Wiper DAEWOO LACETTI 2004 Service Workshop Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2549 of 2643

NUBIRA/LACETTIFRONT 4–15

4–2. REPAIR PROCEDURE

1. Remove the related parts.

S Hood, radiator grill and front bumper.

S Door and fender.

S Wiper, cowl and windshield.

S Weatherstrip and pillar trims.

S Instrument panel and wiring harness.

S Carpet and others.

2. Roughly pull out and straighten the damaged area.

S Check the damage to the wheelhouse and roof before

removing the brace wheelhouse and front pillar and de-

termine the extent of the damage.

S Use the frame straightener to roughly pull out and repair

the damaged front pillar before removing the brace

wheelhouse and front panel.

Note : Pull out until the pillar is lined up with the surface

of the windshield and do not pull out more than neces-

sary.

Fig. 23

3. Remove the brace wheelhouse.

S Center punch around the spot weld imprints.

S Use the special spot cutter to drill holes at the spot weld

nuggets on the brace wheelhouse.

S Remove the MIG weld areas with a disc sander.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind–

ing.

S Using a chisel, pry off the welded flange from the front

body pillar and wheelhouse.

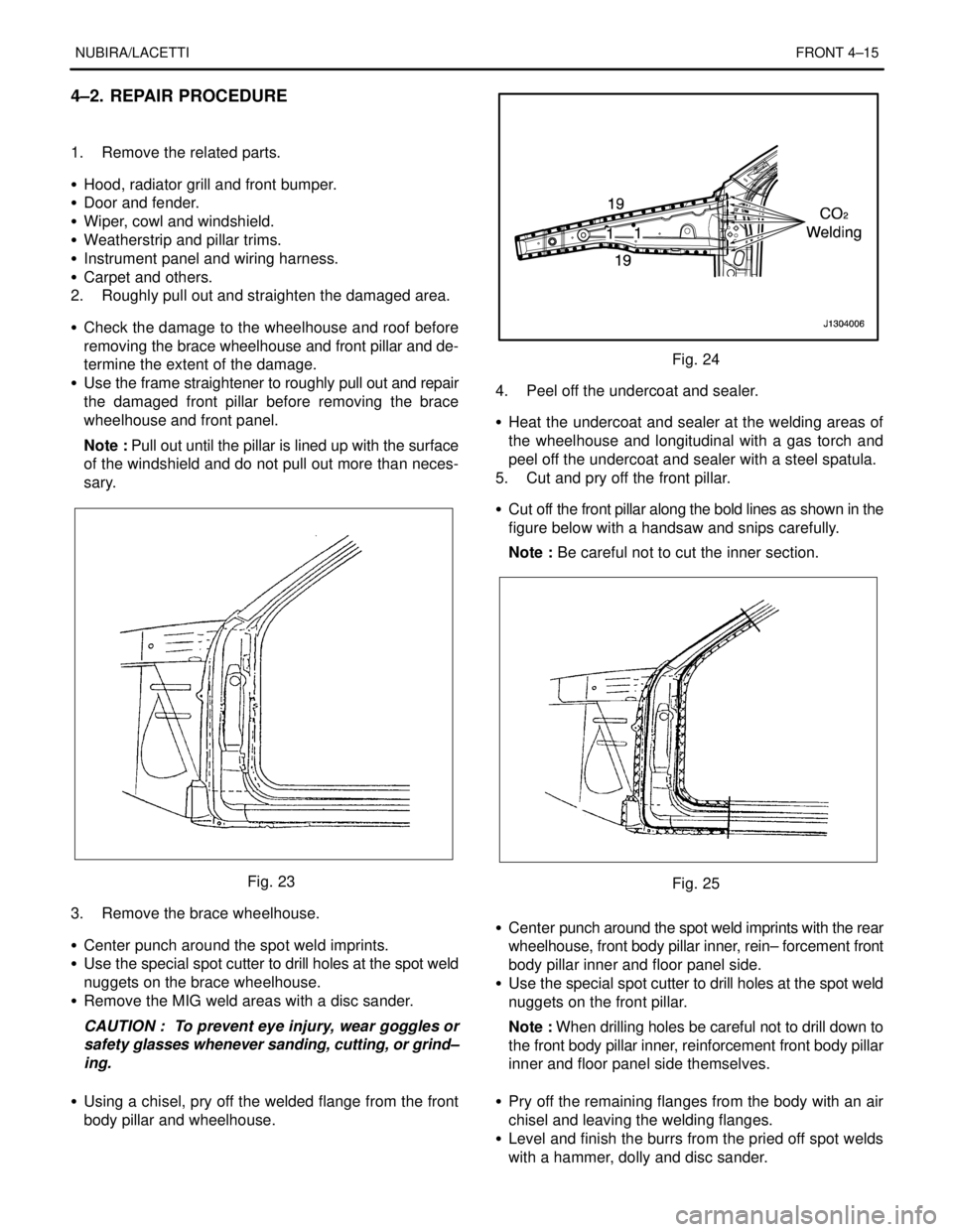

Fig. 24

4. Peel off the undercoat and sealer.

S Heat the undercoat and sealer at the welding areas of

the wheelhouse and longitudinal with a gas torch and

peel off the undercoat and sealer with a steel spatula.

5. Cut and pry off the front pillar.

S Cut off the front pillar along the bold lines as shown in the

figure below with a handsaw and snips carefully.

Note : Be careful not to cut the inner section.

Fig. 25

S Center punch around the spot weld imprints with the rear

wheelhouse, front body pillar inner, rein– forcement front

body pillar inner and floor panel side.

S Use the special spot cutter to drill holes at the spot weld

nuggets on the front pillar.

Note : When drilling holes be careful not to drill down to

the front body pillar inner, reinforcement front body pillar

inner and floor panel side themselves.

S Pry off the remaining flanges from the body with an air

chisel and leaving the welding flanges.

S Level and finish the burrs from the pried off spot welds

with a hammer, dolly and disc sander.

Page 2551 of 2643

NUBIRA/LACETTIFRONT 4–17

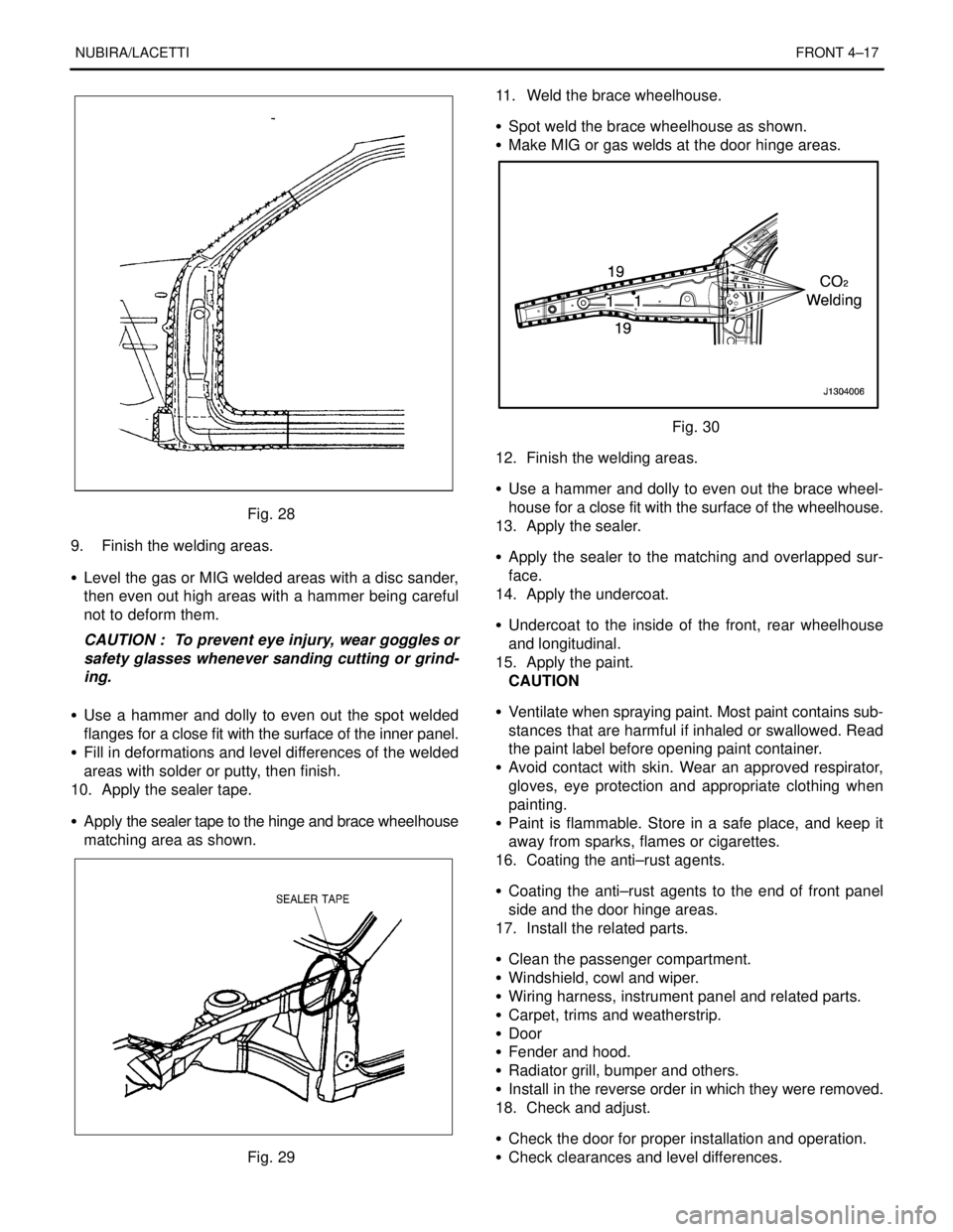

Fig. 28

9. Finish the welding areas.

S Level the gas or MIG welded areas with a disc sander,

then even out high areas with a hammer being careful

not to deform them.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding cutting or grind-

ing.

S Use a hammer and dolly to even out the spot welded

flanges for a close fit with the surface of the inner panel.

S Fill in deformations and level differences of the welded

areas with solder or putty, then finish.

10. Apply the sealer tape.

S Apply the sealer tape to the hinge and brace wheelhouse

matching area as shown.

Fig. 2911. Weld the brace wheelhouse.

S Spot weld the brace wheelhouse as shown.

S Make MIG or gas welds at the door hinge areas.

Fig. 30

12. Finish the welding areas.

S Use a hammer and dolly to even out the brace wheel-

house for a close fit with the surface of the wheelhouse.

13. Apply the sealer.

S Apply the sealer to the matching and overlapped sur-

face.

14. Apply the undercoat.

S Undercoat to the inside of the front, rear wheelhouse

and longitudinal.

15. Apply the paint.

CAUTION

S Ventilate when spraying paint. Most paint contains sub-

stances that are harmful if inhaled or swallowed. Read

the paint label before opening paint container.

S Avoid contact with skin. Wear an approved respirator,

gloves, eye protection and appropriate clothing when

painting.

S Paint is flammable. Store in a safe place, and keep it

away from sparks, flames or cigarettes.

16. Coating the anti–rust agents.

S Coating the anti–rust agents to the end of front panel

side and the door hinge areas.

17. Install the related parts.

S Clean the passenger compartment.

S Windshield, cowl and wiper.

S Wiring harness, instrument panel and related parts.

S Carpet, trims and weatherstrip.

S Door

S Fender and hood.

S Radiator grill, bumper and others.

S Install in the reverse order in which they were removed.

18. Check and adjust.

S Check the door for proper installation and operation.

S Check clearances and level differences.

Page 2555 of 2643

NUBIRA/LACETTI ROOF, BACK PANEL AND REAR FLOOR PANEL 5–3

1–2. REPAIR PROCEDURE

1. Remove the related parts.

S Room lamp, door weatherstrip and pillar trims.

S Headlining and wiring harness.

S Wiper, cowl and windshield.

S Rear glass and others.

2. Pull out and straighten the damaged area to approxi-

mately the original shape.

Note : Use heat–resistant protective cover for protect

painting areas, seats, carpets and other parts.

S Attach the car to the frame straightener by tightening the

underbody clamps at the horizontal pinch welds.

S Before cutting off the roof panel, pull them out so that

they are restored to the original shape.

S Do not pull out more than necessary.

S Pull out and straighten the related damaged parts to

approximately their original shape.

Note : Make sure that the right and left pillars are parallel

with the windshield surface. Check the door for proper

opening and closing.

3. Keep the body, level.

S Jack up the body, and place safety stands at the four

designated places of the frame door opening.

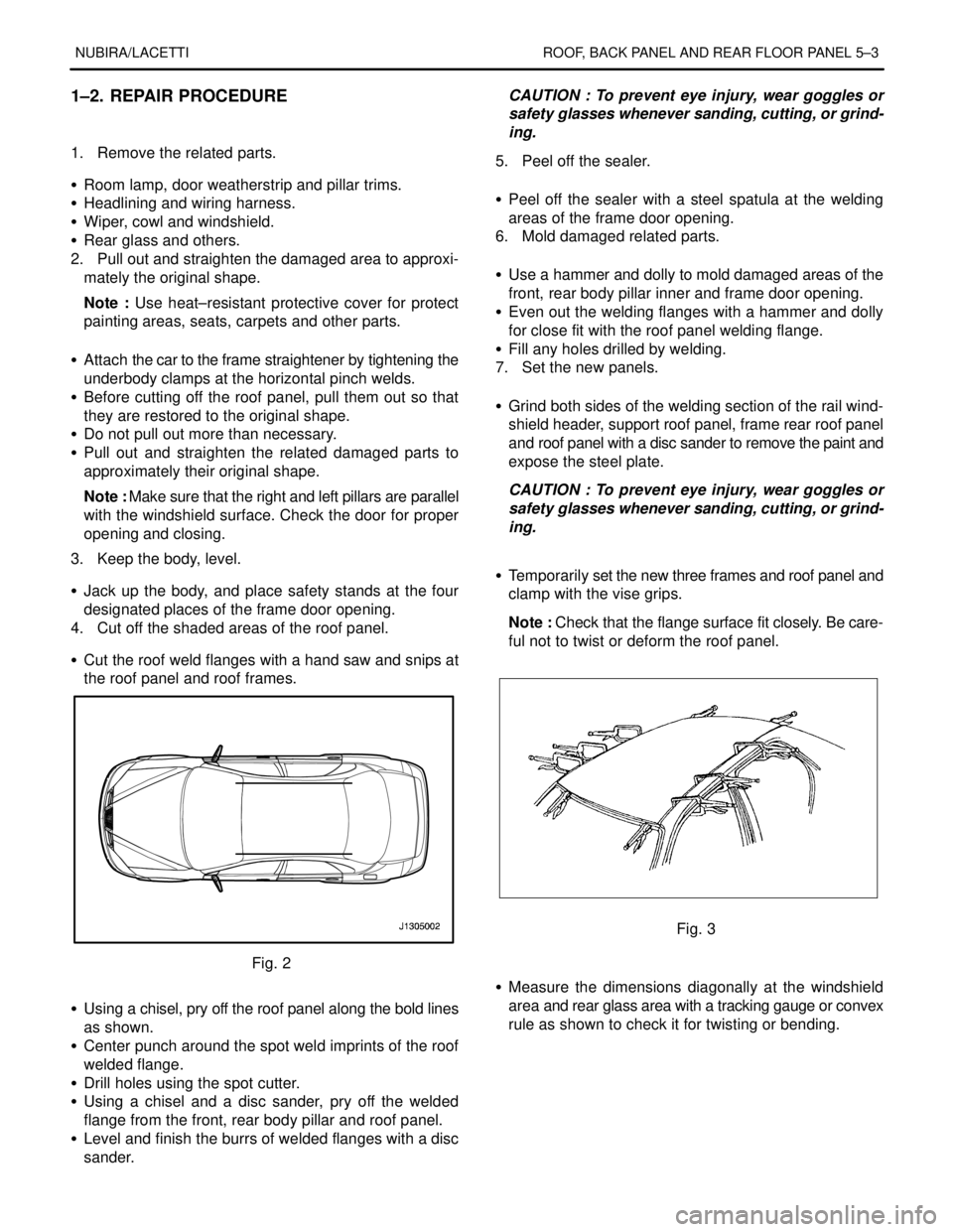

4. Cut off the shaded areas of the roof panel.

S Cut the roof weld flanges with a hand saw and snips at

the roof panel and roof frames.

Fig. 2

S Using a chisel, pry off the roof panel along the bold lines

as shown.

S Center punch around the spot weld imprints of the roof

welded flange.

S Drill holes using the spot cutter.

S Using a chisel and a disc sander, pry off the welded

flange from the front, rear body pillar and roof panel.

S Level and finish the burrs of welded flanges with a disc

sander.CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

5. Peel off the sealer.

S Peel off the sealer with a steel spatula at the welding

areas of the frame door opening.

6. Mold damaged related parts.

S Use a hammer and dolly to mold damaged areas of the

front, rear body pillar inner and frame door opening.

S Even out the welding flanges with a hammer and dolly

for close fit with the roof panel welding flange.

S Fill any holes drilled by welding.

7. Set the new panels.

S Grind both sides of the welding section of the rail wind-

shield header, support roof panel, frame rear roof panel

and roof panel with a disc sander to remove the paint and

expose the steel plate.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

S Temporarily set the new three frames and roof panel and

clamp with the vise grips.

Note : Check that the flange surface fit closely. Be care-

ful not to twist or deform the roof panel.

Fig. 3

S Measure the dimensions diagonally at the windshield

area and rear glass area with a tracking gauge or convex

rule as shown to check it for twisting or bending.

Page 2557 of 2643

NUBIRA/LACETTI ROOF, BACK PANEL AND REAR FLOOR PANEL 5–5

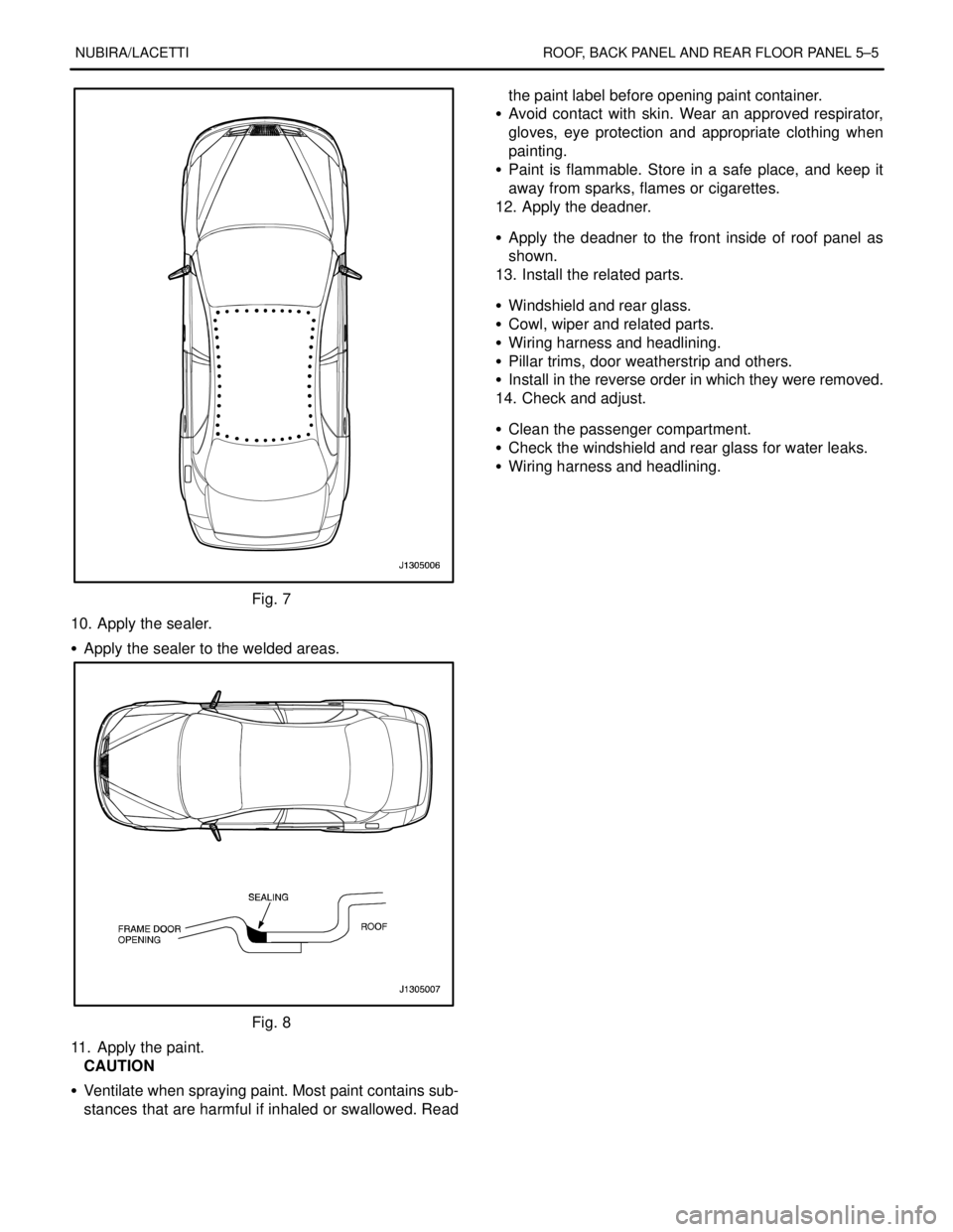

Fig. 7

10. Apply the sealer.

S Apply the sealer to the welded areas.

Fig. 8

11. Apply the paint.

CAUTION

S Ventilate when spraying paint. Most paint contains sub-

stances that are harmful if inhaled or swallowed. Readthe paint label before opening paint container.

S Avoid contact with skin. Wear an approved respirator,

gloves, eye protection and appropriate clothing when

painting.

S Paint is flammable. Store in a safe place, and keep it

away from sparks, flames or cigarettes.

12. Apply the deadner.

S Apply the deadner to the front inside of roof panel as

shown.

13. Install the related parts.

S Windshield and rear glass.

S Cowl, wiper and related parts.

S Wiring harness and headlining.

S Pillar trims, door weatherstrip and others.

S Install in the reverse order in which they were removed.

14. Check and adjust.

S Clean the passenger compartment.

S Check the windshield and rear glass for water leaks.

S Wiring harness and headlining.

Page 2581 of 2643

7–4 FENDER, HOOD, TAILGATE AND TRUNK LID NUBIRA/LACETTI

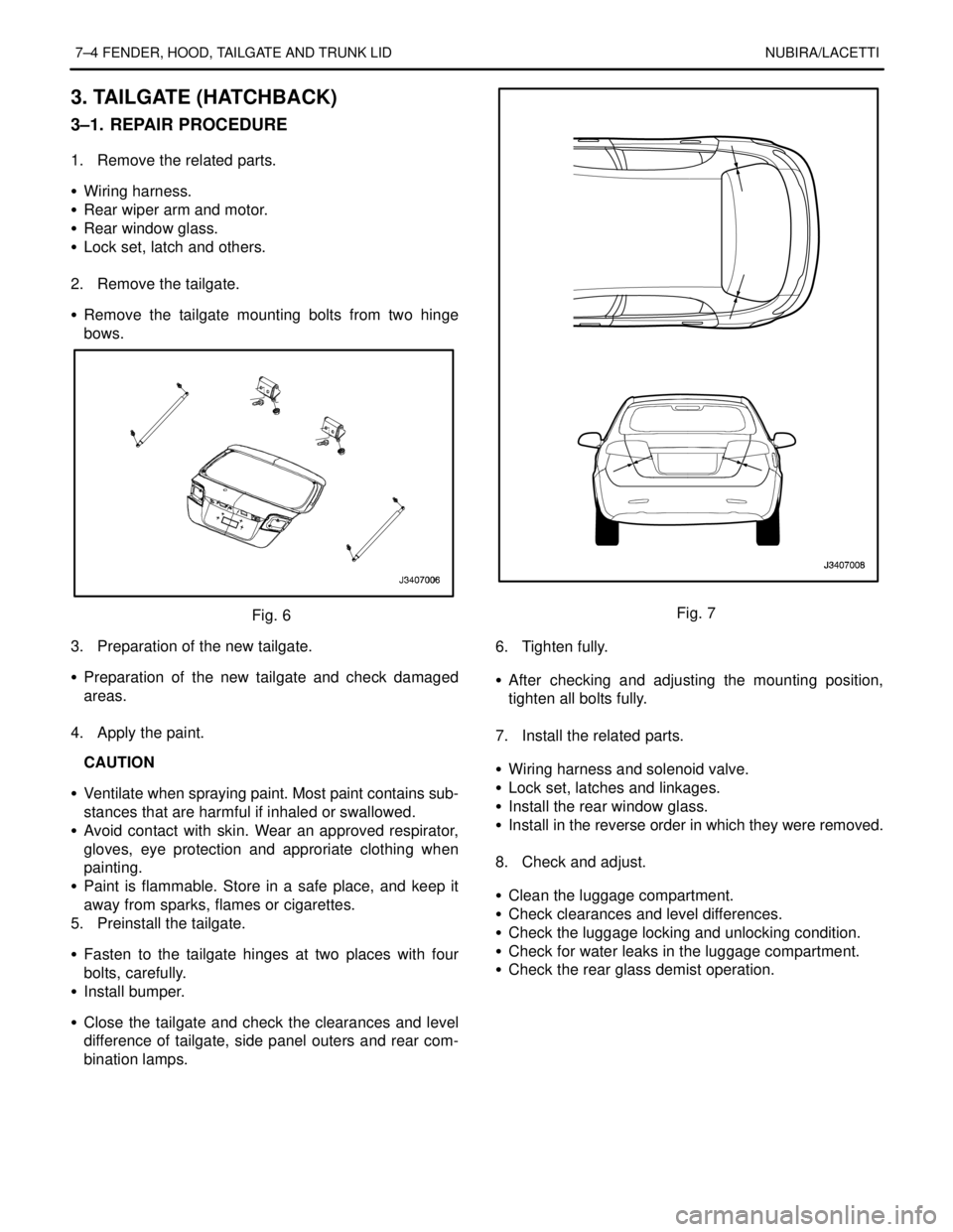

3. TAILGATE (HATCHBACK)

3–1. REPAIR PROCEDURE

1. Remove the related parts.

S Wiring harness.

S Rear wiper arm and motor.

S Rear window glass.

S Lock set, latch and others.

.

2. Remove the tailgate.

S Remove the tailgate mounting bolts from two hinge

bows.

Fig. 6

3. Preparation of the new tailgate.

S Preparation of the new tailgate and check damaged

areas.

.

4. Apply the paint.

CAUTION

S Ventilate when spraying paint. Most paint contains sub-

stances that are harmful if inhaled or swallowed.

S Avoid contact with skin. Wear an approved respirator,

gloves, eye protection and approriate clothing when

painting.

S Paint is flammable. Store in a safe place, and keep it

away from sparks, flames or cigarettes.

5. Preinstall the tailgate.

S Fasten to the tailgate hinges at two places with four

bolts, carefully.

S Install bumper.

S Close the tailgate and check the clearances and level

difference of tailgate, side panel outers and rear com-

bination lamps.Fig. 7

6. Tighten fully.

S After checking and adjusting the mounting position,

tighten all bolts fully.

.

7. Install the related parts.

S Wiring harness and solenoid valve.

S Lock set, latches and linkages.

S Install the rear window glass.

S Install in the reverse order in which they were removed.

.

8. Check and adjust.

S Clean the luggage compartment.

S Check clearances and level differences.

S Check the luggage locking and unlocking condition.

S Check for water leaks in the luggage compartment.

S Check the rear glass demist operation.