Section 5 DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 915 of 2643

2B – 8IWHEEL ALIGNMENT

DAEWOO V–121 BL4

PRELIMINARY INSPECTION

ChecksAction

Check the tires for proper inflation pressures and normal

tread wear.Inflate the tires to the proper tire pressure. Replace the

tires as needed.

Check the wheel bearings for looseness.Tighten the axle nut to the proper specification. Replace

the strut wheel bearing as needed.

Check for loose ball joints and tie rod ends.Tighten the ball joints and the tie rods.

Check the runout of the wheels and the tires.Measure and correct the tire runout.

Check the vehicle trim heights.Correct the trim heights. Make the correction before ad-

justing the toe.

Check for loose rack and pinion mounting.Tighten the mounting brackets for the rack and pinion as-

sembly.

Check for improperly operating struts.Replace the strut assembly.

Check for loose control arms.Tighten the control arm attachment bolts. Replace the con-

trol arm bushings as needed.

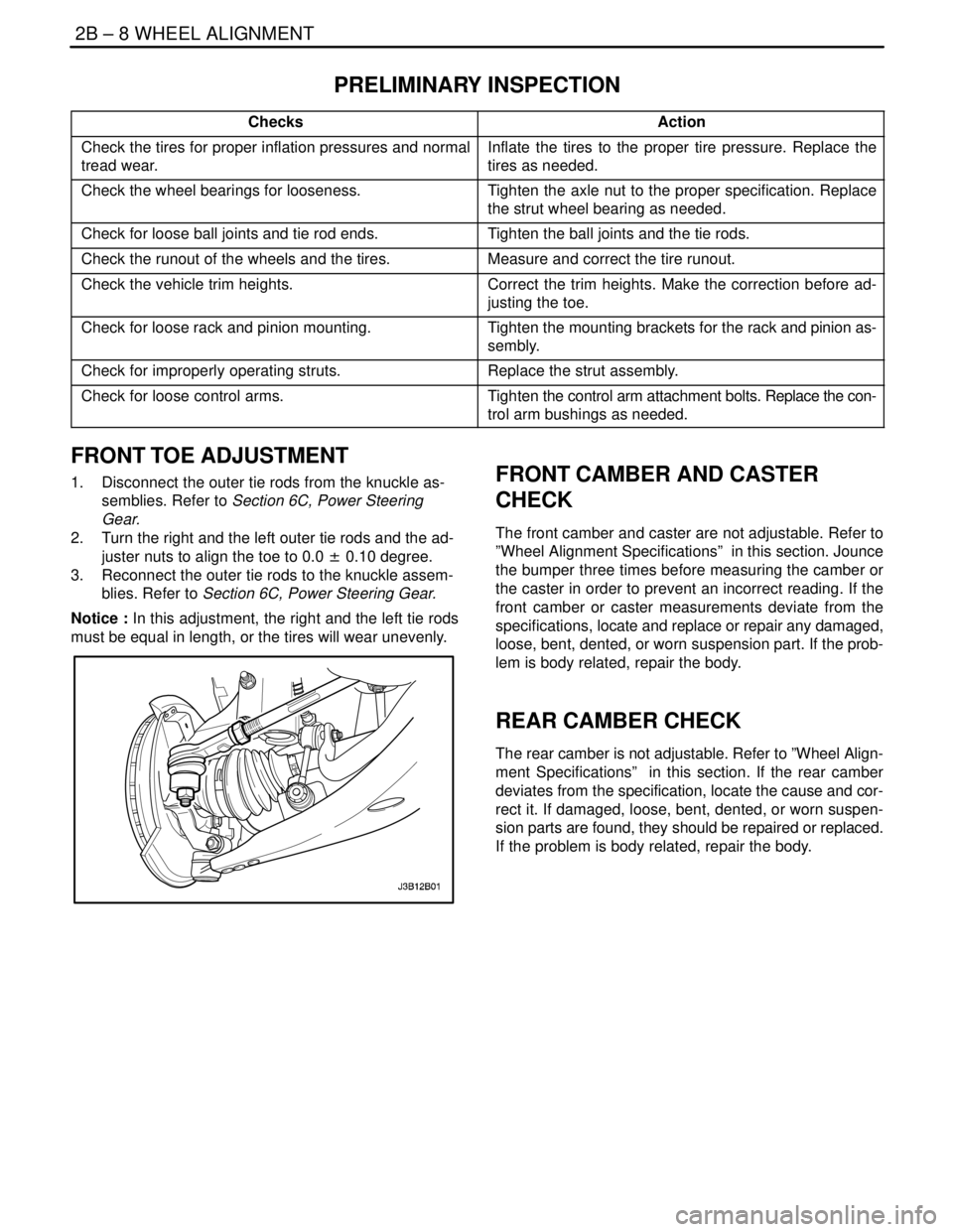

FRONT TOE ADJUSTMENT

1. Disconnect the outer tie rods from the knuckle as-

semblies. Refer to Section 6C, Power Steering

Gear.

2. Turn the right and the left outer tie rods and the ad-

juster nuts to align the toe to 0.0 ± 0.10 degree.

3. Reconnect the outer tie rods to the knuckle assem-

blies. Refer to Section 6C, Power Steering Gear.

Notice : In this adjustment, the right and the left tie rods

must be equal in length, or the tires will wear unevenly.FRONT CAMBER AND CASTER

CHECK

The front camber and caster are not adjustable. Refer to

”Wheel Alignment Specifications” in this section. Jounce

the bumper three times before measuring the camber or

the caster in order to prevent an incorrect reading. If the

front camber or caster measurements deviate from the

specifications, locate and replace or repair any damaged,

loose, bent, dented, or worn suspension part. If the prob-

lem is body related, repair the body.

REAR CAMBER CHECK

The rear camber is not adjustable. Refer to ”Wheel Align-

ment Specifications” in this section. If the rear camber

deviates from the specification, locate the cause and cor-

rect it. If damaged, loose, bent, dented, or worn suspen-

sion parts are found, they should be repaired or replaced.

If the problem is body related, repair the body.

Page 916 of 2643

WHEEL ALIGNMENT 2B – 9

DAEWOO V–121 BL4

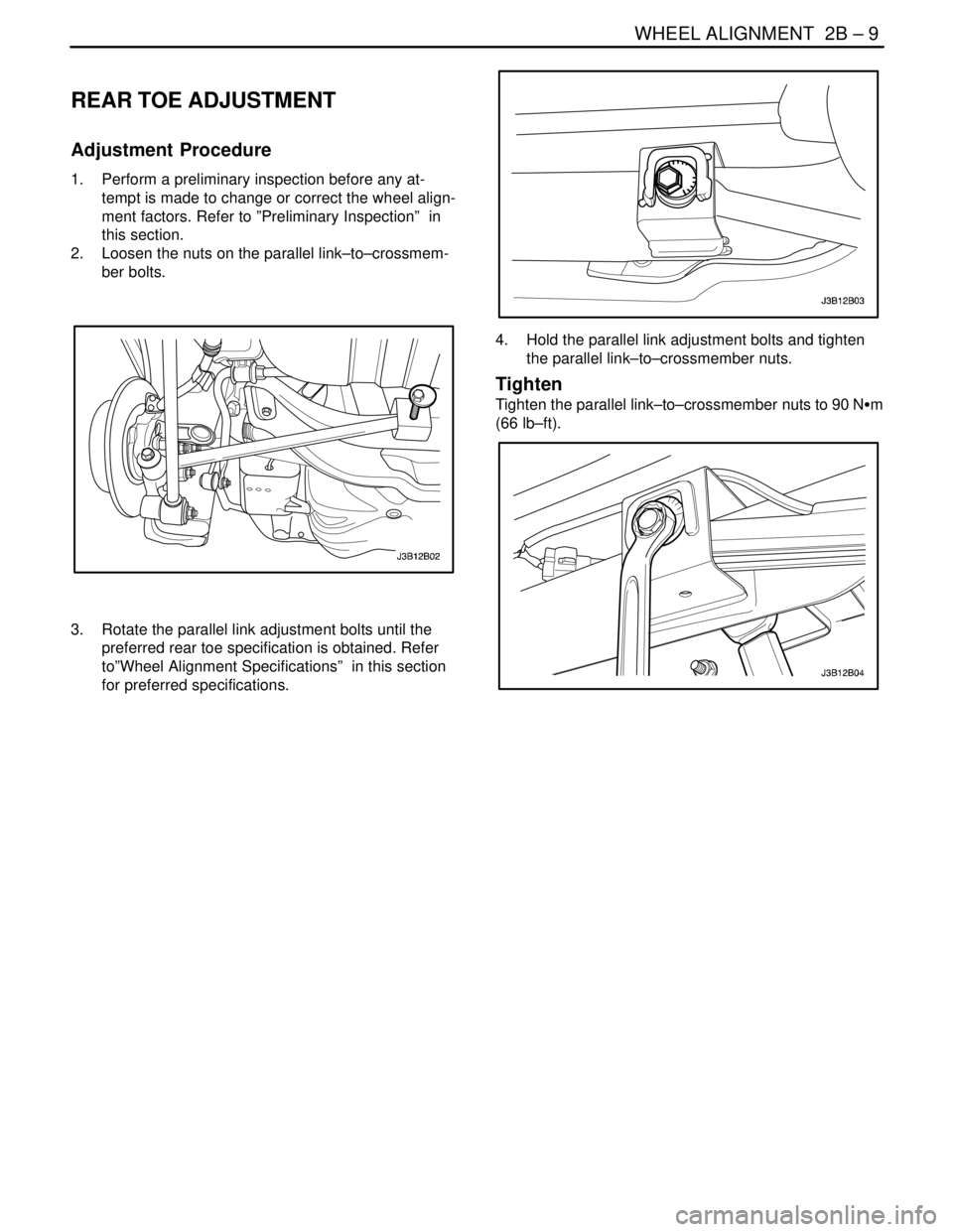

REAR TOE ADJUSTMENT

Adjustment Procedure

1. Perform a preliminary inspection before any at-

tempt is made to change or correct the wheel align-

ment factors. Refer to ”Preliminary Inspection” in

this section.

2. Loosen the nuts on the parallel link–to–crossmem-

ber bolts.

3. Rotate the parallel link adjustment bolts until the

preferred rear toe specification is obtained. Refer

to”Wheel Alignment Specifications” in this section

for preferred specifications.

4. Hold the parallel link adjustment bolts and tighten

the parallel link–to–crossmember nuts.

Tighten

Tighten the parallel link–to–crossmember nuts to 90 NSm

(66 lb–ft).

Page 918 of 2643

SECTION : 2C

FRONT SUSPENSION

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS2C–2 . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 2C–2. . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 2C–2. . . . . . . . . . .

SPECIAL TOOLS2C–3 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 2C–3. . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS2C–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strut Dampener 2C–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Ball Joint and Knuckle 2C–6. . . . . . . . . . . . . . . . . . . . . .

Excessive Friction Check 2C–6. . . . . . . . . . . . . . . . . . .

COMPONENT LOCATOR2C–7 . . . . . . . . . . . . . . . . . . . .

Front Suspension 2C–7. . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR2C–9 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 2C–9. . . . . . . . . . . . . . . . . . . . .

Stabilizer Shaft and Insulators 2C–9. . . . . . . . . . . . . . . Stabilizer Link 2C–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Knuckle Assembly 2C–10. . . . . . . . . . . . . . . . . . . . . . . .

Hub and Bearing 2C–13. . . . . . . . . . . . . . . . . . . . . . . . .

Control Arm 2C–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strut Assembly 2C–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Crossmember Assembly 2C–18. . . . . . . . . . . . . . . . . . .

UNIT REPAIR 2C–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ball Joint 2C–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Arm Bushings 2C–21. . . . . . . . . . . . . . . . . . . . .

Front Strut Assembly 2C–22. . . . . . . . . . . . . . . . . . . . . .

Knuckle 2C–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION 2C–25 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Suspension 2C–25. . . . . . . . . . . . . . . . . . . . . . . . .

Page 923 of 2643

2C – 6IFRONT SUSPENSION

DAEWOO V–121 BL4

BALL JOINT AND KNUCKLE

Ball Joint Inspection

1. Raise the front of the vehicle to allow the front sus-

pension to hang free.

2. Grasp the tire at the top and the bottom.

3. Move the top of the tire in an in–and–out motion.

4. Look for any horizontal movement of the knuckle

relative to the control arm.

5. Ball joints must be replaced under the following

conditions:

S The joint is loose.

S The ball seal is cut.

S The ball stud is disconnected from the knuckle.

S The ball stud is loose at the knuckle.

S The ball stud can be twisted in its socket with

finger pressure.

Ball Stud Inspection

Make sure to check the tightness of the ball stud in the

knuckle boss during each inspection of the ball joint. One

way to inspect the ball stud for wear is to shake the wheel

and feel for movement of the stud end at the knuckle boss.Another way to inspect the ball stud for wear is to check

the fastener torque at the pinch nut. A loose nut can indi-

cate a stressed stud or a hole in the knuckle boss.

Worn or damaged ball joints and knuckles must be re-

placed.

EXCESSIVE FRICTION CHECK

Use the following procedure to check for excessive friction

in the front suspension:

1. Enlist the help of another technician to lift up on the

front bumper, raising the vehicle as high as pos-

sible.

2. Slowly release the bumper, allowing the vehicle to

assume its normal trim height. See ”General Speci-

fications” in this section.

3. Measure the distance from the street level to the

center of the bumper.

4. Push down on the bumper, release slowly, and al-

low the vehicle to assume its normal trim height.

5. Measure the distance from the street level to the

center of the bumper.

6. The difference between the two measurements

should be less than 12.7 mm (0.5 inch). If the differ-

ence exceeds this limit, inspect the control arms,

the struts, and the ball joints for damage or wear.

Page 926 of 2643

FRONT SUSPENSION 2C – 9

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

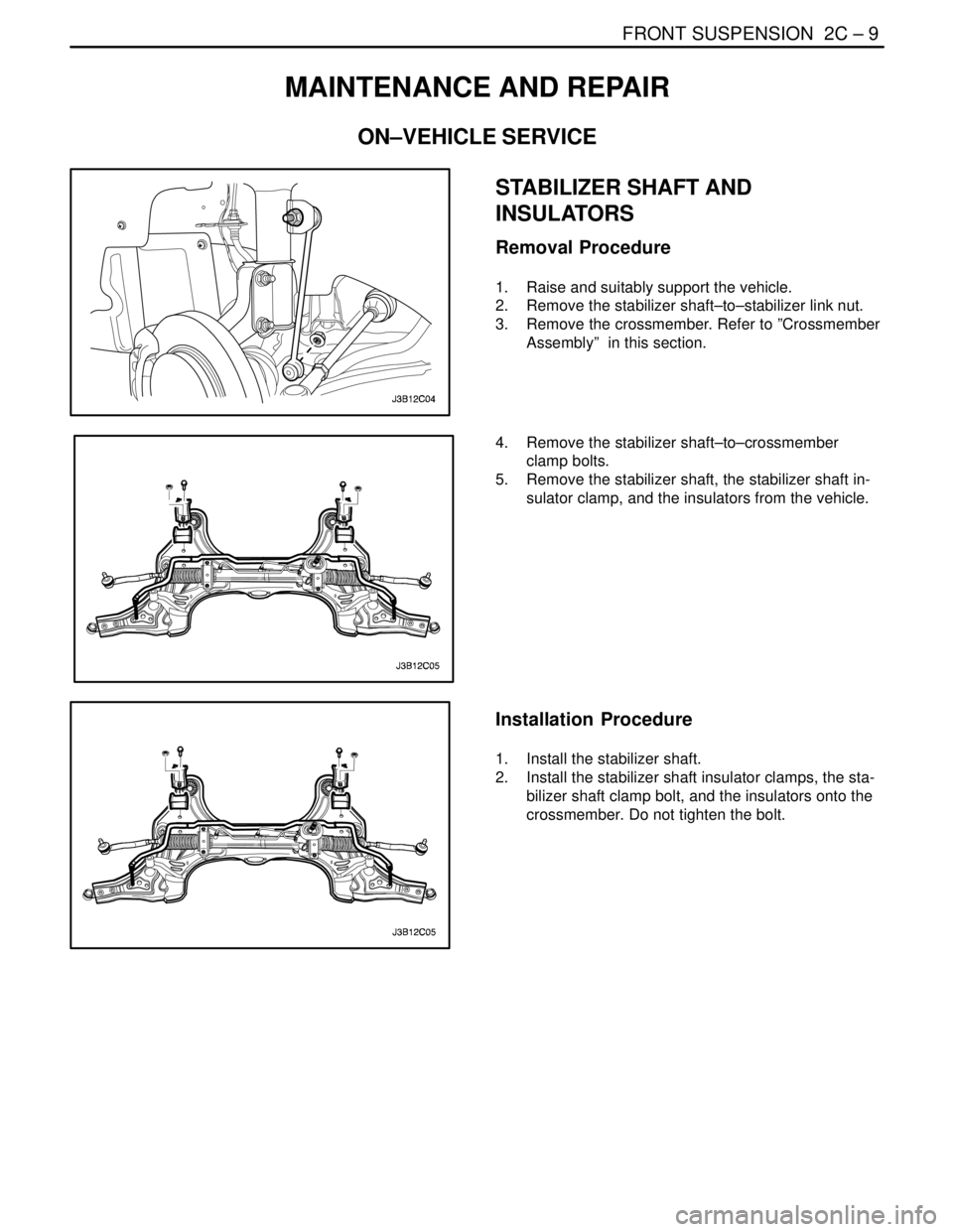

STABILIZER SHAFT AND

INSULATORS

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the stabilizer shaft–to–stabilizer link nut.

3. Remove the crossmember. Refer to ”Crossmember

Assembly” in this section.

4. Remove the stabilizer shaft–to–crossmember

clamp bolts.

5. Remove the stabilizer shaft, the stabilizer shaft in-

sulator clamp, and the insulators from the vehicle.

Installation Procedure

1. Install the stabilizer shaft.

2. Install the stabilizer shaft insulator clamps, the sta-

bilizer shaft clamp bolt, and the insulators onto the

crossmember. Do not tighten the bolt.

Page 927 of 2643

2C – 10IFRONT SUSPENSION

DAEWOO V–121 BL4

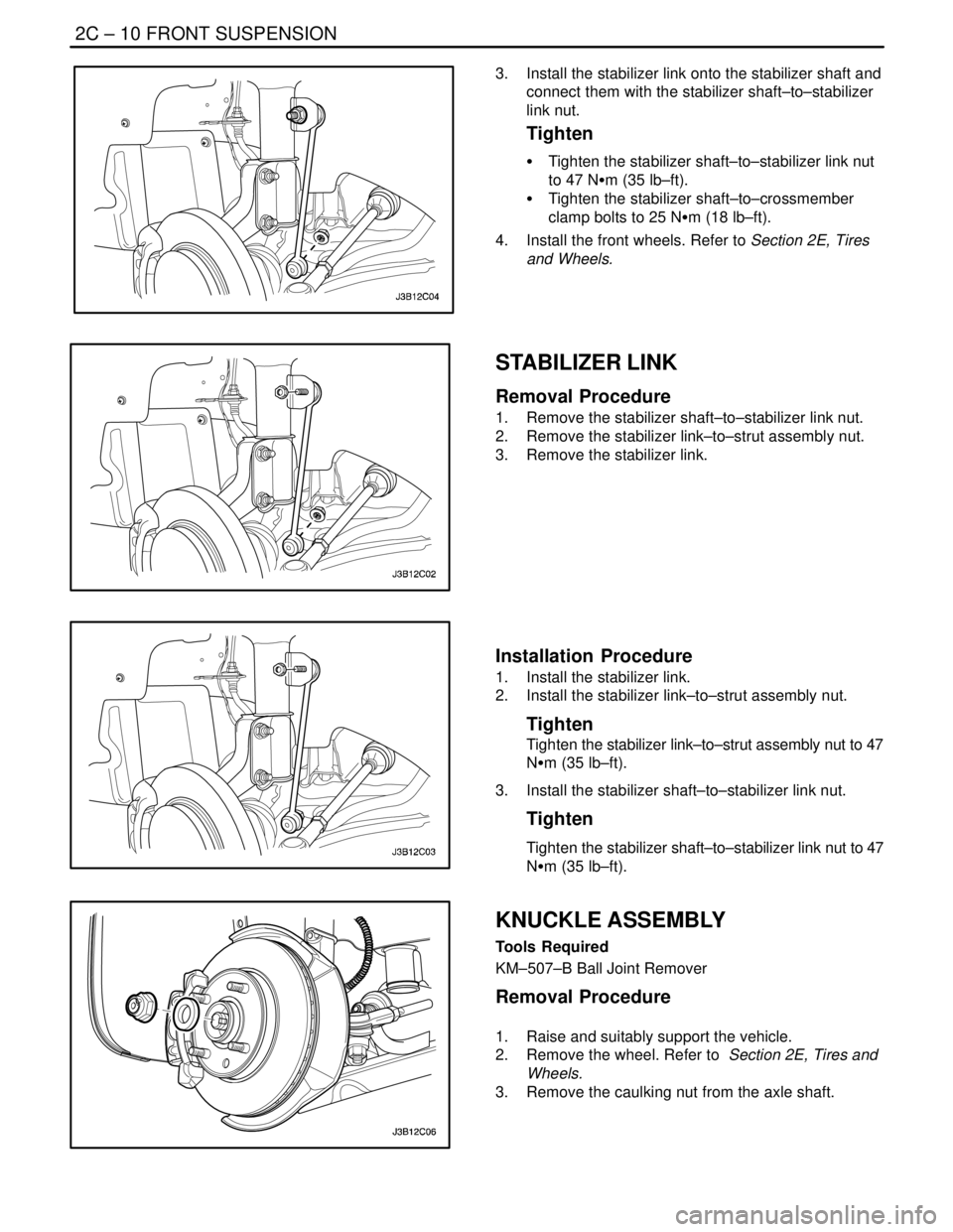

3. Install the stabilizer link onto the stabilizer shaft and

connect them with the stabilizer shaft–to–stabilizer

link nut.

Tighten

S Tighten the stabilizer shaft–to–stabilizer link nut

to 47 NSm (35 lb–ft).

S Tighten the stabilizer shaft–to–crossmember

clamp bolts to 25 NSm (18 lb–ft).

4. Install the front wheels. Refer to Section 2E, Tires

and Wheels.

STABILIZER LINK

Removal Procedure

1. Remove the stabilizer shaft–to–stabilizer link nut.

2. Remove the stabilizer link–to–strut assembly nut.

3. Remove the stabilizer link.

Installation Procedure

1. Install the stabilizer link.

2. Install the stabilizer link–to–strut assembly nut.

Tighten

Tighten the stabilizer link–to–strut assembly nut to 47

NSm (35 lb–ft).

3. Install the stabilizer shaft–to–stabilizer link nut.

Tighten

Tighten the stabilizer shaft–to–stabilizer link nut to 47

NSm (35 lb–ft).

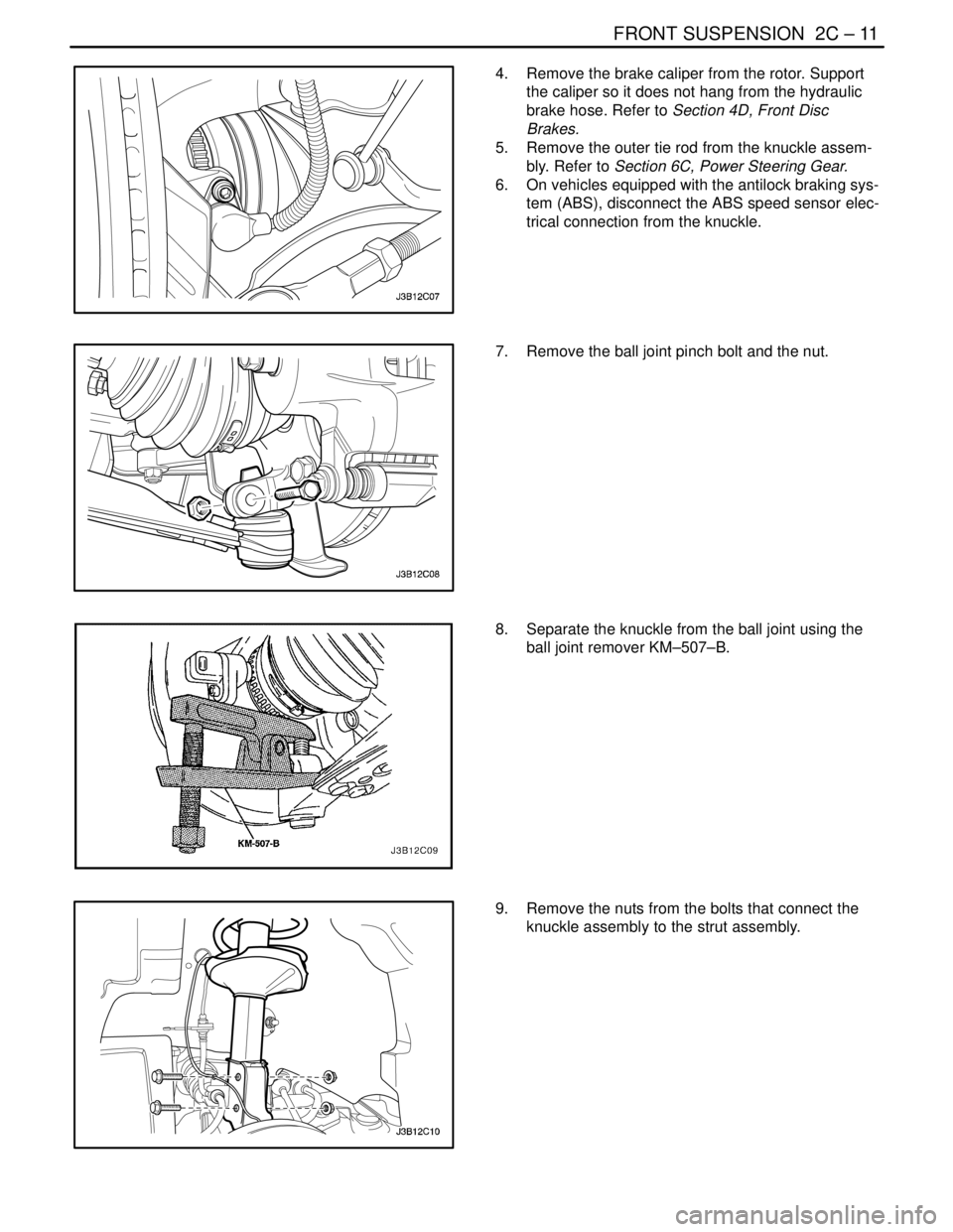

KNUCKLE ASSEMBLY

Tools Required

KM–507–B Ball Joint Remover

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. Remove the caulking nut from the axle shaft.

Page 928 of 2643

FRONT SUSPENSION 2C – 11

DAEWOO V–121 BL4

4. Remove the brake caliper from the rotor. Support

the caliper so it does not hang from the hydraulic

brake hose. Refer to Section 4D, Front Disc

Brakes.

5. Remove the outer tie rod from the knuckle assem-

bly. Refer to Section 6C, Power Steering Gear.

6. On vehicles equipped with the antilock braking sys-

tem (ABS), disconnect the ABS speed sensor elec-

trical connection from the knuckle.

7. Remove the ball joint pinch bolt and the nut.

8. Separate the knuckle from the ball joint using the

ball joint remover KM–507–B.

9. Remove the nuts from the bolts that connect the

knuckle assembly to the strut assembly.

Page 930 of 2643

FRONT SUSPENSION 2C – 13

DAEWOO V–121 BL4

7. Connect the outer tie rod to the knuckle assembly.

Refer to Section 6C, Power Steering Gear.

8. Install the brake caliper onto the rotor. Refer to

Section 4D, Front Disc Brakes.

9. Install the caulking nut onto the axle shaft.

Tighten

Tighten the drive axle–to–hub caulking nut to 150

NSm (111 lb–ft). Loosen the nut, then retighten it to

275 NSm (126 lb–ft).

10. Install the wheel. Refer to Section 2E, Tires and

Wheels.

11. Lower the vehicle.

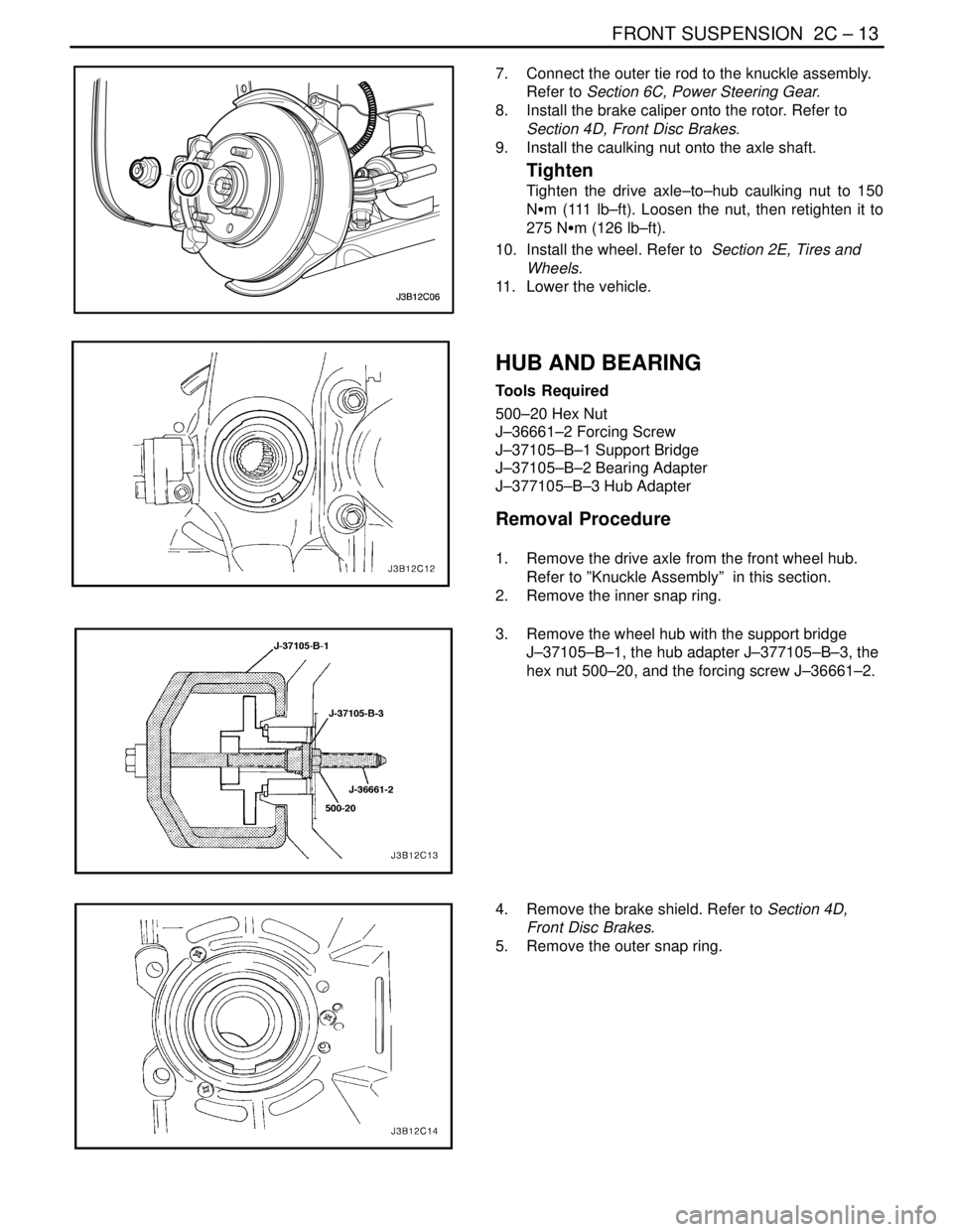

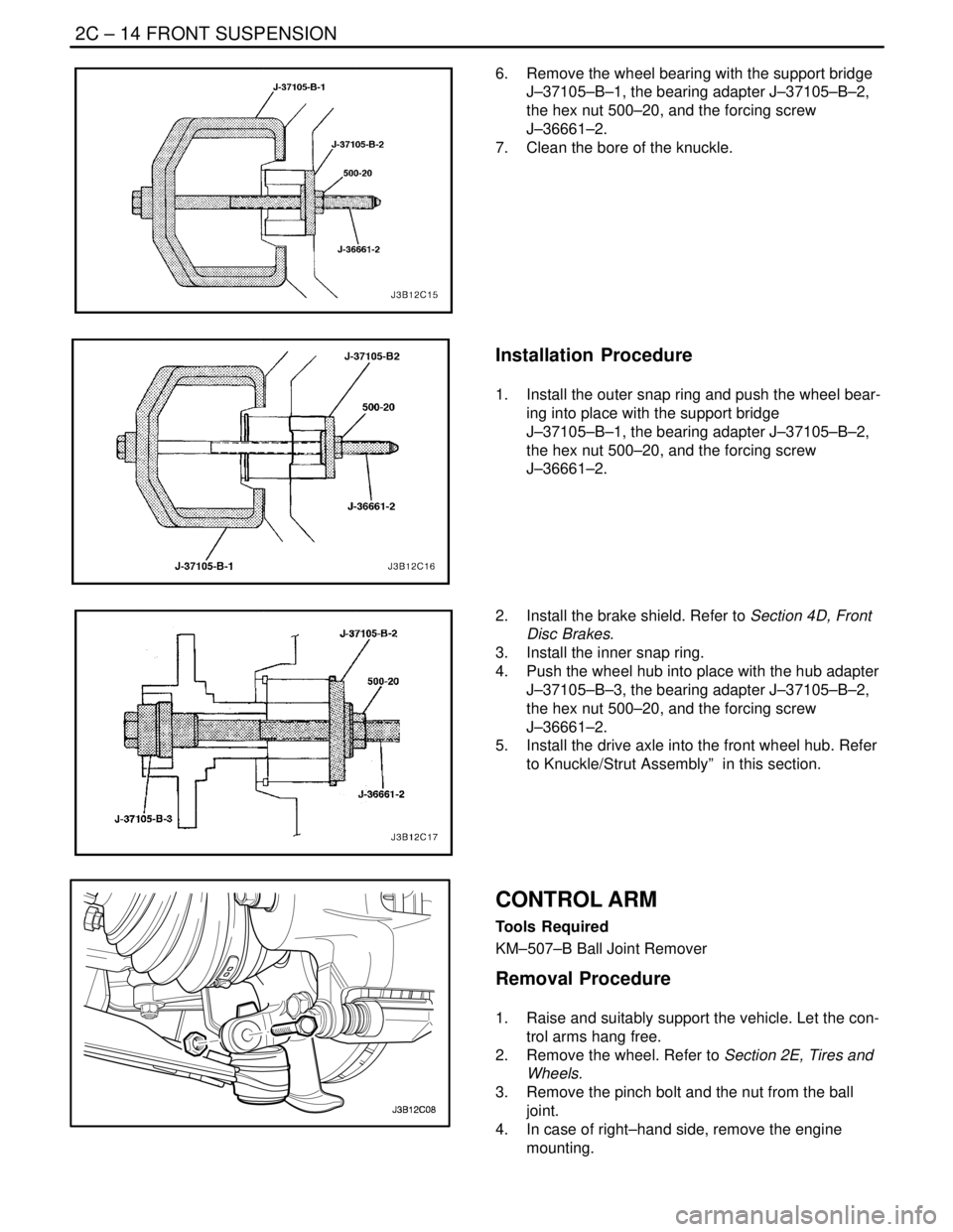

HUB AND BEARING

Tools Required

500–20 Hex Nut

J–36661–2 Forcing Screw

J–37105–B–1 Support Bridge

J–37105–B–2 Bearing Adapter

J–377105–B–3 Hub Adapter

Removal Procedure

1. Remove the drive axle from the front wheel hub.

Refer to ”Knuckle Assembly” in this section.

2. Remove the inner snap ring.

3. Remove the wheel hub with the support bridge

J–37105–B–1, the hub adapter J–377105–B–3, the

hex nut 500–20, and the forcing screw J–36661–2.

4. Remove the brake shield. Refer to Section 4D,

Front Disc Brakes.

5. Remove the outer snap ring.

Page 931 of 2643

2C – 14IFRONT SUSPENSION

DAEWOO V–121 BL4

6. Remove the wheel bearing with the support bridge

J–37105–B–1, the bearing adapter J–37105–B–2,

the hex nut 500–20, and the forcing screw

J–36661–2.

7. Clean the bore of the knuckle.

Installation Procedure

1. Install the outer snap ring and push the wheel bear-

ing into place with the support bridge

J–37105–B–1, the bearing adapter J–37105–B–2,

the hex nut 500–20, and the forcing screw

J–36661–2.

2. Install the brake shield. Refer to Section 4D, Front

Disc Brakes.

3. Install the inner snap ring.

4. Push the wheel hub into place with the hub adapter

J–37105–B–3, the bearing adapter J–37105–B–2,

the hex nut 500–20, and the forcing screw

J–36661–2.

5. Install the drive axle into the front wheel hub. Refer

to Knuckle/Strut Assembly” in this section.

CONTROL ARM

Tools Required

KM–507–B Ball Joint Remover

Removal Procedure

1. Raise and suitably support the vehicle. Let the con-

trol arms hang free.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. Remove the pinch bolt and the nut from the ball

joint.

4. In case of right–hand side, remove the engine

mounting.

Page 933 of 2643

2C – 16IFRONT SUSPENSION

DAEWOO V–121 BL4

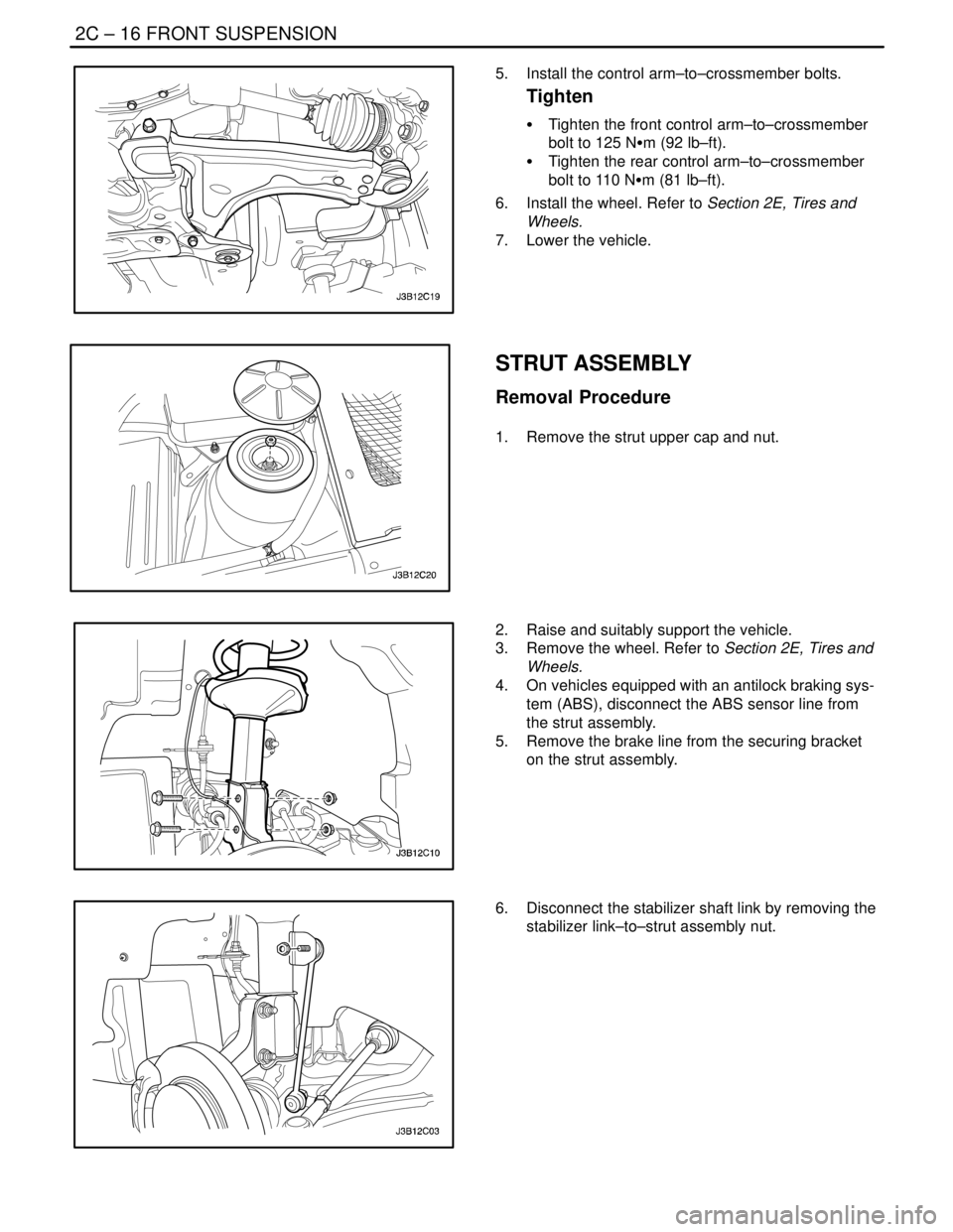

5. Install the control arm–to–crossmember bolts.

Tighten

S Tighten the front control arm–to–crossmember

bolt to 125 NSm (92 lb–ft).

S Tighten the rear control arm–to–crossmember

bolt to 110 NSm (81 lb–ft).

6. Install the wheel. Refer to Section 2E, Tires and

Wheels.

7. Lower the vehicle.

STRUT ASSEMBLY

Removal Procedure

1. Remove the strut upper cap and nut.

2. Raise and suitably support the vehicle.

3. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

4. On vehicles equipped with an antilock braking sys-

tem (ABS), disconnect the ABS sensor line from

the strut assembly.

5. Remove the brake line from the securing bracket

on the strut assembly.

6. Disconnect the stabilizer shaft link by removing the

stabilizer link–to–strut assembly nut.