sensor DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 956 of 2643

2D – 14IREAR SUSPENSION

DAEWOO V–121 BL4

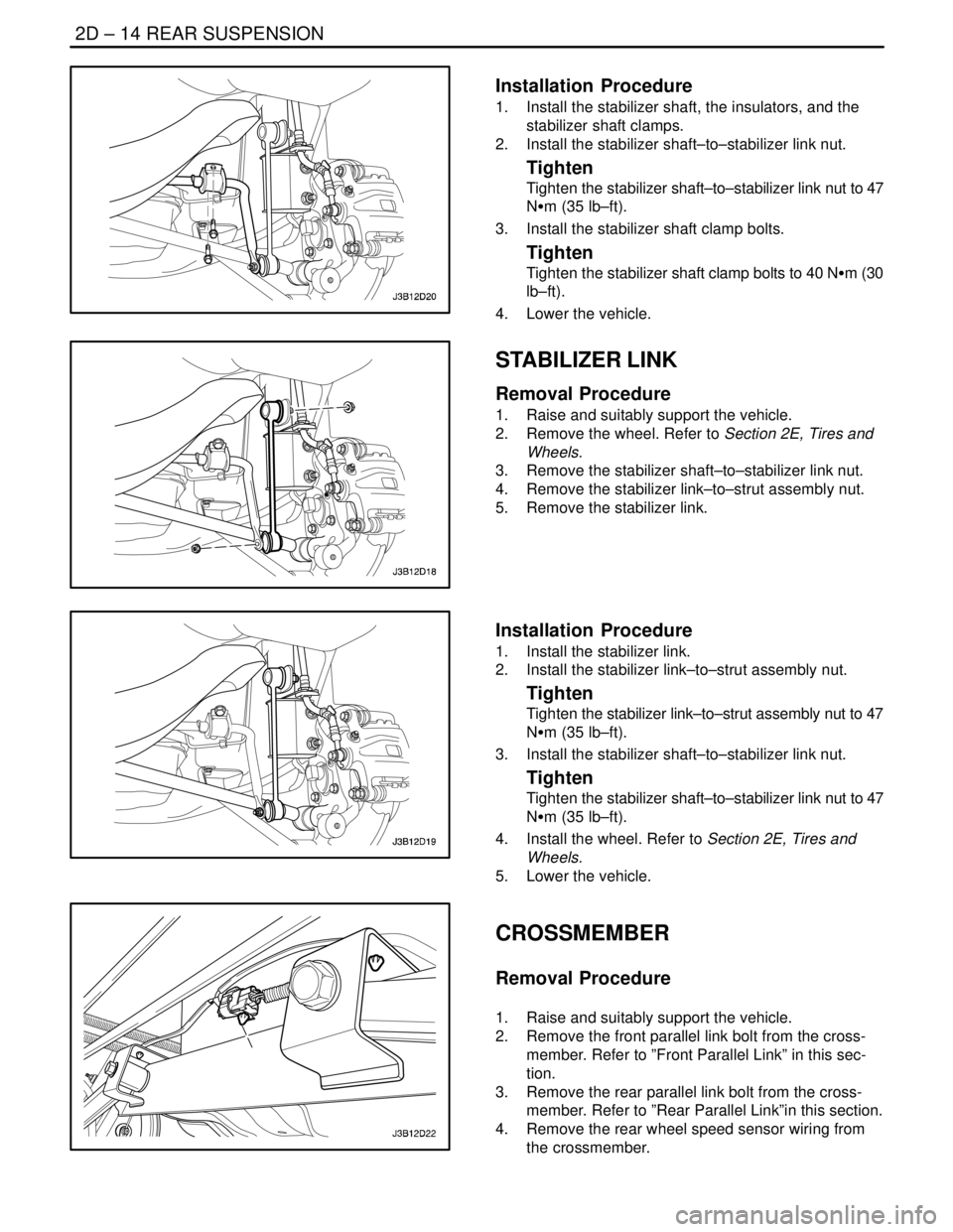

Installation Procedure

1. Install the stabilizer shaft, the insulators, and the

stabilizer shaft clamps.

2. Install the stabilizer shaft–to–stabilizer link nut.

Tighten

Tighten the stabilizer shaft–to–stabilizer link nut to 47

NSm (35 lb–ft).

3. Install the stabilizer shaft clamp bolts.

Tighten

Tighten the stabilizer shaft clamp bolts to 40 NSm (30

lb–ft).

4. Lower the vehicle.

STABILIZER LINK

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. Remove the stabilizer shaft–to–stabilizer link nut.

4. Remove the stabilizer link–to–strut assembly nut.

5. Remove the stabilizer link.

Installation Procedure

1. Install the stabilizer link.

2. Install the stabilizer link–to–strut assembly nut.

Tighten

Tighten the stabilizer link–to–strut assembly nut to 47

NSm (35 lb–ft).

3. Install the stabilizer shaft–to–stabilizer link nut.

Tighten

Tighten the stabilizer shaft–to–stabilizer link nut to 47

NSm (35 lb–ft).

4. Install the wheel. Refer to Section 2E, Tires and

Wheels.

5. Lower the vehicle.

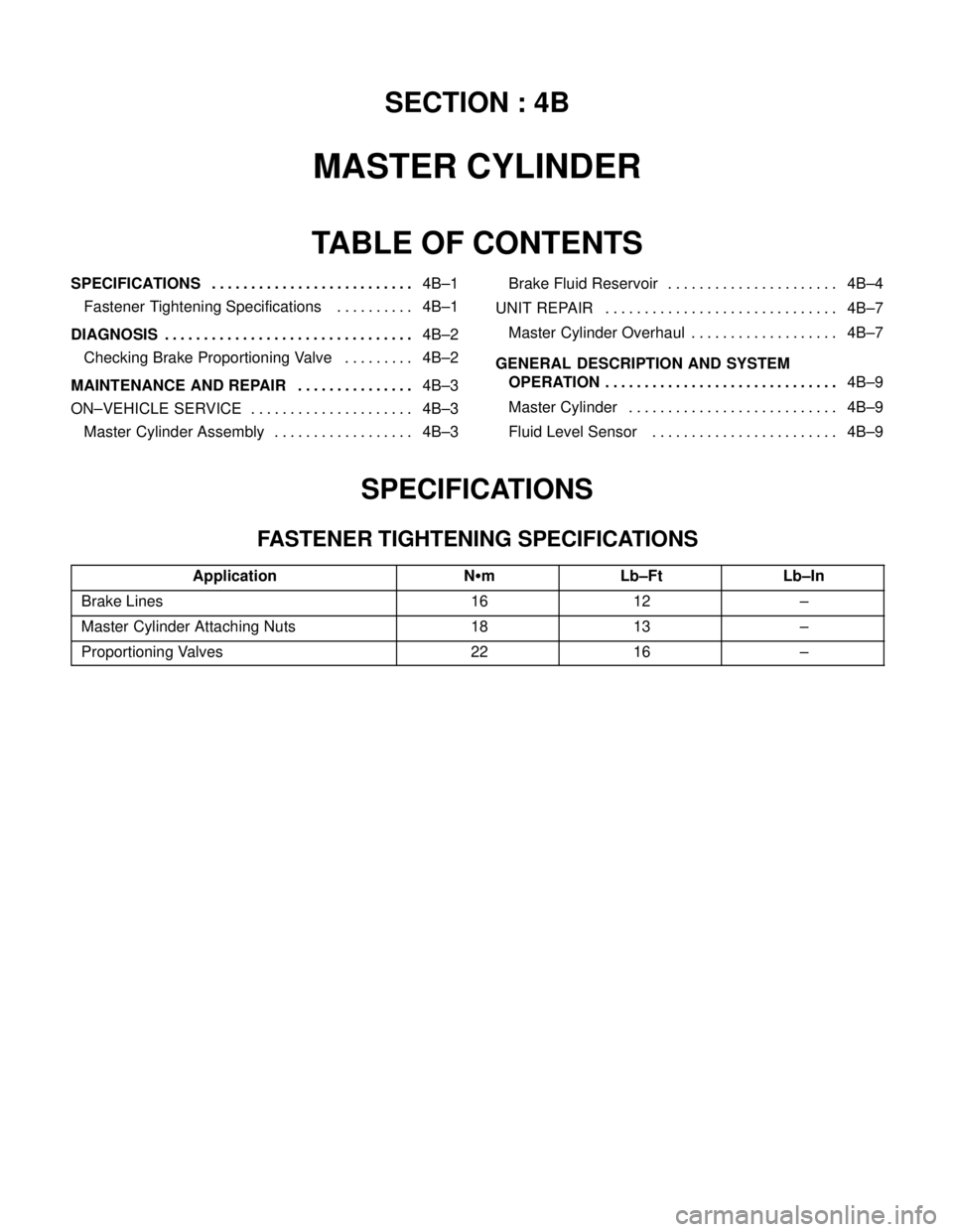

CROSSMEMBER

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the front parallel link bolt from the cross-

member. Refer to ”Front Parallel Link” in this sec-

tion.

3. Remove the rear parallel link bolt from the cross-

member. Refer to ”Rear Parallel Link”in this section.

4. Remove the rear wheel speed sensor wiring from

the crossmember.

Page 957 of 2643

REAR SUSPENSION 2D – 15

DAEWOO V–121 BL4

5. Remove the crossmember–to–body bolts.

6. Remove the crossmember.

Installation Procedure

1. Install the crossmember.

2. Install the crossmember–to–body bolts.

Tighten

Tighten the crossmember–to–body bolts to 112 NSm

(83 lb–ft).

3. Route and install the rear wheel speed sensor wir-

ing.

4. Install the rear parallel link bolt onto the crossmem-

ber. Refer to ”Rear Parallel Link”in this section.

5. Install the front parallel link bolt onto the crossmem-

ber. Refer to ”Front Parallel Link” in this section.

6. Lower the vehicle.

HUB AND BEARING ASSEMBLY

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. On vehicles equipped with rear drum brakes, re-

move the rear brake drum detent screw and brake

drum. Refer to Section 4E2, Rear Drum Brakes.

4. On vehicles equipped with rear disc brakes, remove

the rear brake caliper and rear brake disc. Refer to

Section 4E1, Rear Disc Brakes.

5. Remove the hub bolts and hub assembly.

Page 1015 of 2643

USAGE AND CAPACITY OF FUSES IN FUSE BLOCKW4–3

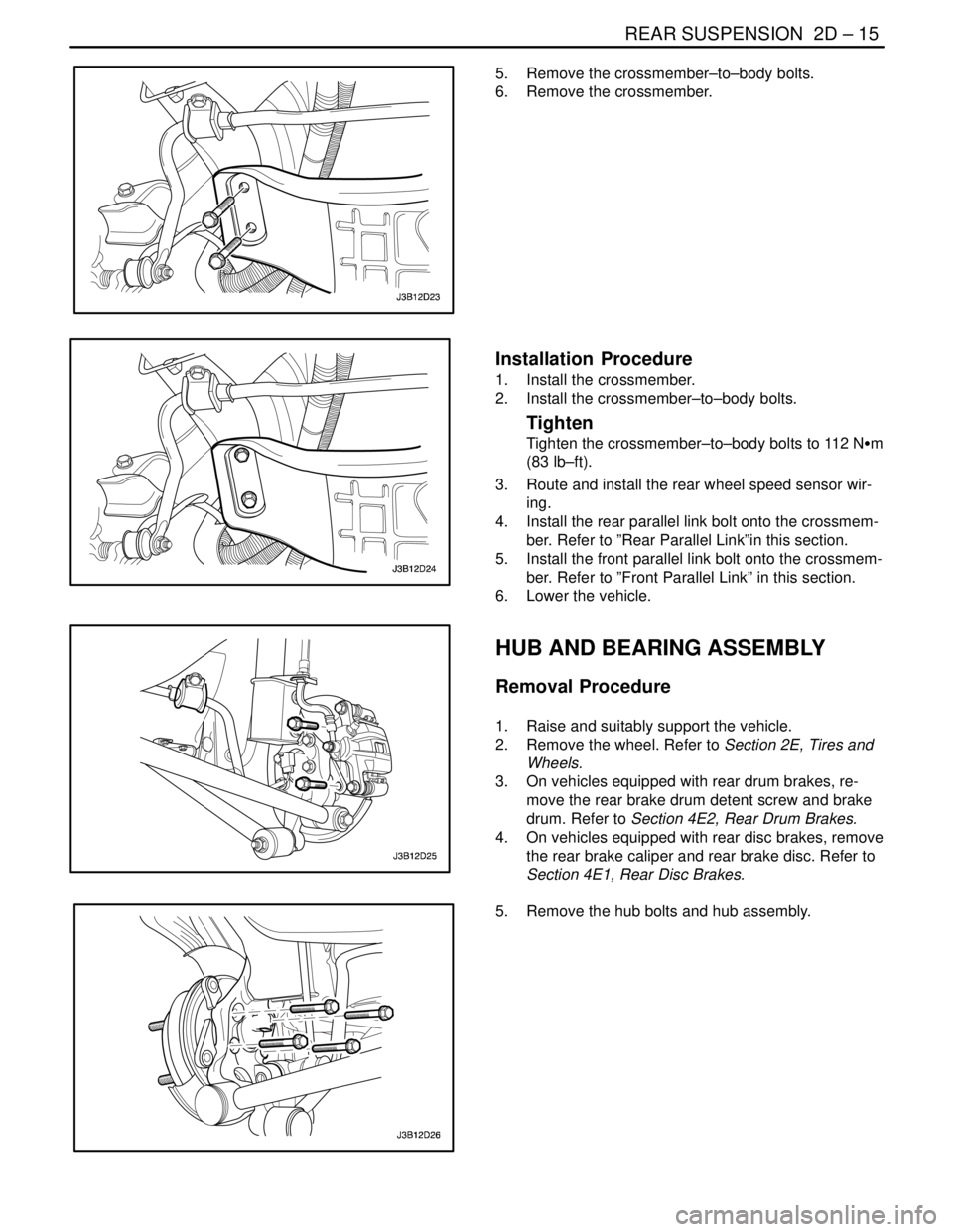

2. I.P FUSE BLOCK

1) POSITION OF FUSE AND RELAY

2) USAGE OF FUSE IN I.P FUSE BLOCK

Power

Supply

ClassificationFuse

NoCapacityUsage

IGN1 (15)Blade TypeF110ASDM

FuseF210ATCM, ECM, Generator, VGIS,VSS

F315AHazard Switch

F410ACluster, Chime Bell, Brake Switch, SSPS Module,

A/C Control Switch

–F5––

IGN2 (15A)F610AA/C Comp. Relay, Defog Relay, Power Window

Relay, Head Lamp Relay

F720ABlower Relay, A/C Control Switch, FATC

F815AElectric Mirror Switch, Folding Mirror, Sun Roof

Module

IGN1 (15)F925AWiper Motor, Wiper Switch

–F10––

IGN1 (15)F1110AEBCM, Oil Feeding Connector

F1210AImmobilizer, Anti Theft Control Unit, Rain Sensor

Unit

30 BAT(+)F1310ATCM

F1415AHazard Switch

F1515AAnti Theft Control Unit

F1610ADLC

ACC (15C)F1710AAudio, Clock

F1815AExtra Power Jack

F1915ACigar Lighter

IGN1 (15)F2010AReverse Lamp Switch, PNP Switch

30 BAT(+)F2115ARear Fog Relay

F2215AClock, FATC, A/C Control Switch

F2315AAudio

F2410AImmobilizer

Page 1034 of 2643

SECTION : 4B

MASTER CYLINDER

TABLE OF CONTENTS

SPECIFICATIONS4B–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 4B–1. . . . . . . . . .

DIAGNOSIS4B–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Brake Proportioning Valve 4B–2. . . . . . . . .

MAINTENANCE AND REPAIR4B–3 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 4B–3. . . . . . . . . . . . . . . . . . . . .

Master Cylinder Assembly 4B–3. . . . . . . . . . . . . . . . . . Brake Fluid Reservoir 4B–4. . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 4B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Master Cylinder Overhaul 4B–7. . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION4B–9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Master Cylinder 4B–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Level Sensor 4B–9. . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Brake Lines1612–

Master Cylinder Attaching Nuts1813–

Proportioning Valves2216–

Page 1042 of 2643

MASTER CYLINDER 4B – 9

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

MASTER CYLINDER

The master cylinder is designed for use in a diagonal–split

system. One front and one diagonally opposite rear brake

are served by the primary piston. The opposite front and

rear brakes are served by the secondary piston. The mas-

ter cylinder incorporates the functions of the standard dual

master cylinder, plus a low fluid level indicator and the pro-

portioning valves in the non–antilock braking system. The

proportioning valves limit the outlet pressure to the rear

brakes after a predetermined master cylinder pressure

has been reached.

Important :

S Replace all the components included in the repair

kits used to service this master cylinder.S Lubricate rubber parts with clean brake fluid to ease

assembly.

S Do not use lubricated shop air on brake parts, as

this may damage rubber components.

S If any hydraulic component is removed or discon-

nected, it may be necessary to bleed all or part of

the brake system.

S The torque values specified are for dry, unlubri-

cated fasteners.

S Perform all service operations on a clean bench,

free from all traces of mineral oil.

FLUID LEVEL SENSOR

The master cylinder is equipped with a fluid level sensor.

This sensor will activate the BRAKE light if a low fluid level

condition is detected. Once the fluid level is corrected, the

BRAKE light will go out.

Page 1063 of 2643

4E1 – 6IREAR DISC BRAKES

DAEWOO V–121 BL4

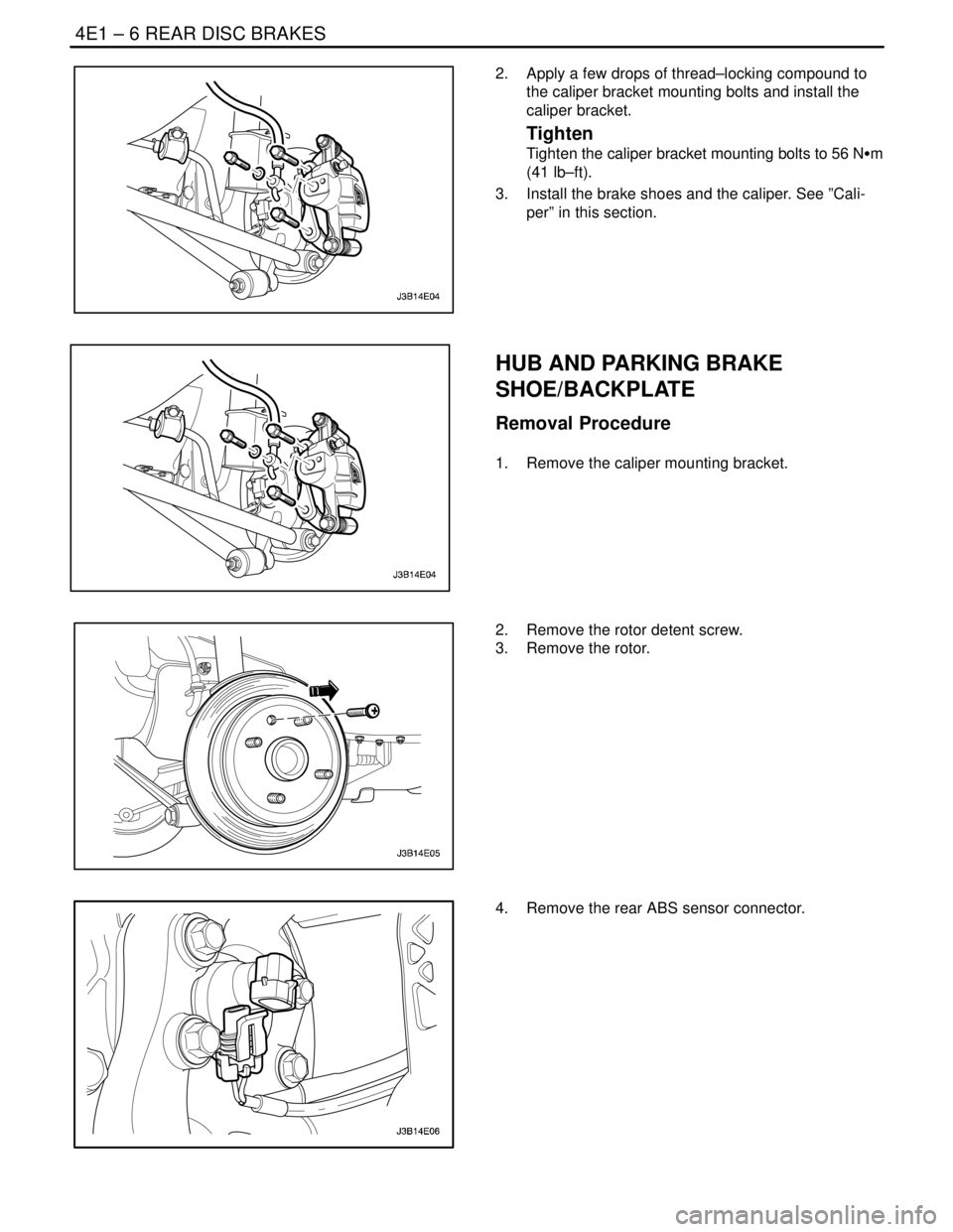

2. Apply a few drops of thread–locking compound to

the caliper bracket mounting bolts and install the

caliper bracket.

Tighten

Tighten the caliper bracket mounting bolts to 56 NSm

(41 lb–ft).

3. Install the brake shoes and the caliper. See ”Cali-

per” in this section.

HUB AND PARKING BRAKE

SHOE/BACKPLATE

Removal Procedure

1. Remove the caliper mounting bracket.

2. Remove the rotor detent screw.

3. Remove the rotor.

4. Remove the rear ABS sensor connector.

Page 1066 of 2643

REAR DISC BRAKES 4E1 – 9

DAEWOO V–121 BL4

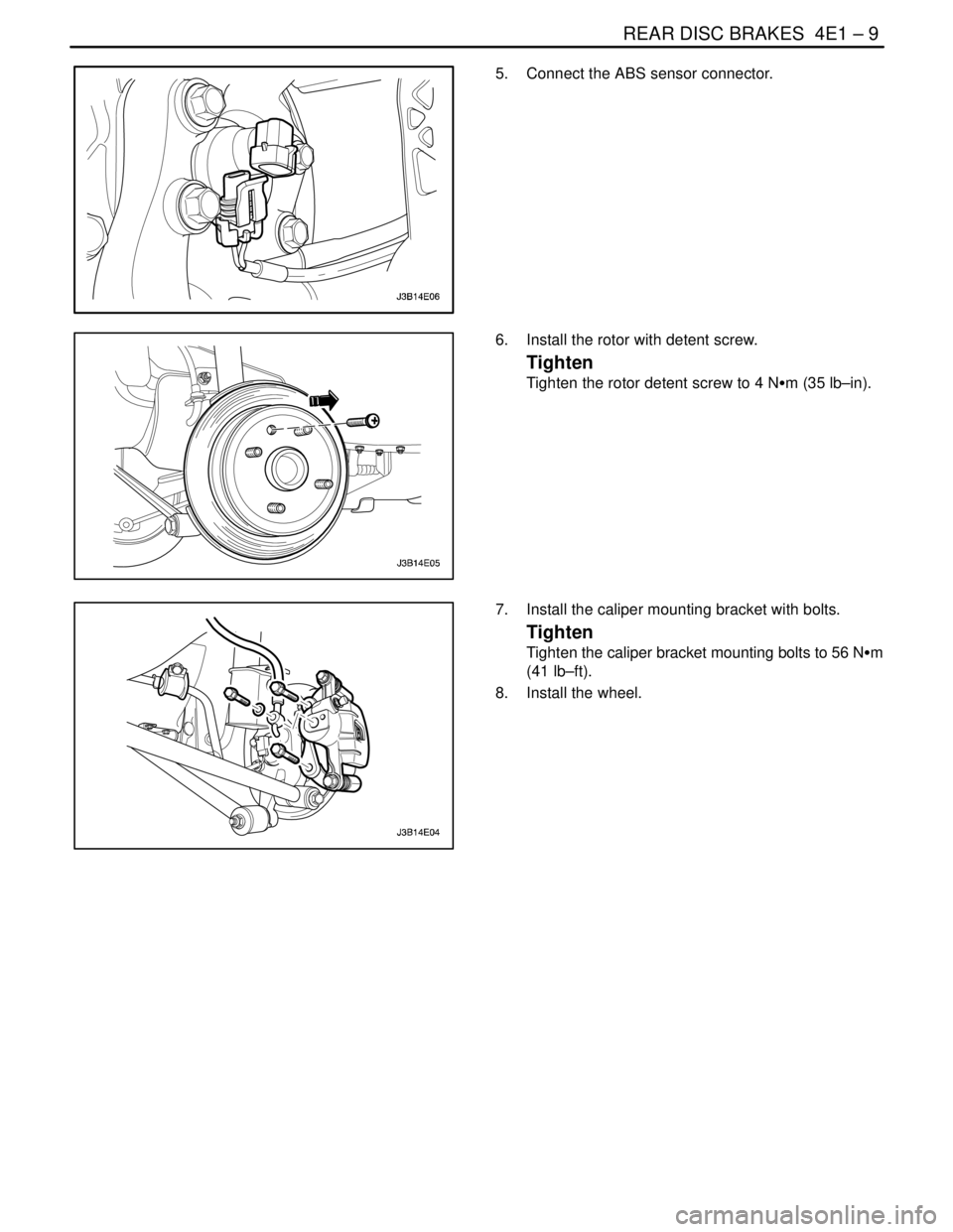

5. Connect the ABS sensor connector.

6. Install the rotor with detent screw.

Tighten

Tighten the rotor detent screw to 4 NSm (35 lb–in).

7. Install the caliper mounting bracket with bolts.

Tighten

Tighten the caliper bracket mounting bolts to 56 NSm

(41 lb–ft).

8. Install the wheel.

Page 1077 of 2643

4E2 – 8IREAR DRUM BRAKES

DAEWOO V–121 BL4

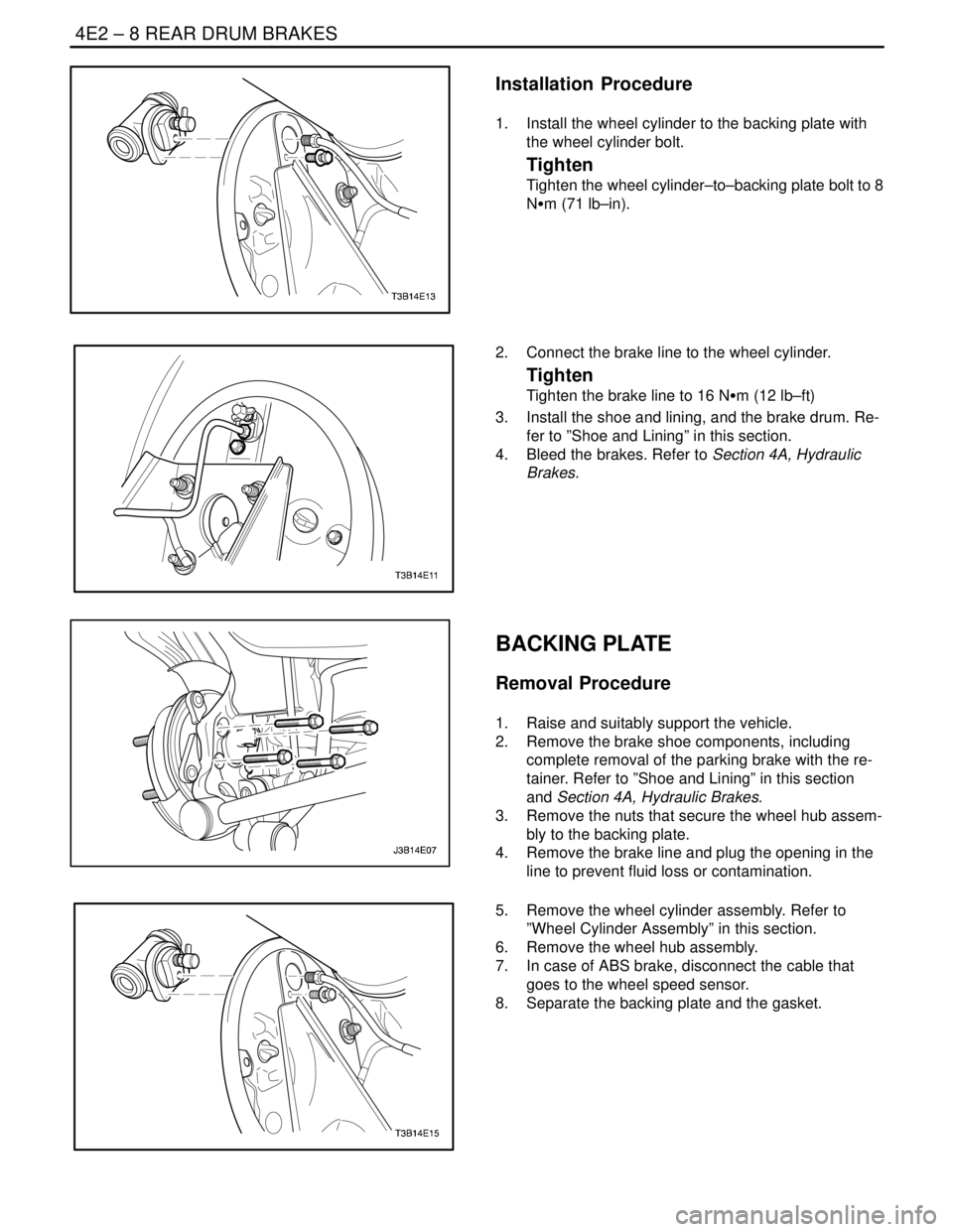

Installation Procedure

1. Install the wheel cylinder to the backing plate with

the wheel cylinder bolt.

Tighten

Tighten the wheel cylinder–to–backing plate bolt to 8

NSm (71 lb–in).

2. Connect the brake line to the wheel cylinder.

Tighten

Tighten the brake line to 16 NSm (12 lb–ft)

3. Install the shoe and lining, and the brake drum. Re-

fer to ”Shoe and Lining” in this section.

4. Bleed the brakes. Refer to Section 4A, Hydraulic

Brakes.

BACKING PLATE

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the brake shoe components, including

complete removal of the parking brake with the re-

tainer. Refer to ”Shoe and Lining” in this section

and Section 4A, Hydraulic Brakes.

3. Remove the nuts that secure the wheel hub assem-

bly to the backing plate.

4. Remove the brake line and plug the opening in the

line to prevent fluid loss or contamination.

5. Remove the wheel cylinder assembly. Refer to

”Wheel Cylinder Assembly” in this section.

6. Remove the wheel hub assembly.

7. In case of ABS brake, disconnect the cable that

goes to the wheel speed sensor.

8. Separate the backing plate and the gasket.

Page 1082 of 2643

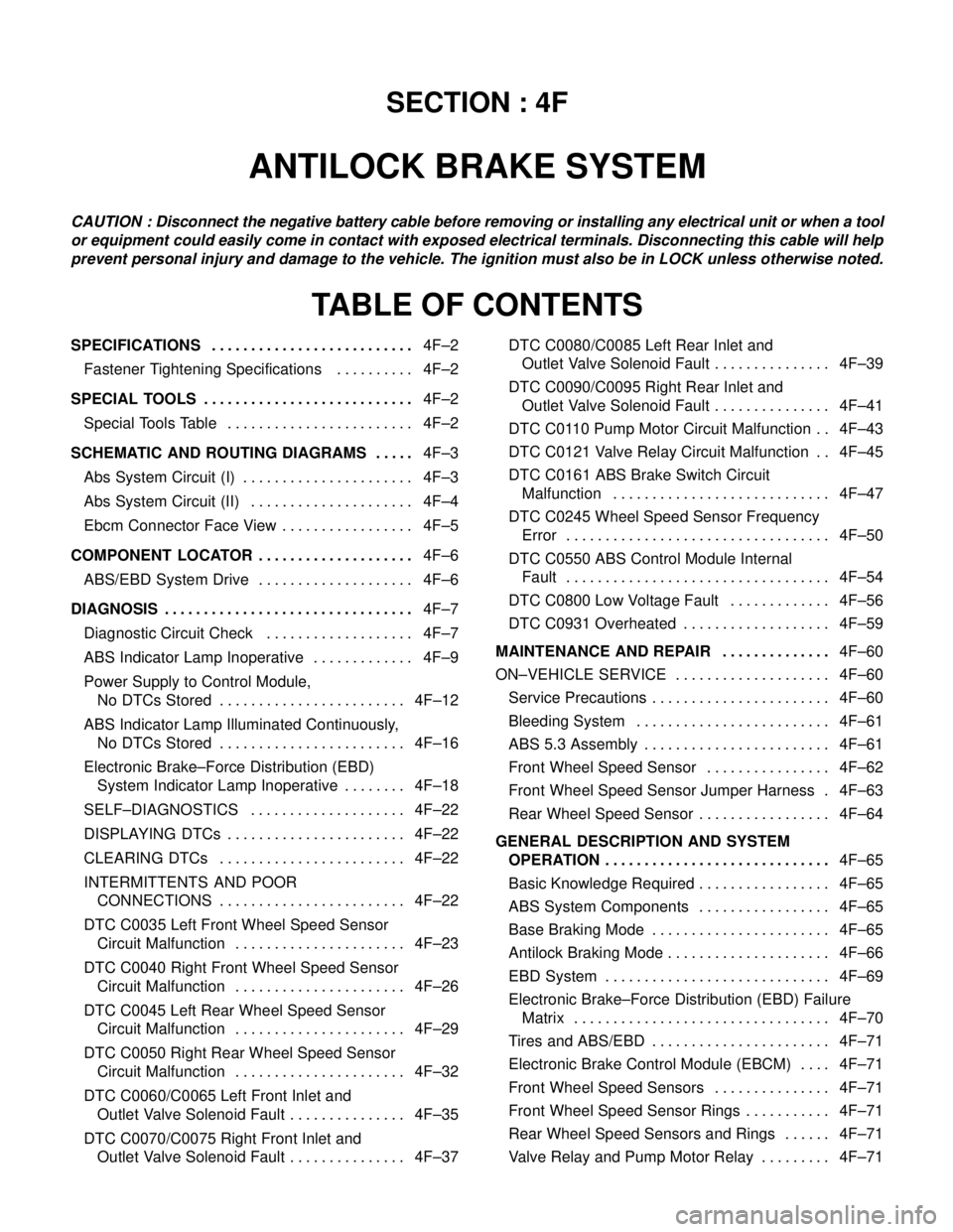

SECTION : 4F

ANTILOCK BRAKE SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS4F–2 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 4F–2. . . . . . . . . .

SPECIAL TOOLS4F–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 4F–2. . . . . . . . . . . . . . . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS4F–3 . . . . .

Abs System Circuit (I) 4F–3. . . . . . . . . . . . . . . . . . . . . .

Abs System Circuit (II) 4F–4. . . . . . . . . . . . . . . . . . . . .

Ebcm Connector Face View 4F–5. . . . . . . . . . . . . . . . .

COMPONENT LOCATOR4F–6 . . . . . . . . . . . . . . . . . . . .

ABS/EBD System Drive 4F–6. . . . . . . . . . . . . . . . . . . .

DIAGNOSIS4F–7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Circuit Check 4F–7. . . . . . . . . . . . . . . . . . .

ABS Indicator Lamp Inoperative 4F–9. . . . . . . . . . . . .

Power Supply to Control Module,

No DTCs Stored 4F–12. . . . . . . . . . . . . . . . . . . . . . . .

ABS Indicator Lamp Illuminated Continuously,

No DTCs Stored 4F–16. . . . . . . . . . . . . . . . . . . . . . . .

Electronic Brake–Force Distribution (EBD)

System Indicator Lamp Inoperative 4F–18. . . . . . . .

SELF–DIAGNOSTICS 4F–22. . . . . . . . . . . . . . . . . . . .

DISPLAYING DTCs 4F–22. . . . . . . . . . . . . . . . . . . . . . .

CLEARING DTCs 4F–22. . . . . . . . . . . . . . . . . . . . . . . .

INTERMITTENTS AND POOR

CONNECTIONS 4F–22. . . . . . . . . . . . . . . . . . . . . . . .

DTC C0035 Left Front Wheel Speed Sensor

Circuit Malfunction 4F–23. . . . . . . . . . . . . . . . . . . . . .

DTC C0040 Right Front Wheel Speed Sensor

Circuit Malfunction 4F–26. . . . . . . . . . . . . . . . . . . . . .

DTC C0045 Left Rear Wheel Speed Sensor

Circuit Malfunction 4F–29. . . . . . . . . . . . . . . . . . . . . .

DTC C0050 Right Rear Wheel Speed Sensor

Circuit Malfunction 4F–32. . . . . . . . . . . . . . . . . . . . . .

DTC C0060/C0065 Left Front Inlet and

Outlet Valve Solenoid Fault 4F–35. . . . . . . . . . . . . . .

DTC C0070/C0075 Right Front Inlet and

Outlet Valve Solenoid Fault 4F–37. . . . . . . . . . . . . . . DTC C0080/C0085 Left Rear Inlet and

Outlet Valve Solenoid Fault 4F–39. . . . . . . . . . . . . . .

DTC C0090/C0095 Right Rear Inlet and

Outlet Valve Solenoid Fault 4F–41. . . . . . . . . . . . . . .

DTC C0110 Pump Motor Circuit Malfunction 4F–43. .

DTC C0121 Valve Relay Circuit Malfunction 4F–45. .

DTC C0161 ABS Brake Switch Circuit

Malfunction 4F–47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC C0245 Wheel Speed Sensor Frequency

Error 4F–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC C0550 ABS Control Module Internal

Fault 4F–54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC C0800 Low Voltage Fault 4F–56. . . . . . . . . . . . .

DTC C0931 Overheated 4F–59. . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR4F–60 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 4F–60. . . . . . . . . . . . . . . . . . . .

Service Precautions 4F–60. . . . . . . . . . . . . . . . . . . . . . .

Bleeding System 4F–61. . . . . . . . . . . . . . . . . . . . . . . . .

ABS 5.3 Assembly 4F–61. . . . . . . . . . . . . . . . . . . . . . . .

Front Wheel Speed Sensor 4F–62. . . . . . . . . . . . . . . .

Front Wheel Speed Sensor Jumper Harness 4F–63.

Rear Wheel Speed Sensor 4F–64. . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION4F–65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Knowledge Required 4F–65. . . . . . . . . . . . . . . . .

ABS System Components 4F–65. . . . . . . . . . . . . . . . .

Base Braking Mode 4F–65. . . . . . . . . . . . . . . . . . . . . . .

Antilock Braking Mode 4F–66. . . . . . . . . . . . . . . . . . . . .

EBD System 4F–69. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electronic Brake–Force Distribution (EBD) Failure

Matrix 4F–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tires and ABS/EBD 4F–71. . . . . . . . . . . . . . . . . . . . . . .

Electronic Brake Control Module (EBCM) 4F–71. . . .

Front Wheel Speed Sensors 4F–71. . . . . . . . . . . . . . .

Front Wheel Speed Sensor Rings 4F–71. . . . . . . . . . .

Rear Wheel Speed Sensors and Rings 4F–71. . . . . .

Valve Relay and Pump Motor Relay 4F–71. . . . . . . . .

Page 1083 of 2643

4F – 2IANTILOCK BRAKE SYSTEM

DAEWOO V–121 BL4

Wiring Harness 4F–71. . . . . . . . . . . . . . . . . . . . . . . . . . . Indicators 4F–71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

ABS 5.3 Mounting Nuts1511–

Brake Pipe Nuts2216–

Front Wheel Speed Sensor Bolt8–71

SPECIAL TOOLS

SPECIAL TOOLS TABLE

Scan Tool