Wiper DAEWOO LACETTI 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1961 of 2643

STEERING WHEEL AND COLUMN 6E – 7

DAEWOO V–121 BL4

Front or Rear Turn Signal Lights Not Flashing

ChecksAction

Check for a faulty turn signal switch.Replace the turn signal switch.

Check the chassis–to–column connector for an improper

connection.Reconnect the chassis–to–column connector.

Turn Signal Lights Flash Very Slowly

ChecksAction

Check the chassis–to–column connector for an improper

connection.Reconnect the chassis–to–column connector.

Ignition Switch

Electrical System Will Not Function

ChecksAction

Check the ignition switch for damage.Replace the ignition switch.

Check the ignition switch for improper installation.Remove and inspect the ignition switch. Reinstall the igni-

tion switch.

Check the ignition switch electrical connector for improper

installation.Reconnect the ignition switch electrical connector.

Replace the ignition switch electrical connector.

Ignition Switch Will Not Turn

ChecksAction

Check the ignition switch for damage.Replace the ignition switch.

Check the ignition switch for improper installation.Remove and inspect the ignition switch. Reinstall the igni-

tion switch.

Wiper Lever and Switch

Switch Inoperative: No LOW, HIGH, INTERMITTENT or WASH

ChecksAction

Check the wiper lever and switch for damage.Replace the wiper lever and switch.

Check the wiper lever and switch for improper installation.Remove and inspect the wiper lever and switch.

Reinstall the wiper lever and switch.

Page 1963 of 2643

STEERING WHEEL AND COLUMN 6E – 9

DAEWOO V–121 BL4

3. Install the upper and the lower steering column cov-

er panels. Install the upper and the lower steering

column cover panel screws.

Tighten

Tighten the upper and the lower steering column cov-

er panel screws to 2.5 NSm (22 lb–in).

4. Connect the negative battery cable.

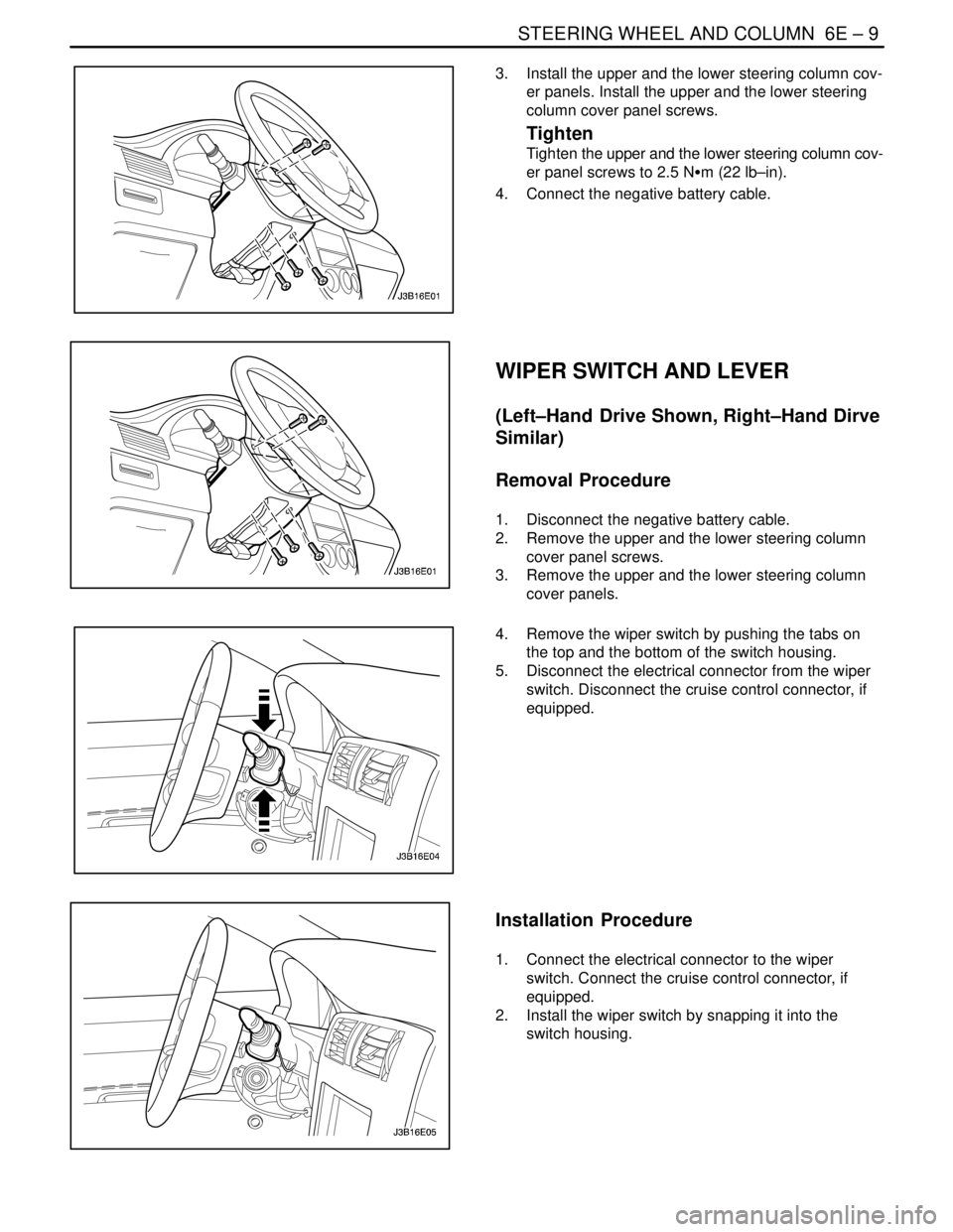

WIPER SWITCH AND LEVER

(Left–Hand Drive Shown, Right–Hand Dirve

Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the upper and the lower steering column

cover panel screws.

3. Remove the upper and the lower steering column

cover panels.

4. Remove the wiper switch by pushing the tabs on

the top and the bottom of the switch housing.

5. Disconnect the electrical connector from the wiper

switch. Disconnect the cruise control connector, if

equipped.

Installation Procedure

1. Connect the electrical connector to the wiper

switch. Connect the cruise control connector, if

equipped.

2. Install the wiper switch by snapping it into the

switch housing.

Page 1969 of 2643

STEERING WHEEL AND COLUMN 6E – 15

DAEWOO V–121 BL4

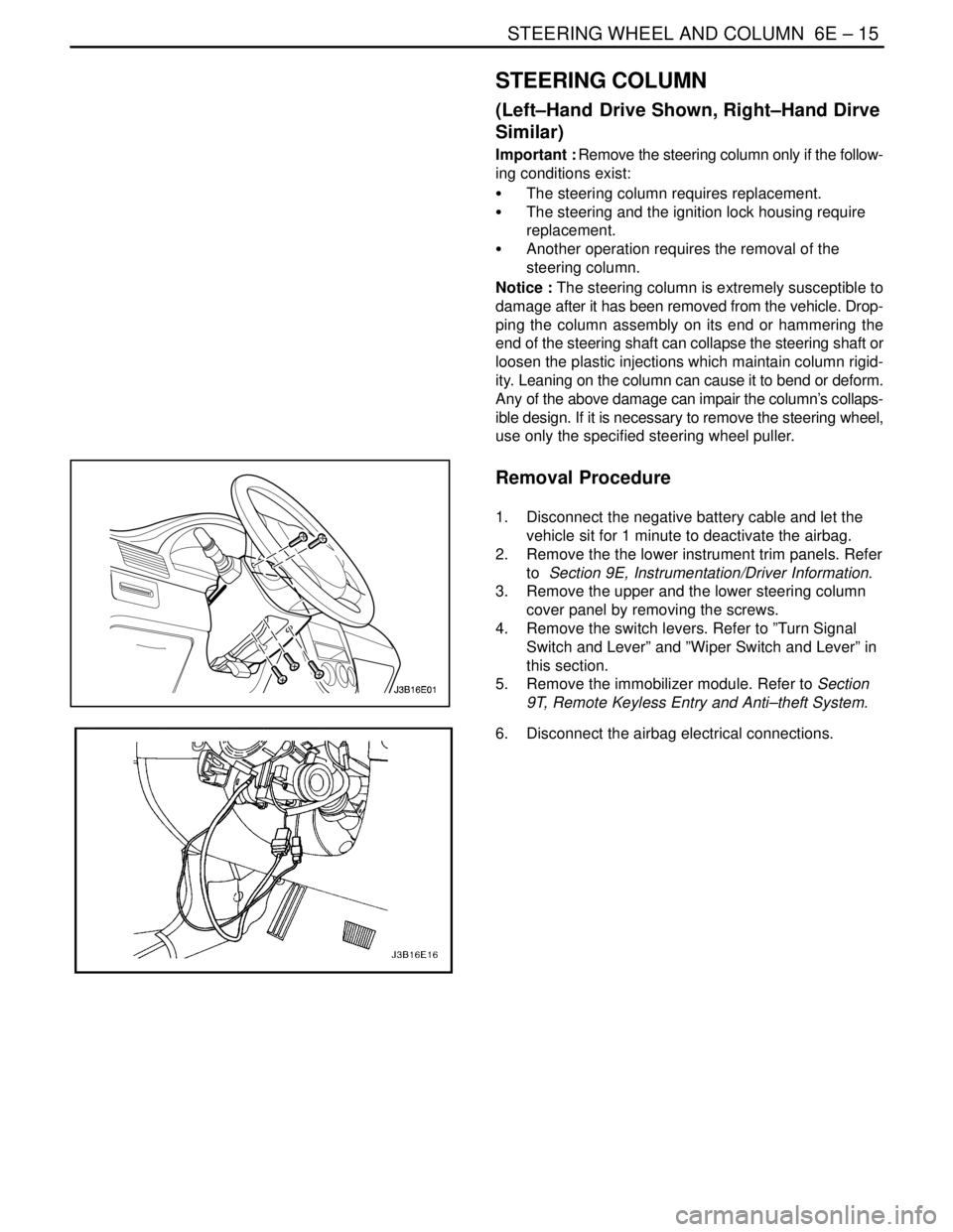

STEERING COLUMN

(Left–Hand Drive Shown, Right–Hand Dirve

Similar)

Important : Remove the steering column only if the follow-

ing conditions exist:

S The steering column requires replacement.

S The steering and the ignition lock housing require

replacement.

S Another operation requires the removal of the

steering column.

Notice : The steering column is extremely susceptible to

damage after it has been removed from the vehicle. Drop-

ping the column assembly on its end or hammering the

end of the steering shaft can collapse the steering shaft or

loosen the plastic injections which maintain column rigid-

ity. Leaning on the column can cause it to bend or deform.

Any of the above damage can impair the column’s collaps-

ible design. If it is necessary to remove the steering wheel,

use only the specified steering wheel puller.

Removal Procedure

1. Disconnect the negative battery cable and let the

vehicle sit for 1 minute to deactivate the airbag.

2. Remove the the lower instrument trim panels. Refer

to Section 9E, Instrumentation/Driver Information.

3. Remove the upper and the lower steering column

cover panel by removing the screws.

4. Remove the switch levers. Refer to ”Turn Signal

Switch and Lever” and ”Wiper Switch and Lever” in

this section.

5. Remove the immobilizer module. Refer to Section

9T, Remote Keyless Entry and Anti–theft System.

6. Disconnect the airbag electrical connections.

Page 1972 of 2643

6E – 18ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

6. Connect the ignition switch electrical connection.

7. Connect the airbag electrical connections.

8. Install the switch levers. Refer to ”Turn Signal

Switch and Lever” and ”Wiper Switch and Lever” in

this section.

9. Install the immobilizer module. Refer to Section 9T,

Remote Keyless Entry and Anti–theft System.

10. Install the lower instrument trim panels. Refer to

Section 9E, Instrumentation/Driver Information.

11. Install the upper and the lower steering column cov-

er panel with the screws..

Tighten

Tighten the upper and the lower steering column pan-

el screws to 2.5 NSm (22 lb–in).

12. Inspect the steering wheel in a straight–ahead posi-

tion. Refer to Section 6C, Power Steering Gear.

13. Connect the negative battery cable.

Page 1974 of 2643

6E – 20ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

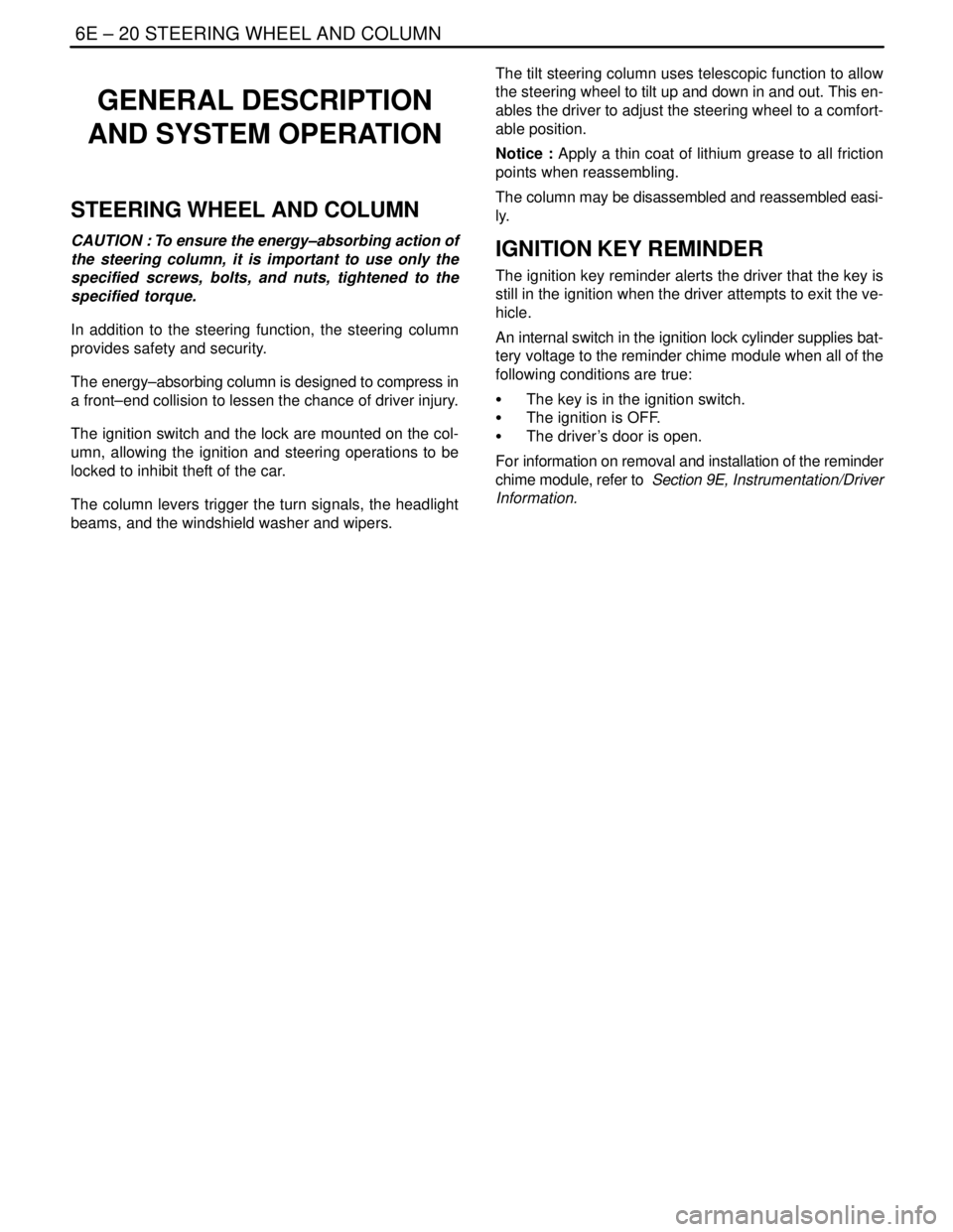

GENERAL DESCRIPTION

AND SYSTEM OPERATION

STEERING WHEEL AND COLUMN

CAUTION : To ensure the energy–absorbing action of

the steering column, it is important to use only the

specified screws, bolts, and nuts, tightened to the

specified torque.

In addition to the steering function, the steering column

provides safety and security.

The energy–absorbing column is designed to compress in

a front–end collision to lessen the chance of driver injury.

The ignition switch and the lock are mounted on the col-

umn, allowing the ignition and steering operations to be

locked to inhibit theft of the car.

The column levers trigger the turn signals, the headlight

beams, and the windshield washer and wipers.The tilt steering column uses telescopic function to allow

the steering wheel to tilt up and down in and out. This en-

ables the driver to adjust the steering wheel to a comfort-

able position.

Notice : Apply a thin coat of lithium grease to all friction

points when reassembling.

The column may be disassembled and reassembled easi-

ly.IGNITION KEY REMINDER

The ignition key reminder alerts the driver that the key is

still in the ignition when the driver attempts to exit the ve-

hicle.

An internal switch in the ignition lock cylinder supplies bat-

tery voltage to the reminder chime module when all of the

following conditions are true:

S The key is in the ignition switch.

S The ignition is OFF.

S The driver’s door is open.

For information on removal and installation of the reminder

chime module, refer to Section 9E, Instrumentation/Driver

Information.

Page 2220 of 2643

9A – 14IBODY WIRING SYSTEM

DAEWOO V–121 BL4

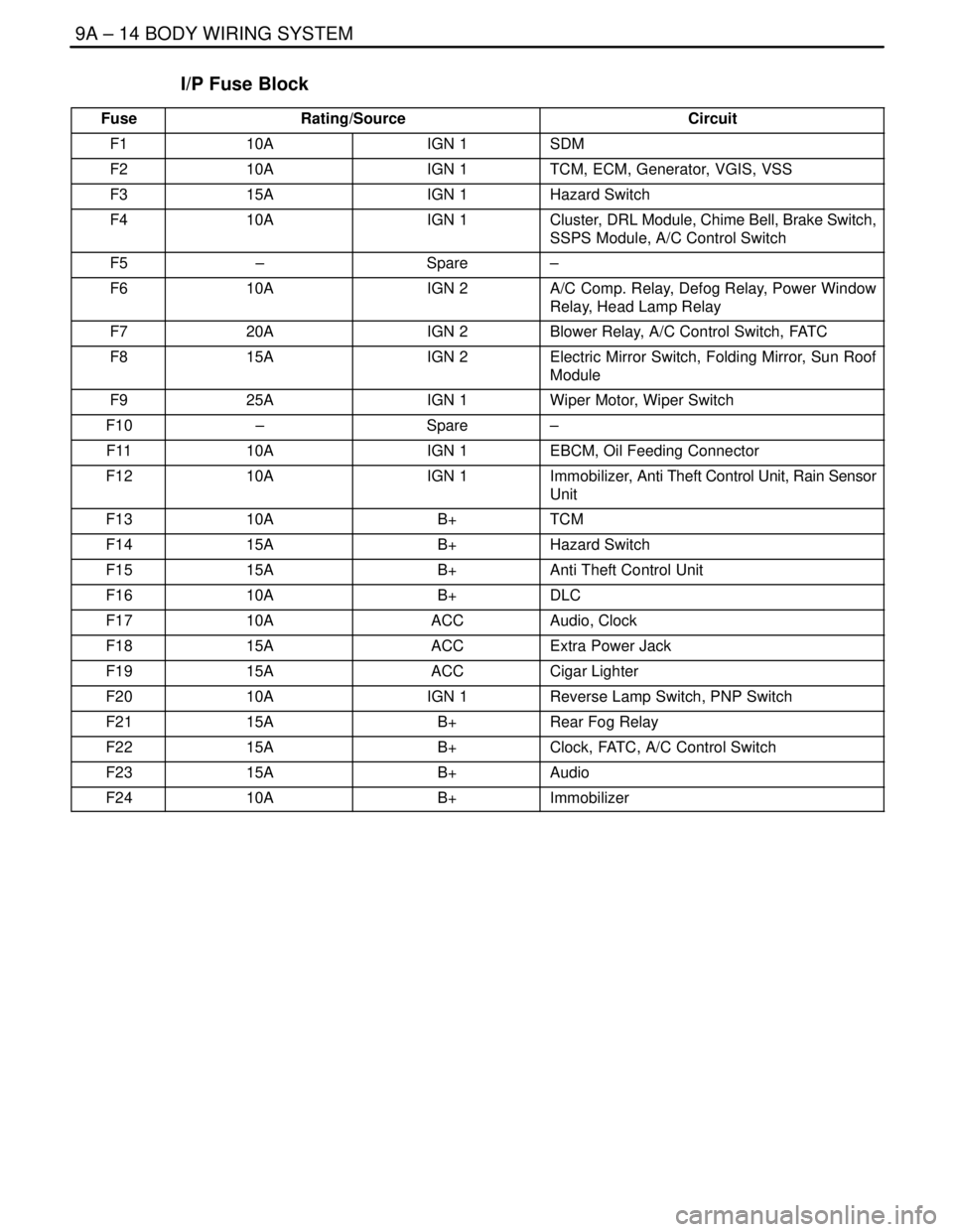

I/P Fuse Block

FuseRating/SourceCircuit

F110AIGN 1SDM

F210AIGN 1TCM, ECM, Generator, VGIS, VSS

F315AIGN 1Hazard Switch

F410AIGN 1Cluster, DRL Module, Chime Bell, Brake Switch,

SSPS Module, A/C Control Switch

F5–Spare–

F610AIGN 2A/C Comp. Relay, Defog Relay, Power Window

Relay, Head Lamp Relay

F720AIGN 2Blower Relay, A/C Control Switch, FATC

F815AIGN 2Electric Mirror Switch, Folding Mirror, Sun Roof

Module

F925AIGN 1Wiper Motor, Wiper Switch

F10–Spare–

F1110AIGN 1EBCM, Oil Feeding Connector

F1210AIGN 1Immobilizer, Anti Theft Control Unit, Rain Sensor

Unit

F1310AB+TCM

F1415AB+Hazard Switch

F1515AB+Anti Theft Control Unit

F1610AB+DLC

F1710AACCAudio, Clock

F1815AACCExtra Power Jack

F1915AACCCigar Lighter

F2010AIGN 1Reverse Lamp Switch, PNP Switch

F2115AB+Rear Fog Relay

F2215AB+Clock, FATC, A/C Control Switch

F2315AB+Audio

F2410AB+Immobilizer

Page 2278 of 2643

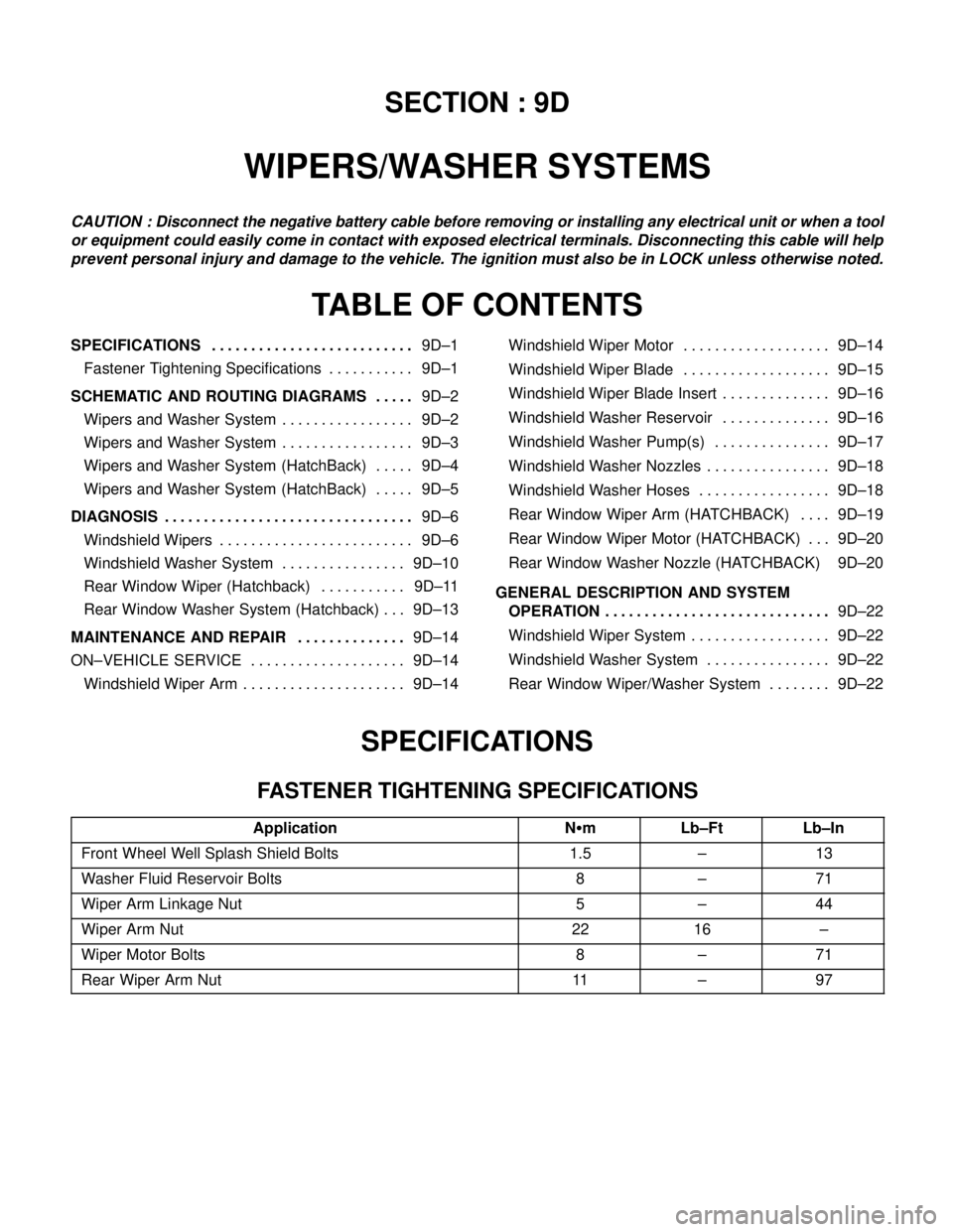

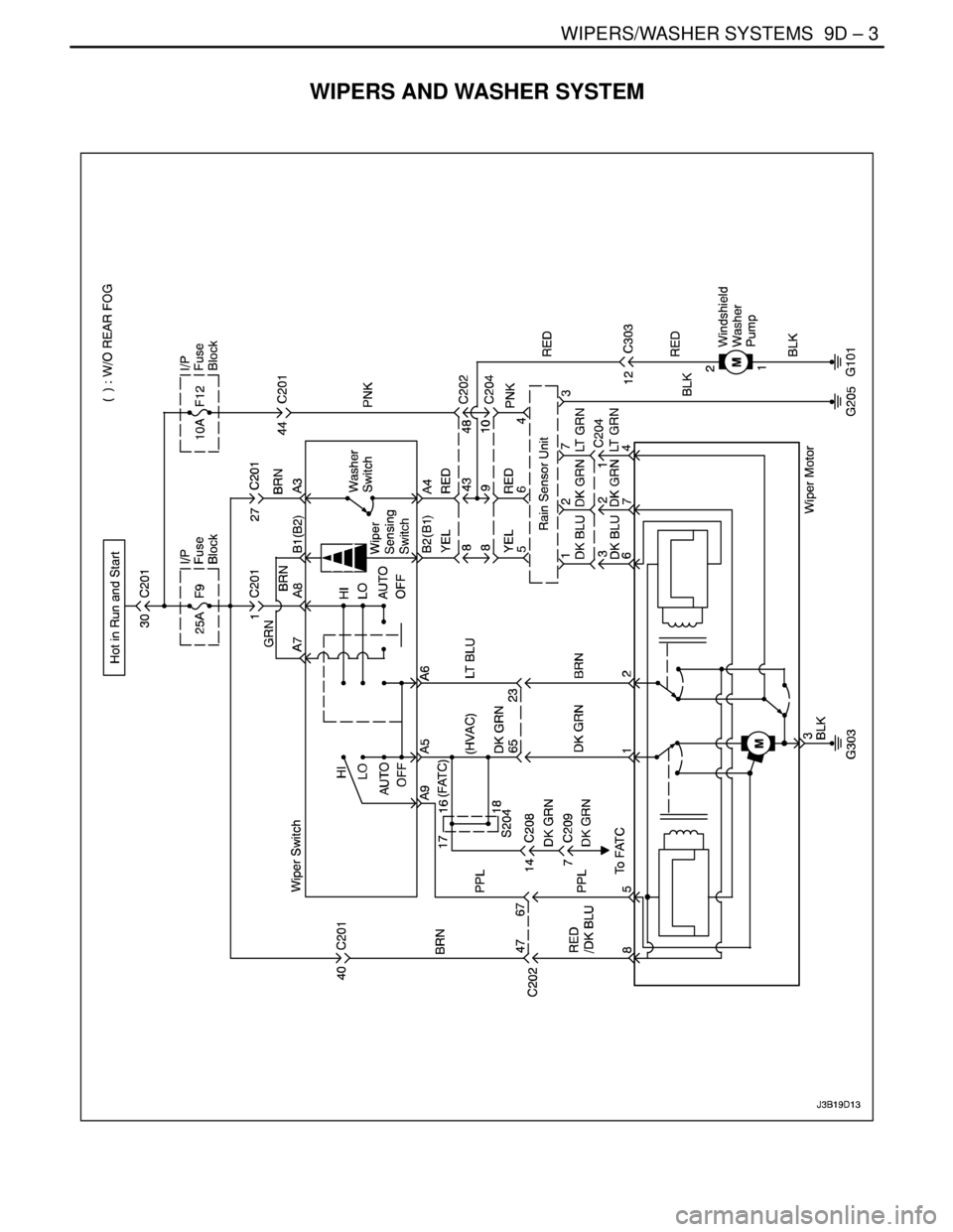

SECTION : 9D

WIPERS/WASHER SYSTEMS

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9D–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9D–1. . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9D–2 . . . . .

Wipers and Washer System 9D–2. . . . . . . . . . . . . . . . .

Wipers and Washer System 9D–3. . . . . . . . . . . . . . . . .

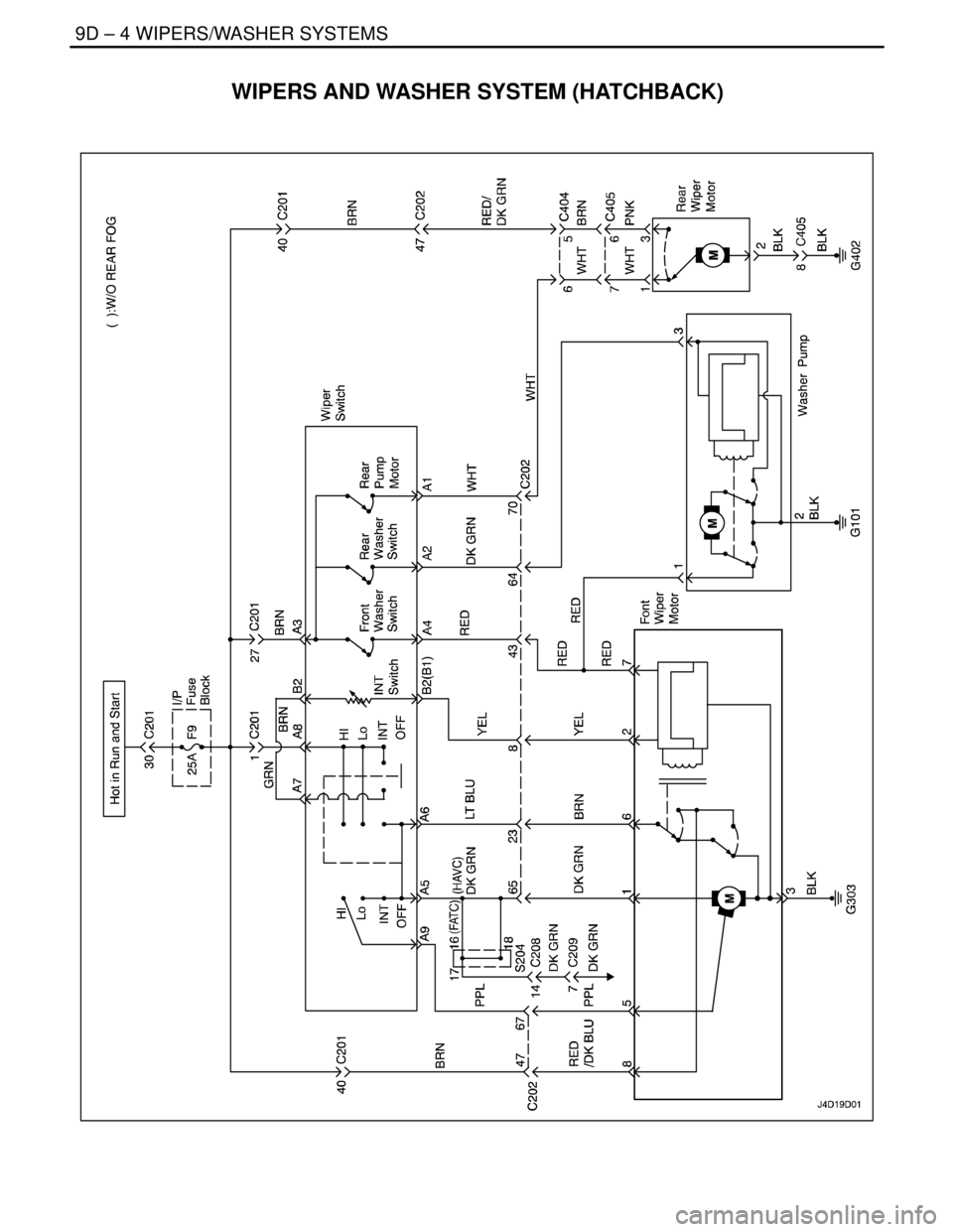

Wipers and Washer System (HatchBack) 9D–4. . . . .

Wipers and Washer System (HatchBack) 9D–5. . . . .

DIAGNOSIS9D–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windshield Wipers 9D–6. . . . . . . . . . . . . . . . . . . . . . . . .

Windshield Washer System 9D–10. . . . . . . . . . . . . . . .

Rear Window Wiper (Hatchback) 9D–11. . . . . . . . . . .

Rear Window Washer System (Hatchback) 9D–13. . .

MAINTENANCE AND REPAIR9D–14 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9D–14. . . . . . . . . . . . . . . . . . . .

Windshield Wiper Arm 9D–14. . . . . . . . . . . . . . . . . . . . . Windshield Wiper Motor 9D–14. . . . . . . . . . . . . . . . . . .

Windshield Wiper Blade 9D–15. . . . . . . . . . . . . . . . . . .

Windshield Wiper Blade Insert 9D–16. . . . . . . . . . . . . .

Windshield Washer Reservoir 9D–16. . . . . . . . . . . . . .

Windshield Washer Pump(s) 9D–17. . . . . . . . . . . . . . .

Windshield Washer Nozzles 9D–18. . . . . . . . . . . . . . . .

Windshield Washer Hoses 9D–18. . . . . . . . . . . . . . . . .

Rear Window Wiper Arm (HATCHBACK) 9D–19. . . .

Rear Window Wiper Motor (HATCHBACK) 9D–20. . .

Rear Window Washer Nozzle (HATCHBACK) 9D–20

GENERAL DESCRIPTION AND SYSTEM

OPERATION9D–22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windshield Wiper System 9D–22. . . . . . . . . . . . . . . . . .

Windshield Washer System 9D–22. . . . . . . . . . . . . . . .

Rear Window Wiper/Washer System 9D–22. . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Front Wheel Well Splash Shield Bolts1.5–13

Washer Fluid Reservoir Bolts8–71

Wiper Arm Linkage Nut5–44

Wiper Arm Nut2216–

Wiper Motor Bolts8–71

Rear Wiper Arm Nut11–97

Page 2279 of 2643

9D – 2IWIPERS/WASHER SYSTEMS

DAEWOO V–121 BL4

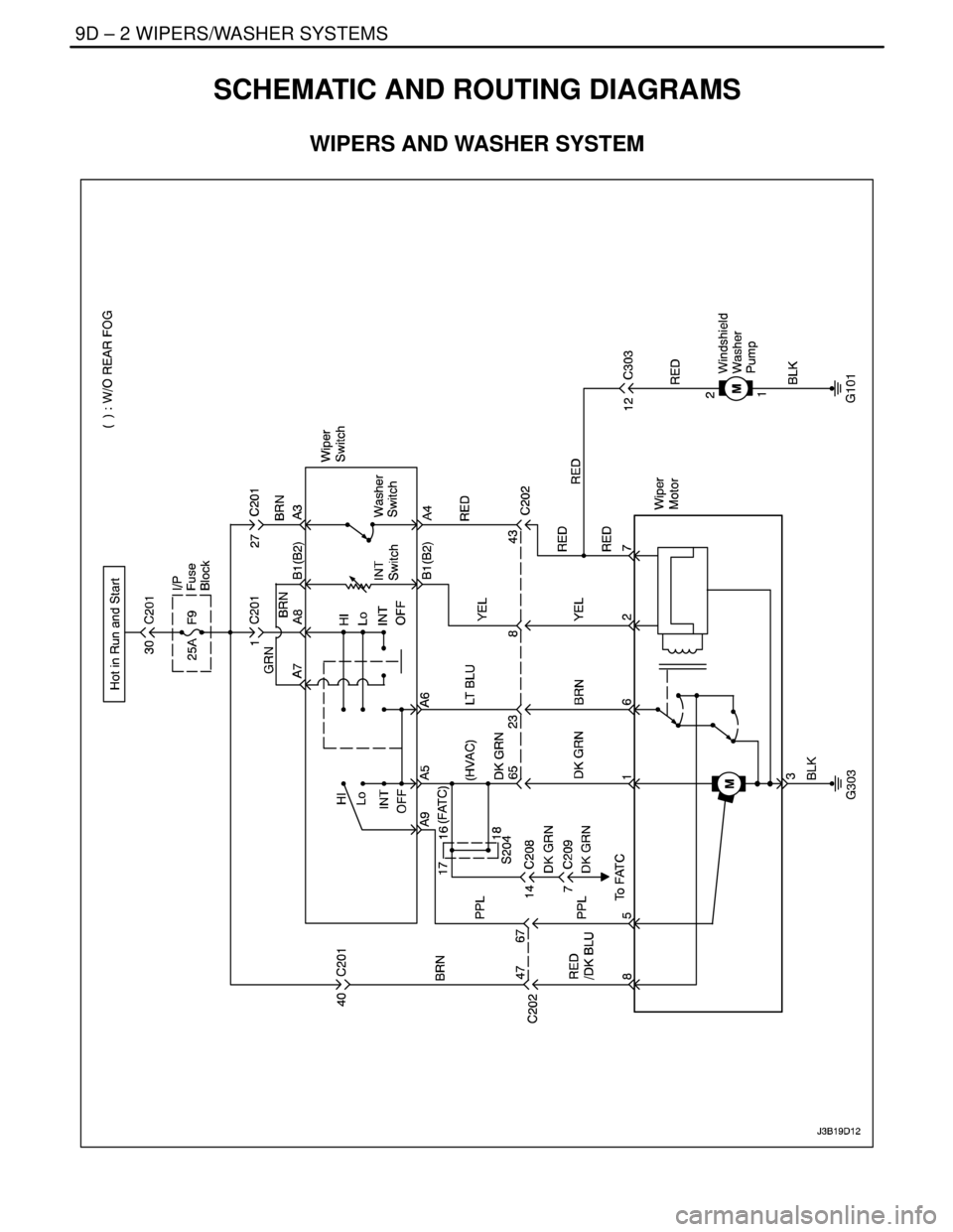

SCHEMATIC AND ROUTING DIAGRAMS

WIPERS AND WASHER SYSTEM

Page 2280 of 2643

WIPERS/WASHER SYSTEMS 9D – 3

DAEWOO V–121 BL4

WIPERS AND WASHER SYSTEM

Page 2281 of 2643

9D – 4IWIPERS/WASHER SYSTEMS

DAEWOO V–121 BL4

WIPERS AND WASHER SYSTEM (HATCHBACK)