Lamp DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2030 of 2643

7B – 28IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

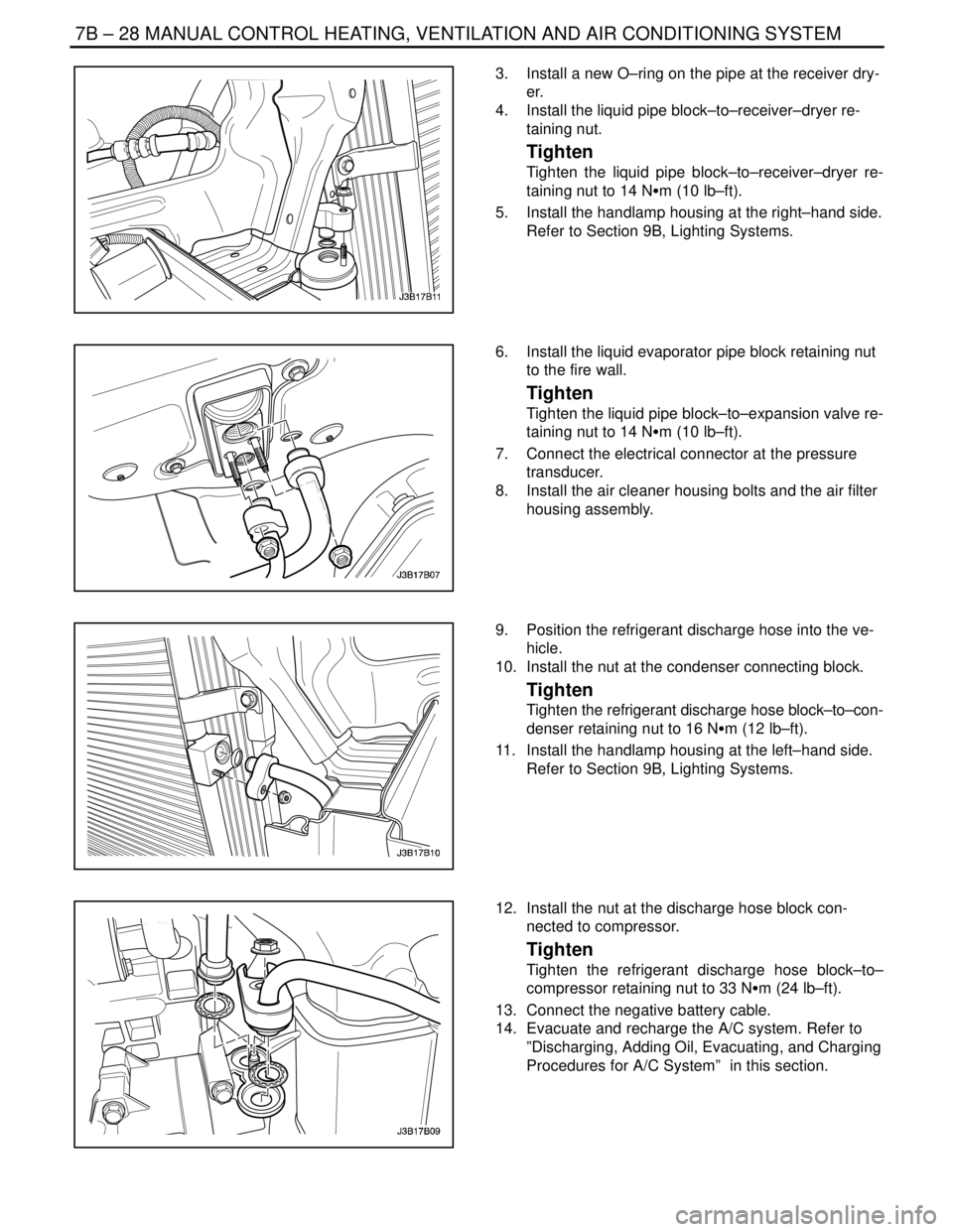

3. Install a new O–ring on the pipe at the receiver dry-

er.

4. Install the liquid pipe block–to–receiver–dryer re-

taining nut.

Tighten

Tighten the liquid pipe block–to–receiver–dryer re-

taining nut to 14 NSm (10 lb–ft).

5. Install the handlamp housing at the right–hand side.

Refer to Section 9B, Lighting Systems.

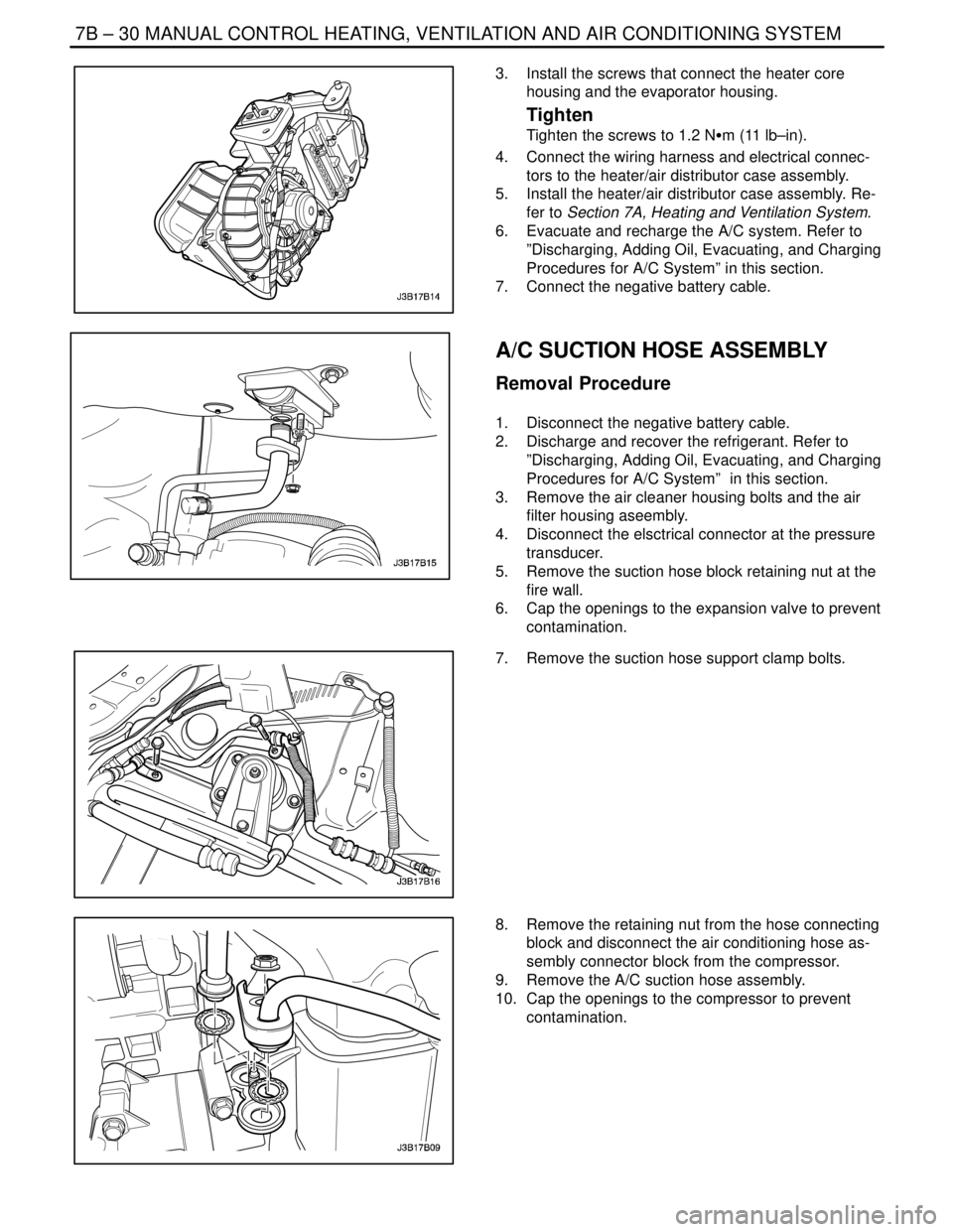

6. Install the liquid evaporator pipe block retaining nut

to the fire wall.

Tighten

Tighten the liquid pipe block–to–expansion valve re-

taining nut to 14 NSm (10 lb–ft).

7. Connect the electrical connector at the pressure

transducer.

8. Install the air cleaner housing bolts and the air filter

housing assembly.

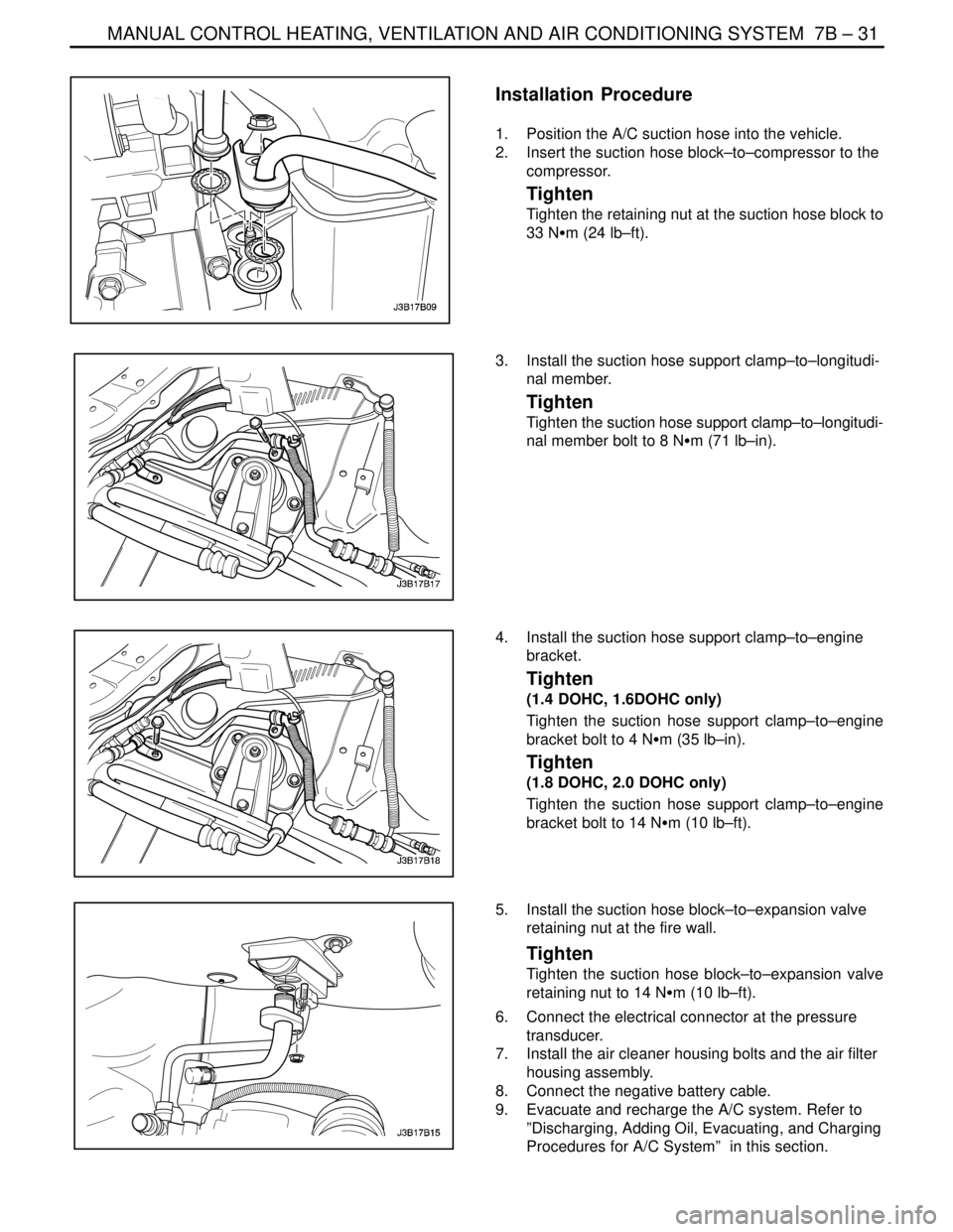

9. Position the refrigerant discharge hose into the ve-

hicle.

10. Install the nut at the condenser connecting block.

Tighten

Tighten the refrigerant discharge hose block–to–con-

denser retaining nut to 16 NSm (12 lb–ft).

11. Install the handlamp housing at the left–hand side.

Refer to Section 9B, Lighting Systems.

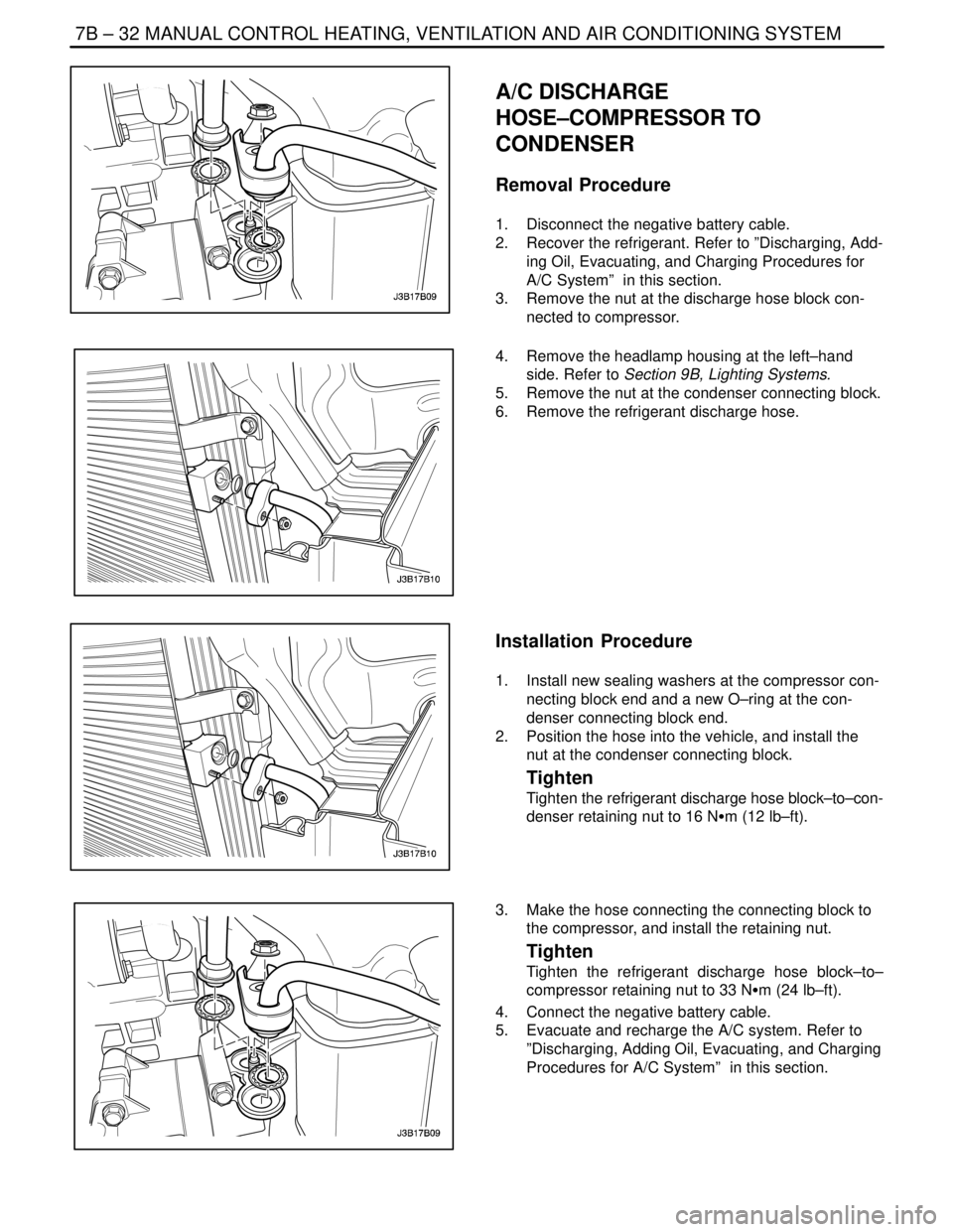

12. Install the nut at the discharge hose block con-

nected to compressor.

Tighten

Tighten the refrigerant discharge hose block–to–

compressor retaining nut to 33 NSm (24 lb–ft).

13. Connect the negative battery cable.

14. Evacuate and recharge the A/C system. Refer to

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System” in this section.

Page 2032 of 2643

7B – 30IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

3. Install the screws that connect the heater core

housing and the evaporator housing.

Tighten

Tighten the screws to 1.2 NSm (11 lb–in).

4. Connect the wiring harness and electrical connec-

tors to the heater/air distributor case assembly.

5. Install the heater/air distributor case assembly. Re-

fer to Section 7A, Heating and Ventilation System.

6. Evacuate and recharge the A/C system. Refer to

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System” in this section.

7. Connect the negative battery cable.

A/C SUCTION HOSE ASSEMBLY

Removal Procedure

1. Disconnect the negative battery cable.

2. Discharge and recover the refrigerant. Refer to

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System” in this section.

3. Remove the air cleaner housing bolts and the air

filter housing aseembly.

4. Disconnect the elsctrical connector at the pressure

transducer.

5. Remove the suction hose block retaining nut at the

fire wall.

6. Cap the openings to the expansion valve to prevent

contamination.

7. Remove the suction hose support clamp bolts.

8. Remove the retaining nut from the hose connecting

block and disconnect the air conditioning hose as-

sembly connector block from the compressor.

9. Remove the A/C suction hose assembly.

10. Cap the openings to the compressor to prevent

contamination.

Page 2033 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 31

DAEWOO V–121 BL4

Installation Procedure

1. Position the A/C suction hose into the vehicle.

2. Insert the suction hose block–to–compressor to the

compressor.

Tighten

Tighten the retaining nut at the suction hose block to

33 NSm (24 lb–ft).

3. Install the suction hose support clamp–to–longitudi-

nal member.

Tighten

Tighten the suction hose support clamp–to–longitudi-

nal member bolt to 8 NSm (71 lb–in).

4. Install the suction hose support clamp–to–engine

bracket.

Tighten

(1.4 DOHC, 1.6DOHC only)

Tighten the suction hose support clamp–to–engine

bracket bolt to 4 NSm (35 lb–in).

Tighten

(1.8 DOHC, 2.0 DOHC only)

Tighten the suction hose support clamp–to–engine

bracket bolt to 14 NSm (10 lb–ft).

5. Install the suction hose block–to–expansion valve

retaining nut at the fire wall.

Tighten

Tighten the suction hose block–to–expansion valve

retaining nut to 14 NSm (10 lb–ft).

6. Connect the electrical connector at the pressure

transducer.

7. Install the air cleaner housing bolts and the air filter

housing assembly.

8. Connect the negative battery cable.

9. Evacuate and recharge the A/C system. Refer to

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System” in this section.

Page 2034 of 2643

7B – 32IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

A/C DISCHARGE

HOSE–COMPRESSOR TO

CONDENSER

Removal Procedure

1. Disconnect the negative battery cable.

2. Recover the refrigerant. Refer to ”Discharging, Add-

ing Oil, Evacuating, and Charging Procedures for

A/C System” in this section.

3. Remove the nut at the discharge hose block con-

nected to compressor.

4. Remove the headlamp housing at the left–hand

side. Refer to Section 9B, Lighting Systems.

5. Remove the nut at the condenser connecting block.

6. Remove the refrigerant discharge hose.

Installation Procedure

1. Install new sealing washers at the compressor con-

necting block end and a new O–ring at the con-

denser connecting block end.

2. Position the hose into the vehicle, and install the

nut at the condenser connecting block.

Tighten

Tighten the refrigerant discharge hose block–to–con-

denser retaining nut to 16 NSm (12 lb–ft).

3. Make the hose connecting the connecting block to

the compressor, and install the retaining nut.

Tighten

Tighten the refrigerant discharge hose block–to–

compressor retaining nut to 33 NSm (24 lb–ft).

4. Connect the negative battery cable.

5. Evacuate and recharge the A/C system. Refer to

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System” in this section.

Page 2035 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 33

DAEWOO V–121 BL4

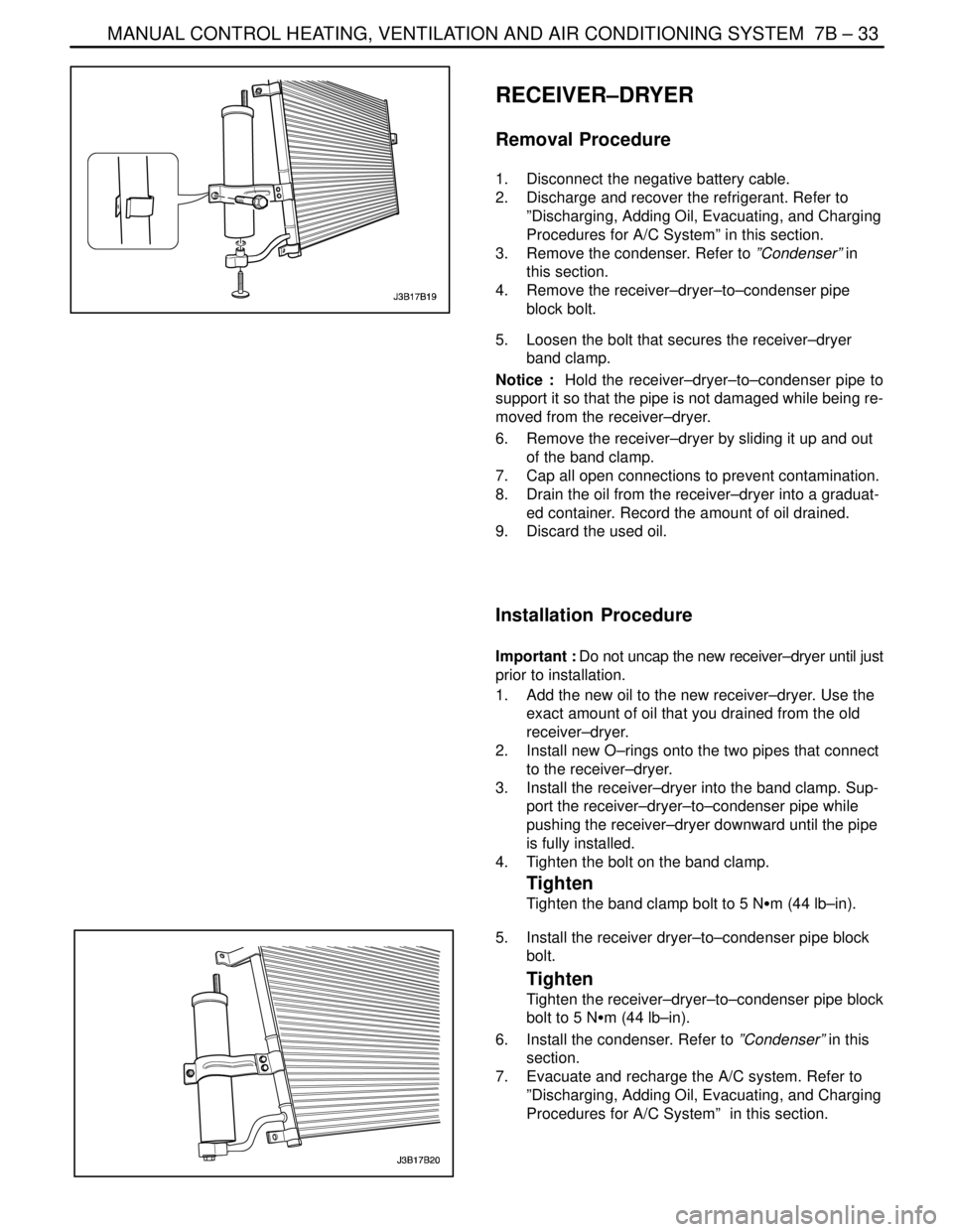

RECEIVER–DRYER

Removal Procedure

1. Disconnect the negative battery cable.

2. Discharge and recover the refrigerant. Refer to

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System” in this section.

3. Remove the condenser. Refer to ”Condenser” in

this section.

4. Remove the receiver–dryer–to–condenser pipe

block bolt.

5. Loosen the bolt that secures the receiver–dryer

band clamp.

Notice : Hold the receiver–dryer–to–condenser pipe to

support it so that the pipe is not damaged while being re-

moved from the receiver–dryer.

6. Remove the receiver–dryer by sliding it up and out

of the band clamp.

7. Cap all open connections to prevent contamination.

8. Drain the oil from the receiver–dryer into a graduat-

ed container. Record the amount of oil drained.

9. Discard the used oil.

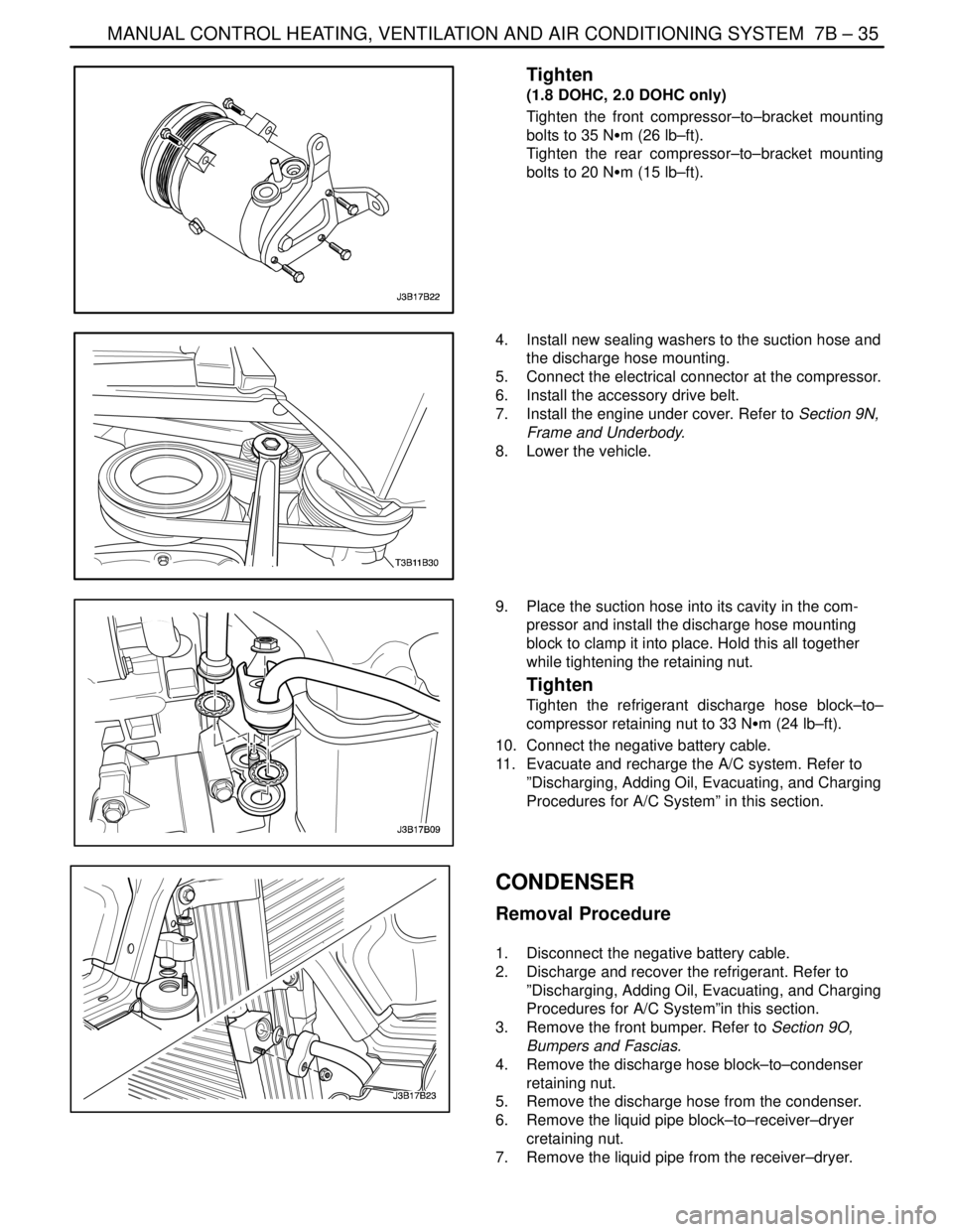

Installation Procedure

Important : Do not uncap the new receiver–dryer until just

prior to installation.

1. Add the new oil to the new receiver–dryer. Use the

exact amount of oil that you drained from the old

receiver–dryer.

2. Install new O–rings onto the two pipes that connect

to the receiver–dryer.

3. Install the receiver–dryer into the band clamp. Sup-

port the receiver–dryer–to–condenser pipe while

pushing the receiver–dryer downward until the pipe

is fully installed.

4. Tighten the bolt on the band clamp.

Tighten

Tighten the band clamp bolt to 5 NSm (44 lb–in).

5. Install the receiver dryer–to–condenser pipe block

bolt.

Tighten

Tighten the receiver–dryer–to–condenser pipe block

bolt to 5 NSm (44 lb–in).

6. Install the condenser. Refer to ”Condenser” in this

section.

7. Evacuate and recharge the A/C system. Refer to

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System” in this section.

Page 2037 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 35

DAEWOO V–121 BL4

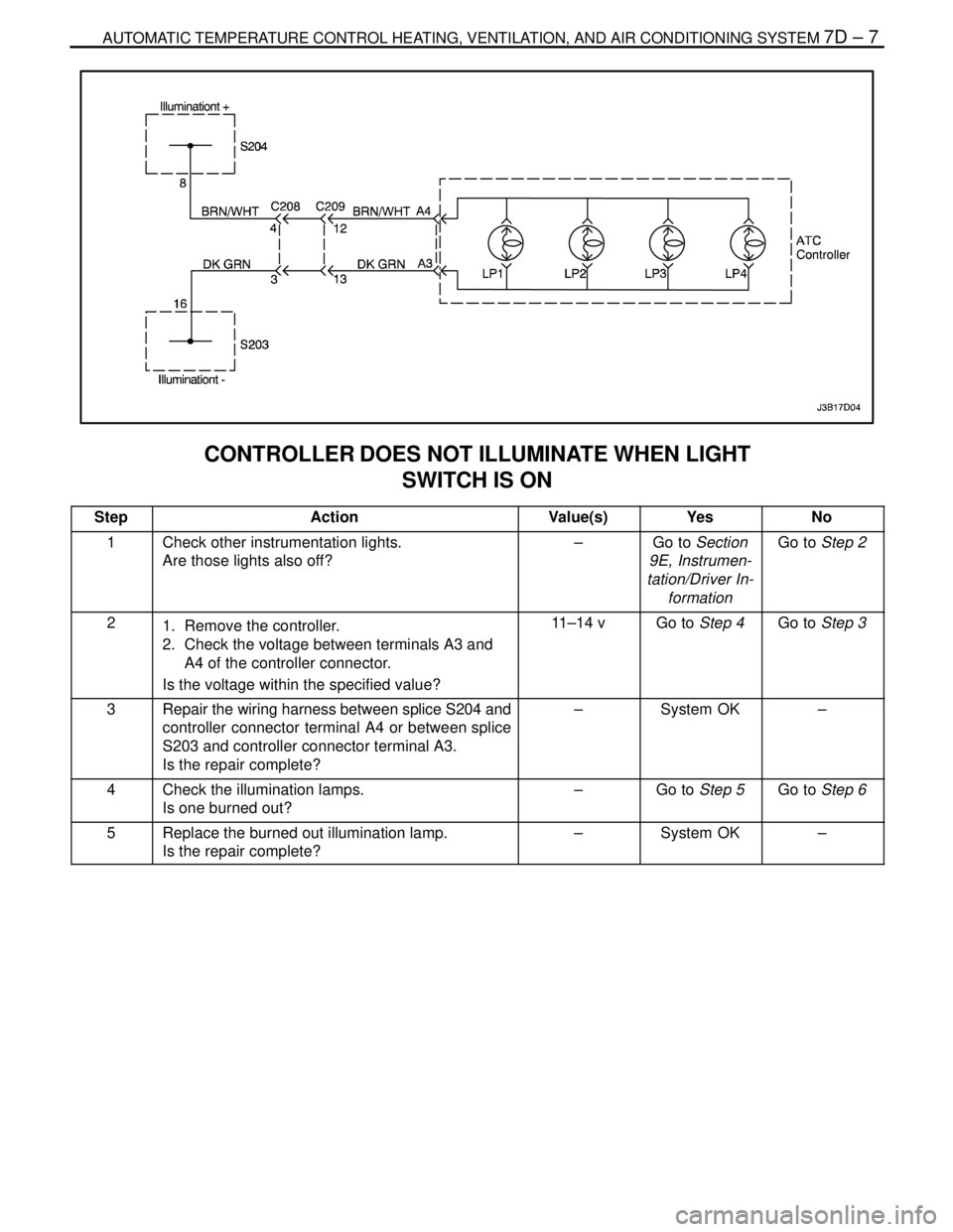

Tighten

(1.8 DOHC, 2.0 DOHC only)

Tighten the front compressor–to–bracket mounting

bolts to 35 NSm (26 lb–ft).

Tighten the rear compressor–to–bracket mounting

bolts to 20 NSm (15 lb–ft).

4. Install new sealing washers to the suction hose and

the discharge hose mounting.

5. Connect the electrical connector at the compressor.

6. Install the accessory drive belt.

7. Install the engine under cover. Refer to Section 9N,

Frame and Underbody.

8. Lower the vehicle.

9. Place the suction hose into its cavity in the com-

pressor and install the discharge hose mounting

block to clamp it into place. Hold this all together

while tightening the retaining nut.

Tighten

Tighten the refrigerant discharge hose block–to–

compressor retaining nut to 33 NSm (24 lb–ft).

10. Connect the negative battery cable.

11. Evacuate and recharge the A/C system. Refer to

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System” in this section.

CONDENSER

Removal Procedure

1. Disconnect the negative battery cable.

2. Discharge and recover the refrigerant. Refer to

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System”in this section.

3. Remove the front bumper. Refer to Section 9O,

Bumpers and Fascias.

4. Remove the discharge hose block–to–condenser

retaining nut.

5. Remove the discharge hose from the condenser.

6. Remove the liquid pipe block–to–receiver–dryer

cretaining nut.

7. Remove the liquid pipe from the receiver–dryer.

Page 2062 of 2643

AUTOMATIC TEMPERATURE CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7D – 7

DAEWOO V–121 BL4

CONTROLLER DOES NOT ILLUMINATE WHEN LIGHT

SWITCH IS ON

StepActionValue(s)YesNo

1Check other instrumentation lights.

Are those lights also off?–Go to Section

9E, Instrumen-

tation/Driver In-

formationGo to Step 2

21. Remove the controller.

2. Check the voltage between terminals A3 and

A4 of the controller connector.

Is the voltage within the specified value?11–14 vGo to Step 4Go to Step 3

3Repair the wiring harness between splice S204 and

controller connector terminal A4 or between splice

S203 and controller connector terminal A3.

Is the repair complete?–System OK–

4Check the illumination lamps.

Is one burned out?–Go to Step 5Go to Step 6

5Replace the burned out illumination lamp.

Is the repair complete?–System OK–

Page 2098 of 2643

SEAT BELTS 8A – 3

DAEWOO V–121 BL4

DIAGNOSIS

DRIVER SEAT BELT WARNING

Seat Belt Warning Lamp Does Not Turn On at Any Time

StepActionValue(s)YesNo

1Check the seat belt warning fuse F4.

Is fuse F4 blown?–Go to Step 2Go to Step 3

21. Check for a short circuit and repair if neces-

sary.

2. Replace the fuse.

Is the repair complete?–System OK–

31. Turn the ignition ON.

2. Check the voltage at fuse F4.

Is the voltage equal to the specified value?11–14 vGo to Step 5Go to Step 4

4Repair the open power supply circuit for fuse F4.

Is the repair complete?–System OK–

51. Disconnect the seat belt switch connector (lo-

cated under the driver’s seat).

2. Connect a jumper between the terminals on the

harness side of the seat belt switch connector.

3. Turn the ignition ON.

Does the seat belt warning lamp turn on?–Go to Step 6Go to Step 7

6Replace the seat belt switch.

Is the repair complete?–System OK–

71. Remove the instrument cluster.

2. Check the seat belt warning lamp bulb.

Is the bulb OK?–Go to Step 9Go to Step 8

8Replace the warning lamp bulb.

Is the repair complete?–System OK–

9Repair the open circuit between instrument cluster

terminal A11 and ground.

Is the repair complete?–System OK–

Page 2105 of 2643

SECTION : 8B

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition mujst be also be in LOCK unless otherwise noted

TABLE OF CONTENTS

SPECIFICATIONS8B–3 . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 8B–3. . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 8B–3. . . . . . . . . . .

SPECIAL TOOLS8B–3 . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS TABLE 8B–3. . . . . . . . . . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS8B–4 . . . . .

Supplemental Inflatable Restraints(SIR)

Electronical Schematic 8B–4. . . . . . . . . . . . . . . . . . . .

SIR Component Locator 8B–5. . . . . . . . . . . . . . . . . . . .

DIAGNOSIS8B–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) 8B–6. . . . . . . . . . . . . .

Scan Tool Diagnostics 8B–7. . . . . . . . . . . . . . . . . . . . . .

SIR Diagnostic System Check 8B–8. . . . . . . . . . . . . . .

Sensing and Diagnostic Module (SDM) Integrity

check 8B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 1 Driver Airbag Deployment Loop Resistance

Is High 8B–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 2 Driver Airbag Deployment Loop Resistance

Is Low 8B–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 3 Driver Airbag Deployment Loop Is Shorted

To Ground 8B–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 4 Driver Airbag Deployment Loop Is Shorted

To Power 8B–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 5 Passenger Airbag Deployment Loop

Resistance Is High 8B–20. . . . . . . . . . . . . . . . . . . . . .

DTC 6 Passenger Airbag Deployment Loop

Resistance Is Low 8B–22. . . . . . . . . . . . . . . . . . . . . .

DTC 7 Passenger Airbag Deployment Loop Is

Shorted To Ground 8B–24. . . . . . . . . . . . . . . . . . . . . .

DTC 8 Passenger Airbag Deployment Loop Is

Shorted To Power 8B–26. . . . . . . . . . . . . . . . . . . . . . .

DTC 9 Driver Belt Pretensioner Deployment

Loop Resistance Is High 8B–28. . . . . . . . . . . . . . . . .

DTC 10 Driver Belt Pretensioner Deployment

Loop Resistance Is Low 8B–30. . . . . . . . . . . . . . . . . .

DTC 11 Driver Belt Pretensioner Deployment

Loop Is Shorted To Ground 8B–32. . . . . . . . . . . . . . . DTC 12 Driver Belt Pretensioner Deployment

Loop Is Shorted To Power 8B–34. . . . . . . . . . . . . . . .

DTC 13 Passenger Belt Pretensioner Deployment

Loop Resistance Is High 8B–36. . . . . . . . . . . . . . . . .

DTC 14 Passenger Belt Pretensioner Deployment

Loop Resistance Is Low 8B–38. . . . . . . . . . . . . . . . . .

DTC 15 Passenger Belt Pretensioner Deployment

Loop Is Shorted To Ground 8B–40. . . . . . . . . . . . . . .

DTC 16 Passenger Belt Pretensioner Deployment

Loop Is Shorted To Power 8B–42. . . . . . . . . . . . . . . .

DTC 23 Battery Voltage high 8B–44. . . . . . . . . . . . . . .

DTC 24 Battery Voltage Low 8B–46. . . . . . . . . . . . . . .

DTC 25 Airbag Warning Lamp Failure 8B–48. . . . . . .

DTC 31 Internal Sensing Diagnostic Module

(SDM) Failure 8B–50. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 32 Airbag Inflation Record By Frontal

Collision 8B–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 33 Driver Side Airbag Inflation Record By

Side Impact 8B–52. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 34 Passenger Side Airbag Inflation Record

By Side Impact 8B–53. . . . . . . . . . . . . . . . . . . . . . . . .

DTC 35 Belt Pretensioner Explosion Record 8B–54. .

DTC 38 Side Airbag And Belt Pretensioner

Explosion Count Over 5 8B–55. . . . . . . . . . . . . . . . . .

DTC 52 Driver Side Airbag Deployment Loop

Resistance Is High 8B–56. . . . . . . . . . . . . . . . . . . . . .

DTC 53 Driver Side Airbag Deployment Loop

Resistance Is Low 8B–58. . . . . . . . . . . . . . . . . . . . . .

DTC 54 Driver Side Airbag Deployment Loop Is

Shorted To Ground 8B–60. . . . . . . . . . . . . . . . . . . . . .

DTC 55 Driver Side Airbag Deployment Loop Is

Shorted To Power 8B–62. . . . . . . . . . . . . . . . . . . . . . .

DTC 56 Passenger Side Airbag Deployment Loop

Resistance Is High 8B–64. . . . . . . . . . . . . . . . . . . . . .

DTC 57 Passenger Side Airbag Deployment Loop

Resistance Is Low 8B–66. . . . . . . . . . . . . . . . . . . . . .

DTC 58 Passenger Side Airbag Deployment Loop

Is Shorted To Ground 8B–68. . . . . . . . . . . . . . . . . . . .

DTC 59 Passenger Side Airbag Deployment Loop

Is Shorted To Power 8B–70. . . . . . . . . . . . . . . . . . . . .

Page 2106 of 2643

8B – 2ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

DTC 80 Driver Side Airbag Sensor Loop Is

Shorted To Power 8B–72. . . . . . . . . . . . . . . . . . . . . . .

DTC 81 Driver Side Airbag Sensor Loop Is

Shorted To Ground 8B–74. . . . . . . . . . . . . . . . . . . . . .

DTC 82 Driver Side Airbag Sensor Communication

Error 8B–76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 83 Driver Side Airbag Sensor Failure 8B–78. . .

DTC 84 Passenger Side Airbag Sensor Loop Is

Shorted To Power 8B–80. . . . . . . . . . . . . . . . . . . . . . .

DTC 85 Passenger Side Airbag Sensor Loop Is

Shorted To Ground 8B–82. . . . . . . . . . . . . . . . . . . . . .

DTC 86 Passenger Side Airbag Sensor

Communication Error 8B–84. . . . . . . . . . . . . . . . . . . .

DTC 87 Passenger Side Airbag Sensor Failure 8B–86

MAINTENANCE AND REPAIR8B–88 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 8B–88. . . . . . . . . . . . . . . . . . . .

Disabling the Supplemental Inflatable

Restraints(SIR) 8B–88. . . . . . . . . . . . . . . . . . . . . . . . .

Enabling the Supplemental Inflatable

Restraints(SIR) 8B–88. . . . . . . . . . . . . . . . . . . . . . . . .

Handling, Installation and Diagnosis 8B–89. . . . . . . . .

Repairs and Inspections Required After an

Accident 8B–89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accident With Deployment Components

Replacements 8B–90. . . . . . . . . . . . . . . . . . . . . . . . . . Accident Without Deployment Component

Inspection 8B–90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensing and Diagnostic Module (SDM) 8B–90. . . . . .

Driver Airbag Module 8B–91. . . . . . . . . . . . . . . . . . . . . .

Clock Spring 8B–92. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clock Spring Alignment 8B–93. . . . . . . . . . . . . . . . . . . .

Passenger Airbag Module 8B–94. . . . . . . . . . . . . . . . . .

Side Airbag Sensor 8B–95. . . . . . . . . . . . . . . . . . . . . . .

Front Seat Belt Pretensioner 8B–95. . . . . . . . . . . . . . .

Airbag Module Deployment (Inside of Vehicle) 8B–95

Airbag Module Deployment (Outside of Vehicle) 8B–97

Deployed Airbag Module Disposal Procedure 8B–98.

SIR Wiring Repair 8B–99. . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION8B–100 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplemental Inflatable Restraints(SIR) 8B–100. . . .

Airbag Modules 8B–100. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Seat Belt Pretensioners 8B–101. . . . . . . . . . . . .

Sensing and Diagnostic Module (SDM) 8B–101. . . . .

Airbag Warning Lamp 8B–101. . . . . . . . . . . . . . . . . . . .

Clock Spring 8B–101. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Harness Connectors 8B–102. . . . . . . . . . . . . . .