, then the TP signal circuit is shorted to

ground.

11. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

Page 613 of 2643

ENGINE CONTROLS 1F – 367

DAEWOO V–121 BL4

13. If no faults have been found at this point and no

additional DTCs were set, refer to ”Diagnostic

Aids”for additional checks and information.

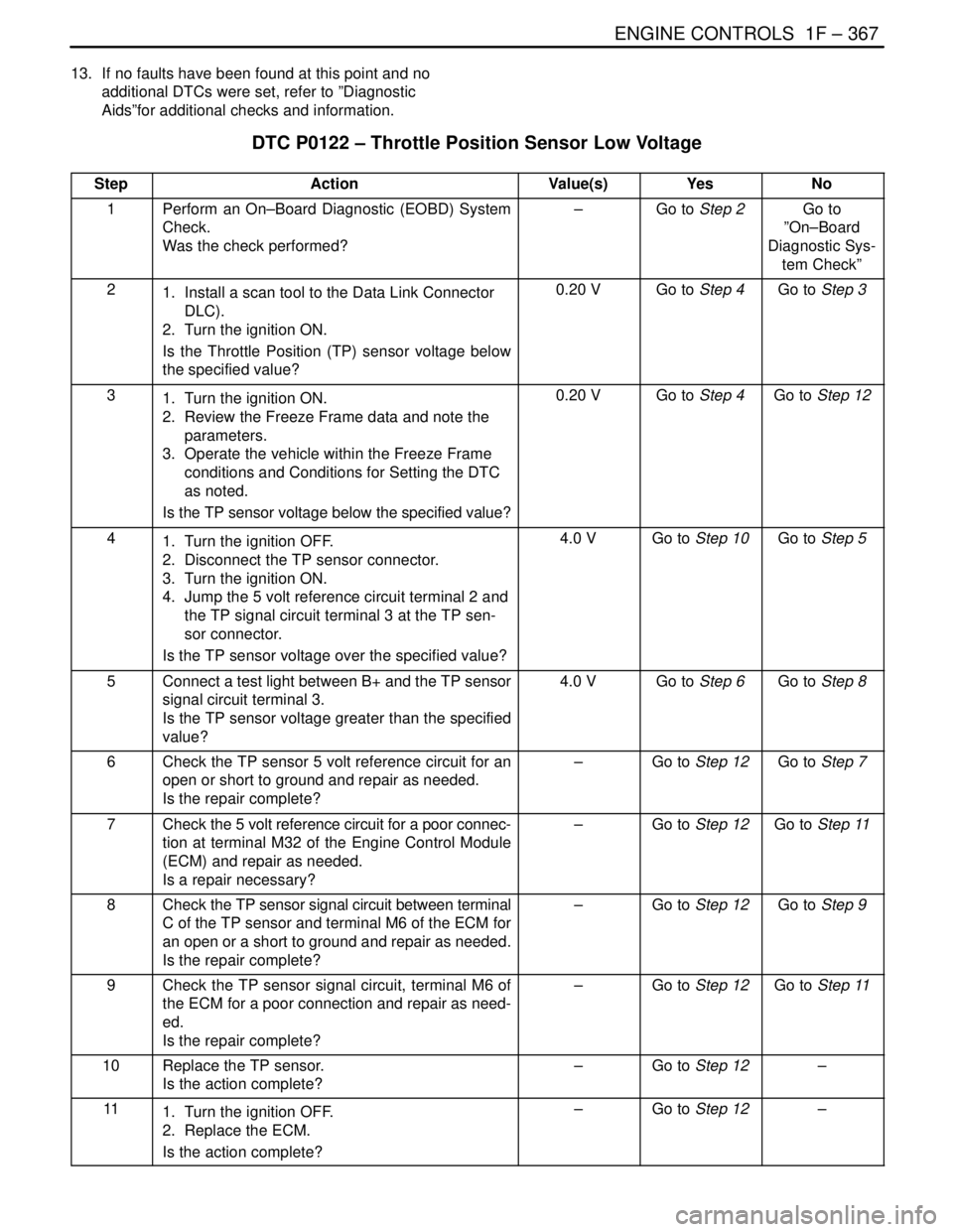

DTC P0122 – Throttle Position Sensor Low Voltage

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

DLC).

2. Turn the ignition ON.

Is the Throttle Position (TP) sensor voltage below

the specified value?0.20 VGo to Step 4Go to Step 3

31. Turn the ignition ON.

2. Review the Freeze Frame data and note the

parameters.

3. Operate the vehicle within the Freeze Frame

conditions and Conditions for Setting the DTC

as noted.

Is the TP sensor voltage below the specified value?0.20 VGo to Step 4Go to Step 12

41. Turn the ignition OFF.

2. Disconnect the TP sensor connector.

3. Turn the ignition ON.

4. Jump the 5 volt reference circuit terminal 2 and

the TP signal circuit terminal 3 at the TP sen-

sor connector.

Is the TP sensor voltage over the specified value?4.0 VGo to Step 10Go to Step 5

5Connect a test light between B+ and the TP sensor

signal circuit terminal 3.

Is the TP sensor voltage greater than the specified

value?4.0 VGo to Step 6Go to Step 8

6Check the TP sensor 5 volt reference circuit for an

open or short to ground and repair as needed.

Is the repair complete?–Go to Step 12Go to Step 7

7Check the 5 volt reference circuit for a poor connec-

tion at terminal M32 of the Engine Control Module

(ECM) and repair as needed.

Is a repair necessary?–Go to Step 12Go to Step 11

8Check the TP sensor signal circuit between terminal

C of the TP sensor and terminal M6 of the ECM for

an open or a short to ground and repair as needed.

Is the repair complete?–Go to Step 12Go to Step 9

9Check the TP sensor signal circuit, terminal M6 of

the ECM for a poor connection and repair as need-

ed.

Is the repair complete?–Go to Step 12Go to Step 11

10Replace the TP sensor.

Is the action complete?–Go to Step 12–

111. Turn the ignition OFF.

2. Replace the ECM.

Is the action complete?–Go to Step 12–

Page 615 of 2643

ENGINE CONTROLS 1F – 369

DAEWOO V–121 BL4

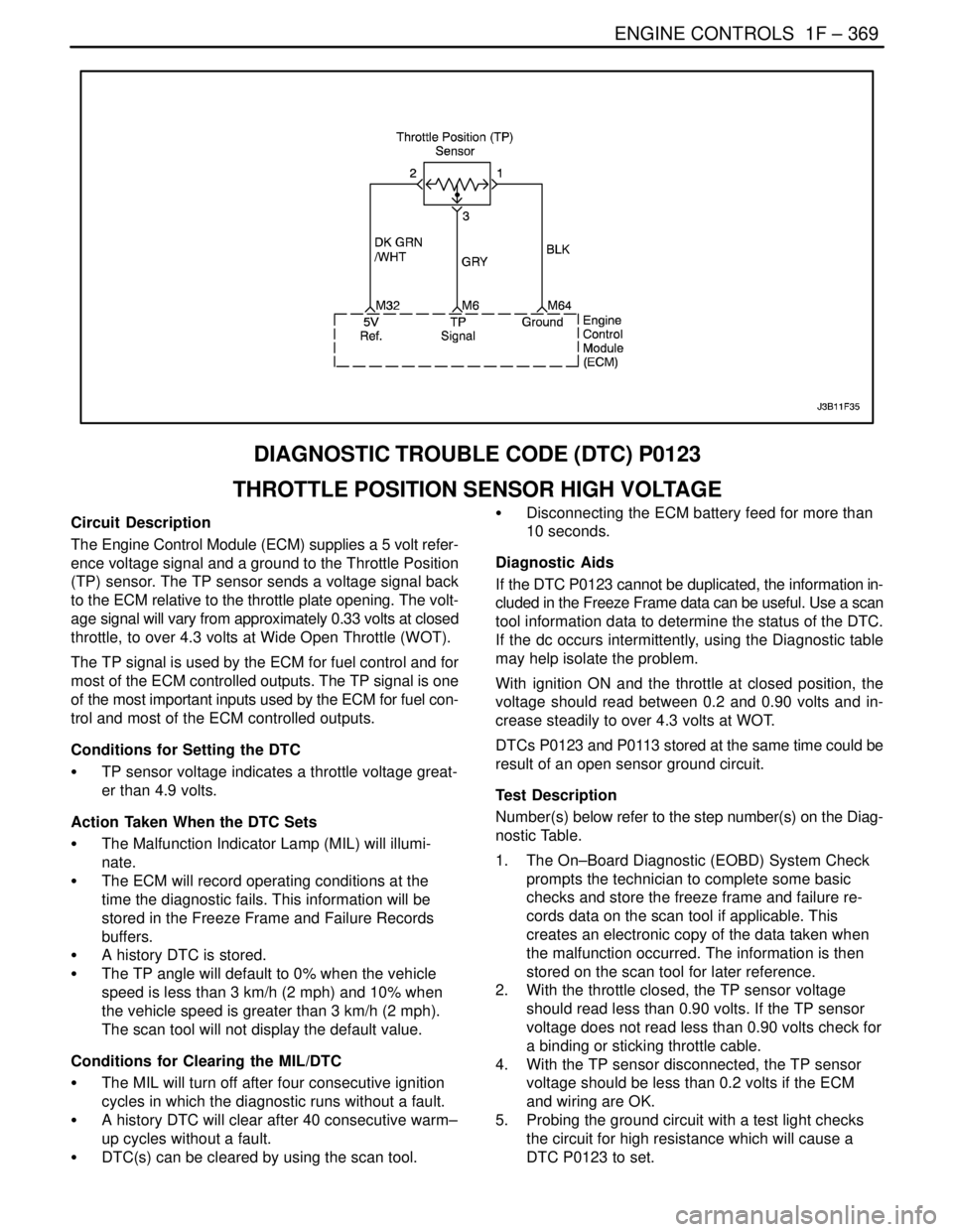

DIAGNOSTIC TROUBLE CODE (DTC) P0123

THROTTLE POSITION SENSOR HIGH VOLTAGE

Circuit Description

The Engine Control Module (ECM) supplies a 5 volt refer-

ence voltage signal and a ground to the Throttle Position

(TP) sensor. The TP sensor sends a voltage signal back

to the ECM relative to the throttle plate opening. The volt-

age signal will vary from approximately 0.33 volts at closed

throttle, to over 4.3 volts at Wide Open Throttle (WOT).

The TP signal is used by the ECM for fuel control and for

most of the ECM controlled outputs. The TP signal is one

of the most important inputs used by the ECM for fuel con-

trol and most of the ECM controlled outputs.

Conditions for Setting the DTC

S TP sensor voltage indicates a throttle voltage great-

er than 4.9 volts.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S The TP angle will default to 0% when the vehicle

speed is less than 3 km/h (2 mph) and 10% when

the vehicle speed is greater than 3 km/h (2 mph).

The scan tool will not display the default value.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

If the DTC P0123 cannot be duplicated, the information in-

cluded in the Freeze Frame data can be useful. Use a scan

tool information data to determine the status of the DTC.

If the dc occurs intermittently, using the Diagnostic table

may help isolate the problem.

With ignition ON and the throttle at closed position, the

voltage should read between 0.2 and 0.90 volts and in-

crease steadily to over 4.3 volts at WOT.

DTCs P0123 and P0113 stored at the same time could be

result of an open sensor ground circuit.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. With the throttle closed, the TP sensor voltage

should read less than 0.90 volts. If the TP sensor

voltage does not read less than 0.90 volts check for

a binding or sticking throttle cable.

4. With the TP sensor disconnected, the TP sensor

voltage should be less than 0.2 volts if the ECM

and wiring are OK.

5. Probing the ground circuit with a test light checks

the circuit for high resistance which will cause a

DTC P0123 to set.

Page 616 of 2643

1F – 370IENGINE CONTROLS

DAEWOO V–121 BL4

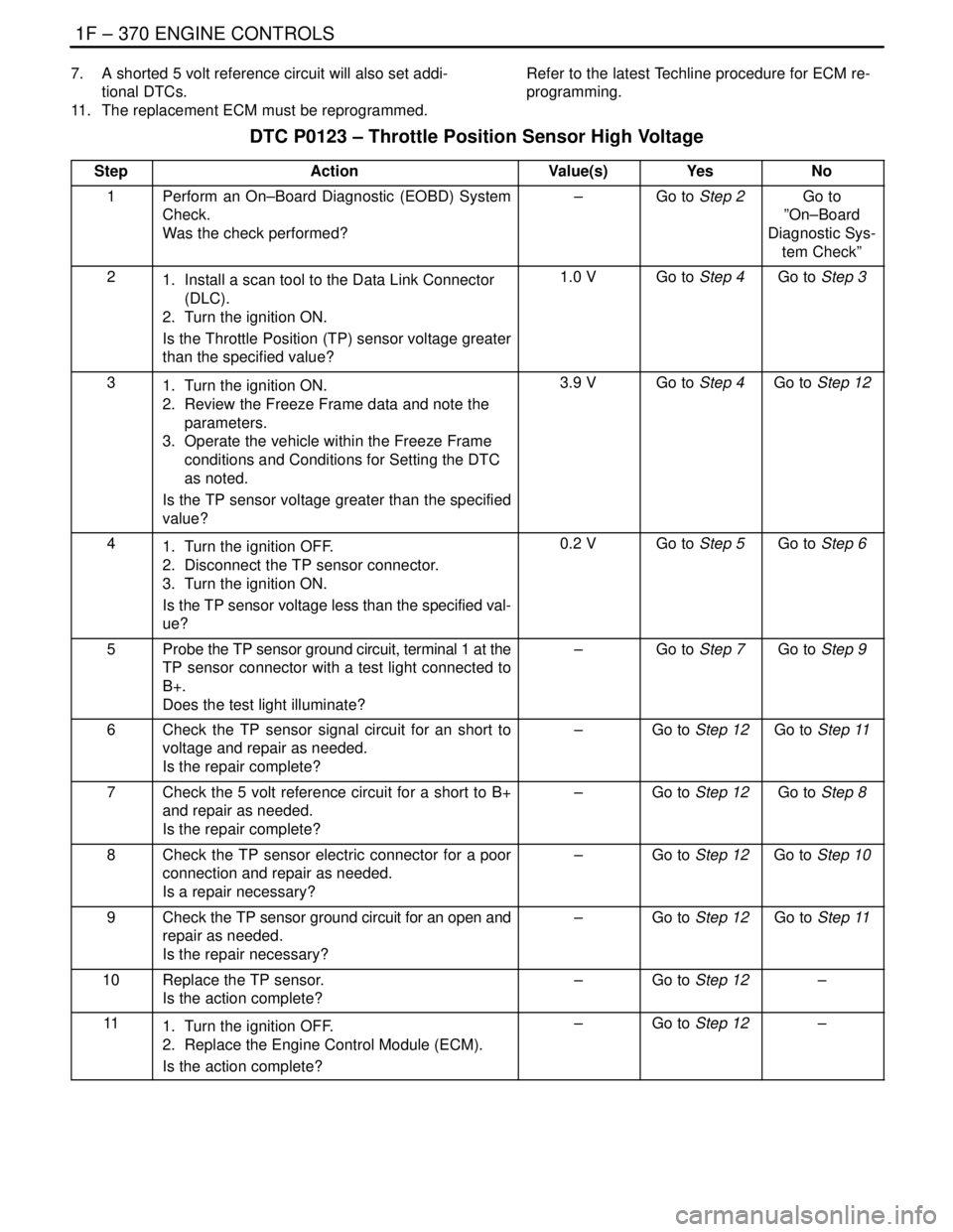

7. A shorted 5 volt reference circuit will also set addi-

tional DTCs.

11. The replacement ECM must be reprogrammed.Refer to the latest Techline procedure for ECM re-

programming.

DTC P0123 – Throttle Position Sensor High Voltage

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON.

Is the Throttle Position (TP) sensor voltage greater

than the specified value?1.0 VGo to Step 4Go to Step 3

31. Turn the ignition ON.

2. Review the Freeze Frame data and note the

parameters.

3. Operate the vehicle within the Freeze Frame

conditions and Conditions for Setting the DTC

as noted.

Is the TP sensor voltage greater than the specified

value?3.9 VGo to Step 4Go to Step 12

41. Turn the ignition OFF.

2. Disconnect the TP sensor connector.

3. Turn the ignition ON.

Is the TP sensor voltage less than the specified val-

ue?0.2 VGo to Step 5Go to Step 6

5Probe the TP sensor ground circuit, terminal 1 at the

TP sensor connector with a test light connected to

B+.

Does the test light illuminate?–Go to Step 7Go to Step 9

6Check the TP sensor signal circuit for an short to

voltage and repair as needed.

Is the repair complete?–Go to Step 12Go to Step 11

7Check the 5 volt reference circuit for a short to B+

and repair as needed.

Is the repair complete?–Go to Step 12Go to Step 8

8Check the TP sensor electric connector for a poor

connection and repair as needed.

Is a repair necessary?–Go to Step 12Go to Step 10

9Check the TP sensor ground circuit for an open and

repair as needed.

Is the repair necessary?–Go to Step 12Go to Step 11

10Replace the TP sensor.

Is the action complete?–Go to Step 12–

111. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the action complete?–Go to Step 12–

Page 619 of 2643

ENGINE CONTROLS 1F – 373

DAEWOO V–121 BL4

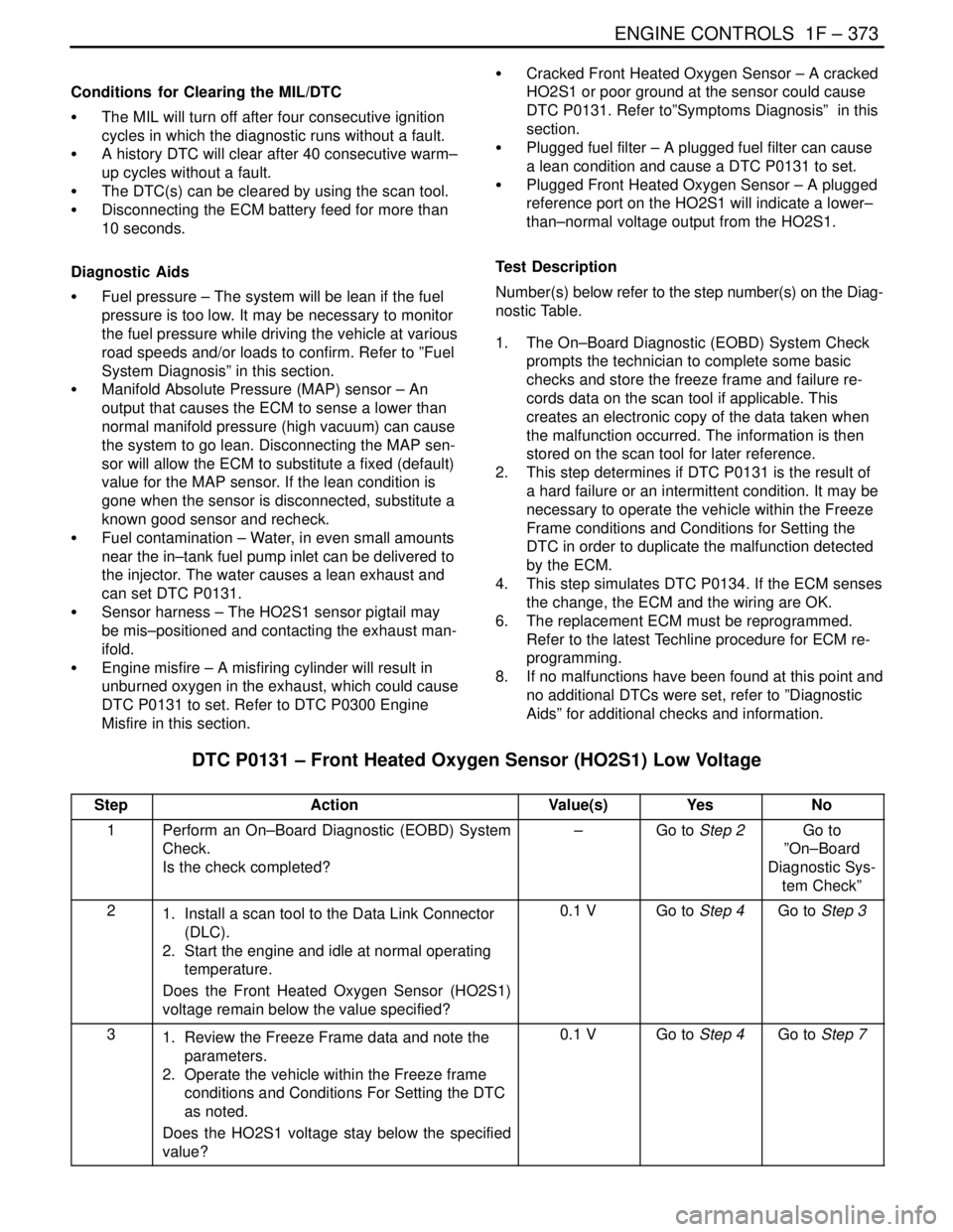

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

S Fuel pressure – The system will be lean if the fuel

pressure is too low. It may be necessary to monitor

the fuel pressure while driving the vehicle at various

road speeds and/or loads to confirm. Refer to ”Fuel

System Diagnosis” in this section.

S Manifold Absolute Pressure (MAP) sensor – An

output that causes the ECM to sense a lower than

normal manifold pressure (high vacuum) can cause

the system to go lean. Disconnecting the MAP sen-

sor will allow the ECM to substitute a fixed (default)

value for the MAP sensor. If the lean condition is

gone when the sensor is disconnected, substitute a

known good sensor and recheck.

S Fuel contamination – Water, in even small amounts

near the in–tank fuel pump inlet can be delivered to

the injector. The water causes a lean exhaust and

can set DTC P0131.

S Sensor harness – The HO2S1 sensor pigtail may

be mis–positioned and contacting the exhaust man-

ifold.

S Engine misfire – A misfiring cylinder will result in

unburned oxygen in the exhaust, which could cause

DTC P0131 to set. Refer to DTC P0300 Engine

Misfire in this section.S Cracked Front Heated Oxygen Sensor – A cracked

HO2S1 or poor ground at the sensor could cause

DTC P0131. Refer to”Symptoms Diagnosis” in this

section.

S Plugged fuel filter – A plugged fuel filter can cause

a lean condition and cause a DTC P0131 to set.

S Plugged Front Heated Oxygen Sensor – A plugged

reference port on the HO2S1 will indicate a lower–

than–normal voltage output from the HO2S1.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. This step determines if DTC P0131 is the result of

a hard failure or an intermittent condition. It may be

necessary to operate the vehicle within the Freeze

Frame conditions and Conditions for Setting the

DTC in order to duplicate the malfunction detected

by the ECM.

4. This step simulates DTC P0134. If the ECM senses

the change, the ECM and the wiring are OK.

6. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

8. If no malfunctions have been found at this point and

no additional DTCs were set, refer to ”Diagnostic

Aids” for additional checks and information.

DTC P0131 – Front Heated Oxygen Sensor (HO2S1) Low Voltage

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the check completed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Start the engine and idle at normal operating

temperature.

Does the Front Heated Oxygen Sensor (HO2S1)

voltage remain below the value specified?0.1 VGo to Step 4Go to Step 3

31. Review the Freeze Frame data and note the

parameters.

2. Operate the vehicle within the Freeze frame

conditions and Conditions For Setting the DTC

as noted.

Does the HO2S1 voltage stay below the specified

value?0.1 VGo to Step 4Go to Step 7

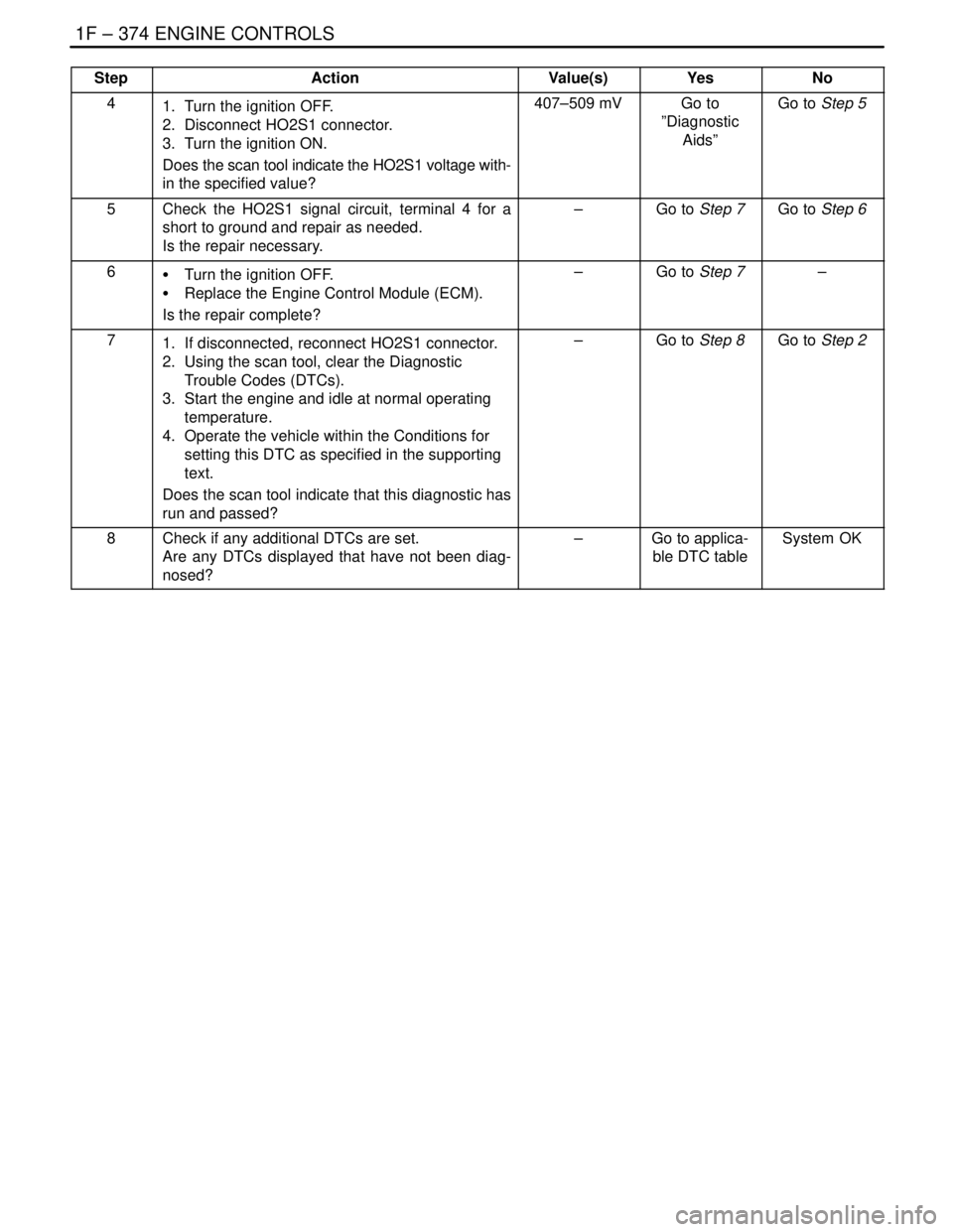

Page 620 of 2643

1F – 374IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

41. Turn the ignition OFF.

2. Disconnect HO2S1 connector.

3. Turn the ignition ON.

Does the scan tool indicate the HO2S1 voltage with-

in the specified value?407–509 mVGo to

”Diagnostic

Aids”Go to Step 5

5Check the HO2S1 signal circuit, terminal 4 for a

short to ground and repair as needed.

Is the repair necessary.–Go to Step 7Go to Step 6

6S Turn the ignition OFF.

S Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 7–

71. If disconnected, reconnect HO2S1 connector.

2. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

3. Start the engine and idle at normal operating

temperature.

4. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 8Go to Step 2

8Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to applica-

ble DTC tableSystem OK

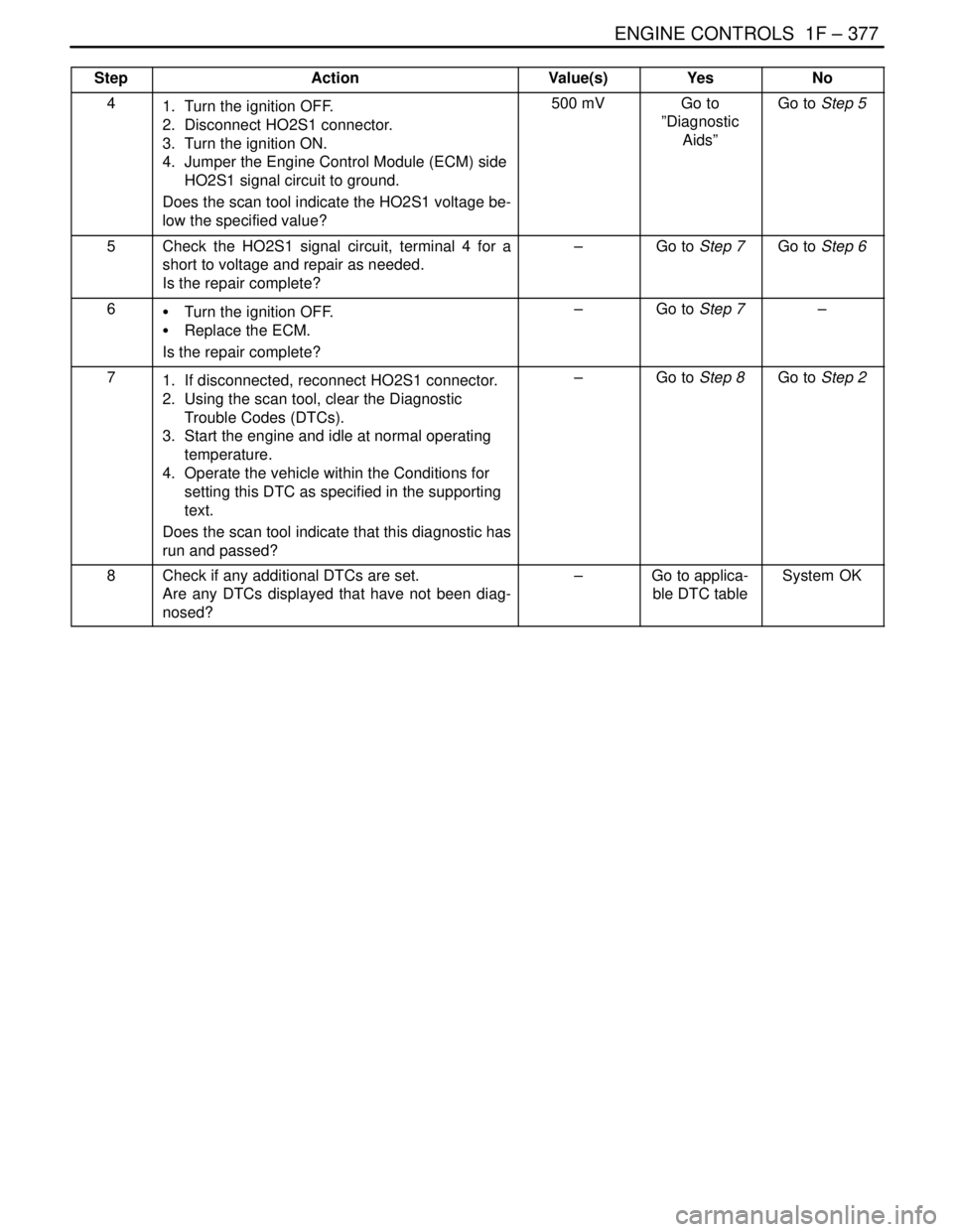

Page 623 of 2643

ENGINE CONTROLS 1F – 377

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

41. Turn the ignition OFF.

2. Disconnect HO2S1 connector.

3. Turn the ignition ON.

4. Jumper the Engine Control Module (ECM) side

HO2S1 signal circuit to ground.

Does the scan tool indicate the HO2S1 voltage be-

low the specified value?500 mVGo to

”Diagnostic

Aids”Go to Step 5

5Check the HO2S1 signal circuit, terminal 4 for a

short to voltage and repair as needed.

Is the repair complete?–Go to Step 7Go to Step 6

6S Turn the ignition OFF.

S Replace the ECM.

Is the repair complete?–Go to Step 7–

71. If disconnected, reconnect HO2S1 connector.

2. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

3. Start the engine and idle at normal operating

temperature.

4. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 8Go to Step 2

8Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to applica-

ble DTC tableSystem OK

Page 626 of 2643

1F – 380IENGINE CONTROLS

DAEWOO V–121 BL4

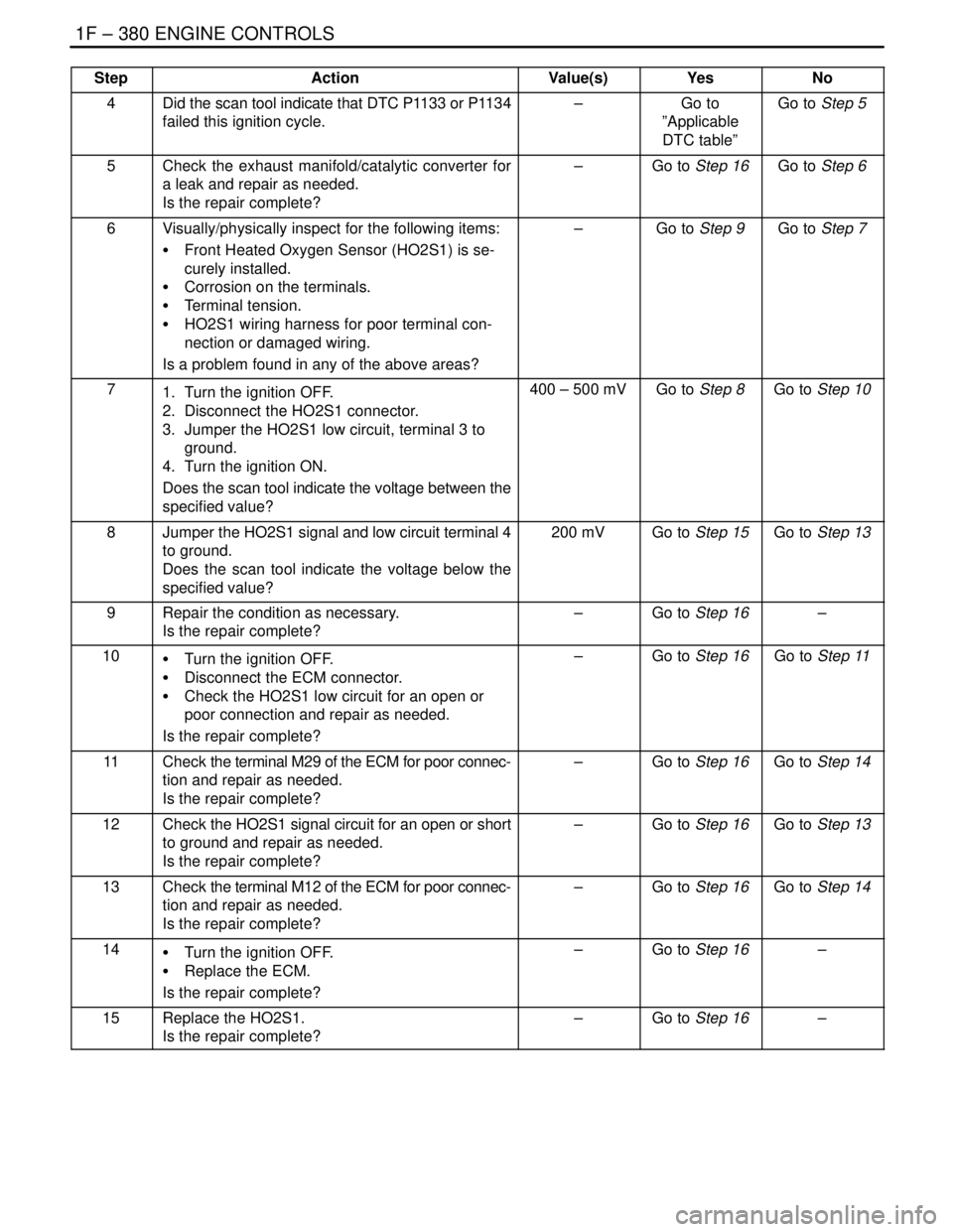

StepNo Yes Value(s) Action

4Did the scan tool indicate that DTC P1133 or P1134

failed this ignition cycle.–Go to

”Applicable

DTC table”Go to Step 5

5Check the exhaust manifold/catalytic converter for

a leak and repair as needed.

Is the repair complete?–Go to Step 16Go to Step 6

6Visually/physically inspect for the following items:

S Front Heated Oxygen Sensor (HO2S1) is se-

curely installed.

S Corrosion on the terminals.

S Terminal tension.

S HO2S1 wiring harness for poor terminal con-

nection or damaged wiring.

Is a problem found in any of the above areas?–Go to Step 9Go to Step 7

71. Turn the ignition OFF.

2. Disconnect the HO2S1 connector.

3. Jumper the HO2S1 low circuit, terminal 3 to

ground.

4. Turn the ignition ON.

Does the scan tool indicate the voltage between the

specified value?400 – 500 mVGo to Step 8Go to Step 10

8Jumper the HO2S1 signal and low circuit terminal 4

to ground.

Does the scan tool indicate the voltage below the

specified value?200 mVGo to Step 15Go to Step 13

9Repair the condition as necessary.

Is the repair complete?–Go to Step 16–

10S Turn the ignition OFF.

S Disconnect the ECM connector.

S Check the HO2S1 low circuit for an open or

poor connection and repair as needed.

Is the repair complete?–Go to Step 16Go to Step 11

11Check the terminal M29 of the ECM for poor connec-

tion and repair as needed.

Is the repair complete?–Go to Step 16Go to Step 14

12Check the HO2S1 signal circuit for an open or short

to ground and repair as needed.

Is the repair complete?–Go to Step 16Go to Step 13

13Check the terminal M12 of the ECM for poor connec-

tion and repair as needed.

Is the repair complete?–Go to Step 16Go to Step 14

14S Turn the ignition OFF.

S Replace the ECM.

Is the repair complete?–Go to Step 16–

15Replace the HO2S1.

Is the repair complete?–Go to Step 16–

Page 629 of 2643

ENGINE CONTROLS 1F – 383

DAEWOO V–121 BL4

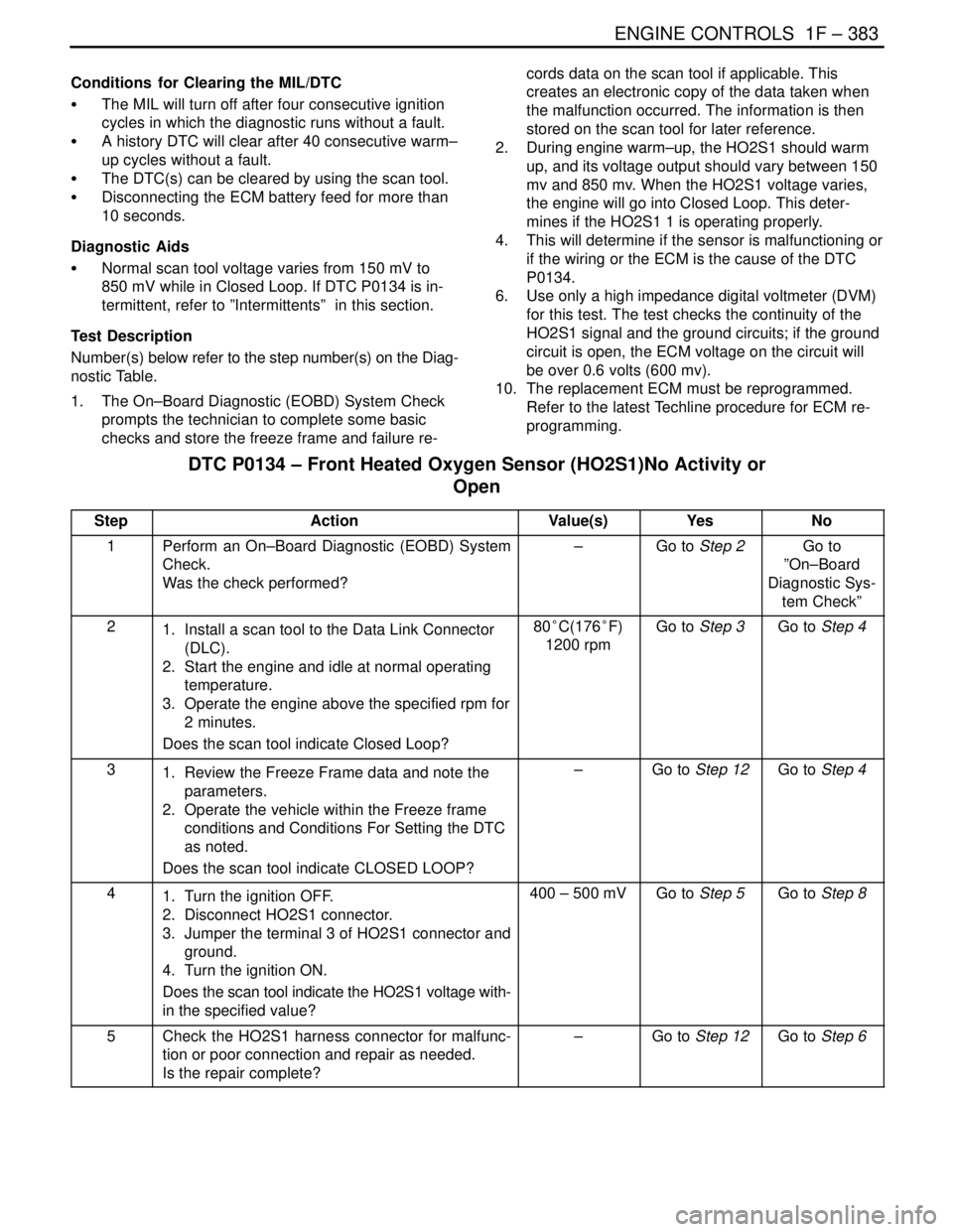

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

S Normal scan tool voltage varies from 150 mV to

850 mV while in Closed Loop. If DTC P0134 is in-

termittent, refer to ”Intermittents” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. During engine warm–up, the HO2S1 should warm

up, and its voltage output should vary between 150

mv and 850 mv. When the HO2S1 voltage varies,

the engine will go into Closed Loop. This deter-

mines if the HO2S1 1 is operating properly.

4. This will determine if the sensor is malfunctioning or

if the wiring or the ECM is the cause of the DTC

P0134.

6. Use only a high impedance digital voltmeter (DVM)

for this test. The test checks the continuity of the

HO2S1 signal and the ground circuits; if the ground

circuit is open, the ECM voltage on the circuit will

be over 0.6 volts (600 mv).

10. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

DTC P0134 – Front Heated Oxygen Sensor (HO2S1)No Activity or

Open

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Start the engine and idle at normal operating

temperature.

3. Operate the engine above the specified rpm for

2 minutes.

Does the scan tool indicate Closed Loop?80°C(176°F)

1200 rpmGo to Step 3Go to Step 4

31. Review the Freeze Frame data and note the

parameters.

2. Operate the vehicle within the Freeze frame

conditions and Conditions For Setting the DTC

as noted.

Does the scan tool indicate CLOSED LOOP?–Go to Step 12Go to Step 4

41. Turn the ignition OFF.

2. Disconnect HO2S1 connector.

3. Jumper the terminal 3 of HO2S1 connector and

ground.

4. Turn the ignition ON.

Does the scan tool indicate the HO2S1 voltage with-

in the specified value?400 – 500 mVGo to Step 5Go to Step 8

5Check the HO2S1 harness connector for malfunc-

tion or poor connection and repair as needed.

Is the repair complete?–Go to Step 12Go to Step 6