Lamp DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 814 of 2643

1F – 568IENGINE CONTROLS

DAEWOO V–121 BL4

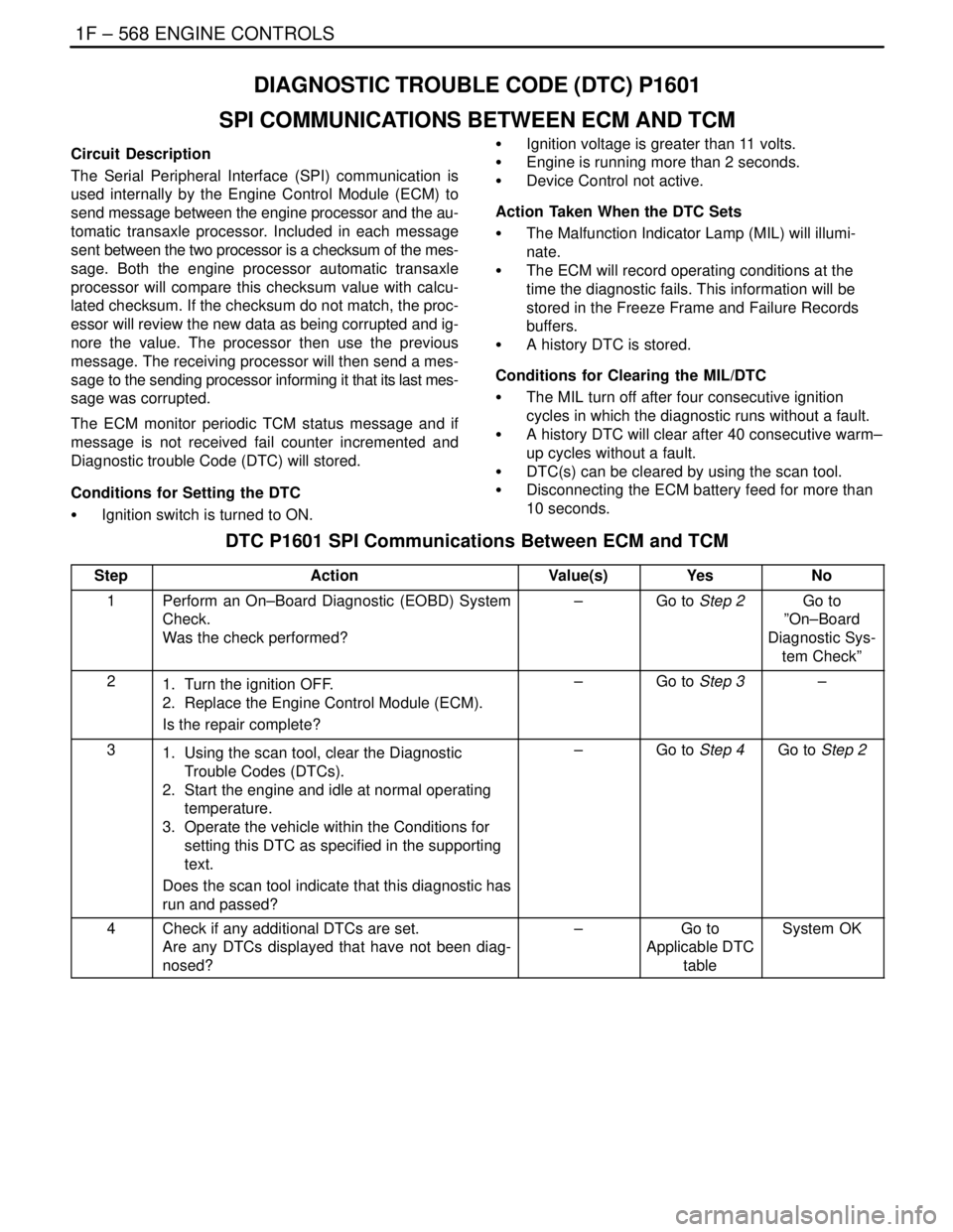

DIAGNOSTIC TROUBLE CODE (DTC) P1601

SPI COMMUNICATIONS BETWEEN ECM AND TCM

Circuit Description

The Serial Peripheral Interface (SPI) communication is

used internally by the Engine Control Module (ECM) to

send message between the engine processor and the au-

tomatic transaxle processor. Included in each message

sent between the two processor is a checksum of the mes-

sage. Both the engine processor automatic transaxle

processor will compare this checksum value with calcu-

lated checksum. If the checksum do not match, the proc-

essor will review the new data as being corrupted and ig-

nore the value. The processor then use the previous

message. The receiving processor will then send a mes-

sage to the sending processor informing it that its last mes-

sage was corrupted.

The ECM monitor periodic TCM status message and if

message is not received fail counter incremented and

Diagnostic trouble Code (DTC) will stored.

Conditions for Setting the DTC

S Ignition switch is turned to ON.S Ignition voltage is greater than 11 volts.

S Engine is running more than 2 seconds.

S Device Control not active.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P1601 SPI Communications Between ECM and TCM

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3–

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 815 of 2643

ENGINE CONTROLS 1F – 569

DAEWOO V–121 BL4

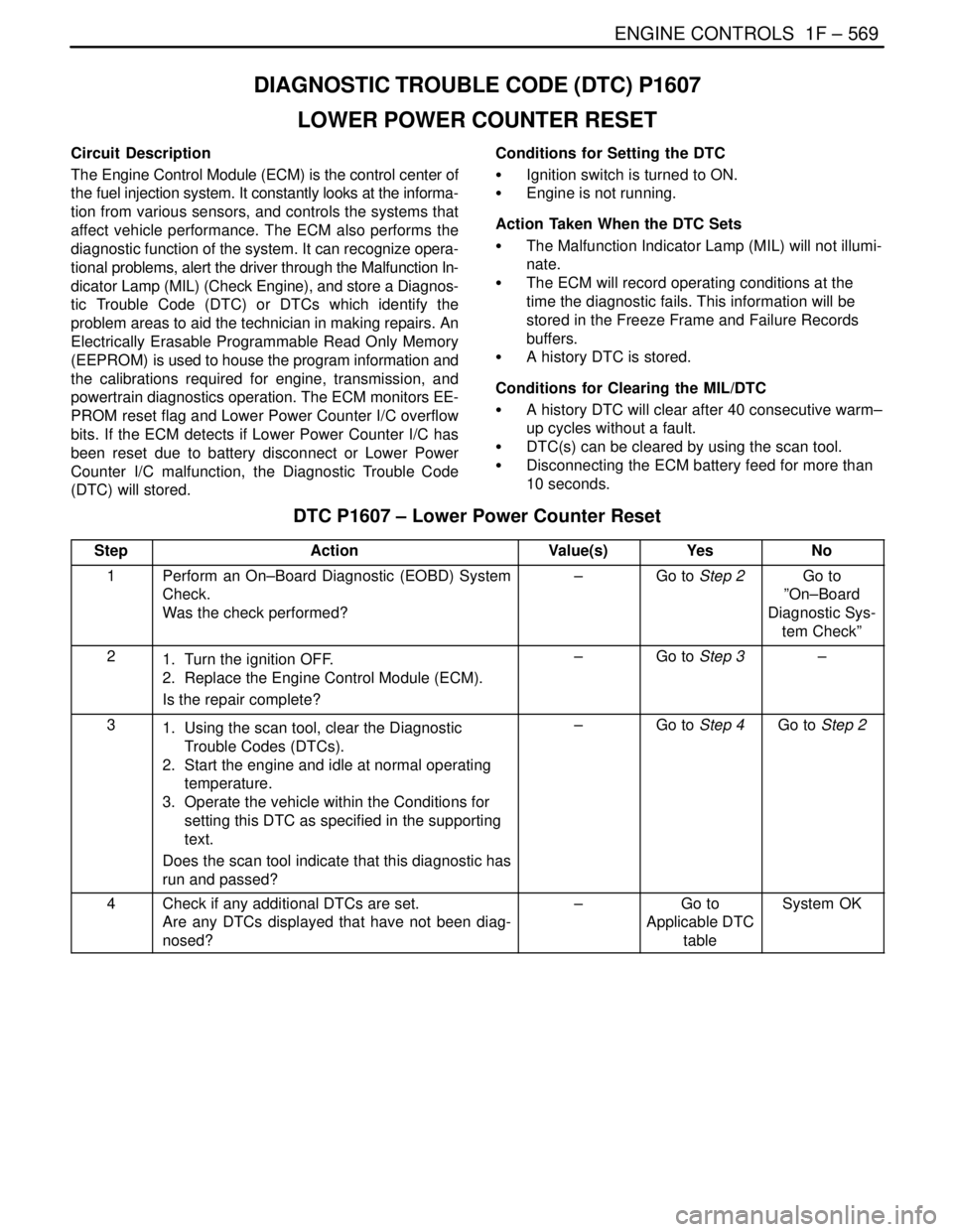

DIAGNOSTIC TROUBLE CODE (DTC) P1607

LOWER POWER COUNTER RESET

Circuit Description

The Engine Control Module (ECM) is the control center of

the fuel injection system. It constantly looks at the informa-

tion from various sensors, and controls the systems that

affect vehicle performance. The ECM also performs the

diagnostic function of the system. It can recognize opera-

tional problems, alert the driver through the Malfunction In-

dicator Lamp (MIL) (Check Engine), and store a Diagnos-

tic Trouble Code (DTC) or DTCs which identify the

problem areas to aid the technician in making repairs. An

Electrically Erasable Programmable Read Only Memory

(EEPROM) is used to house the program information and

the calibrations required for engine, transmission, and

powertrain diagnostics operation. The ECM monitors EE-

PROM reset flag and Lower Power Counter I/C overflow

bits. If the ECM detects if Lower Power Counter I/C has

been reset due to battery disconnect or Lower Power

Counter I/C malfunction, the Diagnostic Trouble Code

(DTC) will stored.Conditions for Setting the DTC

S Ignition switch is turned to ON.

S Engine is not running.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P1607 – Lower Power Counter Reset

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3–

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 816 of 2643

1F – 570IENGINE CONTROLS

DAEWOO V–121 BL4

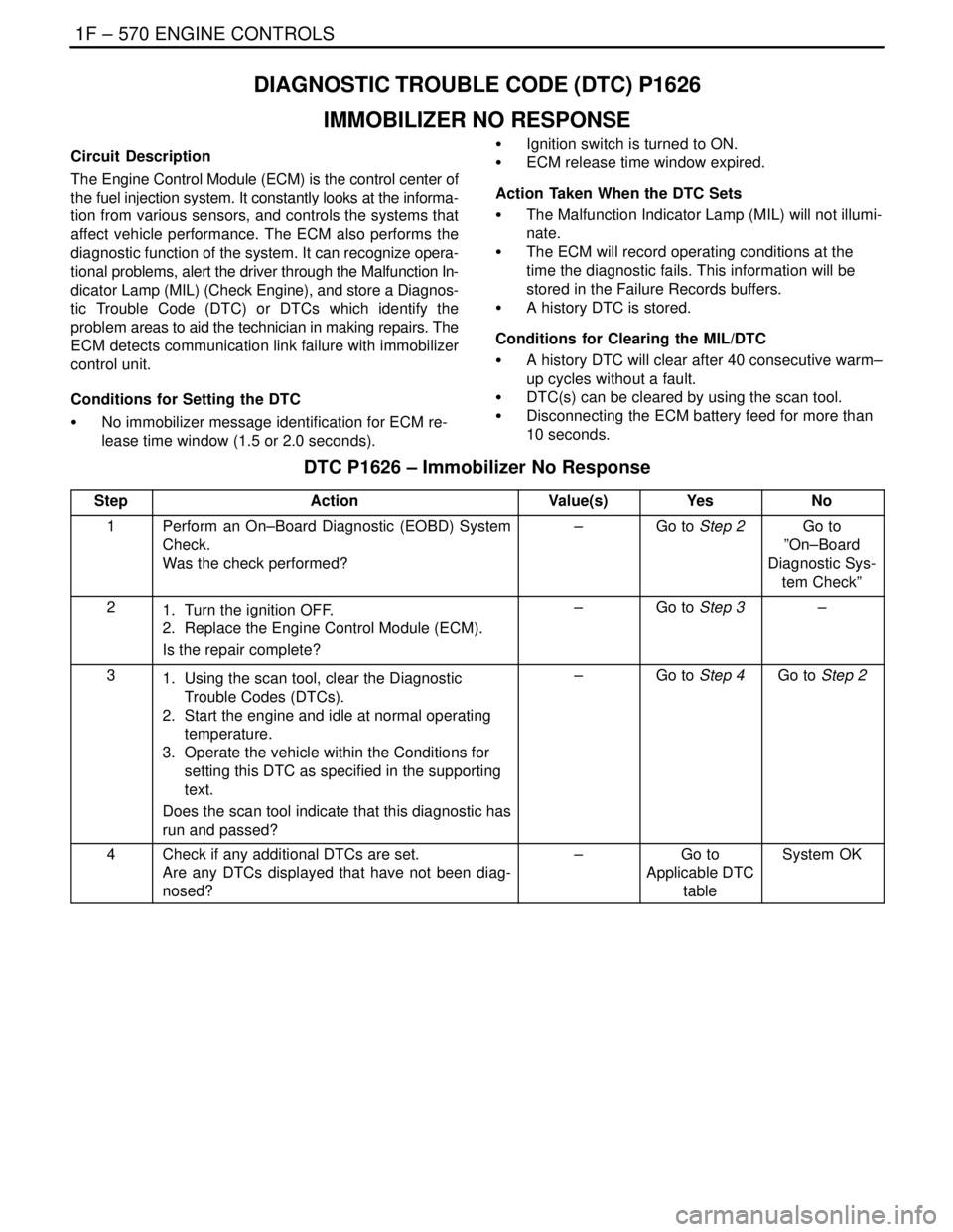

DIAGNOSTIC TROUBLE CODE (DTC) P1626

IMMOBILIZER NO RESPONSE

Circuit Description

The Engine Control Module (ECM) is the control center of

the fuel injection system. It constantly looks at the informa-

tion from various sensors, and controls the systems that

affect vehicle performance. The ECM also performs the

diagnostic function of the system. It can recognize opera-

tional problems, alert the driver through the Malfunction In-

dicator Lamp (MIL) (Check Engine), and store a Diagnos-

tic Trouble Code (DTC) or DTCs which identify the

problem areas to aid the technician in making repairs. The

ECM detects communication link failure with immobilizer

control unit.

Conditions for Setting the DTC

S No immobilizer message identification for ECM re-

lease time window (1.5 or 2.0 seconds).S Ignition switch is turned to ON.

S ECM release time window expired.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P1626 – Immobilizer No Response

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3–

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 817 of 2643

ENGINE CONTROLS 1F – 571

DAEWOO V–121 BL4

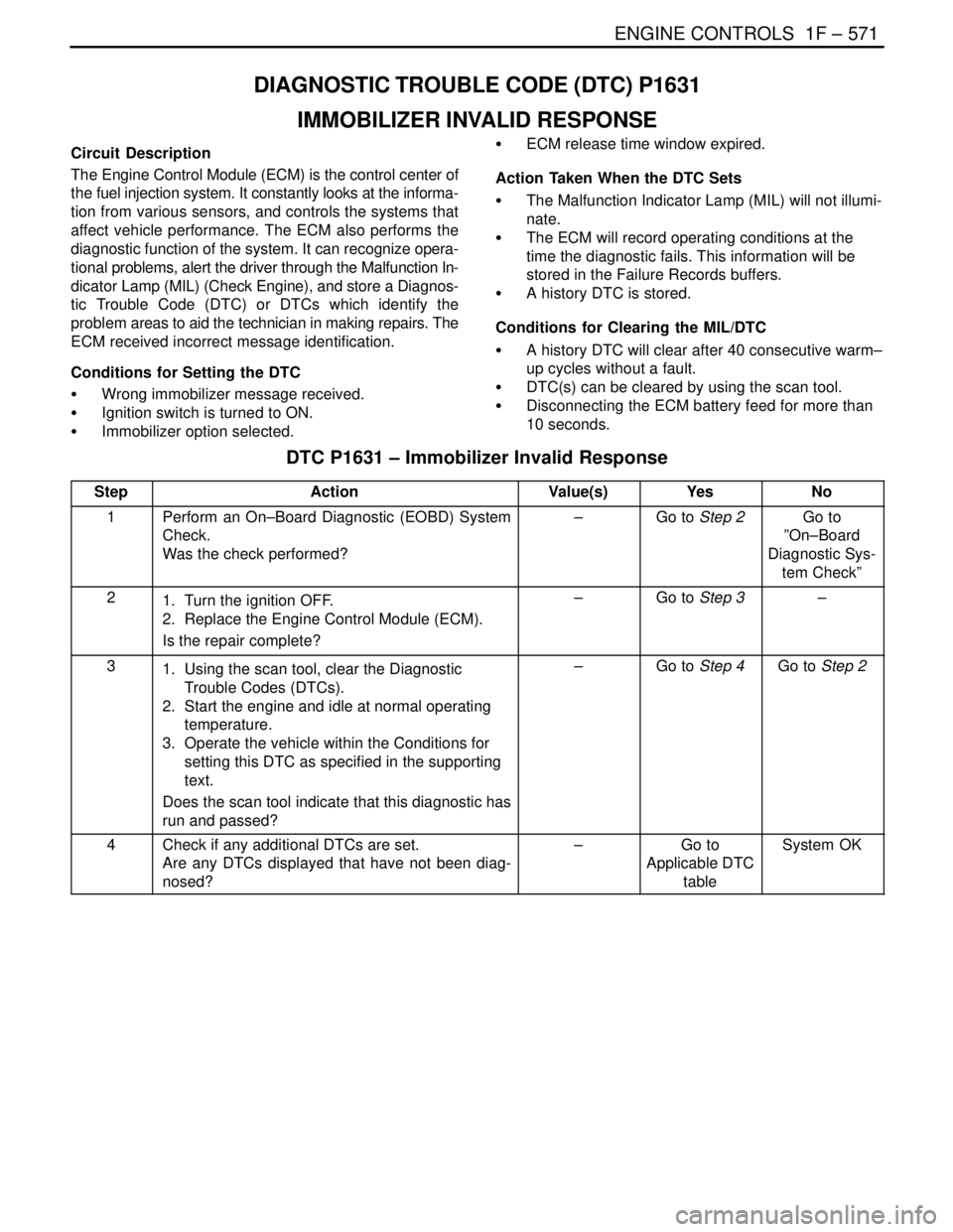

DIAGNOSTIC TROUBLE CODE (DTC) P1631

IMMOBILIZER INVALID RESPONSE

Circuit Description

The Engine Control Module (ECM) is the control center of

the fuel injection system. It constantly looks at the informa-

tion from various sensors, and controls the systems that

affect vehicle performance. The ECM also performs the

diagnostic function of the system. It can recognize opera-

tional problems, alert the driver through the Malfunction In-

dicator Lamp (MIL) (Check Engine), and store a Diagnos-

tic Trouble Code (DTC) or DTCs which identify the

problem areas to aid the technician in making repairs. The

ECM received incorrect message identification.

Conditions for Setting the DTC

S Wrong immobilizer message received.

S Ignition switch is turned to ON.

S Immobilizer option selected.S ECM release time window expired.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P1631 – Immobilizer Invalid Response

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3–

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 818 of 2643

1F – 572IENGINE CONTROLS

DAEWOO V–121 BL4

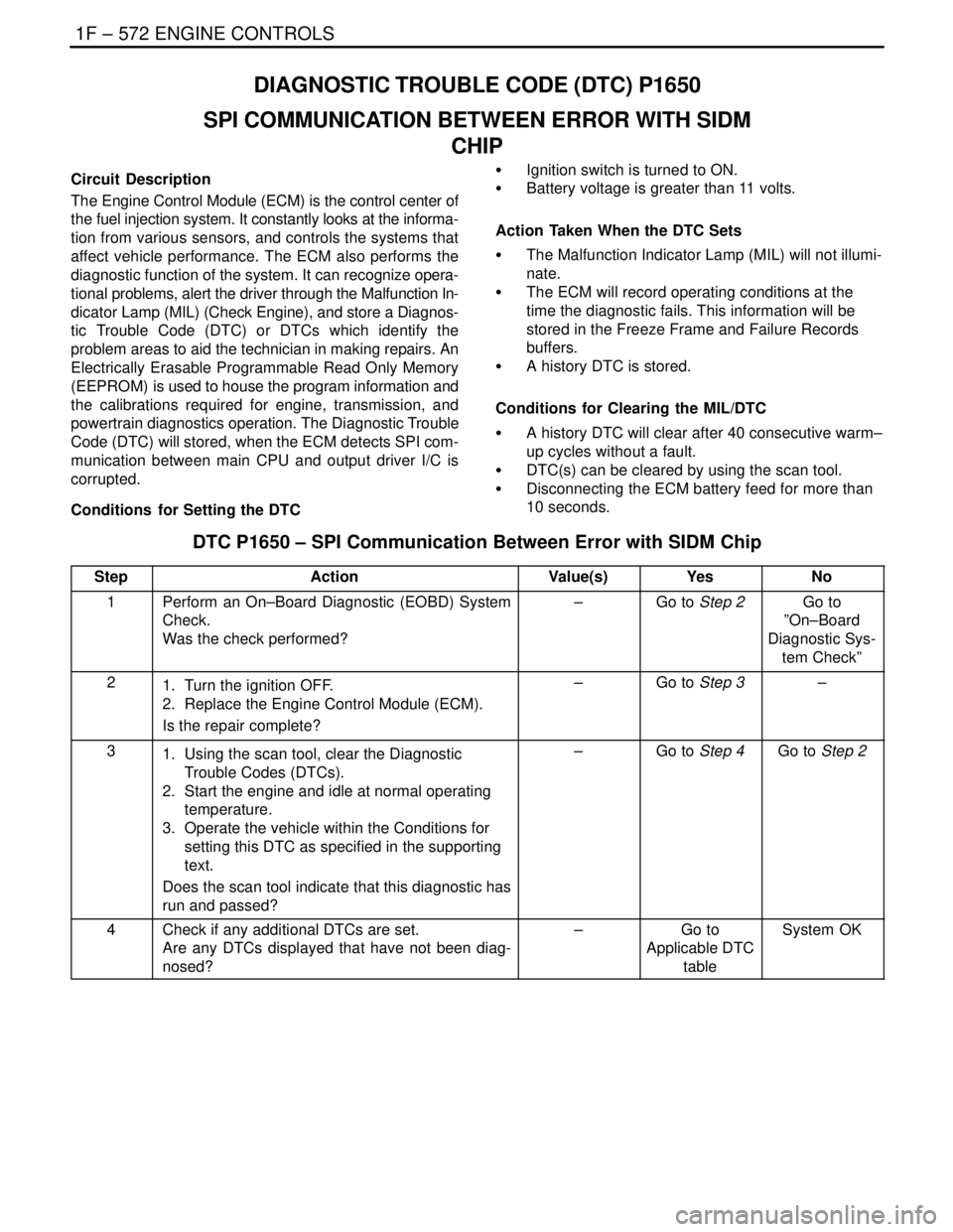

DIAGNOSTIC TROUBLE CODE (DTC) P1650

SPI COMMUNICATION BETWEEN ERROR WITH SIDM

CHIP

Circuit Description

The Engine Control Module (ECM) is the control center of

the fuel injection system. It constantly looks at the informa-

tion from various sensors, and controls the systems that

affect vehicle performance. The ECM also performs the

diagnostic function of the system. It can recognize opera-

tional problems, alert the driver through the Malfunction In-

dicator Lamp (MIL) (Check Engine), and store a Diagnos-

tic Trouble Code (DTC) or DTCs which identify the

problem areas to aid the technician in making repairs. An

Electrically Erasable Programmable Read Only Memory

(EEPROM) is used to house the program information and

the calibrations required for engine, transmission, and

powertrain diagnostics operation. The Diagnostic Trouble

Code (DTC) will stored, when the ECM detects SPI com-

munication between main CPU and output driver I/C is

corrupted.

Conditions for Setting the DTCS Ignition switch is turned to ON.

S Battery voltage is greater than 11 volts.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P1650 – SPI Communication Between Error with SIDM Chip

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3–

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 819 of 2643

ENGINE CONTROLS 1F – 573

DAEWOO V–121 BL4

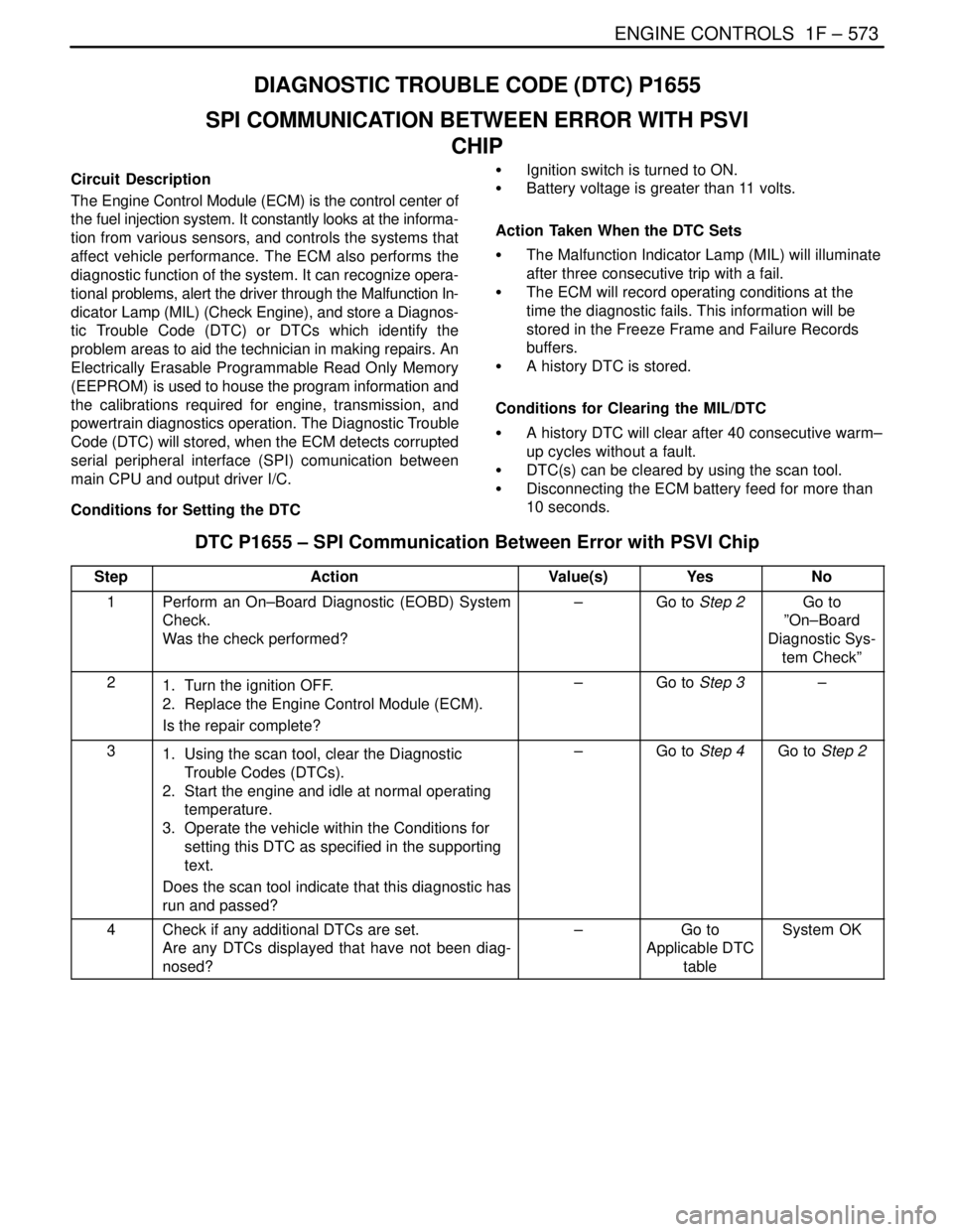

DIAGNOSTIC TROUBLE CODE (DTC) P1655

SPI COMMUNICATION BETWEEN ERROR WITH PSVI

CHIP

Circuit Description

The Engine Control Module (ECM) is the control center of

the fuel injection system. It constantly looks at the informa-

tion from various sensors, and controls the systems that

affect vehicle performance. The ECM also performs the

diagnostic function of the system. It can recognize opera-

tional problems, alert the driver through the Malfunction In-

dicator Lamp (MIL) (Check Engine), and store a Diagnos-

tic Trouble Code (DTC) or DTCs which identify the

problem areas to aid the technician in making repairs. An

Electrically Erasable Programmable Read Only Memory

(EEPROM) is used to house the program information and

the calibrations required for engine, transmission, and

powertrain diagnostics operation. The Diagnostic Trouble

Code (DTC) will stored, when the ECM detects corrupted

serial peripheral interface (SPI) comunication between

main CPU and output driver I/C.

Conditions for Setting the DTCS Ignition switch is turned to ON.

S Battery voltage is greater than 11 volts.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P1655 – SPI Communication Between Error with PSVI Chip

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3–

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 820 of 2643

1F – 574IENGINE CONTROLS

DAEWOO V–121 BL4

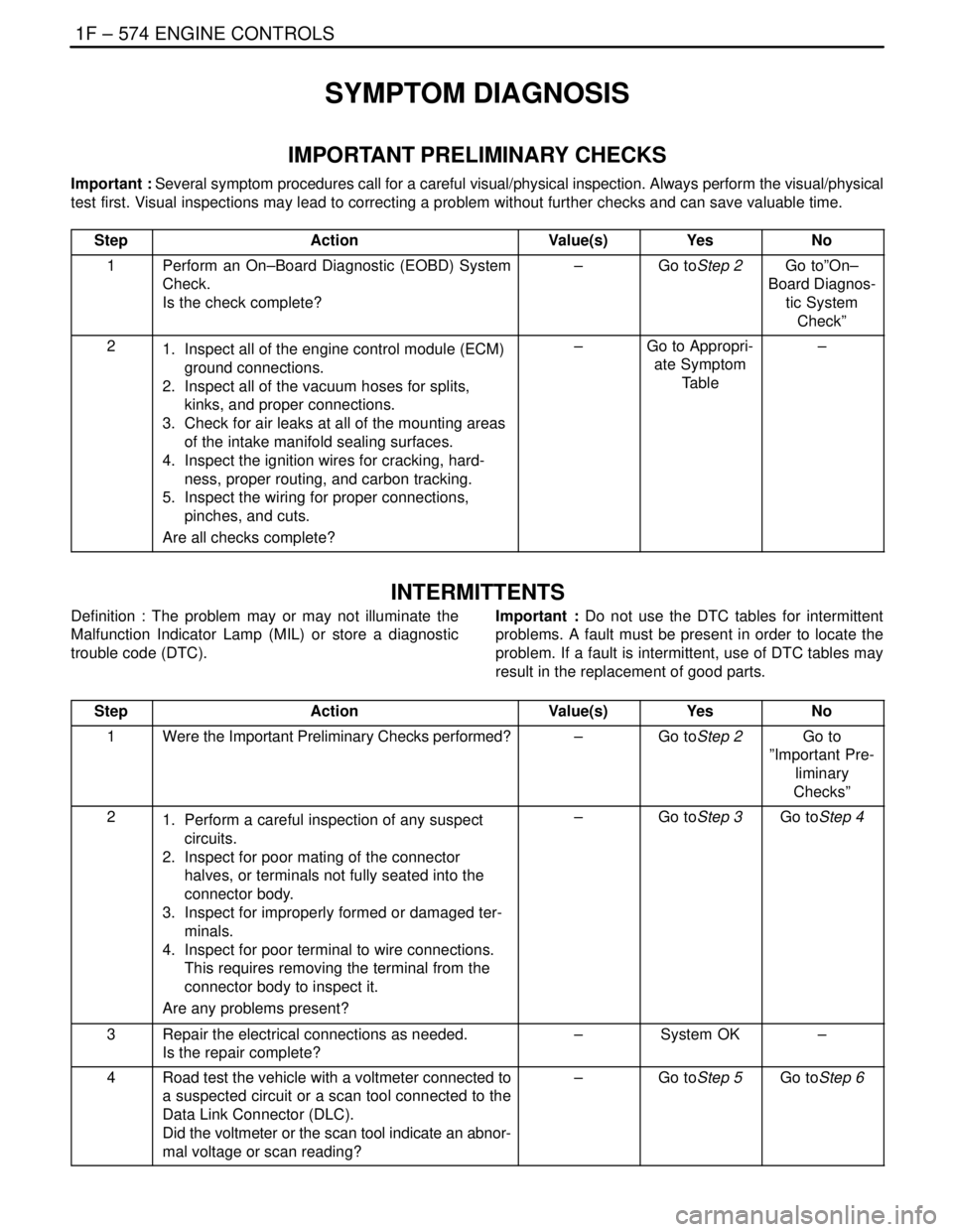

SYMPTOM DIAGNOSIS

IMPORTANT PRELIMINARY CHECKS

Important : Several symptom procedures call for a careful visual/physical inspection. Always perform the visual/physical

test first. Visual inspections may lead to correcting a problem without further checks and can save valuable time.

Step

ActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the check complete?–Go toStep 2Go to”On–

Board Diagnos-

tic System

Check”

21. Inspect all of the engine control module (ECM)

ground connections.

2. Inspect all of the vacuum hoses for splits,

kinks, and proper connections.

3. Check for air leaks at all of the mounting areas

of the intake manifold sealing surfaces.

4. Inspect the ignition wires for cracking, hard-

ness, proper routing, and carbon tracking.

5. Inspect the wiring for proper connections,

pinches, and cuts.

Are all checks complete?–Go to Appropri-

ate Symptom

Table–

INTERMITTENTS

Definition : The problem may or may not illuminate the

Malfunction Indicator Lamp (MIL) or store a diagnostic

trouble code (DTC).Important : Do not use the DTC tables for intermittent

problems. A fault must be present in order to locate the

problem. If a fault is intermittent, use of DTC tables may

result in the replacement of good parts.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Perform a careful inspection of any suspect

circuits.

2. Inspect for poor mating of the connector

halves, or terminals not fully seated into the

connector body.

3. Inspect for improperly formed or damaged ter-

minals.

4. Inspect for poor terminal to wire connections.

This requires removing the terminal from the

connector body to inspect it.

Are any problems present?–Go toStep 3Go toStep 4

3Repair the electrical connections as needed.

Is the repair complete?–System OK–

4Road test the vehicle with a voltmeter connected to

a suspected circuit or a scan tool connected to the

Data Link Connector (DLC).

Did the voltmeter or the scan tool indicate an abnor-

mal voltage or scan reading?–Go toStep 5Go toStep 6

Page 821 of 2643

ENGINE CONTROLS 1F – 575

DAEWOO V–121 BL4

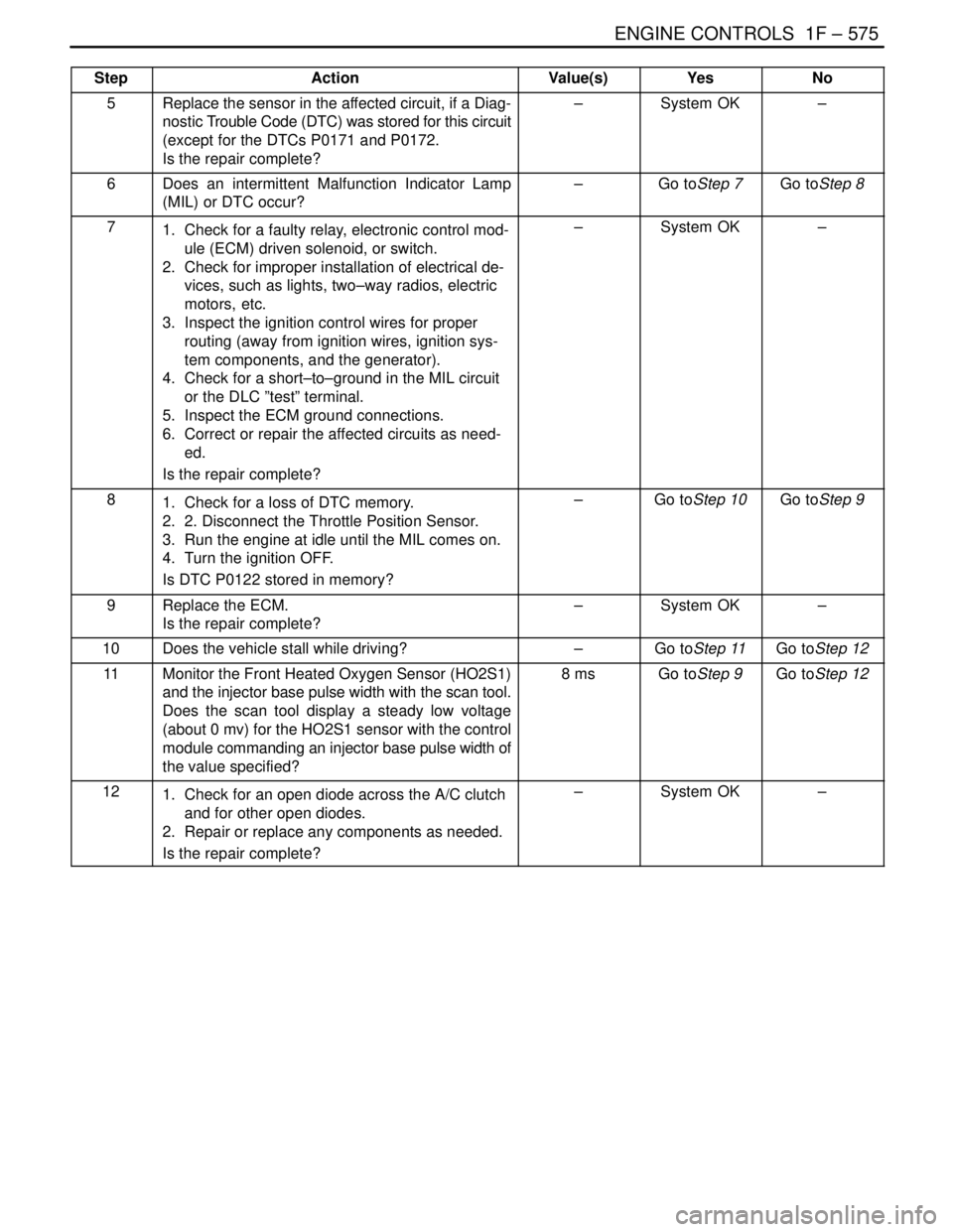

StepNo Yes Value(s) Action

5Replace the sensor in the affected circuit, if a Diag-

nostic Trouble Code (DTC) was stored for this circuit

(except for the DTCs P0171 and P0172.

Is the repair complete?–System OK–

6Does an intermittent Malfunction Indicator Lamp

(MIL) or DTC occur?–Go toStep 7Go toStep 8

71. Check for a faulty relay, electronic control mod-

ule (ECM) driven solenoid, or switch.

2. Check for improper installation of electrical de-

vices, such as lights, two–way radios, electric

motors, etc.

3. Inspect the ignition control wires for proper

routing (away from ignition wires, ignition sys-

tem components, and the generator).

4. Check for a short–to–ground in the MIL circuit

or the DLC ”test” terminal.

5. Inspect the ECM ground connections.

6. Correct or repair the affected circuits as need-

ed.

Is the repair complete?–System OK–

81. Check for a loss of DTC memory.

2. 2. Disconnect the Throttle Position Sensor.

3. Run the engine at idle until the MIL comes on.

4. Turn the ignition OFF.

Is DTC P0122 stored in memory?–Go toStep 10Go toStep 9

9Replace the ECM.

Is the repair complete?–System OK–

10Does the vehicle stall while driving?–Go toStep 11Go toStep 12

11Monitor the Front Heated Oxygen Sensor (HO2S1)

and the injector base pulse width with the scan tool.

Does the scan tool display a steady low voltage

(about 0 mv) for the HO2S1 sensor with the control

module commanding an injector base pulse width of

the value specified?8 msGo toStep 9Go toStep 12

121. Check for an open diode across the A/C clutch

and for other open diodes.

2. Repair or replace any components as needed.

Is the repair complete?–System OK–

Page 840 of 2643

1F – 594IENGINE CONTROLS

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

FUEL SYSTEM PRESSURE RELIEF

Procedure

CAUTION : The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pressure

before disconnecting the fuel lines.

1. Remove the fuel cap.

2. Remove the fuel pump fuse Ef18 from the engine

fuse block.

3. Start the engine and allow the engine to stall.

4. Crank the engine for an additional 10 seconds.

FUEL TANK

Removal Procedure

CAUTION : The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pressure

before disconnecting the fuel lines.

1. Relieve the fuel pressure. Refer to ” Fuel System

Pressure Relief ” in this section.

2. Disconnect the negative battery cable.

3. Drain the fuel tank.

4. Remove the front muffler. Refer to Section 1G, Ex-

haust System

5. Remove the fuel tank filler tube clamp at the fuel

tank.

6. Disconnect the fuel tank filler tube.

7. Disconnect the fuel vapor line near the fuel tank

filler tube.

8. Disconnect the fuel pump harness connector.

Page 842 of 2643

1F – 596IENGINE CONTROLS

DAEWOO V–121 BL4

7. Connect the fuel pump harness connector.

8. Connect the fuel vapor line.

9. Connect the fuel tank filler tube.

10. Connect the fuel tank vent tube.

11. Install the fuel tank filler tube clamp at the fuel tank.

12. Install the front muffler. Refer to Section 1G, Ex-

haust System

13. Connect the negative battery cable.

14. Fill the fuel tank.

15. Perform a leak check of the fuel tank and the fuel

line connections.

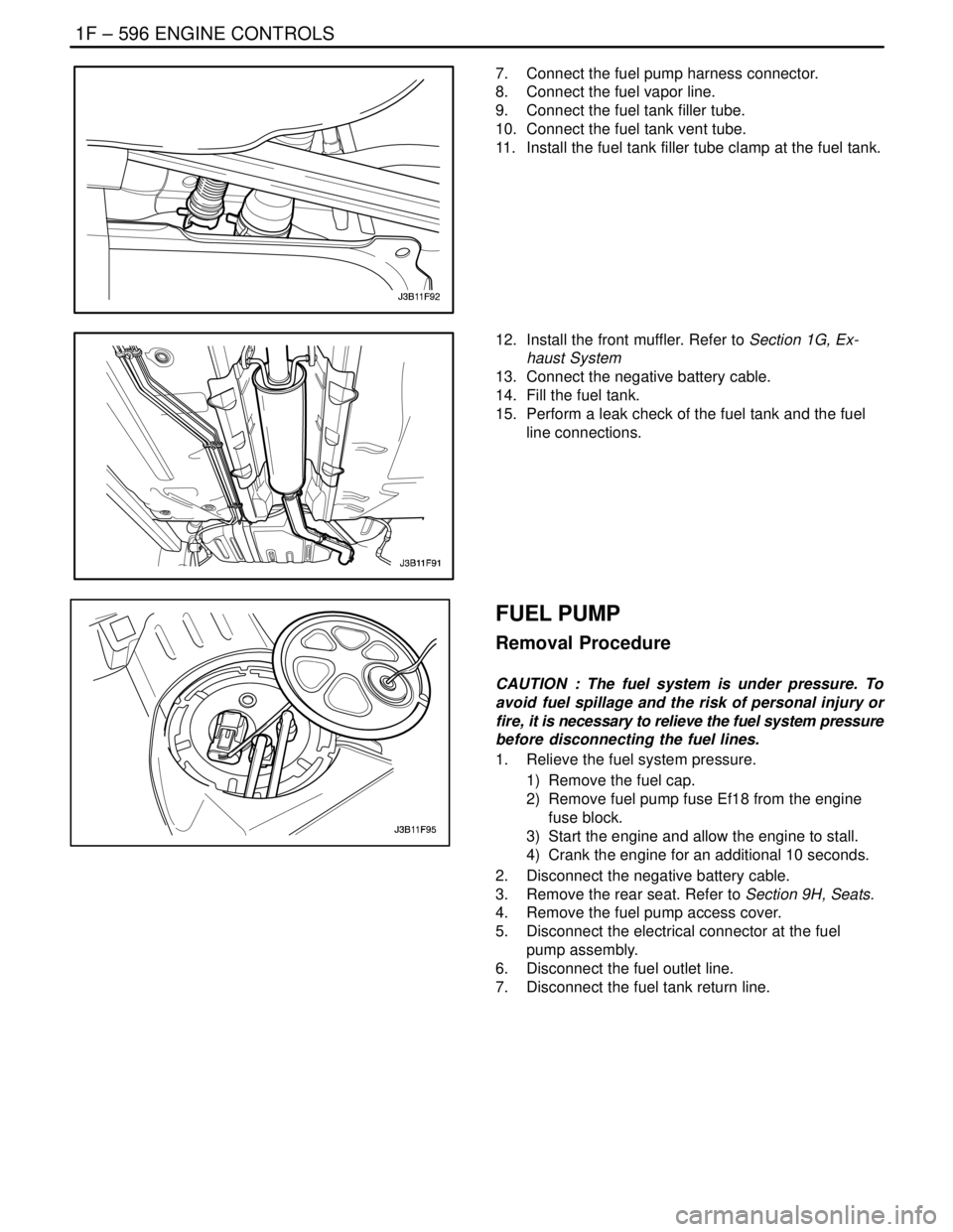

FUEL PUMP

Removal Procedure

CAUTION : The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pressure

before disconnecting the fuel lines.

1. Relieve the fuel system pressure.

1) Remove the fuel cap.

2) Remove fuel pump fuse Ef18 from the engine

fuse block.

3) Start the engine and allow the engine to stall.

4) Crank the engine for an additional 10 seconds.

2. Disconnect the negative battery cable.

3. Remove the rear seat. Refer to Section 9H, Seats.

4. Remove the fuel pump access cover.

5. Disconnect the electrical connector at the fuel

pump assembly.

6. Disconnect the fuel outlet line.

7. Disconnect the fuel tank return line.