Transaxle DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1879 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 55

DAEWOO V–121 BL4

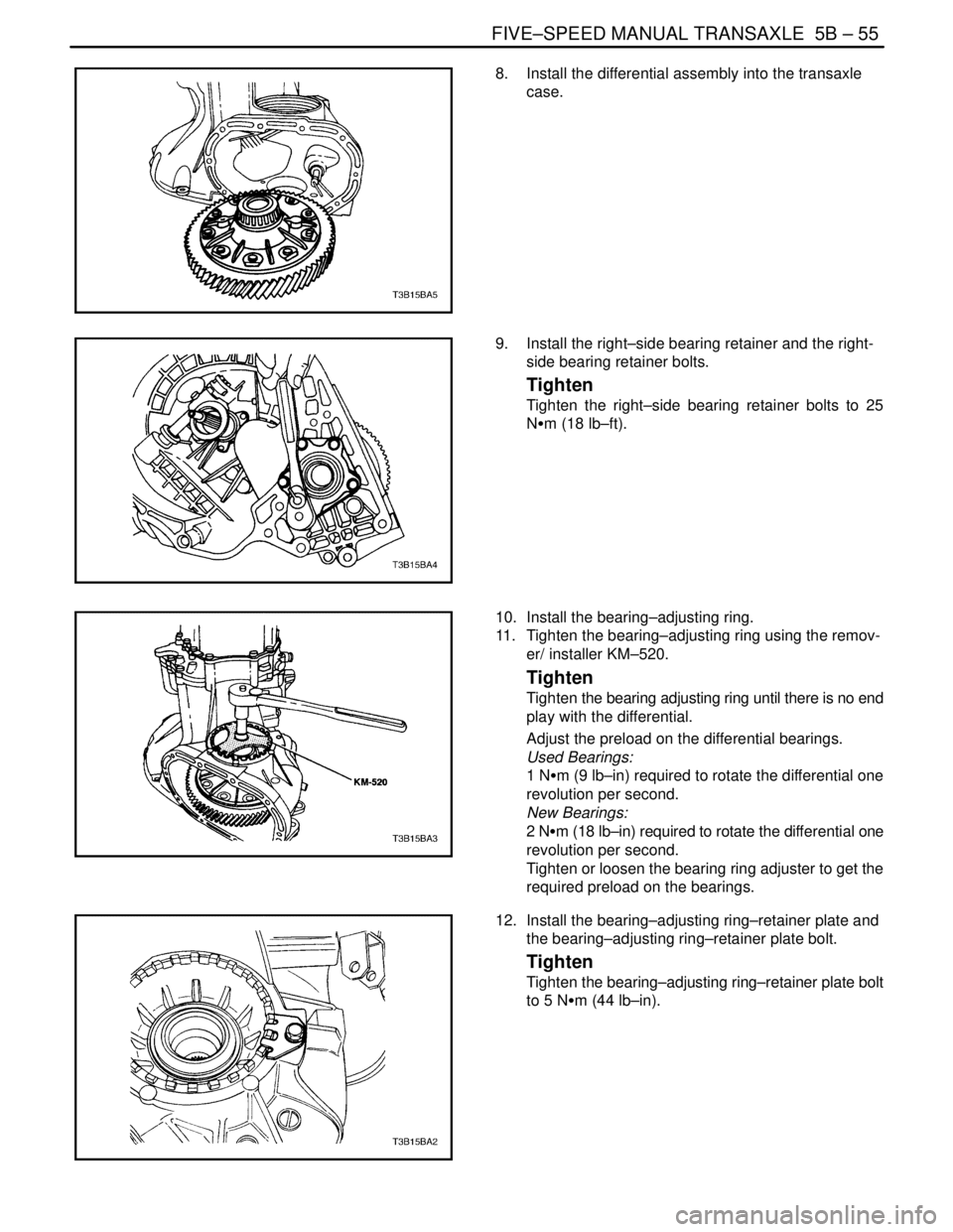

8. Install the differential assembly into the transaxle

case.

9. Install the right–side bearing retainer and the right-

side bearing retainer bolts.

Tighten

Tighten the right–side bearing retainer bolts to 25

NSm (18 lb–ft).

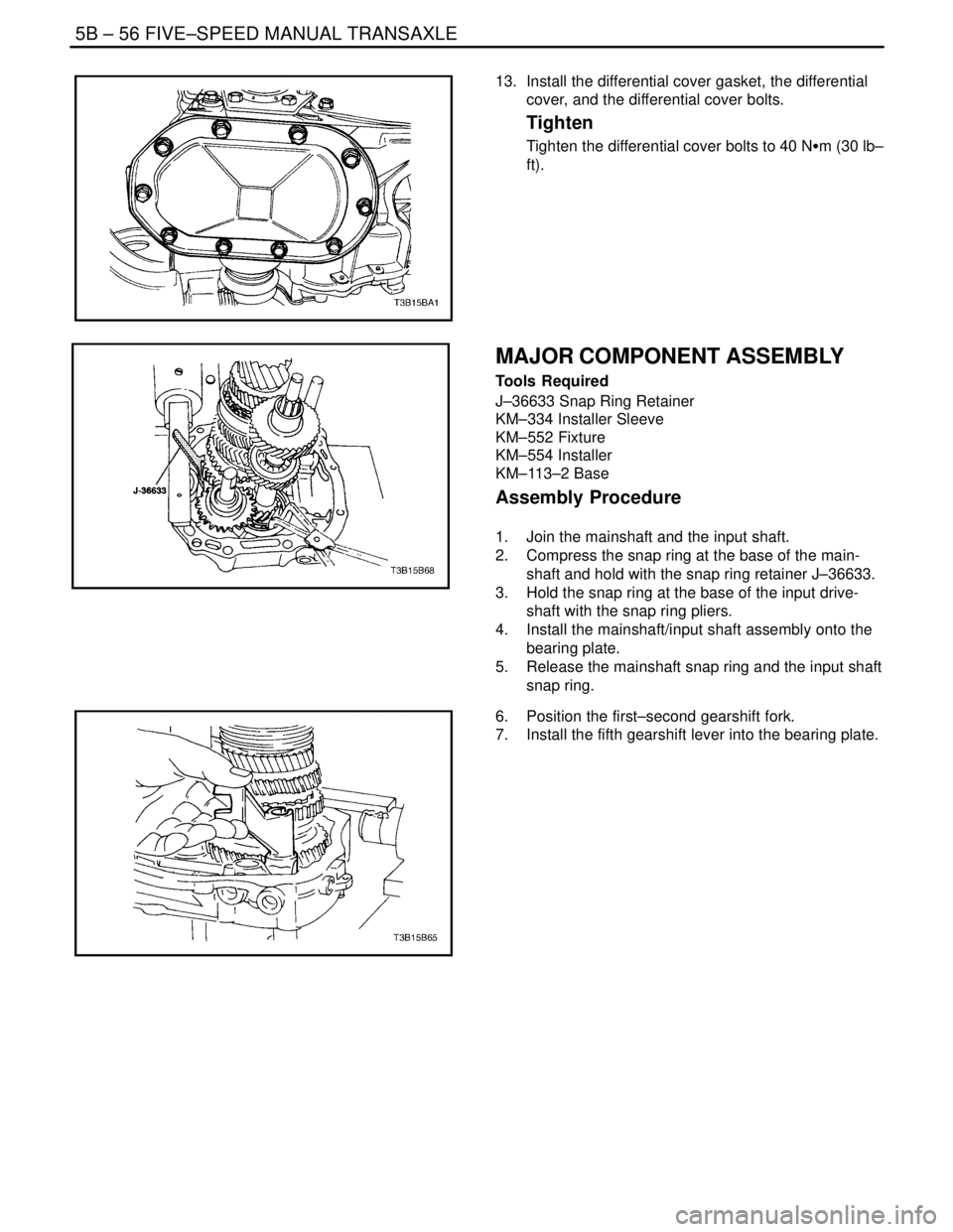

10. Install the bearing–adjusting ring.

11. Tighten the bearing–adjusting ring using the remov-

er/ installer KM–520.

Tighten

Tighten the bearing adjusting ring until there is no end

play with the differential.

Adjust the preload on the differential bearings.

Used Bearings:

1 NSm (9 lb–in) required to rotate the differential one

revolution per second.

New Bearings:

2 NSm (18 lb–in) required to rotate the differential one

revolution per second.

Tighten or loosen the bearing ring adjuster to get the

required preload on the bearings.

12. Install the bearing–adjusting ring–retainer plate and

the bearing–adjusting ring–retainer plate bolt.

Tighten

Tighten the bearing–adjusting ring–retainer plate bolt

to 5 NSm (44 lb–in).

Page 1880 of 2643

5B – 56IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

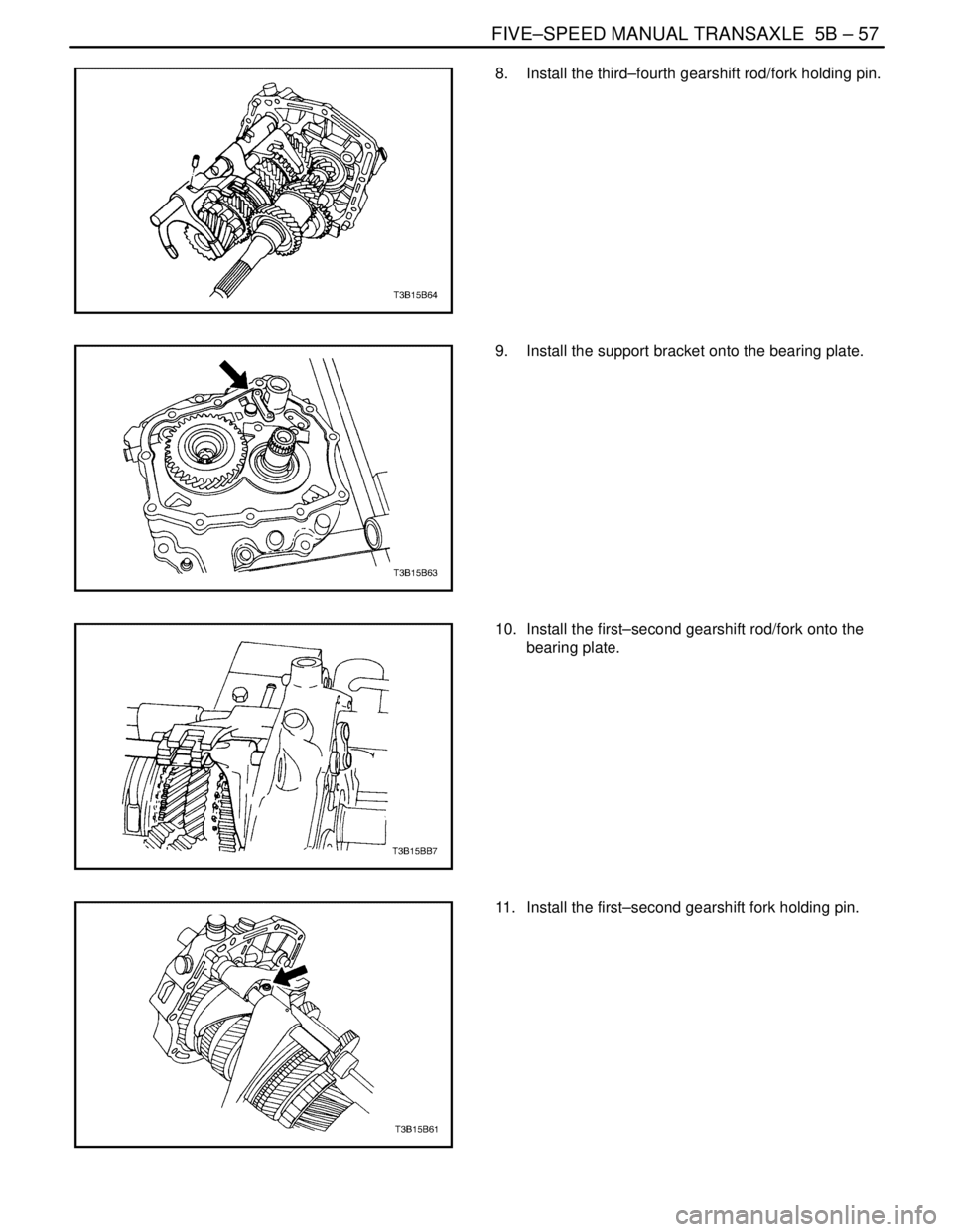

13. Install the differential cover gasket, the differential

cover, and the differential cover bolts.

Tighten

Tighten the differential cover bolts to 40 NSm (30 lb–

ft).

MAJOR COMPONENT ASSEMBLY

Tools Required

J–36633 Snap Ring Retainer

KM–334 Installer Sleeve

KM–552 Fixture

KM–554 Installer

KM–113–2 Base

Assembly Procedure

1. Join the mainshaft and the input shaft.

2. Compress the snap ring at the base of the main-

shaft and hold with the snap ring retainer J–36633.

3. Hold the snap ring at the base of the input drive-

shaft with the snap ring pliers.

4. Install the mainshaft/input shaft assembly onto the

bearing plate.

5. Release the mainshaft snap ring and the input shaft

snap ring.

6. Position the first–second gearshift fork.

7. Install the fifth gearshift lever into the bearing plate.

Page 1881 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 57

DAEWOO V–121 BL4

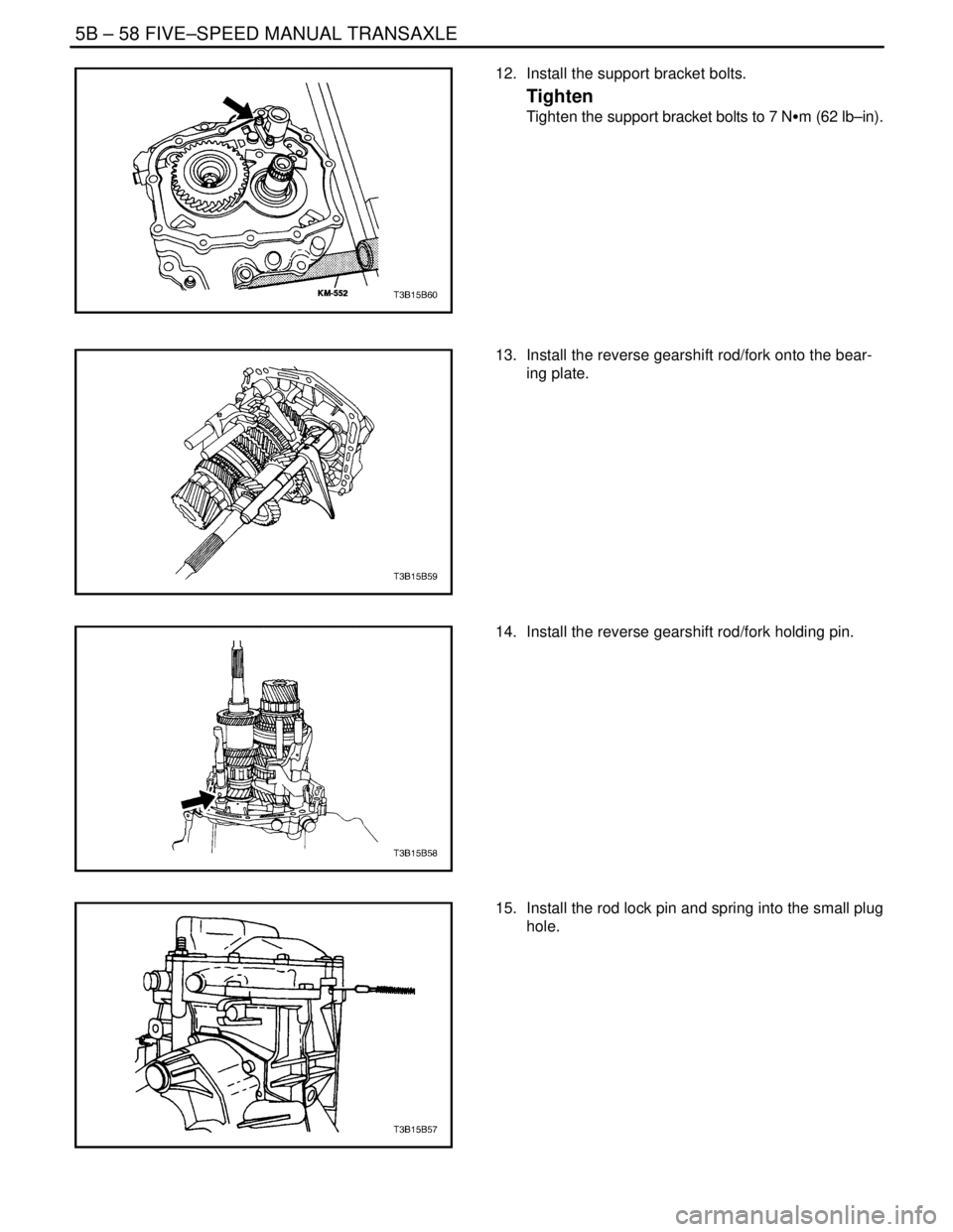

8. Install the third–fourth gearshift rod/fork holding pin.

9. Install the support bracket onto the bearing plate.

10. Install the first–second gearshift rod/fork onto the

bearing plate.

11. Install the first–second gearshift fork holding pin.

Page 1882 of 2643

5B – 58IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

12. Install the support bracket bolts.

Tighten

Tighten the support bracket bolts to 7 NSm (62 lb–in).

13. Install the reverse gearshift rod/fork onto the bear-

ing plate.

14. Install the reverse gearshift rod/fork holding pin.

15. Install the rod lock pin and spring into the small plug

hole.

Page 1883 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 59

DAEWOO V–121 BL4

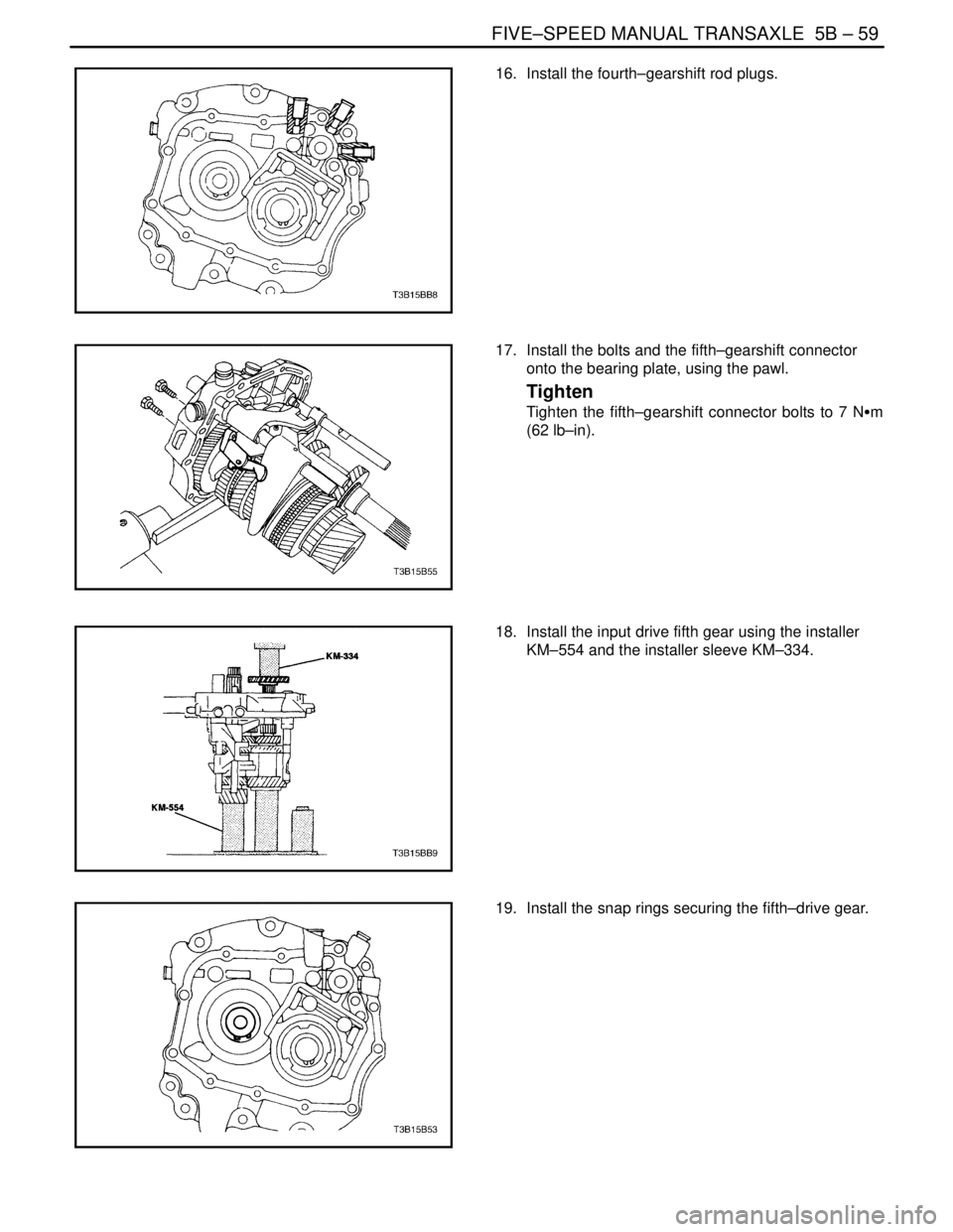

16. Install the fourth–gearshift rod plugs.

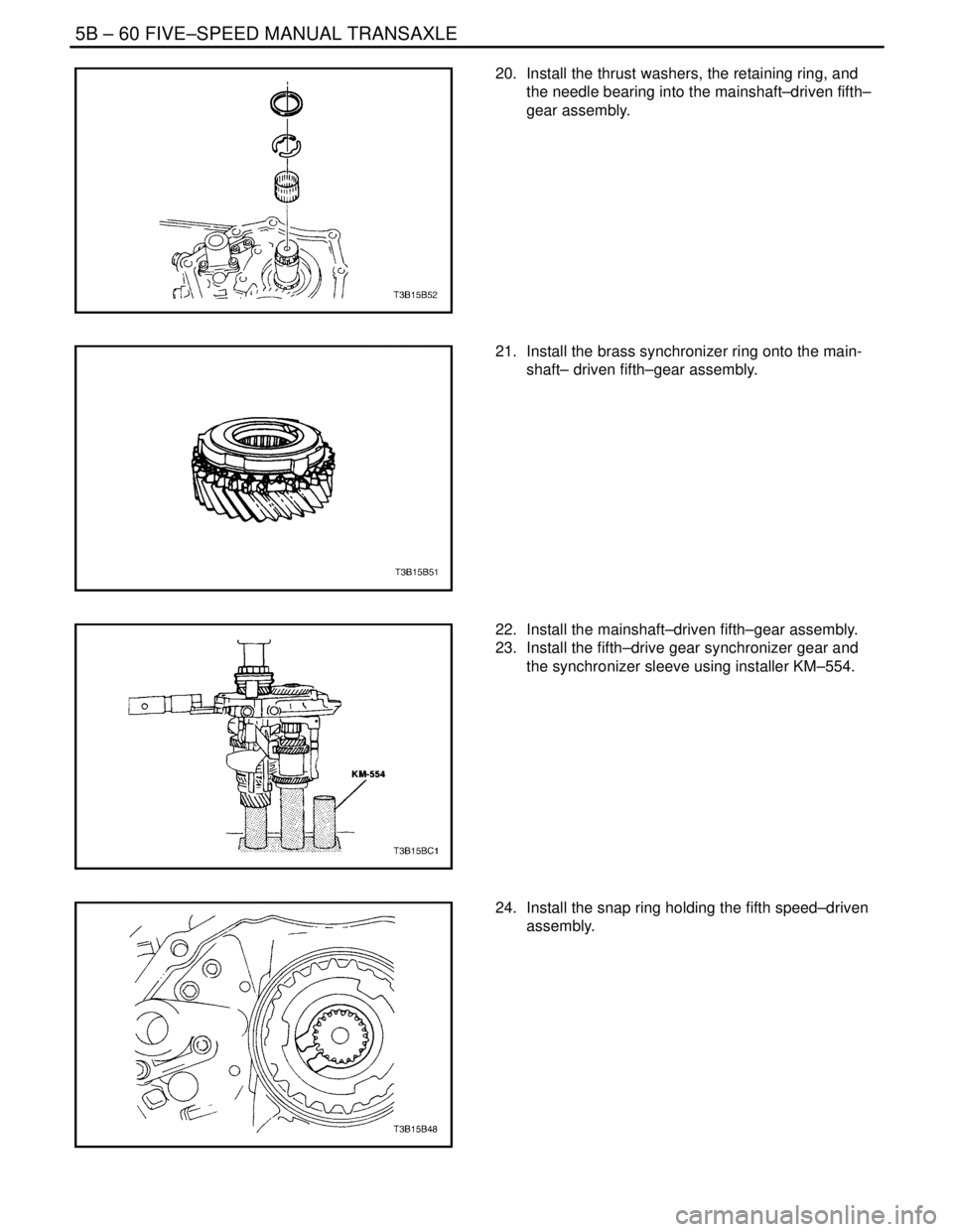

17. Install the bolts and the fifth–gearshift connector

onto the bearing plate, using the pawl.

Tighten

Tighten the fifth–gearshift connector bolts to 7 NSm

(62 lb–in).

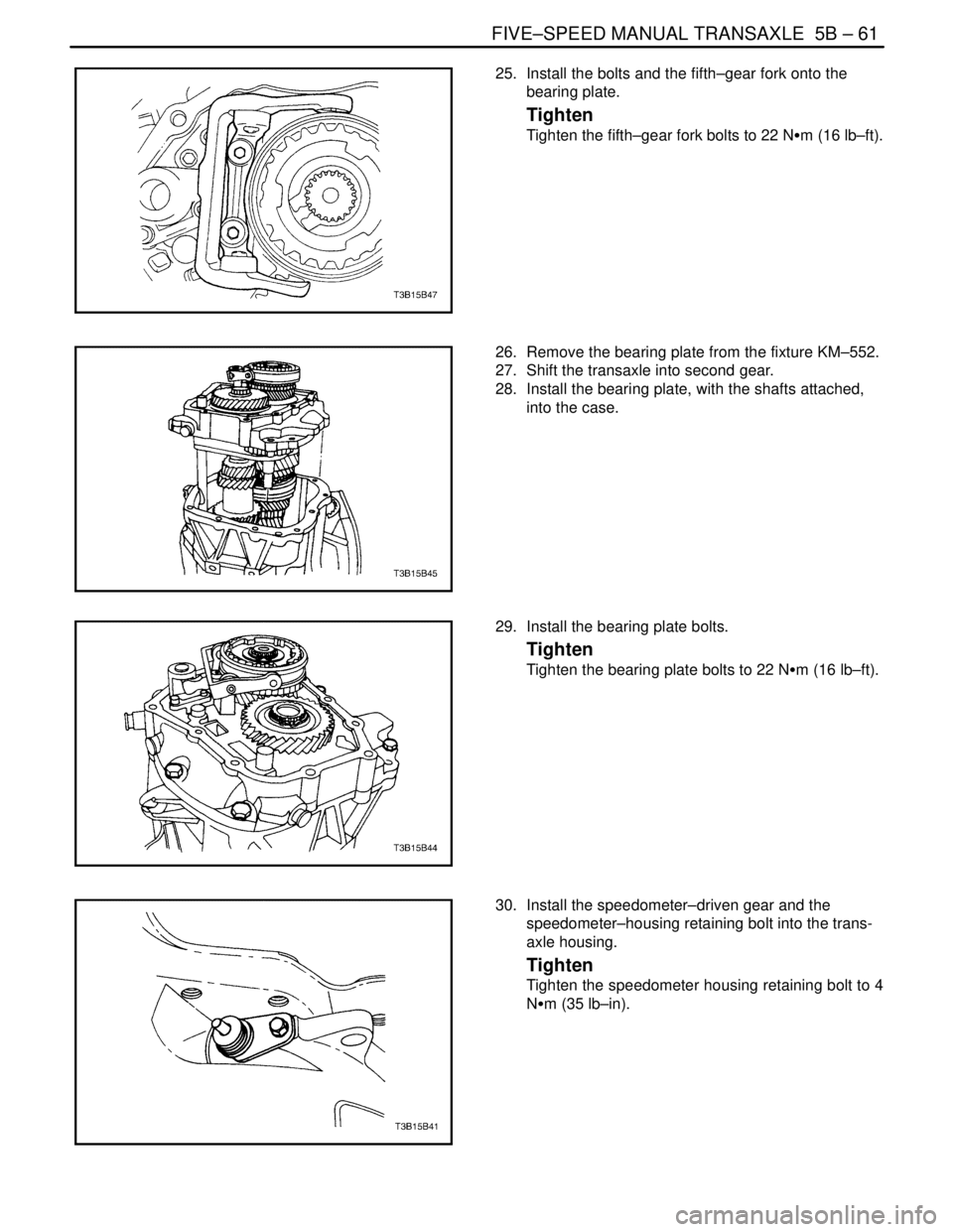

18. Install the input drive fifth gear using the installer

KM–554 and the installer sleeve KM–334.

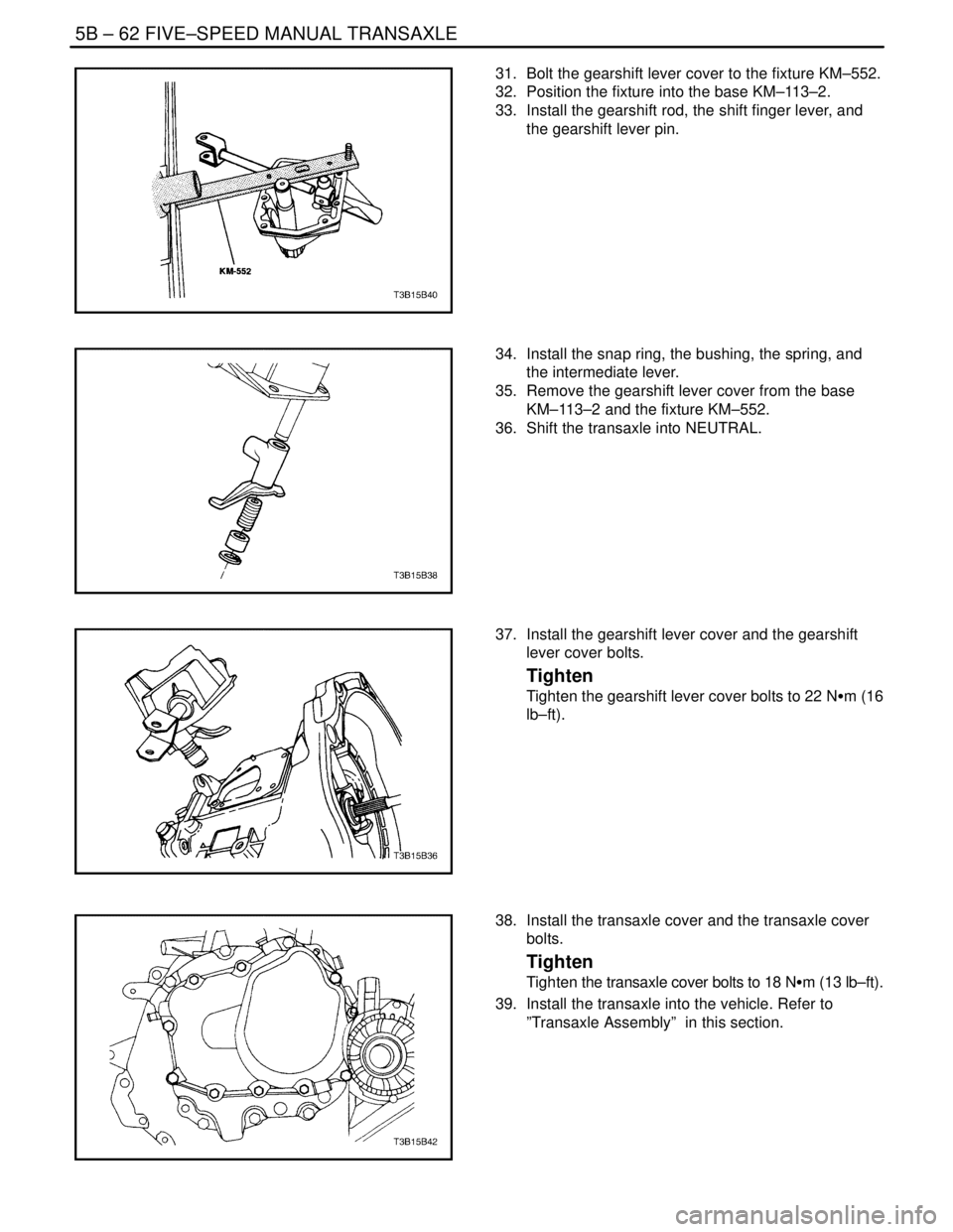

19. Install the snap rings securing the fifth–drive gear.

Page 1884 of 2643

5B – 60IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

20. Install the thrust washers, the retaining ring, and

the needle bearing into the mainshaft–driven fifth–

gear assembly.

21. Install the brass synchronizer ring onto the main-

shaft– driven fifth–gear assembly.

22. Install the mainshaft–driven fifth–gear assembly.

23. Install the fifth–drive gear synchronizer gear and

the synchronizer sleeve using installer KM–554.

24. Install the snap ring holding the fifth speed–driven

assembly.

Page 1885 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 61

DAEWOO V–121 BL4

25. Install the bolts and the fifth–gear fork onto the

bearing plate.

Tighten

Tighten the fifth–gear fork bolts to 22 NSm (16 lb–ft).

26. Remove the bearing plate from the fixture KM–552.

27. Shift the transaxle into second gear.

28. Install the bearing plate, with the shafts attached,

into the case.

29. Install the bearing plate bolts.

Tighten

Tighten the bearing plate bolts to 22 NSm (16 lb–ft).

30. Install the speedometer–driven gear and the

speedometer–housing retaining bolt into the trans-

axle housing.

Tighten

Tighten the speedometer housing retaining bolt to 4

NSm (35 lb–in).

Page 1886 of 2643

5B – 62IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

31. Bolt the gearshift lever cover to the fixture KM–552.

32. Position the fixture into the base KM–113–2.

33. Install the gearshift rod, the shift finger lever, and

the gearshift lever pin.

34. Install the snap ring, the bushing, the spring, and

the intermediate lever.

35. Remove the gearshift lever cover from the base

KM–113–2 and the fixture KM–552.

36. Shift the transaxle into NEUTRAL.

37. Install the gearshift lever cover and the gearshift

lever cover bolts.

Tighten

Tighten the gearshift lever cover bolts to 22 NSm (16

lb–ft).

38. Install the transaxle cover and the transaxle cover

bolts.

Tighten

Tighten the transaxle cover bolts to 18 NSm (13 lb–ft).

39. Install the transaxle into the vehicle. Refer to

”Transaxle Assembly” in this section.

Page 1887 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 63

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

FIVE–SPEED MANUAL TRANSAXLE

This five–speed transaxle assembly is a transmission of

constant–mesh design.

Combined in the assembly are:

S All forward gears.

S The reverse gear.

S The differential output.

The basic components of the five–speed transaxle as-

sembly units are the:

S Transaxle case.

S Input shaft.

S Input shaft gears.S Output shaft.

S Output shaft gears.

S Ring gear and differential assembly.

Forward Gear

Shifting to a forward gear is accomplished through a com-

bination of synchronizers with blocker rings controlled by

sliding shift forks.

Reverse Gear

Reverse gear is not synchronized and uses a sliding idler

gear arrangement.

Differential Assembly

The differential is a conventional arrangement of gears

that is supported by tapered roller bearings. The final out-

put gear turns the ring gear and differential assembly

which turns the drive axle shafts.

Page 1895 of 2643

5C – 8ICLUTCH

DAEWOO V–121 BL4

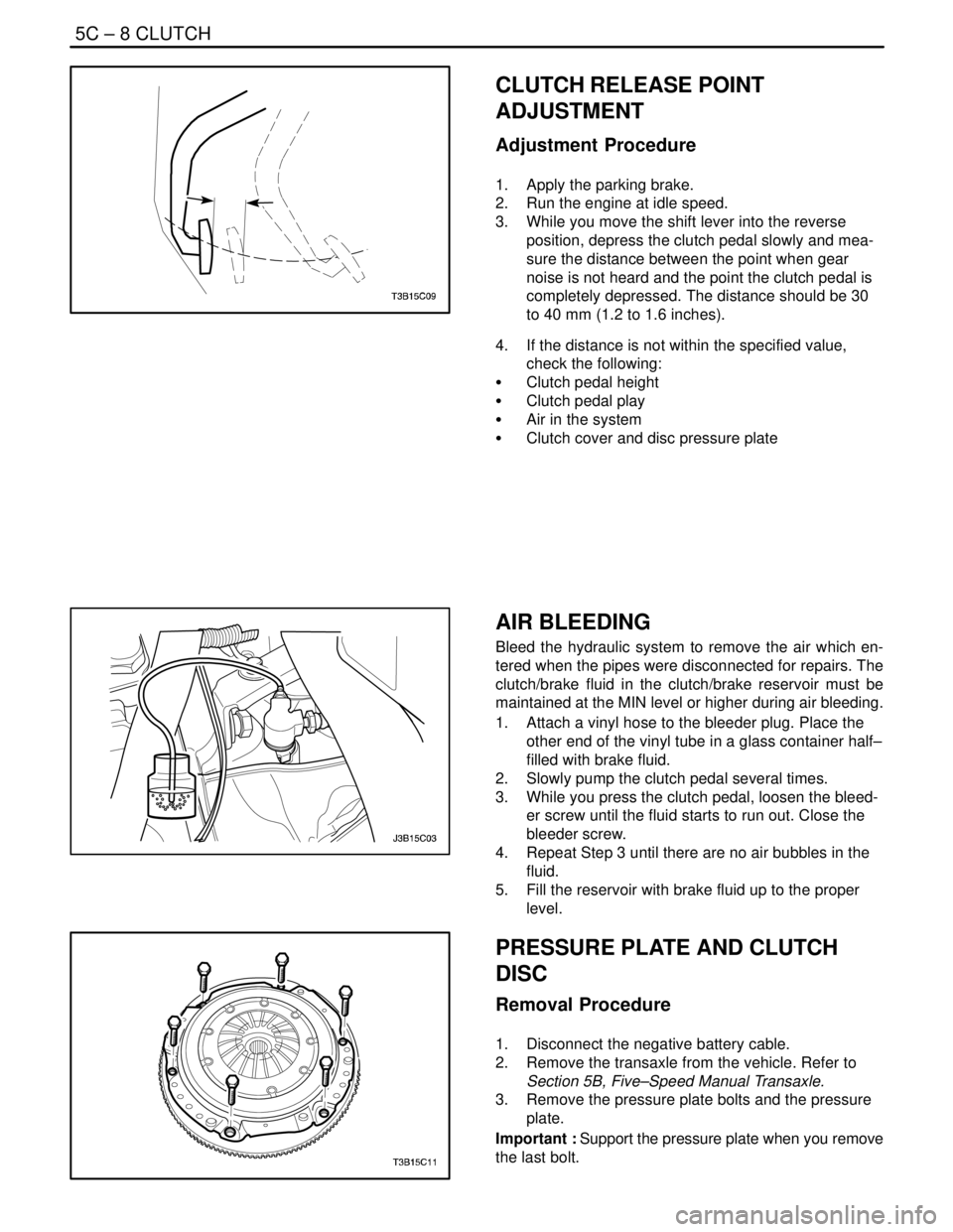

CLUTCH RELEASE POINT

ADJUSTMENT

Adjustment Procedure

1. Apply the parking brake.

2. Run the engine at idle speed.

3. While you move the shift lever into the reverse

position, depress the clutch pedal slowly and mea-

sure the distance between the point when gear

noise is not heard and the point the clutch pedal is

completely depressed. The distance should be 30

to 40 mm (1.2 to 1.6 inches).

4. If the distance is not within the specified value,

check the following:

S Clutch pedal height

S Clutch pedal play

S Air in the system

S Clutch cover and disc pressure plate

AIR BLEEDING

Bleed the hydraulic system to remove the air which en-

tered when the pipes were disconnected for repairs. The

clutch/brake fluid in the clutch/brake reservoir must be

maintained at the MIN level or higher during air bleeding.

1. Attach a vinyl hose to the bleeder plug. Place the

other end of the vinyl tube in a glass container half–

filled with brake fluid.

2. Slowly pump the clutch pedal several times.

3. While you press the clutch pedal, loosen the bleed-

er screw until the fluid starts to run out. Close the

bleeder screw.

4. Repeat Step 3 until there are no air bubbles in the

fluid.

5. Fill the reservoir with brake fluid up to the proper

level.

PRESSURE PLATE AND CLUTCH

DISC

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the transaxle from the vehicle. Refer to

Section 5B, Five–Speed Manual Transaxle.

3. Remove the pressure plate bolts and the pressure

plate.

Important : Support the pressure plate when you remove

the last bolt.