battery DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2460 of 2643

ROOF 9Q – 11

DAEWOO V–121 BL4

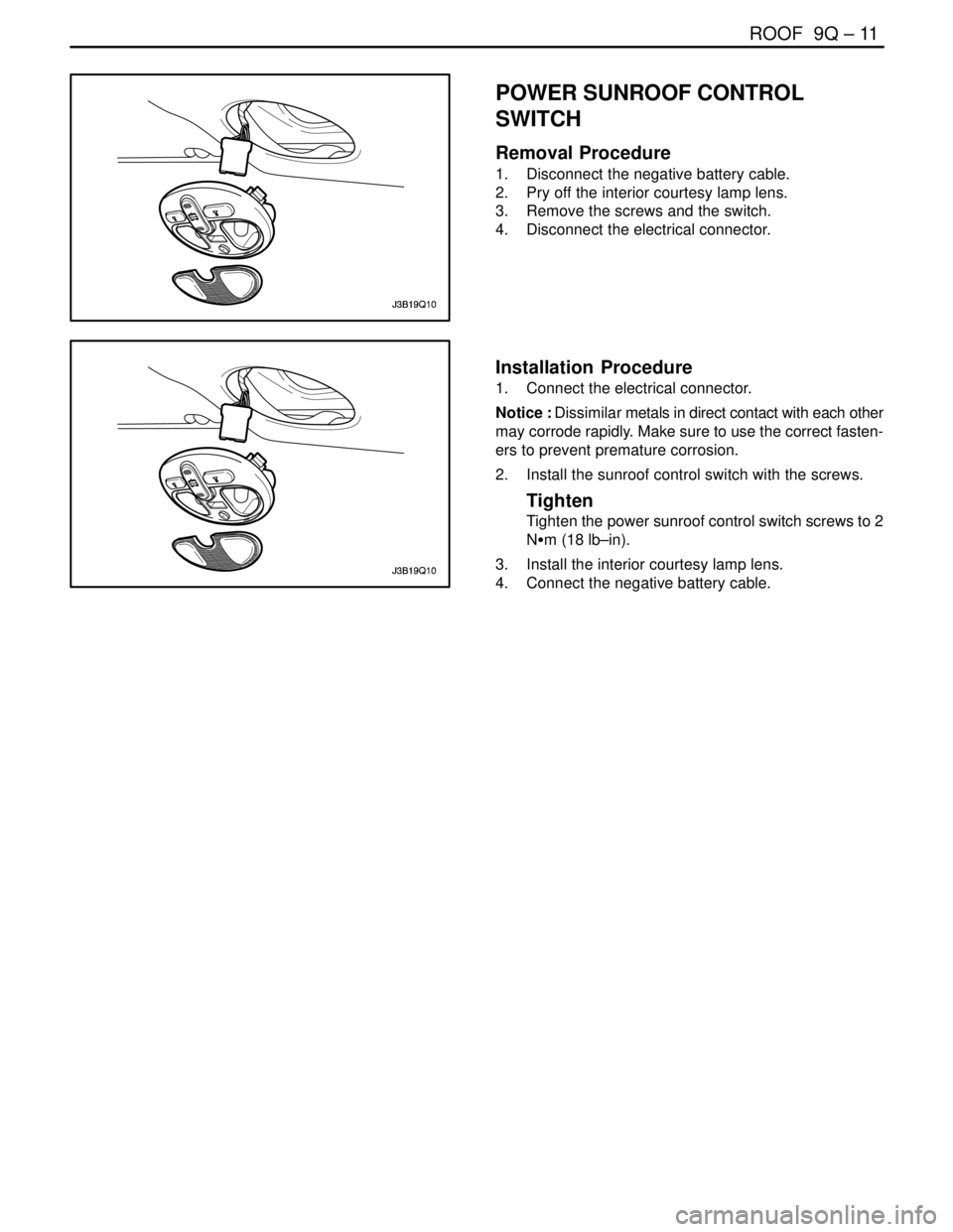

POWER SUNROOF CONTROL

SWITCH

Removal Procedure

1. Disconnect the negative battery cable.

2. Pry off the interior courtesy lamp lens.

3. Remove the screws and the switch.

4. Disconnect the electrical connector.

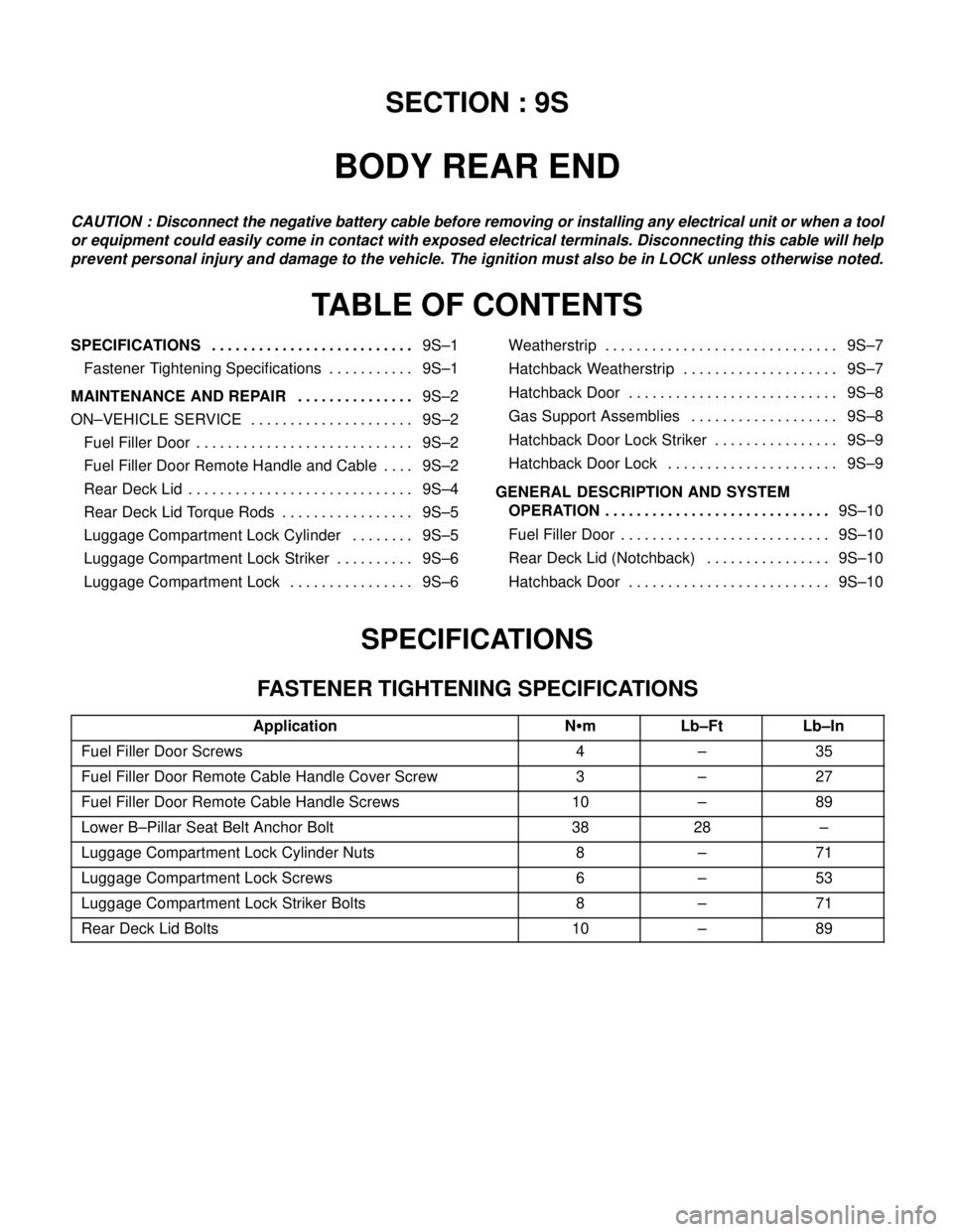

Installation Procedure

1. Connect the electrical connector.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the sunroof control switch with the screws.

Tighten

Tighten the power sunroof control switch screws to 2

NSm (18 lb–in).

3. Install the interior courtesy lamp lens.

4. Connect the negative battery cable.

Page 2472 of 2643

SECTION : 9S

BODY REAR END

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9S–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9S–1. . . . . . . . . . .

MAINTENANCE AND REPAIR9S–2 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9S–2. . . . . . . . . . . . . . . . . . . . .

Fuel Filler Door 9S–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filler Door Remote Handle and Cable 9S–2. . . .

Rear Deck Lid 9S–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Deck Lid Torque Rods 9S–5. . . . . . . . . . . . . . . . .

Luggage Compartment Lock Cylinder 9S–5. . . . . . . .

Luggage Compartment Lock Striker 9S–6. . . . . . . . . .

Luggage Compartment Lock 9S–6. . . . . . . . . . . . . . . . Weatherstrip 9S–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hatchback Weatherstrip 9S–7. . . . . . . . . . . . . . . . . . . .

Hatchback Door 9S–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Support Assemblies 9S–8. . . . . . . . . . . . . . . . . . .

Hatchback Door Lock Striker 9S–9. . . . . . . . . . . . . . . .

Hatchback Door Lock 9S–9. . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9S–10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filler Door 9S–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Deck Lid (Notchback) 9S–10. . . . . . . . . . . . . . . .

Hatchback Door 9S–10. . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Fuel Filler Door Screws4–35

Fuel Filler Door Remote Cable Handle Cover Screw3–27

Fuel Filler Door Remote Cable Handle Screws10–89

Lower B–Pillar Seat Belt Anchor Bolt3828–

Luggage Compartment Lock Cylinder Nuts8–71

Luggage Compartment Lock Screws6–53

Luggage Compartment Lock Striker Bolts8–71

Rear Deck Lid Bolts10–89

Page 2475 of 2643

9S – 4IBODY REAR END

DAEWOO V–121 BL4

8. Install the lower B–pillar seat belt anchor with the

bolt.

Tighten

Tighten the lower B–pillar seat belt anchor bolt to 38

NSm (28 lb–ft).

9. Connect the cable to the fuel filler door.

10. Install the luggage compartment wheelhouse trim

panels and the luggage compartment rear trim pan-

el. Refer to Section 9G, Interior Trim.

11. Close the luggage compartment.

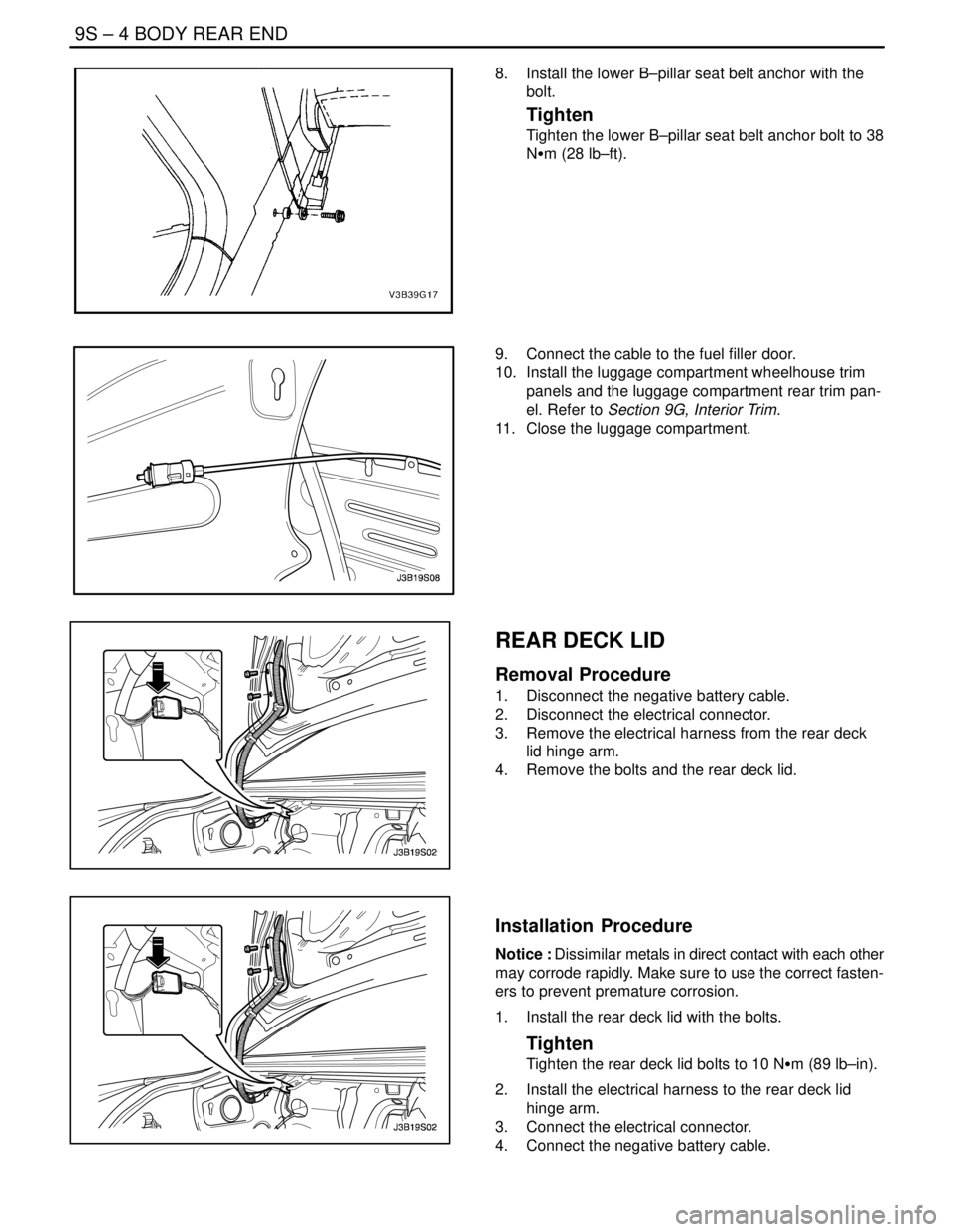

REAR DECK LID

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector.

3. Remove the electrical harness from the rear deck

lid hinge arm.

4. Remove the bolts and the rear deck lid.

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the rear deck lid with the bolts.

Tighten

Tighten the rear deck lid bolts to 10 NSm (89 lb–in).

2. Install the electrical harness to the rear deck lid

hinge arm.

3. Connect the electrical connector.

4. Connect the negative battery cable.

Page 2477 of 2643

9S – 6IBODY REAR END

DAEWOO V–121 BL4

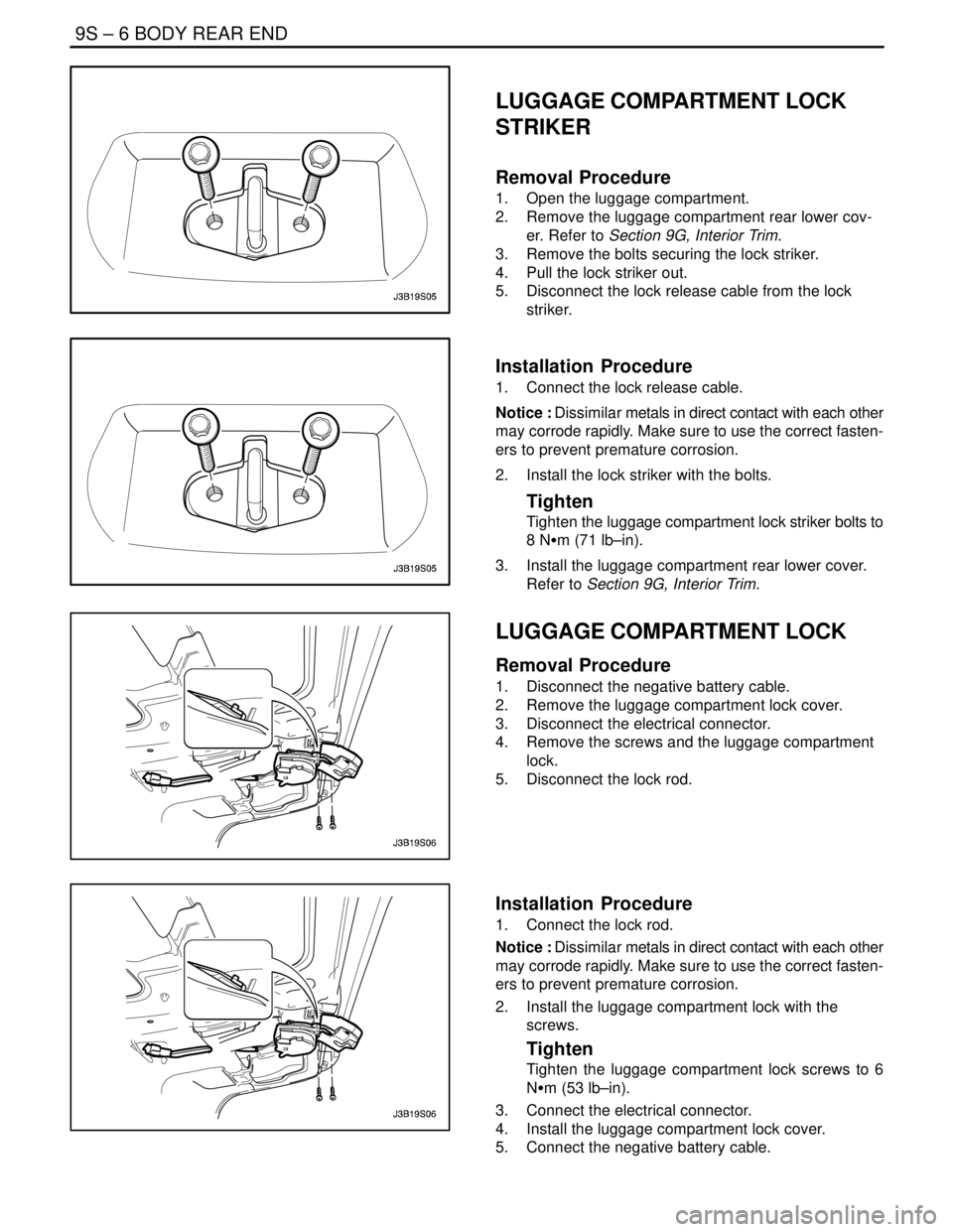

LUGGAGE COMPARTMENT LOCK

STRIKER

Removal Procedure

1. Open the luggage compartment.

2. Remove the luggage compartment rear lower cov-

er. Refer to Section 9G, Interior Trim.

3. Remove the bolts securing the lock striker.

4. Pull the lock striker out.

5. Disconnect the lock release cable from the lock

striker.

Installation Procedure

1. Connect the lock release cable.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the lock striker with the bolts.

Tighten

Tighten the luggage compartment lock striker bolts to

8 NSm (71 lb–in).

3. Install the luggage compartment rear lower cover.

Refer to Section 9G, Interior Trim.

LUGGAGE COMPARTMENT LOCK

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the luggage compartment lock cover.

3. Disconnect the electrical connector.

4. Remove the screws and the luggage compartment

lock.

5. Disconnect the lock rod.

Installation Procedure

1. Connect the lock rod.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the luggage compartment lock with the

screws.

Tighten

Tighten the luggage compartment lock screws to 6

NSm (53 lb–in).

3. Connect the electrical connector.

4. Install the luggage compartment lock cover.

5. Connect the negative battery cable.

Page 2482 of 2643

SECTION : 9T1

REMOTE KEYLESS ENTRY AND ANTI–THEFT

SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS 9T1–1 . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9T1–1. . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9T1–2 . . . .

Notchback Remote Keyless Entry and Anti–Theft

System 9T1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hatchback Remote Keyless Entry and Anti–Theft

System 9T1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Module/Receiver Connector 9T1–4. . . . . . . . .

MAINTENANCE AND REPAIR9T1–5 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9T1–5. . . . . . . . . . . . . . . . . . . .

Control Module/Receiver 9T1–5. . . . . . . . . . . . . . . . . . .

Siren (General Only) 9T1–5. . . . . . . . . . . . . . . . . . . . . . Remote Keyless Entry Transmitter

Programming 9T1–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9T1–8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Keyless Entry and Anti–Theft System 9T1–8

Remote Locking and Unlocking 9T1–8. . . . . . . . . . . . .

Security Indicator 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . .

Intrusion Sensing 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . .

Siren (General Only) 9T1–8. . . . . . . . . . . . . . . . . . . . . .

Vehicle Locator 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Autolocking (Safety Lock) 9T1–9. . . . . . . . . . . . . . . . . .

Control Module/Receiver 9T1–9. . . . . . . . . . . . . . . . . . .

Fault or Alarm Indication 9T1–9. . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Siren Braket Mounting Bolts.8–71

Page 2485 of 2643

9T1 – 4IREMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM

DAEWOO V–121 BL4

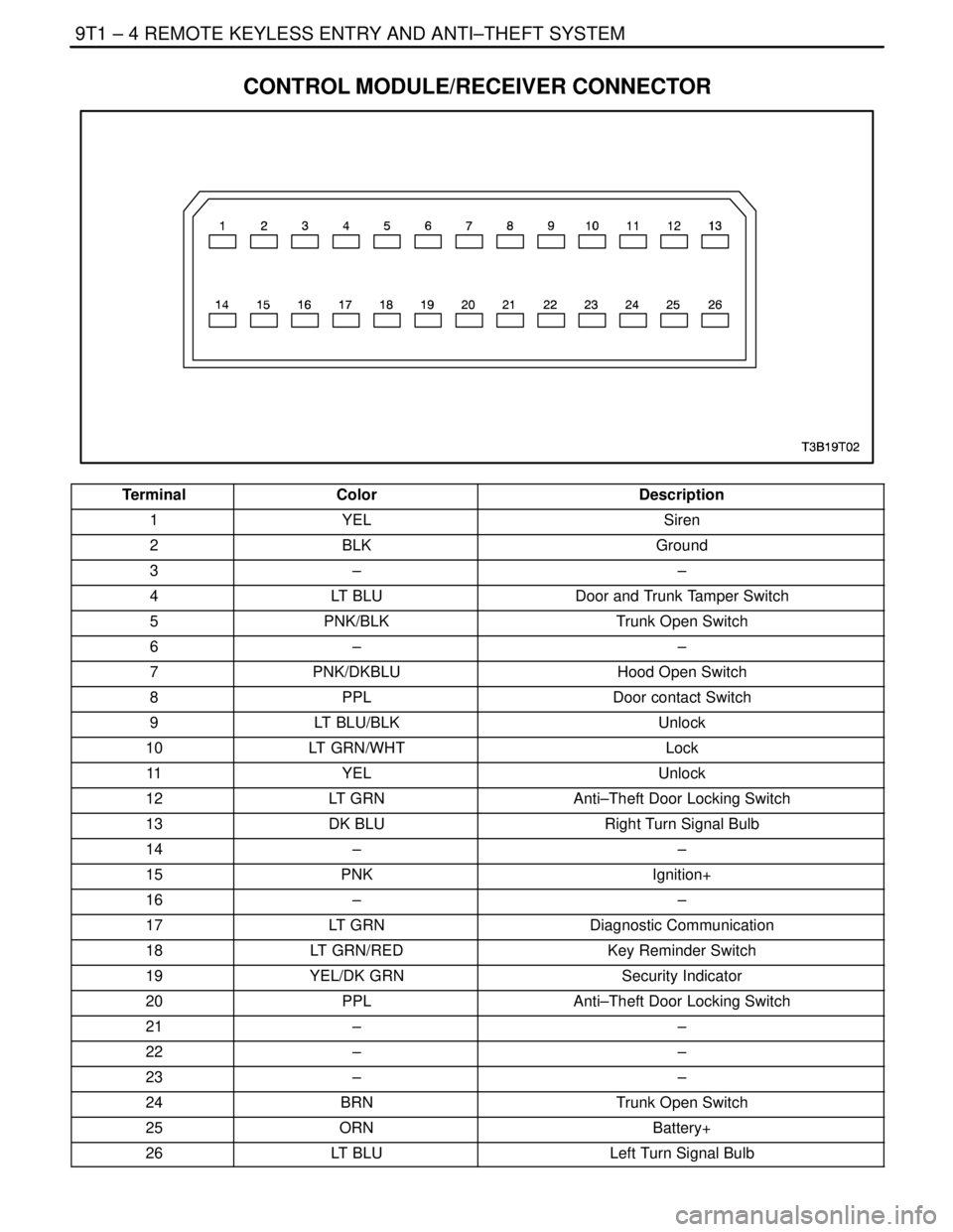

CONTROL MODULE/RECEIVER CONNECTOR

TerminalColorDescription

1YELSiren

2BLKGround

3––

4LT BLUDoor and Trunk Tamper Switch

5PNK/BLKTrunk Open Switch

6––

7PNK/DKBLUHood Open Switch

8PPLDoor contact Switch

9LT BLU/BLKUnlock

10LT GRN/WHTLock

11YELUnlock

12LT GRNAnti–Theft Door Locking Switch

13DK BLURight Turn Signal Bulb

14––

15PNKIgnition+

16––

17LT GRNDiagnostic Communication

18LT GRN/REDKey Reminder Switch

19YEL/DK GRNSecurity Indicator

20PPLAnti–Theft Door Locking Switch

21––

22––

23––

24BRNTrunk Open Switch

25ORNBattery+

26LT BLULeft Turn Signal Bulb

Page 2486 of 2643

REMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM 9T1 – 5

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

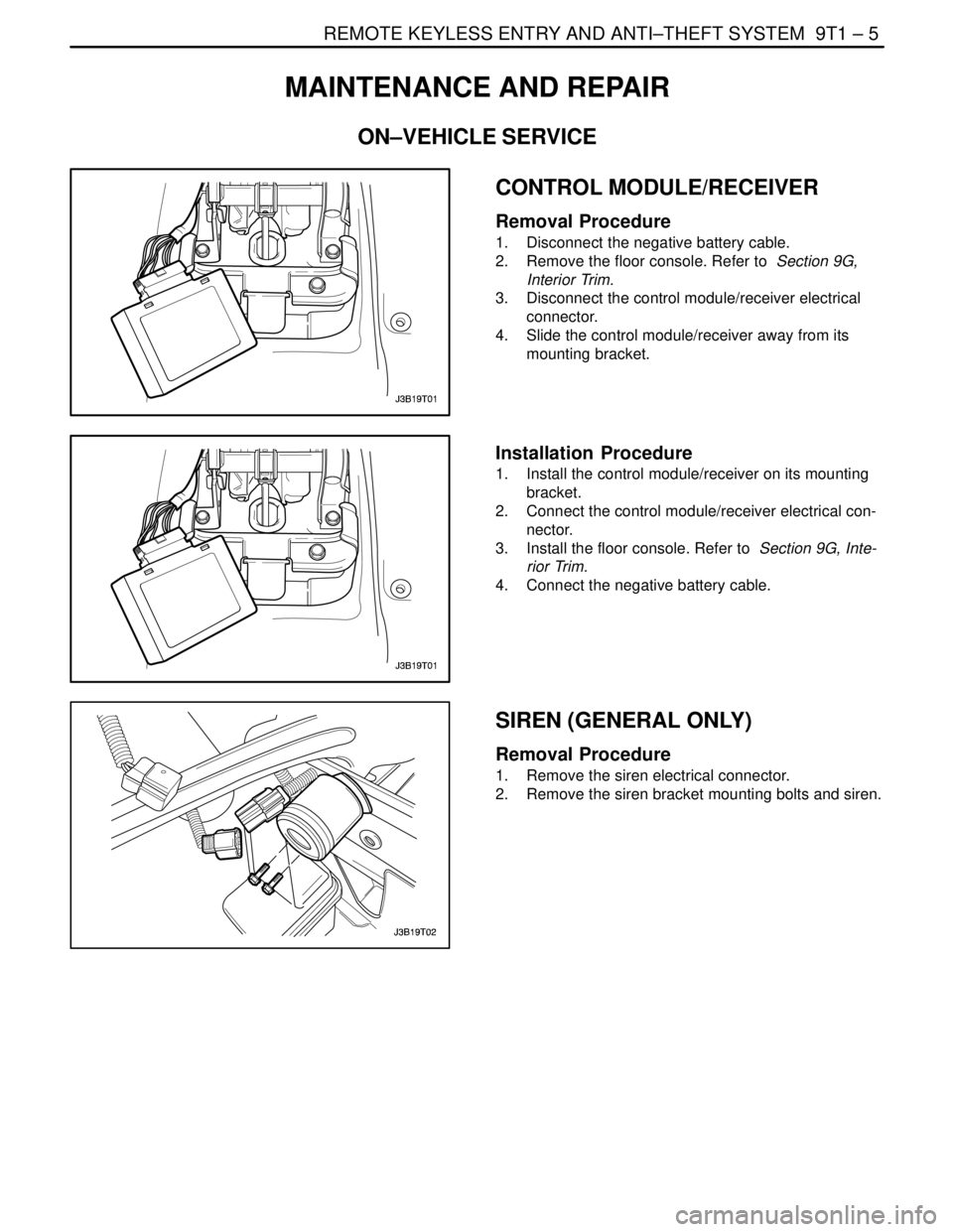

CONTROL MODULE/RECEIVER

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the floor console. Refer to Section 9G,

Interior Trim.

3. Disconnect the control module/receiver electrical

connector.

4. Slide the control module/receiver away from its

mounting bracket.

Installation Procedure

1. Install the control module/receiver on its mounting

bracket.

2. Connect the control module/receiver electrical con-

nector.

3. Install the floor console. Refer to Section 9G, Inte-

rior Trim.

4. Connect the negative battery cable.

SIREN (GENERAL ONLY)

Removal Procedure

1. Remove the siren electrical connector.

2. Remove the siren bracket mounting bolts and siren.

Page 2489 of 2643

9T1 – 8IREMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

REMOTE KEYLESS ENTRY AND

ANTI–THEFT SYSTEM

The remote keyless entry and anti–theft system can per-

form the following functions:

S Remotely lock and unlock the vehicle doors by

means of a hand–held, high–frequency transmitter.

S Sense intrusion into the vehicle.

S Activate a warning in the event of an intrusion.

S Help the driver find the vehicle in a parking area.

S Automatically re–lock the doors if the door or the

trunk is not opened within 30 seconds after the ve-

hicle has been unlocked by the remote keyless

entry.

S Communicate serial data to a scan tool to help

diagnose system faults.

The remote keyless entry and anti–theft system consists

of the following components:

S Keyless entry and anti–theft control module/receiv-

er.

S Security indicator.

S Trunk open switch (NOTCHBACK).

S Trunk tamper switch (NOTCHBACK).

S Front door tamper switches.

S Door contact switches.

S Central door lock relay.

S Turn signal bulbs.

S Siren.

S Hood open switch.

REMOTE LOCKING AND UNLOCKING

The hand–held transmitter locks and unlocks the vehicle

doors by sending radio waves to the control module/re-

ceiver in the vehicle. The effective range of the transmitter

varies between 5 and 10 meters, (approximately 16 to 32

feet), depending on whether or not objects, such as other

vehicles are blocking the path of the radio waves.

The transmitter has a LOCK button and an UNLOCK but-

ton which only function when the ignition is OFF. Pressing

the UNLOCK button has the following effects:

S The doors are unlocked.

S The turn signal bulbs flash twice.

S The control module is disarmed.

Pressing the LOCK button has the following effects:

S The doors are locked.

S The turn signal bulbs flash once.

S The control module is armed.

The transmitter has a replaceable battery. The battery is

designed to last at least two years before replacement is

necessary.

SECURITY INDICATOR

There is a security indicator on the instrument panel. After

the LOCK button of the transmitter is pressed, the module

is placed in the armed mode, and the security indicator

flashes. The security indicator turns ON for 0.1 second

and OFF for 0.7 second. It then flashes at that frequency

until the control module/receiver is disarmed.

INTRUSION SENSING

The anti–theft function is armed if the transmitter sends

the LOCK message to the control module/receiver when

the ignition is OFF. When the hood, door, or trunk is

opened, the hood open, door contact, or trunk open switch

sends a ”ground” signal to the control module/receiver.

Unless the control module/receiver is disarmed, the siren

will be activated when the ”ground” signal is received from

the trunk open, hood open, or door contact switches.

The following actions disarm the anti–theft system:

S An UNLOCK message is received from the trans-

mitter.

S Key operation is detected by the tamper switches.

(The tamper switches are operated by the lock cyl-

inders in the front doors and trunk.)

The alarm will also be activated if the control module/re-

ceiver detects voltage from the ignition before either of the

following conditions occur:

S An UNLOCK message is received from the trans-

mitter.

S Key operation is indicated by the tamper switches.

SIREN (GENERAL ONLY)

The remote keyless entry system is armed when the

LOCK message is received from the transmitter when the

ignition is OFF. When the system is armed, it will activate

the siren and flash the turn signals for 28 seconds if any

of the following conditions occur:

S Close all the windows.

S Turn the ignition key to LOCK and remove the key.

S Have all passengers get out of the vehicle.

S Close all doors, the hood and the turnk lid.

S The control module/receiver detects ignition voltage

while the system is armed.

The siren will not operate if any of the following conditions

occur after the system has been armed:

S The door is opened with the key.

S The trunk is opened with the key.

S The UNLOCK or LOCK button on the remote trans-

mitter is pressed within 2 seconds after the siren is

activated.

VEHICLE LOCATOR

The remote keyless entry system assists the driver in lo-

cating the vehicle. When the vehicle is unlocked with the

remote control, the turn signals flash twice to indicate the

location of the vehicle. The duration of the flashes and the

Page 2491 of 2643

SECTION : 9T2

IMMOBILIZER ANTI–THEFT SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SCHEMATIC AND ROUTING DIAGRAMS9T2–2 . . . .

Immobilizer Anti–Theft System 9T2–2. . . . . . . . . . . . .

DIAGNOSTIC INFORMATION AND

PROCEDURES9T2–3 . . . . . . . . . . . . . . . . . . . . . . . . . .

Immobilizer System

(MR–140, HV–240, SIRIUS D4) 9T2–3. . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1626 (MR–140,

HV–240), P1628 (SIRIUS) 9T2–4. . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1631 (MR–140,

HV–240), P1629 (SIRIUS D4) 9T2–6. . . . . . . . . . . .

Key Status Errors

(MR–140, HV–240, SIRIUS D4) 9T2–8. . . . . . . . . . .

Communication Between Immobilizer Control Unit and

Test Equipment

(MR–140, HV–240, SIRIUS D4) 9T2–8. . . . . . . . . . . MAINTENANCE AND REPAIR9T2–9 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9T2–9. . . . . . . . . . . . . . . . . . . .

Key Coding Procedure 9T2–9. . . . . . . . . . . . . . . . . . . .

ID Code Reprogramming 9T2–9. . . . . . . . . . . . . . . . . .

Transponder 9T2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Immobilizer Control Unit 9T2–9. . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9T2–11 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Immobilizer System 9T2–11. . . . . . . . . . . . . . . . . . . . . .

Electronically Coded Keys 9T2–11. . . . . . . . . . . . . . . .

Detection Coil 9T2–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Immobilizer Control Unit 9T2–11. . . . . . . . . . . . . . . . . .

Serial Data Link 9T2–12. . . . . . . . . . . . . . . . . . . . . . . . .

Electronic Control Moudle (ECM) 9T2–12. . . . . . . . . .

Page 2510 of 2643

1–2 GENERAL INFORMATIONNUBIRA/LACETTI

1. GENERAL INSTRUCTION

This publication is designed to help you the body repair

technician with your specialized work. Vehicle bodywork

has changed a great deal over the years. As vehicles

have developed technically, vehicle bodywork has also

had to meet new requirements with design, changes to

reconcile apparently conflicting demands to name just a

few examples:

S strength and safety ; low weight

S spaciousness ; good aerodynamices

S high quality ; low price

.

The durability and ease of repair of the bodywork also

plays an important part.

.

Nowadays, the use of highly automated production

equipment makes it possible to maintain the tightest

tolerances and thus ensure a high level of quality.

.

When bodywork is damaged, the customer rightly ex-

pects it to be expertly repaired to the same quality stan-

dards.

.

At the same time, for his safety, the customer expects

you to have comprehensive knowledge of materials,

measuring and straightening methods, possible distor-

tion, optimum corrosion prevention and much more be-

sides.

.

This publication is designed to help you update your

knowledge and give you an idea of what you require to

rectify moderate or severe accident damage, for your

own safety and for the satisfaction of your customers.

2. IMPORTANT SAFETY NOTICE

2–1. BEFORE BEGINNING WORK

S Disconnect the battery to reduce the possibility of fire

caused by electrical shorts.

S Check for fuel leaks and repair as necessary.

S Remove the fuel tank and/or fuel lines if welding equip-

ment is to be used near the fuel system.

S Before welding, sanding or cutting, protect carpets and

seats with fire–proof covers.

S Follow standard safety practices when using toxic or

flammable liquids.

S Use standard safety equipment when spraying paint,

welding, cutting, sanding or grinding. Standard safety

equipment includes.

S Respirator and filter masks: Designed to filter out toxic

fumes, mist, dust or other airborn particles. Use a respi-

rator or filter mask designed to protect you from the haz-

ards of the particular job; some respirators, for example,

are designed to filter out only dust and airborn particles,

not toxic fumes.

S Safety goggles or glasses: Designed to protect your

eyes from projectiles, dust particles or splashing liquid.

S Gloves: Rubber gloves protect against corrosive chemi-

cals. Welding gloves protect against burns and abra-

sions caused by welding, sanding or grinding.

S Safety shoes: Non–slip soles protect against slipping.

Metal toe inserts protect against falling objects.

S Ear plugs: Protect eardrums from harmful noise levels.

.

2–2. DURING WORK

S Do not smoke while working near the fuel system.

S Deposit gas or solvent–soaked shop towels in an ap-

proved container.

S Brake lining contains asbestos, which can cause cancer.

Do not use an air hose to blow off brake assemblies: use

only an approved vacuum cleaner, and wear an ap-

proved filter mask or respirator.

S Always attach a safety cable when using a hydraulic ram

or a frame straightening table: do not stand in direct line

with the chains used on such equipment.