coolant level DAEWOO LACETTI 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 441 of 2643

ENGINE CONTROLS 1F – 195

DAEWOO V–121 BL4

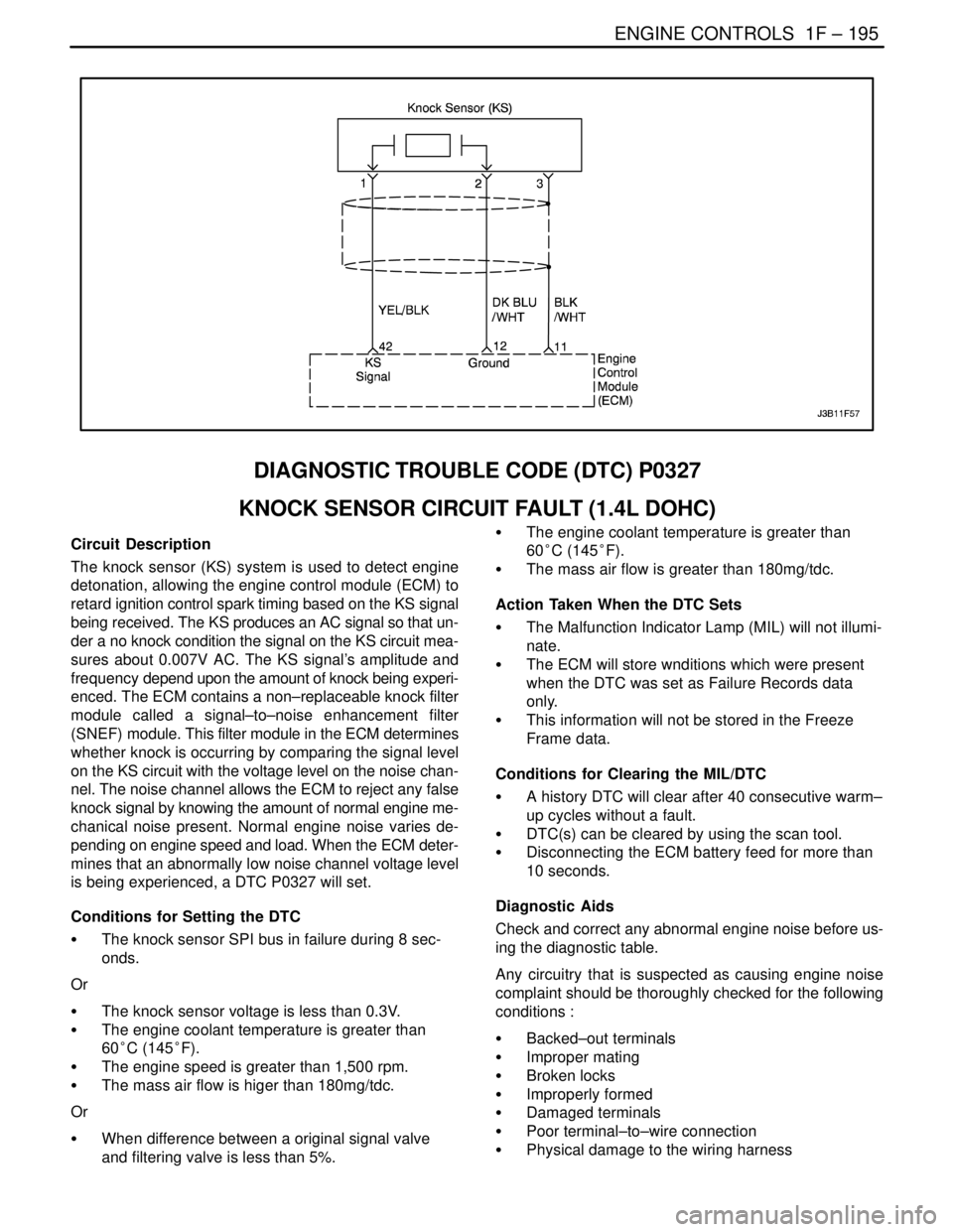

DIAGNOSTIC TROUBLE CODE (DTC) P0327

KNOCK SENSOR CIRCUIT FAULT (1.4L DOHC)

Circuit Description

The knock sensor (KS) system is used to detect engine

detonation, allowing the engine control module (ECM) to

retard ignition control spark timing based on the KS signal

being received. The KS produces an AC signal so that un-

der a no knock condition the signal on the KS circuit mea-

sures about 0.007V AC. The KS signal’s amplitude and

frequency depend upon the amount of knock being experi-

enced. The ECM contains a non–replaceable knock filter

module called a signal–to–noise enhancement filter

(SNEF) module. This filter module in the ECM determines

whether knock is occurring by comparing the signal level

on the KS circuit with the voltage level on the noise chan-

nel. The noise channel allows the ECM to reject any false

knock signal by knowing the amount of normal engine me-

chanical noise present. Normal engine noise varies de-

pending on engine speed and load. When the ECM deter-

mines that an abnormally low noise channel voltage level

is being experienced, a DTC P0327 will set.

Conditions for Setting the DTC

S The knock sensor SPI bus in failure during 8 sec-

onds.

Or

S The knock sensor voltage is less than 0.3V.

S The engine coolant temperature is greater than

60°C (145°F).

S The engine speed is greater than 1,500 rpm.

S The mass air flow is higer than 180mg/tdc.

Or

S When difference between a original signal valve

and filtering valve is less than 5%.S The engine coolant temperature is greater than

60°C (145°F).

S The mass air flow is greater than 180mg/tdc.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store wnditions which were present

when the DTC was set as Failure Records data

only.

S This information will not be stored in the Freeze

Frame data.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check and correct any abnormal engine noise before us-

ing the diagnostic table.

Any circuitry that is suspected as causing engine noise

complaint should be thoroughly checked for the following

conditions :

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

S Physical damage to the wiring harness

Page 444 of 2643

1F – 198IENGINE CONTROLS

DAEWOO V–121 BL4

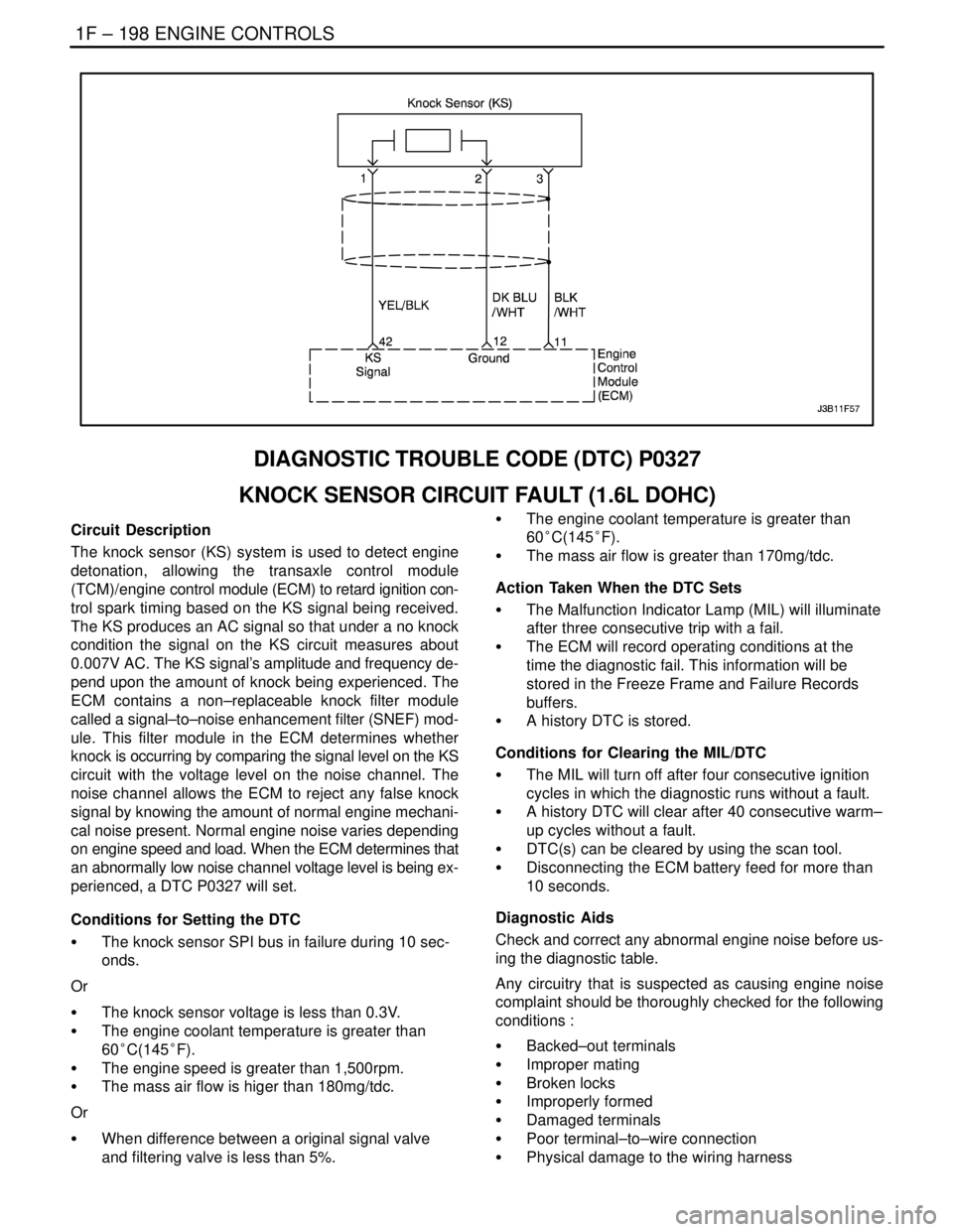

DIAGNOSTIC TROUBLE CODE (DTC) P0327

KNOCK SENSOR CIRCUIT FAULT (1.6L DOHC)

Circuit Description

The knock sensor (KS) system is used to detect engine

detonation, allowing the transaxle control module

(TCM)/engine control module (ECM) to retard ignition con-

trol spark timing based on the KS signal being received.

The KS produces an AC signal so that under a no knock

condition the signal on the KS circuit measures about

0.007V AC. The KS signal’s amplitude and frequency de-

pend upon the amount of knock being experienced. The

ECM contains a non–replaceable knock filter module

called a signal–to–noise enhancement filter (SNEF) mod-

ule. This filter module in the ECM determines whether

knock is occurring by comparing the signal level on the KS

circuit with the voltage level on the noise channel. The

noise channel allows the ECM to reject any false knock

signal by knowing the amount of normal engine mechani-

cal noise present. Normal engine noise varies depending

on engine speed and load. When the ECM determines that

an abnormally low noise channel voltage level is being ex-

perienced, a DTC P0327 will set.

Conditions for Setting the DTC

S The knock sensor SPI bus in failure during 10 sec-

onds.

Or

S The knock sensor voltage is less than 0.3V.

S The engine coolant temperature is greater than

60°C(145°F).

S The engine speed is greater than 1,500rpm.

S The mass air flow is higer than 180mg/tdc.

Or

S When difference between a original signal valve

and filtering valve is less than 5%.S The engine coolant temperature is greater than

60°C(145°F).

S The mass air flow is greater than 170mg/tdc.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check and correct any abnormal engine noise before us-

ing the diagnostic table.

Any circuitry that is suspected as causing engine noise

complaint should be thoroughly checked for the following

conditions :

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

S Physical damage to the wiring harness

Page 464 of 2643

1F – 218IENGINE CONTROLS

DAEWOO V–121 BL4

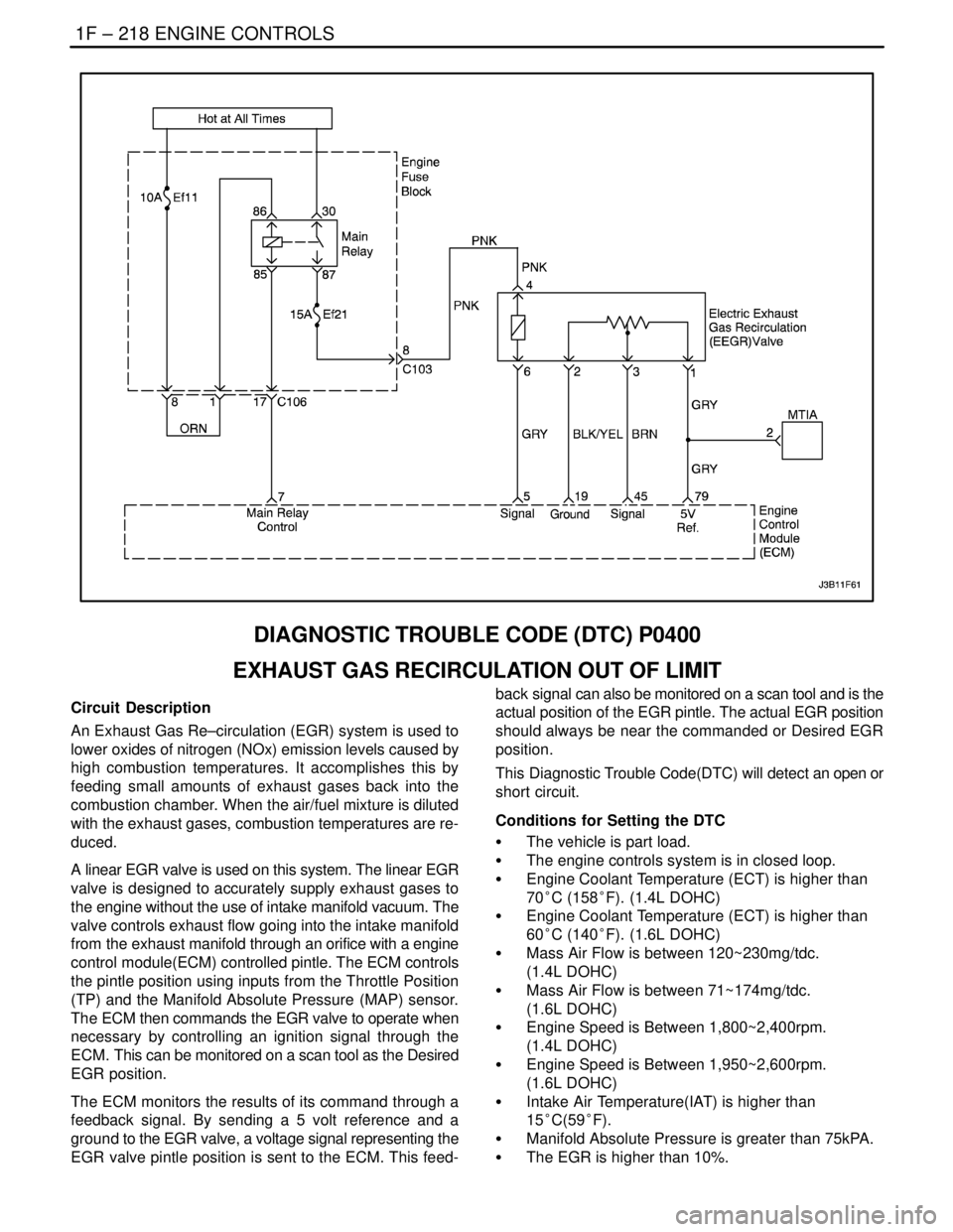

DIAGNOSTIC TROUBLE CODE (DTC) P0400

EXHAUST GAS RECIRCULATION OUT OF LIMIT

Circuit Description

An Exhaust Gas Re–circulation (EGR) system is used to

lower oxides of nitrogen (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced.

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with a engine

control module(ECM) controlled pintle. The ECM controls

the pintle position using inputs from the Throttle Position

(TP) and the Manifold Absolute Pressure (MAP) sensor.

The ECM then commands the EGR valve to operate when

necessary by controlling an ignition signal through the

ECM. This can be monitored on a scan tool as the Desired

EGR position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The actual EGR position

should always be near the commanded or Desired EGR

position.

This Diagnostic Trouble Code(DTC) will detect an open or

short circuit.

Conditions for Setting the DTC

S The vehicle is part load.

S The engine controls system is in closed loop.

S Engine Coolant Temperature (ECT) is higher than

70°C (158°F). (1.4L DOHC)

S Engine Coolant Temperature (ECT) is higher than

60°C (140°F). (1.6L DOHC)

S Mass Air Flow is between 120~230mg/tdc.

(1.4L DOHC)

S Mass Air Flow is between 71~174mg/tdc.

(1.6L DOHC)

S Engine Speed is Between 1,800~2,400rpm.

(1.4L DOHC)

S Engine Speed is Between 1,950~2,600rpm.

(1.6L DOHC)

S Intake Air Temperature(IAT) is higher than

15°C(59°F).

S Manifold Absolute Pressure is greater than 75kPA.

S The EGR is higher than 10%.

Page 503 of 2643

ENGINE CONTROLS 1F – 257

DAEWOO V–121 BL4

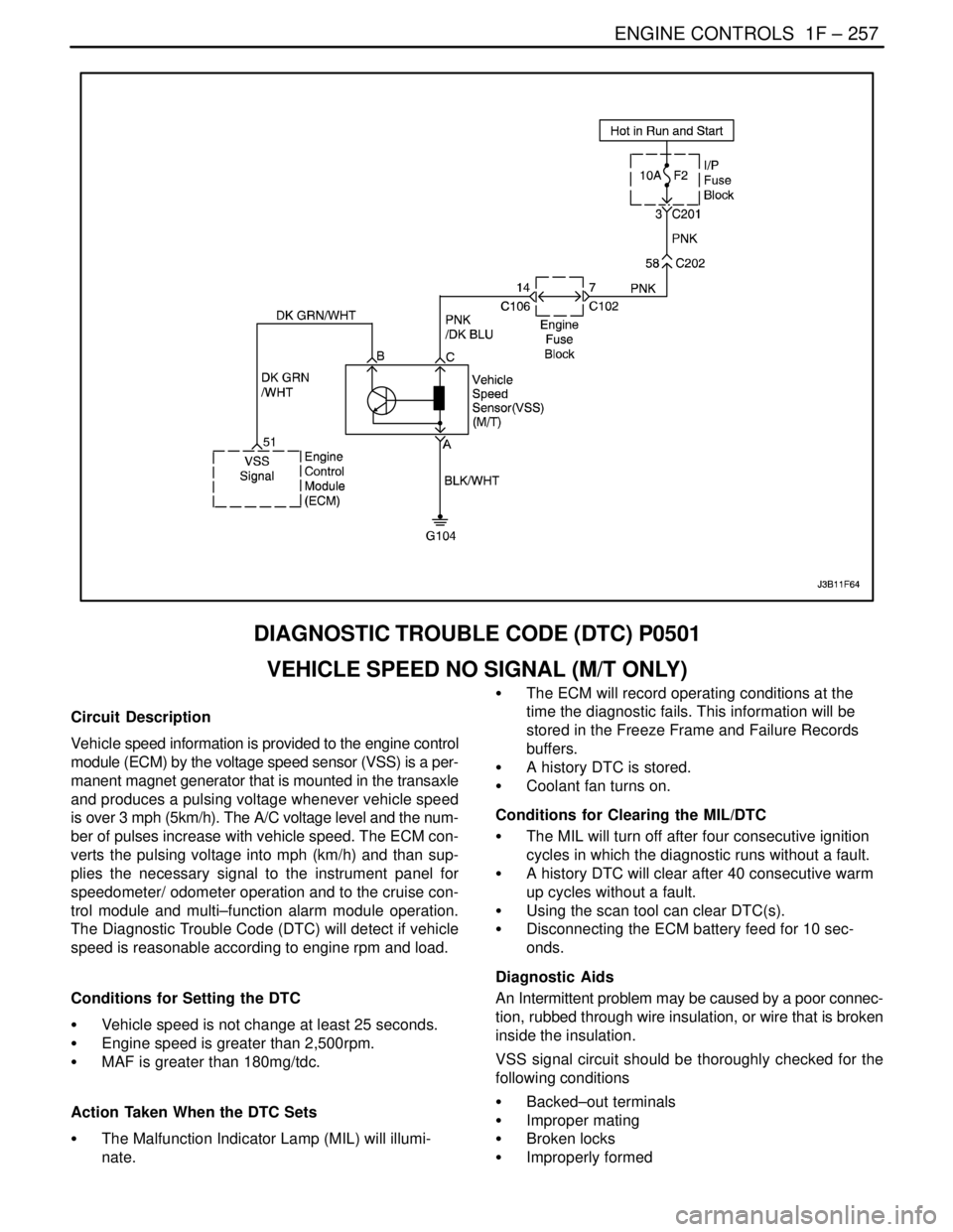

DIAGNOSTIC TROUBLE CODE (DTC) P0501

VEHICLE SPEED NO SIGNAL (M/T ONLY)

Circuit Description

Vehicle speed information is provided to the engine control

module (ECM) by the voltage speed sensor (VSS) is a per-

manent magnet generator that is mounted in the transaxle

and produces a pulsing voltage whenever vehicle speed

is over 3 mph (5km/h). The A/C voltage level and the num-

ber of pulses increase with vehicle speed. The ECM con-

verts the pulsing voltage into mph (km/h) and than sup-

plies the necessary signal to the instrument panel for

speedometer/ odometer operation and to the cruise con-

trol module and multi–function alarm module operation.

The Diagnostic Trouble Code (DTC) will detect if vehicle

speed is reasonable according to engine rpm and load.

Conditions for Setting the DTC

S Vehicle speed is not change at least 25 seconds.

S Engine speed is greater than 2,500rpm.

S MAF is greater than 180mg/tdc.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S Coolant fan turns on.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Using the scan tool can clear DTC(s).

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An Intermittent problem may be caused by a poor connec-

tion, rubbed through wire insulation, or wire that is broken

inside the insulation.

VSS signal circuit should be thoroughly checked for the

following conditions

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

Page 554 of 2643

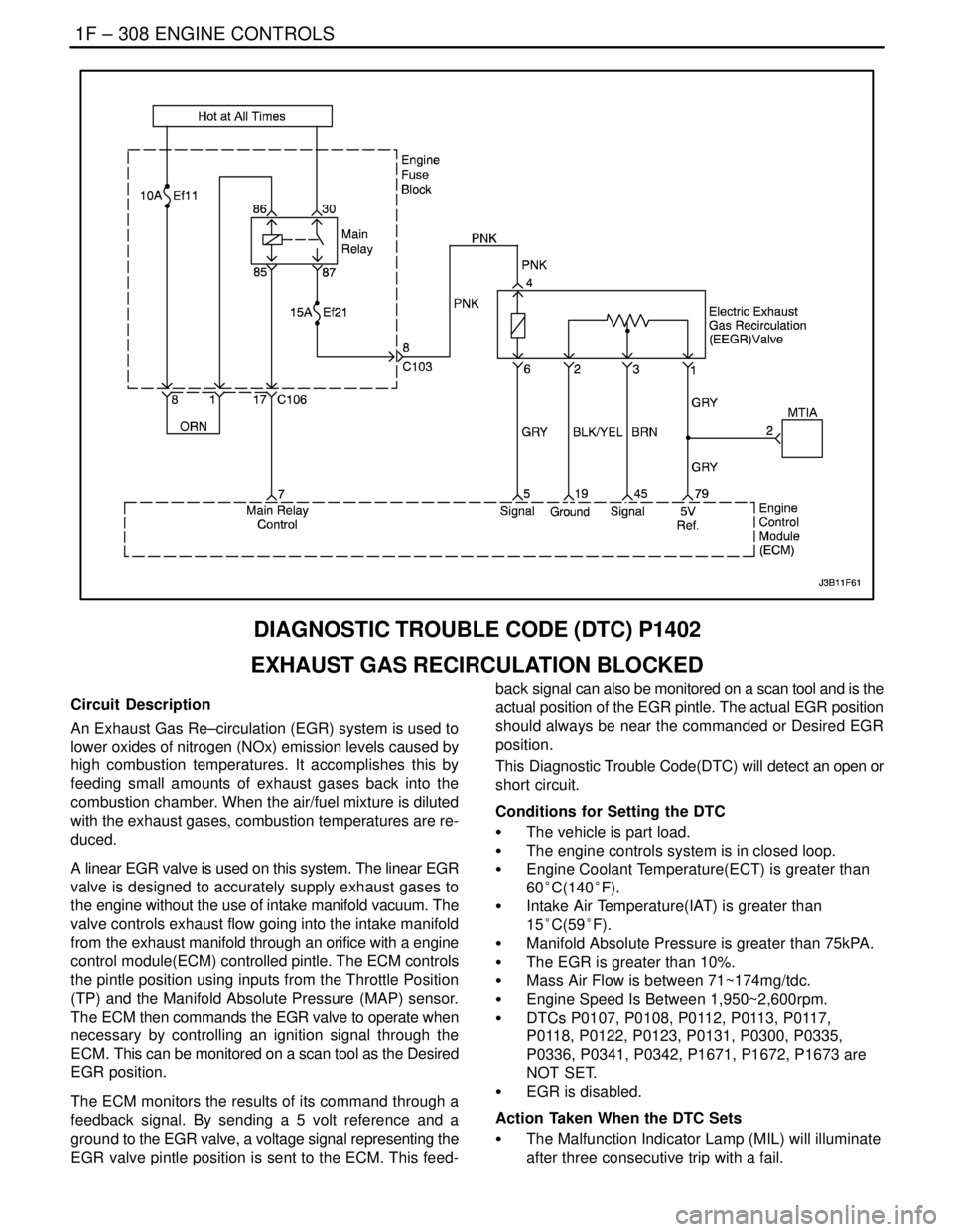

1F – 308IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P1402

EXHAUST GAS RECIRCULATION BLOCKED

Circuit Description

An Exhaust Gas Re–circulation (EGR) system is used to

lower oxides of nitrogen (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced.

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with a engine

control module(ECM) controlled pintle. The ECM controls

the pintle position using inputs from the Throttle Position

(TP) and the Manifold Absolute Pressure (MAP) sensor.

The ECM then commands the EGR valve to operate when

necessary by controlling an ignition signal through the

ECM. This can be monitored on a scan tool as the Desired

EGR position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The actual EGR position

should always be near the commanded or Desired EGR

position.

This Diagnostic Trouble Code(DTC) will detect an open or

short circuit.

Conditions for Setting the DTC

S The vehicle is part load.

S The engine controls system is in closed loop.

S Engine Coolant Temperature(ECT) is greater than

60°C(140°F).

S Intake Air Temperature(IAT) is greater than

15°C(59°F).

S Manifold Absolute Pressure is greater than 75kPA.

S The EGR is greater than 10%.

S Mass Air Flow is between 71~174mg/tdc.

S Engine Speed Is Between 1,950~2,600rpm.

S DTCs P0107, P0108, P0112, P0113, P0117,

P0118, P0122, P0123, P0131, P0300, P0335,

P0336, P0341, P0342, P1671, P1672, P1673 are

NOT SET.

S EGR is disabled.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

Page 556 of 2643

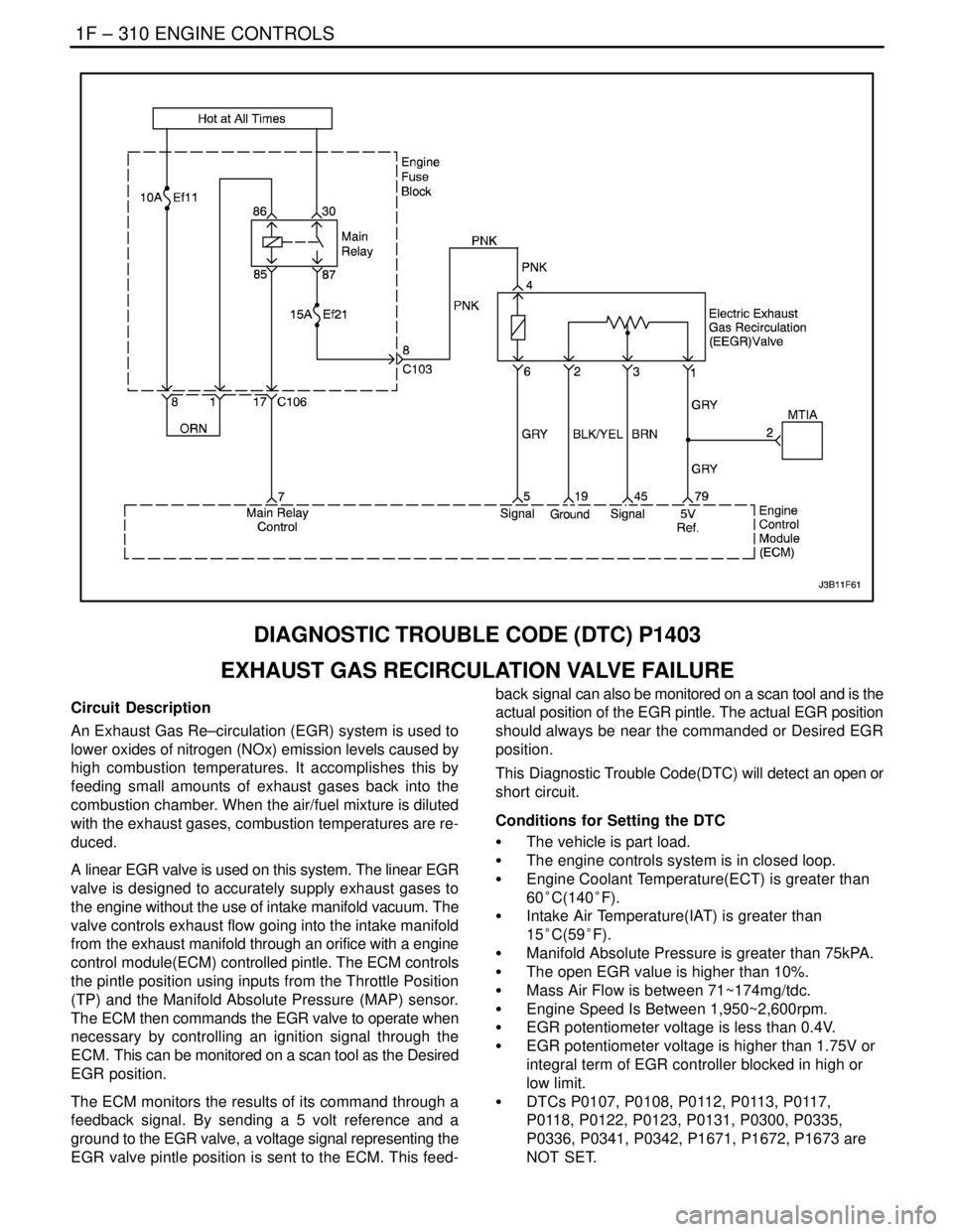

1F – 310IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P1403

EXHAUST GAS RECIRCULATION VALVE FAILURE

Circuit Description

An Exhaust Gas Re–circulation (EGR) system is used to

lower oxides of nitrogen (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced.

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with a engine

control module(ECM) controlled pintle. The ECM controls

the pintle position using inputs from the Throttle Position

(TP) and the Manifold Absolute Pressure (MAP) sensor.

The ECM then commands the EGR valve to operate when

necessary by controlling an ignition signal through the

ECM. This can be monitored on a scan tool as the Desired

EGR position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The actual EGR position

should always be near the commanded or Desired EGR

position.

This Diagnostic Trouble Code(DTC) will detect an open or

short circuit.

Conditions for Setting the DTC

S The vehicle is part load.

S The engine controls system is in closed loop.

S Engine Coolant Temperature(ECT) is greater than

60°C(140°F).

S Intake Air Temperature(IAT) is greater than

15°C(59°F).

S Manifold Absolute Pressure is greater than 75kPA.

S The open EGR value is higher than 10%.

S Mass Air Flow is between 71~174mg/tdc.

S Engine Speed Is Between 1,950~2,600rpm.

S EGR potentiometer voltage is less than 0.4V.

S EGR potentiometer voltage is higher than 1.75V or

integral term of EGR controller blocked in high or

low limit.

S DTCs P0107, P0108, P0112, P0113, P0117,

P0118, P0122, P0123, P0131, P0300, P0335,

P0336, P0341, P0342, P1671, P1672, P1673 are

NOT SET.

Page 591 of 2643

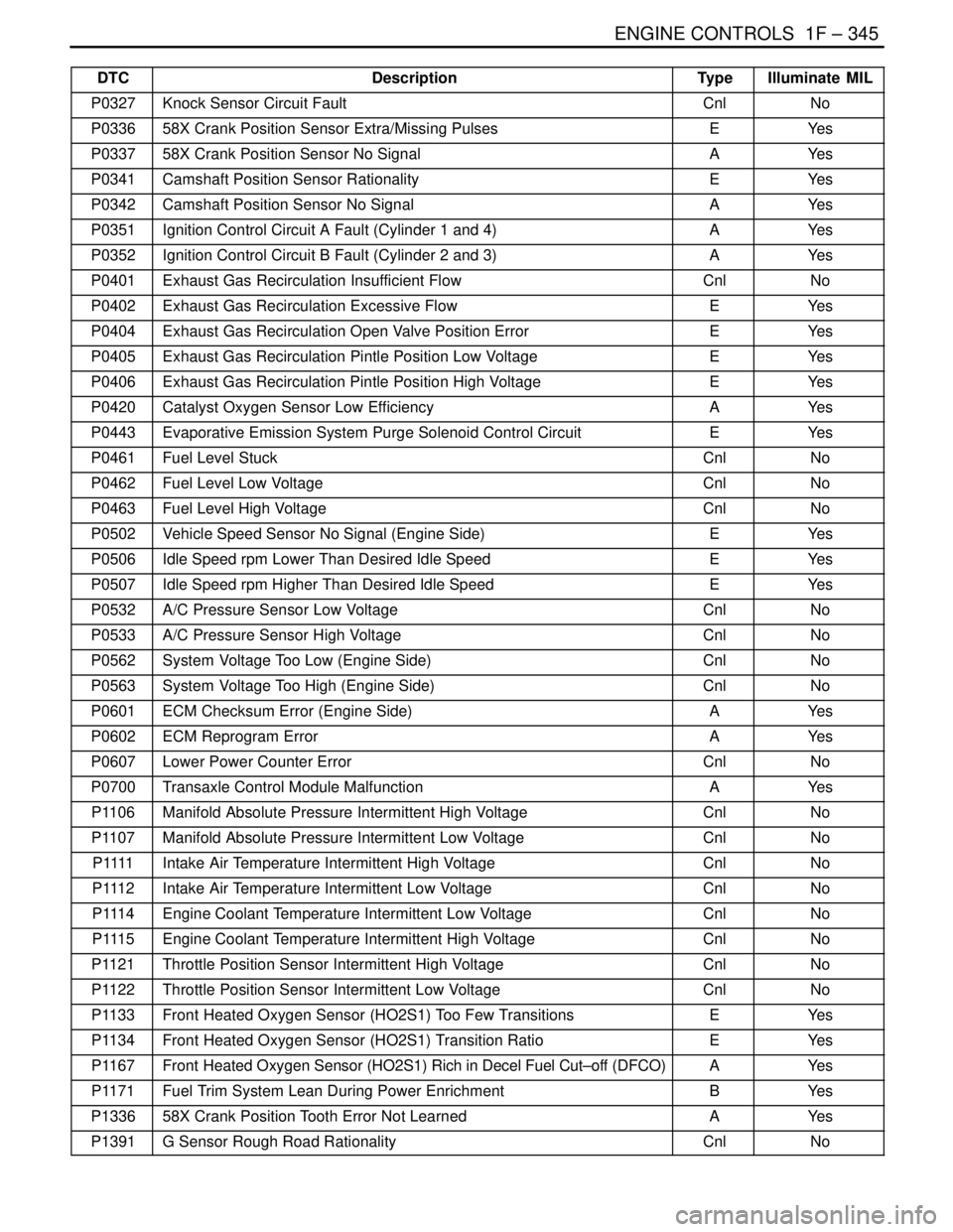

ENGINE CONTROLS 1F – 345

DAEWOO V–121 BL4

DTCIlluminate MIL Type Description

P0327Knock Sensor Circuit FaultCnlNo

P033658X Crank Position Sensor Extra/Missing PulsesEYe s

P033758X Crank Position Sensor No SignalAYe s

P0341Camshaft Position Sensor RationalityEYe s

P0342Camshaft Position Sensor No SignalAYe s

P0351Ignition Control Circuit A Fault (Cylinder 1 and 4)AYe s

P0352Ignition Control Circuit B Fault (Cylinder 2 and 3)AYe s

P0401Exhaust Gas Recirculation Insufficient FlowCnlNo

P0402Exhaust Gas Recirculation Excessive FlowEYe s

P0404Exhaust Gas Recirculation Open Valve Position ErrorEYe s

P0405Exhaust Gas Recirculation Pintle Position Low VoltageEYe s

P0406Exhaust Gas Recirculation Pintle Position High VoltageEYe s

P0420Catalyst Oxygen Sensor Low EfficiencyAYe s

P0443Evaporative Emission System Purge Solenoid Control CircuitEYe s

P0461Fuel Level StuckCnlNo

P0462Fuel Level Low VoltageCnlNo

P0463Fuel Level High VoltageCnlNo

P0502Vehicle Speed Sensor No Signal (Engine Side)EYe s

P0506Idle Speed rpm Lower Than Desired Idle SpeedEYe s

P0507Idle Speed rpm Higher Than Desired Idle SpeedEYe s

P0532A/C Pressure Sensor Low VoltageCnlNo

P0533A/C Pressure Sensor High VoltageCnlNo

P0562System Voltage Too Low (Engine Side)CnlNo

P0563System Voltage Too High (Engine Side)CnlNo

P0601ECM Checksum Error (Engine Side)AYe s

P0602ECM Reprogram ErrorAYe s

P0607Lower Power Counter ErrorCnlNo

P0700Transaxle Control Module MalfunctionAYe s

P1106Manifold Absolute Pressure Intermittent High VoltageCnlNo

P1107Manifold Absolute Pressure Intermittent Low VoltageCnlNo

P 1111Intake Air Temperature Intermittent High VoltageCnlNo

P1112Intake Air Temperature Intermittent Low VoltageCnlNo

P1114Engine Coolant Temperature Intermittent Low VoltageCnlNo

P1115Engine Coolant Temperature Intermittent High VoltageCnlNo

P1121Throttle Position Sensor Intermittent High VoltageCnlNo

P1122Throttle Position Sensor Intermittent Low VoltageCnlNo

P1133Front Heated Oxygen Sensor (HO2S1) Too Few TransitionsEYe s

P1134Front Heated Oxygen Sensor (HO2S1) Transition RatioEYe s

P1167Front Heated Oxygen Sensor (HO2S1) Rich in Decel Fuel Cut–off (DFCO)AYe s

P1171Fuel Trim System Lean During Power EnrichmentBYe s

P133658X Crank Position Tooth Error Not LearnedAYe s

P1391G Sensor Rough Road RationalityCnlNo

Page 646 of 2643

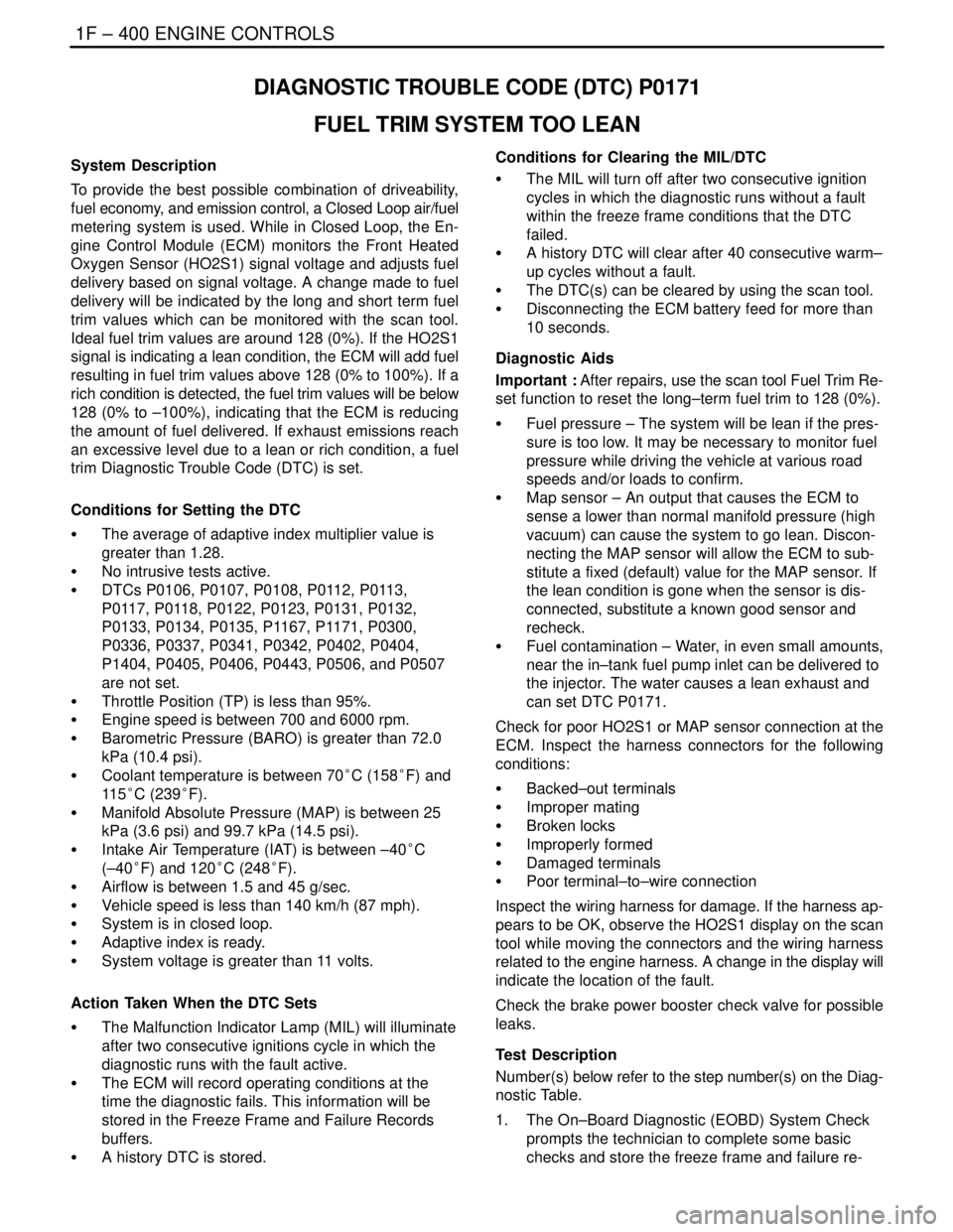

1F – 400IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0171

FUEL TRIM SYSTEM TOO LEAN

System Description

To provide the best possible combination of driveability,

fuel economy, and emission control, a Closed Loop air/fuel

metering system is used. While in Closed Loop, the En-

gine Control Module (ECM) monitors the Front Heated

Oxygen Sensor (HO2S1) signal voltage and adjusts fuel

delivery based on signal voltage. A change made to fuel

delivery will be indicated by the long and short term fuel

trim values which can be monitored with the scan tool.

Ideal fuel trim values are around 128 (0%). If the HO2S1

signal is indicating a lean condition, the ECM will add fuel

resulting in fuel trim values above 128 (0% to 100%). If a

rich condition is detected, the fuel trim values will be below

128 (0% to –100%), indicating that the ECM is reducing

the amount of fuel delivered. If exhaust emissions reach

an excessive level due to a lean or rich condition, a fuel

trim Diagnostic Trouble Code (DTC) is set.

Conditions for Setting the DTC

S The average of adaptive index multiplier value is

greater than 1.28.

S No intrusive tests active.

S DTCs P0106, P0107, P0108, P0112, P0113,

P0117, P0118, P0122, P0123, P0131, P0132,

P0133, P0134, P0135, P1167, P1171, P0300,

P0336, P0337, P0341, P0342, P0402, P0404,

P1404, P0405, P0406, P0443, P0506, and P0507

are not set.

S Throttle Position (TP) is less than 95%.

S Engine speed is between 700 and 6000 rpm.

S Barometric Pressure (BARO) is greater than 72.0

kPa (10.4 psi).

S Coolant temperature is between 70°C (158°F) and

11 5°C (239°F).

S Manifold Absolute Pressure (MAP) is between 25

kPa (3.6 psi) and 99.7 kPa (14.5 psi).

S Intake Air Temperature (IAT) is between –40°C

(–40°F) and 120°C (248°F).

S Airflow is between 1.5 and 45 g/sec.

S Vehicle speed is less than 140 km/h (87 mph).

S System is in closed loop.

S Adaptive index is ready.

S System voltage is greater than 11 volts.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after two consecutive ignitions cycle in which the

diagnostic runs with the fault active.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.Conditions for Clearing the MIL/DTC

S The MIL will turn off after two consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Important : After repairs, use the scan tool Fuel Trim Re-

set function to reset the long–term fuel trim to 128 (0%).

S Fuel pressure – The system will be lean if the pres-

sure is too low. It may be necessary to monitor fuel

pressure while driving the vehicle at various road

speeds and/or loads to confirm.

S Map sensor – An output that causes the ECM to

sense a lower than normal manifold pressure (high

vacuum) can cause the system to go lean. Discon-

necting the MAP sensor will allow the ECM to sub-

stitute a fixed (default) value for the MAP sensor. If

the lean condition is gone when the sensor is dis-

connected, substitute a known good sensor and

recheck.

S Fuel contamination – Water, in even small amounts,

near the in–tank fuel pump inlet can be delivered to

the injector. The water causes a lean exhaust and

can set DTC P0171.

Check for poor HO2S1 or MAP sensor connection at the

ECM. Inspect the harness connectors for the following

conditions:

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

Inspect the wiring harness for damage. If the harness ap-

pears to be OK, observe the HO2S1 display on the scan

tool while moving the connectors and the wiring harness

related to the engine harness. A change in the display will

indicate the location of the fault.

Check the brake power booster check valve for possible

leaks.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

Page 650 of 2643

1F – 404IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0172

FUEL TRIM SYSTEM TOO RICH

System Description

To provide the best possible combination of driveability,

fuel economy, and emission control, a Closed Loop air/fuel

metering system is used. While in Closed Loop, the En-

gine Control Module (ECM) monitors the Front Heated

Oxygen Sensor (HO2S1) signal voltage and adjusts fuel

delivery based on signal voltage. A change made to fuel

delivery will be indicated by the long and short term fuel

trim values which can be monitored with the scan tool.

Ideal fuel trim values are around 128 (0%). If the HO2S1

signal is indicating a lean condition, the ECM will add fuel

resulting in fuel trim values above 128 (0% to 100%). If a

rich condition is detected, the fuel trim values will be below

128 (0% to –100%), indicating that the ECM is reducing

the amount of fuel delivered. If exhaust emissions reach

an excessive level due to a lean or rich condition, a fuel

trim Diagnostic Trouble Code (DTC) is set.

Conditions for Setting the DTC

S The average of adaptive index multiplier value is

less than 0.75.

S No intrusive tests active.

S DTCs P0106, P0107, P0108, P0112, P0113,

P0117, P0118, P0122, P0123, P0131, P0132,

P0133, P0134, P0135, P1167, P1171, P0336,

P0337, P0341, P0342, P0402, P0404, P1404,

P0405, P0406, P0443, P0506, and P0507 are not

set.

S Throttle Position (TP) is less than 95%.

S Engine speed is between 700 and 6000 rpm.

S Barometric Pressure (BARO) is greater than 72.0

kPa (10.4 psi).

S Coolant temperature is between 70°C (158°F) and

11 5°C (239°F).

S Manifold Absolute Pressure (MAP) is between 25

kPa (3.6 psi) and 99.7 kPa (14.5 psi).

S Intake Air Temperature (IAT) is between –40°C

(–40°F) and 120°C (248°F).

S Airflow is between 1.5 and 45 g/sec.

S Vehicle speed is less than 140 km/h (87 mph).

S System is in closed loop.

S Adaptive index is ready.

S System voltage is greater than 11 volts.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after two consecutive ignitions cycle in which the

diagnostic runs with the fault active (SOHC).

S The Malfunction Indicator Lamp (MIL) will illuminate

after first consecutive ignitions cycle (DOHC).

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.Conditions for Clearing the MIL/DTC

S The MIL will turn off after two consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Important : After repairs, use the scan tool Fuel Trim Re-

set function to reset the long–term fuel trim to 128 (0%).

Check for poor connection at the ECM. Inspect the har-

ness connectors for the following conditions:

S Backed–out terminals.

S Improper mating.

S Broken locks.

S Improperly formed.

S Damaged terminals.

S Poor terminal–to–wire connection.

Inspect the wiring harness for damage. If the harness ap-

pears to be OK, observe the HO2S1 display on the scan

tool while moving the connectors and the wiring harness

related to the engine harness. A change in the display will

indicate the location of the fault.

If a DTC P1404 is also set, check the 5 volt reference cir-

cuits for a short to voltage.

Check for a restricted exhaust system.

A shorted 5 volt reference circuit may cause a DTC P0172

to set. Check the 5 volt reference sensors for abnormal

readings.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

5. A clogged air cleaner filter element restricts the air-

flow coming into the engine. This step checks the

condition of the air cleaner filter.

17. A leaky injector can cause a rich condition and set

DTC P0172. Refer to ”Fuel Injector Balance Test”

in this section.

19. A loose TP sensor may not set a TP sensor related

DTC, but may cause the system to become rich by

a higher–than–actual TP reading.

Page 667 of 2643

ENGINE CONTROLS 1F – 421

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0300

MULTIPLE CYLINDER MISFIRE DETECTED

System Description

The Engine Control Module (ECM) monitors the crank-

shaft and camshaft positions to detect if the engine is mis-

firing. The ECM looks for a quick drop in crankshaft speed.

This test is executed in blocks of 100 engine revolution

tests. It may take between one to several tests to store a

Diagnostic Trouble Code (DTC) and illuminate the Mal-

function Indicator Lamp (MIL). Under light misfire condi-

tions, it may also take more than one trip to set a DTC. Se-

vere misfire will flash the MIL, indicating that catalyst

damage is possible.

Conditions for Setting the DTC

S Emission threshold is 3%.

S 20 engine cycles have occurred since cranking has

started.

S A/C compressor clutch has not just engaged or dis-

engaged.

S Engine load and engine speed is in a detectable

region and is at or above zero torque.

S Camshaft Position (CMP) sensor is in synchroniza-

tion.

S Exhaust Gas Recirculation (EGR) flow diagnostic is

not in progress.

S Fuel level is greater than 12% of rated tank capac-

ity.

S Decel Fuel Cutoff (DFCO) not active.

S Throttle position change is less than 3% per 125

ms.

S Vehicle has not encountered an abusive engine

speed of 7000 rpm.

S Crankshaft speed patters are normal.

S Throttle position is less than 3% when vehicle

speed is greater than 10 km/h (6 mph).

S Vehicle voltage is between 11 and 16 volts.

S Engine Coolant Temperature (ECT) is between

–7°C (19°F) and 120°C (248°F).

S There is the correct ratio between Crankshaft Posi-

tion (CKP) sensor pulses and CMP sensor pulses.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0336, P0337, P0341, P0342 and

P0502 are not set.

Action Taken When the DTC Sets

S The MIL will illuminate after two consecutive ignition

cycles in which the diagnostic runs with the fault

active.

Or

S The MIL will illuminate immediately and flash if mis-

fire is present.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent can also be the result of a defective reluctor

wheel. Remove the CKP sensor and inspect the reluctor

wheel through the sensor mount hole. Check for porosity

and the condition of wheel. If the DTC is intermittent refer

to ”Symptoms Diagnosis” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. A visual/physical inspection should include check-

ing the following components:

S The wiring for proper connections, pinches or

cuts.

S The ECM grounds for being clean and tight.

S The vacuum hoses for splits, kinks, and proper

connections as shown on the Vehicle Emission

Information label. Check thoroughly for any type

of leak or restriction.

S For air leaks at the throttle body mounting area

and intake manifold sealing surfaces.

5. When all the accumulators are relatively equal, then

the misfire is being caused by something that af-

fects the entire engine. When they are not then the

misfire is being caused by something that is specif-

ic to two or more cylinders.

6. Whenever the misfire is not present operating the

vehicle may be necessary to duplicate the condi-

tions in the Freeze Frame Data in order to detect

misfire. Depending on the engine load, the condi-

tions may have to be maintained for up to 20 sec-

onds. Whenever the misfire accumulators start to

increment, then misfire is present. A history misfire

counter will store the number of misfires that have

occurred until the DTC is cleared.