DAEWOO LACETTI 2004 Service Repair Manual

Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2201 of 2643

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR) 8B – 97

DAEWOO V–121 BL4

AIRBAG MODULE DEPLOYMENT

(OUTSIDE OF VEHICLE)

If the vehicle is within the warranty period, contact the

Daewoo regional service manager for approval or

special instructions before deploying the airbag mod-

ules.

Deploy airbag modules in following situations :

S If the vehicle is to be strapped. Refer to”Airbag

Module Deployment(Inside of Vehicle” in this sec-

tion.

S If an airbag module is damaged during transit, stor-

age or service.

CAUTION : To avoid injury while deploying an air-

bag or a pretensioner outside the vehicle, ob-

serve the following precaution :

S Deploy the airbags only in an evacuated area. Ser-

vice personnel who must be present during the de-

ployment should be at least 10 meters(33 feet) in

front of the vehicle.

S Do not connect the voltage source until after having

completed all other preparations for the deployment

of airbags.

S Allow a deployed airbag module or pretensioner

cool for 30 minutes before handling.

S Wear gloves and eye protection during the disposal

procedure.

S If the deployment fails, disconnect the voltage

source and wait 5 minutes before approaching the

vehicle.

1. Position the airbag module face up, on flat ground

outdoors, at least 10 meters(33 feet) from the any

obstacles or people.

2. Place a vehicle battery at least 10 meters(33 feet)

away from the airbag module.

3. Deploy the airbag module.

4. Please follow detailed Airbag Module deployment

procedure as below.

5. Cut the yellow wires to the airbag module/preten-

sioner.

6. Strip 13mm(0.5 inch) of the insulation from the end

of the wires leading to the airbag module/preten-

sioner.

7. Use two additional wires, each at least 10 me-

ters(33 feet) long, to reach from the deployment

battery to the airbag module/pretensioner.

8. Strip 13mm(0.5 inch) of the insulation from the

ends of these two additional wires.

9. Twist the two wires together at one end.

10. Place the twisted ends of the two wires near the

deployment battery. Do not connect the wires to the

battery at this time.

Page 2202 of 2643

8B – 98ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

11. Using the free ends of the 10 meters(33 feet) wires

leading to the airbag module/pretensioner, make

two splices, one at each wires from the airbag mod-

ule/pretensioner.

12. Wrap the splices with insulating tape.

13. Now that the free ends of the 10 meters(33 feet)

wires are spliced to the airbag module/pretensioner

wires, and the ends that are twisted together are

near the deployment battery, clear the area.

14. Untwist the wires that near the deployment battery.

15. Touch one wire to the positive battery terminal and

touch the other wire to the negative battery termi-

nal. The airbag will deploy.

16. Using proper precautions, dispose of the deployed

airbags/pretensioners. Refer to ”Deployed Airbag

Module Disposal Procedure” in this section.

DEPLOYED AIRBAG MODULE

DISPOSAL PROCEDURE

CAUTION : After deployment, a powdery residue

may be on the surface of the airbag. The powder

primarily consists of cornstarch(used to lubri-

cate the bag as it inflates) and by–products of the

chemical reaction. The sodium hydroxide then

quickly reacts with atmospheric moisture and is

converted to sodium carbonate and sodium bi-

carbonate(also known as baking soda). There-

fore, it is unlikely that sodium hydroxide will be

presents after deployment.

CAUTION : Be sure to wear gloves and eye

protection during the disposal procedure.

CAUTION : After deployment, the metal surfaces

of the airbag module will be hot. In order to avoid

the risk of an injury or a fire do not place the

deployed airbag module near any flammable ob-

jects, and allow the airbag module to cool 30 min-

utes before handling.

Deploy an airbag or pretensioner before disposing of

it.

This includes those in a whole vehicle being

scrapped. If the vehicle is still within the warranty peri-

od contact the Daewoo regional service manager for

approval or special instructions before deploying an

airbag module or a pretensioner. Deployed airbag

module or pretensioner should be disposed of in the

same manner as other scrap parts, with the addition

of the following steps :

1. Place the deployed airbag or pretensioner in a

sturdy plastic bag.

2. Seal the plastic bag securely.

3. Wash your hands and rinse them with water after

handling a deployed airbag.

Page 2203 of 2643

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR) 8B – 99

DAEWOO V–121 BL4

SIR WIRING REPAIR

Connector Repair

CAUTION : Before attempting any repairs, the SIR

must be disabled. Refer to ”Disabling the SIR”in

this section for instructions on how to disable the

SIR.

The terminals in the SIR are made of special metal to

provide necessary contact integrity for the sensitive,

low energy circuits. These terminals are available

only in connector repair assembly packs. Do not sub-

stitute any other terminals for those in the assembly

packs.

Wire Repair

CAUTION : Before attempting any repairs, the SIR

must be disabled. Refer to ”Disabling the SIR”in

this section for instructions on how to disable the

SIR.

Do not repair any wires of supplemental inflatable re-

straints(SIR). Replace any damaged wires with new

one.

Page 2204 of 2643

8B – 100ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

SUPPLEMENTAL INFLATABLE

RESTRAINTS(SIR)

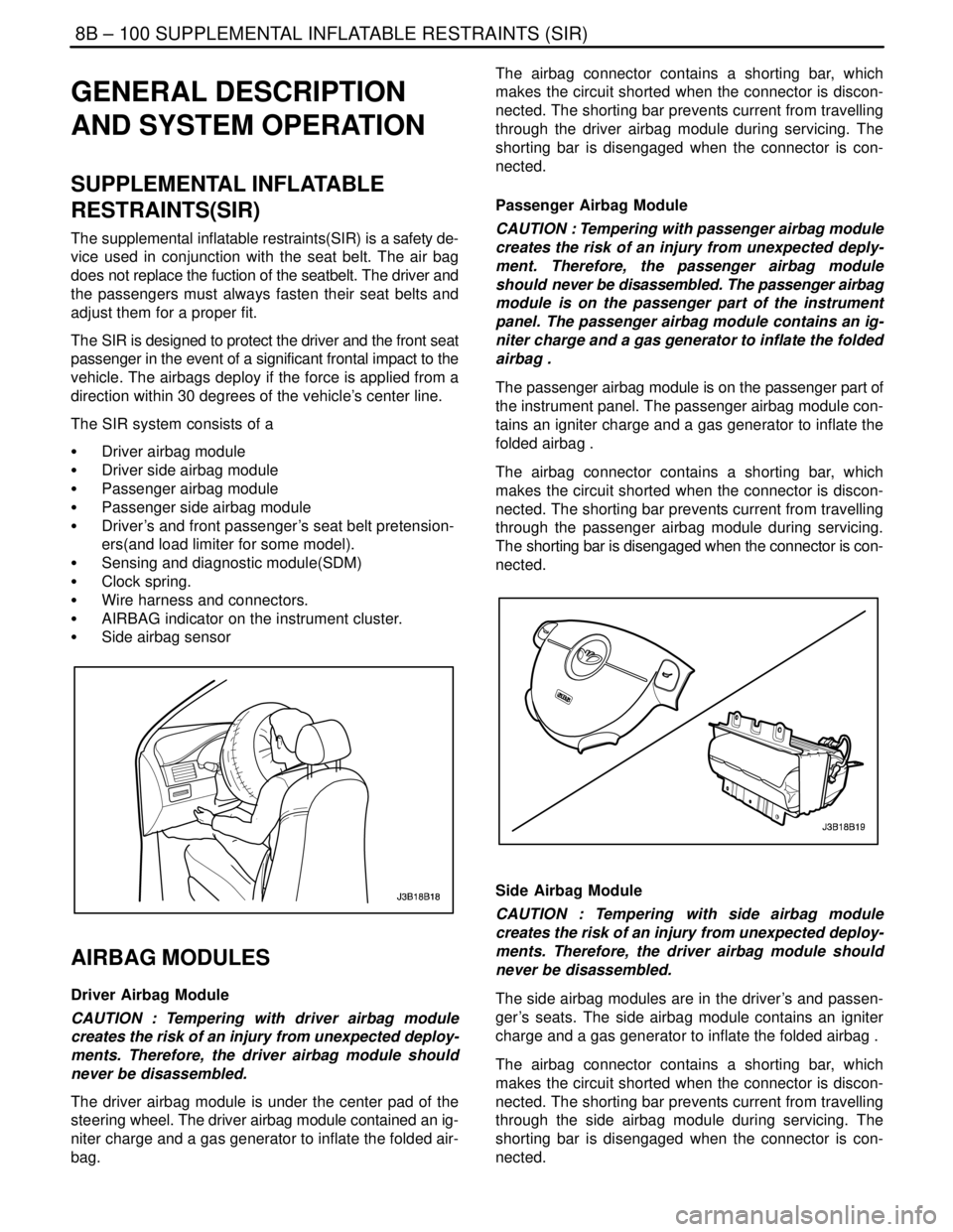

The supplemental inflatable restraints(SIR) is a safety de-

vice used in conjunction with the seat belt. The air bag

does not replace the fuction of the seatbelt. The driver and

the passengers must always fasten their seat belts and

adjust them for a proper fit.

The SIR is designed to protect the driver and the front seat

passenger in the event of a significant frontal impact to the

vehicle. The airbags deploy if the force is applied from a

direction within 30 degrees of the vehicle’s center line.

The SIR system consists of a

S Driver airbag module

S Driver side airbag module

S Passenger airbag module

S Passenger side airbag module

S Driver’s and front passenger’s seat belt pretension-

ers(and load limiter for some model).

S Sensing and diagnostic module(SDM)

S Clock spring.

S Wire harness and connectors.

S AIRBAG indicator on the instrument cluster.

S Side airbag sensor

AIRBAG MODULES

Driver Airbag Module

CAUTION : Tempering with driver airbag module

creates the risk of an injury from unexpected deploy-

ments. Therefore, the driver airbag module should

never be disassembled.

The driver airbag module is under the center pad of the

steering wheel. The driver airbag module contained an ig-

niter charge and a gas generator to inflate the folded air-

bag.The airbag connector contains a shorting bar, which

makes the circuit shorted when the connector is discon-

nected. The shorting bar prevents current from travelling

through the driver airbag module during servicing. The

shorting bar is disengaged when the connector is con-

nected.

Passenger Airbag Module

CAUTION : Tempering with passenger airbag module

creates the risk of an injury from unexpected deply-

ment. Therefore, the passenger airbag module

should never be disassembled. The passenger airbag

module is on the passenger part of the instrument

panel. The passenger airbag module contains an ig-

niter charge and a gas generator to inflate the folded

airbag .

The passenger airbag module is on the passenger part of

the instrument panel. The passenger airbag module con-

tains an igniter charge and a gas generator to inflate the

folded airbag .

The airbag connector contains a shorting bar, which

makes the circuit shorted when the connector is discon-

nected. The shorting bar prevents current from travelling

through the passenger airbag module during servicing.

The shorting bar is disengaged when the connector is con-

nected.

Side Airbag Module

CAUTION : Tempering with side airbag module

creates the risk of an injury from unexpected deploy-

ments. Therefore, the driver airbag module should

never be disassembled.

The side airbag modules are in the driver’s and passen-

ger’s seats. The side airbag module contains an igniter

charge and a gas generator to inflate the folded airbag .

The airbag connector contains a shorting bar, which

makes the circuit shorted when the connector is discon-

nected. The shorting bar prevents current from travelling

through the side airbag module during servicing. The

shorting bar is disengaged when the connector is con-

nected.

Page 2205 of 2643

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR) 8B – 101

DAEWOO V–121 BL4

FRONT SEAT BELT

PRETENSIONERS

CAUTION : Tempering with seat belt pretensioner

creates the risk of an injury from unexpected deploy-

ment. Therefore, the driver airbag module should

never be disassembled.

The seat belt pretensioners(with load limiter for some ve-

hicles) are assembled with each front seat belt retractors

to retract the seat belt webbing when accounted frontal

collision. The seat belt pretensioners are controlled by

sensing and diagnostic module(SDM). The seat belt pre-

tensioner contains an igniter charge and a gas generator

to pull the seat belt webbing. The seat belt pretensioner

must be replaced after an accident that causes its activa-

tion.

The seat belt pretensioner also contains a shorting bar to

prevent current from travelling through the seat belt pre-

tensioner during servicing. The shorting bar is disengaged

when the connector is connected.

SENSING AND DIAGNOSTIC

MODULE (SDM)

CAUTION : During the service procedures, be careful

when handling the SDM. Never shake or jar the SDM.

Never apply power to SIR when the SDM is not rigidly

attached to the vehicle. All SDM mounting bolts and

grounding nuts must be fully tightened. Failure to fol-

low these precautions could cause deployment and

result in personal injury.

The SDM is located on the floor beneath the floor console

assembly. The SDM performs the following functions :

S Monitors the supplemental inflatable restraints(SIR)

electrical components and sets a diagnostic trouble

code(DTC) when malfunction is detected.

S Records any faults that are discovered.

S Displays SIR diagnostic trouble codes and system

status information when connected to a scan tool.

S Illuminates the airbag indicator to alert the driver to

any fault.S Provides a reserve power source to deploy the air-

bags and pretensioners if an accident has disabled

the normal power source.

S Monitors vehicle velocity changes to detect frontal

impacts, which are severe enough to warrant de-

ployment.

S Causes current to flow through the airbag modules

and pretensioner to cause deployment if a frontal

impact of sufficient force is detected.

The SDM contains no user–serviceable parts.

AIRBAG WARNING LAMP

The instrument cluster contains an airbag warning indica-

tor and sensing and diagnostic module(SDM). The SDM

performs a turn–on test when the ignition is turned ON.

The SDM flashes the airbag indicator seven times by sup-

plying an intermittent ground to the indicator lamp circuit.

After flashing seven times, the airbag indicator will turn off

if no more malfunctions have been detected.

If the SDM has detected malfunctions in the internal and

external circuits, which could potentially affect the opera-

tion of the supplemental inflatable restraints(SIR), the air-

bag indicator stays on. Some malfunctions could result in

non–deployment when necessary or deployment under

conditions which would not normally result in deployment.

When the SDM is not properly attached to its connector,

the airbag circuit is shorted to ground because there is a

shorting bar in the SDM electrical connector. The shorting

bar is disengaged when proper connection is made, but if

a poor connection exists the SDM connector supplied a

ground to the airbag indicator independently of the SDM,

and the airbag indicator turns on.

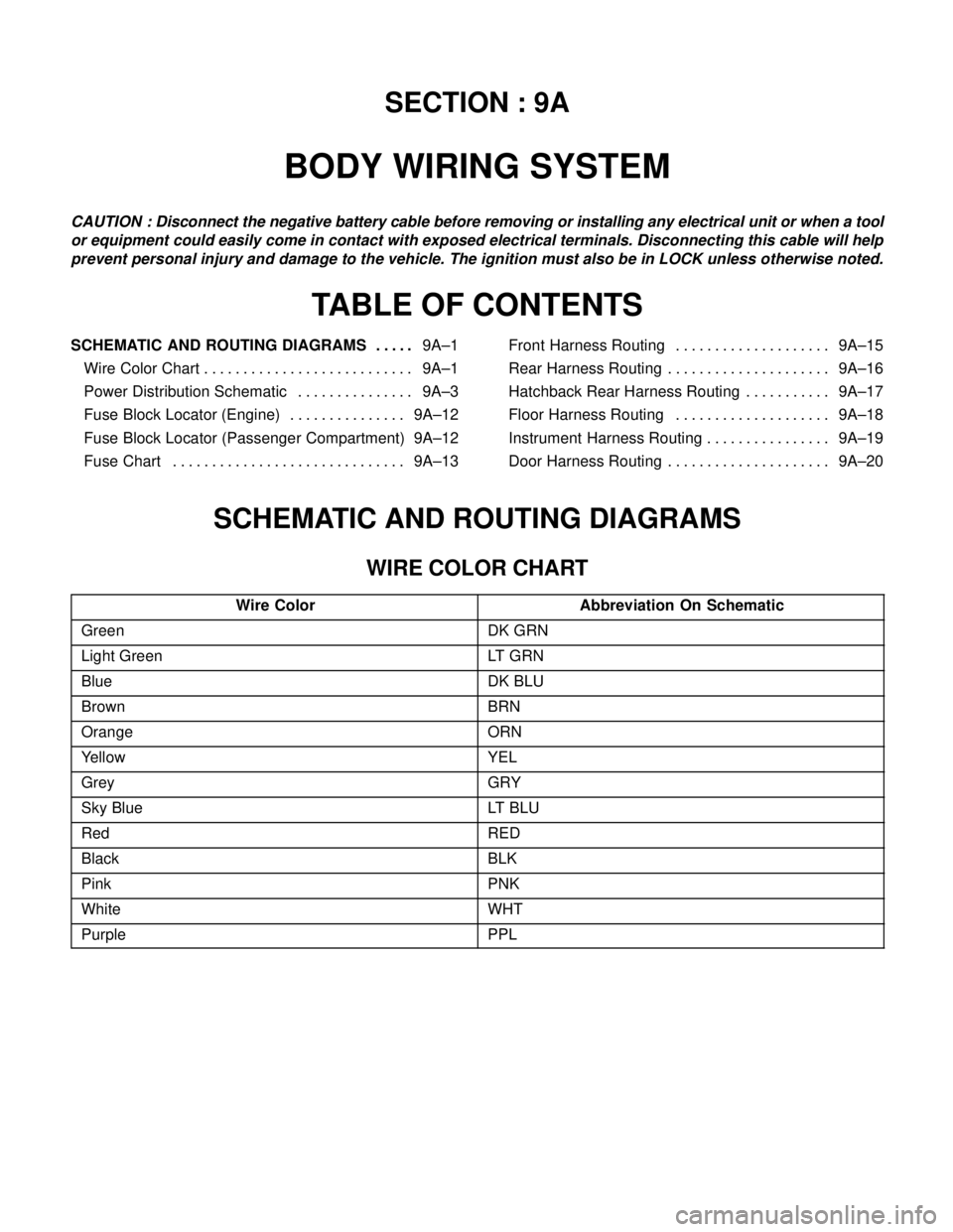

CLOCK SPRING

CAUTION : Disassembling the clock spring can cause

injury or cause the clock spring to malfunction.

CAUTION : Over–rotating the clock spring (over 3 and

one quarter turns to one direction) without the steer-

ing wheel in position could damage the clock spring

and result in an inoperative driver airbag.

There is a coil assembly in the steering which is referred

to as a clock spring because of its internal resemblance to

the type of spring used in a mechanical clock. The coil

Page 2206 of 2643

8B – 102ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

spring should never be disassembled, and there is no

timekeeping function. The clock spring contains two or

three current–carrying coils. One of the current–carrying

coils maintains continuous contact within the driver de-

ployment loop while the steering wheel is rotated. The

clock spring also contains coils that maintain continuous

contact for horn and remote audio control switch circuit.

Turning the steering wheel in one direction tightens the

coil, and turning the steering wheel in the opposite direc-

tion loosens the coil. Do not turn the clock spring when the

steering wheel is not attached. Refer to ”Clock Spring” in

this section for proper installation of the clock spring.

The clock spring also includes the wiring and the connec-

tors for the horn circuit and the driver airbag circuit. A yel-

low two–way connector on the lower steering column is at-

tached to the clock spring wiring. The yellow connector to

the airbag contains a shorting bar which connects the driv-

er high circuit to driver low circuit when the connector is

disconnected.

The shorting bar prevents current from travelling through

the driver airbag module during servicing. The shorting bar

is disengaged when the clock spring connector is con-

nected.WIRING HARNESS CONNECTORS

If the sensing and diagnostic module (SDM) electrical con-

nector is not attached properly, a built in shorting bar will

connect the wire from airbag warning lamp with the SDM

ground wire. This turns on the airbag indicator . To prevent

deployment during servicing, additional shorting bars are

located in following locations :

S The clock spring electrical connector at the lower

steering column.

S The passenger airbag module.

S The driver airbag module.

S The seat belt pretensioners.

The shorting bar is only a backup safety device. Always

disable the supplemental inflatable restraints(SIR) before

beginning any service procedure.

Page 2207 of 2643

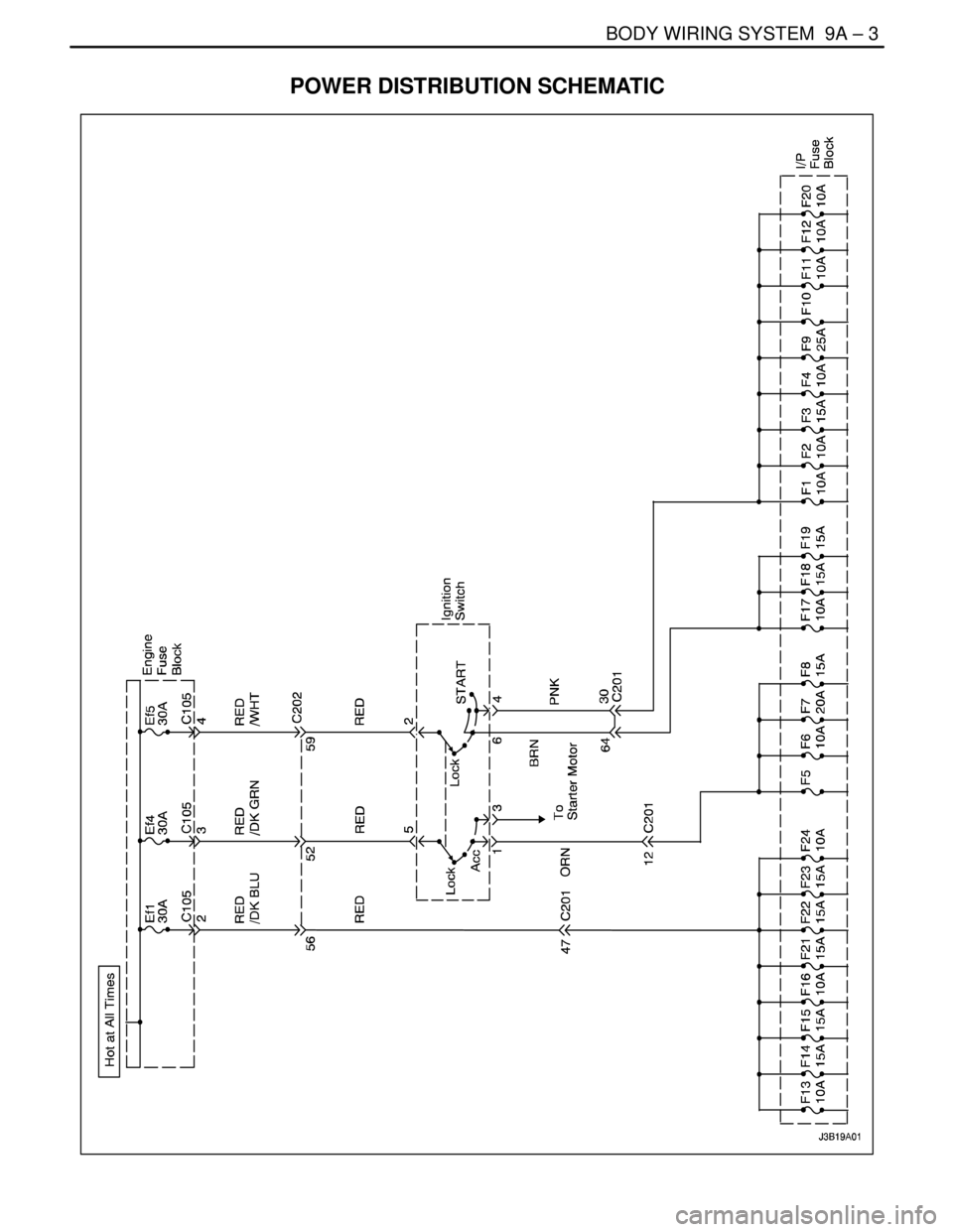

SECTION : 9A

BODY WIRING SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SCHEMATIC AND ROUTING DIAGRAMS9A–1 . . . . .

Wire Color Chart 9A–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution Schematic 9A–3. . . . . . . . . . . . . . .

Fuse Block Locator (Engine) 9A–12. . . . . . . . . . . . . . .

Fuse Block Locator (Passenger Compartment) 9A–12

Fuse Chart 9A–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Front Harness Routing 9A–15. . . . . . . . . . . . . . . . . . . .

Rear Harness Routing 9A–16. . . . . . . . . . . . . . . . . . . . .

Hatchback Rear Harness Routing 9A–17. . . . . . . . . . .

Floor Harness Routing 9A–18. . . . . . . . . . . . . . . . . . . .

Instrument Harness Routing 9A–19. . . . . . . . . . . . . . . .

Door Harness Routing 9A–20. . . . . . . . . . . . . . . . . . . . .

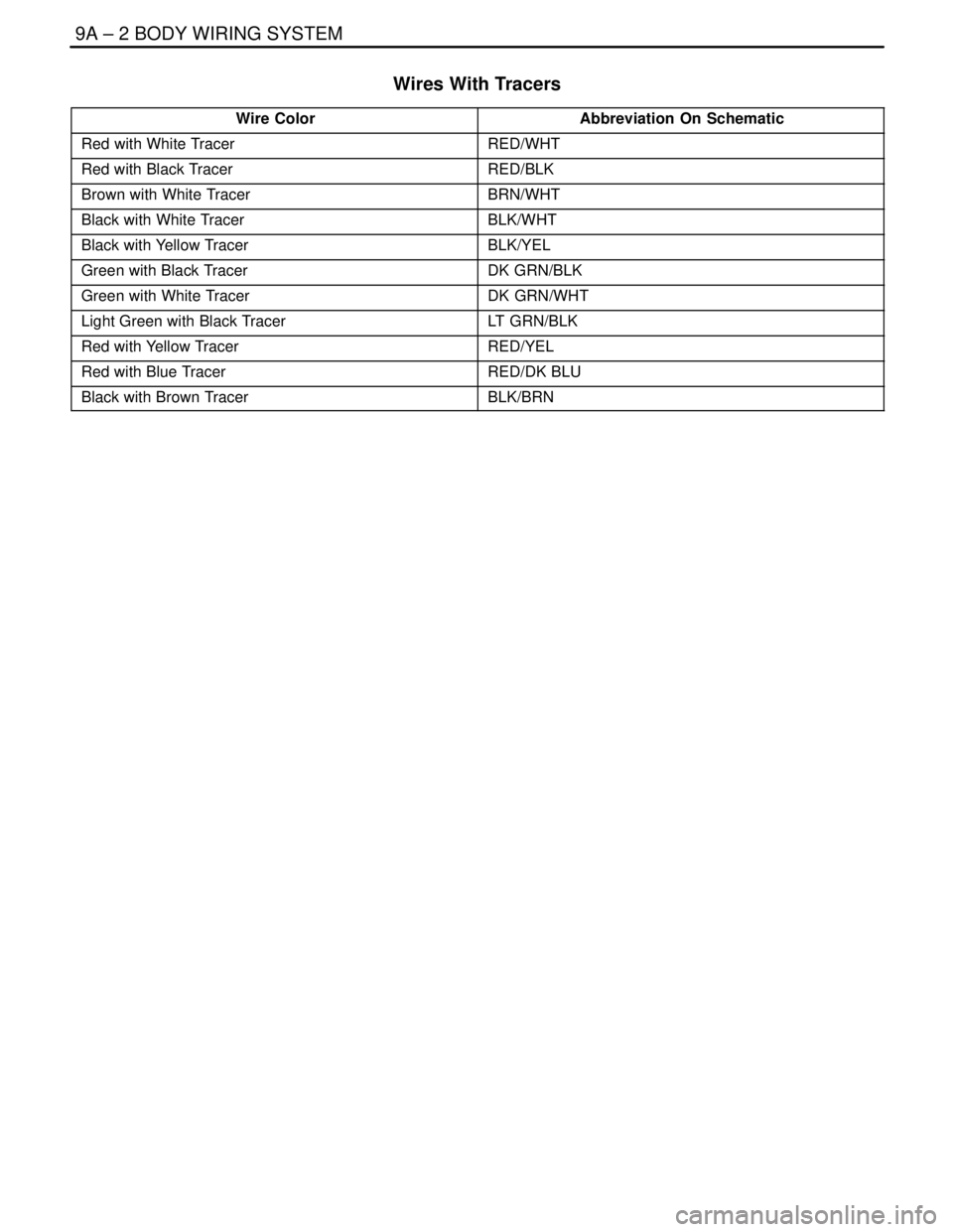

SCHEMATIC AND ROUTING DIAGRAMS

WIRE COLOR CHART

Wire ColorAbbreviation On Schematic

GreenDK GRN

Light GreenLT GRN

BlueDK BLU

BrownBRN

OrangeORN

YellowYEL

GreyGRY

Sky BlueLT BLU

RedRED

BlackBLK

PinkPNK

WhiteWHT

PurplePPL

Page 2208 of 2643

9A – 2IBODY WIRING SYSTEM

DAEWOO V–121 BL4

Wires With Tracers

Wire ColorAbbreviation On Schematic

Red with White TracerRED/WHT

Red with Black TracerRED/BLK

Brown with White TracerBRN/WHT

Black with White TracerBLK/WHT

Black with Yellow TracerBLK/YEL

Green with Black TracerDK GRN/BLK

Green with White TracerDK GRN/WHT

Light Green with Black TracerLT GRN/BLK

Red with Yellow TracerRED/YEL

Red with Blue TracerRED/DK BLU

Black with Brown TracerBLK/BRN

Page 2209 of 2643

BODY WIRING SYSTEM 9A – 3

DAEWOO V–121 BL4

POWER DISTRIBUTION SCHEMATIC

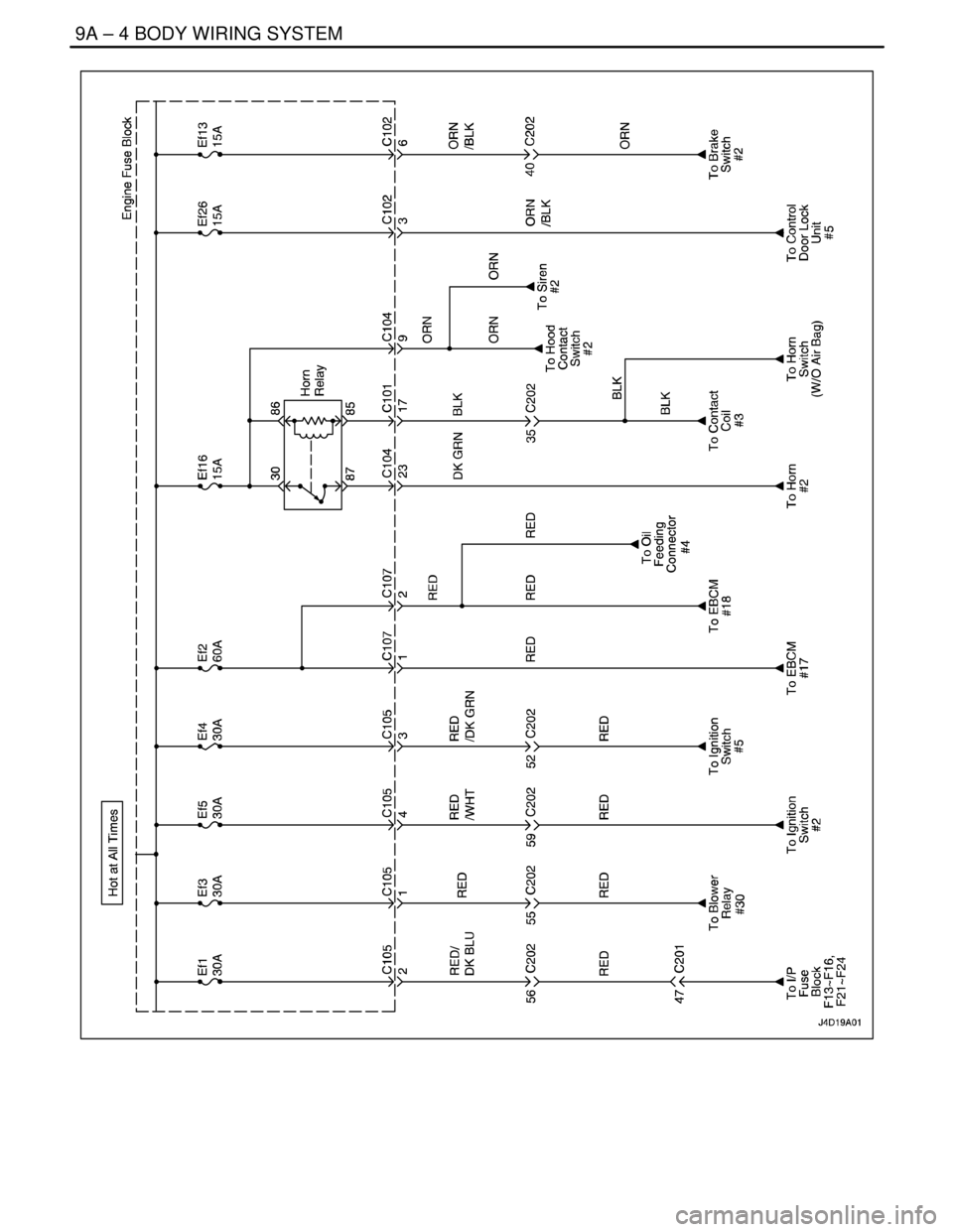

Page 2210 of 2643

9A – 4IBODY WIRING SYSTEM

DAEWOO V–121 BL4