engine electrical DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1554 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 205

DAEWOO V–121 BL4

7. Lower the vehicle.

8. Connect the transaxle wiring harness and the PNP

switch electrical connector.

9. Refill the transaxle fluid. Refer to ”Transaxle Fluid

Level Checking Procedure” in this section.

10. Connect the negative battery cable.

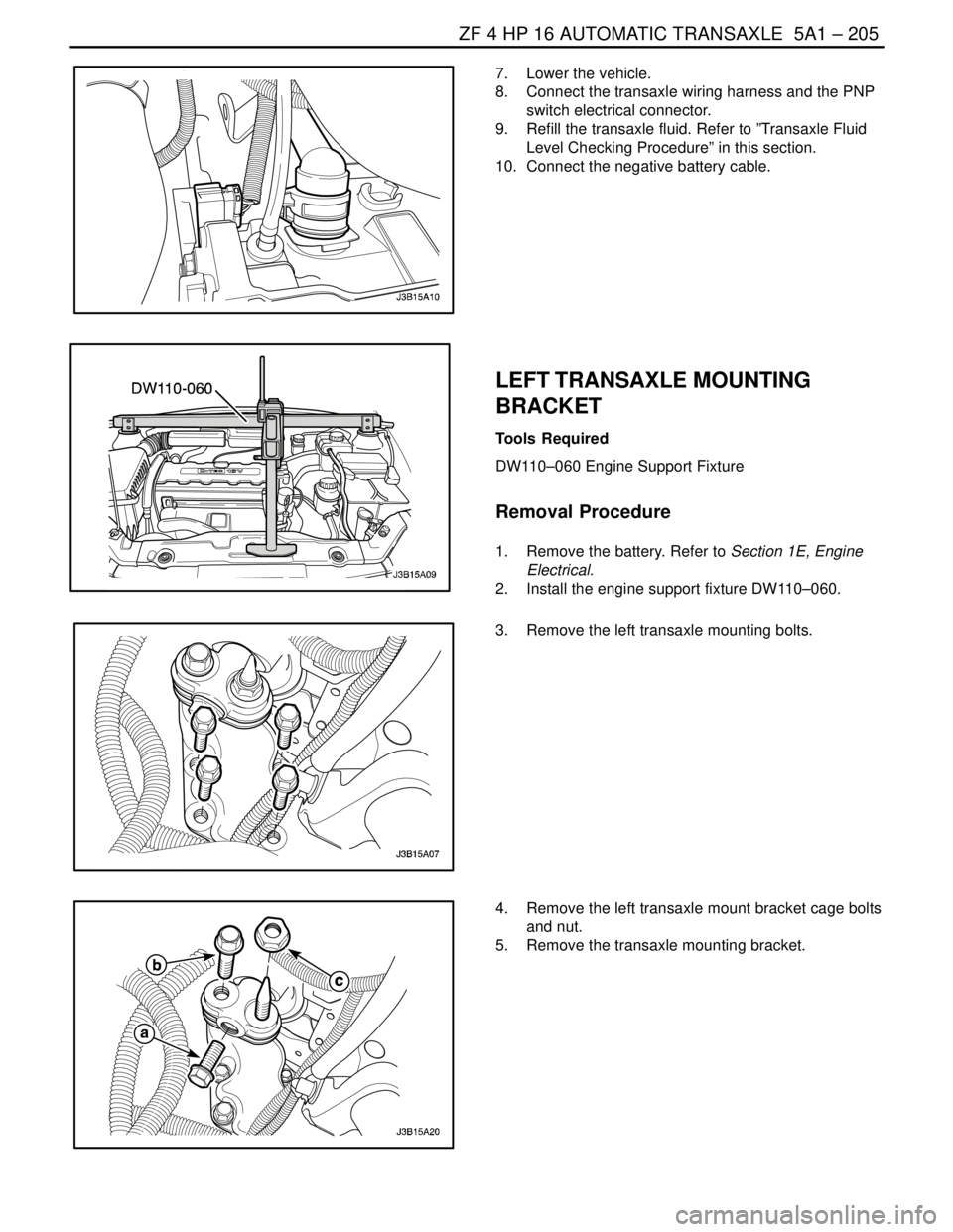

LEFT TRANSAXLE MOUNTING

BRACKET

Tools Required

DW110–060 Engine Support Fixture

Removal Procedure

1. Remove the battery. Refer to Section 1E, Engine

Electrical.

2. Install the engine support fixture DW110–060.

3. Remove the left transaxle mounting bolts.

4. Remove the left transaxle mount bracket cage bolts

and nut.

5. Remove the transaxle mounting bracket.

Page 1555 of 2643

5A1 – 206IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

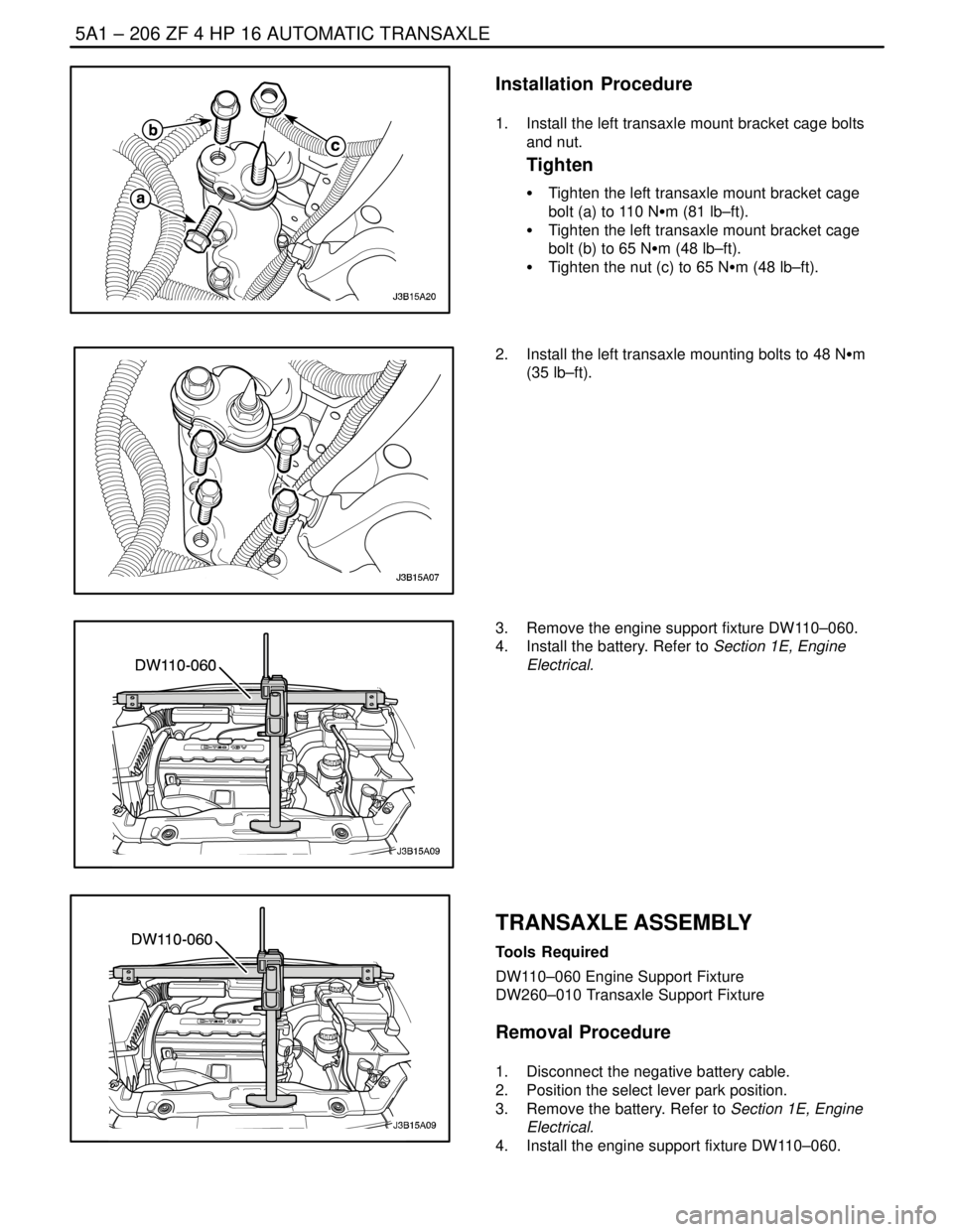

Installation Procedure

1. Install the left transaxle mount bracket cage bolts

and nut.

Tighten

S Tighten the left transaxle mount bracket cage

bolt (a) to 110 NSm (81 lb–ft).

S Tighten the left transaxle mount bracket cage

bolt (b) to 65 NSm (48 lb–ft).

S Tighten the nut (c) to 65 NSm (48 lb–ft).

2. Install the left transaxle mounting bolts to 48 NSm

(35 lb–ft).

3. Remove the engine support fixture DW110–060.

4. Install the battery. Refer to Section 1E, Engine

Electrical.

TRANSAXLE ASSEMBLY

Tools Required

DW110–060 Engine Support Fixture

DW260–010 Transaxle Support Fixture

Removal Procedure

1. Disconnect the negative battery cable.

2. Position the select lever park position.

3. Remove the battery. Refer to Section 1E, Engine

Electrical.

4. Install the engine support fixture DW110–060.

Page 1560 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 211

DAEWOO V–121 BL4

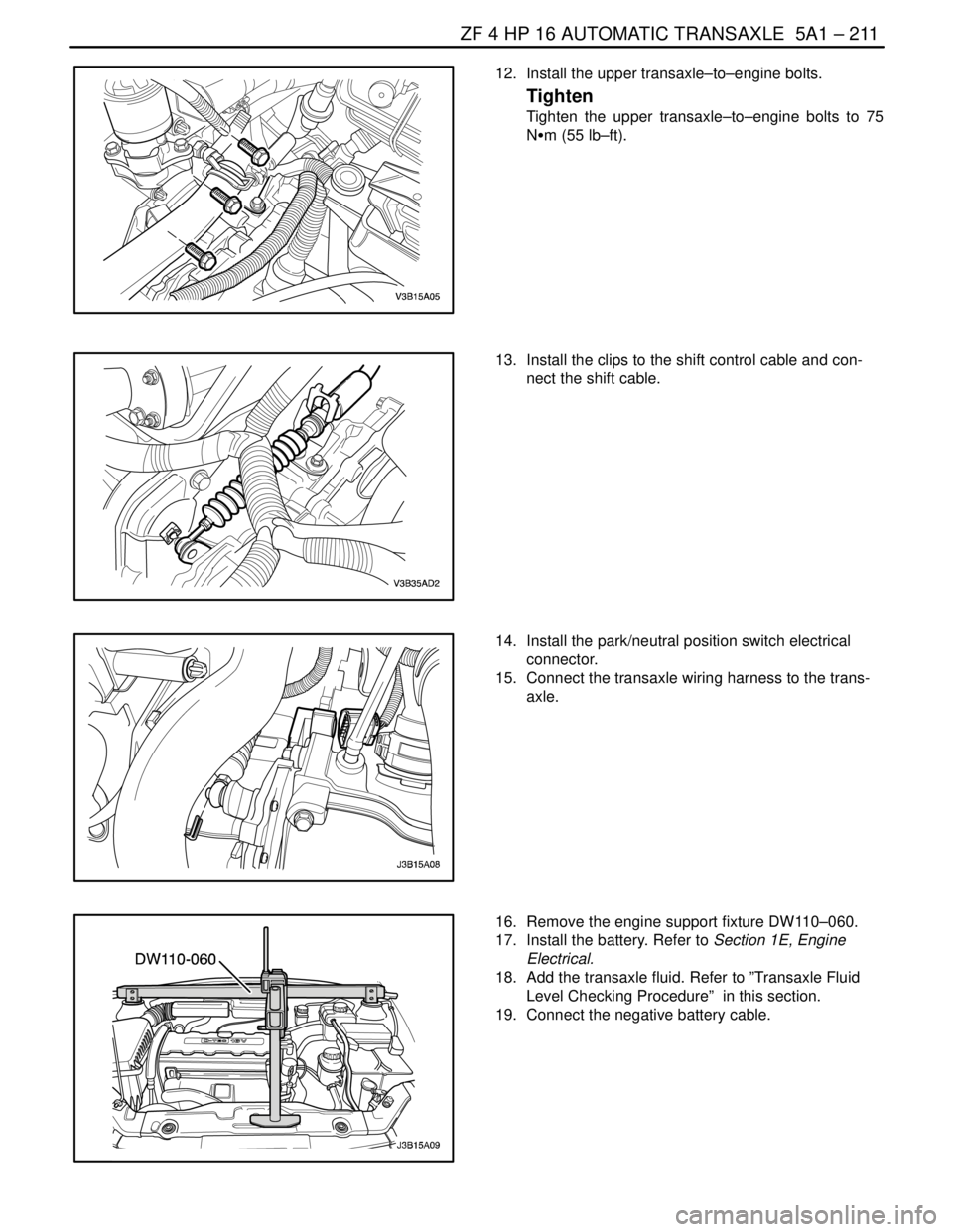

12. Install the upper transaxle–to–engine bolts.

Tighten

Tighten the upper transaxle–to–engine bolts to 75

NSm (55 lb–ft).

13. Install the clips to the shift control cable and con-

nect the shift cable.

14. Install the park/neutral position switch electrical

connector.

15. Connect the transaxle wiring harness to the trans-

axle.

16. Remove the engine support fixture DW110–060.

17. Install the battery. Refer to Section 1E, Engine

Electrical.

18. Add the transaxle fluid. Refer to ”Transaxle Fluid

Level Checking Procedure” in this section.

19. Connect the negative battery cable.

Page 1591 of 2643

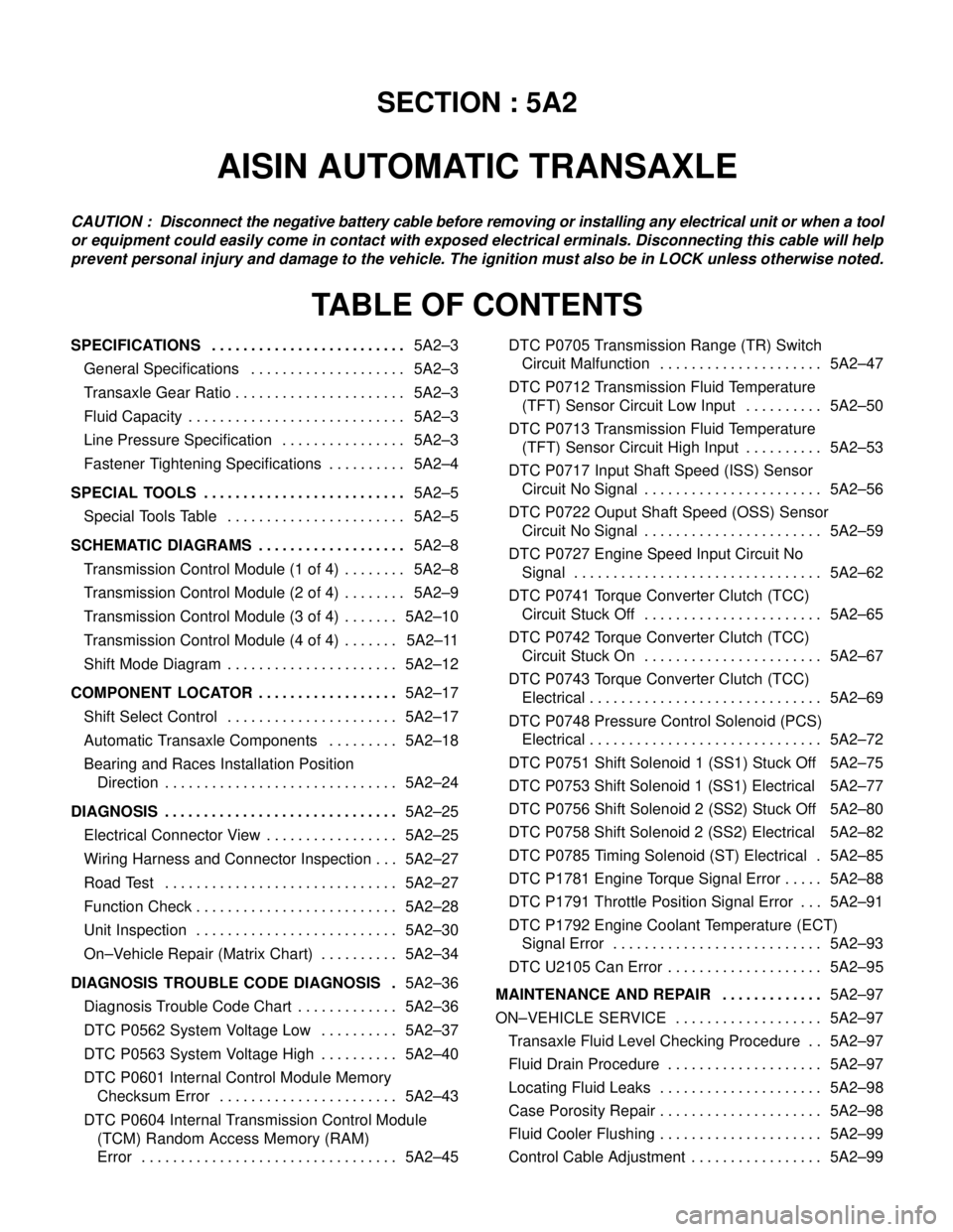

SECTION : 5A2

AISIN AUTOMATIC TRANSAXLE

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical erminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS5A2–3 . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 5A2–3. . . . . . . . . . . . . . . . . . . .

Transaxle Gear Ratio 5A2–3. . . . . . . . . . . . . . . . . . . . . .

Fluid Capacity 5A2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Pressure Specification 5A2–3. . . . . . . . . . . . . . . .

Fastener Tightening Specifications 5A2–4. . . . . . . . . .

SPECIAL TOOLS5A2–5 . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 5A2–5. . . . . . . . . . . . . . . . . . . . . . .

SCHEMATIC DIAGRAMS5A2–8 . . . . . . . . . . . . . . . . . . .

Transmission Control Module (1 of 4) 5A2–8. . . . . . . .

Transmission Control Module (2 of 4) 5A2–9. . . . . . . .

Transmission Control Module (3 of 4) 5A2–10. . . . . . .

Transmission Control Module (4 of 4) 5A2–11. . . . . . .

Shift Mode Diagram 5A2–12. . . . . . . . . . . . . . . . . . . . . .

COMPONENT LOCATOR5A2–17 . . . . . . . . . . . . . . . . . .

Shift Select Control 5A2–17. . . . . . . . . . . . . . . . . . . . . .

Automatic Transaxle Components 5A2–18. . . . . . . . .

Bearing and Races Installation Position

Direction 5A2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS5A2–25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Connector View 5A2–25. . . . . . . . . . . . . . . . .

Wiring Harness and Connector Inspection 5A2–27. . .

Road Test 5A2–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function Check 5A2–28. . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Inspection 5A2–30. . . . . . . . . . . . . . . . . . . . . . . . . .

On–Vehicle Repair (Matrix Chart) 5A2–34. . . . . . . . . .

DIAGNOSIS TROUBLE CODE DIAGNOSIS5A2–36 .

Diagnosis Trouble Code Chart 5A2–36. . . . . . . . . . . . .

DTC P0562 System Voltage Low 5A2–37. . . . . . . . . .

DTC P0563 System Voltage High 5A2–40. . . . . . . . . .

DTC P0601 Internal Control Module Memory

Checksum Error 5A2–43. . . . . . . . . . . . . . . . . . . . . . .

DTC P0604 Internal Transmission Control Module

(TCM) Random Access Memory (RAM)

Error 5A2–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DTC P0705 Transmission Range (TR) Switch

Circuit Malfunction 5A2–47. . . . . . . . . . . . . . . . . . . . .

DTC P0712 Transmission Fluid Temperature

(TFT) Sensor Circuit Low Input 5A2–50. . . . . . . . . .

DTC P0713 Transmission Fluid Temperature

(TFT) Sensor Circuit High Input 5A2–53. . . . . . . . . .

DTC P0717 Input Shaft Speed (ISS) Sensor

Circuit No Signal 5A2–56. . . . . . . . . . . . . . . . . . . . . . .

DTC P0722 Ouput Shaft Speed (OSS) Sensor

Circuit No Signal 5A2–59. . . . . . . . . . . . . . . . . . . . . . .

DTC P0727 Engine Speed Input Circuit No

Signal 5A2–62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0741 Torque Converter Clutch (TCC)

Circuit Stuck Off 5A2–65. . . . . . . . . . . . . . . . . . . . . . .

DTC P0742 Torque Converter Clutch (TCC)

Circuit Stuck On 5A2–67. . . . . . . . . . . . . . . . . . . . . . .

DTC P0743 Torque Converter Clutch (TCC)

Electrical 5A2–69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0748 Pressure Control Solenoid (PCS)

Electrical 5A2–72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0751 Shift Solenoid 1 (SS1) Stuck Off 5A2–75

DTC P0753 Shift Solenoid 1 (SS1) Electrical 5A2–77

DTC P0756 Shift Solenoid 2 (SS2) Stuck Off 5A2–80

DTC P0758 Shift Solenoid 2 (SS2) Electrical 5A2–82

DTC P0785 Timing Solenoid (ST) Electrical 5A2–85.

DTC P1781 Engine Torque Signal Error 5A2–88. . . . .

DTC P1791 Throttle Position Signal Error 5A2–91. . .

DTC P1792 Engine Coolant Temperature (ECT)

Signal Error 5A2–93. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC U2105 Can Error 5A2–95. . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR5A2–97 . . . . . . . . . . . . .

ON–VEHICLE SERVICE 5A2–97. . . . . . . . . . . . . . . . . . .

Transaxle Fluid Level Checking Procedure 5A2–97. .

Fluid Drain Procedure 5A2–97. . . . . . . . . . . . . . . . . . . .

Locating Fluid Leaks 5A2–98. . . . . . . . . . . . . . . . . . . . .

Case Porosity Repair 5A2–98. . . . . . . . . . . . . . . . . . . . .

Fluid Cooler Flushing 5A2–99. . . . . . . . . . . . . . . . . . . . .

Control Cable Adjustment 5A2–99. . . . . . . . . . . . . . . . .

Page 1626 of 2643

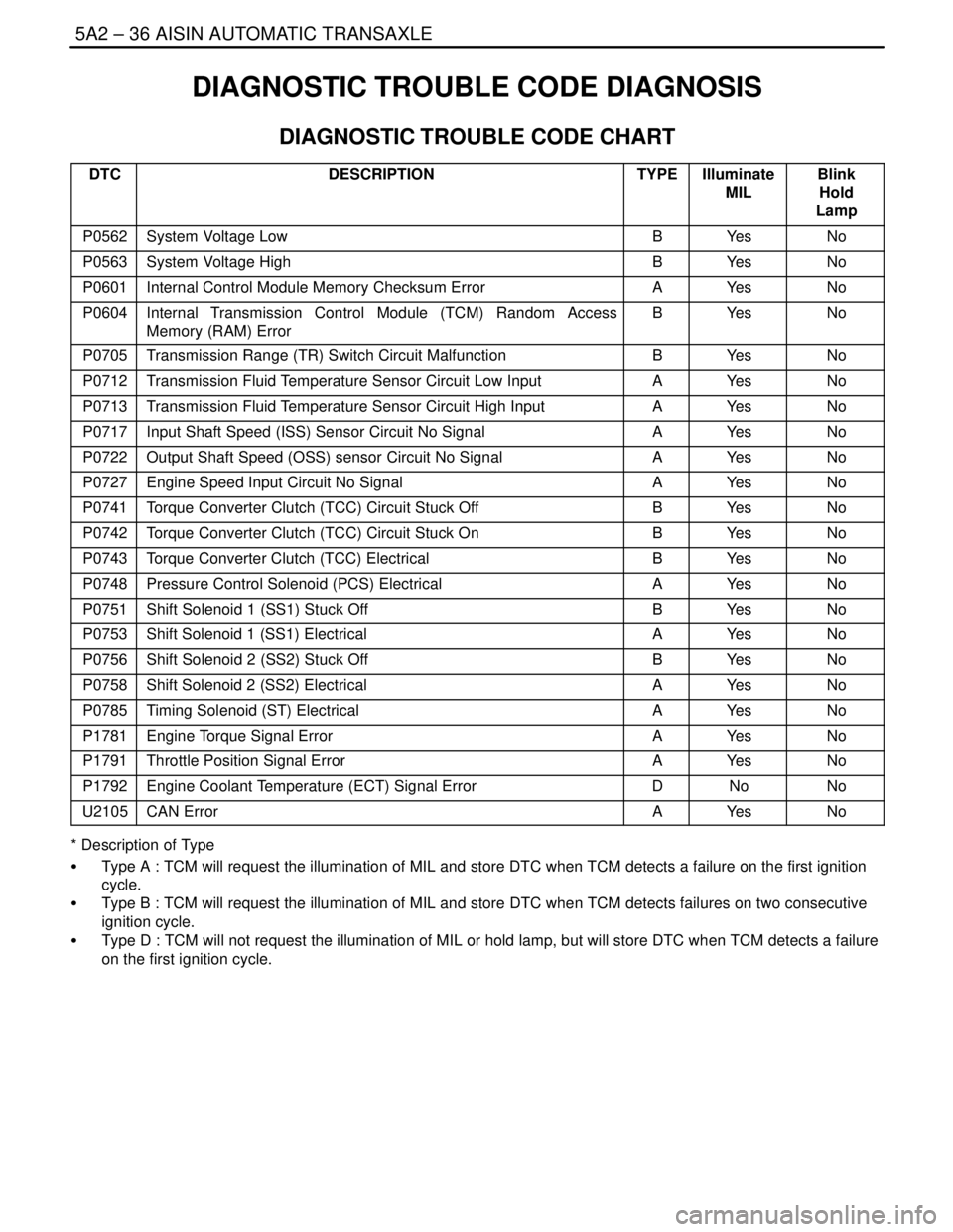

5A2 – 36IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE DIAGNOSIS

DIAGNOSTIC TROUBLE CODE CHART

DTCDESCRIPTIONTYPEIlluminate

MILBlink

Hold

Lamp

P0562System Voltage LowBYe sNo

P0563System Voltage HighBYe sNo

P0601Internal Control Module Memory Checksum ErrorAYe sNo

P0604Internal Transmission Control Module (TCM) Random Access

Memory (RAM) ErrorBYe sNo

P0705Transmission Range (TR) Switch Circuit MalfunctionBYe sNo

P0712Transmission Fluid Temperature Sensor Circuit Low InputAYe sNo

P0713Transmission Fluid Temperature Sensor Circuit High InputAYe sNo

P0717Input Shaft Speed (ISS) Sensor Circuit No SignalAYe sNo

P0722Output Shaft Speed (OSS) sensor Circuit No SignalAYe sNo

P0727Engine Speed Input Circuit No SignalAYe sNo

P0741Torque Converter Clutch (TCC) Circuit Stuck OffBYe sNo

P0742Torque Converter Clutch (TCC) Circuit Stuck OnBYe sNo

P0743Torque Converter Clutch (TCC) ElectricalBYe sNo

P0748Pressure Control Solenoid (PCS) ElectricalAYe sNo

P0751Shift Solenoid 1 (SS1) Stuck OffBYe sNo

P0753Shift Solenoid 1 (SS1) ElectricalAYe sNo

P0756Shift Solenoid 2 (SS2) Stuck OffBYe sNo

P0758Shift Solenoid 2 (SS2) ElectricalAYe sNo

P0785Timing Solenoid (ST) ElectricalAYe sNo

P1781Engine Torque Signal ErrorAYe sNo

P1791Throttle Position Signal ErrorAYe sNo

P1792Engine Coolant Temperature (ECT) Signal ErrorDNoNo

U2105CAN ErrorAYe sNo

* Description of Type

S Type A : TCM will request the illumination of MIL and store DTC when TCM detects a failure on the first ignition

cycle.

S Type B : TCM will request the illumination of MIL and store DTC when TCM detects failures on two consecutive

ignition cycle.

S Type D : TCM will not request the illumination of MIL or hold lamp, but will store DTC when TCM detects a failure

on the first ignition cycle.

Page 1655 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 65

DAEWOO V–121 BL4

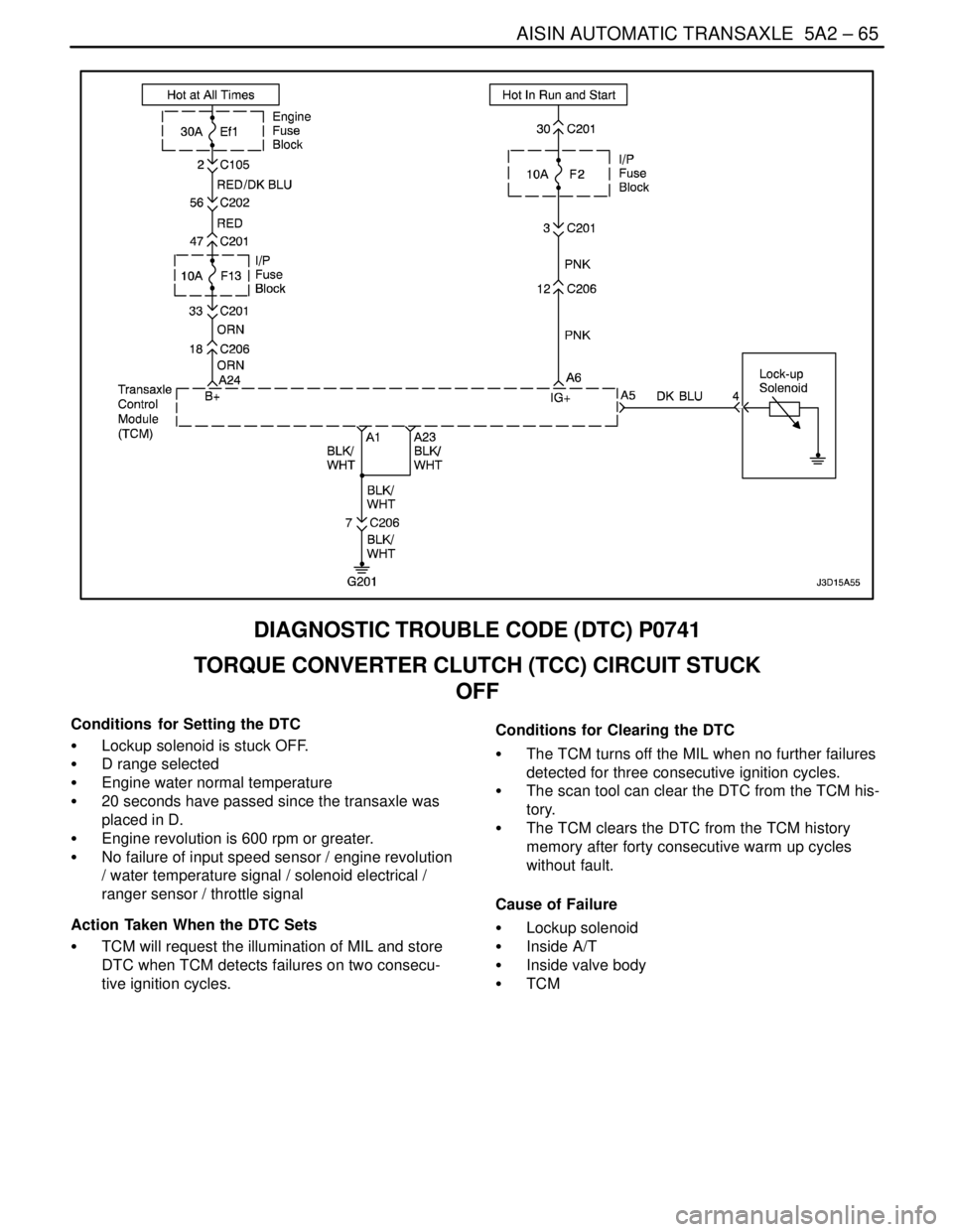

DIAGNOSTIC TROUBLE CODE (DTC) P0741

TORQUE CONVERTER CLUTCH (TCC) CIRCUIT STUCK

OFF

Conditions for Setting the DTC

S Lockup solenoid is stuck OFF.

S D range selected

S Engine water normal temperature

S 20 seconds have passed since the transaxle was

placed in D.

S Engine revolution is 600 rpm or greater.

S No failure of input speed sensor / engine revolution

/ water temperature signal / solenoid electrical /

ranger sensor / throttle signal

Action Taken When the DTC Sets

S TCM will request the illumination of MIL and store

DTC when TCM detects failures on two consecu-

tive ignition cycles.Conditions for Clearing the DTC

S The TCM turns off the MIL when no further failures

detected for three consecutive ignition cycles.

S The scan tool can clear the DTC from the TCM his-

tory.

S The TCM clears the DTC from the TCM history

memory after forty consecutive warm up cycles

without fault.

Cause of Failure

S Lockup solenoid

S Inside A/T

S Inside valve body

S TCM

Page 1657 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 67

DAEWOO V–121 BL4

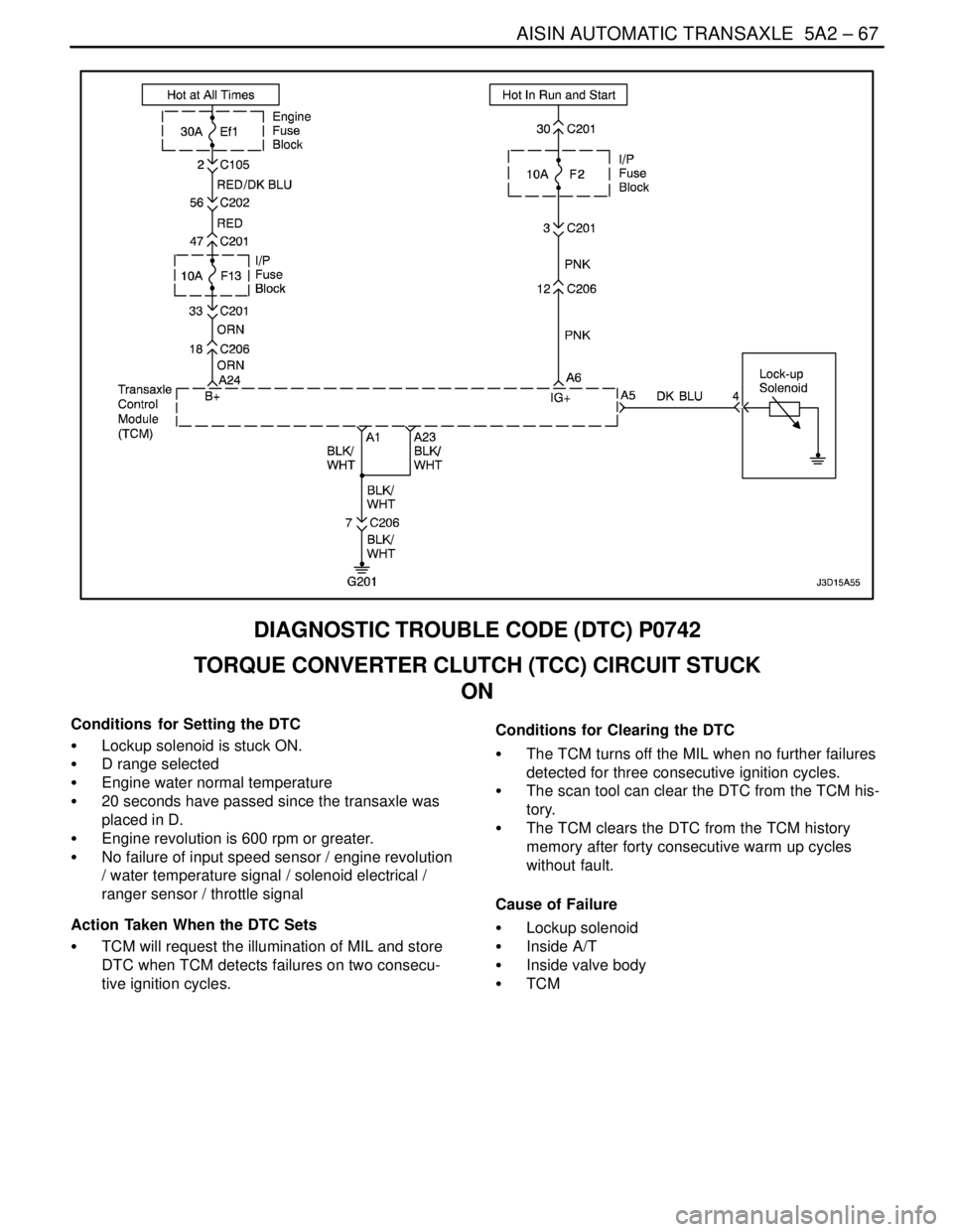

DIAGNOSTIC TROUBLE CODE (DTC) P0742

TORQUE CONVERTER CLUTCH (TCC) CIRCUIT STUCK

ON

Conditions for Setting the DTC

S Lockup solenoid is stuck ON.

S D range selected

S Engine water normal temperature

S 20 seconds have passed since the transaxle was

placed in D.

S Engine revolution is 600 rpm or greater.

S No failure of input speed sensor / engine revolution

/ water temperature signal / solenoid electrical /

ranger sensor / throttle signal

Action Taken When the DTC Sets

S TCM will request the illumination of MIL and store

DTC when TCM detects failures on two consecu-

tive ignition cycles.Conditions for Clearing the DTC

S The TCM turns off the MIL when no further failures

detected for three consecutive ignition cycles.

S The scan tool can clear the DTC from the TCM his-

tory.

S The TCM clears the DTC from the TCM history

memory after forty consecutive warm up cycles

without fault.

Cause of Failure

S Lockup solenoid

S Inside A/T

S Inside valve body

S TCM

Page 1660 of 2643

5A2 – 70IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

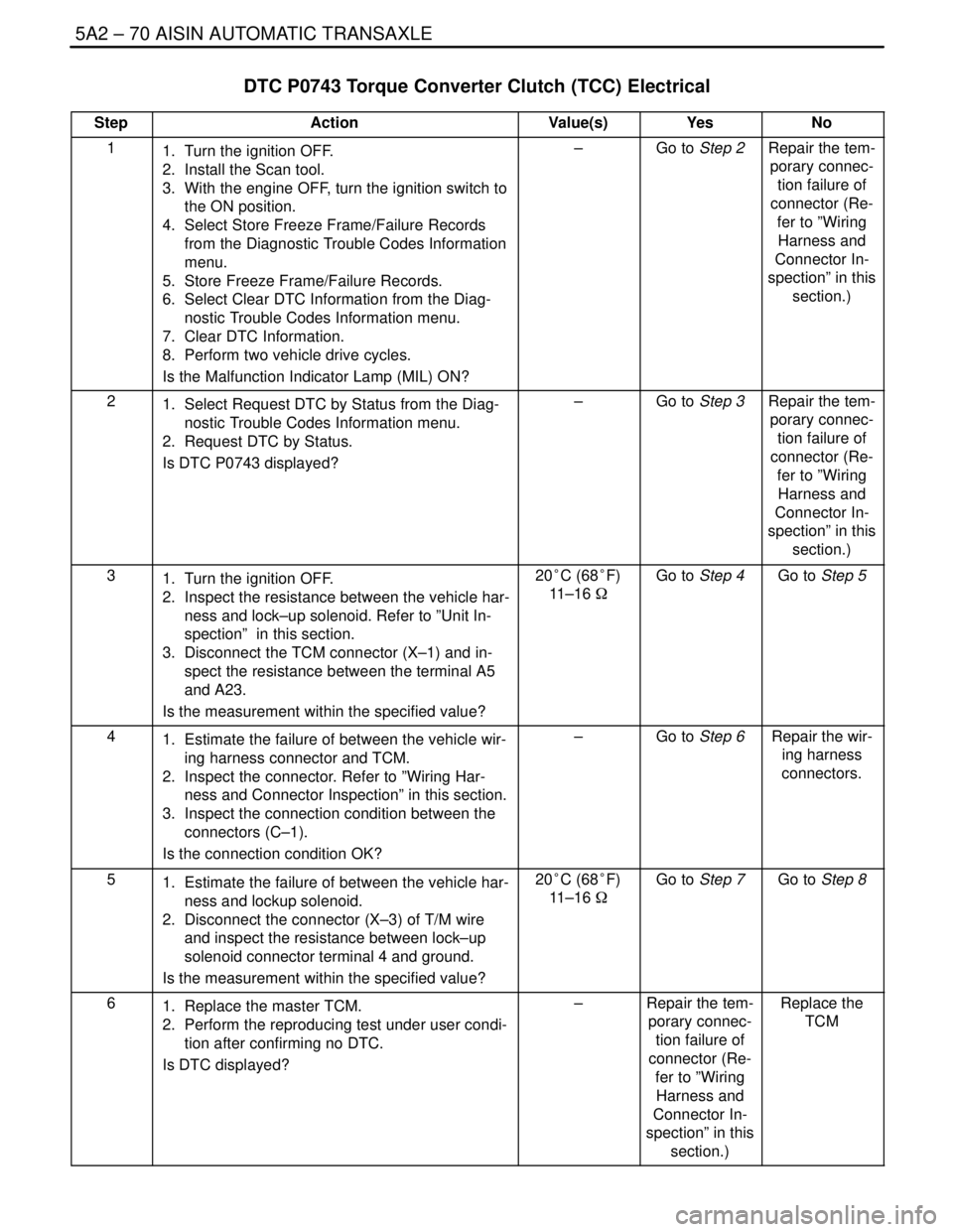

DTC P0743 Torque Converter Clutch (TCC) Electrical

StepActionValue(s)YesNo

11. Turn the ignition OFF.

2. Install the Scan tool.

3. With the engine OFF, turn the ignition switch to

the ON position.

4. Select Store Freeze Frame/Failure Records

from the Diagnostic Trouble Codes Information

menu.

5. Store Freeze Frame/Failure Records.

6. Select Clear DTC Information from the Diag-

nostic Trouble Codes Information menu.

7. Clear DTC Information.

8. Perform two vehicle drive cycles.

Is the Malfunction Indicator Lamp (MIL) ON?–Go to Step 2Repair the tem-

porary connec-

tion failure of

connector (Re-

fer to ”Wiring

Harness and

Connector In-

spection” in this

section.)

21. Select Request DTC by Status from the Diag-

nostic Trouble Codes Information menu.

2. Request DTC by Status.

Is DTC P0743 displayed?–Go to Step 3Repair the tem-

porary connec-

tion failure of

connector (Re-

fer to ”Wiring

Harness and

Connector In-

spection” in this

section.)

31. Turn the ignition OFF.

2. Inspect the resistance between the vehicle har-

ness and lock–up solenoid. Refer to ”Unit In-

spection” in this section.

3. Disconnect the TCM connector (X–1) and in-

spect the resistance between the terminal A5

and A23.

Is the measurement within the specified value?20°C (68°F)

11–16 WGo to Step 4Go to Step 5

41. Estimate the failure of between the vehicle wir-

ing harness connector and TCM.

2. Inspect the connector. Refer to ”Wiring Har-

ness and Connector Inspection” in this section.

3. Inspect the connection condition between the

connectors (C–1).

Is the connection condition OK?–Go to Step 6Repair the wir-

ing harness

connectors.

51. Estimate the failure of between the vehicle har-

ness and lockup solenoid.

2. Disconnect the connector (X–3) of T/M wire

and inspect the resistance between lock–up

solenoid connector terminal 4 and ground.

Is the measurement within the specified value?20°C (68°F)

11–16 WGo to Step 7Go to Step 8

61. Replace the master TCM.

2. Perform the reproducing test under user condi-

tion after confirming no DTC.

Is DTC displayed?–Repair the tem-

porary connec-

tion failure of

connector (Re-

fer to ”Wiring

Harness and

Connector In-

spection” in this

section.)Replace the

TCM

Page 1662 of 2643

5A2 – 72IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

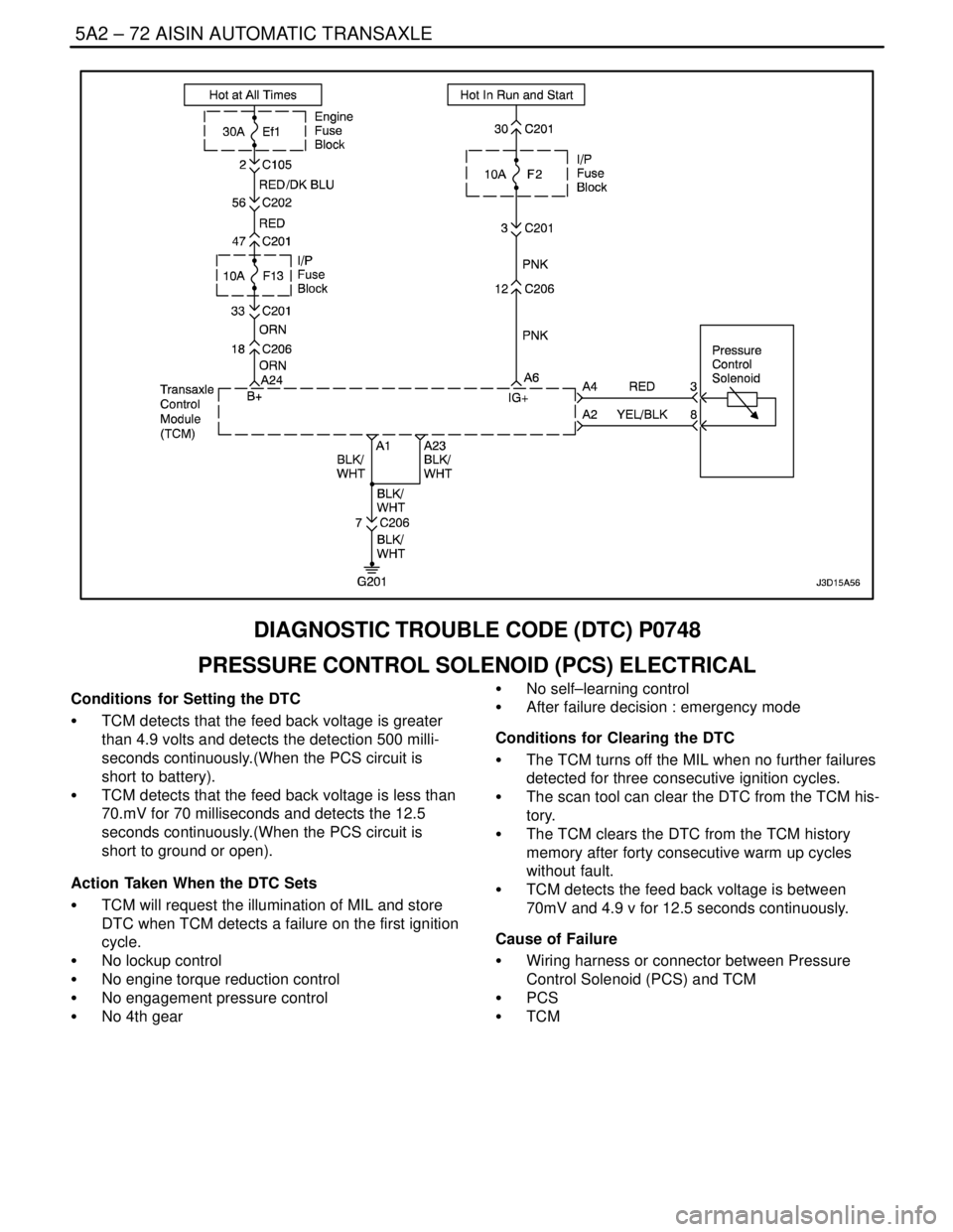

DIAGNOSTIC TROUBLE CODE (DTC) P0748

PRESSURE CONTROL SOLENOID (PCS) ELECTRICAL

Conditions for Setting the DTC

S TCM detects that the feed back voltage is greater

than 4.9 volts and detects the detection 500 milli-

seconds continuously.(When the PCS circuit is

short to battery).

S TCM detects that the feed back voltage is less than

70.mV for 70 milliseconds and detects the 12.5

seconds continuously.(When the PCS circuit is

short to ground or open).

Action Taken When the DTC Sets

S TCM will request the illumination of MIL and store

DTC when TCM detects a failure on the first ignition

cycle.

S No lockup control

S No engine torque reduction control

S No engagement pressure control

S No 4th gearS No self–learning control

S After failure decision : emergency mode

Conditions for Clearing the DTC

S The TCM turns off the MIL when no further failures

detected for three consecutive ignition cycles.

S The scan tool can clear the DTC from the TCM his-

tory.

S The TCM clears the DTC from the TCM history

memory after forty consecutive warm up cycles

without fault.

S TCM detects the feed back voltage is between

70mV and 4.9 v for 12.5 seconds continuously.

Cause of Failure

S Wiring harness or connector between Pressure

Control Solenoid (PCS) and TCM

S PCS

S TCM

Page 1663 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 73

DAEWOO V–121 BL4

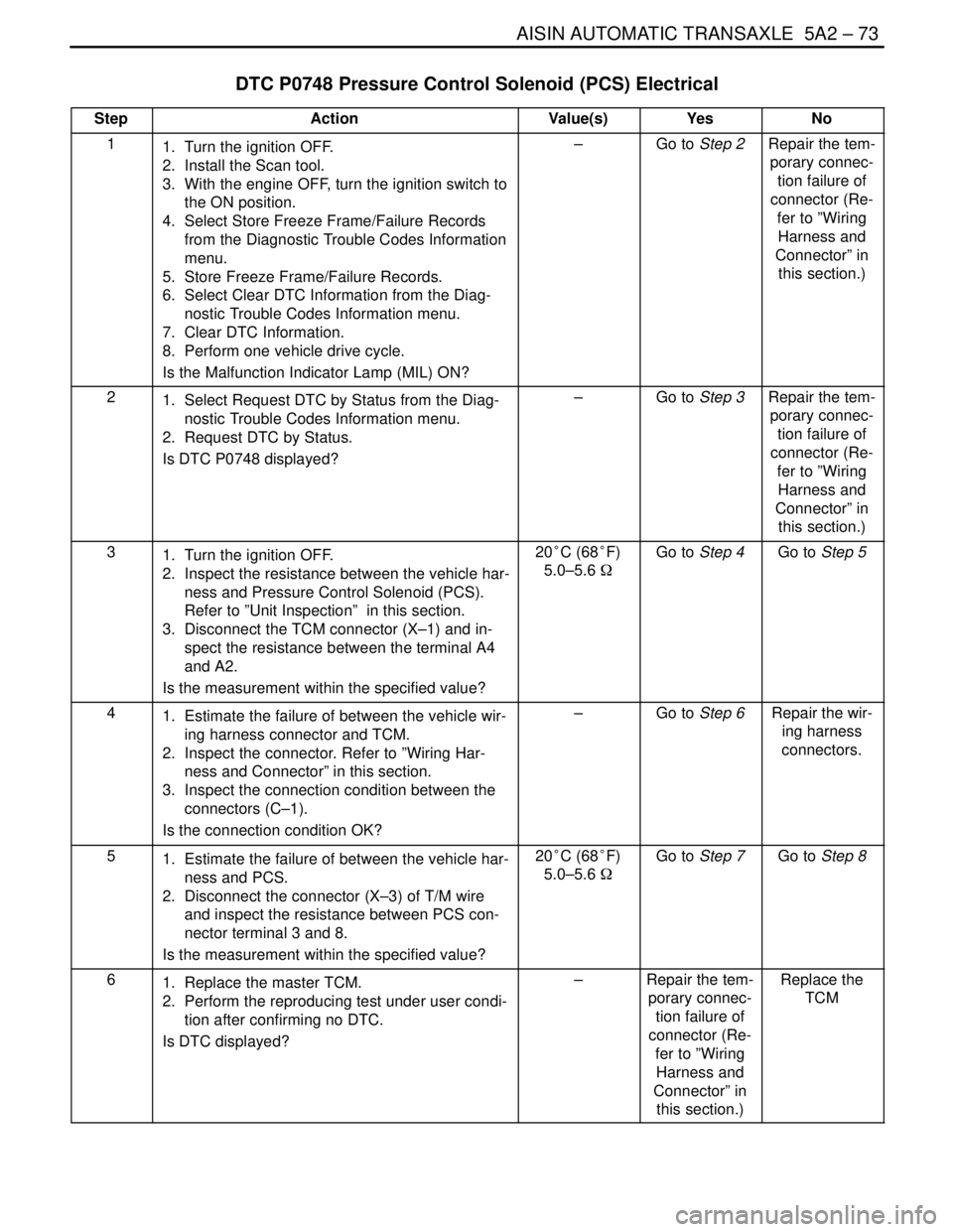

DTC P0748 Pressure Control Solenoid (PCS) Electrical

StepActionValue(s)YesNo

11. Turn the ignition OFF.

2. Install the Scan tool.

3. With the engine OFF, turn the ignition switch to

the ON position.

4. Select Store Freeze Frame/Failure Records

from the Diagnostic Trouble Codes Information

menu.

5. Store Freeze Frame/Failure Records.

6. Select Clear DTC Information from the Diag-

nostic Trouble Codes Information menu.

7. Clear DTC Information.

8. Perform one vehicle drive cycle.

Is the Malfunction Indicator Lamp (MIL) ON?–Go to Step 2Repair the tem-

porary connec-

tion failure of

connector (Re-

fer to ”Wiring

Harness and

Connector” in

this section.)

21. Select Request DTC by Status from the Diag-

nostic Trouble Codes Information menu.

2. Request DTC by Status.

Is DTC P0748 displayed?–Go to Step 3Repair the tem-

porary connec-

tion failure of

connector (Re-

fer to ”Wiring

Harness and

Connector” in

this section.)

31. Turn the ignition OFF.

2. Inspect the resistance between the vehicle har-

ness and Pressure Control Solenoid (PCS).

Refer to ”Unit Inspection” in this section.

3. Disconnect the TCM connector (X–1) and in-

spect the resistance between the terminal A4

and A2.

Is the measurement within the specified value?20°C (68°F)

5.0–5.6 WGo to Step 4Go to Step 5

41. Estimate the failure of between the vehicle wir-

ing harness connector and TCM.

2. Inspect the connector. Refer to ”Wiring Har-

ness and Connector” in this section.

3. Inspect the connection condition between the

connectors (C–1).

Is the connection condition OK?–Go to Step 6Repair the wir-

ing harness

connectors.

51. Estimate the failure of between the vehicle har-

ness and PCS.

2. Disconnect the connector (X–3) of T/M wire

and inspect the resistance between PCS con-

nector terminal 3 and 8.

Is the measurement within the specified value?20°C (68°F)

5.0–5.6 WGo to Step 7Go to Step 8

61. Replace the master TCM.

2. Perform the reproducing test under user condi-

tion after confirming no DTC.

Is DTC displayed?–Repair the tem-

porary connec-

tion failure of

connector (Re-

fer to ”Wiring

Harness and

Connector” in

this section.)Replace the

TCM