DAEWOO LACETTI 2004 Service Repair Manual

LACETTI 2004

DAEWOO

DAEWOO

https://www.carmanualsonline.info/img/54/56877/w960_56877-0.png

DAEWOO LACETTI 2004 Service Repair Manual

Page 1749 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 159

DAEWOO V–121 BL4

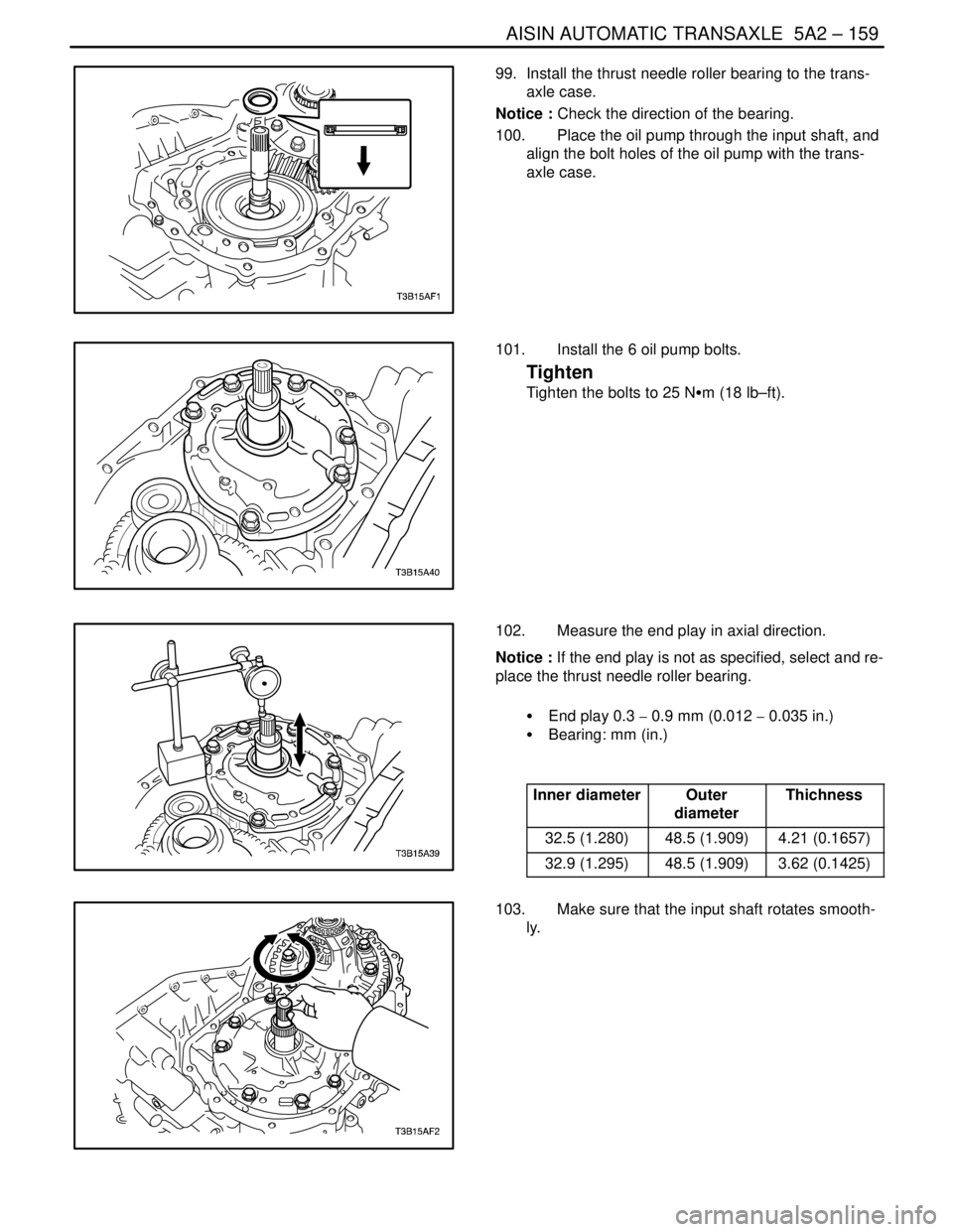

99. Install the thrust needle roller bearing to the trans-

axle case.

Notice : Check the direction of the bearing.

100. Place the oil pump through the input shaft, and

align the bolt holes of the oil pump with the trans-

axle case.

101. Install the 6 oil pump bolts.

Tighten

Tighten the bolts to 25 NSm (18 lb–ft).

102. Measure the end play in axial direction.

Notice : If the end play is not as specified, select and re-

place the thrust needle roller bearing.

S End play 0.3 � 0.9 mm (0.012 � 0.035 in.)

S Bearing: mm (in.)

Inner diameter

Outer

diameterThichness

32.5 (1.280)48.5 (1.909)4.21 (0.1657)

32.9 (1.295)48.5 (1.909)3.62 (0.1425)

103. Make sure that the input shaft rotates smooth-

ly.

Page 1750 of 2643

5A2 – 160IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

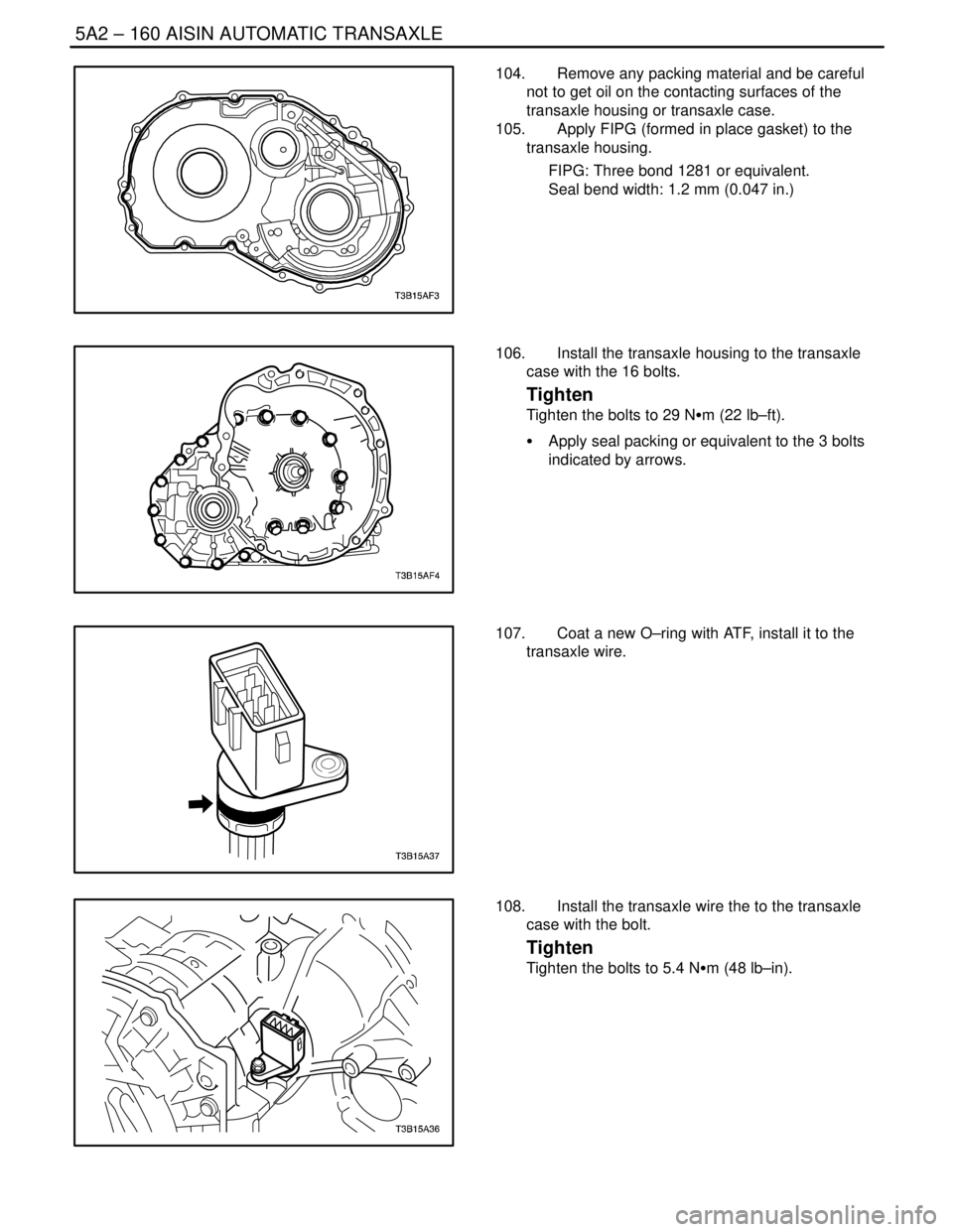

104. Remove any packing material and be careful

not to get oil on the contacting surfaces of the

transaxle housing or transaxle case.

105. Apply FIPG (formed in place gasket) to the

transaxle housing.

FIPG: Three bond 1281 or equivalent.

Seal bend width: 1.2 mm (0.047 in.)

106. Install the transaxle housing to the transaxle

case with the 16 bolts.

Tighten

Tighten the bolts to 29 NSm (22 lb–ft).

S Apply seal packing or equivalent to the 3 bolts

indicated by arrows.

107. Coat a new O–ring with ATF, install it to the

transaxle wire.

108. Install the transaxle wire the to the transaxle

case with the bolt.

Tighten

Tighten the bolts to 5.4 NSm (48 lb–in).

Page 1751 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 161

DAEWOO V–121 BL4

109. Coat new 6 O–rings with ATF and install them

to the pistons.

110. Coat the 3 springs and 3 accumulator pistons

with ATF, install them to the holes.

S Accumulator spring:

Spring

Free length

Outer

diameter

mm(in.)Color

B1(O/D & 2nd

brake)47.13(1.8555)/

16.0(0.630)Pink

C1(Forward

clutch)57.90(2.2795)/

17.2(0.677)–

C2(Direct

clutch)57.20(2.2520)/

17.5(0.689)Green

111. Coat a new apply gasket with ATF, install it to

the transaxle case.

112. Coat a new brake drum gasket with ATF, install

it to the transaxle case.

113. Install the spring and check valve.

Page 1752 of 2643

5A2 – 162IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

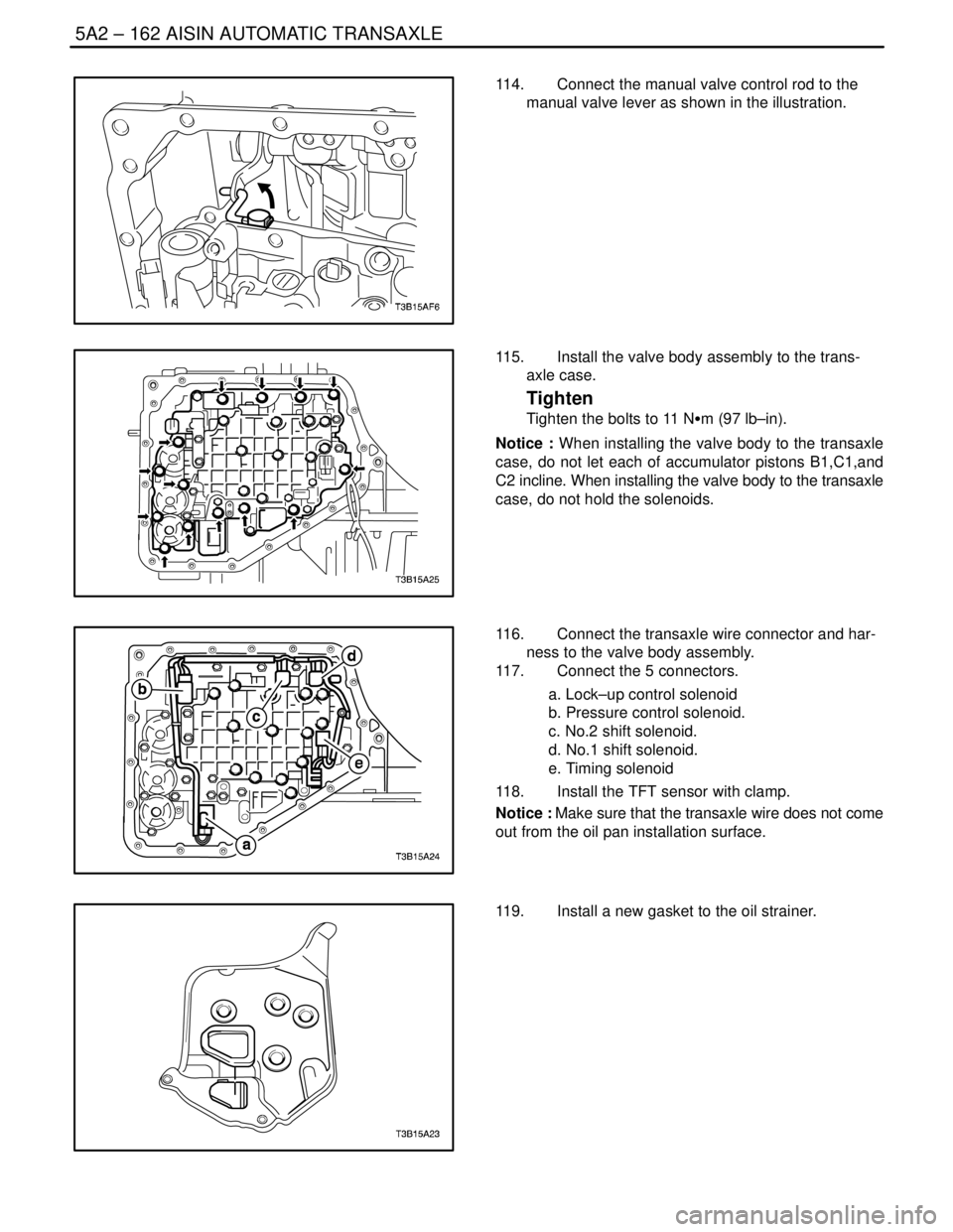

114. Connect the manual valve control rod to the

manual valve lever as shown in the illustration.

115. Install the valve body assembly to the trans-

axle case.

Tighten

Tighten the bolts to 11 NSm (97 lb–in).

Notice : When installing the valve body to the transaxle

case, do not let each of accumulator pistons B1,C1,and

C2 incline. When installing the valve body to the transaxle

case, do not hold the solenoids.

116. Connect the transaxle wire connector and har-

ness to the valve body assembly.

117. Connect the 5 connectors.

a. Lock–up control solenoid

b. Pressure control solenoid.

c. No.2 shift solenoid.

d. No.1 shift solenoid.

e. Timing solenoid

118. Install the TFT sensor with clamp.

Notice : Make sure that the transaxle wire does not come

out from the oil pan installation surface.

119. Install a new gasket to the oil strainer.

Page 1753 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 163

DAEWOO V–121 BL4

120. Install the oil strainer to the valve body with the

3 bolts.

Tighten

Tighten the bolts to 9.8 NSm (87 lb–in).

121. Install the 2 magnets in the oil pan.

122. Install a new gasket to the oil pan and install

them to the transaxle case with the 18 bolts.

Tighten

Tighten the bolts to 7 NSm (62 lb–in).

123. Install the output shaft speed (OSS) sensor.

Tighten

Tighten the bolt to 7.4 NSm (65 lb–in).

Page 1754 of 2643

5A2 – 164IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

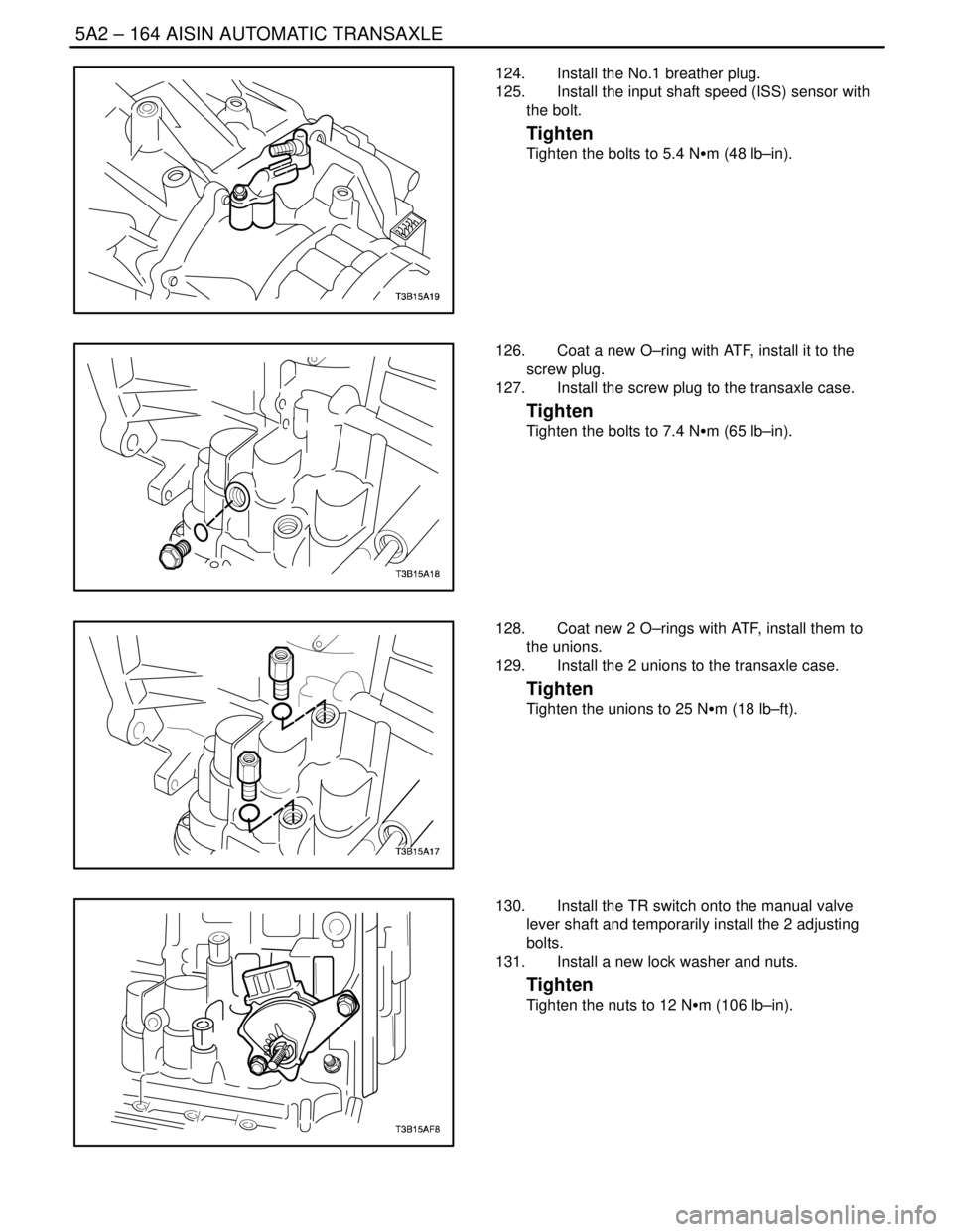

124. Install the No.1 breather plug.

125. Install the input shaft speed (ISS) sensor with

the bolt.

Tighten

Tighten the bolts to 5.4 NSm (48 lb–in).

126. Coat a new O–ring with ATF, install it to the

screw plug.

127. Install the screw plug to the transaxle case.

Tighten

Tighten the bolts to 7.4 NSm (65 lb–in).

128. Coat new 2 O–rings with ATF, install them to

the unions.

129. Install the 2 unions to the transaxle case.

Tighten

Tighten the unions to 25 NSm (18 lb–ft).

130. Install the TR switch onto the manual valve

lever shaft and temporarily install the 2 adjusting

bolts.

131. Install a new lock washer and nuts.

Tighten

Tighten the nuts to 12 NSm (106 lb–in).

Page 1755 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 165

DAEWOO V–121 BL4

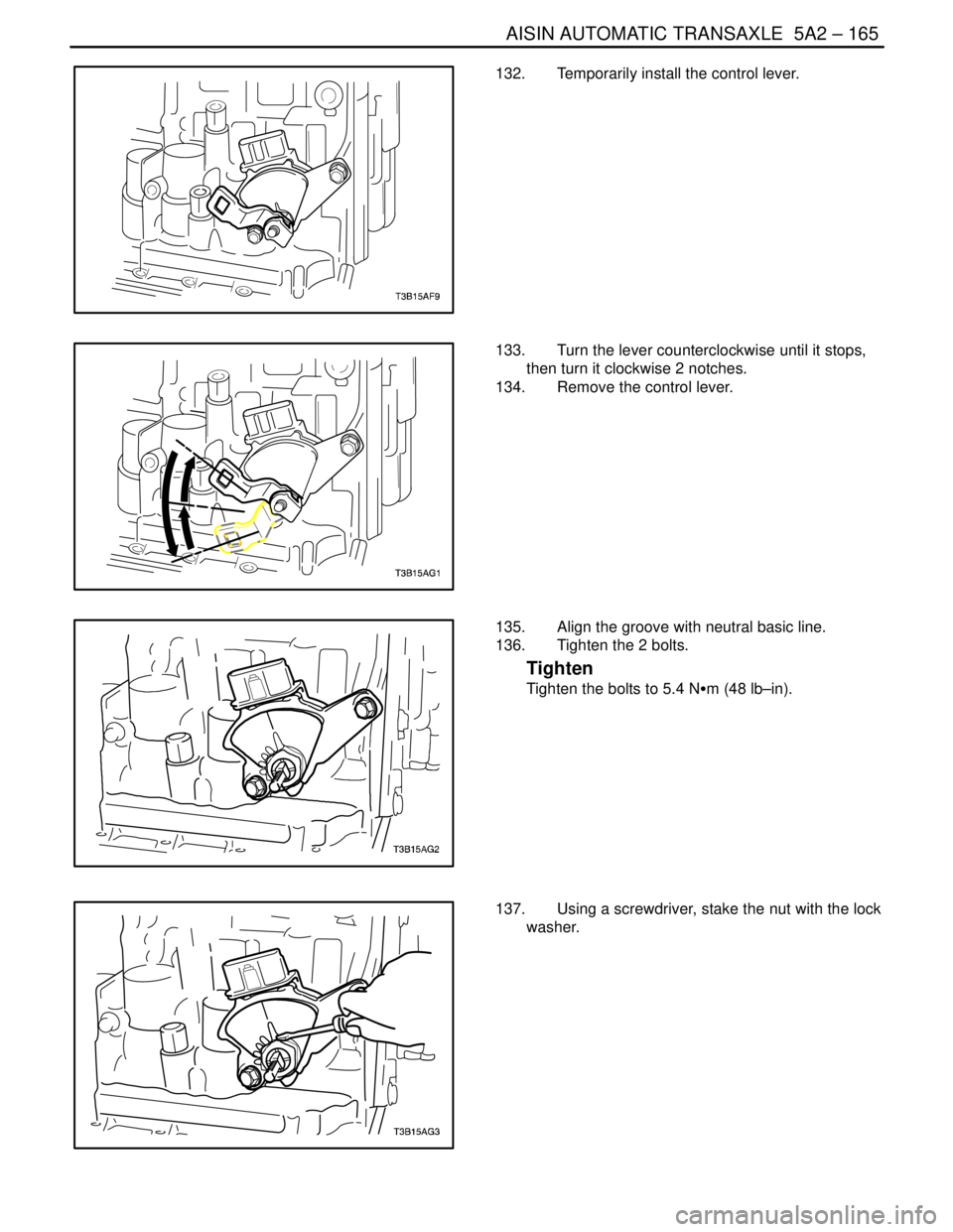

132. Temporarily install the control lever.

133. Turn the lever counterclockwise until it stops,

then turn it clockwise 2 notches.

134. Remove the control lever.

135. Align the groove with neutral basic line.

136. Tighten the 2 bolts.

Tighten

Tighten the bolts to 5.4 NSm (48 lb–in).

137. Using a screwdriver, stake the nut with the lock

washer.

Page 1756 of 2643

5A2 – 166IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

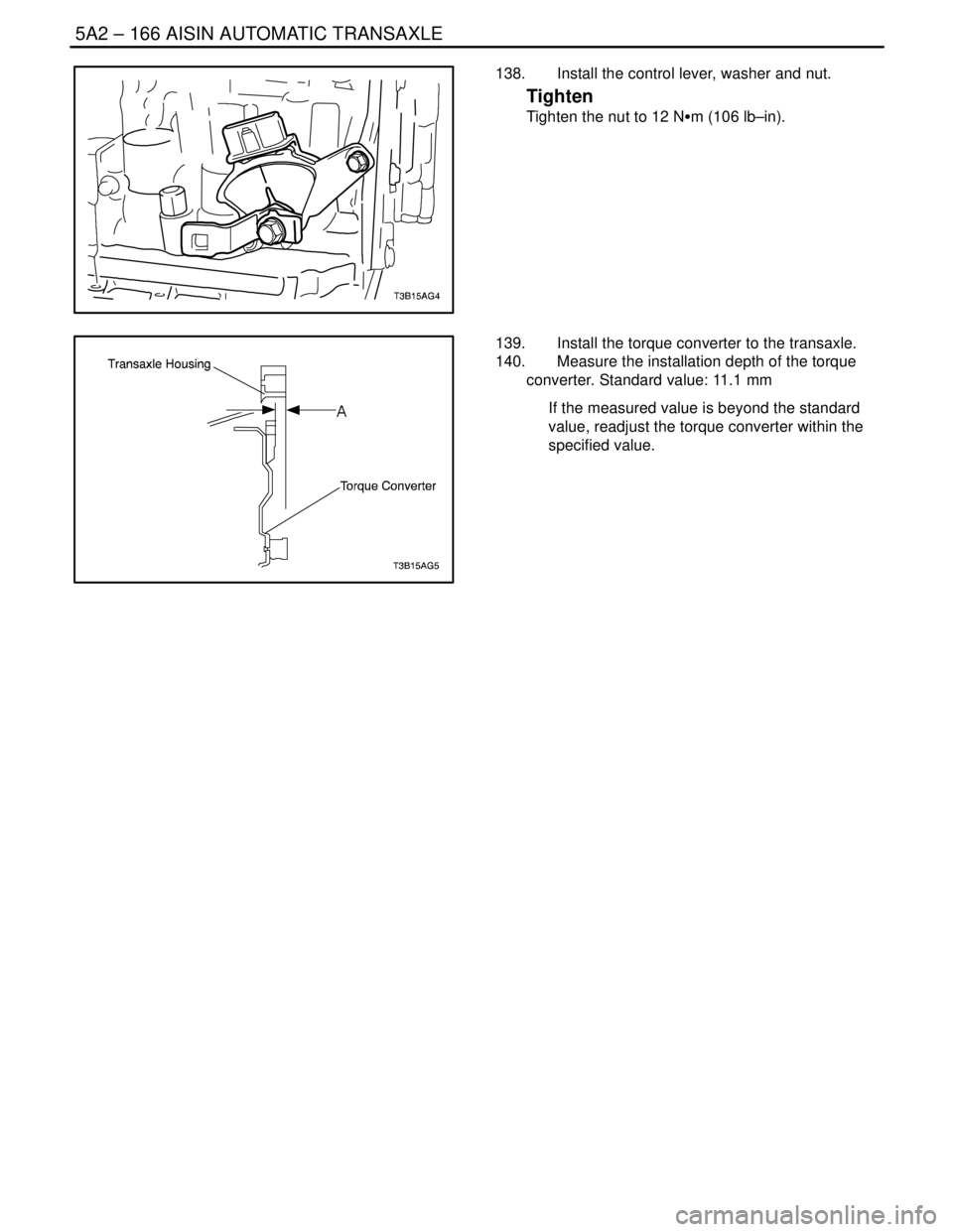

138. Install the control lever, washer and nut.

Tighten

Tighten the nut to 12 NSm (106 lb–in).

139. Install the torque converter to the transaxle.

140. Measure the installation depth of the torque

converter. Standard value: 11.1 mm

If the measured value is beyond the standard

value, readjust the torque converter within the

specified value.

Page 1757 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 167

DAEWOO V–121 BL4

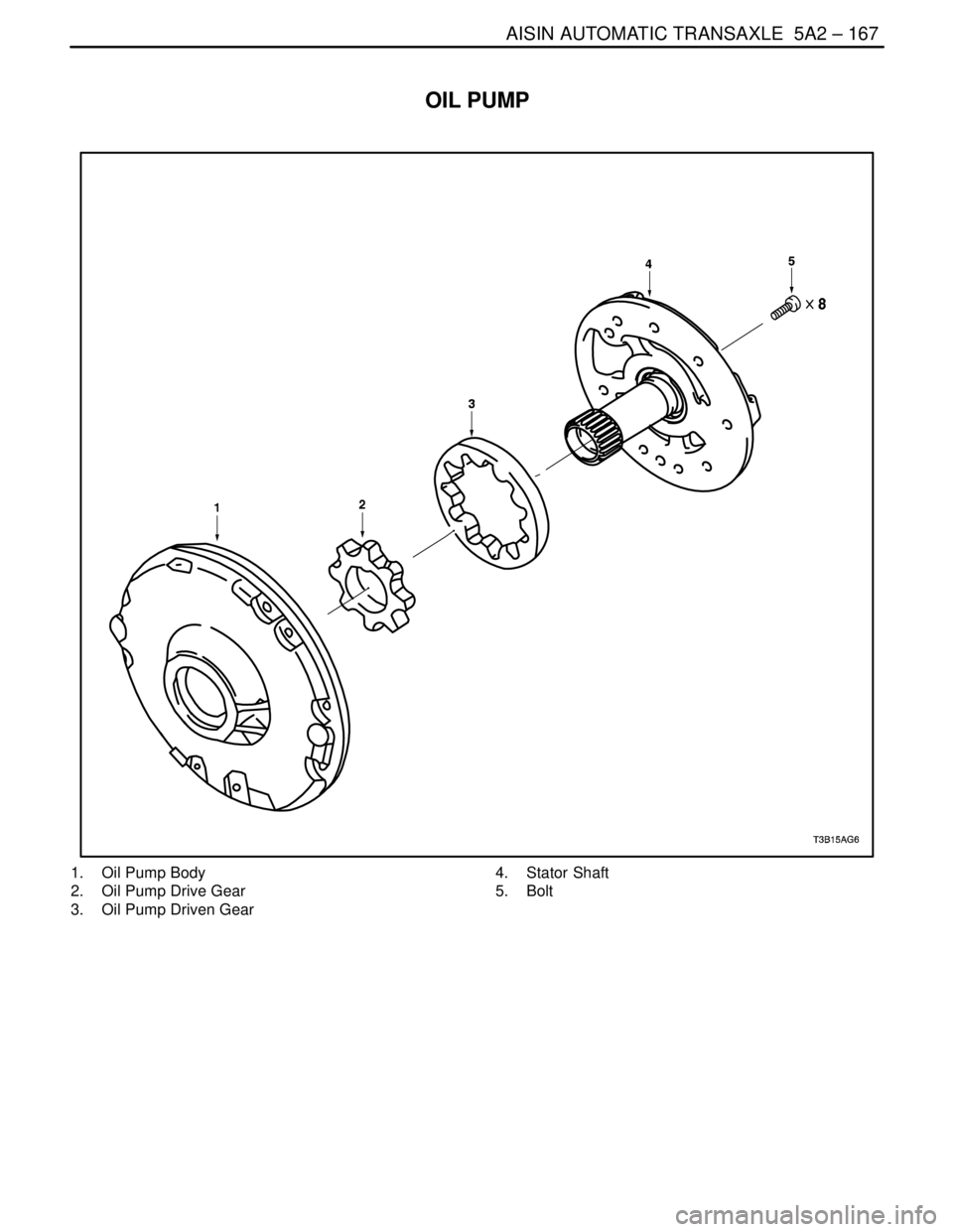

OIL PUMP

1. Oil Pump Body

2. Oil Pump Drive Gear

3. Oil Pump Driven Gear4. Stator Shaft

5. Bolt

Page 1758 of 2643

5A2 – 168IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

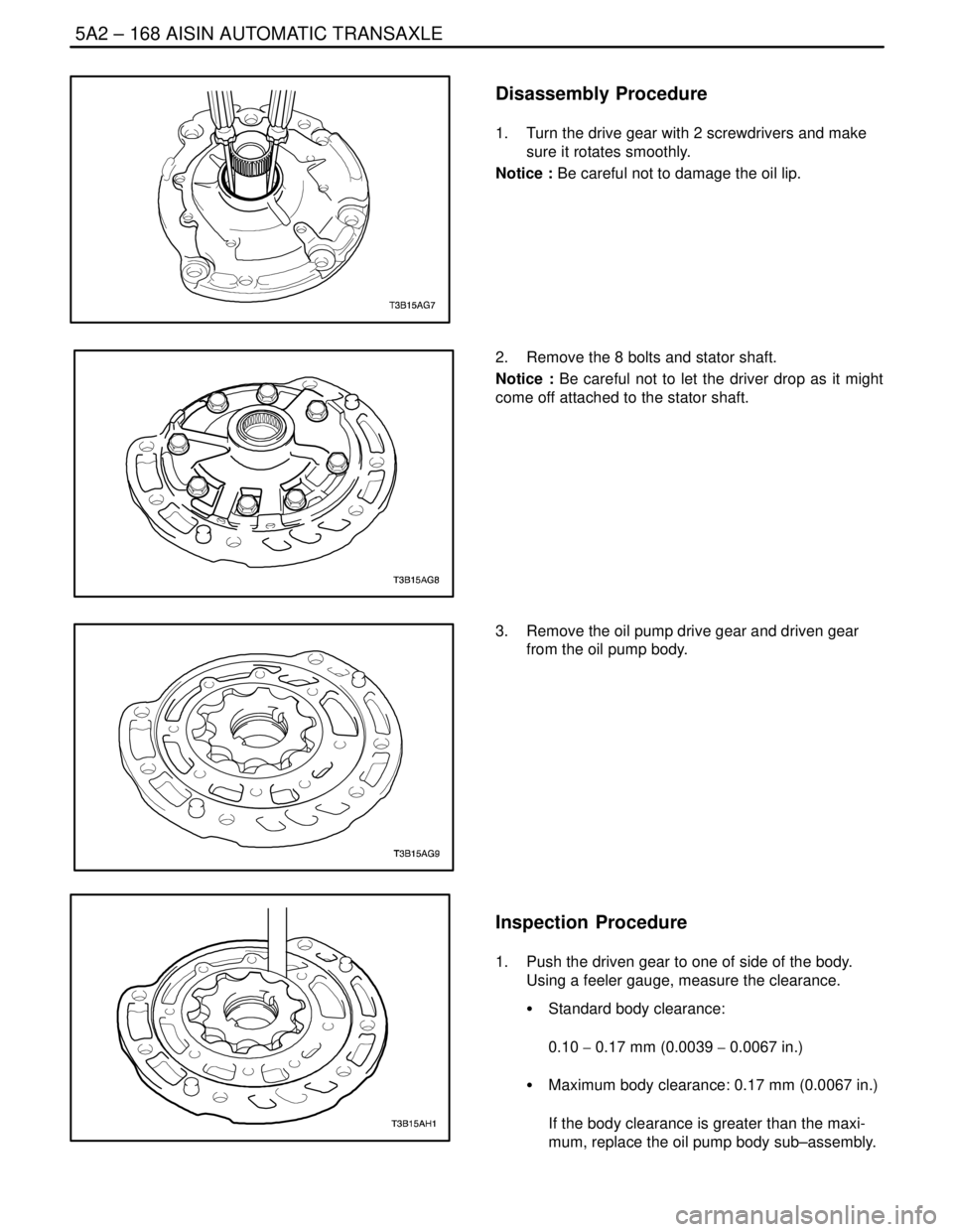

Disassembly Procedure

1. Turn the drive gear with 2 screwdrivers and make

sure it rotates smoothly.

Notice : Be careful not to damage the oil lip.

2. Remove the 8 bolts and stator shaft.

Notice : Be careful not to let the driver drop as it might

come off attached to the stator shaft.

3. Remove the oil pump drive gear and driven gear

from the oil pump body.

Inspection Procedure

1. Push the driven gear to one of side of the body.

Using a feeler gauge, measure the clearance.

S Standard body clearance:

0.10 � 0.17 mm (0.0039 � 0.0067 in.)

S Maximum body clearance: 0.17 mm (0.0067 in.)

If the body clearance is greater than the maxi-

mum, replace the oil pump body sub–assembly.