ignition DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 796 of 2643

1F – 550IENGINE CONTROLS

DAEWOO V–121 BL4

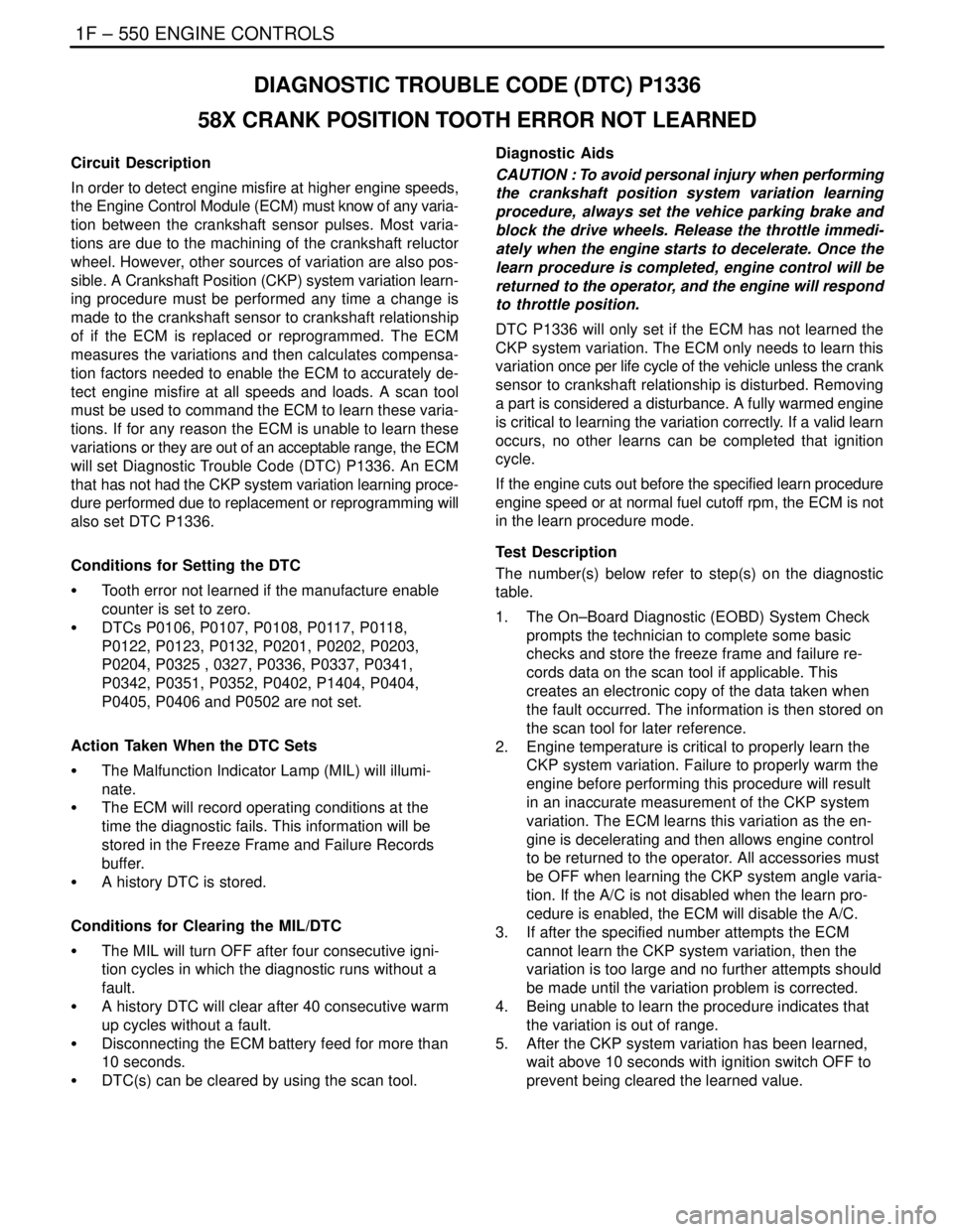

DIAGNOSTIC TROUBLE CODE (DTC) P1336

58X CRANK POSITION TOOTH ERROR NOT LEARNED

Circuit Description

In order to detect engine misfire at higher engine speeds,

the Engine Control Module (ECM) must know of any varia-

tion between the crankshaft sensor pulses. Most varia-

tions are due to the machining of the crankshaft reluctor

wheel. However, other sources of variation are also pos-

sible. A Crankshaft Position (CKP) system variation learn-

ing procedure must be performed any time a change is

made to the crankshaft sensor to crankshaft relationship

of if the ECM is replaced or reprogrammed. The ECM

measures the variations and then calculates compensa-

tion factors needed to enable the ECM to accurately de-

tect engine misfire at all speeds and loads. A scan tool

must be used to command the ECM to learn these varia-

tions. If for any reason the ECM is unable to learn these

variations or they are out of an acceptable range, the ECM

will set Diagnostic Trouble Code (DTC) P1336. An ECM

that has not had the CKP system variation learning proce-

dure performed due to replacement or reprogramming will

also set DTC P1336.

Conditions for Setting the DTC

S Tooth error not learned if the manufacture enable

counter is set to zero.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0132, P0201, P0202, P0203,

P0204, P0325 , 0327, P0336, P0337, P0341,

P0342, P0351, P0352, P0402, P1404, P0404,

P0405, P0406 and P0502 are not set.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffer.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn OFF after four consecutive igni-

tion cycles in which the diagnostic runs without a

fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Disconnecting the ECM battery feed for more than

10 seconds.

S DTC(s) can be cleared by using the scan tool.Diagnostic Aids

CAUTION : To avoid personal injury when performing

the crankshaft position system variation learning

procedure, always set the vehice parking brake and

block the drive wheels. Release the throttle immedi-

ately when the engine starts to decelerate. Once the

learn procedure is completed, engine control will be

returned to the operator, and the engine will respond

to throttle position.

DTC P1336 will only set if the ECM has not learned the

CKP system variation. The ECM only needs to learn this

variation once per life cycle of the vehicle unless the crank

sensor to crankshaft relationship is disturbed. Removing

a part is considered a disturbance. A fully warmed engine

is critical to learning the variation correctly. If a valid learn

occurs, no other learns can be completed that ignition

cycle.

If the engine cuts out before the specified learn procedure

engine speed or at normal fuel cutoff rpm, the ECM is not

in the learn procedure mode.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the fault occurred. The information is then stored on

the scan tool for later reference.

2. Engine temperature is critical to properly learn the

CKP system variation. Failure to properly warm the

engine before performing this procedure will result

in an inaccurate measurement of the CKP system

variation. The ECM learns this variation as the en-

gine is decelerating and then allows engine control

to be returned to the operator. All accessories must

be OFF when learning the CKP system angle varia-

tion. If the A/C is not disabled when the learn pro-

cedure is enabled, the ECM will disable the A/C.

3. If after the specified number attempts the ECM

cannot learn the CKP system variation, then the

variation is too large and no further attempts should

be made until the variation problem is corrected.

4. Being unable to learn the procedure indicates that

the variation is out of range.

5. After the CKP system variation has been learned,

wait above 10 seconds with ignition switch OFF to

prevent being cleared the learned value.

Page 797 of 2643

ENGINE CONTROLS 1F – 551

DAEWOO V–121 BL4

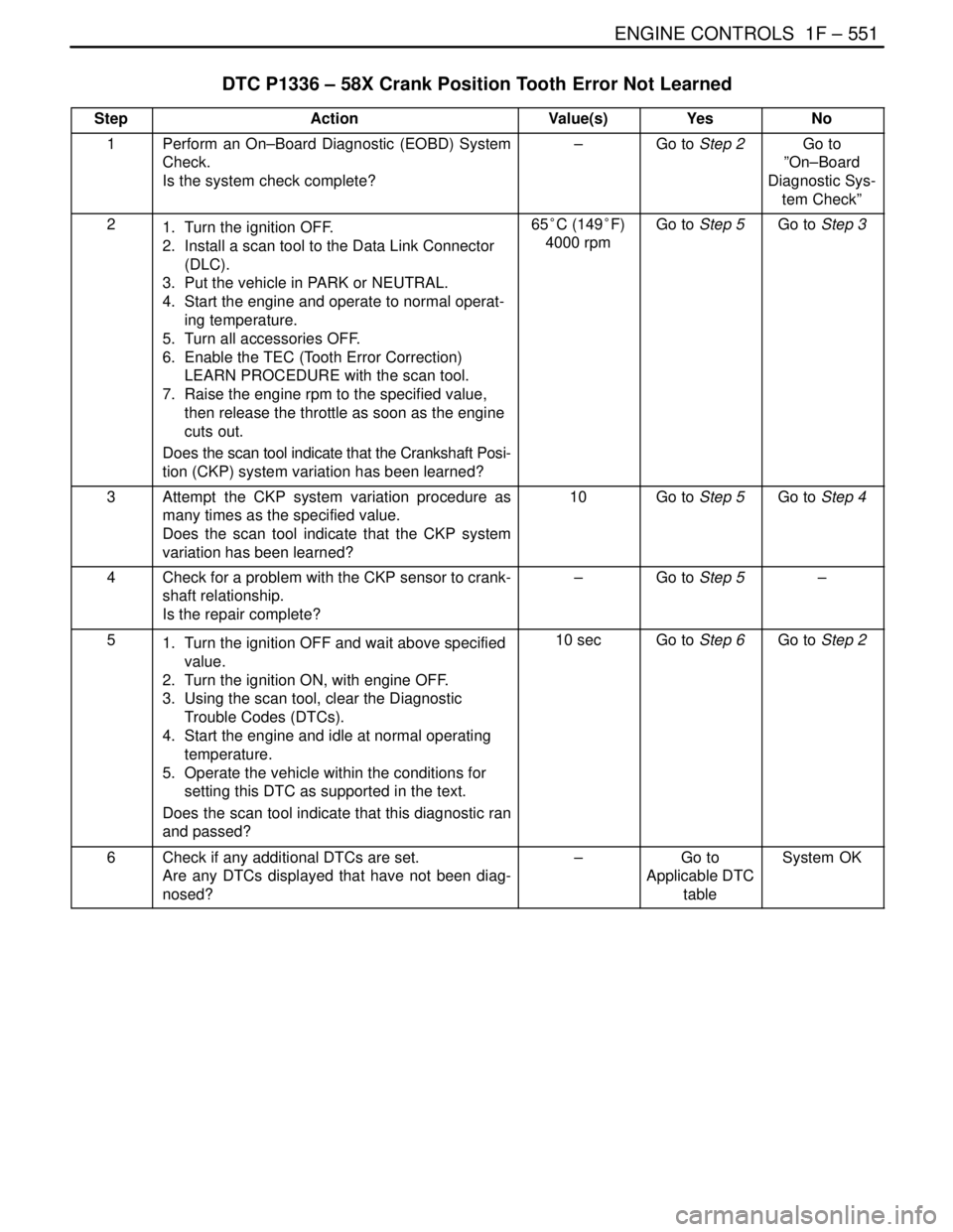

DTC P1336 – 58X Crank Position Tooth Error Not Learned

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Install a scan tool to the Data Link Connector

(DLC).

3. Put the vehicle in PARK or NEUTRAL.

4. Start the engine and operate to normal operat-

ing temperature.

5. Turn all accessories OFF.

6. Enable the TEC (Tooth Error Correction)

LEARN PROCEDURE with the scan tool.

7. Raise the engine rpm to the specified value,

then release the throttle as soon as the engine

cuts out.

Does the scan tool indicate that the Crankshaft Posi-

tion (CKP) system variation has been learned?65°C (149°F)

4000 rpmGo to Step 5Go to Step 3

3Attempt the CKP system variation procedure as

many times as the specified value.

Does the scan tool indicate that the CKP system

variation has been learned?10Go to Step 5Go to Step 4

4Check for a problem with the CKP sensor to crank-

shaft relationship.

Is the repair complete?–Go to Step 5–

51. Turn the ignition OFF and wait above specified

value.

2. Turn the ignition ON, with engine OFF.

3. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

4. Start the engine and idle at normal operating

temperature.

5. Operate the vehicle within the conditions for

setting this DTC as supported in the text.

Does the scan tool indicate that this diagnostic ran

and passed?10 secGo to Step 6Go to Step 2

6Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 799 of 2643

ENGINE CONTROLS 1F – 553

DAEWOO V–121 BL4

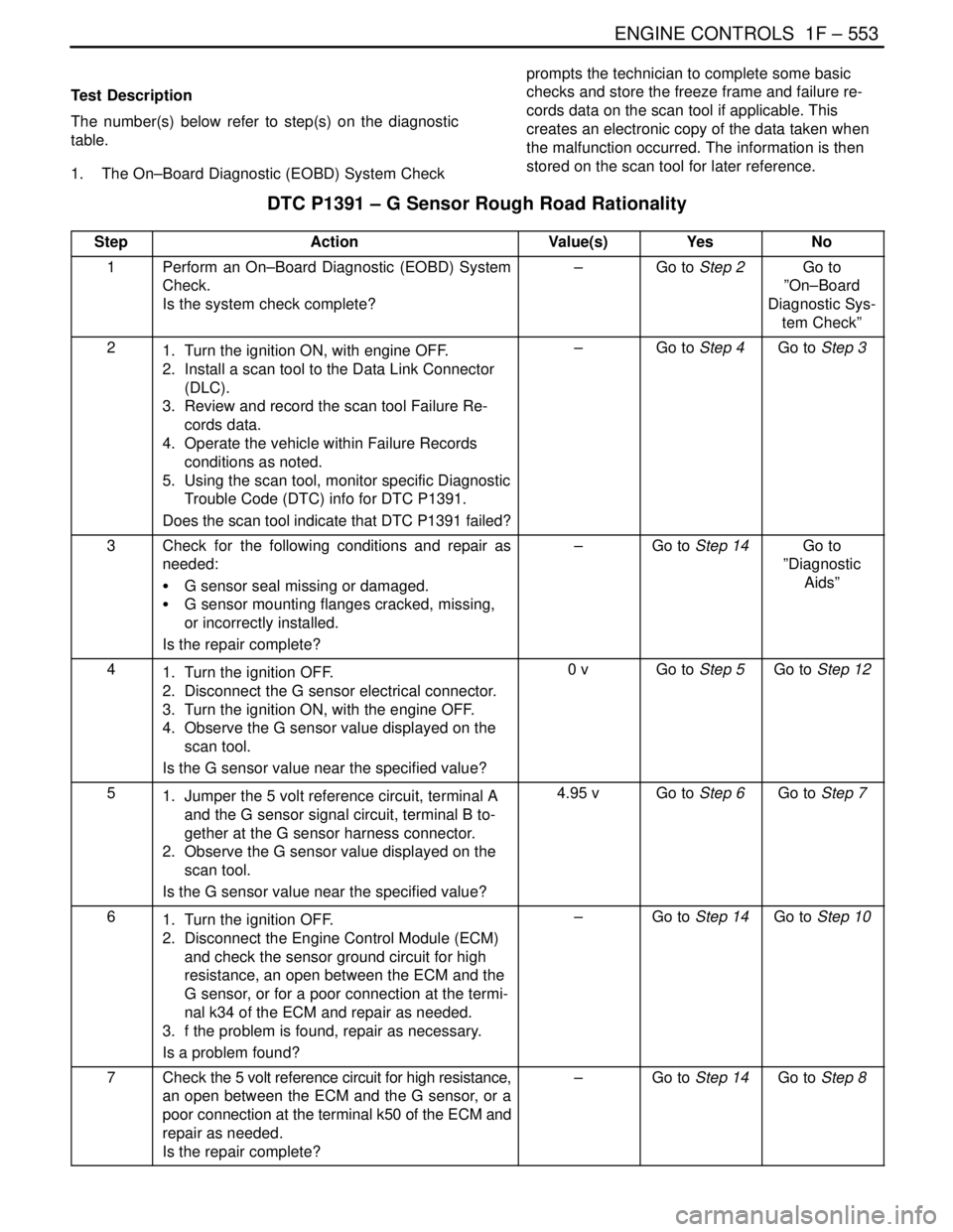

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. The On–Board Diagnostic (EOBD) System Checkprompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

DTC P1391 – G Sensor Rough Road Rationality

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition ON, with engine OFF.

2. Install a scan tool to the Data Link Connector

(DLC).

3. Review and record the scan tool Failure Re-

cords data.

4. Operate the vehicle within Failure Records

conditions as noted.

5. Using the scan tool, monitor specific Diagnostic

Trouble Code (DTC) info for DTC P1391.

Does the scan tool indicate that DTC P1391 failed?–Go to Step 4Go to Step 3

3Check for the following conditions and repair as

needed:

S G sensor seal missing or damaged.

S G sensor mounting flanges cracked, missing,

or incorrectly installed.

Is the repair complete?–Go to Step 14Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Disconnect the G sensor electrical connector.

3. Turn the ignition ON, with the engine OFF.

4. Observe the G sensor value displayed on the

scan tool.

Is the G sensor value near the specified value?0 vGo to Step 5Go to Step 12

51. Jumper the 5 volt reference circuit, terminal A

and the G sensor signal circuit, terminal B to-

gether at the G sensor harness connector.

2. Observe the G sensor value displayed on the

scan tool.

Is the G sensor value near the specified value?4.95 vGo to Step 6Go to Step 7

61. Turn the ignition OFF.

2. Disconnect the Engine Control Module (ECM)

and check the sensor ground circuit for high

resistance, an open between the ECM and the

G sensor, or for a poor connection at the termi-

nal k34 of the ECM and repair as needed.

3. f the problem is found, repair as necessary.

Is a problem found?–Go to Step 14Go to Step 10

7Check the 5 volt reference circuit for high resistance,

an open between the ECM and the G sensor, or a

poor connection at the terminal k50 of the ECM and

repair as needed.

Is the repair complete?–Go to Step 14Go to Step 8

Page 800 of 2643

1F – 554IENGINE CONTROLS

DAEWOO V–121 BL4

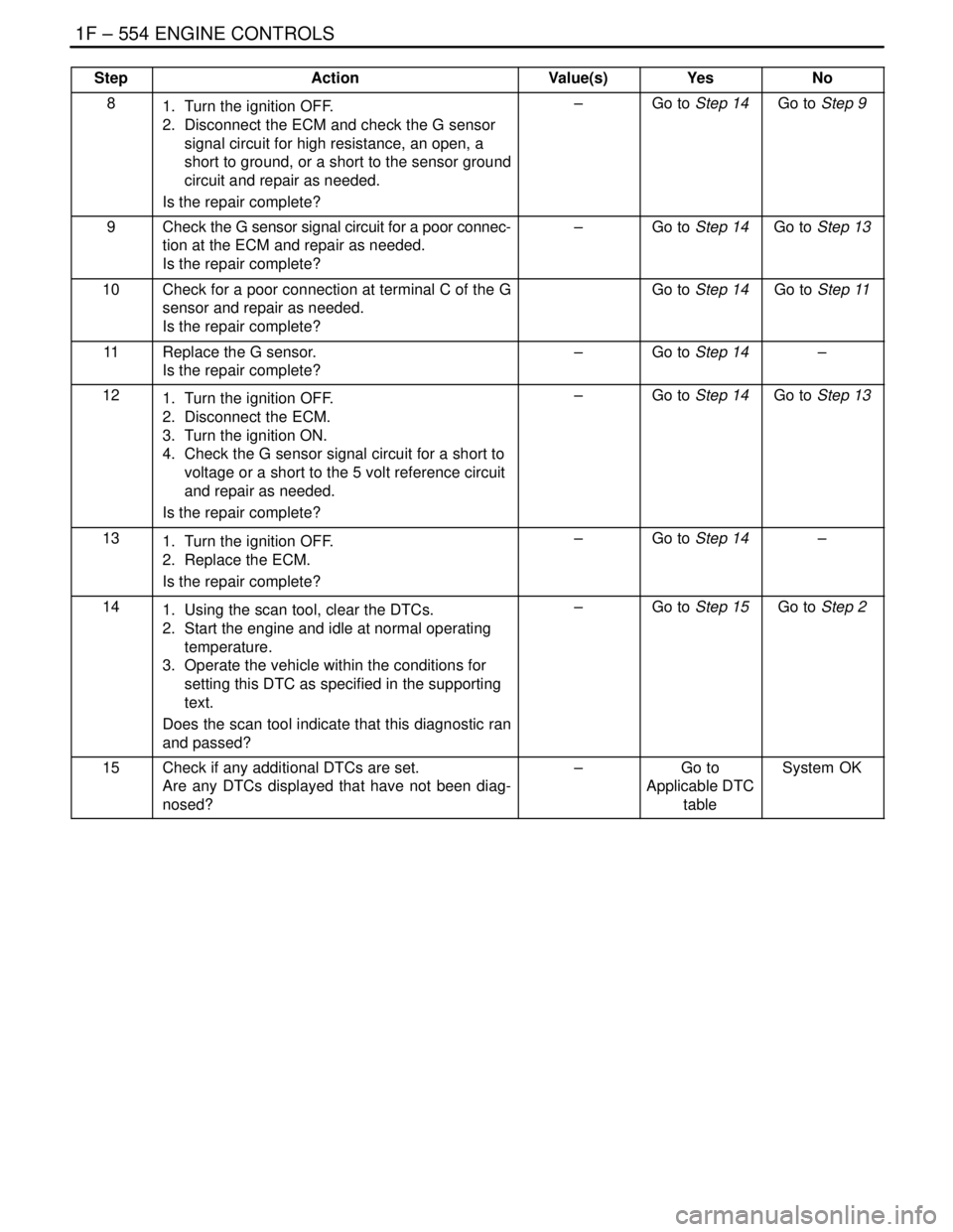

StepNo Yes Value(s) Action

81. Turn the ignition OFF.

2. Disconnect the ECM and check the G sensor

signal circuit for high resistance, an open, a

short to ground, or a short to the sensor ground

circuit and repair as needed.

Is the repair complete?–Go to Step 14Go to Step 9

9Check the G sensor signal circuit for a poor connec-

tion at the ECM and repair as needed.

Is the repair complete?–Go to Step 14Go to Step 13

10Check for a poor connection at terminal C of the G

sensor and repair as needed.

Is the repair complete?Go to Step 14Go to Step 11

11Replace the G sensor.

Is the repair complete?–Go to Step 14–

121. Turn the ignition OFF.

2. Disconnect the ECM.

3. Turn the ignition ON.

4. Check the G sensor signal circuit for a short to

voltage or a short to the 5 volt reference circuit

and repair as needed.

Is the repair complete?–Go to Step 14Go to Step 13

131. Turn the ignition OFF.

2. Replace the ECM.

Is the repair complete?–Go to Step 14–

141. Using the scan tool, clear the DTCs.

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic ran

and passed?–Go to Step 15Go to Step 2

15Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 802 of 2643

1F – 556IENGINE CONTROLS

DAEWOO V–121 BL4

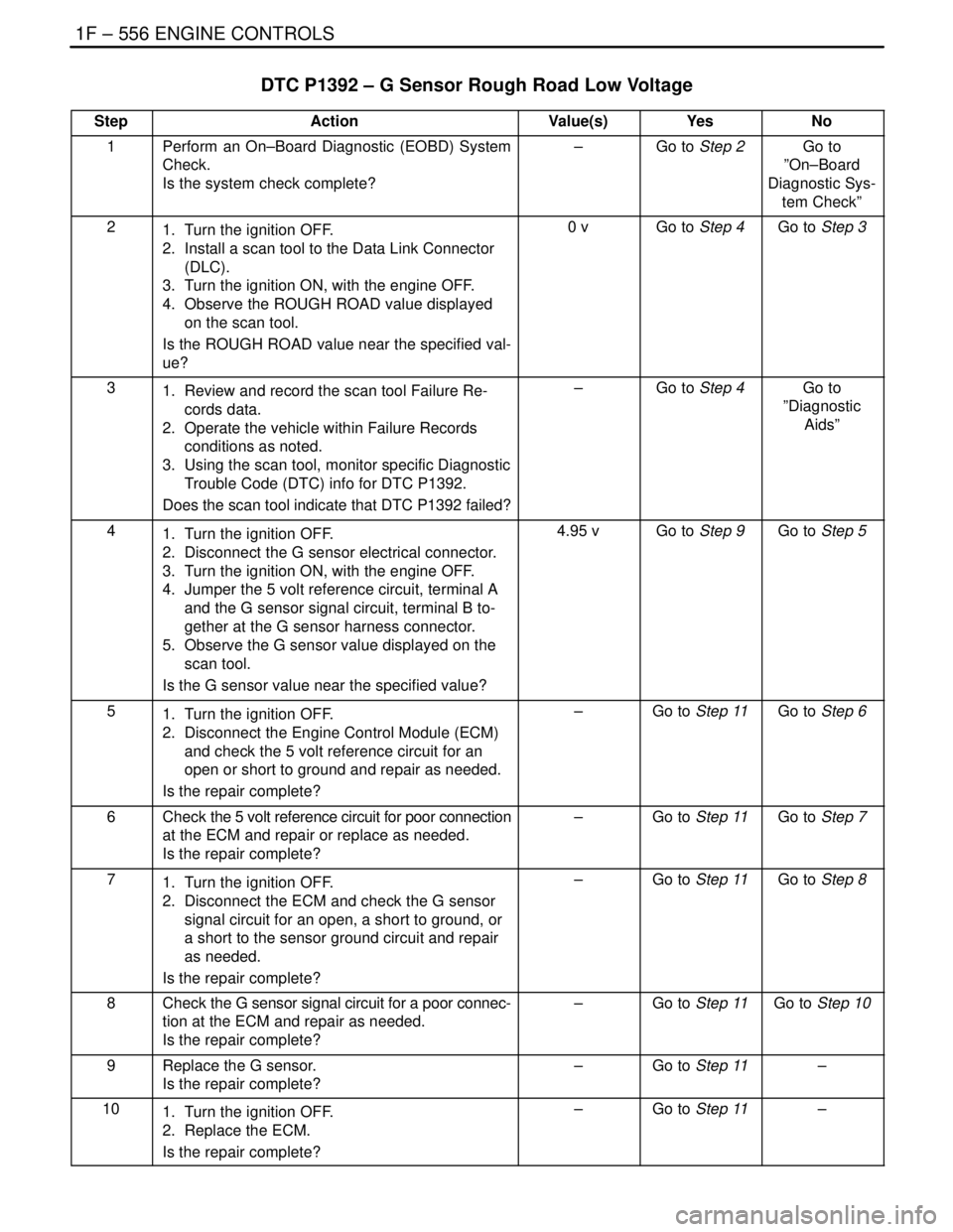

DTC P1392 – G Sensor Rough Road Low Voltage

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Install a scan tool to the Data Link Connector

(DLC).

3. Turn the ignition ON, with the engine OFF.

4. Observe the ROUGH ROAD value displayed

on the scan tool.

Is the ROUGH ROAD value near the specified val-

ue?0 vGo to Step 4Go to Step 3

31. Review and record the scan tool Failure Re-

cords data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using the scan tool, monitor specific Diagnostic

Trouble Code (DTC) info for DTC P1392.

Does the scan tool indicate that DTC P1392 failed?–Go to Step 4Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Disconnect the G sensor electrical connector.

3. Turn the ignition ON, with the engine OFF.

4. Jumper the 5 volt reference circuit, terminal A

and the G sensor signal circuit, terminal B to-

gether at the G sensor harness connector.

5. Observe the G sensor value displayed on the

scan tool.

Is the G sensor value near the specified value?4.95 vGo to Step 9Go to Step 5

51. Turn the ignition OFF.

2. Disconnect the Engine Control Module (ECM)

and check the 5 volt reference circuit for an

open or short to ground and repair as needed.

Is the repair complete?–Go to Step 11Go to Step 6

6Check the 5 volt reference circuit for poor connection

at the ECM and repair or replace as needed.

Is the repair complete?–Go to Step 11Go to Step 7

71. Turn the ignition OFF.

2. Disconnect the ECM and check the G sensor

signal circuit for an open, a short to ground, or

a short to the sensor ground circuit and repair

as needed.

Is the repair complete?–Go to Step 11Go to Step 8

8Check the G sensor signal circuit for a poor connec-

tion at the ECM and repair as needed.

Is the repair complete?–Go to Step 11Go to Step 10

9Replace the G sensor.

Is the repair complete?–Go to Step 11–

101. Turn the ignition OFF.

2. Replace the ECM.

Is the repair complete?–Go to Step 11–

Page 805 of 2643

ENGINE CONTROLS 1F – 559

DAEWOO V–121 BL4

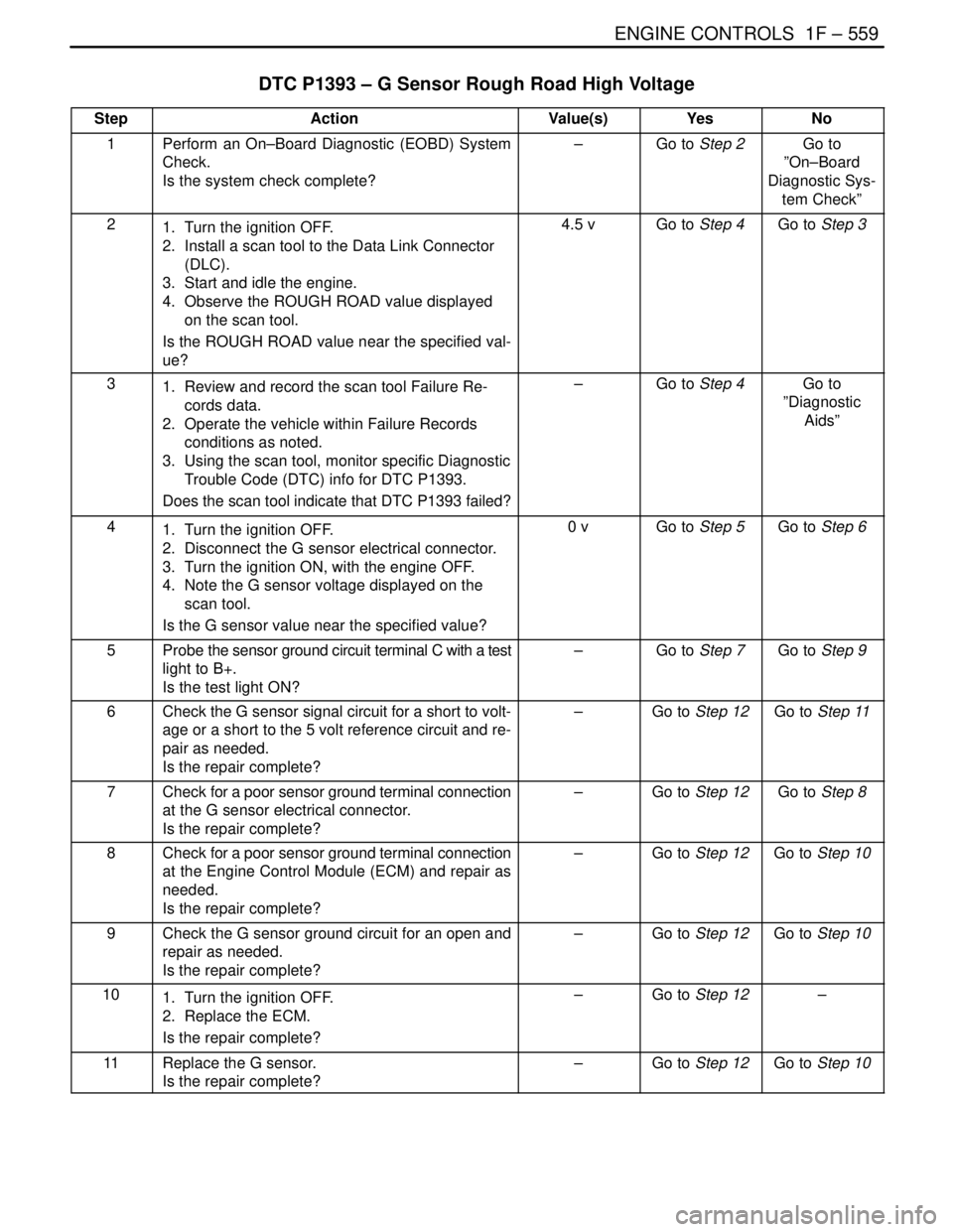

DTC P1393 – G Sensor Rough Road High Voltage

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Install a scan tool to the Data Link Connector

(DLC).

3. Start and idle the engine.

4. Observe the ROUGH ROAD value displayed

on the scan tool.

Is the ROUGH ROAD value near the specified val-

ue?4.5 vGo to Step 4Go to Step 3

31. Review and record the scan tool Failure Re-

cords data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using the scan tool, monitor specific Diagnostic

Trouble Code (DTC) info for DTC P1393.

Does the scan tool indicate that DTC P1393 failed?–Go to Step 4Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Disconnect the G sensor electrical connector.

3. Turn the ignition ON, with the engine OFF.

4. Note the G sensor voltage displayed on the

scan tool.

Is the G sensor value near the specified value?0 vGo to Step 5Go to Step 6

5Probe the sensor ground circuit terminal C with a test

light to B+.

Is the test light ON?–Go to Step 7Go to Step 9

6Check the G sensor signal circuit for a short to volt-

age or a short to the 5 volt reference circuit and re-

pair as needed.

Is the repair complete?–Go to Step 12Go to Step 11

7Check for a poor sensor ground terminal connection

at the G sensor electrical connector.

Is the repair complete?–Go to Step 12Go to Step 8

8Check for a poor sensor ground terminal connection

at the Engine Control Module (ECM) and repair as

needed.

Is the repair complete?–Go to Step 12Go to Step 10

9Check the G sensor ground circuit for an open and

repair as needed.

Is the repair complete?–Go to Step 12Go to Step 10

101. Turn the ignition OFF.

2. Replace the ECM.

Is the repair complete?–Go to Step 12–

11Replace the G sensor.

Is the repair complete?–Go to Step 12Go to Step 10

Page 808 of 2643

1F – 562IENGINE CONTROLS

DAEWOO V–121 BL4

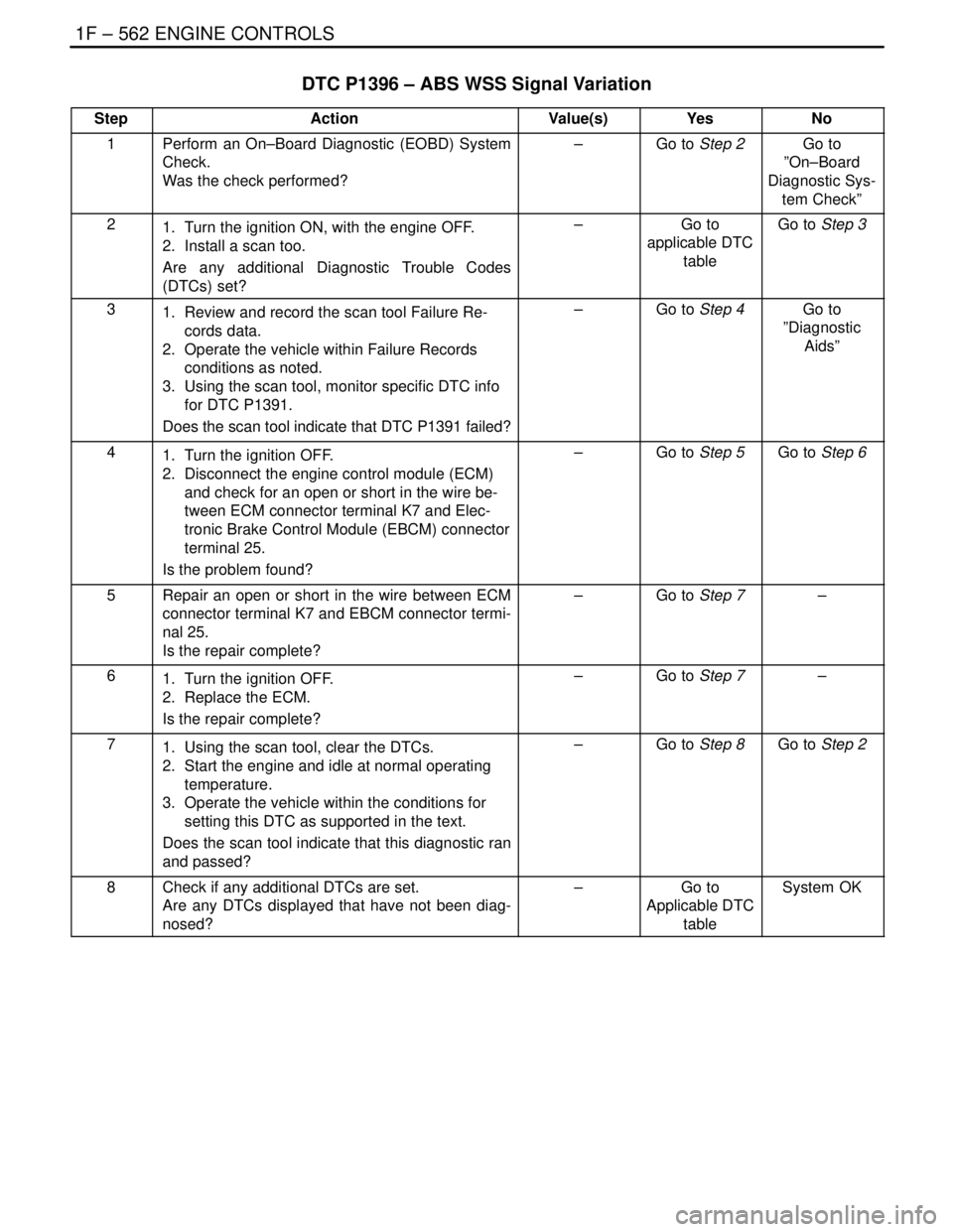

DTC P1396 – ABS WSS Signal Variation

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition ON, with the engine OFF.

2. Install a scan too.

Are any additional Diagnostic Trouble Codes

(DTCs) set?–Go to

applicable DTC

tableGo to Step 3

31. Review and record the scan tool Failure Re-

cords data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using the scan tool, monitor specific DTC info

for DTC P1391.

Does the scan tool indicate that DTC P1391 failed?–Go to Step 4Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Disconnect the engine control module (ECM)

and check for an open or short in the wire be-

tween ECM connector terminal K7 and Elec-

tronic Brake Control Module (EBCM) connector

terminal 25.

Is the problem found?–Go to Step 5Go to Step 6

5Repair an open or short in the wire between ECM

connector terminal K7 and EBCM connector termi-

nal 25.

Is the repair complete?–Go to Step 7–

61. Turn the ignition OFF.

2. Replace the ECM.

Is the repair complete?–Go to Step 7–

71. Using the scan tool, clear the DTCs.

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting this DTC as supported in the text.

Does the scan tool indicate that this diagnostic ran

and passed?–Go to Step 8Go to Step 2

8Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 810 of 2643

1F – 564IENGINE CONTROLS

DAEWOO V–121 BL4

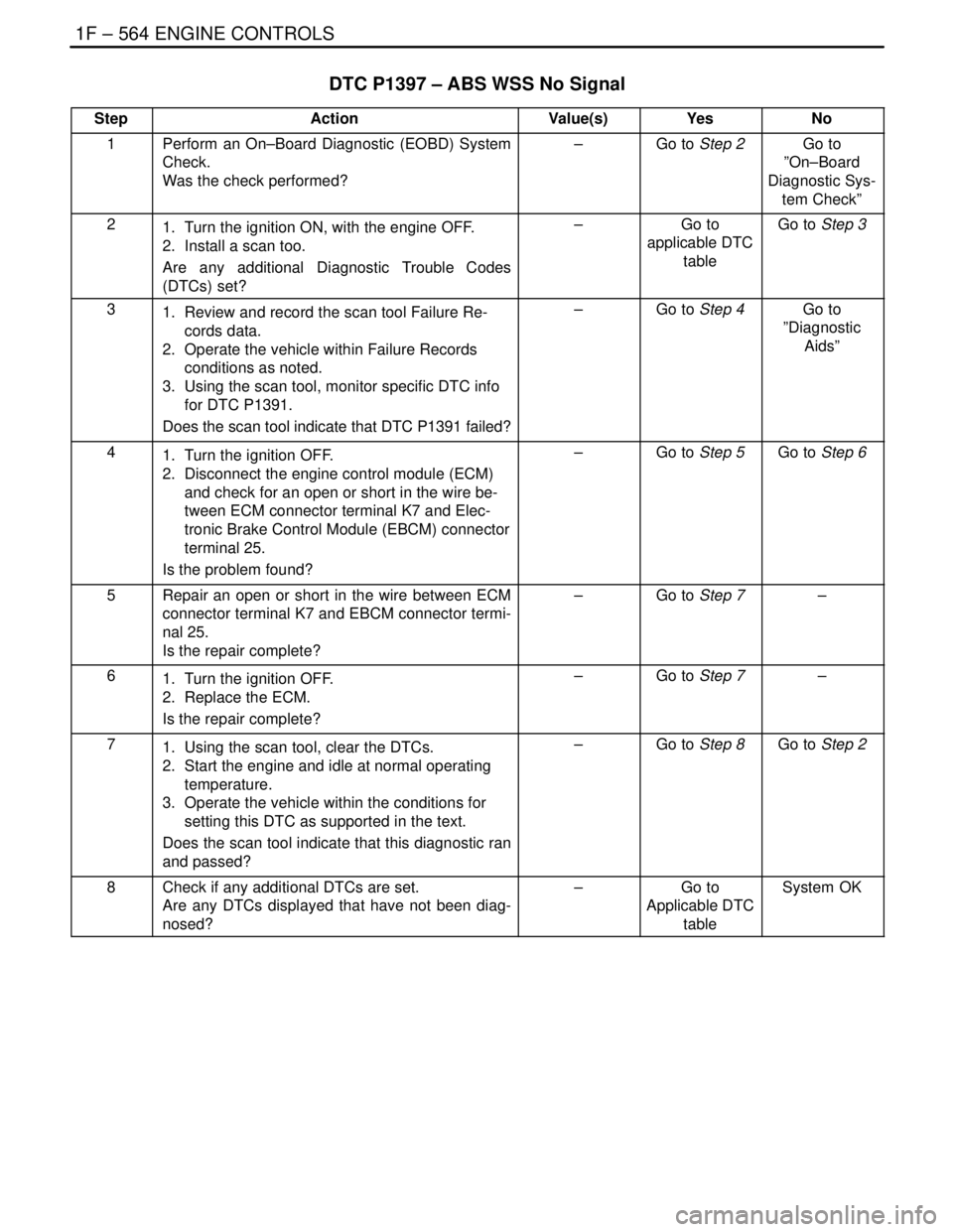

DTC P1397 – ABS WSS No Signal

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition ON, with the engine OFF.

2. Install a scan too.

Are any additional Diagnostic Trouble Codes

(DTCs) set?–Go to

applicable DTC

tableGo to Step 3

31. Review and record the scan tool Failure Re-

cords data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using the scan tool, monitor specific DTC info

for DTC P1391.

Does the scan tool indicate that DTC P1391 failed?–Go to Step 4Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Disconnect the engine control module (ECM)

and check for an open or short in the wire be-

tween ECM connector terminal K7 and Elec-

tronic Brake Control Module (EBCM) connector

terminal 25.

Is the problem found?–Go to Step 5Go to Step 6

5Repair an open or short in the wire between ECM

connector terminal K7 and EBCM connector termi-

nal 25.

Is the repair complete?–Go to Step 7–

61. Turn the ignition OFF.

2. Replace the ECM.

Is the repair complete?–Go to Step 7–

71. Using the scan tool, clear the DTCs.

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting this DTC as supported in the text.

Does the scan tool indicate that this diagnostic ran

and passed?–Go to Step 8Go to Step 2

8Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 811 of 2643

ENGINE CONTROLS 1F – 565

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P1404

EXHAUST GAS RECIRCULATION CLOSED VALVE

PINTLE ERROR

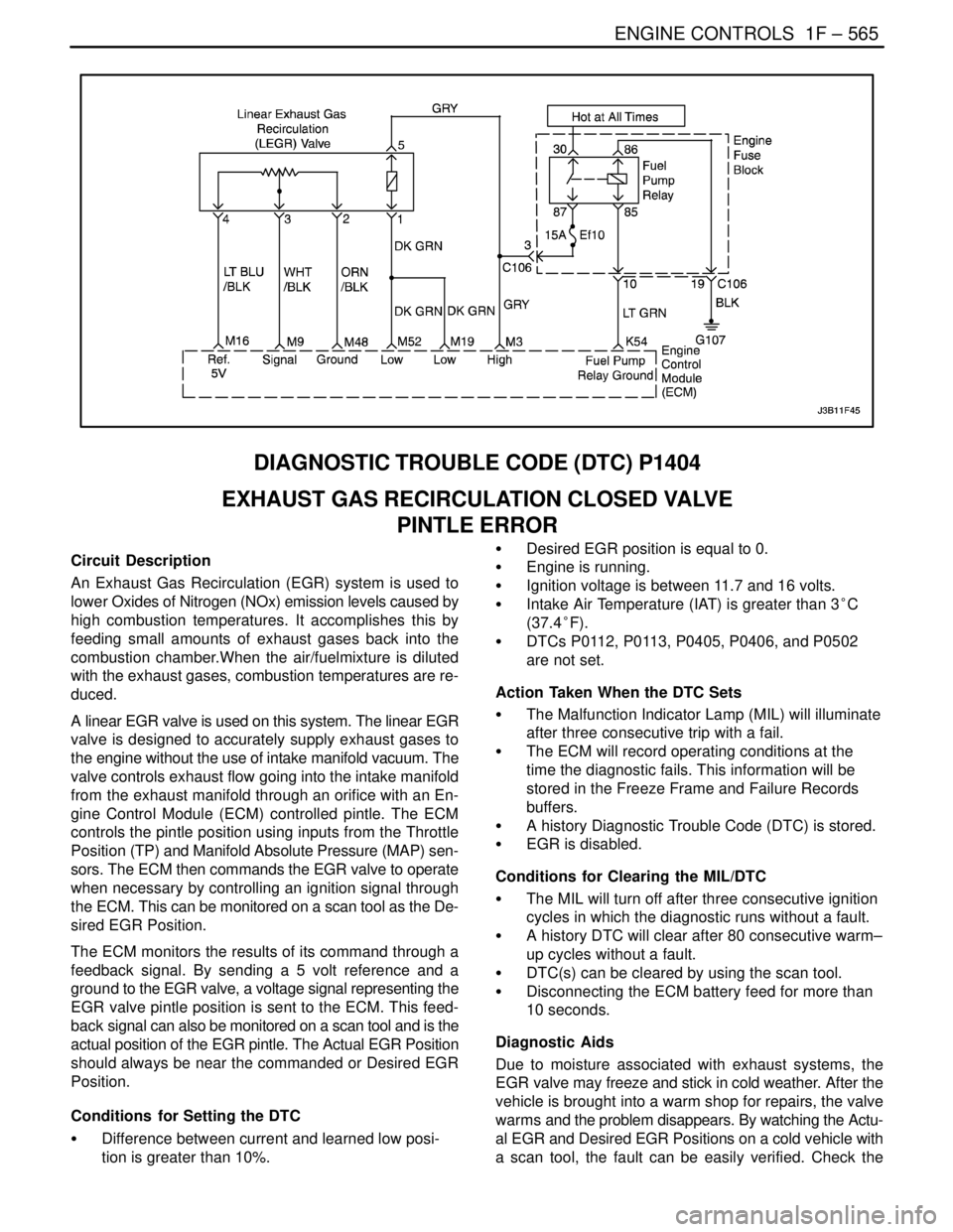

Circuit Description

An Exhaust Gas Recirculation (EGR) system is used to

lower Oxides of Nitrogen (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber.When the air/fuelmixture is diluted

with the exhaust gases, combustion temperatures are re-

duced.

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with an En-

gine Control Module (ECM) controlled pintle. The ECM

controls the pintle position using inputs from the Throttle

Position (TP) and Manifold Absolute Pressure (MAP) sen-

sors. The ECM then commands the EGR valve to operate

when necessary by controlling an ignition signal through

the ECM. This can be monitored on a scan tool as the De-

sired EGR Position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-

back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The Actual EGR Position

should always be near the commanded or Desired EGR

Position.

Conditions for Setting the DTC

S Difference between current and learned low posi-

tion is greater than 10%.S Desired EGR position is equal to 0.

S Engine is running.

S Ignition voltage is between 11.7 and 16 volts.

S Intake Air Temperature (IAT) is greater than 3°C

(37.4°F).

S DTCs P0112, P0113, P0405, P0406, and P0502

are not set.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history Diagnostic Trouble Code (DTC) is stored.

S EGR is disabled.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after three consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 80 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Due to moisture associated with exhaust systems, the

EGR valve may freeze and stick in cold weather. After the

vehicle is brought into a warm shop for repairs, the valve

warms and the problem disappears. By watching the Actu-

al EGR and Desired EGR Positions on a cold vehicle with

a scan tool, the fault can be easily verified. Check the

Page 812 of 2643

1F – 566IENGINE CONTROLS

DAEWOO V–121 BL4

freeze frame data to determine if the DTC set when the ve-

hicle was cold by viewing the Engine Coolant Temperature

(ECT).

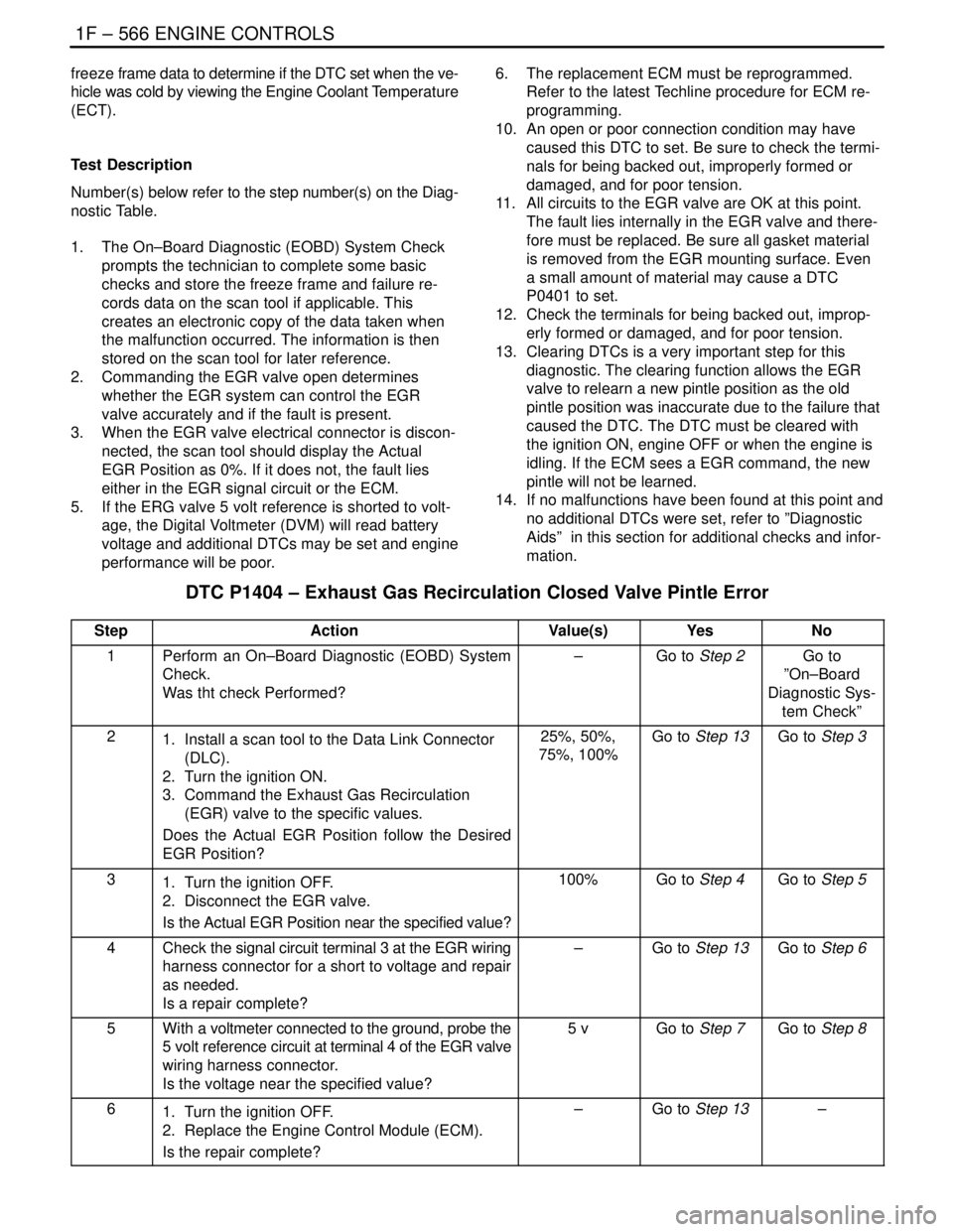

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. Commanding the EGR valve open determines

whether the EGR system can control the EGR

valve accurately and if the fault is present.

3. When the EGR valve electrical connector is discon-

nected, the scan tool should display the Actual

EGR Position as 0%. If it does not, the fault lies

either in the EGR signal circuit or the ECM.

5. If the ERG valve 5 volt reference is shorted to volt-

age, the Digital Voltmeter (DVM) will read battery

voltage and additional DTCs may be set and engine

performance will be poor.6. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

10. An open or poor connection condition may have

caused this DTC to set. Be sure to check the termi-

nals for being backed out, improperly formed or

damaged, and for poor tension.

11. All circuits to the EGR valve are OK at this point.

The fault lies internally in the EGR valve and there-

fore must be replaced. Be sure all gasket material

is removed from the EGR mounting surface. Even

a small amount of material may cause a DTC

P0401 to set.

12. Check the terminals for being backed out, improp-

erly formed or damaged, and for poor tension.

13. Clearing DTCs is a very important step for this

diagnostic. The clearing function allows the EGR

valve to relearn a new pintle position as the old

pintle position was inaccurate due to the failure that

caused the DTC. The DTC must be cleared with

the ignition ON, engine OFF or when the engine is

idling. If the ECM sees a EGR command, the new

pintle will not be learned.

14. If no malfunctions have been found at this point and

no additional DTCs were set, refer to ”Diagnostic

Aids” in this section for additional checks and infor-

mation.

DTC P1404 – Exhaust Gas Recirculation Closed Valve Pintle Error

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was tht check Performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON.

3. Command the Exhaust Gas Recirculation

(EGR) valve to the specific values.

Does the Actual EGR Position follow the Desired

EGR Position?25%, 50%,

75%, 100%Go to Step 13Go to Step 3

31. Turn the ignition OFF.

2. Disconnect the EGR valve.

Is the Actual EGR Position near the specified value?100%Go to Step 4Go to Step 5

4Check the signal circuit terminal 3 at the EGR wiring

harness connector for a short to voltage and repair

as needed.

Is a repair complete?–Go to Step 13Go to Step 6

5With a voltmeter connected to the ground, probe the

5 volt reference circuit at terminal 4 of the EGR valve

wiring harness connector.

Is the voltage near the specified value?5 vGo to Step 7Go to Step 8

61. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 13–