Map DAEWOO LACETTI 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 363 of 2643

ENGINE CONTROLS 1F – 117

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0108

MANIFOLD ABSOLUTE PRESSURE SENSOR HIGH

VOLTAGE

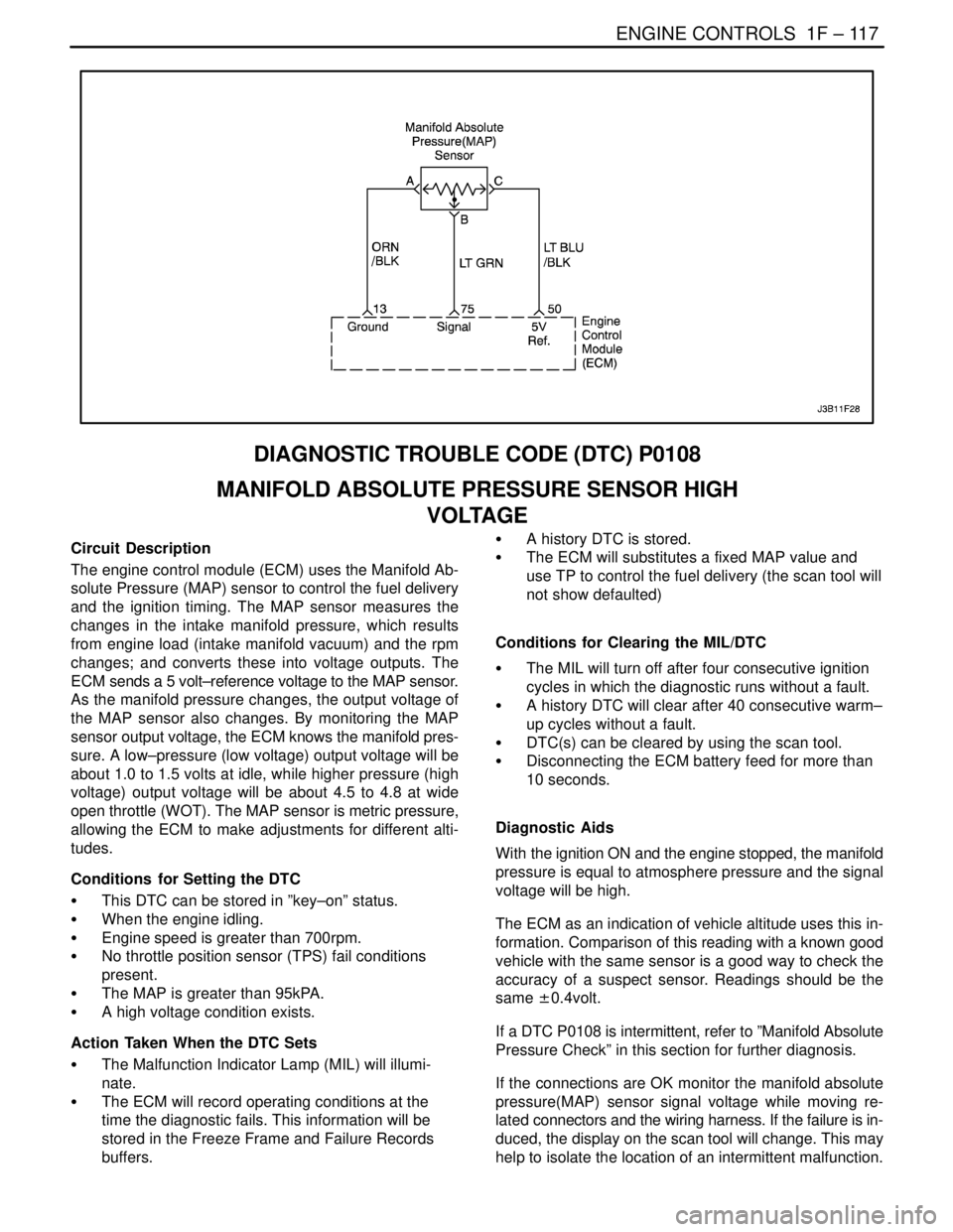

Circuit Description

The engine control module (ECM) uses the Manifold Ab-

solute Pressure (MAP) sensor to control the fuel delivery

and the ignition timing. The MAP sensor measures the

changes in the intake manifold pressure, which results

from engine load (intake manifold vacuum) and the rpm

changes; and converts these into voltage outputs. The

ECM sends a 5 volt–reference voltage to the MAP sensor.

As the manifold pressure changes, the output voltage of

the MAP sensor also changes. By monitoring the MAP

sensor output voltage, the ECM knows the manifold pres-

sure. A low–pressure (low voltage) output voltage will be

about 1.0 to 1.5 volts at idle, while higher pressure (high

voltage) output voltage will be about 4.5 to 4.8 at wide

open throttle (WOT). The MAP sensor is metric pressure,

allowing the ECM to make adjustments for different alti-

tudes.

Conditions for Setting the DTC

S This DTC can be stored in ”key–on” status.

S When the engine idling.

S Engine speed is greater than 700rpm.

S No throttle position sensor (TPS) fail conditions

present.

S The MAP is greater than 95kPA.

S A high voltage condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

S The ECM will substitutes a fixed MAP value and

use TP to control the fuel delivery (the scan tool will

not show defaulted)

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

With the ignition ON and the engine stopped, the manifold

pressure is equal to atmosphere pressure and the signal

voltage will be high.

The ECM as an indication of vehicle altitude uses this in-

formation. Comparison of this reading with a known good

vehicle with the same sensor is a good way to check the

accuracy of a suspect sensor. Readings should be the

same ±0.4volt.

If a DTC P0108 is intermittent, refer to ”Manifold Absolute

Pressure Check” in this section for further diagnosis.

If the connections are OK monitor the manifold absolute

pressure(MAP) sensor signal voltage while moving re-

lated connectors and the wiring harness. If the failure is in-

duced, the display on the scan tool will change. This may

help to isolate the location of an intermittent malfunction.

Page 364 of 2643

1F – 118IENGINE CONTROLS

DAEWOO V–121 BL4

DTC P0108 – Manifold Absolute Pressure Sensor High Voltage

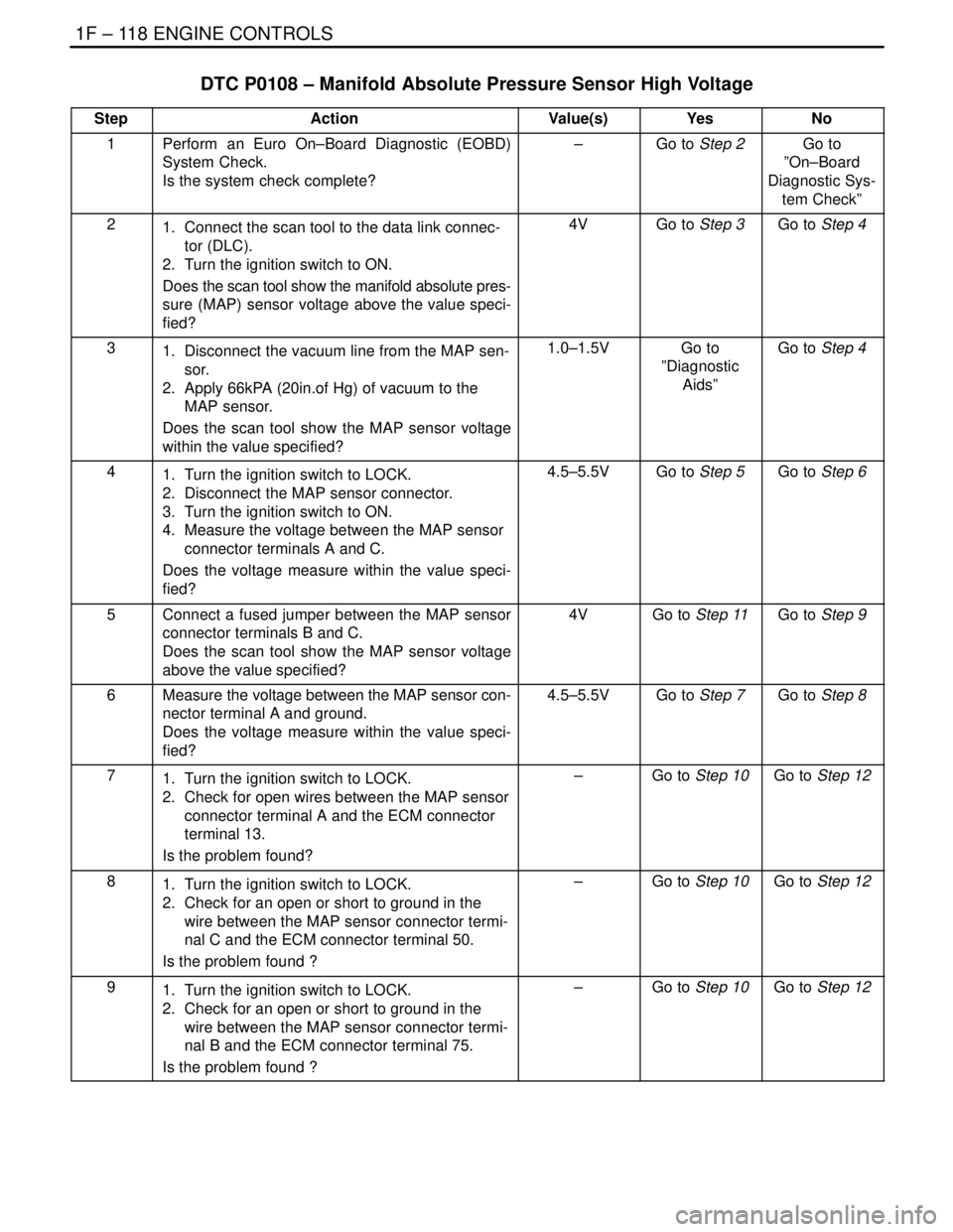

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Connect the scan tool to the data link connec-

tor (DLC).

2. Turn the ignition switch to ON.

Does the scan tool show the manifold absolute pres-

sure (MAP) sensor voltage above the value speci-

fied?4VGo to Step 3Go to Step 4

31. Disconnect the vacuum line from the MAP sen-

sor.

2. Apply 66kPA (20in.of Hg) of vacuum to the

MAP sensor.

Does the scan tool show the MAP sensor voltage

within the value specified?1.0–1.5VGo to

”Diagnostic

Aids”Go to Step 4

41. Turn the ignition switch to LOCK.

2. Disconnect the MAP sensor connector.

3. Turn the ignition switch to ON.

4. Measure the voltage between the MAP sensor

connector terminals A and C.

Does the voltage measure within the value speci-

fied?4.5–5.5VGo to Step 5Go to Step 6

5Connect a fused jumper between the MAP sensor

connector terminals B and C.

Does the scan tool show the MAP sensor voltage

above the value specified?4VGo to Step 11Go to Step 9

6Measure the voltage between the MAP sensor con-

nector terminal A and ground.

Does the voltage measure within the value speci-

fied?4.5–5.5VGo to Step 7Go to Step 8

71. Turn the ignition switch to LOCK.

2. Check for open wires between the MAP sensor

connector terminal A and the ECM connector

terminal 13.

Is the problem found?–Go to Step 10Go to Step 12

81. Turn the ignition switch to LOCK.

2. Check for an open or short to ground in the

wire between the MAP sensor connector termi-

nal C and the ECM connector terminal 50.

Is the problem found ?–Go to Step 10Go to Step 12

91. Turn the ignition switch to LOCK.

2. Check for an open or short to ground in the

wire between the MAP sensor connector termi-

nal B and the ECM connector terminal 75.

Is the problem found ?–Go to Step 10Go to Step 12

Page 374 of 2643

1F – 128IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0118

ENGINE COOLANT TEMPERATURE SENSOR HIGH

VOLTAGE

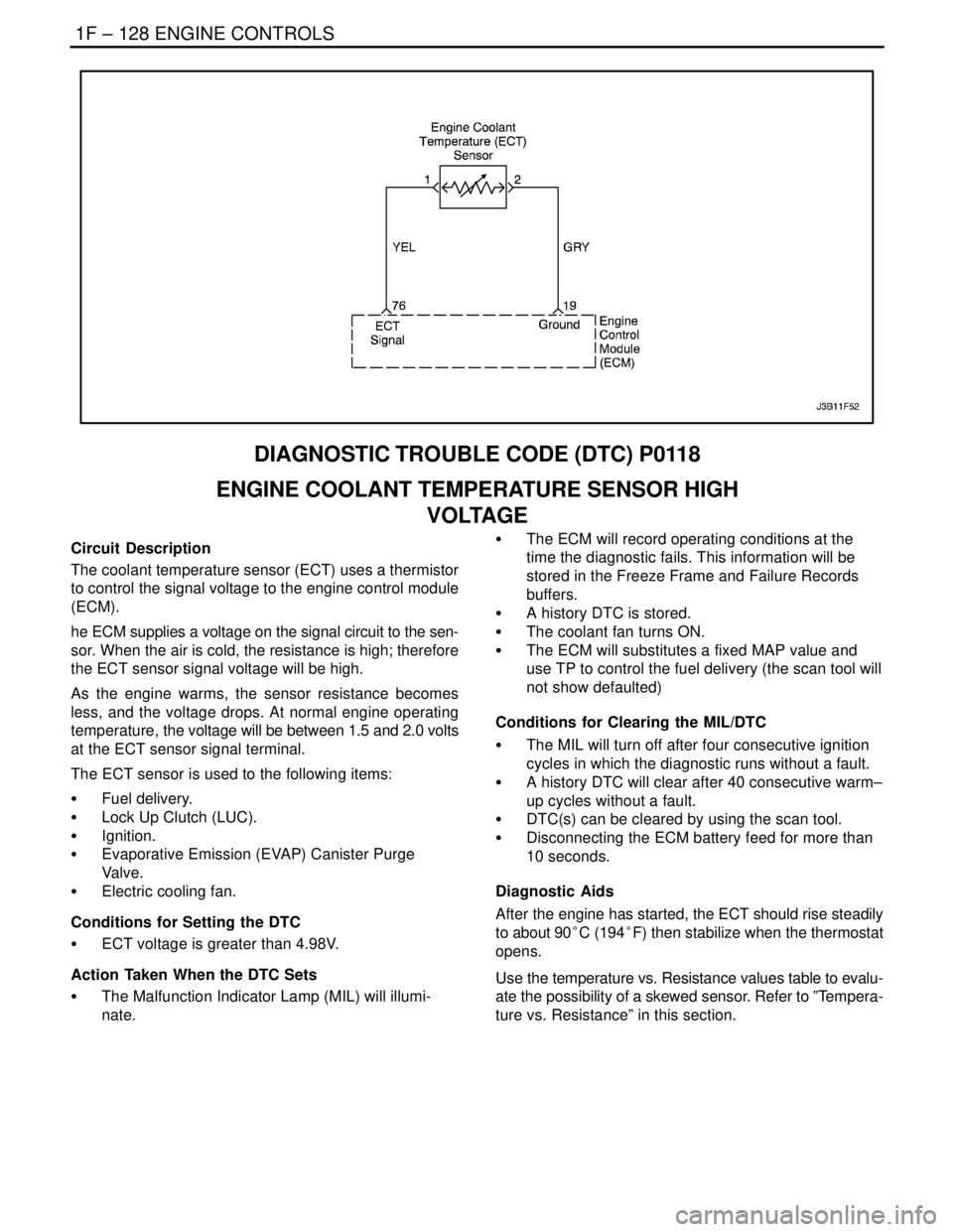

Circuit Description

The coolant temperature sensor (ECT) uses a thermistor

to control the signal voltage to the engine control module

(ECM).

he ECM supplies a voltage on the signal circuit to the sen-

sor. When the air is cold, the resistance is high; therefore

the ECT sensor signal voltage will be high.

As the engine warms, the sensor resistance becomes

less, and the voltage drops. At normal engine operating

temperature, the voltage will be between 1.5 and 2.0 volts

at the ECT sensor signal terminal.

The ECT sensor is used to the following items:

S Fuel delivery.

S Lock Up Clutch (LUC).

S Ignition.

S Evaporative Emission (EVAP) Canister Purge

Valve.

S Electric cooling fan.

Conditions for Setting the DTC

S ECT voltage is greater than 4.98V.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S The coolant fan turns ON.

S The ECM will substitutes a fixed MAP value and

use TP to control the fuel delivery (the scan tool will

not show defaulted)

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

After the engine has started, the ECT should rise steadily

to about 90°C (194°F) then stabilize when the thermostat

opens.

Use the temperature vs. Resistance values table to evalu-

ate the possibility of a skewed sensor. Refer to ”Tempera-

ture vs. Resistance” in this section.

Page 404 of 2643

1F – 158IENGINE CONTROLS

DAEWOO V–121 BL4

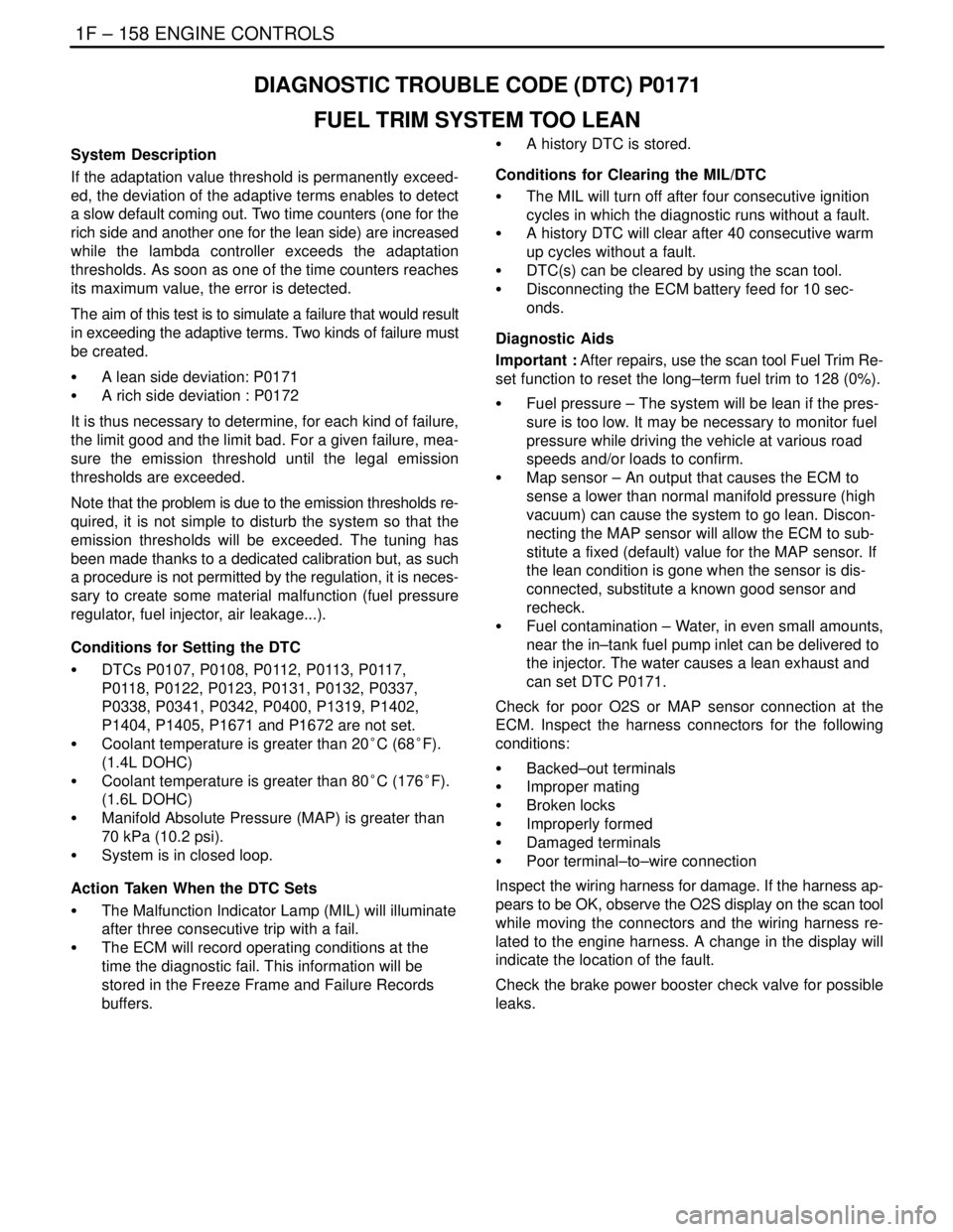

DIAGNOSTIC TROUBLE CODE (DTC) P0171

FUEL TRIM SYSTEM TOO LEAN

System Description

If the adaptation value threshold is permanently exceed-

ed, the deviation of the adaptive terms enables to detect

a slow default coming out. Two time counters (one for the

rich side and another one for the lean side) are increased

while the lambda controller exceeds the adaptation

thresholds. As soon as one of the time counters reaches

its maximum value, the error is detected.

The aim of this test is to simulate a failure that would result

in exceeding the adaptive terms. Two kinds of failure must

be created.

S A lean side deviation: P0171

S A rich side deviation : P0172

It is thus necessary to determine, for each kind of failure,

the limit good and the limit bad. For a given failure, mea-

sure the emission threshold until the legal emission

thresholds are exceeded.

Note that the problem is due to the emission thresholds re-

quired, it is not simple to disturb the system so that the

emission thresholds will be exceeded. The tuning has

been made thanks to a dedicated calibration but, as such

a procedure is not permitted by the regulation, it is neces-

sary to create some material malfunction (fuel pressure

regulator, fuel injector, air leakage...).

Conditions for Setting the DTC

S DTCs P0107, P0108, P0112, P0113, P0117,

P0118, P0122, P0123, P0131, P0132, P0337,

P0338, P0341, P0342, P0400, P1319, P1402,

P1404, P1405, P1671 and P1672 are not set.

S Coolant temperature is greater than 20°C (68°F).

(1.4L DOHC)

S Coolant temperature is greater than 80°C (176°F).

(1.6L DOHC)

S Manifold Absolute Pressure (MAP) is greater than

70 kPa (10.2 psi).

S System is in closed loop.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

Important : After repairs, use the scan tool Fuel Trim Re-

set function to reset the long–term fuel trim to 128 (0%).

S Fuel pressure – The system will be lean if the pres-

sure is too low. It may be necessary to monitor fuel

pressure while driving the vehicle at various road

speeds and/or loads to confirm.

S Map sensor – An output that causes the ECM to

sense a lower than normal manifold pressure (high

vacuum) can cause the system to go lean. Discon-

necting the MAP sensor will allow the ECM to sub-

stitute a fixed (default) value for the MAP sensor. If

the lean condition is gone when the sensor is dis-

connected, substitute a known good sensor and

recheck.

S Fuel contamination – Water, in even small amounts,

near the in–tank fuel pump inlet can be delivered to

the injector. The water causes a lean exhaust and

can set DTC P0171.

Check for poor O2S or MAP sensor connection at the

ECM. Inspect the harness connectors for the following

conditions:

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

Inspect the wiring harness for damage. If the harness ap-

pears to be OK, observe the O2S display on the scan tool

while moving the connectors and the wiring harness re-

lated to the engine harness. A change in the display will

indicate the location of the fault.

Check the brake power booster check valve for possible

leaks.

Page 405 of 2643

ENGINE CONTROLS 1F – 159

DAEWOO V–121 BL4

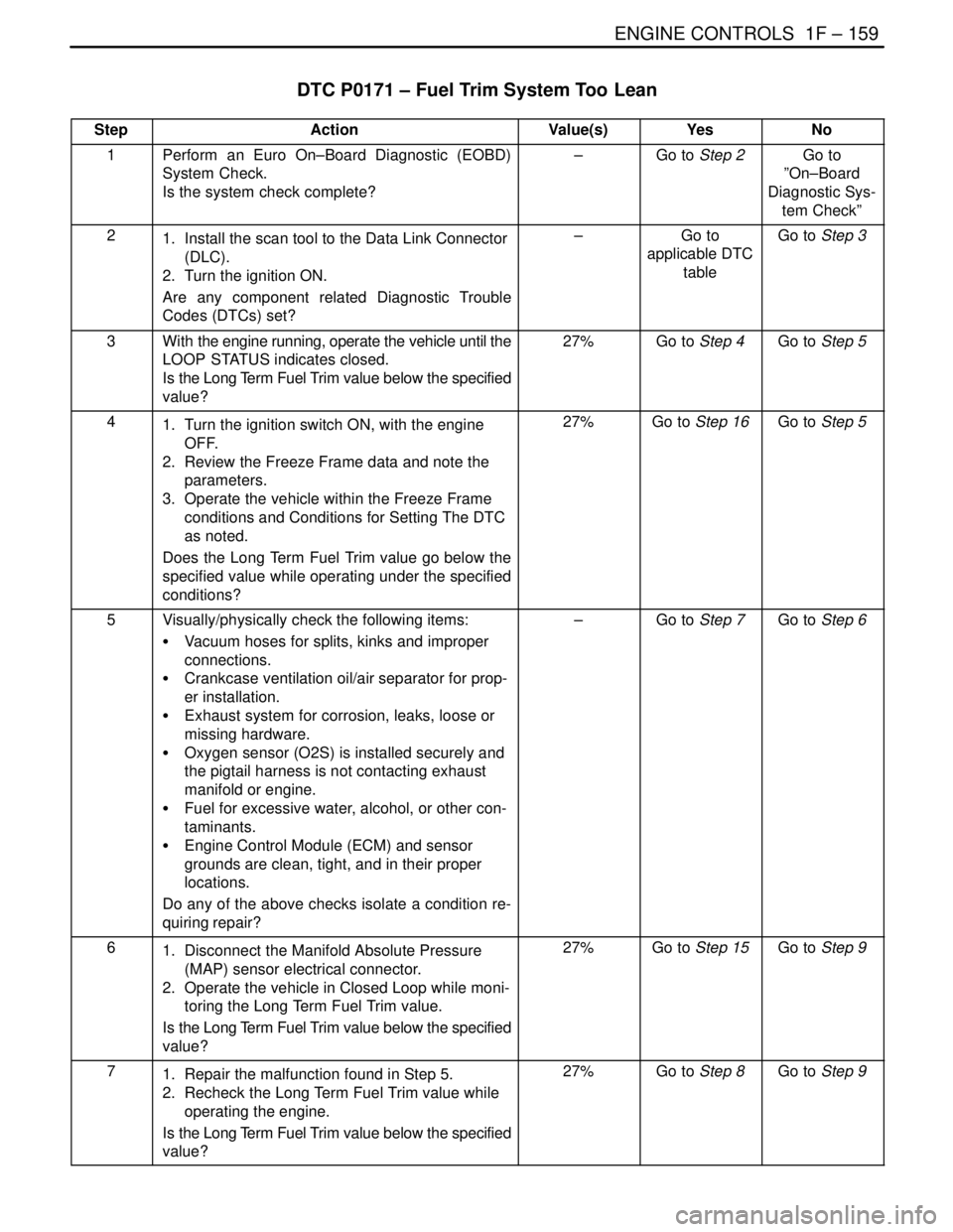

DTC P0171 – Fuel Trim System Too Lean

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install the scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON.

Are any component related Diagnostic Trouble

Codes (DTCs) set?–Go to

applicable DTC

tableGo to Step 3

3With the engine running, operate the vehicle until the

LOOP STATUS indicates closed.

Is the Long Term Fuel Trim value below the specified

value?27%Go to Step 4Go to Step 5

41. Turn the ignition switch ON, with the engine

OFF.

2. Review the Freeze Frame data and note the

parameters.

3. Operate the vehicle within the Freeze Frame

conditions and Conditions for Setting The DTC

as noted.

Does the Long Term Fuel Trim value go below the

specified value while operating under the specified

conditions?27%Go to Step 16Go to Step 5

5Visually/physically check the following items:

S Vacuum hoses for splits, kinks and improper

connections.

S Crankcase ventilation oil/air separator for prop-

er installation.

S Exhaust system for corrosion, leaks, loose or

missing hardware.

S Oxygen sensor (O2S) is installed securely and

the pigtail harness is not contacting exhaust

manifold or engine.

S Fuel for excessive water, alcohol, or other con-

taminants.

S Engine Control Module (ECM) and sensor

grounds are clean, tight, and in their proper

locations.

Do any of the above checks isolate a condition re-

quiring repair?–Go to Step 7Go to Step 6

61. Disconnect the Manifold Absolute Pressure

(MAP) sensor electrical connector.

2. Operate the vehicle in Closed Loop while moni-

toring the Long Term Fuel Trim value.

Is the Long Term Fuel Trim value below the specified

value?27%Go to Step 15Go to Step 9

71. Repair the malfunction found in Step 5.

2. Recheck the Long Term Fuel Trim value while

operating the engine.

Is the Long Term Fuel Trim value below the specified

value?27%Go to Step 8Go to Step 9

Page 406 of 2643

1F – 160IENGINE CONTROLS

DAEWOO V–121 BL4

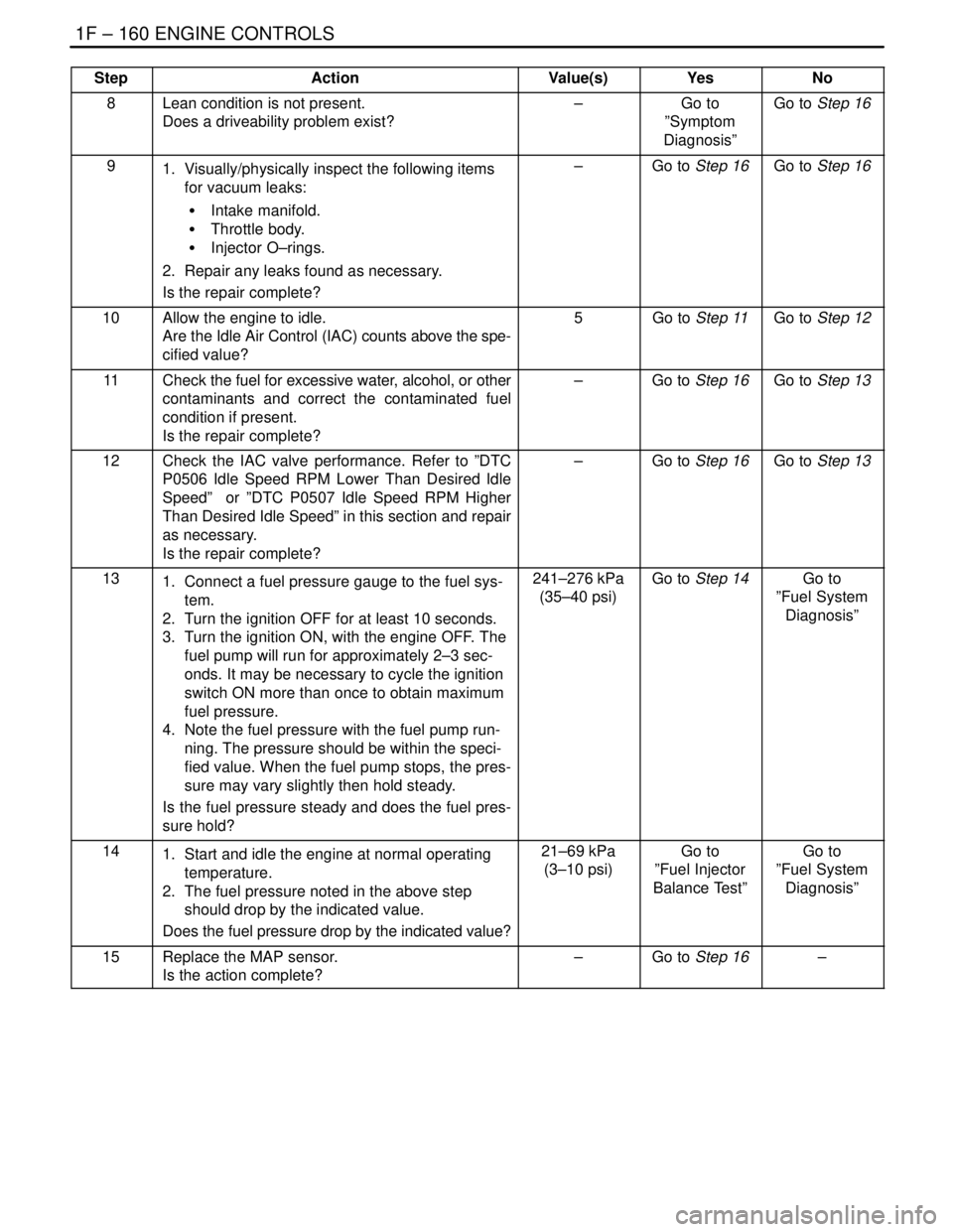

StepNo Yes Value(s) Action

8Lean condition is not present.

Does a driveability problem exist?–Go to

”Symptom

Diagnosis”Go to Step 16

91. Visually/physically inspect the following items

for vacuum leaks:

S Intake manifold.

S Throttle body.

S Injector O–rings.

2. Repair any leaks found as necessary.

Is the repair complete?–Go to Step 16Go to Step 16

10Allow the engine to idle.

Are the Idle Air Control (IAC) counts above the spe-

cified value?5Go to Step 11Go to Step 12

11Check the fuel for excessive water, alcohol, or other

contaminants and correct the contaminated fuel

condition if present.

Is the repair complete?–Go to Step 16Go to Step 13

12Check the IAC valve performance. Refer to ”DTC

P0506 Idle Speed RPM Lower Than Desired Idle

Speed” or ”DTC P0507 Idle Speed RPM Higher

Than Desired Idle Speed” in this section and repair

as necessary.

Is the repair complete?–Go to Step 16Go to Step 13

131. Connect a fuel pressure gauge to the fuel sys-

tem.

2. Turn the ignition OFF for at least 10 seconds.

3. Turn the ignition ON, with the engine OFF. The

fuel pump will run for approximately 2–3 sec-

onds. It may be necessary to cycle the ignition

switch ON more than once to obtain maximum

fuel pressure.

4. Note the fuel pressure with the fuel pump run-

ning. The pressure should be within the speci-

fied value. When the fuel pump stops, the pres-

sure may vary slightly then hold steady.

Is the fuel pressure steady and does the fuel pres-

sure hold?241–276 kPa

(35–40 psi)Go to Step 14Go to

”Fuel System

Diagnosis”

141. Start and idle the engine at normal operating

temperature.

2. The fuel pressure noted in the above step

should drop by the indicated value.

Does the fuel pressure drop by the indicated value?21–69 kPa

(3–10 psi)Go to

”Fuel Injector

Balance Test”Go to

”Fuel System

Diagnosis”

15Replace the MAP sensor.

Is the action complete?–Go to Step 16–

Page 408 of 2643

1F – 162IENGINE CONTROLS

DAEWOO V–121 BL4

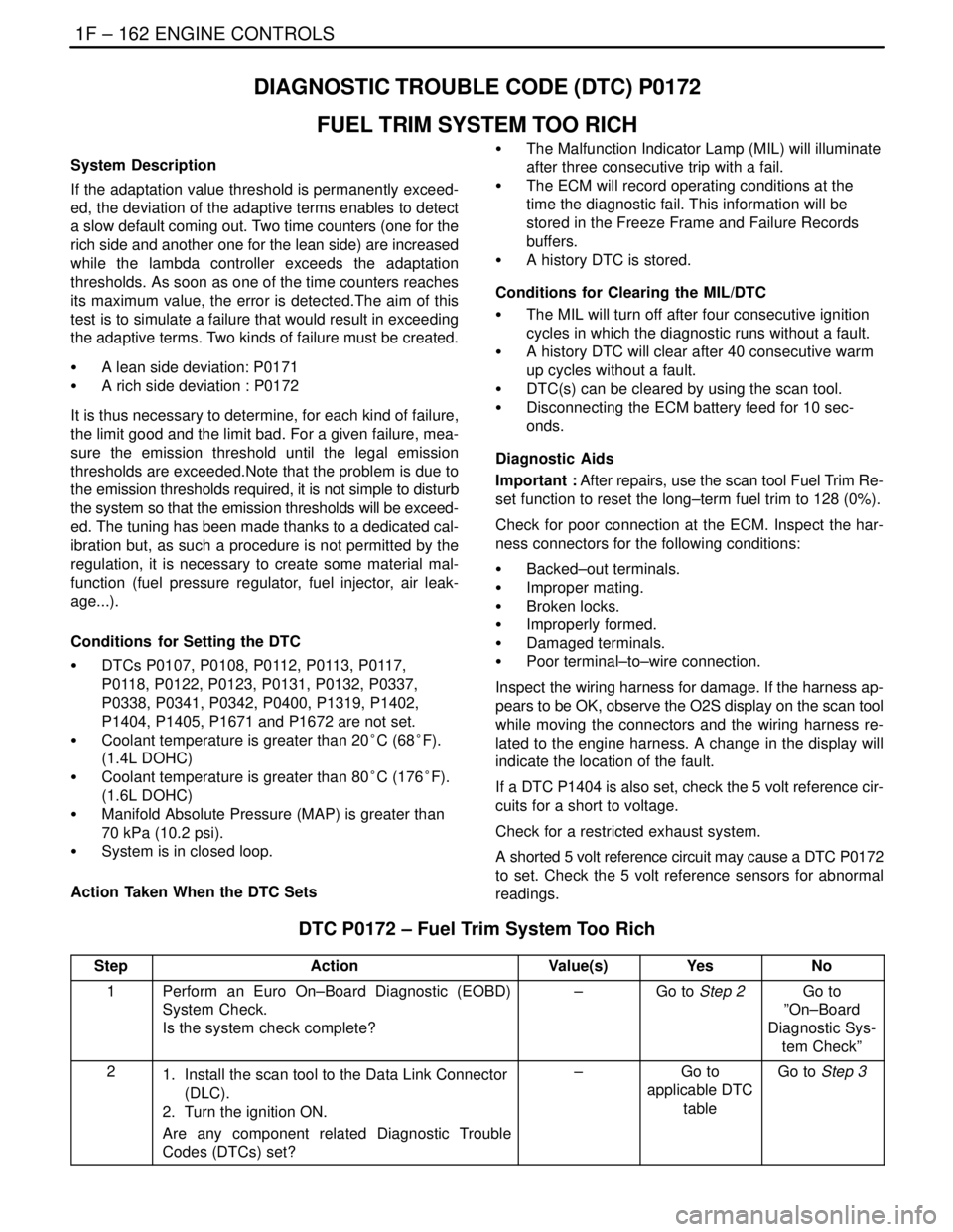

DIAGNOSTIC TROUBLE CODE (DTC) P0172

FUEL TRIM SYSTEM TOO RICH

System Description

If the adaptation value threshold is permanently exceed-

ed, the deviation of the adaptive terms enables to detect

a slow default coming out. Two time counters (one for the

rich side and another one for the lean side) are increased

while the lambda controller exceeds the adaptation

thresholds. As soon as one of the time counters reaches

its maximum value, the error is detected.The aim of this

test is to simulate a failure that would result in exceeding

the adaptive terms. Two kinds of failure must be created.

S A lean side deviation: P0171

S A rich side deviation : P0172

It is thus necessary to determine, for each kind of failure,

the limit good and the limit bad. For a given failure, mea-

sure the emission threshold until the legal emission

thresholds are exceeded.Note that the problem is due to

the emission thresholds required, it is not simple to disturb

the system so that the emission thresholds will be exceed-

ed. The tuning has been made thanks to a dedicated cal-

ibration but, as such a procedure is not permitted by the

regulation, it is necessary to create some material mal-

function (fuel pressure regulator, fuel injector, air leak-

age...).

Conditions for Setting the DTC

S DTCs P0107, P0108, P0112, P0113, P0117,

P0118, P0122, P0123, P0131, P0132, P0337,

P0338, P0341, P0342, P0400, P1319, P1402,

P1404, P1405, P1671 and P1672 are not set.

S Coolant temperature is greater than 20°C (68°F).

(1.4L DOHC)

S Coolant temperature is greater than 80°C (176°F).

(1.6L DOHC)

S Manifold Absolute Pressure (MAP) is greater than

70 kPa (10.2 psi).

S System is in closed loop.

Action Taken When the DTC SetsS The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

Important : After repairs, use the scan tool Fuel Trim Re-

set function to reset the long–term fuel trim to 128 (0%).

Check for poor connection at the ECM. Inspect the har-

ness connectors for the following conditions:

S Backed–out terminals.

S Improper mating.

S Broken locks.

S Improperly formed.

S Damaged terminals.

S Poor terminal–to–wire connection.

Inspect the wiring harness for damage. If the harness ap-

pears to be OK, observe the O2S display on the scan tool

while moving the connectors and the wiring harness re-

lated to the engine harness. A change in the display will

indicate the location of the fault.

If a DTC P1404 is also set, check the 5 volt reference cir-

cuits for a short to voltage.

Check for a restricted exhaust system.

A shorted 5 volt reference circuit may cause a DTC P0172

to set. Check the 5 volt reference sensors for abnormal

readings.

DTC P0172 – Fuel Trim System Too Rich

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install the scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON.

Are any component related Diagnostic Trouble

Codes (DTCs) set?–Go to

applicable DTC

tableGo to Step 3

Page 409 of 2643

ENGINE CONTROLS 1F – 163

DAEWOO V–121 BL4

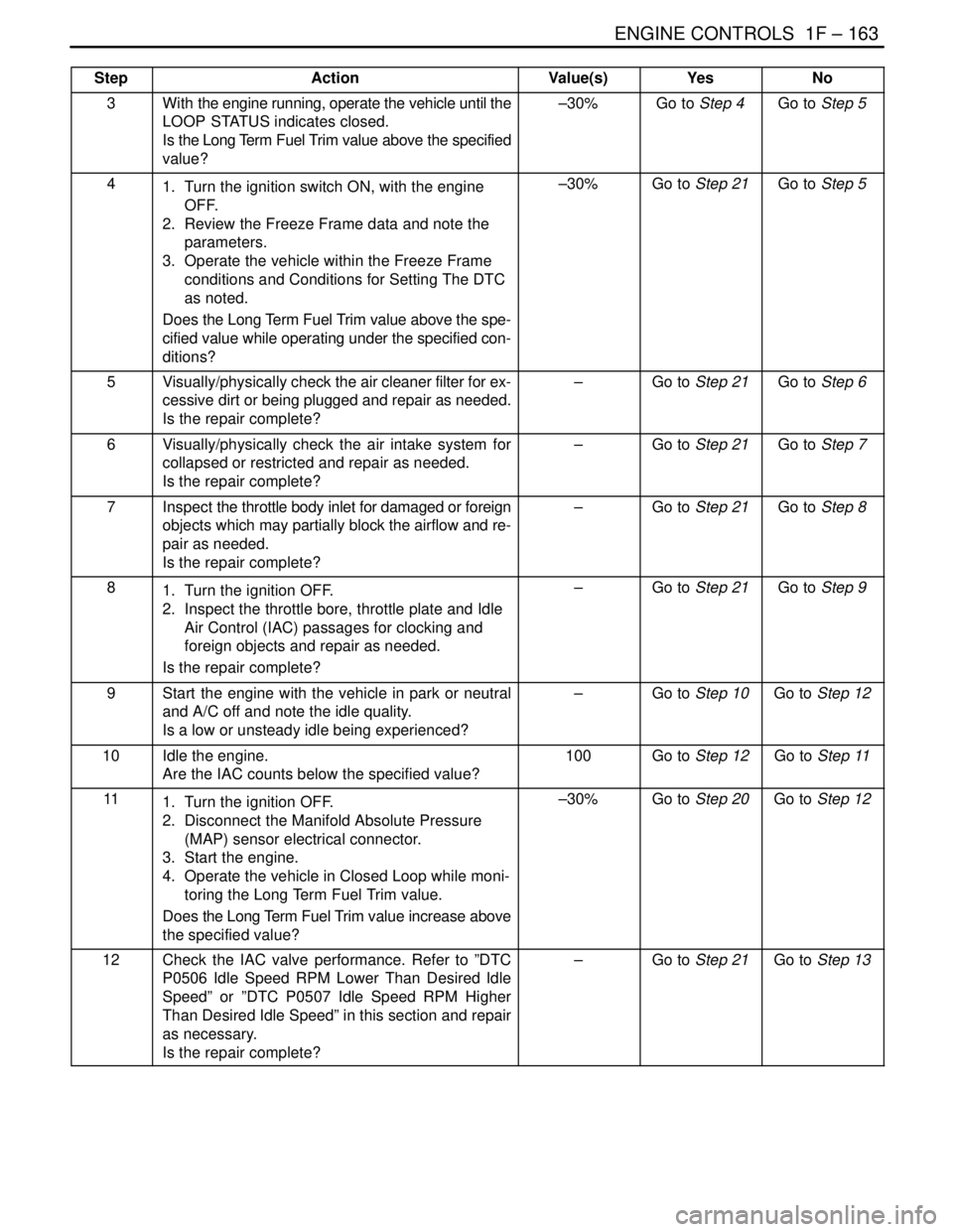

StepNo Yes Value(s) Action

3With the engine running, operate the vehicle until the

LOOP STATUS indicates closed.

Is the Long Term Fuel Trim value above the specified

value?–30%Go to Step 4Go to Step 5

41. Turn the ignition switch ON, with the engine

OFF.

2. Review the Freeze Frame data and note the

parameters.

3. Operate the vehicle within the Freeze Frame

conditions and Conditions for Setting The DTC

as noted.

Does the Long Term Fuel Trim value above the spe-

cified value while operating under the specified con-

ditions?–30%Go to Step 21Go to Step 5

5Visually/physically check the air cleaner filter for ex-

cessive dirt or being plugged and repair as needed.

Is the repair complete?–Go to Step 21Go to Step 6

6Visually/physically check the air intake system for

collapsed or restricted and repair as needed.

Is the repair complete?–Go to Step 21Go to Step 7

7Inspect the throttle body inlet for damaged or foreign

objects which may partially block the airflow and re-

pair as needed.

Is the repair complete?–Go to Step 21Go to Step 8

81. Turn the ignition OFF.

2. Inspect the throttle bore, throttle plate and Idle

Air Control (IAC) passages for clocking and

foreign objects and repair as needed.

Is the repair complete?–Go to Step 21Go to Step 9

9Start the engine with the vehicle in park or neutral

and A/C off and note the idle quality.

Is a low or unsteady idle being experienced?–Go to Step 10Go to Step 12

10Idle the engine.

Are the IAC counts below the specified value?100Go to Step 12Go to Step 11

111. Turn the ignition OFF.

2. Disconnect the Manifold Absolute Pressure

(MAP) sensor electrical connector.

3. Start the engine.

4. Operate the vehicle in Closed Loop while moni-

toring the Long Term Fuel Trim value.

Does the Long Term Fuel Trim value increase above

the specified value?–30%Go to Step 20Go to Step 12

12Check the IAC valve performance. Refer to ”DTC

P0506 Idle Speed RPM Lower Than Desired Idle

Speed” or ”DTC P0507 Idle Speed RPM Higher

Than Desired Idle Speed” in this section and repair

as necessary.

Is the repair complete?–Go to Step 21Go to Step 13

Page 410 of 2643

1F – 164IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

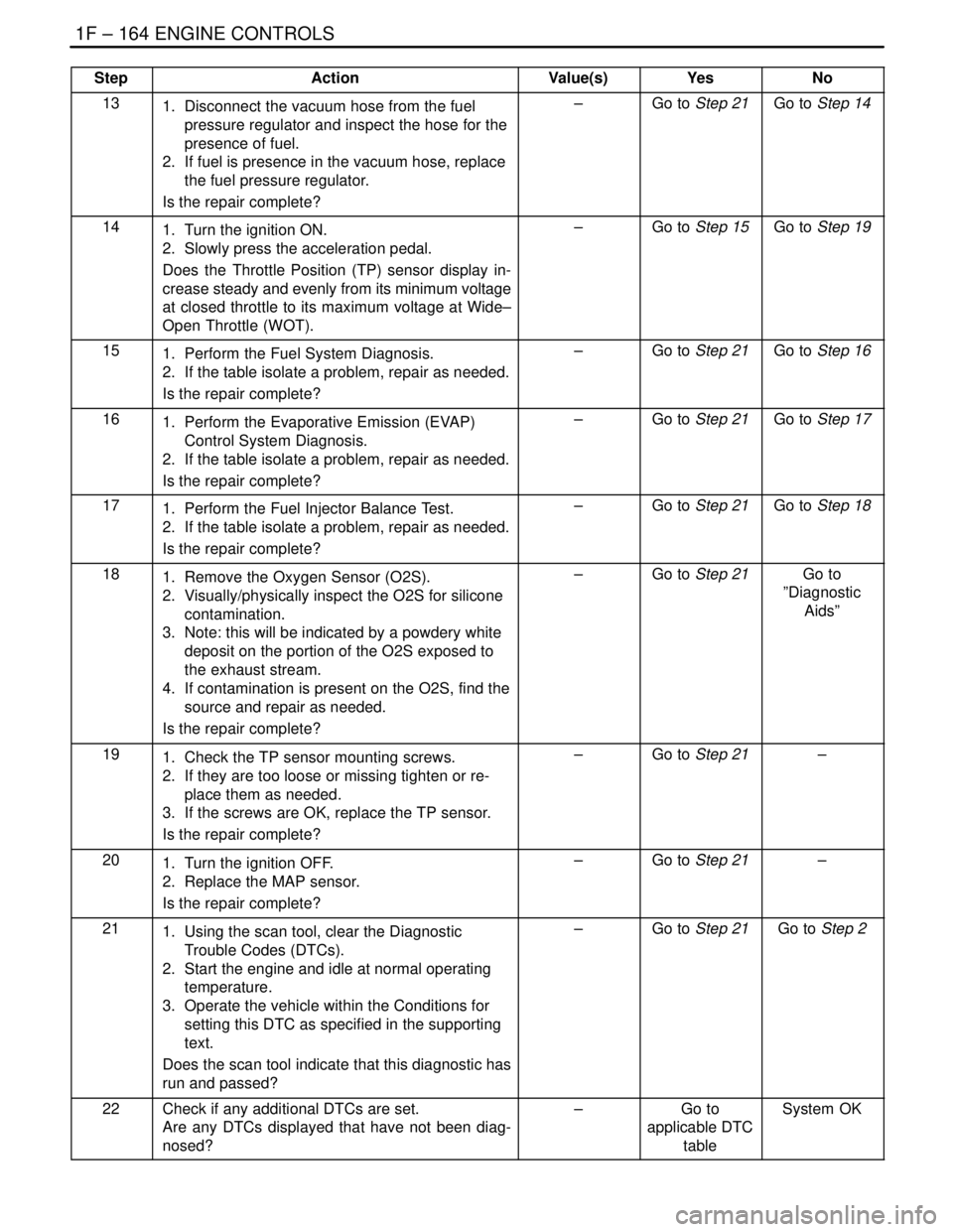

131. Disconnect the vacuum hose from the fuel

pressure regulator and inspect the hose for the

presence of fuel.

2. If fuel is presence in the vacuum hose, replace

the fuel pressure regulator.

Is the repair complete?–Go to Step 21Go to Step 14

141. Turn the ignition ON.

2. Slowly press the acceleration pedal.

Does the Throttle Position (TP) sensor display in-

crease steady and evenly from its minimum voltage

at closed throttle to its maximum voltage at Wide–

Open Throttle (WOT).–Go to Step 15Go to Step 19

151. Perform the Fuel System Diagnosis.

2. If the table isolate a problem, repair as needed.

Is the repair complete?–Go to Step 21Go to Step 16

161. Perform the Evaporative Emission (EVAP)

Control System Diagnosis.

2. If the table isolate a problem, repair as needed.

Is the repair complete?–Go to Step 21Go to Step 17

171. Perform the Fuel Injector Balance Test.

2. If the table isolate a problem, repair as needed.

Is the repair complete?–Go to Step 21Go to Step 18

181. Remove the Oxygen Sensor (O2S).

2. Visually/physically inspect the O2S for silicone

contamination.

3. Note: this will be indicated by a powdery white

deposit on the portion of the O2S exposed to

the exhaust stream.

4. If contamination is present on the O2S, find the

source and repair as needed.

Is the repair complete?–Go to Step 21Go to

”Diagnostic

Aids”

191. Check the TP sensor mounting screws.

2. If they are too loose or missing tighten or re-

place them as needed.

3. If the screws are OK, replace the TP sensor.

Is the repair complete?–Go to Step 21–

201. Turn the ignition OFF.

2. Replace the MAP sensor.

Is the repair complete?–Go to Step 21–

211. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 21Go to Step 2

22Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

applicable DTC

tableSystem OK

Page 464 of 2643

1F – 218IENGINE CONTROLS

DAEWOO V–121 BL4

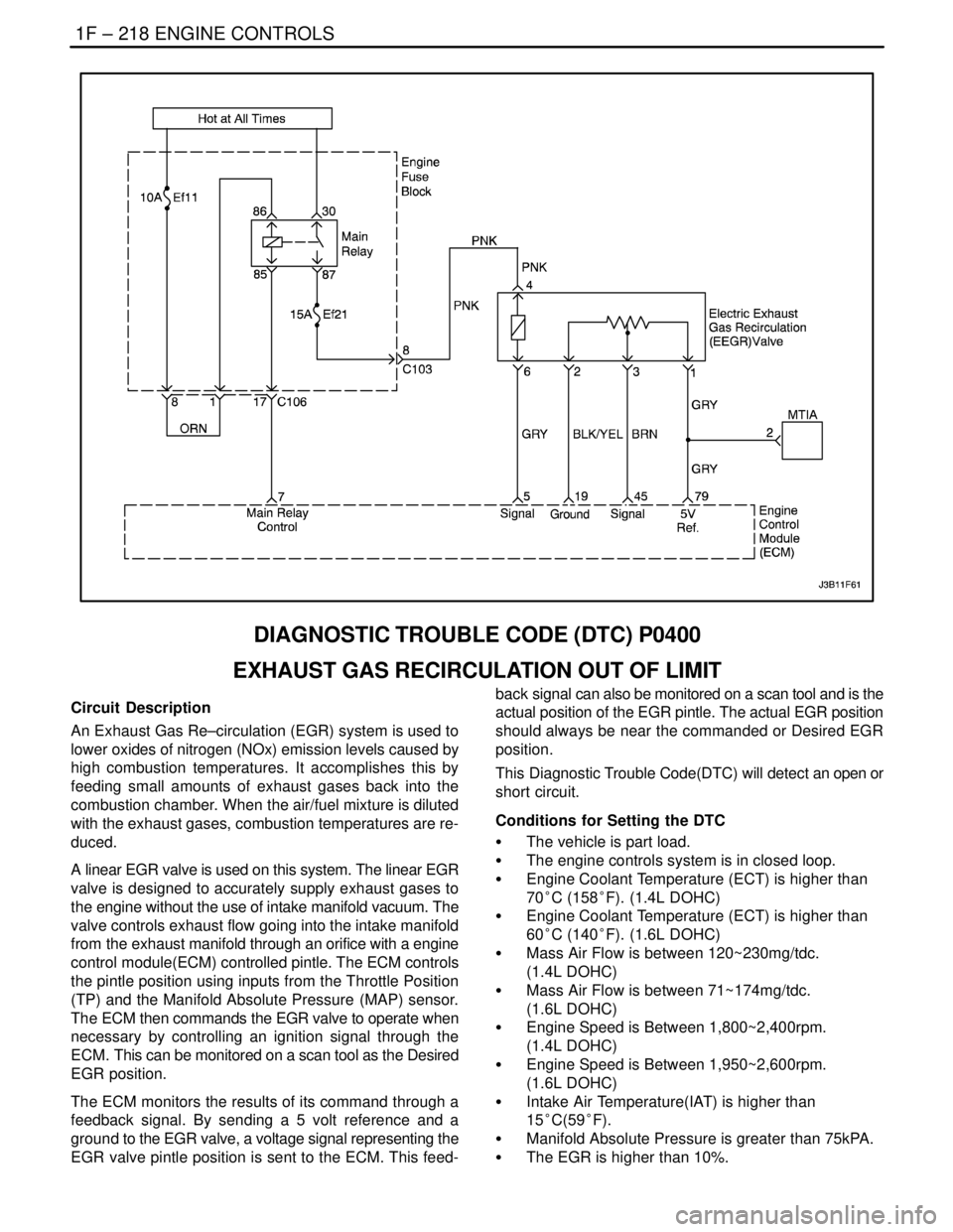

DIAGNOSTIC TROUBLE CODE (DTC) P0400

EXHAUST GAS RECIRCULATION OUT OF LIMIT

Circuit Description

An Exhaust Gas Re–circulation (EGR) system is used to

lower oxides of nitrogen (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced.

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with a engine

control module(ECM) controlled pintle. The ECM controls

the pintle position using inputs from the Throttle Position

(TP) and the Manifold Absolute Pressure (MAP) sensor.

The ECM then commands the EGR valve to operate when

necessary by controlling an ignition signal through the

ECM. This can be monitored on a scan tool as the Desired

EGR position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The actual EGR position

should always be near the commanded or Desired EGR

position.

This Diagnostic Trouble Code(DTC) will detect an open or

short circuit.

Conditions for Setting the DTC

S The vehicle is part load.

S The engine controls system is in closed loop.

S Engine Coolant Temperature (ECT) is higher than

70°C (158°F). (1.4L DOHC)

S Engine Coolant Temperature (ECT) is higher than

60°C (140°F). (1.6L DOHC)

S Mass Air Flow is between 120~230mg/tdc.

(1.4L DOHC)

S Mass Air Flow is between 71~174mg/tdc.

(1.6L DOHC)

S Engine Speed is Between 1,800~2,400rpm.

(1.4L DOHC)

S Engine Speed is Between 1,950~2,600rpm.

(1.6L DOHC)

S Intake Air Temperature(IAT) is higher than

15°C(59°F).

S Manifold Absolute Pressure is greater than 75kPA.

S The EGR is higher than 10%.