Lamp DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 998 of 2643

AUTOMATIC TRANSAXLE DRIVE AXLE 3A – 9

DAEWOO V–121 BL4

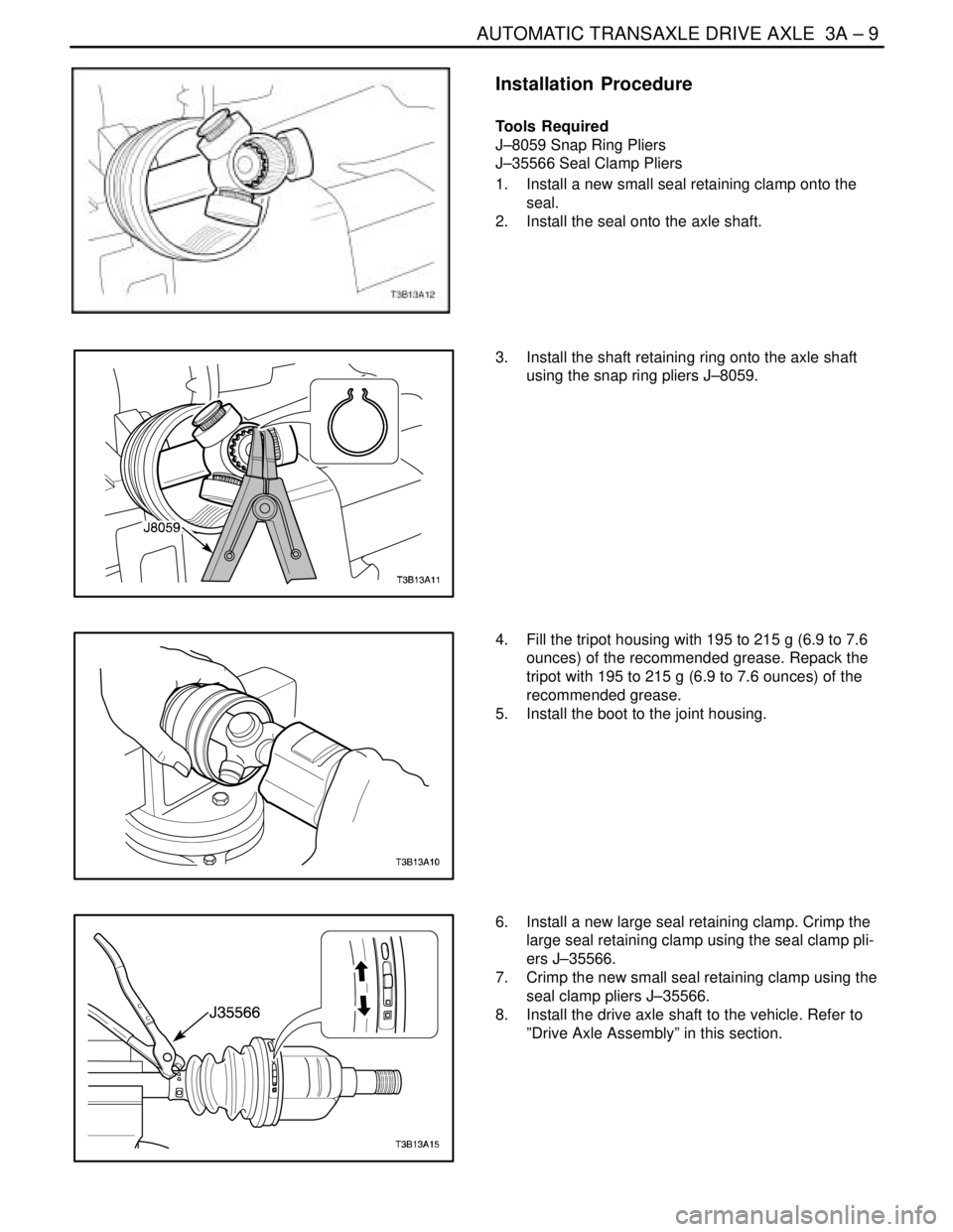

Installation Procedure

Tools Required

J–8059 Snap Ring Pliers

J–35566 Seal Clamp Pliers

1. Install a new small seal retaining clamp onto the

seal.

2. Install the seal onto the axle shaft.

3. Install the shaft retaining ring onto the axle shaft

using the snap ring pliers J–8059.

4. Fill the tripot housing with 195 to 215 g (6.9 to 7.6

ounces) of the recommended grease. Repack the

tripot with 195 to 215 g (6.9 to 7.6 ounces) of the

recommended grease.

5. Install the boot to the joint housing.

6. Install a new large seal retaining clamp. Crimp the

large seal retaining clamp using the seal clamp pli-

ers J–35566.

7. Crimp the new small seal retaining clamp using the

seal clamp pliers J–35566.

8. Install the drive axle shaft to the vehicle. Refer to

”Drive Axle Assembly” in this section.

Page 1001 of 2643

3B – 2IMANUAL TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

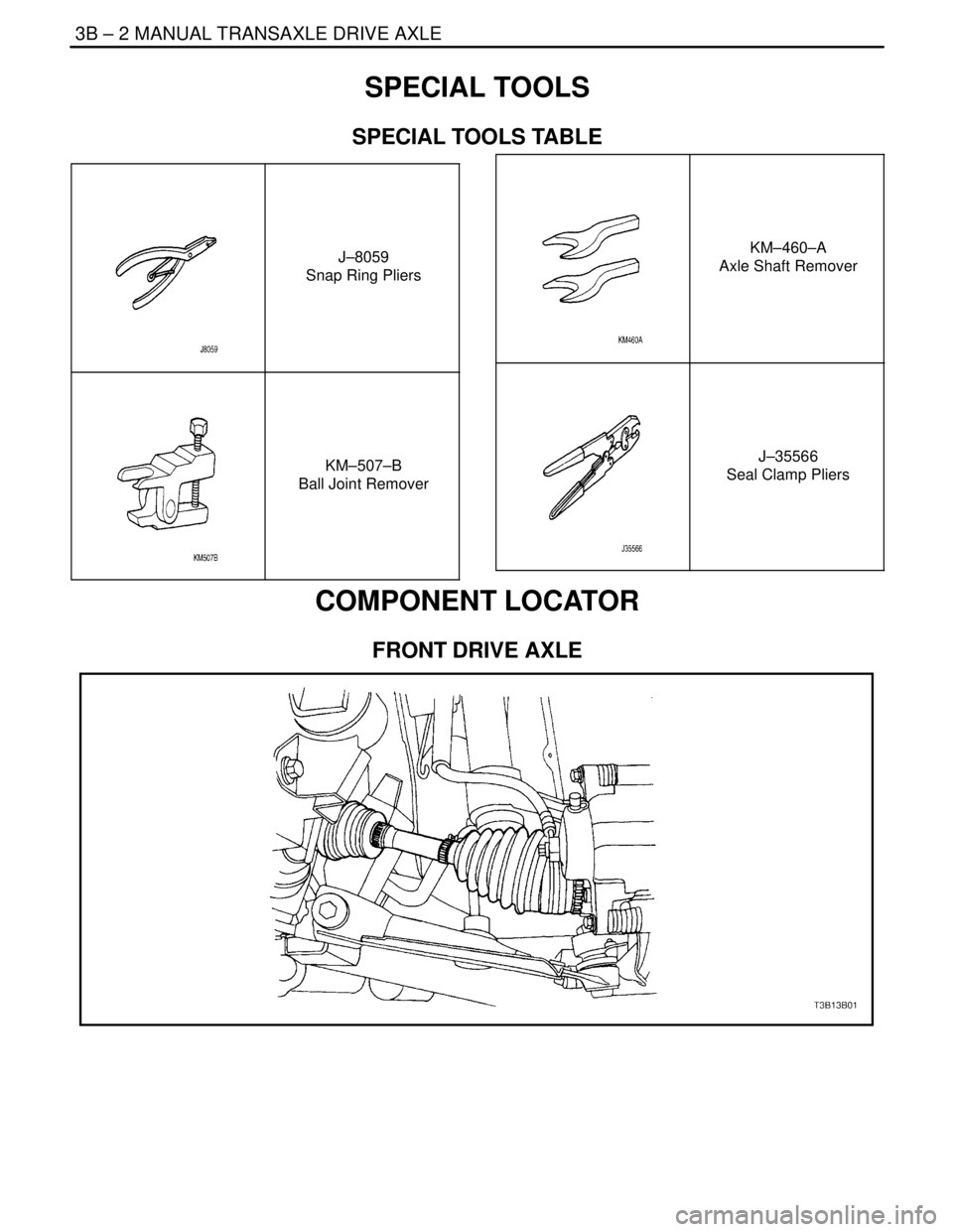

SPECIAL TOOLS

SPECIAL TOOLS TABLE

J–8059

Snap Ring Pliers

KM–507–B

Ball Joint Remover

KM–460–A

Axle Shaft Remover

J–35566

Seal Clamp Pliers

COMPONENT LOCATOR

FRONT DRIVE AXLE

Page 1002 of 2643

MANUAL TRANSAXLE DRIVE AXLE 3B – 3

DAEWOO V–121 BL4

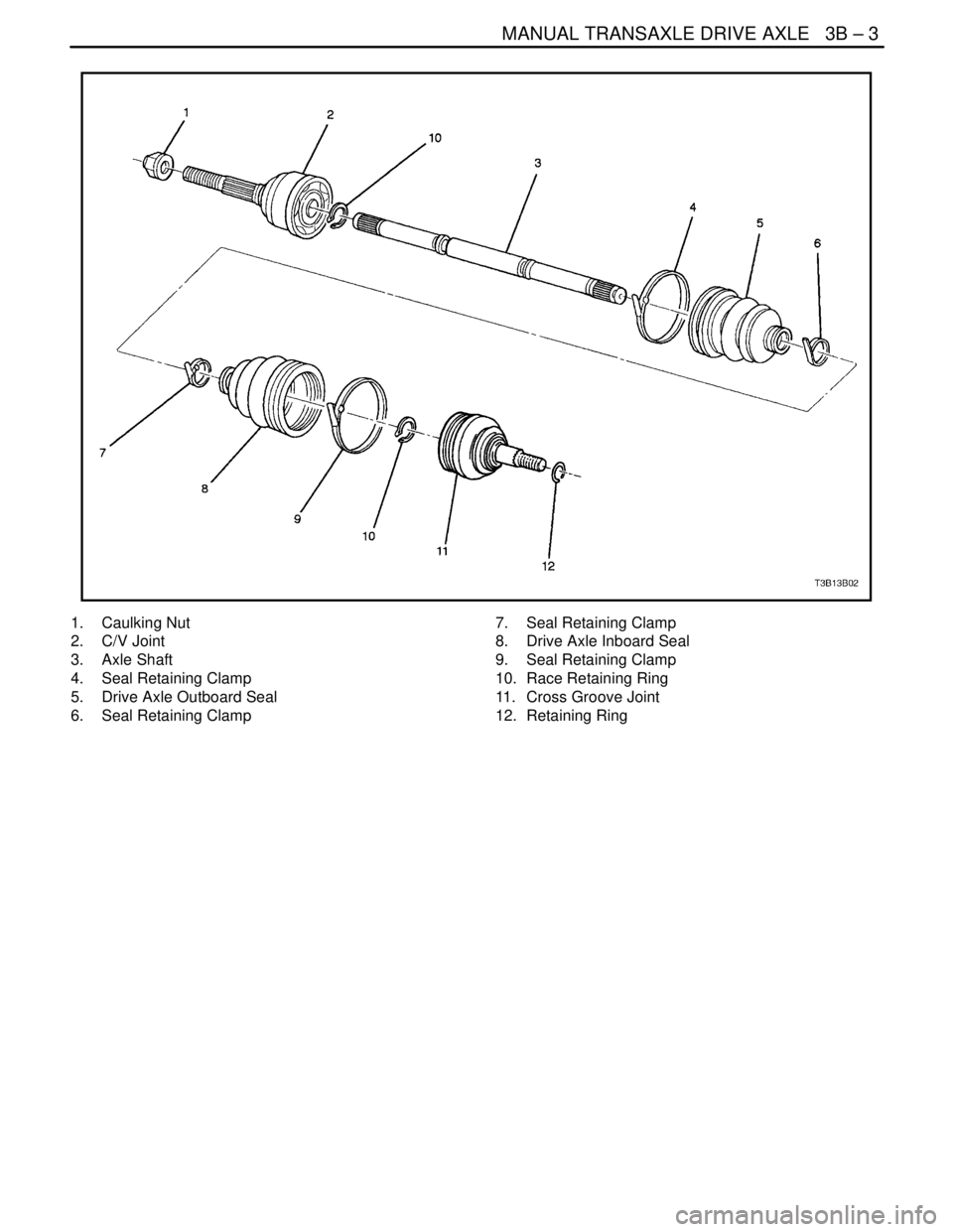

1. Caulking Nut

2. C/V Joint

3. Axle Shaft

4. Seal Retaining Clamp

5. Drive Axle Outboard Seal

6. Seal Retaining Clamp7. Seal Retaining Clamp

8. Drive Axle Inboard Seal

9. Seal Retaining Clamp

10. Race Retaining Ring

11. Cross Groove Joint

12. Retaining Ring

Page 1003 of 2643

3B – 4IMANUAL TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

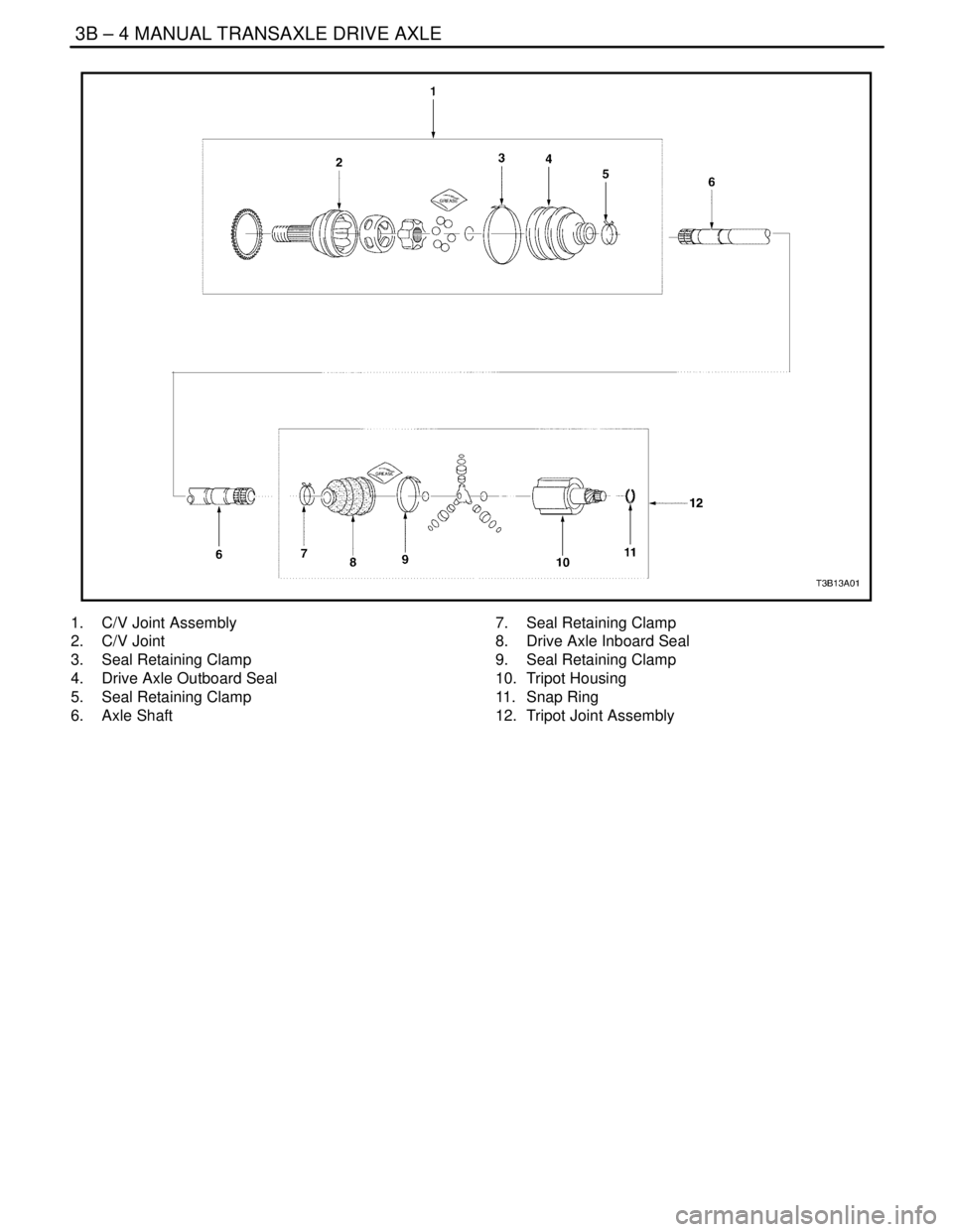

1. C/V Joint Assembly

2. C/V Joint

3. Seal Retaining Clamp

4. Drive Axle Outboard Seal

5. Seal Retaining Clamp

6. Axle Shaft7. Seal Retaining Clamp

8. Drive Axle Inboard Seal

9. Seal Retaining Clamp

10. Tripot Housing

11. Snap Ring

12. Tripot Joint Assembly

Page 1007 of 2643

3B – 8IMANUAL TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

UNIT REPAIR

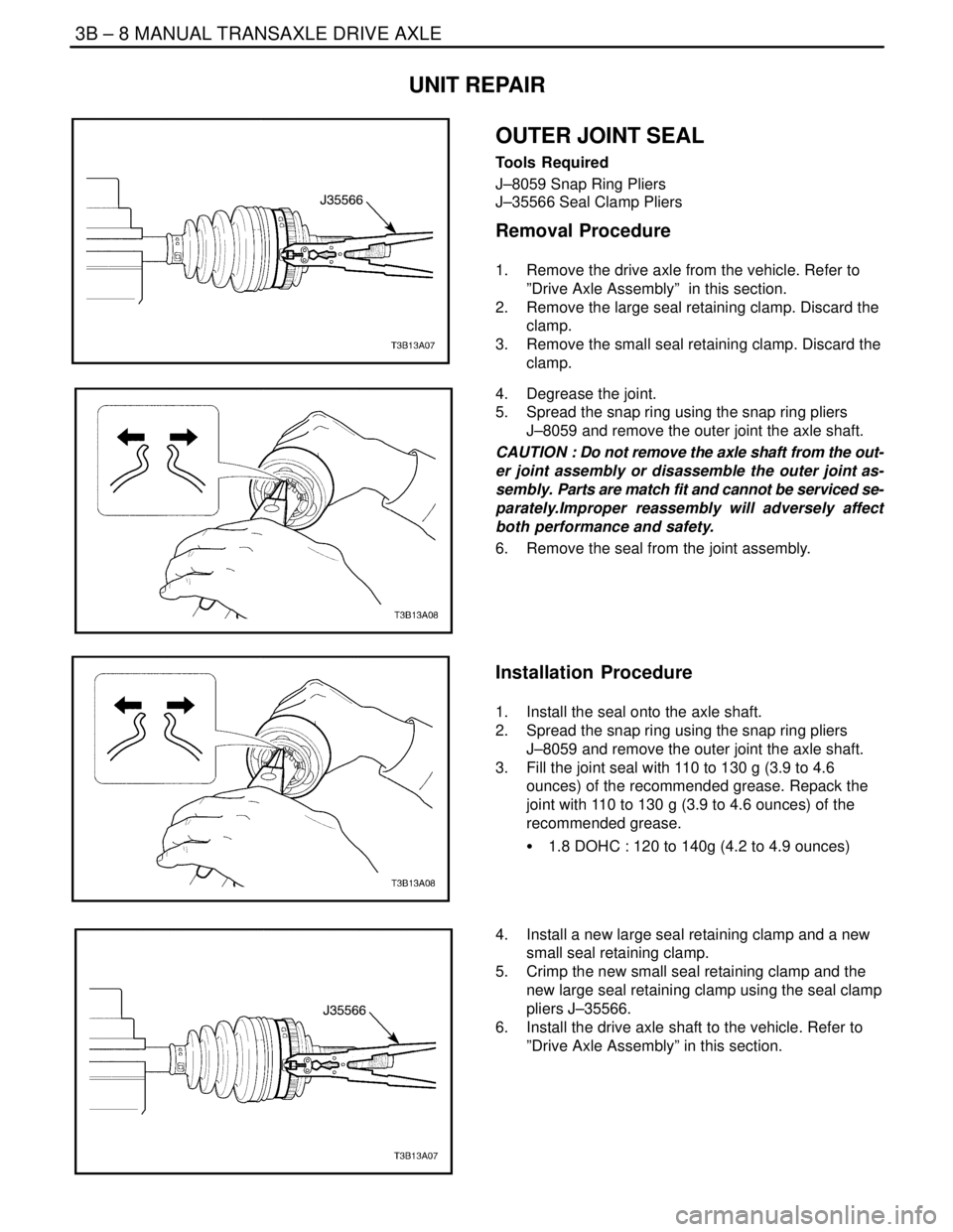

OUTER JOINT SEAL

Tools Required

J–8059 Snap Ring Pliers

J–35566 Seal Clamp Pliers

Removal Procedure

1. Remove the drive axle from the vehicle. Refer to

”Drive Axle Assembly” in this section.

2. Remove the large seal retaining clamp. Discard the

clamp.

3. Remove the small seal retaining clamp. Discard the

clamp.

4. Degrease the joint.

5. Spread the snap ring using the snap ring pliers

J–8059 and remove the outer joint the axle shaft.

CAUTION : Do not remove the axle shaft from the out-

er joint assembly or disassemble the outer joint as-

sembly. Parts are match fit and cannot be serviced se-

parately.Improper reassembly will adversely affect

both performance and safety.

6. Remove the seal from the joint assembly.

Installation Procedure

1. Install the seal onto the axle shaft.

2. Spread the snap ring using the snap ring pliers

J–8059 and remove the outer joint the axle shaft.

3. Fill the joint seal with 110 to 130 g (3.9 to 4.6

ounces) of the recommended grease. Repack the

joint with 110 to 130 g (3.9 to 4.6 ounces) of the

recommended grease.

S 1.8 DOHC : 120 to 140g (4.2 to 4.9 ounces)

4. Install a new large seal retaining clamp and a new

small seal retaining clamp.

5. Crimp the new small seal retaining clamp and the

new large seal retaining clamp using the seal clamp

pliers J–35566.

6. Install the drive axle shaft to the vehicle. Refer to

”Drive Axle Assembly” in this section.

Page 1008 of 2643

MANUAL TRANSAXLE DRIVE AXLE 3B – 9

DAEWOO V–121 BL4

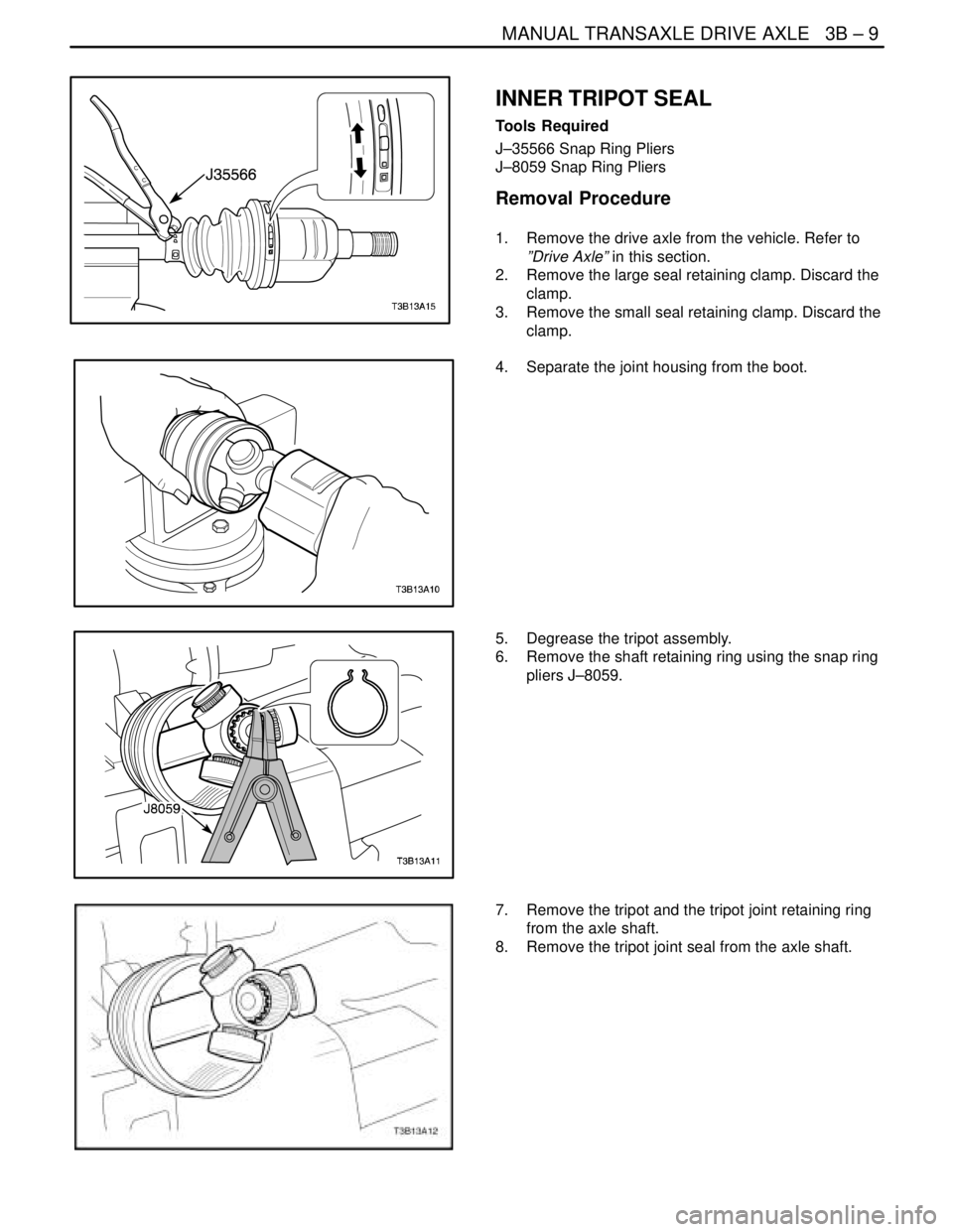

INNER TRIPOT SEAL

Tools Required

J–35566 Snap Ring Pliers

J–8059 Snap Ring Pliers

Removal Procedure

1. Remove the drive axle from the vehicle. Refer to

”Drive Axle” in this section.

2. Remove the large seal retaining clamp. Discard the

clamp.

3. Remove the small seal retaining clamp. Discard the

clamp.

4. Separate the joint housing from the boot.

5. Degrease the tripot assembly.

6. Remove the shaft retaining ring using the snap ring

pliers J–8059.

7. Remove the tripot and the tripot joint retaining ring

from the axle shaft.

8. Remove the tripot joint seal from the axle shaft.

Page 1009 of 2643

3B – 10IMANUAL TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

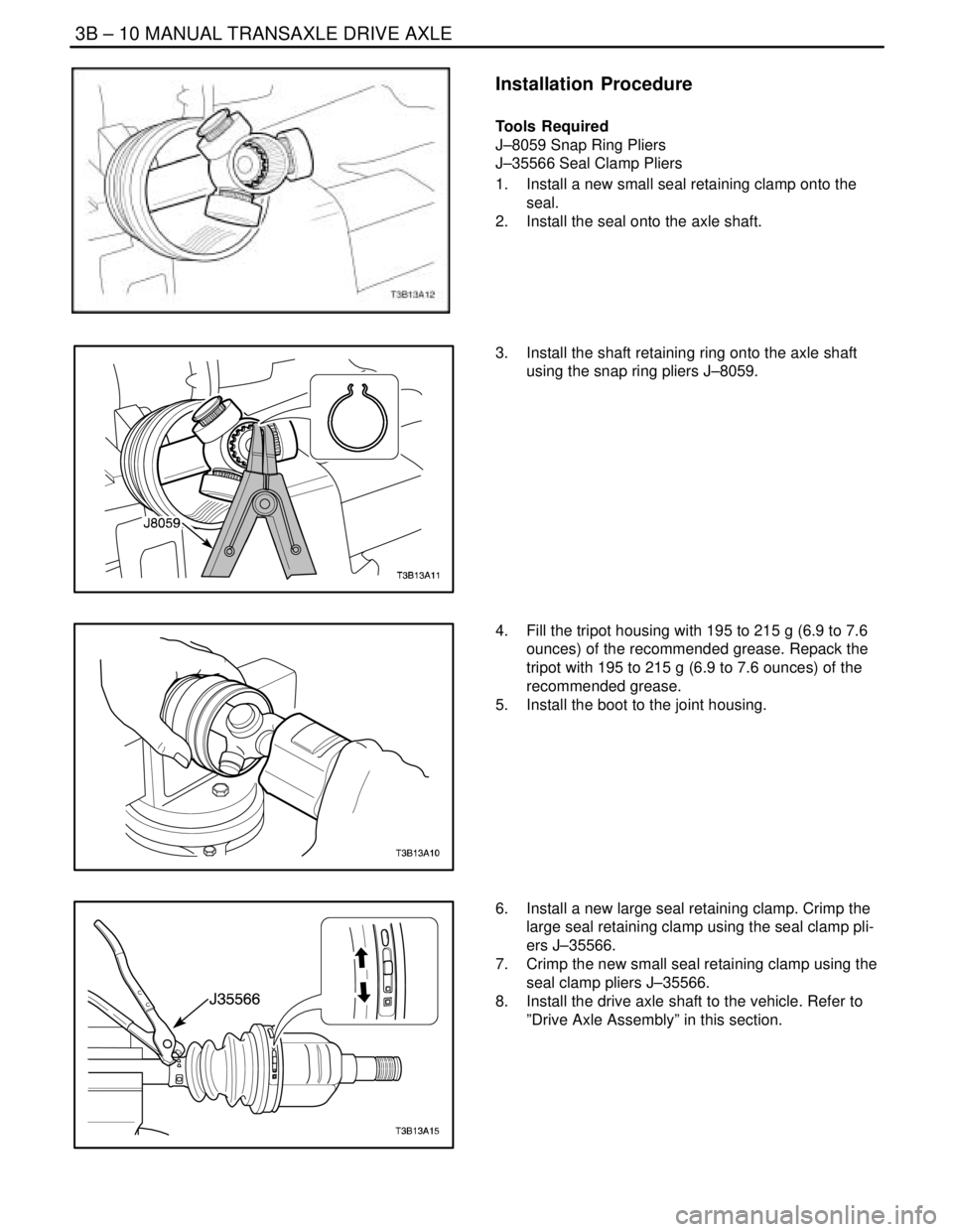

Installation Procedure

Tools Required

J–8059 Snap Ring Pliers

J–35566 Seal Clamp Pliers

1. Install a new small seal retaining clamp onto the

seal.

2. Install the seal onto the axle shaft.

3. Install the shaft retaining ring onto the axle shaft

using the snap ring pliers J–8059.

4. Fill the tripot housing with 195 to 215 g (6.9 to 7.6

ounces) of the recommended grease. Repack the

tripot with 195 to 215 g (6.9 to 7.6 ounces) of the

recommended grease.

5. Install the boot to the joint housing.

6. Install a new large seal retaining clamp. Crimp the

large seal retaining clamp using the seal clamp pli-

ers J–35566.

7. Crimp the new small seal retaining clamp using the

seal clamp pliers J–35566.

8. Install the drive axle shaft to the vehicle. Refer to

”Drive Axle Assembly” in this section.

Page 1010 of 2643

MANUAL TRANSAXLE DRIVE AXLE 3B – 11

DAEWOO V–121 BL4

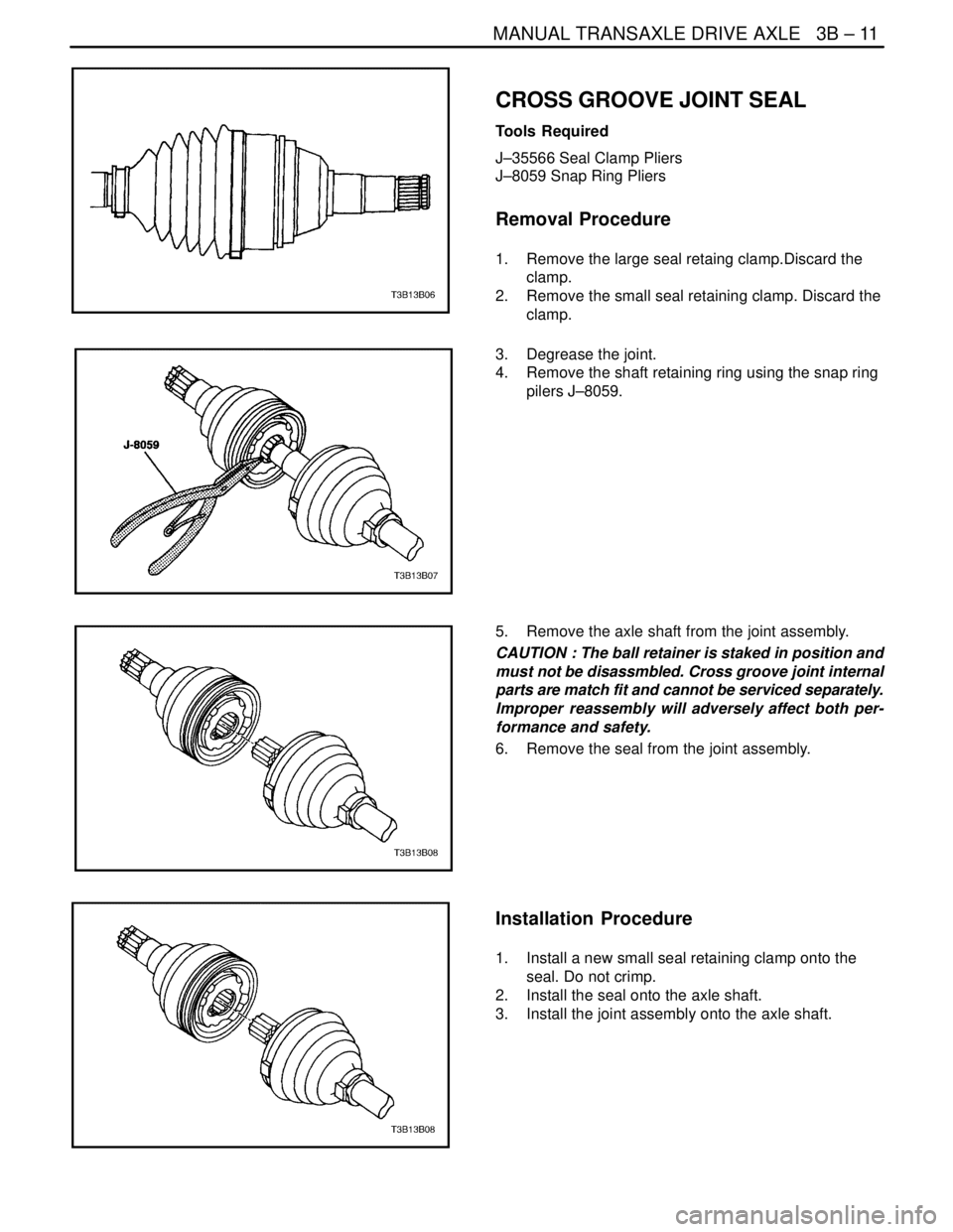

CROSS GROOVE JOINT SEAL

Tools Required

J–35566 Seal Clamp Pliers

J–8059 Snap Ring Pliers

Removal Procedure

1. Remove the large seal retaing clamp.Discard the

clamp.

2. Remove the small seal retaining clamp. Discard the

clamp.

3. Degrease the joint.

4. Remove the shaft retaining ring using the snap ring

pilers J–8059.

5. Remove the axle shaft from the joint assembly.

CAUTION : The ball retainer is staked in position and

must not be disassmbled. Cross groove joint internal

parts are match fit and cannot be serviced separately.

Improper reassembly will adversely affect both per-

formance and safety.

6. Remove the seal from the joint assembly.

Installation Procedure

1. Install a new small seal retaining clamp onto the

seal. Do not crimp.

2. Install the seal onto the axle shaft.

3. Install the joint assembly onto the axle shaft.

Page 1011 of 2643

3B – 12IMANUAL TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

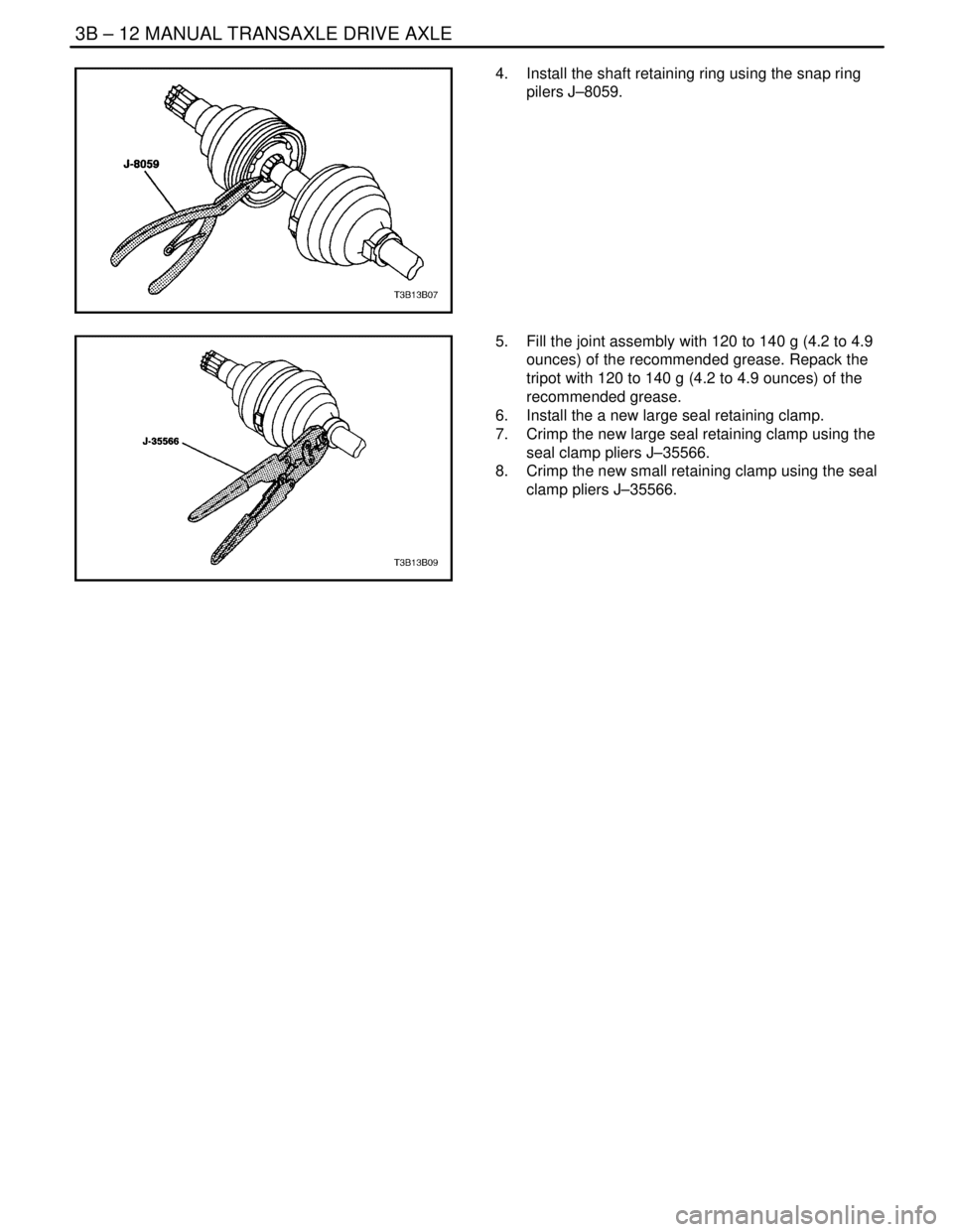

4. Install the shaft retaining ring using the snap ring

pilers J–8059.

5. Fill the joint assembly with 120 to 140 g (4.2 to 4.9

ounces) of the recommended grease. Repack the

tripot with 120 to 140 g (4.2 to 4.9 ounces) of the

recommended grease.

6. Install the a new large seal retaining clamp.

7. Crimp the new large seal retaining clamp using the

seal clamp pliers J–35566.

8. Crimp the new small retaining clamp using the seal

clamp pliers J–35566.

Page 1014 of 2643

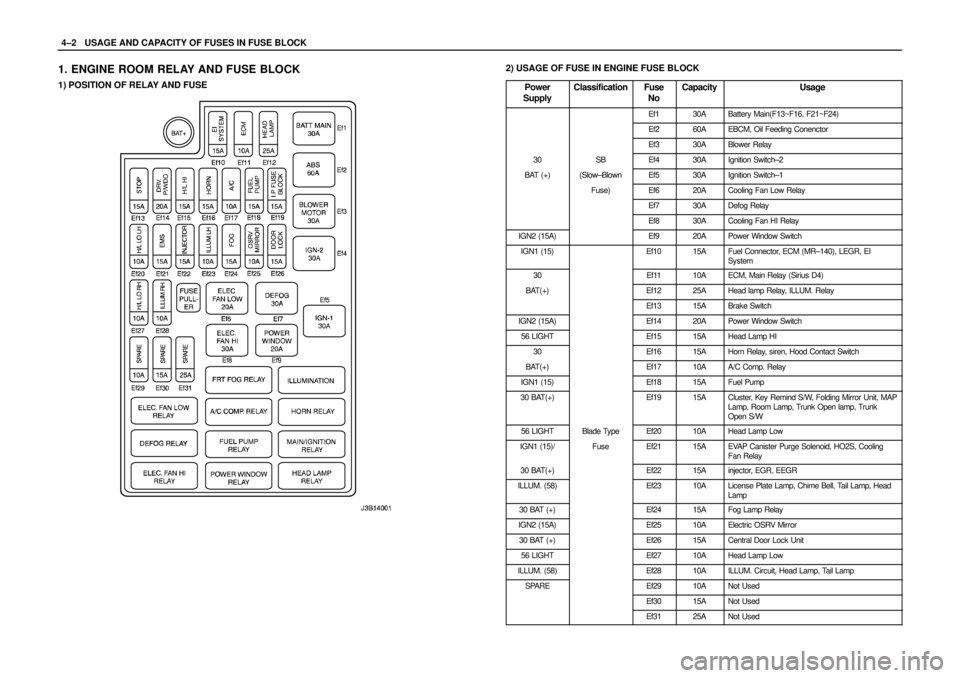

4–2WUSAGE AND CAPACITY OF FUSES IN FUSE BLOCK

1. ENGINE ROOM RELAY AND FUSE BLOCK

1) POSITION OF RELAY AND FUSE

2) USAGE OF FUSE IN ENGINE FUSE BLOCK

Power

Supply

ClassificationFuse

NoCapacityUsage

Ef130ABattery Main(F13~F16, F21~F24)

Ef260AEBCM, Oil Feeding Conenctor

Ef330ABlower Relay

30SBEf430AIgnition Switch–2

BAT (+)(Slow–BlownEf530AIgnition Switch–1

Fuse)Ef620ACooling Fan Low Relay

Ef730ADefog Relay

Ef830ACooling Fan HI Relay

IGN2 (15A)Ef920APower Window Switch

IGN1 (15)Ef1015AFuel Connector, ECM (MR–140), LEGR, EI

System

30Ef1110AECM, Main Relay (Sirius D4)

BAT(+)Ef1225AHead lamp Relay, ILLUM. Relay

Ef1315ABrake Switch

IGN2 (15A)Ef1420APower Window Switch

56 LIGHTEf1515AHead Lamp HI

30Ef1615AHorn Relay, siren, Hood Contact Switch

BAT(+)Ef1710AA/C Comp. Relay

IGN1 (15)Ef1815AFuel Pump

30 BAT(+)Ef1915ACluster, Key Remind S/W, Folding Mirror Unit, MAP

Lamp, Room Lamp, Trunk Open lamp, Trunk

Open S/W

56 LIGHTBlade TypeEf2010AHead Lamp Low

IGN1 (15)/FuseEf2115AEVAP Canister Purge Solenoid, HO2S, Cooling

Fan Relay

30 BAT(+)Ef2215Ainjector, EGR, EEGR

ILLUM. (58)Ef2310ALicense Plate Lamp, Chime Bell, Tail Lamp, Head

Lamp

30 BAT (+)Ef2415AFog Lamp Relay

IGN2 (15A)Ef2510AElectric OSRV Mirror

30 BAT (+)Ef2615ACentral Door Lock Unit

56 LIGHTEf2710AHead Lamp Low

ILLUM. (58)Ef2810AILLUM. Circuit, Head Lamp, Tail Lamp

SPAREEf2910ANot Used

Ef3015ANot Used

Ef3125ANot Used