lock DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1028 of 2643

4A – 12IHYDRAULIC BRAKES

DAEWOO V–121 BL4

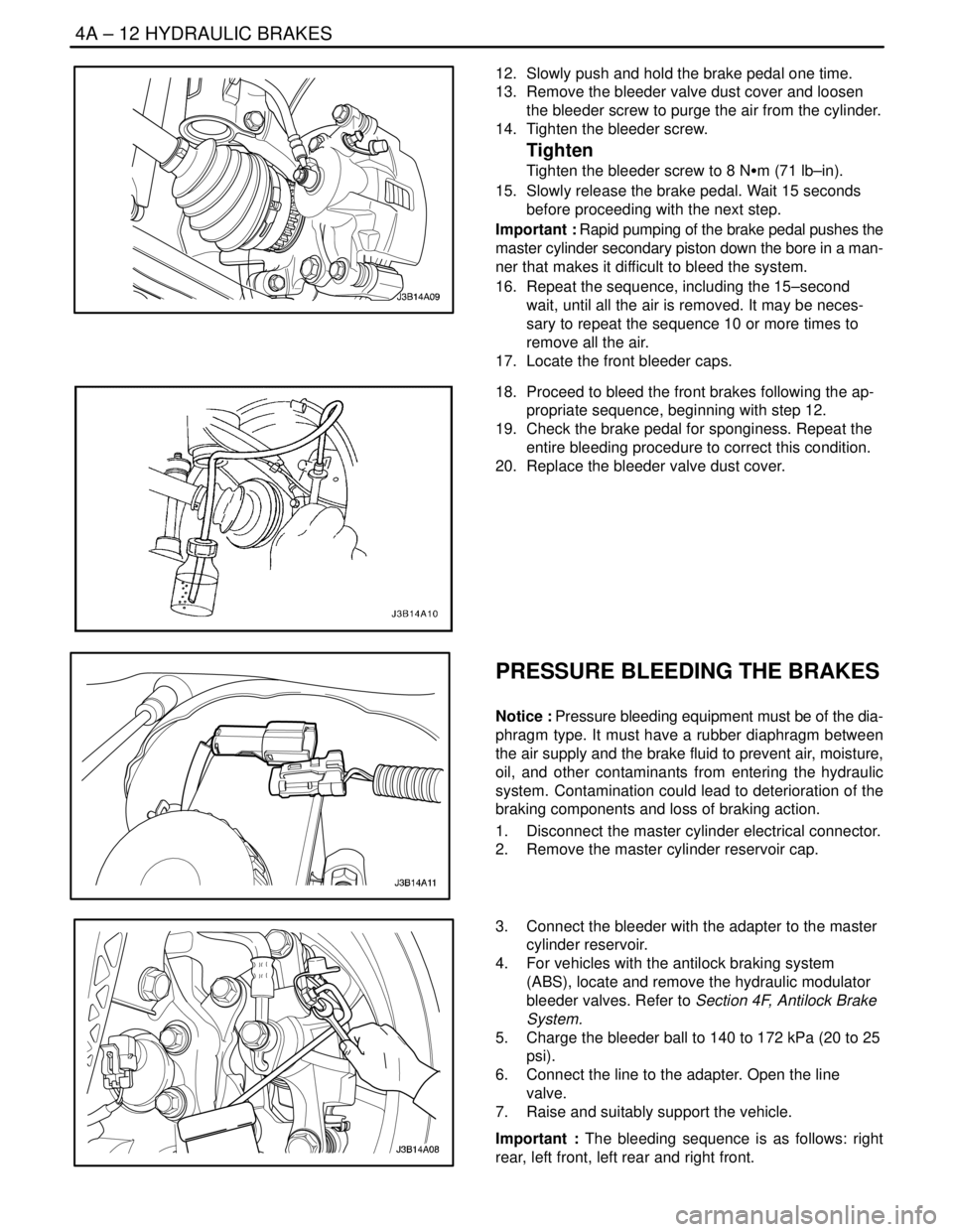

12. Slowly push and hold the brake pedal one time.

13. Remove the bleeder valve dust cover and loosen

the bleeder screw to purge the air from the cylinder.

14. Tighten the bleeder screw.

Tighten

Tighten the bleeder screw to 8 NSm (71 lb–in).

15. Slowly release the brake pedal. Wait 15 seconds

before proceeding with the next step.

Important : Rapid pumping of the brake pedal pushes the

master cylinder secondary piston down the bore in a man-

ner that makes it difficult to bleed the system.

16. Repeat the sequence, including the 15–second

wait, until all the air is removed. It may be neces-

sary to repeat the sequence 10 or more times to

remove all the air.

17. Locate the front bleeder caps.

18. Proceed to bleed the front brakes following the ap-

propriate sequence, beginning with step 12.

19. Check the brake pedal for sponginess. Repeat the

entire bleeding procedure to correct this condition.

20. Replace the bleeder valve dust cover.

PRESSURE BLEEDING THE BRAKES

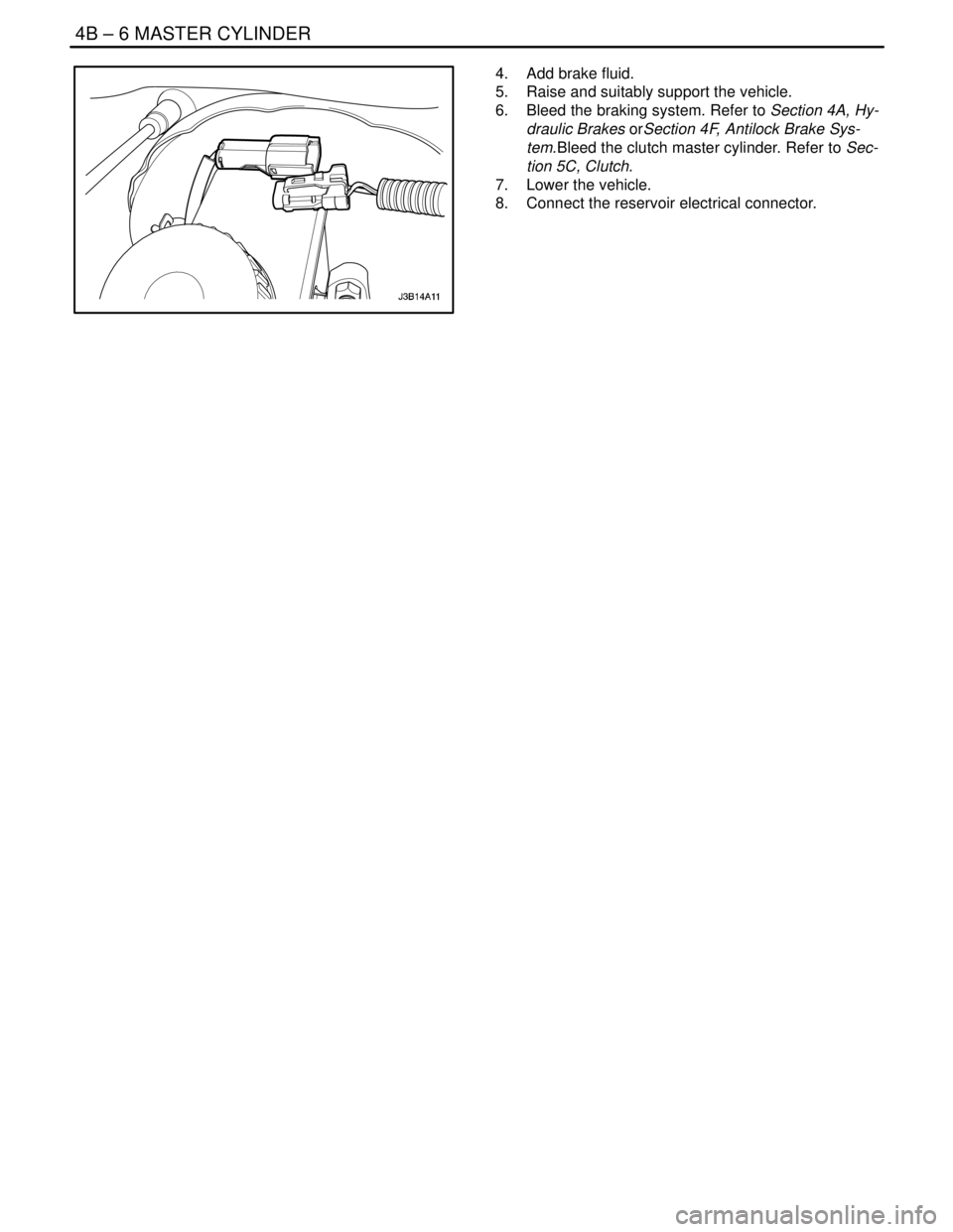

Notice : Pressure bleeding equipment must be of the dia-

phragm type. It must have a rubber diaphragm between

the air supply and the brake fluid to prevent air, moisture,

oil, and other contaminants from entering the hydraulic

system. Contamination could lead to deterioration of the

braking components and loss of braking action.

1. Disconnect the master cylinder electrical connector.

2. Remove the master cylinder reservoir cap.

3. Connect the bleeder with the adapter to the master

cylinder reservoir.

4. For vehicles with the antilock braking system

(ABS), locate and remove the hydraulic modulator

bleeder valves. Refer to Section 4F, Antilock Brake

System.

5. Charge the bleeder ball to 140 to 172 kPa (20 to 25

psi).

6. Connect the line to the adapter. Open the line

valve.

7. Raise and suitably support the vehicle.

Important : The bleeding sequence is as follows: right

rear, left front, left rear and right front.

Page 1039 of 2643

4B – 6IMASTER CYLINDER

DAEWOO V–121 BL4

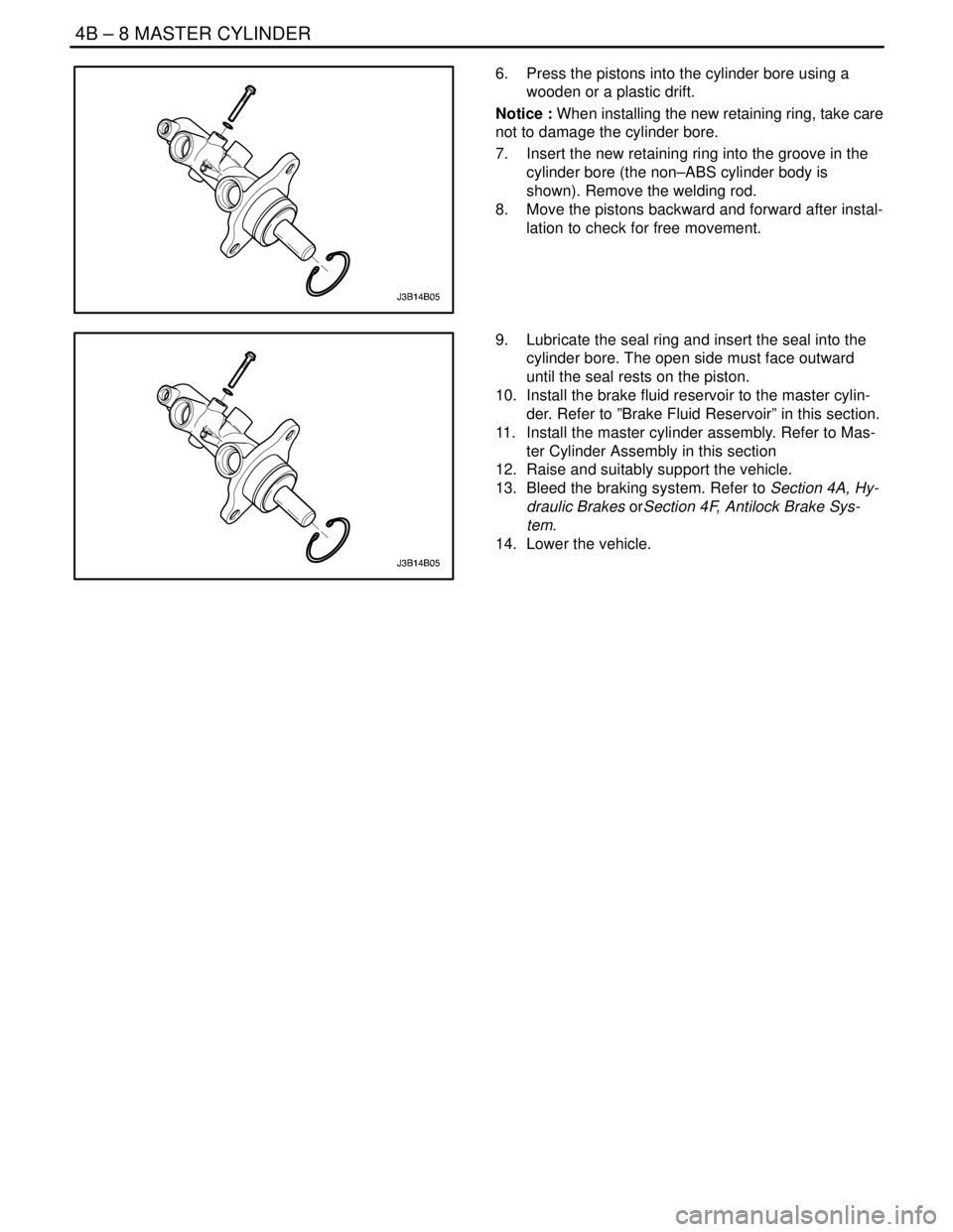

4. Add brake fluid.

5. Raise and suitably support the vehicle.

6. Bleed the braking system. Refer to Section 4A, Hy-

draulic Brakes orSection 4F, Antilock Brake Sys-

tem.Bleed the clutch master cylinder. Refer to Sec-

tion 5C, Clutch.

7. Lower the vehicle.

8. Connect the reservoir electrical connector.

Page 1041 of 2643

4B – 8IMASTER CYLINDER

DAEWOO V–121 BL4

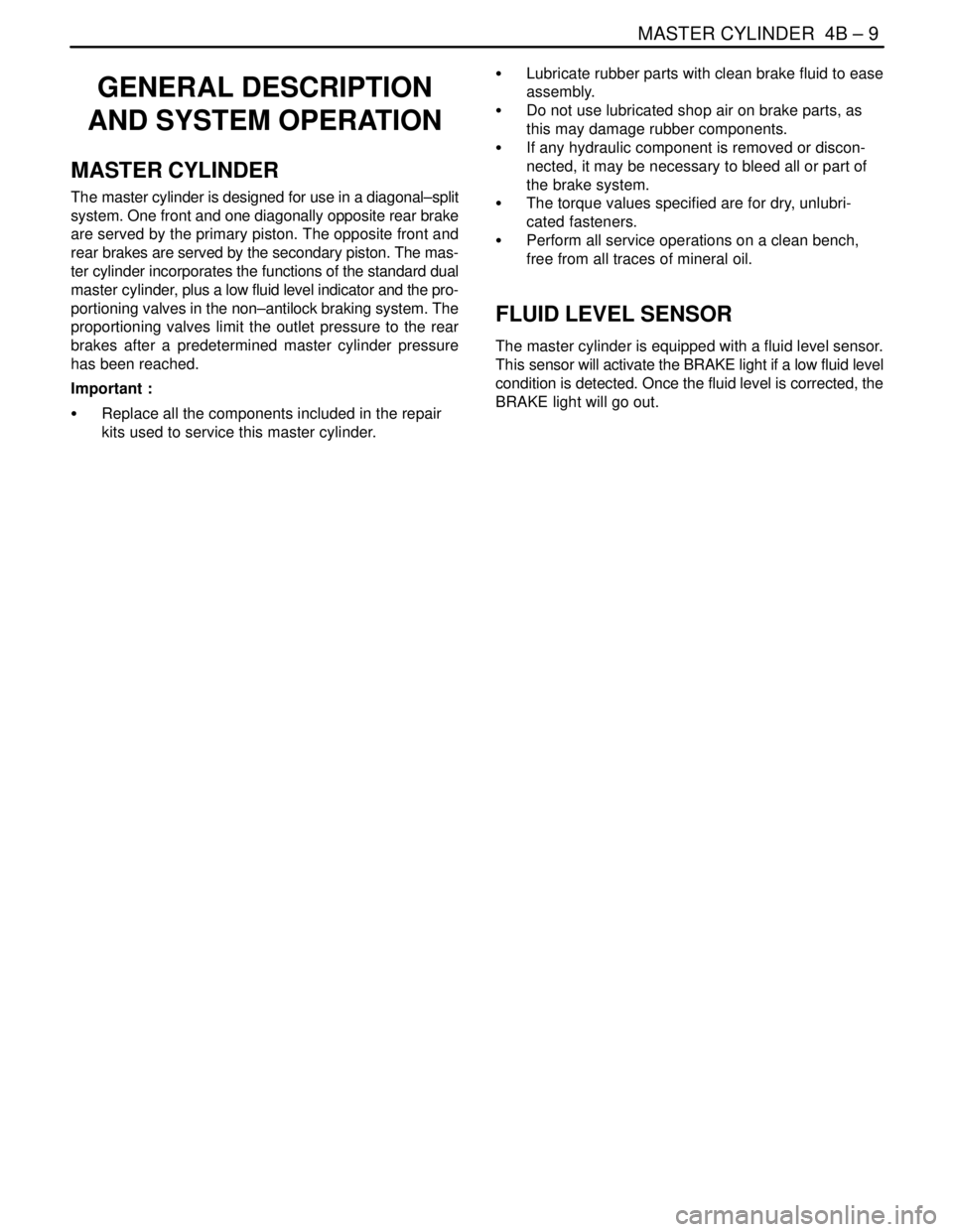

6. Press the pistons into the cylinder bore using a

wooden or a plastic drift.

Notice : When installing the new retaining ring, take care

not to damage the cylinder bore.

7. Insert the new retaining ring into the groove in the

cylinder bore (the non–ABS cylinder body is

shown). Remove the welding rod.

8. Move the pistons backward and forward after instal-

lation to check for free movement.

9. Lubricate the seal ring and insert the seal into the

cylinder bore. The open side must face outward

until the seal rests on the piston.

10. Install the brake fluid reservoir to the master cylin-

der. Refer to ”Brake Fluid Reservoir” in this section.

11. Install the master cylinder assembly. Refer to Mas-

ter Cylinder Assembly in this section

12. Raise and suitably support the vehicle.

13. Bleed the braking system. Refer to Section 4A, Hy-

draulic Brakes orSection 4F, Antilock Brake Sys-

tem.

14. Lower the vehicle.

Page 1042 of 2643

MASTER CYLINDER 4B – 9

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

MASTER CYLINDER

The master cylinder is designed for use in a diagonal–split

system. One front and one diagonally opposite rear brake

are served by the primary piston. The opposite front and

rear brakes are served by the secondary piston. The mas-

ter cylinder incorporates the functions of the standard dual

master cylinder, plus a low fluid level indicator and the pro-

portioning valves in the non–antilock braking system. The

proportioning valves limit the outlet pressure to the rear

brakes after a predetermined master cylinder pressure

has been reached.

Important :

S Replace all the components included in the repair

kits used to service this master cylinder.S Lubricate rubber parts with clean brake fluid to ease

assembly.

S Do not use lubricated shop air on brake parts, as

this may damage rubber components.

S If any hydraulic component is removed or discon-

nected, it may be necessary to bleed all or part of

the brake system.

S The torque values specified are for dry, unlubri-

cated fasteners.

S Perform all service operations on a clean bench,

free from all traces of mineral oil.

FLUID LEVEL SENSOR

The master cylinder is equipped with a fluid level sensor.

This sensor will activate the BRAKE light if a low fluid level

condition is detected. Once the fluid level is corrected, the

BRAKE light will go out.

Page 1062 of 2643

REAR DISC BRAKES 4E1 – 5

DAEWOO V–121 BL4

2. Connect the brake hose with the bolt and ring

seals.

Tighten

Tighten the brake hose inlet bolt and ring seals to 32

NSm (24 lb–ft).

3. Install the rear wheels. Refer to Section 2E, Tires

and Wheels.

4. Lower the vehicle.

5. Fill the master cylinder to the proper level with

clean brake fluid.

6. Bleed the caliper. Refer to Section 4F, Antilock

Brake System and Traction Control System.

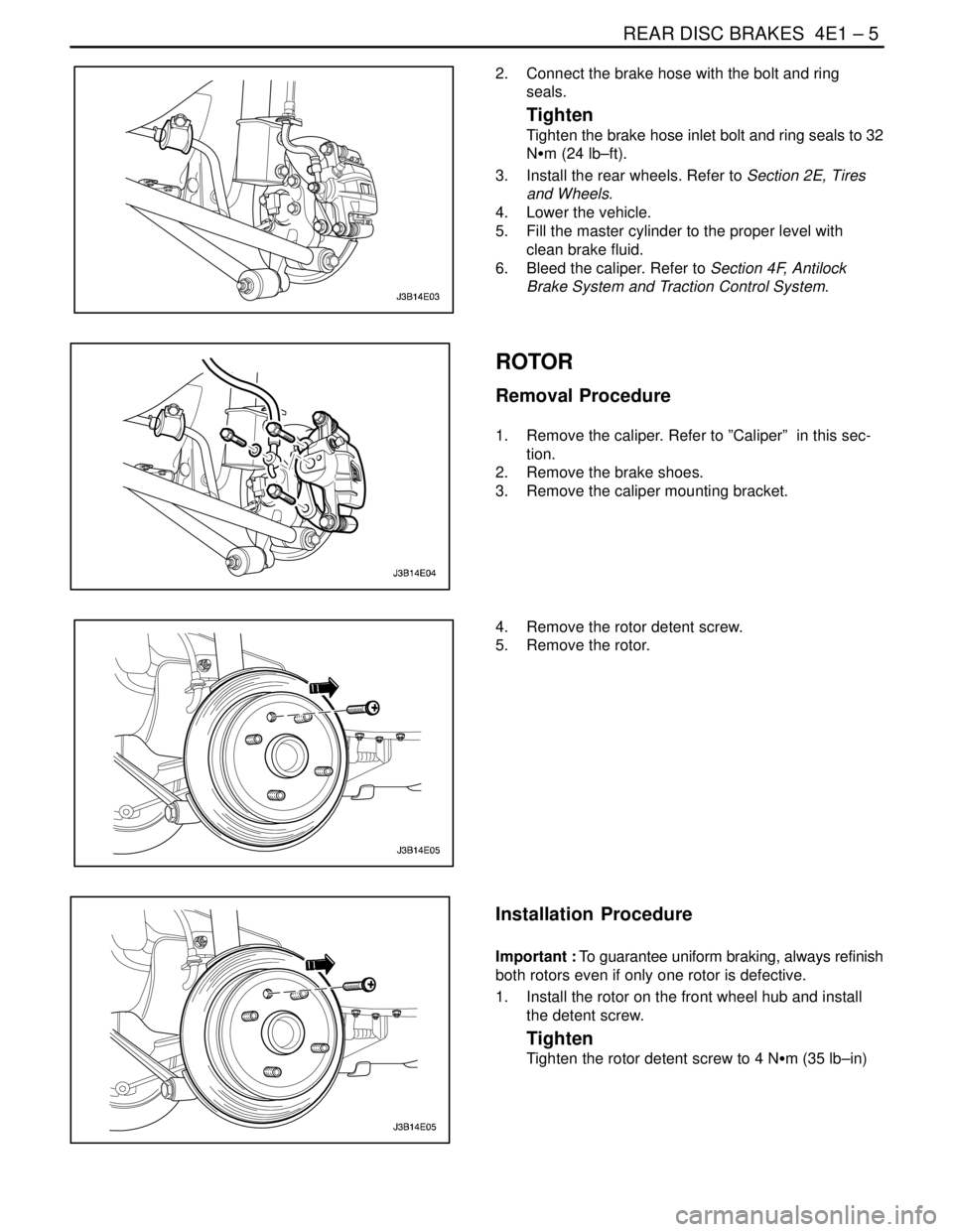

ROTOR

Removal Procedure

1. Remove the caliper. Refer to ”Caliper” in this sec-

tion.

2. Remove the brake shoes.

3. Remove the caliper mounting bracket.

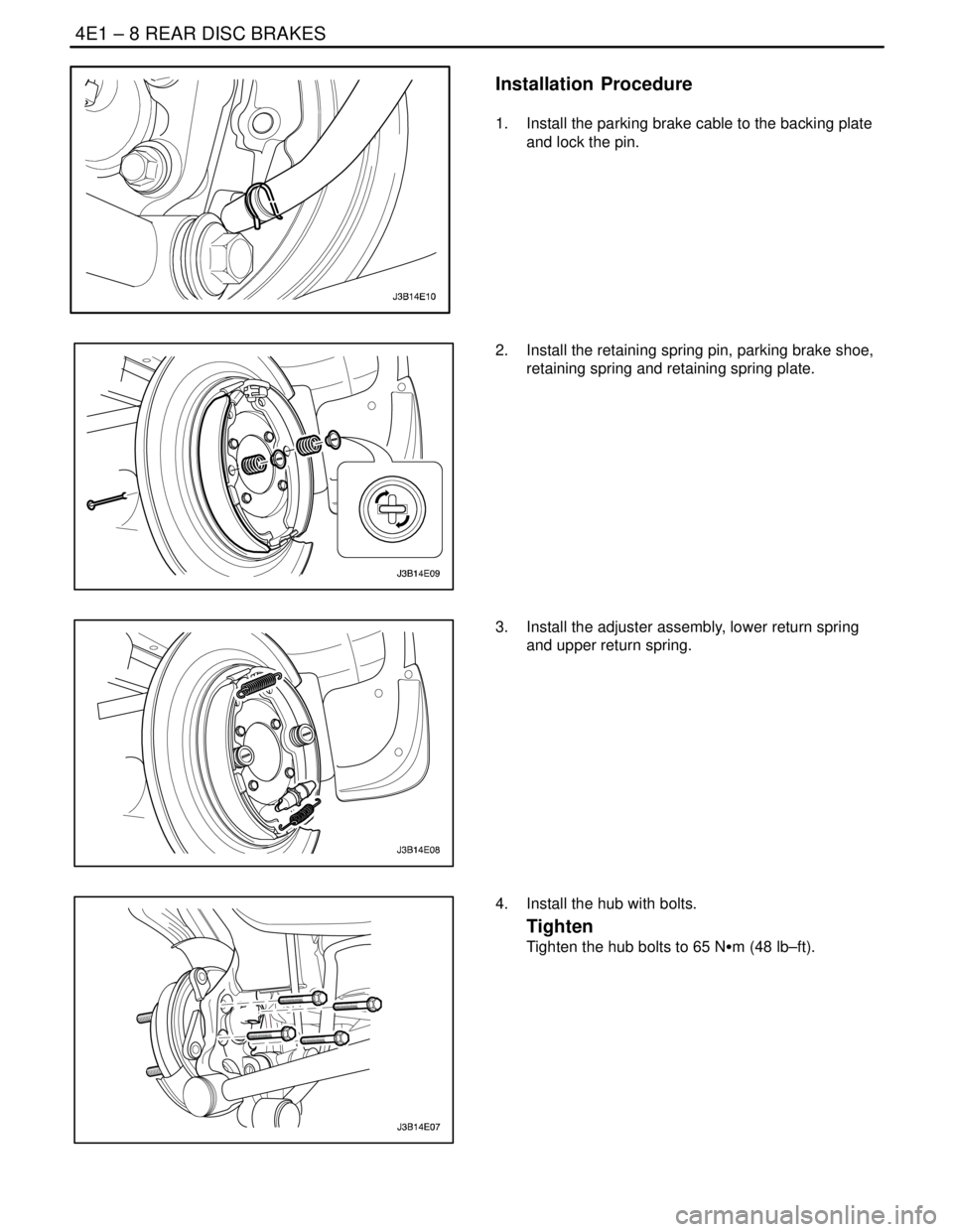

4. Remove the rotor detent screw.

5. Remove the rotor.

Installation Procedure

Important : To guarantee uniform braking, always refinish

both rotors even if only one rotor is defective.

1. Install the rotor on the front wheel hub and install

the detent screw.

Tighten

Tighten the rotor detent screw to 4 NSm (35 lb–in)

Page 1063 of 2643

4E1 – 6IREAR DISC BRAKES

DAEWOO V–121 BL4

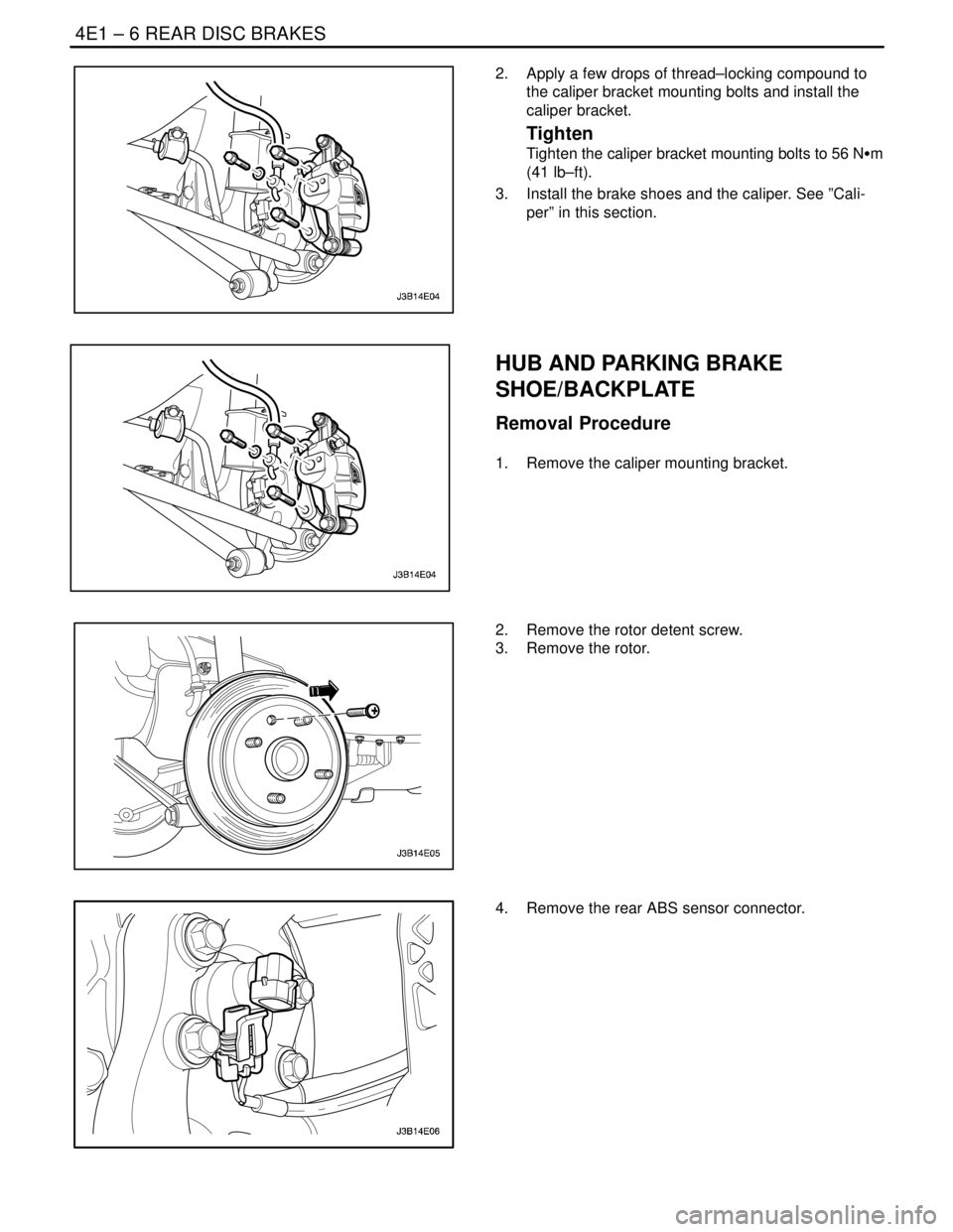

2. Apply a few drops of thread–locking compound to

the caliper bracket mounting bolts and install the

caliper bracket.

Tighten

Tighten the caliper bracket mounting bolts to 56 NSm

(41 lb–ft).

3. Install the brake shoes and the caliper. See ”Cali-

per” in this section.

HUB AND PARKING BRAKE

SHOE/BACKPLATE

Removal Procedure

1. Remove the caliper mounting bracket.

2. Remove the rotor detent screw.

3. Remove the rotor.

4. Remove the rear ABS sensor connector.

Page 1065 of 2643

4E1 – 8IREAR DISC BRAKES

DAEWOO V–121 BL4

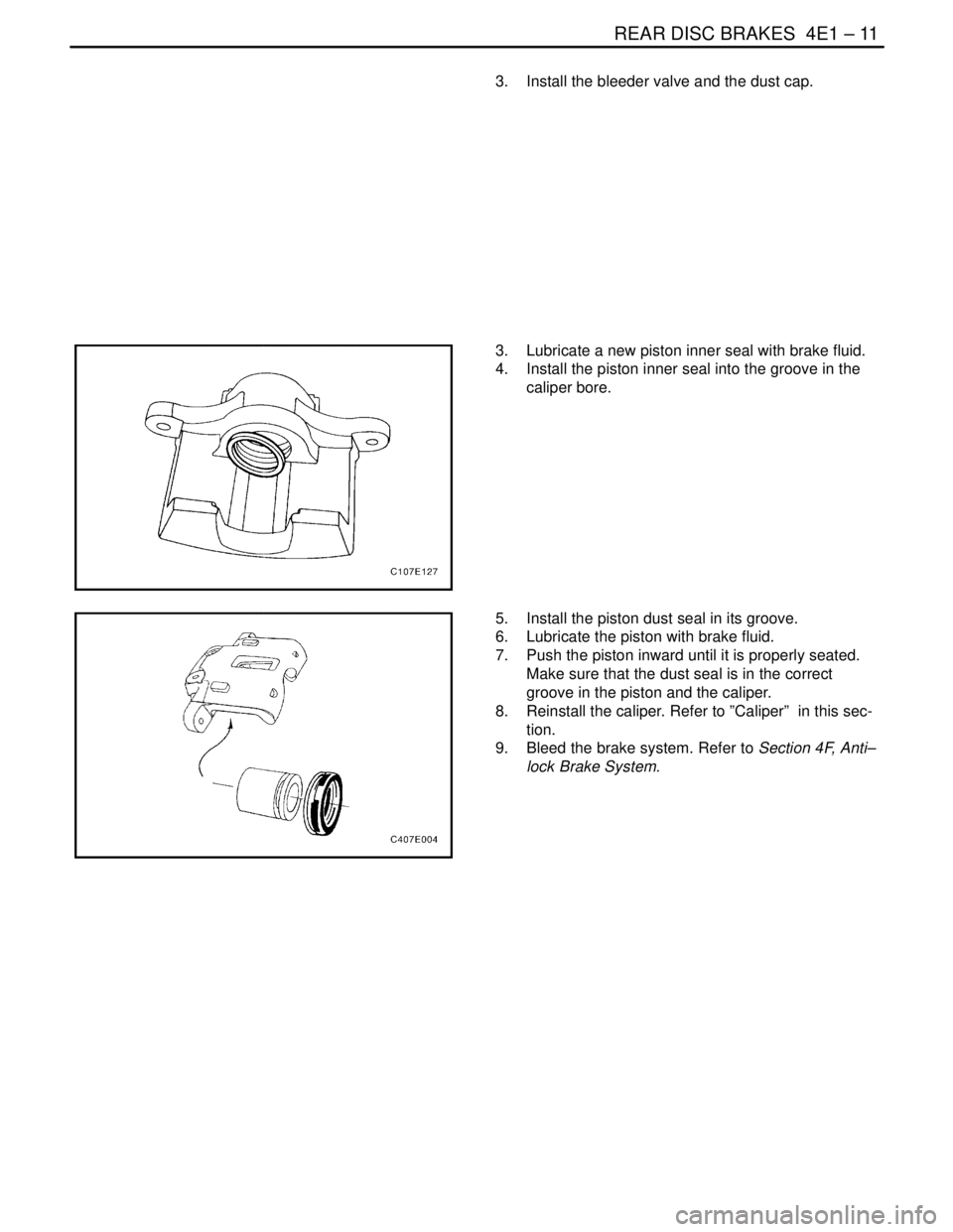

Installation Procedure

1. Install the parking brake cable to the backing plate

and lock the pin.

2. Install the retaining spring pin, parking brake shoe,

retaining spring and retaining spring plate.

3. Install the adjuster assembly, lower return spring

and upper return spring.

4. Install the hub with bolts.

Tighten

Tighten the hub bolts to 65 NSm (48 lb–ft).

Page 1068 of 2643

REAR DISC BRAKES 4E1 – 11

DAEWOO V–121 BL4

3. Install the bleeder valve and the dust cap.

3. Lubricate a new piston inner seal with brake fluid.

4. Install the piston inner seal into the groove in the

caliper bore.

5. Install the piston dust seal in its groove.

6. Lubricate the piston with brake fluid.

7. Push the piston inward until it is properly seated.

Make sure that the dust seal is in the correct

groove in the piston and the caliper.

8. Reinstall the caliper. Refer to ”Caliper” in this sec-

tion.

9. Bleed the brake system. Refer to Section 4F, Anti–

lock Brake System.

Page 1069 of 2643

4E1 – 12IREAR DISC BRAKES

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

DISC BRAKE CALIPER ASSEMBLY

The caliper has a single bore and is mounted to the steer-

ing knuckle with two mounting bolts. Hydraulic pressure,

created by applying the brake pedal, is converted by the

caliper to a stopping force. This force acts equally against

the piston and the bottom of the caliper bore to move the

piston outward and to slide the caliper inward, resulting in

a clamping action on the rotor. This clamping action forces

the linings against the rotor, creating friction to stop the ve-

hicle.S Replace all components included in the repair kits

used to service the caliper.

S Lubricate the rubber parts with clean brake fluid to

ease assembly.

S Do not use lubricated shop air on brake parts, as

damage to the rubber components may result.

S If any hydraulic component is removed or discon-

nected, it may be necessary to bleed all or part of

the brake system. Refer to Section 4F, Anti–lock

Brake System.

S Replace the shoes in axle sets only.

S The torque values specified are for dry, unlubri-

cated fasteners.

S Perform the service operations on a clean bench,

free from oily material.

Page 1075 of 2643

4E2 – 6IREAR DRUM BRAKES

DAEWOO V–121 BL4

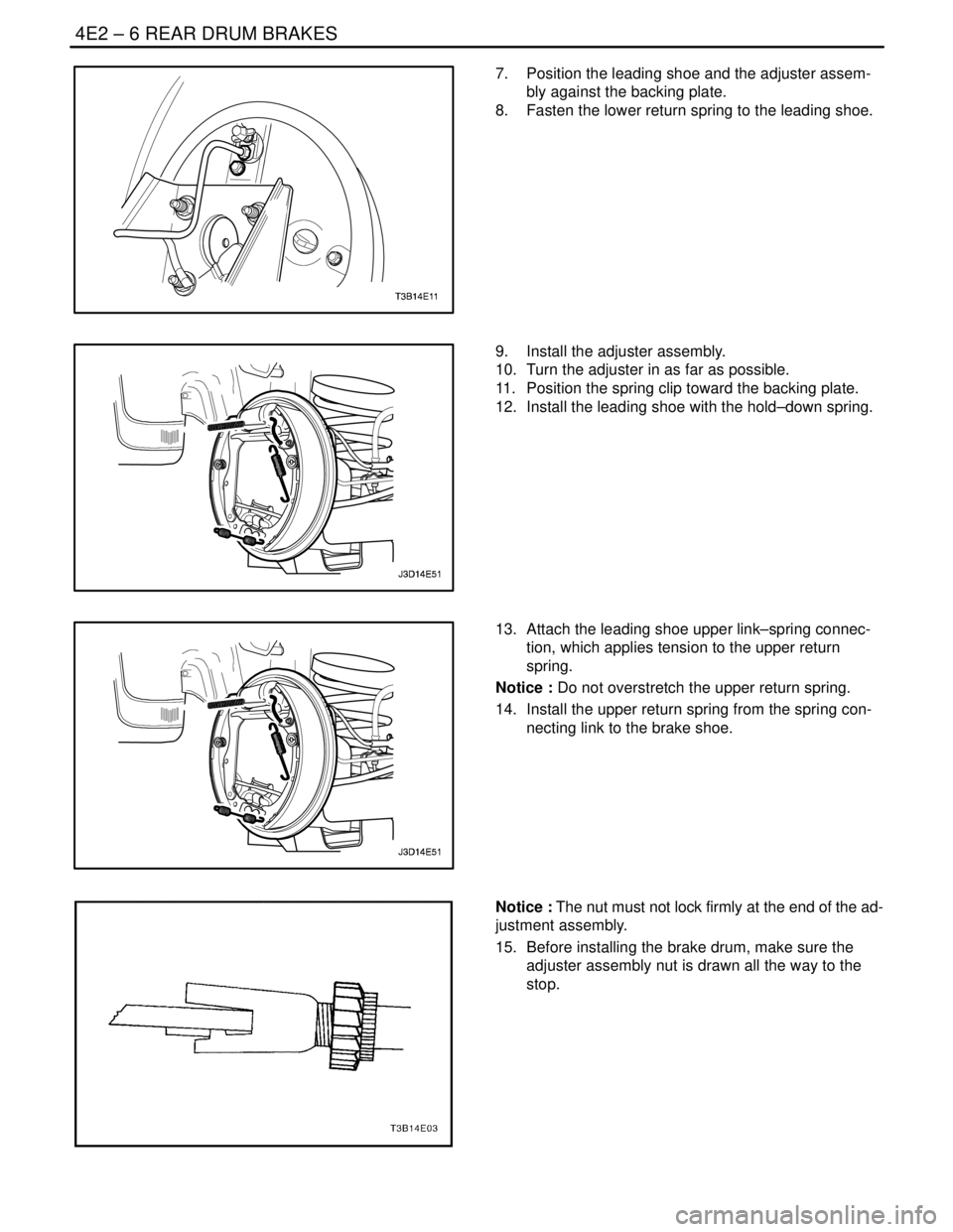

7. Position the leading shoe and the adjuster assem-

bly against the backing plate.

8. Fasten the lower return spring to the leading shoe.

9. Install the adjuster assembly.

10. Turn the adjuster in as far as possible.

11. Position the spring clip toward the backing plate.

12. Install the leading shoe with the hold–down spring.

13. Attach the leading shoe upper link–spring connec-

tion, which applies tension to the upper return

spring.

Notice : Do not overstretch the upper return spring.

14. Install the upper return spring from the spring con-

necting link to the brake shoe.

Notice : The nut must not lock firmly at the end of the ad-

justment assembly.

15. Before installing the brake drum, make sure the

adjuster assembly nut is drawn all the way to the

stop.