transaxle DAEWOO LACETTI 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 49 of 2643

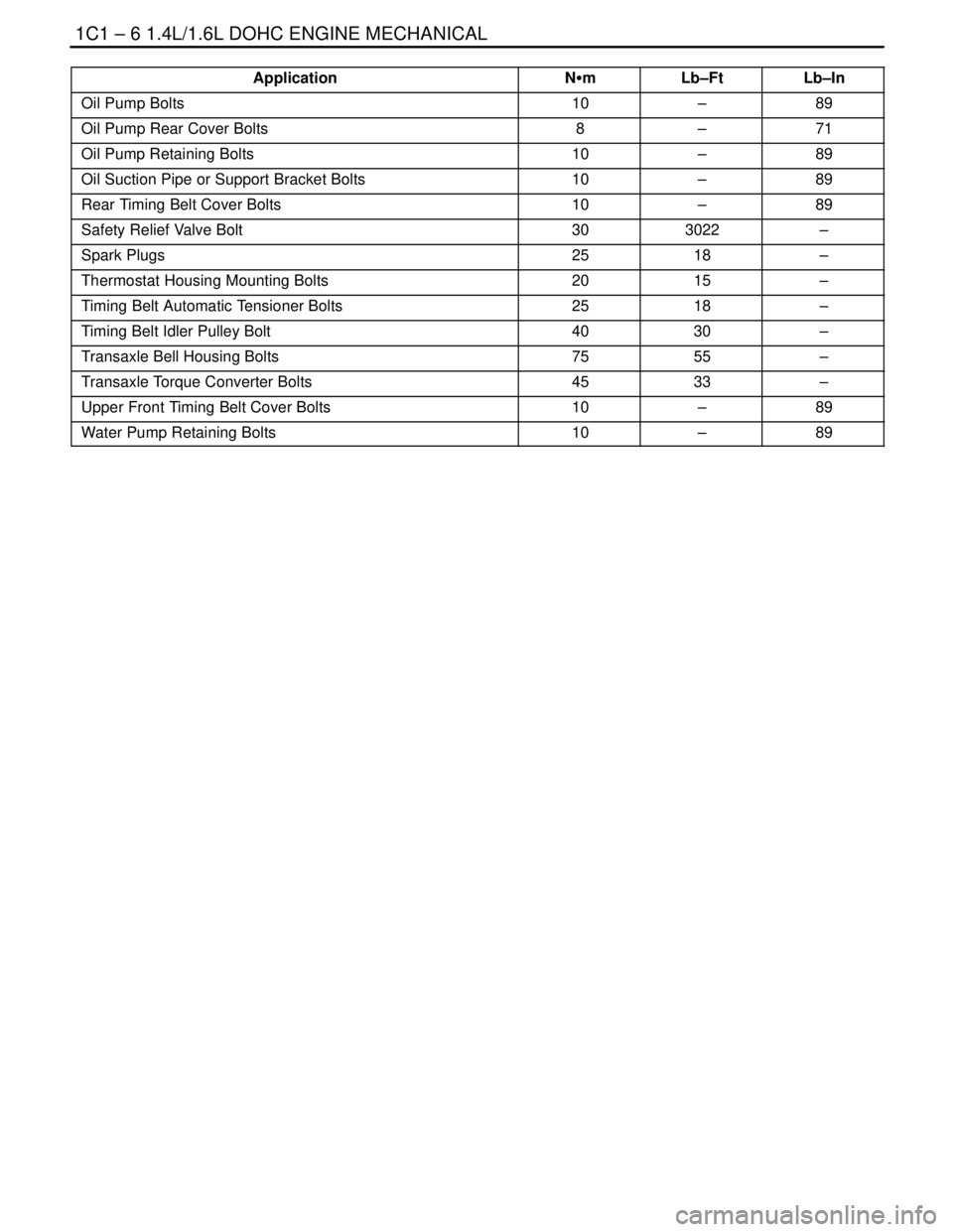

1C1 – 6I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

Application Lb–InLb–Ft NSm

Oil Pump Bolts10–89

Oil Pump Rear Cover Bolts8–71

Oil Pump Retaining Bolts10–89

Oil Suction Pipe or Support Bracket Bolts10–89

Rear Timing Belt Cover Bolts10–89

Safety Relief Valve Bolt303022–

Spark Plugs2518–

Thermostat Housing Mounting Bolts2015–

Timing Belt Automatic Tensioner Bolts2518–

Timing Belt Idler Pulley Bolt4030–

Transaxle Bell Housing Bolts7555–

Transaxle Torque Converter Bolts4533–

Upper Front Timing Belt Cover Bolts10–89

Water Pump Retaining Bolts10–89

Page 57 of 2643

1C1 – 14I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

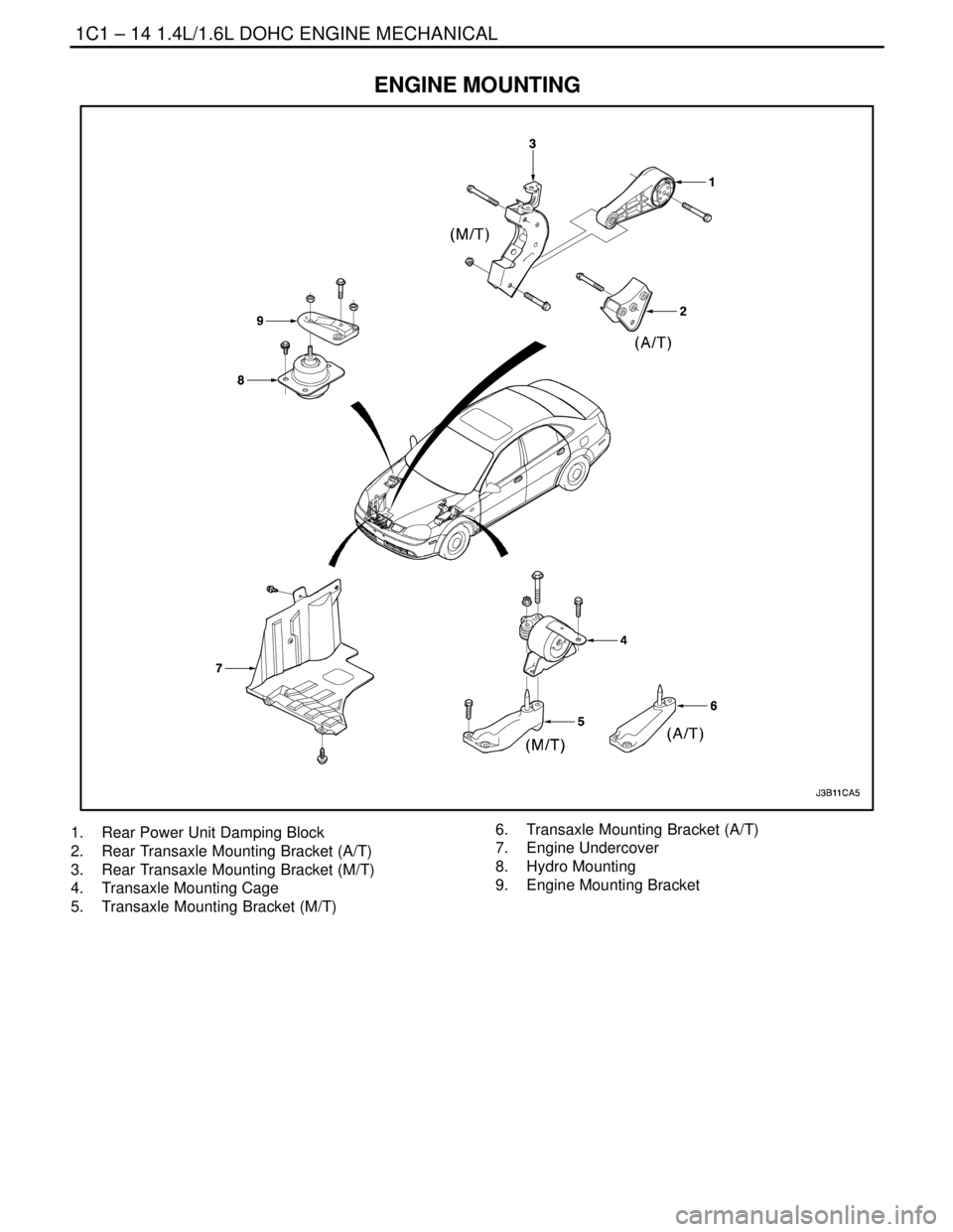

ENGINE MOUNTING

1. Rear Power Unit Damping Block

2. Rear Transaxle Mounting Bracket (A/T)

3. Rear Transaxle Mounting Bracket (M/T)

4. Transaxle Mounting Cage

5. Transaxle Mounting Bracket (M/T)6. Transaxle Mounting Bracket (A/T)

7. Engine Undercover

8. Hydro Mounting

9. Engine Mounting Bracket

Page 81 of 2643

1C1 – 38I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

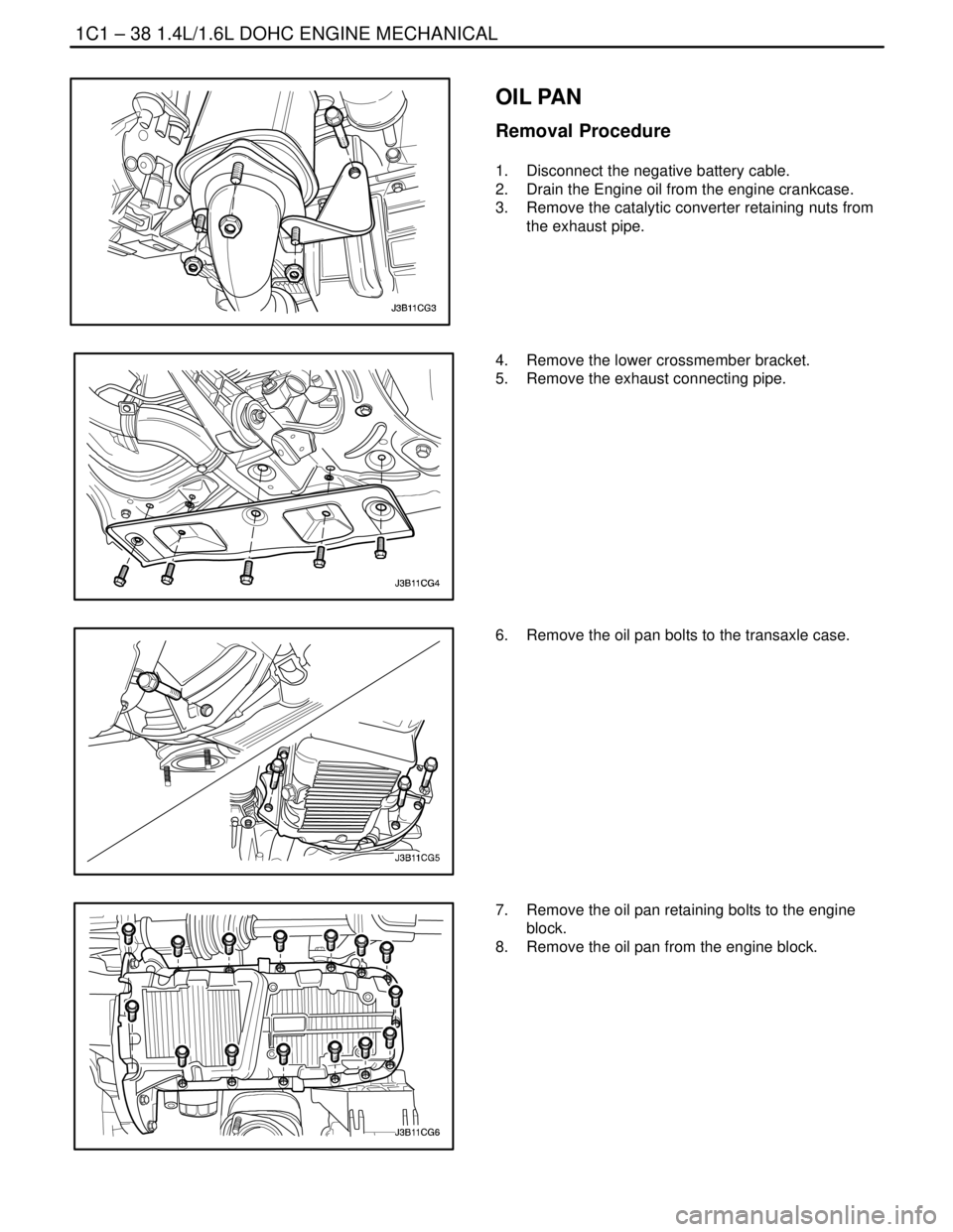

OIL PAN

Removal Procedure

1. Disconnect the negative battery cable.

2. Drain the Engine oil from the engine crankcase.

3. Remove the catalytic converter retaining nuts from

the exhaust pipe.

4. Remove the lower crossmember bracket.

5. Remove the exhaust connecting pipe.

6. Remove the oil pan bolts to the transaxle case.

7. Remove the oil pan retaining bolts to the engine

block.

8. Remove the oil pan from the engine block.

Page 82 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 39

DAEWOO V–121 BL4

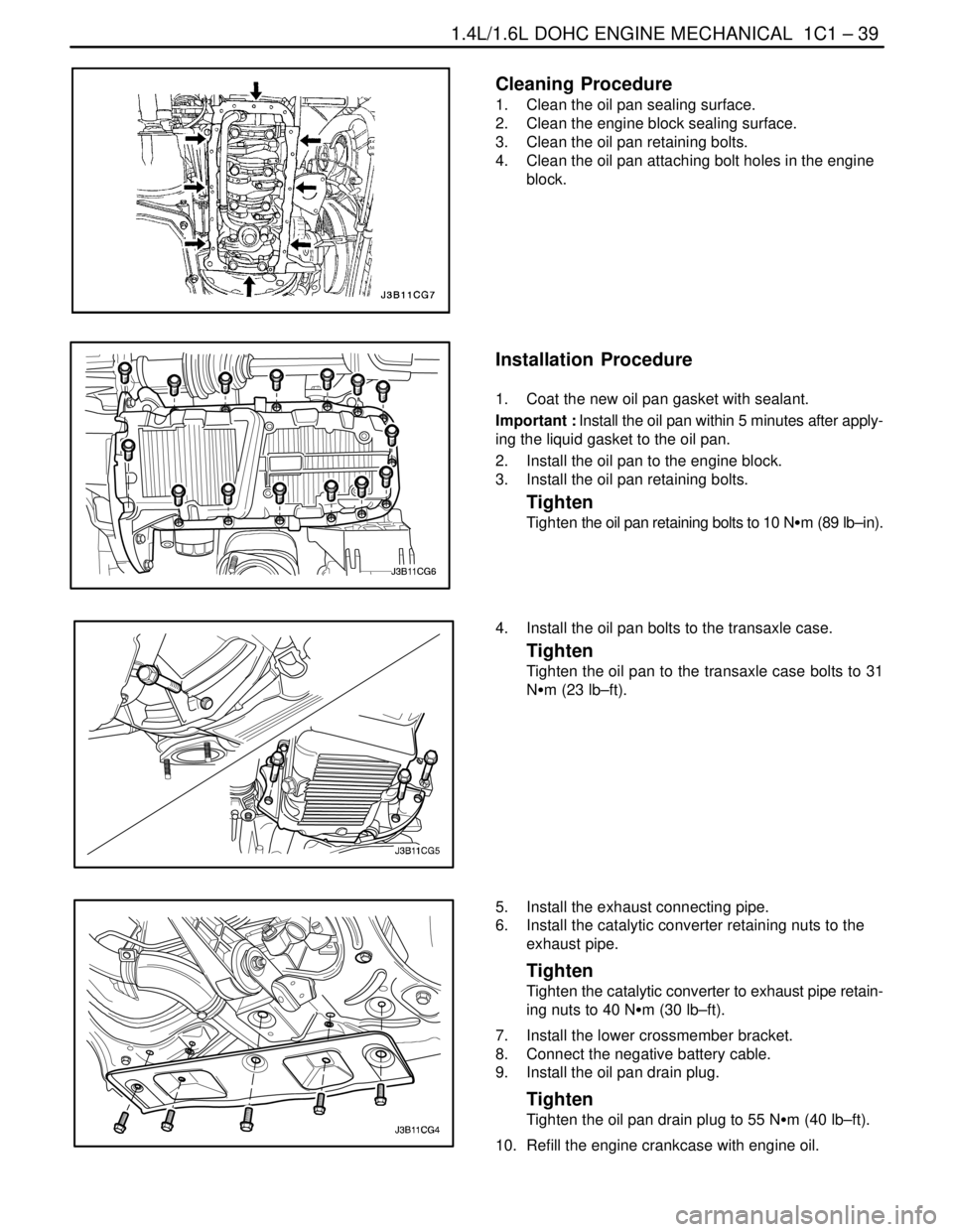

Cleaning Procedure

1. Clean the oil pan sealing surface.

2. Clean the engine block sealing surface.

3. Clean the oil pan retaining bolts.

4. Clean the oil pan attaching bolt holes in the engine

block.

Installation Procedure

1. Coat the new oil pan gasket with sealant.

Important : Install the oil pan within 5 minutes after apply-

ing the liquid gasket to the oil pan.

2. Install the oil pan to the engine block.

3. Install the oil pan retaining bolts.

Tighten

Tighten the oil pan retaining bolts to 10 NSm (89 lb–in).

4. Install the oil pan bolts to the transaxle case.

Tighten

Tighten the oil pan to the transaxle case bolts to 31

NSm (23 lb–ft).

5. Install the exhaust connecting pipe.

6. Install the catalytic converter retaining nuts to the

exhaust pipe.

Tighten

Tighten the catalytic converter to exhaust pipe retain-

ing nuts to 40 NSm (30 lb–ft).

7. Install the lower crossmember bracket.

8. Connect the negative battery cable.

9. Install the oil pan drain plug.

Tighten

Tighten the oil pan drain plug to 55 NSm (40 lb–ft).

10. Refill the engine crankcase with engine oil.

Page 93 of 2643

1C1 – 50I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

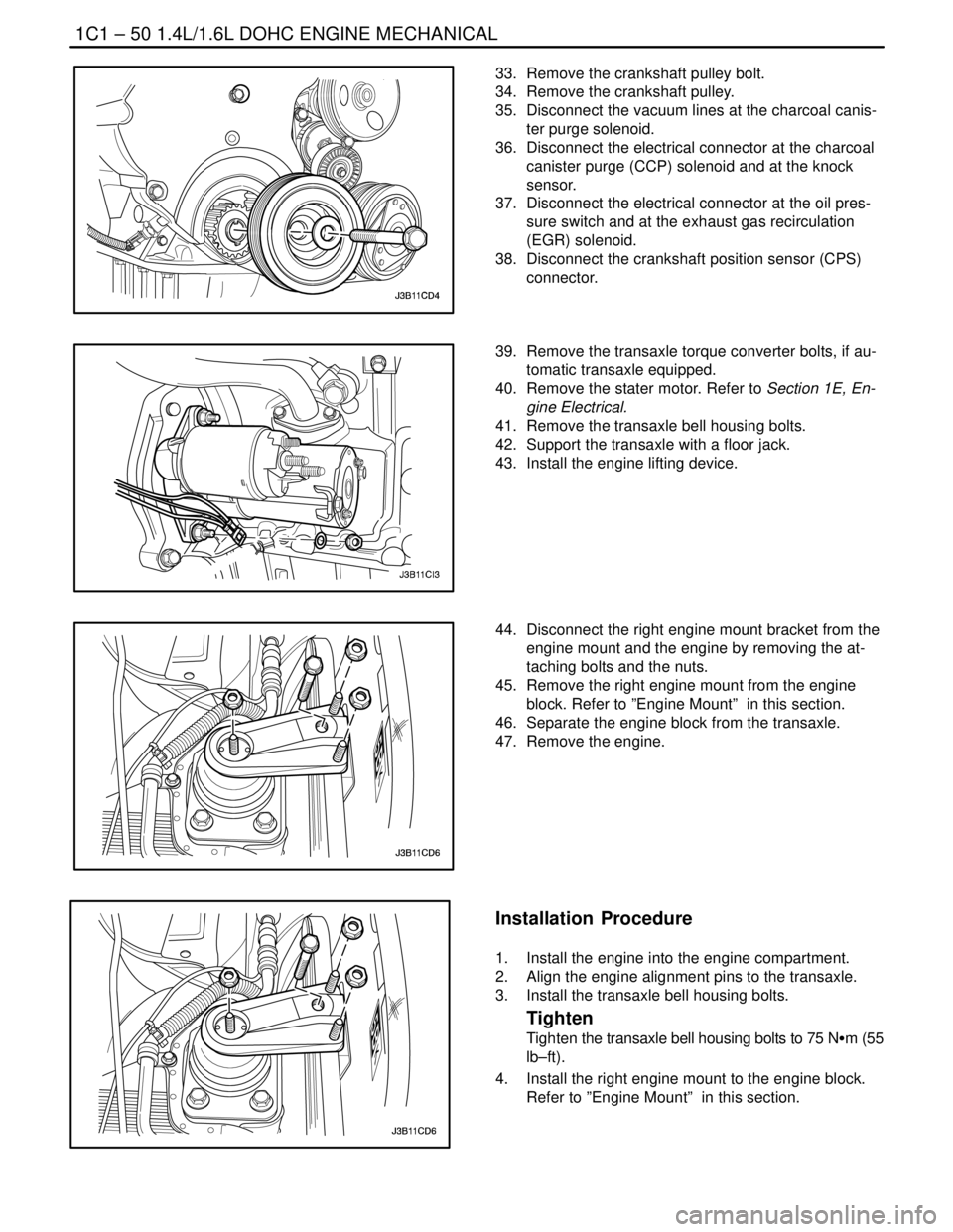

33. Remove the crankshaft pulley bolt.

34. Remove the crankshaft pulley.

35. Disconnect the vacuum lines at the charcoal canis-

ter purge solenoid.

36. Disconnect the electrical connector at the charcoal

canister purge (CCP) solenoid and at the knock

sensor.

37. Disconnect the electrical connector at the oil pres-

sure switch and at the exhaust gas recirculation

(EGR) solenoid.

38. Disconnect the crankshaft position sensor (CPS)

connector.

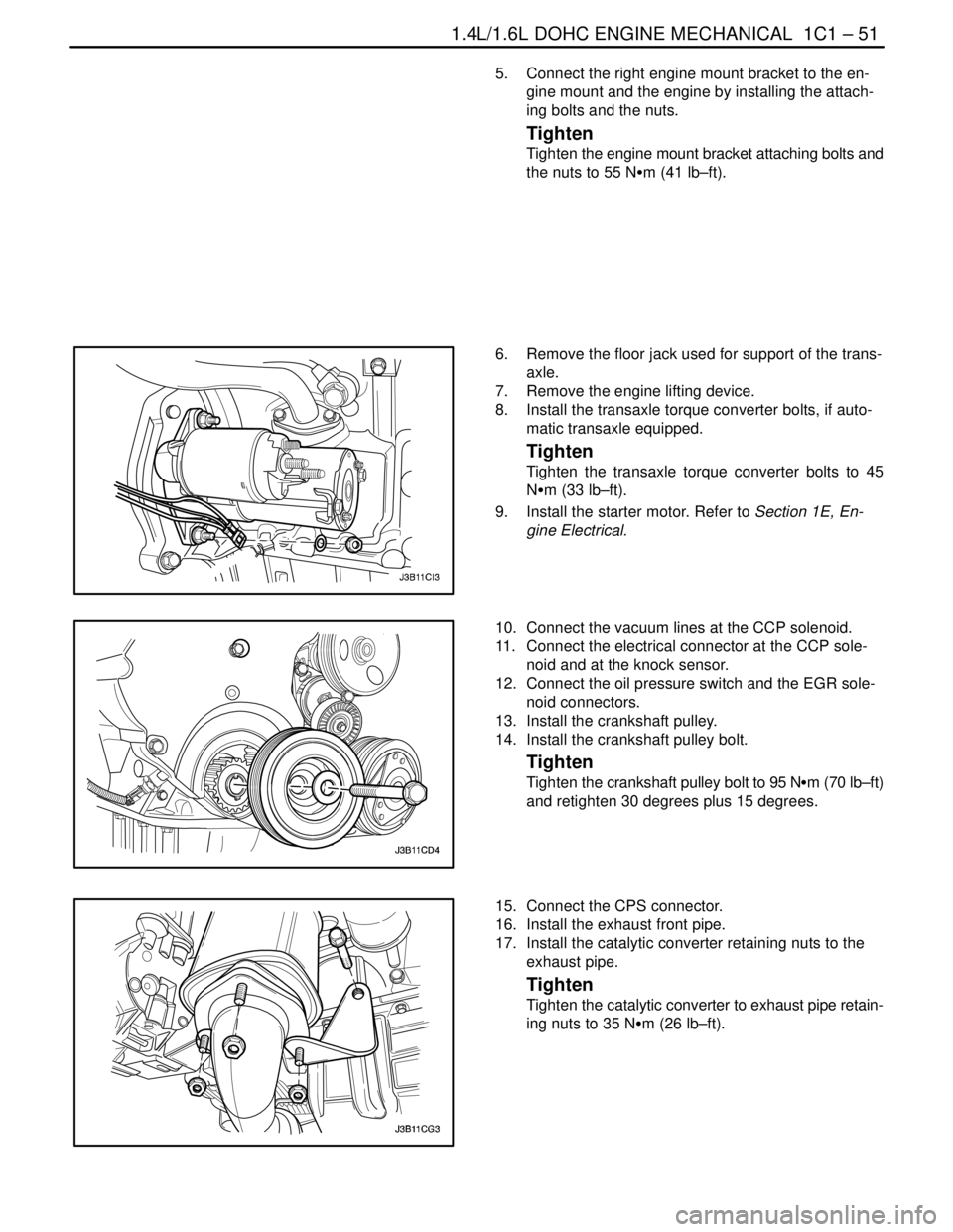

39. Remove the transaxle torque converter bolts, if au-

tomatic transaxle equipped.

40. Remove the stater motor. Refer to Section 1E, En-

gine Electrical.

41. Remove the transaxle bell housing bolts.

42. Support the transaxle with a floor jack.

43. Install the engine lifting device.

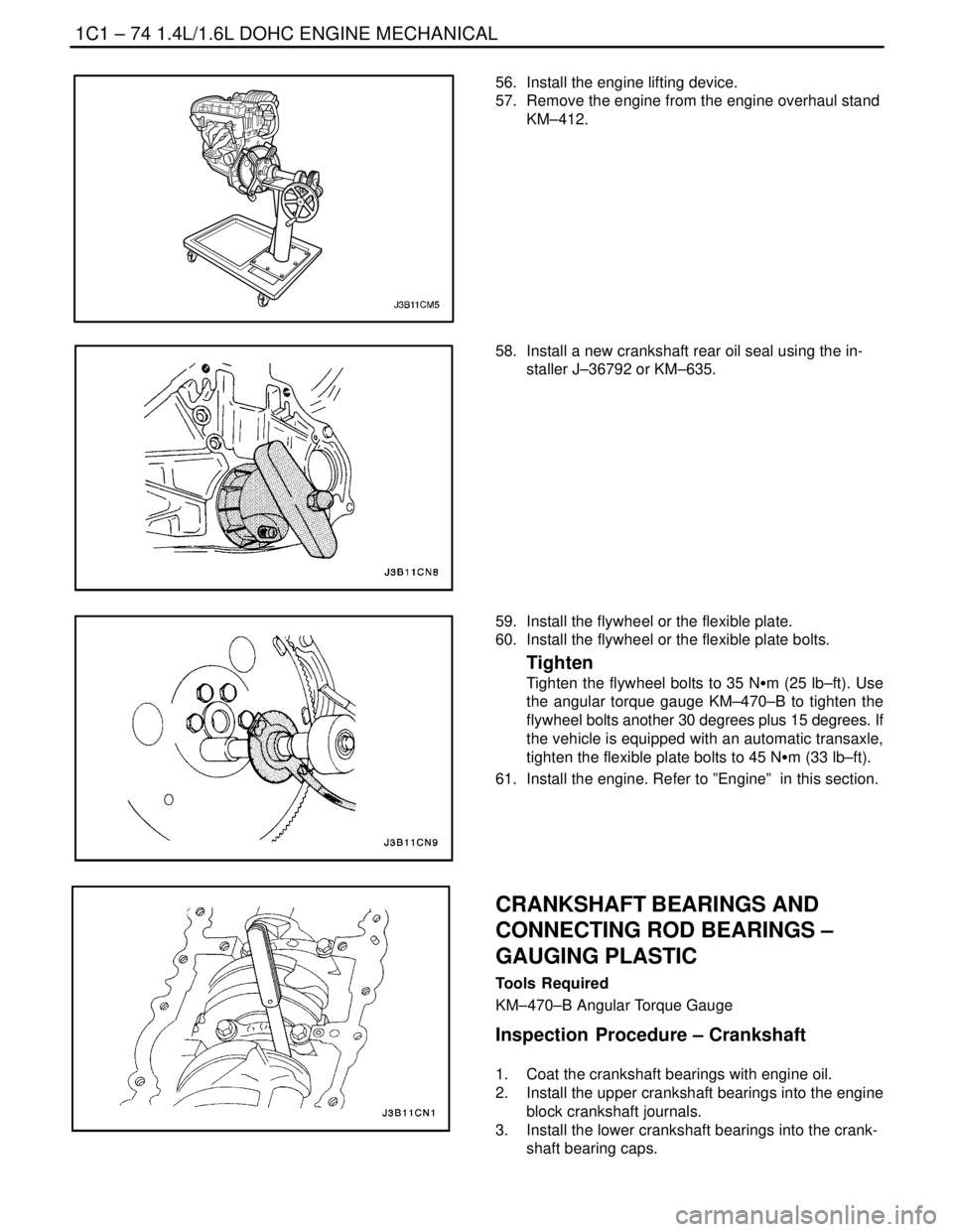

44. Disconnect the right engine mount bracket from the

engine mount and the engine by removing the at-

taching bolts and the nuts.

45. Remove the right engine mount from the engine

block. Refer to ”Engine Mount” in this section.

46. Separate the engine block from the transaxle.

47. Remove the engine.

Installation Procedure

1. Install the engine into the engine compartment.

2. Align the engine alignment pins to the transaxle.

3. Install the transaxle bell housing bolts.

Tighten

Tighten the transaxle bell housing bolts to 75 NSm (55

lb–ft).

4. Install the right engine mount to the engine block.

Refer to ”Engine Mount” in this section.

Page 94 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 51

DAEWOO V–121 BL4

5. Connect the right engine mount bracket to the en-

gine mount and the engine by installing the attach-

ing bolts and the nuts.

Tighten

Tighten the engine mount bracket attaching bolts and

the nuts to 55 NSm (41 lb–ft).

6. Remove the floor jack used for support of the trans-

axle.

7. Remove the engine lifting device.

8. Install the transaxle torque converter bolts, if auto-

matic transaxle equipped.

Tighten

Tighten the transaxle torque converter bolts to 45

NSm (33 lb–ft).

9. Install the starter motor. Refer to Section 1E, En-

gine Electrical.

10. Connect the vacuum lines at the CCP solenoid.

11. Connect the electrical connector at the CCP sole-

noid and at the knock sensor.

12. Connect the oil pressure switch and the EGR sole-

noid connectors.

13. Install the crankshaft pulley.

14. Install the crankshaft pulley bolt.

Tighten

Tighten the crankshaft pulley bolt to 95 NSm (70 lb–ft)

and retighten 30 degrees plus 15 degrees.

15. Connect the CPS connector.

16. Install the exhaust front pipe.

17. Install the catalytic converter retaining nuts to the

exhaust pipe.

Tighten

Tighten the catalytic converter to exhaust pipe retain-

ing nuts to 35 NSm (26 lb–ft).

Page 117 of 2643

1C1 – 74I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

56. Install the engine lifting device.

57. Remove the engine from the engine overhaul stand

KM–412.

58. Install a new crankshaft rear oil seal using the in-

staller J–36792 or KM–635.

59. Install the flywheel or the flexible plate.

60. Install the flywheel or the flexible plate bolts.

Tighten

Tighten the flywheel bolts to 35 NSm (25 lb–ft). Use

the angular torque gauge KM–470–B to tighten the

flywheel bolts another 30 degrees plus 15 degrees. If

the vehicle is equipped with an automatic transaxle,

tighten the flexible plate bolts to 45 NSm (33 lb–ft).

61. Install the engine. Refer to ”Engine” in this section.

CRANKSHAFT BEARINGS AND

CONNECTING ROD BEARINGS –

GAUGING PLASTIC

Tools Required

KM–470–B Angular Torque Gauge

Inspection Procedure – Crankshaft

1. Coat the crankshaft bearings with engine oil.

2. Install the upper crankshaft bearings into the engine

block crankshaft journals.

3. Install the lower crankshaft bearings into the crank-

shaft bearing caps.

Page 124 of 2643

1C2 – 4I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

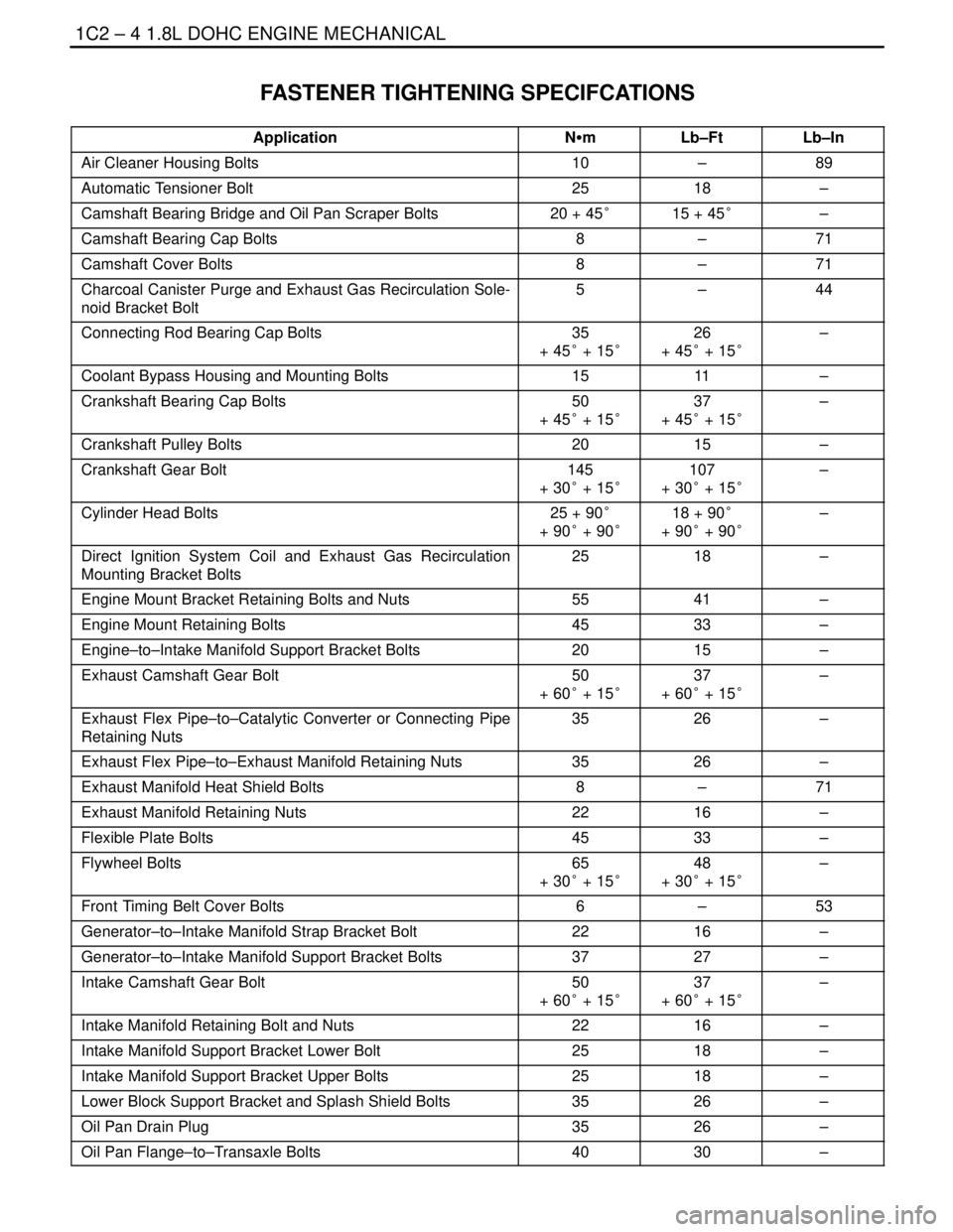

FASTENER TIGHTENING SPECIFCATIONS

ApplicationNSmLb–FtLb–In

Air Cleaner Housing Bolts10–89

Automatic Tensioner Bolt2518–

Camshaft Bearing Bridge and Oil Pan Scraper Bolts20 + 45°15 + 45°–

Camshaft Bearing Cap Bolts8–71

Camshaft Cover Bolts8–71

Charcoal Canister Purge and Exhaust Gas Recirculation Sole-

noid Bracket Bolt5–44

Connecting Rod Bearing Cap Bolts35

+ 45° + 15°26

+ 45° + 15°–

Coolant Bypass Housing and Mounting Bolts1511–

Crankshaft Bearing Cap Bolts50

+ 45° + 15°37

+ 45° + 15°–

Crankshaft Pulley Bolts2015–

Crankshaft Gear Bolt145

+ 30° + 15°107

+ 30° + 15°–

Cylinder Head Bolts25 + 90°

+ 90° + 90°18 + 90°

+ 90° + 90°–

Direct Ignition System Coil and Exhaust Gas Recirculation

Mounting Bracket Bolts2518–

Engine Mount Bracket Retaining Bolts and Nuts5541–

Engine Mount Retaining Bolts4533–

Engine–to–Intake Manifold Support Bracket Bolts2015–

Exhaust Camshaft Gear Bolt50

+ 60° + 15°37

+ 60° + 15°–

Exhaust Flex Pipe–to–Catalytic Converter or Connecting Pipe

Retaining Nuts3526–

Exhaust Flex Pipe–to–Exhaust Manifold Retaining Nuts3526–

Exhaust Manifold Heat Shield Bolts8–71

Exhaust Manifold Retaining Nuts2216–

Flexible Plate Bolts4533–

Flywheel Bolts65

+ 30° + 15°48

+ 30° + 15°–

Front Timing Belt Cover Bolts6–53

Generator–to–Intake Manifold Strap Bracket Bolt2216–

Generator–to–Intake Manifold Support Bracket Bolts3727–

Intake Camshaft Gear Bolt50

+ 60° + 15°37

+ 60° + 15°–

Intake Manifold Retaining Bolt and Nuts2216–

Intake Manifold Support Bracket Lower Bolt2518–

Intake Manifold Support Bracket Upper Bolts2518–

Lower Block Support Bracket and Splash Shield Bolts3526–

Oil Pan Drain Plug3526–

Oil Pan Flange–to–Transaxle Bolts4030–

Page 125 of 2643

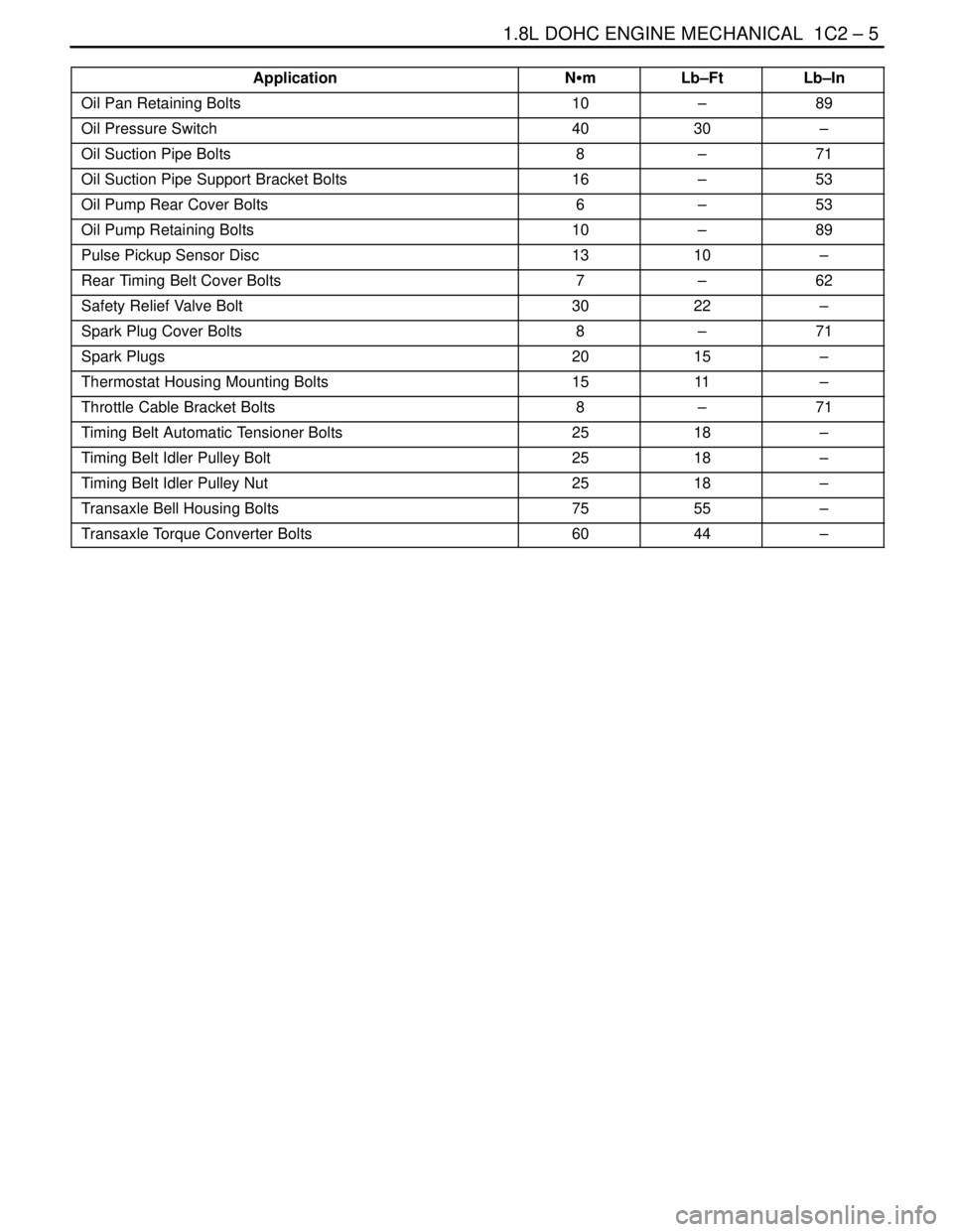

1.8L DOHC ENGINE MECHANICAL 1C2 – 5

DAEWOO V–121 BL4

Application Lb–InLb–Ft NSm

Oil Pan Retaining Bolts10–89

Oil Pressure Switch4030–

Oil Suction Pipe Bolts8–71

Oil Suction Pipe Support Bracket Bolts16–53

Oil Pump Rear Cover Bolts6–53

Oil Pump Retaining Bolts10–89

Pulse Pickup Sensor Disc1310–

Rear Timing Belt Cover Bolts7–62

Safety Relief Valve Bolt3022–

Spark Plug Cover Bolts8–71

Spark Plugs2015–

Thermostat Housing Mounting Bolts1511–

Throttle Cable Bracket Bolts8–71

Timing Belt Automatic Tensioner Bolts2518–

Timing Belt Idler Pulley Bolt2518–

Timing Belt Idler Pulley Nut2518–

Transaxle Bell Housing Bolts7555–

Transaxle Torque Converter Bolts6044–

Page 131 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 11

DAEWOO V–121 BL4

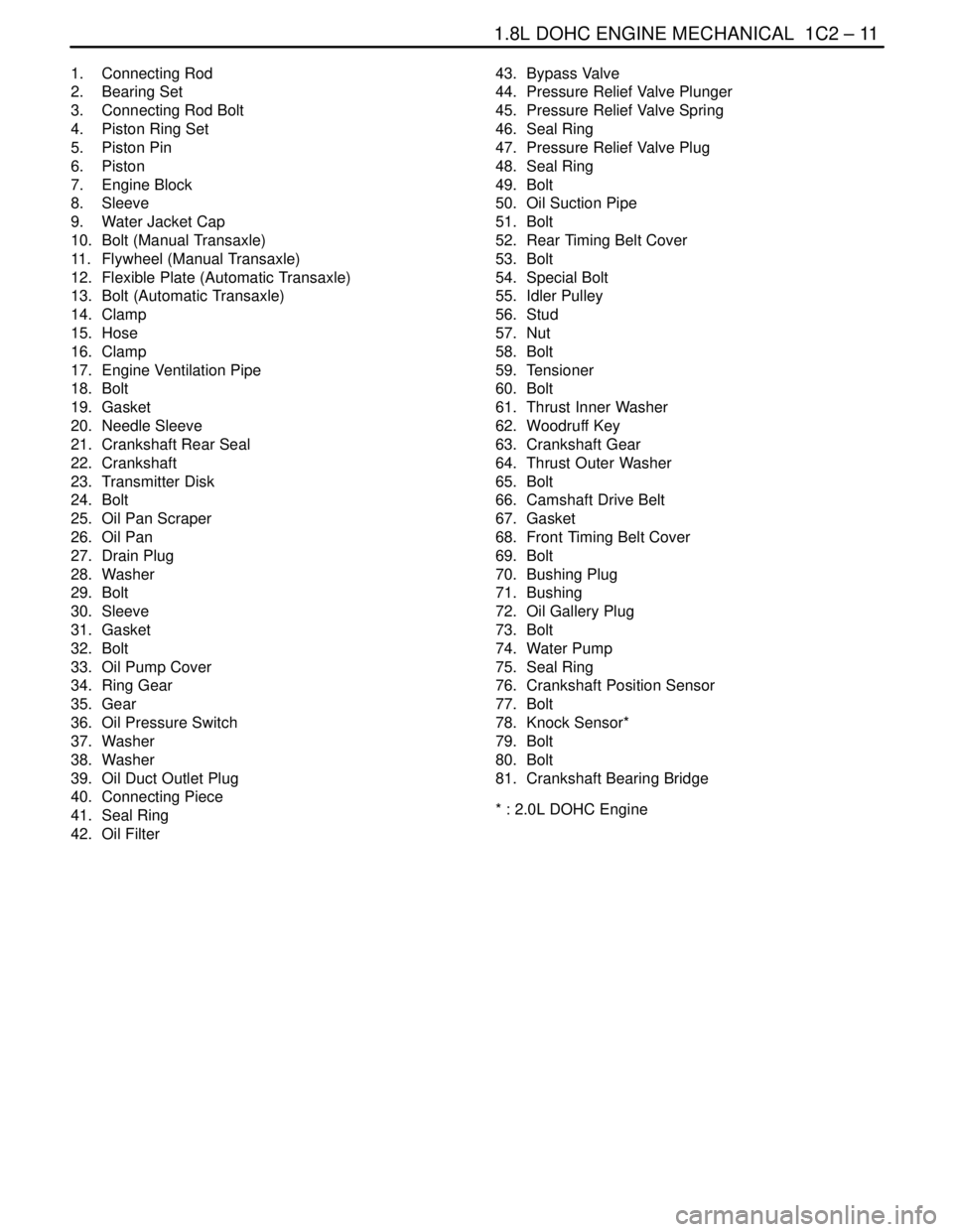

1. Connecting Rod

2. Bearing Set

3. Connecting Rod Bolt

4. Piston Ring Set

5. Piston Pin

6. Piston

7. Engine Block

8. Sleeve

9. Water Jacket Cap

10. Bolt (Manual Transaxle)

11. Flywheel (Manual Transaxle)

12. Flexible Plate (Automatic Transaxle)

13. Bolt (Automatic Transaxle)

14. Clamp

15. Hose

16. Clamp

17. Engine Ventilation Pipe

18. Bolt

19. Gasket

20. Needle Sleeve

21. Crankshaft Rear Seal

22. Crankshaft

23. Transmitter Disk

24. Bolt

25. Oil Pan Scraper

26. Oil Pan

27. Drain Plug

28. Washer

29. Bolt

30. Sleeve

31. Gasket

32. Bolt

33. Oil Pump Cover

34. Ring Gear

35. Gear

36. Oil Pressure Switch

37. Washer

38. Washer

39. Oil Duct Outlet Plug

40. Connecting Piece

41. Seal Ring

42. Oil Filter43. Bypass Valve

44. Pressure Relief Valve Plunger

45. Pressure Relief Valve Spring

46. Seal Ring

47. Pressure Relief Valve Plug

48. Seal Ring

49. Bolt

50. Oil Suction Pipe

51. Bolt

52. Rear Timing Belt Cover

53. Bolt

54. Special Bolt

55. Idler Pulley

56. Stud

57. Nut

58. Bolt

59. Tensioner

60. Bolt

61. Thrust Inner Washer

62. Woodruff Key

63. Crankshaft Gear

64. Thrust Outer Washer

65. Bolt

66. Camshaft Drive Belt

67. Gasket

68. Front Timing Belt Cover

69. Bolt

70. Bushing Plug

71. Bushing

72. Oil Gallery Plug

73. Bolt

74. Water Pump

75. Seal Ring

76. Crankshaft Position Sensor

77. Bolt

78. Knock Sensor*

79. Bolt

80. Bolt

81. Crankshaft Bearing Bridge

* : 2.0L DOHC Engine