Vacuum DAEWOO LACETTI 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 160 of 2643

1C2 – 40I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

Installation Procedure

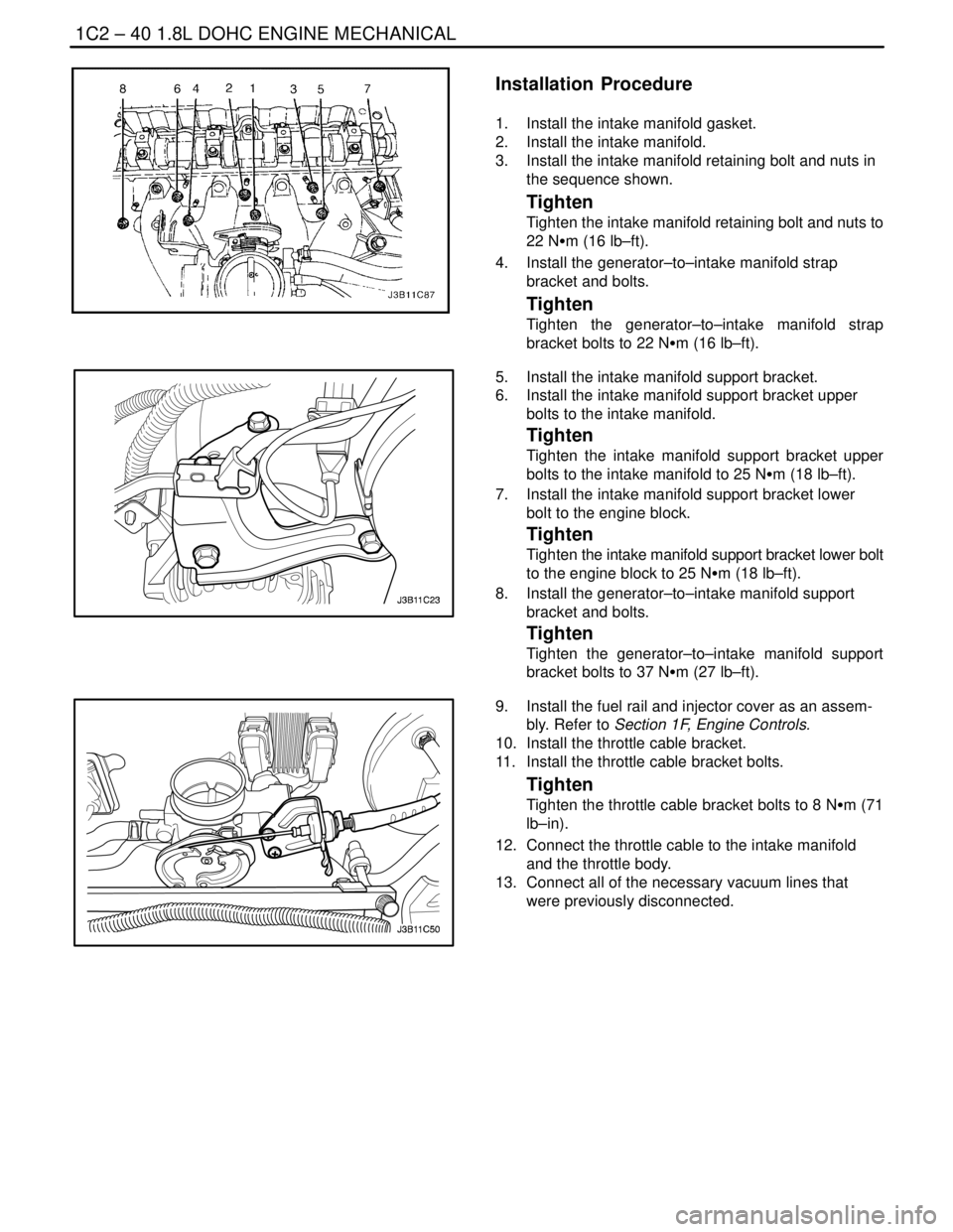

1. Install the intake manifold gasket.

2. Install the intake manifold.

3. Install the intake manifold retaining bolt and nuts in

the sequence shown.

Tighten

Tighten the intake manifold retaining bolt and nuts to

22 NSm (16 lb–ft).

4. Install the generator–to–intake manifold strap

bracket and bolts.

Tighten

Tighten the generator–to–intake manifold strap

bracket bolts to 22 NSm (16 lb–ft).

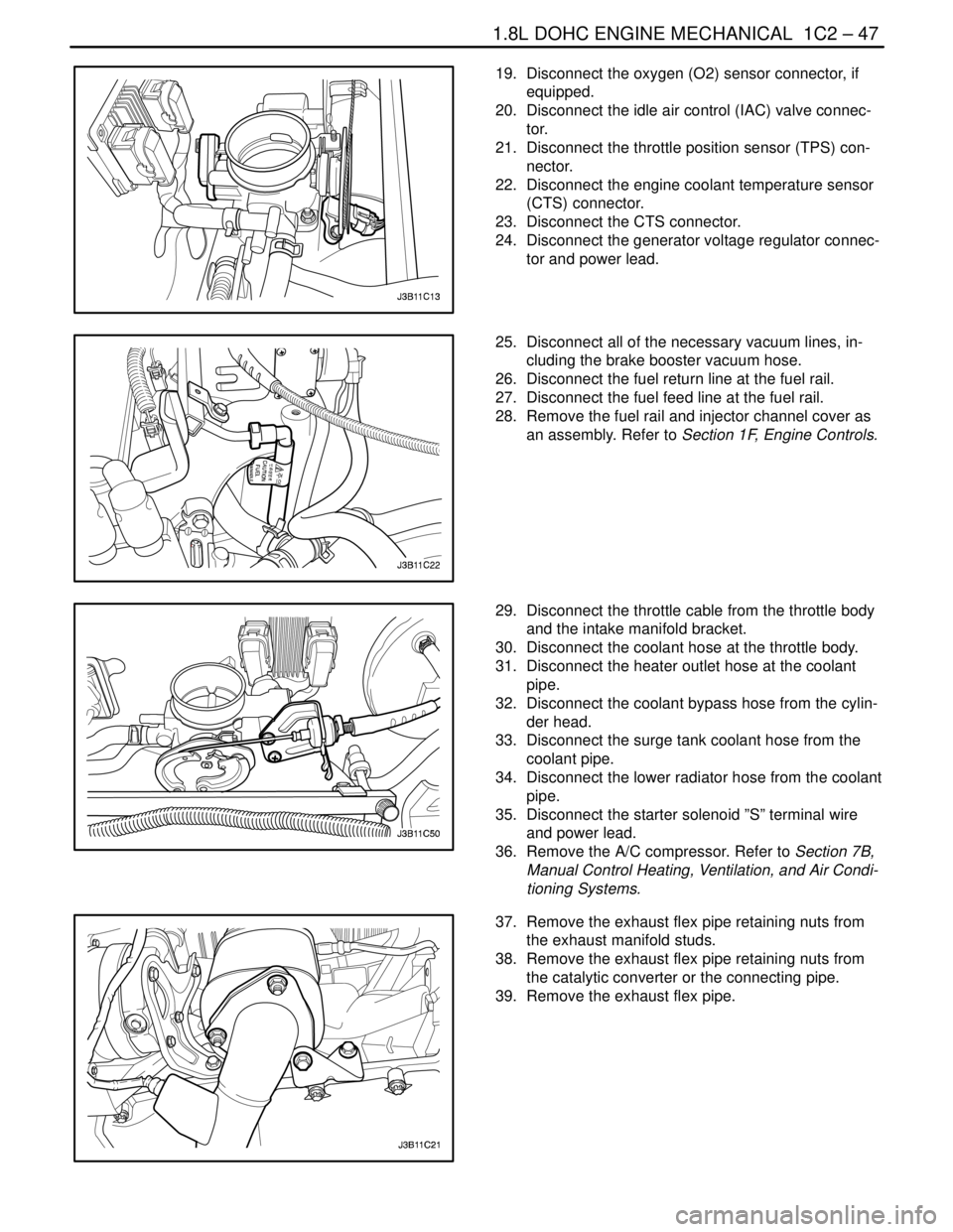

5. Install the intake manifold support bracket.

6. Install the intake manifold support bracket upper

bolts to the intake manifold.

Tighten

Tighten the intake manifold support bracket upper

bolts to the intake manifold to 25 NSm (18 lb–ft).

7. Install the intake manifold support bracket lower

bolt to the engine block.

Tighten

Tighten the intake manifold support bracket lower bolt

to the engine block to 25 NSm (18 lb–ft).

8. Install the generator–to–intake manifold support

bracket and bolts.

Tighten

Tighten the generator–to–intake manifold support

bracket bolts to 37 NSm (27 lb–ft).

9. Install the fuel rail and injector cover as an assem-

bly. Refer to Section 1F, Engine Controls.

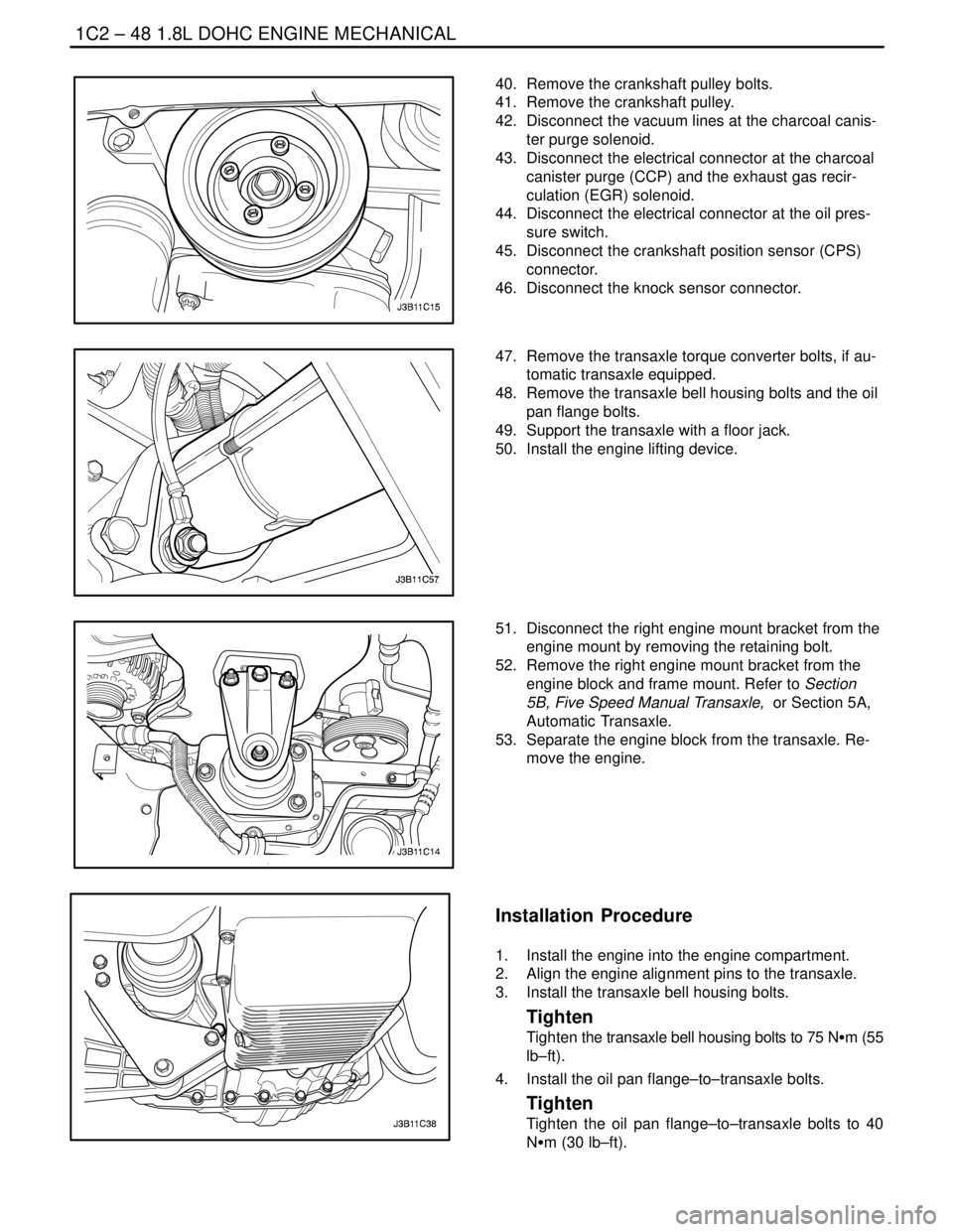

10. Install the throttle cable bracket.

11. Install the throttle cable bracket bolts.

Tighten

Tighten the throttle cable bracket bolts to 8 NSm (71

lb–in).

12. Connect the throttle cable to the intake manifold

and the throttle body.

13. Connect all of the necessary vacuum lines that

were previously disconnected.

Page 167 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 47

DAEWOO V–121 BL4

19. Disconnect the oxygen (O2) sensor connector, if

equipped.

20. Disconnect the idle air control (IAC) valve connec-

tor.

21. Disconnect the throttle position sensor (TPS) con-

nector.

22. Disconnect the engine coolant temperature sensor

(CTS) connector.

23. Disconnect the CTS connector.

24. Disconnect the generator voltage regulator connec-

tor and power lead.

25. Disconnect all of the necessary vacuum lines, in-

cluding the brake booster vacuum hose.

26. Disconnect the fuel return line at the fuel rail.

27. Disconnect the fuel feed line at the fuel rail.

28. Remove the fuel rail and injector channel cover as

an assembly. Refer to Section 1F, Engine Controls.

29. Disconnect the throttle cable from the throttle body

and the intake manifold bracket.

30. Disconnect the coolant hose at the throttle body.

31. Disconnect the heater outlet hose at the coolant

pipe.

32. Disconnect the coolant bypass hose from the cylin-

der head.

33. Disconnect the surge tank coolant hose from the

coolant pipe.

34. Disconnect the lower radiator hose from the coolant

pipe.

35. Disconnect the starter solenoid ”S” terminal wire

and power lead.

36. Remove the A/C compressor. Refer to Section 7B,

Manual Control Heating, Ventilation, and Air Condi-

tioning Systems.

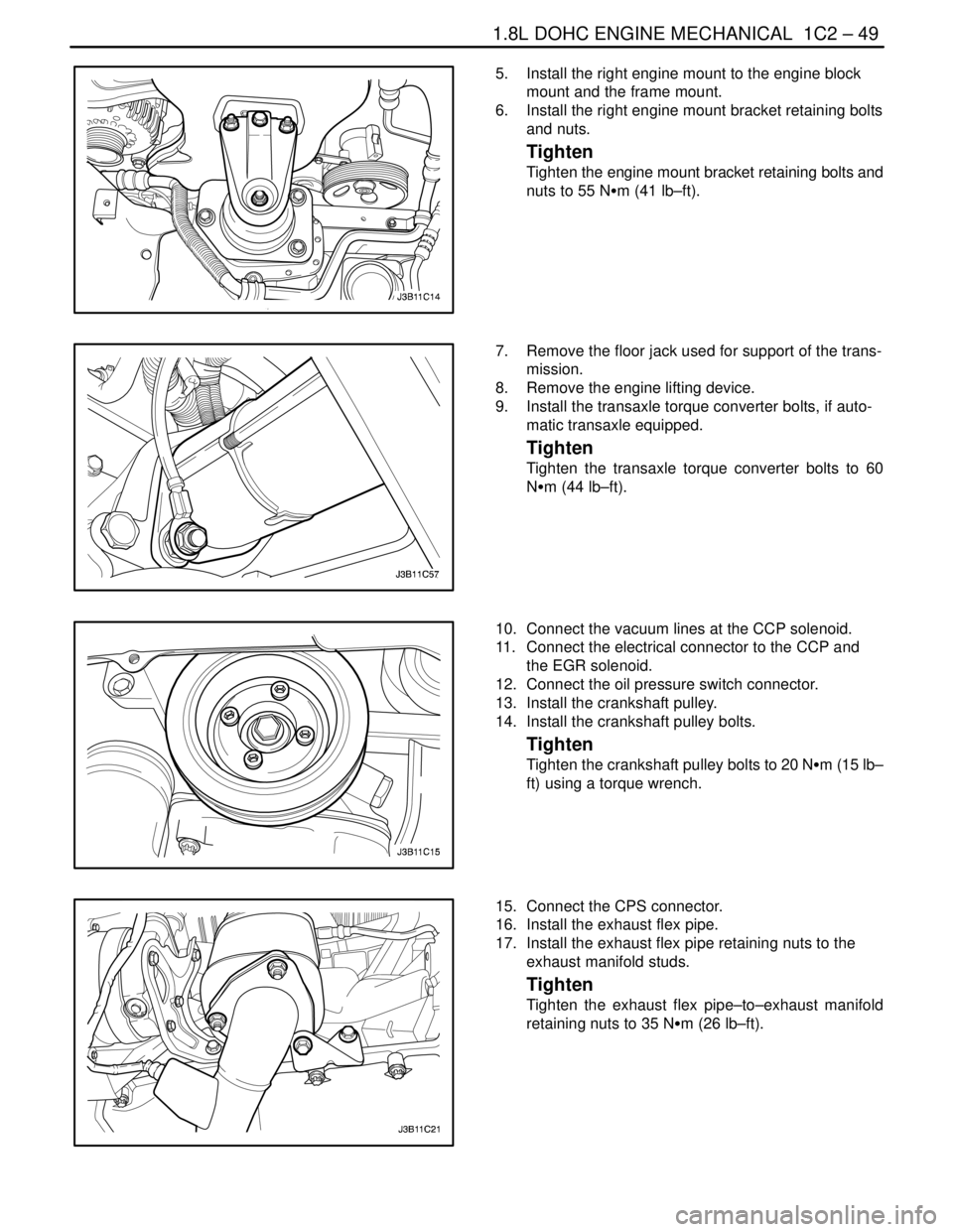

37. Remove the exhaust flex pipe retaining nuts from

the exhaust manifold studs.

38. Remove the exhaust flex pipe retaining nuts from

the catalytic converter or the connecting pipe.

39. Remove the exhaust flex pipe.

Page 168 of 2643

1C2 – 48I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

40. Remove the crankshaft pulley bolts.

41. Remove the crankshaft pulley.

42. Disconnect the vacuum lines at the charcoal canis-

ter purge solenoid.

43. Disconnect the electrical connector at the charcoal

canister purge (CCP) and the exhaust gas recir-

culation (EGR) solenoid.

44. Disconnect the electrical connector at the oil pres-

sure switch.

45. Disconnect the crankshaft position sensor (CPS)

connector.

46. Disconnect the knock sensor connector.

47. Remove the transaxle torque converter bolts, if au-

tomatic transaxle equipped.

48. Remove the transaxle bell housing bolts and the oil

pan flange bolts.

49. Support the transaxle with a floor jack.

50. Install the engine lifting device.

51. Disconnect the right engine mount bracket from the

engine mount by removing the retaining bolt.

52. Remove the right engine mount bracket from the

engine block and frame mount. Refer to Section

5B, Five Speed Manual Transaxle, or Section 5A,

Automatic Transaxle.

53. Separate the engine block from the transaxle. Re-

move the engine.

Installation Procedure

1. Install the engine into the engine compartment.

2. Align the engine alignment pins to the transaxle.

3. Install the transaxle bell housing bolts.

Tighten

Tighten the transaxle bell housing bolts to 75 NSm (55

lb–ft).

4. Install the oil pan flange–to–transaxle bolts.

Tighten

Tighten the oil pan flange–to–transaxle bolts to 40

NSm (30 lb–ft).

Page 169 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 49

DAEWOO V–121 BL4

5. Install the right engine mount to the engine block

mount and the frame mount.

6. Install the right engine mount bracket retaining bolts

and nuts.

Tighten

Tighten the engine mount bracket retaining bolts and

nuts to 55 NSm (41 lb–ft).

7. Remove the floor jack used for support of the trans-

mission.

8. Remove the engine lifting device.

9. Install the transaxle torque converter bolts, if auto-

matic transaxle equipped.

Tighten

Tighten the transaxle torque converter bolts to 60

NSm (44 lb–ft).

10. Connect the vacuum lines at the CCP solenoid.

11. Connect the electrical connector to the CCP and

the EGR solenoid.

12. Connect the oil pressure switch connector.

13. Install the crankshaft pulley.

14. Install the crankshaft pulley bolts.

Tighten

Tighten the crankshaft pulley bolts to 20 NSm (15 lb–

ft) using a torque wrench.

15. Connect the CPS connector.

16. Install the exhaust flex pipe.

17. Install the exhaust flex pipe retaining nuts to the

exhaust manifold studs.

Tighten

Tighten the exhaust flex pipe–to–exhaust manifold

retaining nuts to 35 NSm (26 lb–ft).

Page 170 of 2643

1C2 – 50I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

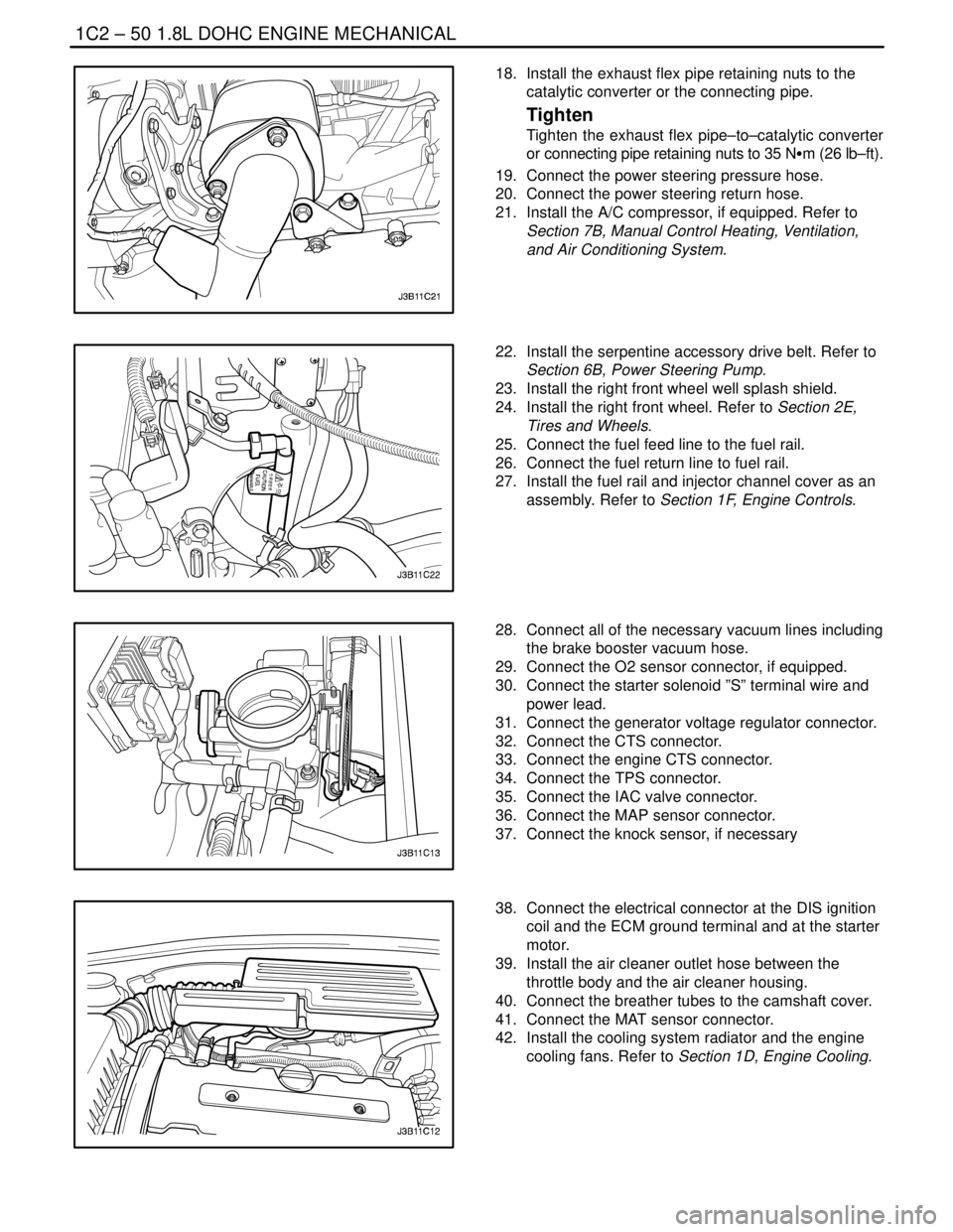

18. Install the exhaust flex pipe retaining nuts to the

catalytic converter or the connecting pipe.

Tighten

Tighten the exhaust flex pipe–to–catalytic converter

or connecting pipe retaining nuts to 35 NSm (26 lb–ft).

19. Connect the power steering pressure hose.

20. Connect the power steering return hose.

21. Install the A/C compressor, if equipped. Refer to

Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System.

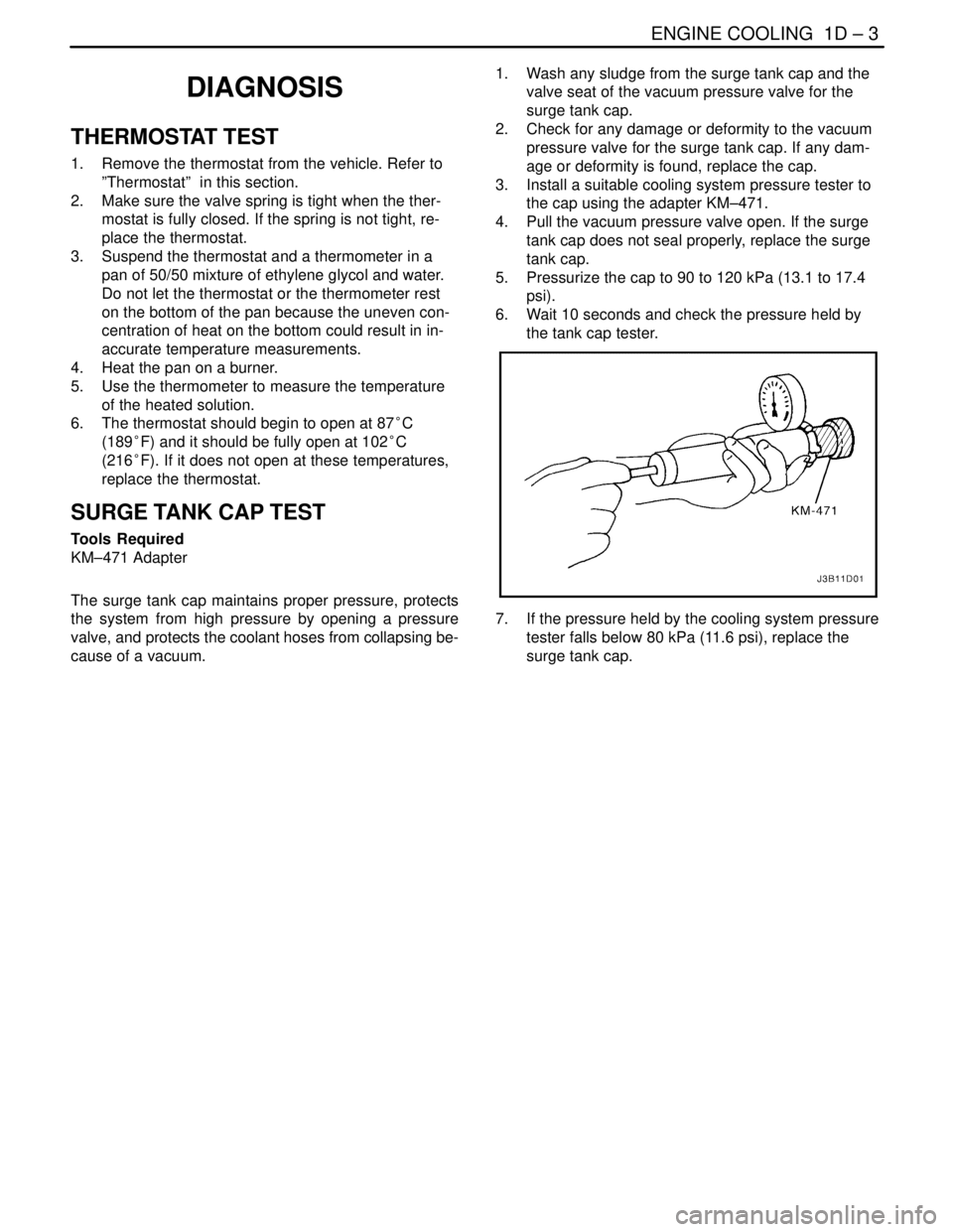

22. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

23. Install the right front wheel well splash shield.

24. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

25. Connect the fuel feed line to the fuel rail.

26. Connect the fuel return line to fuel rail.

27. Install the fuel rail and injector channel cover as an

assembly. Refer to Section 1F, Engine Controls.

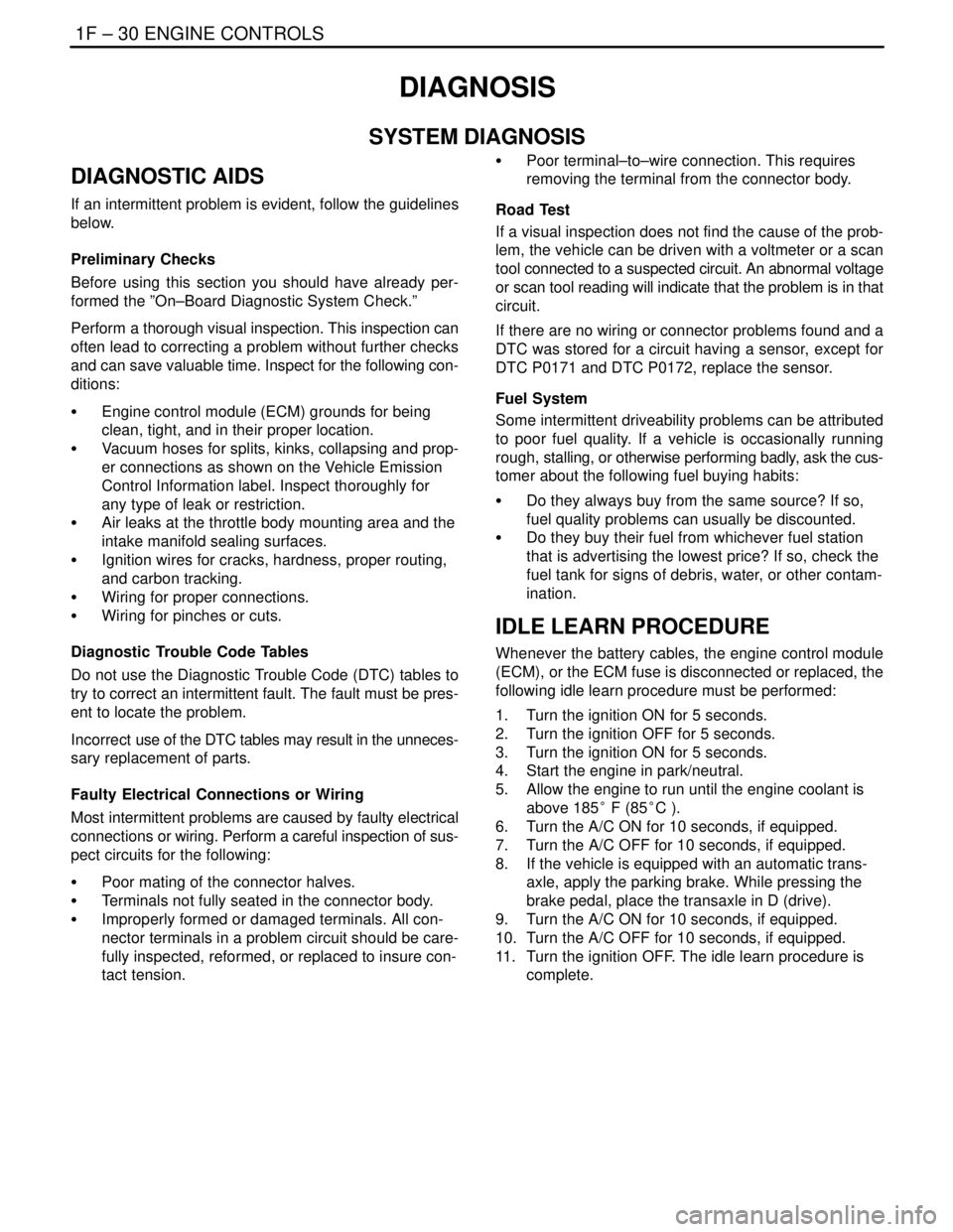

28. Connect all of the necessary vacuum lines including

the brake booster vacuum hose.

29. Connect the O2 sensor connector, if equipped.

30. Connect the starter solenoid ”S” terminal wire and

power lead.

31. Connect the generator voltage regulator connector.

32. Connect the CTS connector.

33. Connect the engine CTS connector.

34. Connect the TPS connector.

35. Connect the IAC valve connector.

36. Connect the MAP sensor connector.

37. Connect the knock sensor, if necessary

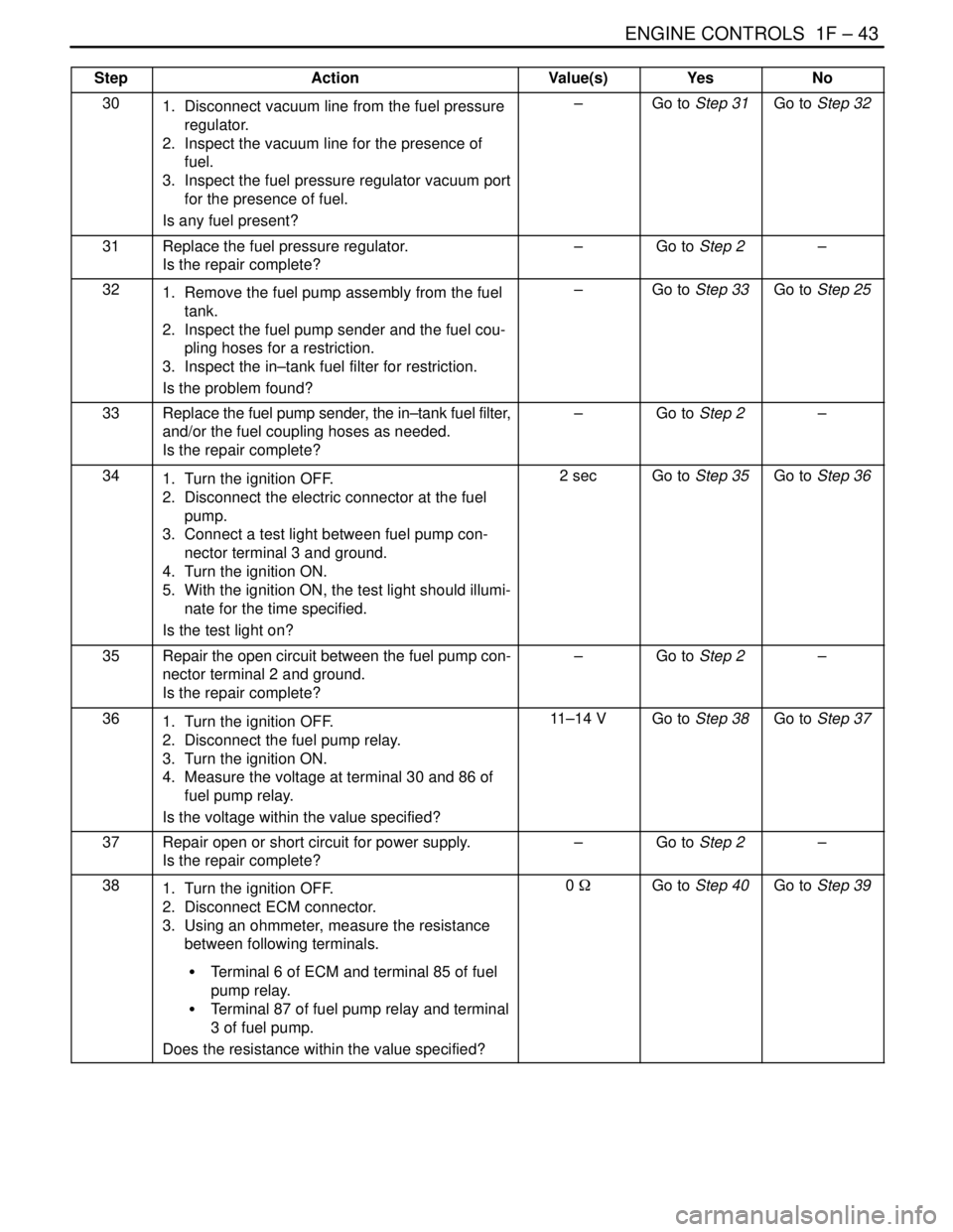

38. Connect the electrical connector at the DIS ignition

coil and the ECM ground terminal and at the starter

motor.

39. Install the air cleaner outlet hose between the

throttle body and the air cleaner housing.

40. Connect the breather tubes to the camshaft cover.

41. Connect the MAT sensor connector.

42. Install the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

Page 198 of 2643

ENGINE COOLING 1D – 3

DAEWOO V–121 BL4

DIAGNOSIS

THERMOSTAT TEST

1. Remove the thermostat from the vehicle. Refer to

”Thermostat” in this section.

2. Make sure the valve spring is tight when the ther-

mostat is fully closed. If the spring is not tight, re-

place the thermostat.

3. Suspend the thermostat and a thermometer in a

pan of 50/50 mixture of ethylene glycol and water.

Do not let the thermostat or the thermometer rest

on the bottom of the pan because the uneven con-

centration of heat on the bottom could result in in-

accurate temperature measurements.

4. Heat the pan on a burner.

5. Use the thermometer to measure the temperature

of the heated solution.

6. The thermostat should begin to open at 87°C

(189°F) and it should be fully open at 102°C

(216°F). If it does not open at these temperatures,

replace the thermostat.

SURGE TANK CAP TEST

Tools Required

KM–471 Adapter

The surge tank cap maintains proper pressure, protects

the system from high pressure by opening a pressure

valve, and protects the coolant hoses from collapsing be-

cause of a vacuum.1. Wash any sludge from the surge tank cap and the

valve seat of the vacuum pressure valve for the

surge tank cap.

2. Check for any damage or deformity to the vacuum

pressure valve for the surge tank cap. If any dam-

age or deformity is found, replace the cap.

3. Install a suitable cooling system pressure tester to

the cap using the adapter KM–471.

4. Pull the vacuum pressure valve open. If the surge

tank cap does not seal properly, replace the surge

tank cap.

5. Pressurize the cap to 90 to 120 kPa (13.1 to 17.4

psi).

6. Wait 10 seconds and check the pressure held by

the tank cap tester.

7. If the pressure held by the cooling system pressure

tester falls below 80 kPa (11.6 psi), replace the

surge tank cap.

Page 276 of 2643

1F – 30IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSIS

SYSTEM DIAGNOSIS

DIAGNOSTIC AIDS

If an intermittent problem is evident, follow the guidelines

below.

Preliminary Checks

Before using this section you should have already per-

formed the ”On–Board Diagnostic System Check.”

Perform a thorough visual inspection. This inspection can

often lead to correcting a problem without further checks

and can save valuable time. Inspect for the following con-

ditions:

S Engine control module (ECM) grounds for being

clean, tight, and in their proper location.

S Vacuum hoses for splits, kinks, collapsing and prop-

er connections as shown on the Vehicle Emission

Control Information label. Inspect thoroughly for

any type of leak or restriction.

S Air leaks at the throttle body mounting area and the

intake manifold sealing surfaces.

S Ignition wires for cracks, hardness, proper routing,

and carbon tracking.

S Wiring for proper connections.

S Wiring for pinches or cuts.

Diagnostic Trouble Code Tables

Do not use the Diagnostic Trouble Code (DTC) tables to

try to correct an intermittent fault. The fault must be pres-

ent to locate the problem.

Incorrect use of the DTC tables may result in the unneces-

sary replacement of parts.

Faulty Electrical Connections or Wiring

Most intermittent problems are caused by faulty electrical

connections or wiring. Perform a careful inspection of sus-

pect circuits for the following:

S Poor mating of the connector halves.

S Terminals not fully seated in the connector body.

S Improperly formed or damaged terminals. All con-

nector terminals in a problem circuit should be care-

fully inspected, reformed, or replaced to insure con-

tact tension.S Poor terminal–to–wire connection. This requires

removing the terminal from the connector body.

Road Test

If a visual inspection does not find the cause of the prob-

lem, the vehicle can be driven with a voltmeter or a scan

tool connected to a suspected circuit. An abnormal voltage

or scan tool reading will indicate that the problem is in that

circuit.

If there are no wiring or connector problems found and a

DTC was stored for a circuit having a sensor, except for

DTC P0171 and DTC P0172, replace the sensor.

Fuel System

Some intermittent driveability problems can be attributed

to poor fuel quality. If a vehicle is occasionally running

rough, stalling, or otherwise performing badly, ask the cus-

tomer about the following fuel buying habits:

S Do they always buy from the same source? If so,

fuel quality problems can usually be discounted.

S Do they buy their fuel from whichever fuel station

that is advertising the lowest price? If so, check the

fuel tank for signs of debris, water, or other contam-

ination.

IDLE LEARN PROCEDURE

Whenever the battery cables, the engine control module

(ECM), or the ECM fuse is disconnected or replaced, the

following idle learn procedure must be performed:

1. Turn the ignition ON for 5 seconds.

2. Turn the ignition OFF for 5 seconds.

3. Turn the ignition ON for 5 seconds.

4. Start the engine in park/neutral.

5. Allow the engine to run until the engine coolant is

above 185° F (85°C ).

6. Turn the A/C ON for 10 seconds, if equipped.

7. Turn the A/C OFF for 10 seconds, if equipped.

8. If the vehicle is equipped with an automatic trans-

axle, apply the parking brake. While pressing the

brake pedal, place the transaxle in D (drive).

9. Turn the A/C ON for 10 seconds, if equipped.

10. Turn the A/C OFF for 10 seconds, if equipped.

11. Turn the ignition OFF. The idle learn procedure is

complete.

Page 289 of 2643

ENGINE CONTROLS 1F – 43

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

301. Disconnect vacuum line from the fuel pressure

regulator.

2. Inspect the vacuum line for the presence of

fuel.

3. Inspect the fuel pressure regulator vacuum port

for the presence of fuel.

Is any fuel present?–Go to Step 31Go to Step 32

31Replace the fuel pressure regulator.

Is the repair complete?–Go to Step 2–

321. Remove the fuel pump assembly from the fuel

tank.

2. Inspect the fuel pump sender and the fuel cou-

pling hoses for a restriction.

3. Inspect the in–tank fuel filter for restriction.

Is the problem found?–Go to Step 33Go to Step 25

33Replace the fuel pump sender, the in–tank fuel filter,

and/or the fuel coupling hoses as needed.

Is the repair complete?–Go to Step 2–

341. Turn the ignition OFF.

2. Disconnect the electric connector at the fuel

pump.

3. Connect a test light between fuel pump con-

nector terminal 3 and ground.

4. Turn the ignition ON.

5. With the ignition ON, the test light should illumi-

nate for the time specified.

Is the test light on?2 secGo to Step 35Go to Step 36

35Repair the open circuit between the fuel pump con-

nector terminal 2 and ground.

Is the repair complete?–Go to Step 2–

361. Turn the ignition OFF.

2. Disconnect the fuel pump relay.

3. Turn the ignition ON.

4. Measure the voltage at terminal 30 and 86 of

fuel pump relay.

Is the voltage within the value specified?11–14 VGo to Step 38Go to Step 37

37Repair open or short circuit for power supply.

Is the repair complete?–Go to Step 2–

381. Turn the ignition OFF.

2. Disconnect ECM connector.

3. Using an ohmmeter, measure the resistance

between following terminals.

S Terminal 6 of ECM and terminal 85 of fuel

pump relay.

S Terminal 87 of fuel pump relay and terminal

3 of fuel pump.

Does the resistance within the value specified?0 WGo to Step 40Go to Step 39

Page 296 of 2643

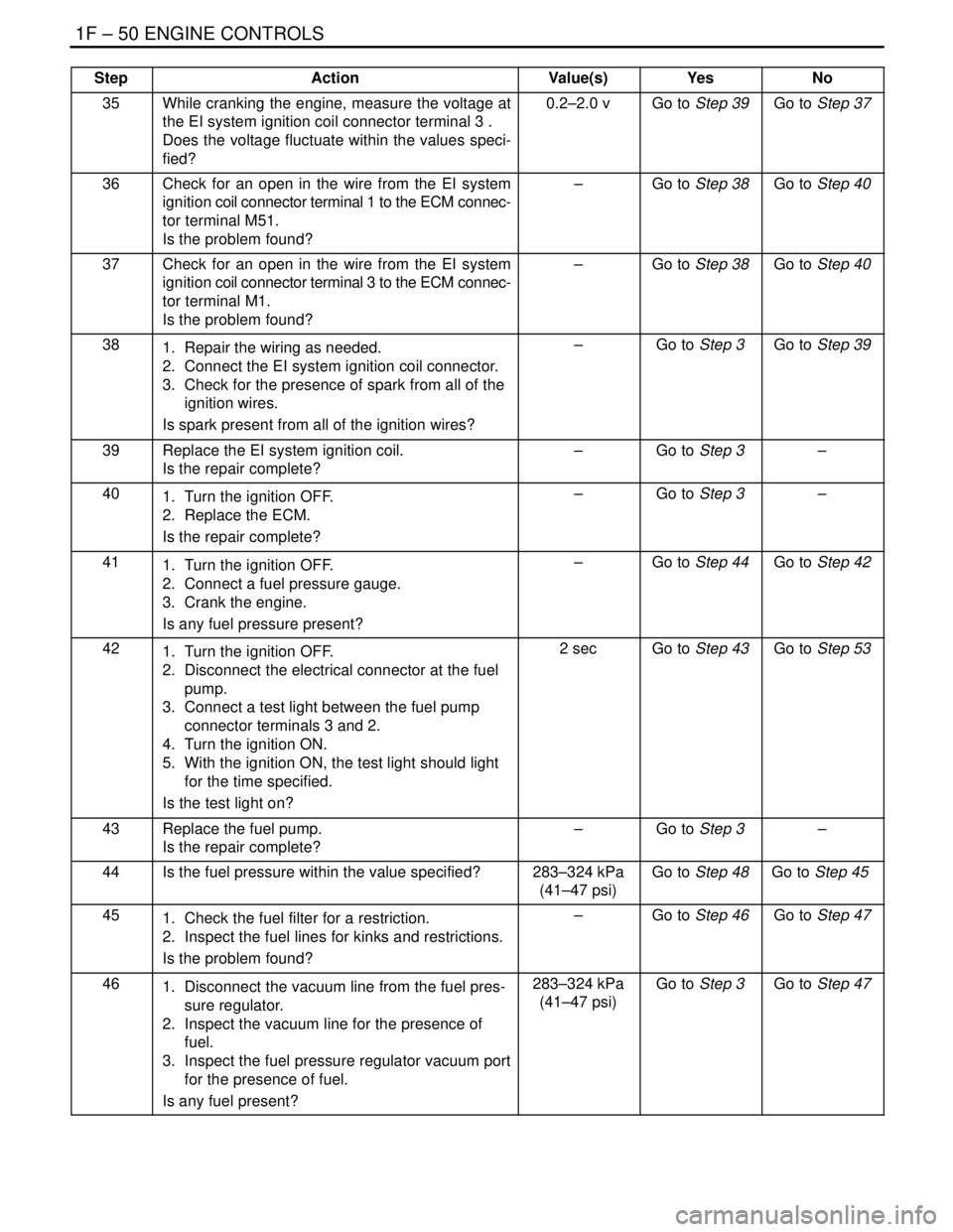

1F – 50IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

35While cranking the engine, measure the voltage at

the EI system ignition coil connector terminal 3 .

Does the voltage fluctuate within the values speci-

fied?0.2–2.0 vGo to Step 39Go to Step 37

36Check for an open in the wire from the EI system

ignition coil connector terminal 1 to the ECM connec-

tor terminal M51.

Is the problem found?–Go to Step 38Go to Step 40

37Check for an open in the wire from the EI system

ignition coil connector terminal 3 to the ECM connec-

tor terminal M1.

Is the problem found?–Go to Step 38Go to Step 40

381. Repair the wiring as needed.

2. Connect the EI system ignition coil connector.

3. Check for the presence of spark from all of the

ignition wires.

Is spark present from all of the ignition wires?–Go to Step 3Go to Step 39

39Replace the EI system ignition coil.

Is the repair complete?–Go to Step 3–

401. Turn the ignition OFF.

2. Replace the ECM.

Is the repair complete?–Go to Step 3–

411. Turn the ignition OFF.

2. Connect a fuel pressure gauge.

3. Crank the engine.

Is any fuel pressure present?–Go to Step 44Go to Step 42

421. Turn the ignition OFF.

2. Disconnect the electrical connector at the fuel

pump.

3. Connect a test light between the fuel pump

connector terminals 3 and 2.

4. Turn the ignition ON.

5. With the ignition ON, the test light should light

for the time specified.

Is the test light on?2 secGo to Step 43Go to Step 53

43Replace the fuel pump.

Is the repair complete?–Go to Step 3–

44Is the fuel pressure within the value specified?283–324 kPa

(41–47 psi)Go to Step 48Go to Step 45

451. Check the fuel filter for a restriction.

2. Inspect the fuel lines for kinks and restrictions.

Is the problem found?–Go to Step 46Go to Step 47

461. Disconnect the vacuum line from the fuel pres-

sure regulator.

2. Inspect the vacuum line for the presence of

fuel.

3. Inspect the fuel pressure regulator vacuum port

for the presence of fuel.

Is any fuel present?283–324 kPa

(41–47 psi)Go to Step 3Go to Step 47

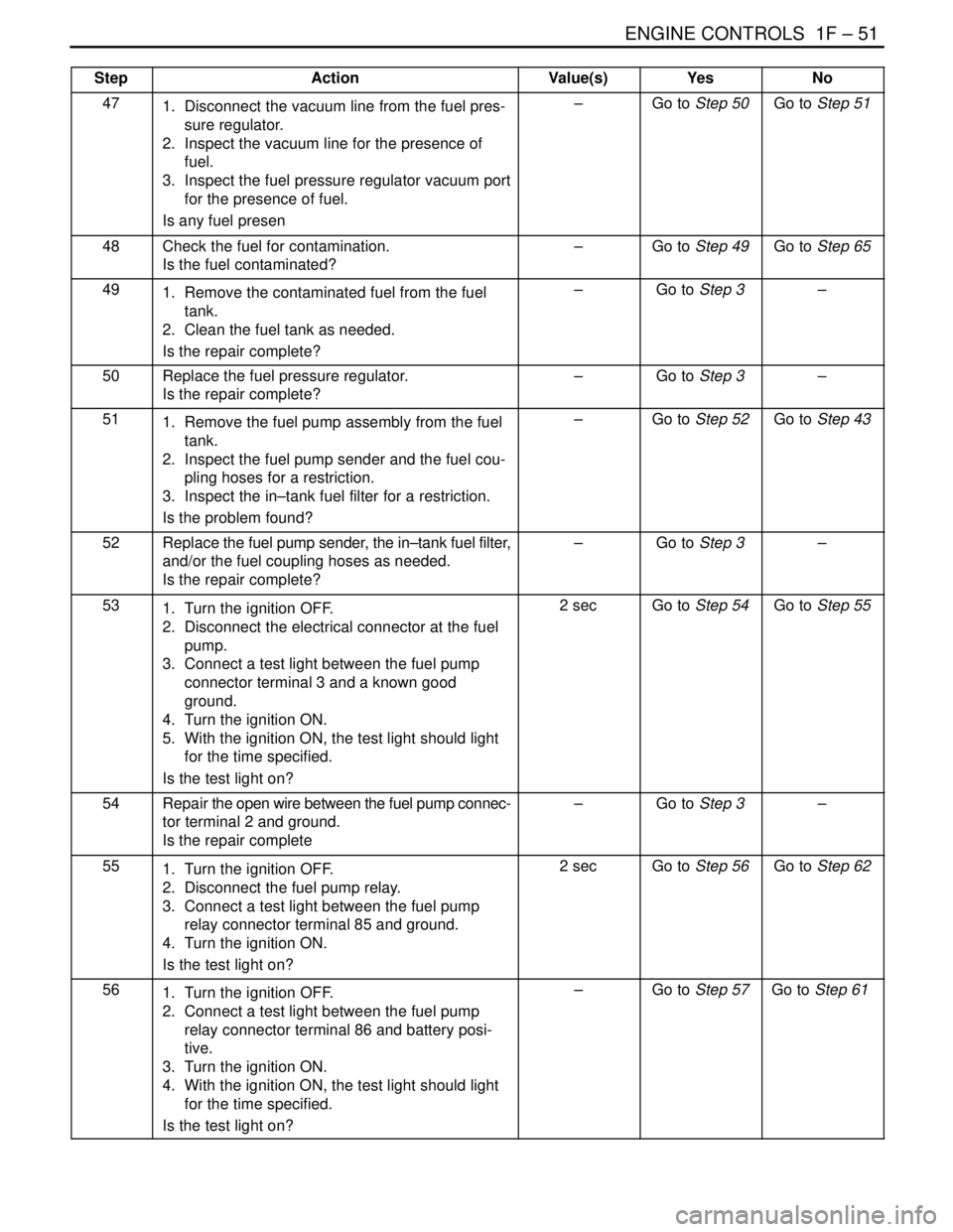

Page 297 of 2643

ENGINE CONTROLS 1F – 51

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

471. Disconnect the vacuum line from the fuel pres-

sure regulator.

2. Inspect the vacuum line for the presence of

fuel.

3. Inspect the fuel pressure regulator vacuum port

for the presence of fuel.

Is any fuel presen–Go to Step 50Go to Step 51

48Check the fuel for contamination.

Is the fuel contaminated?–Go to Step 49Go to Step 65

491. Remove the contaminated fuel from the fuel

tank.

2. Clean the fuel tank as needed.

Is the repair complete?–Go to Step 3–

50Replace the fuel pressure regulator.

Is the repair complete?–Go to Step 3–

511. Remove the fuel pump assembly from the fuel

tank.

2. Inspect the fuel pump sender and the fuel cou-

pling hoses for a restriction.

3. Inspect the in–tank fuel filter for a restriction.

Is the problem found?–Go to Step 52Go to Step 43

52Replace the fuel pump sender, the in–tank fuel filter,

and/or the fuel coupling hoses as needed.

Is the repair complete?–Go to Step 3–

531. Turn the ignition OFF.

2. Disconnect the electrical connector at the fuel

pump.

3. Connect a test light between the fuel pump

connector terminal 3 and a known good

ground.

4. Turn the ignition ON.

5. With the ignition ON, the test light should light

for the time specified.

Is the test light on?2 secGo to Step 54Go to Step 55

54Repair the open wire between the fuel pump connec-

tor terminal 2 and ground.

Is the repair complete–Go to Step 3–

551. Turn the ignition OFF.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 85 and ground.

4. Turn the ignition ON.

Is the test light on?2 secGo to Step 56Go to Step 62

561. Turn the ignition OFF.

2. Connect a test light between the fuel pump

relay connector terminal 86 and battery posi-

tive.

3. Turn the ignition ON.

4. With the ignition ON, the test light should light

for the time specified.

Is the test light on?–Go to Step 57Go to Step 61