tran DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1885 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 61

DAEWOO V–121 BL4

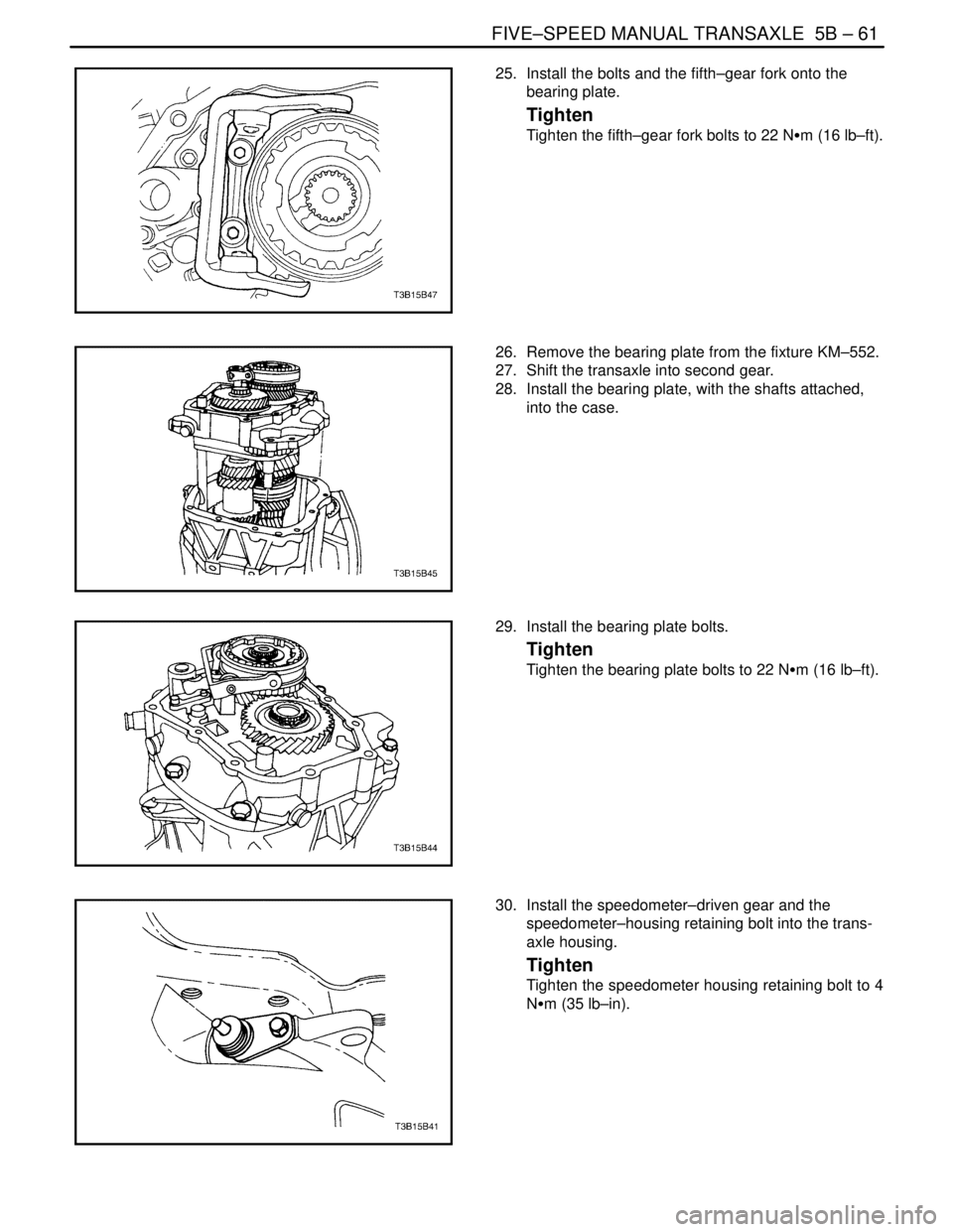

25. Install the bolts and the fifth–gear fork onto the

bearing plate.

Tighten

Tighten the fifth–gear fork bolts to 22 NSm (16 lb–ft).

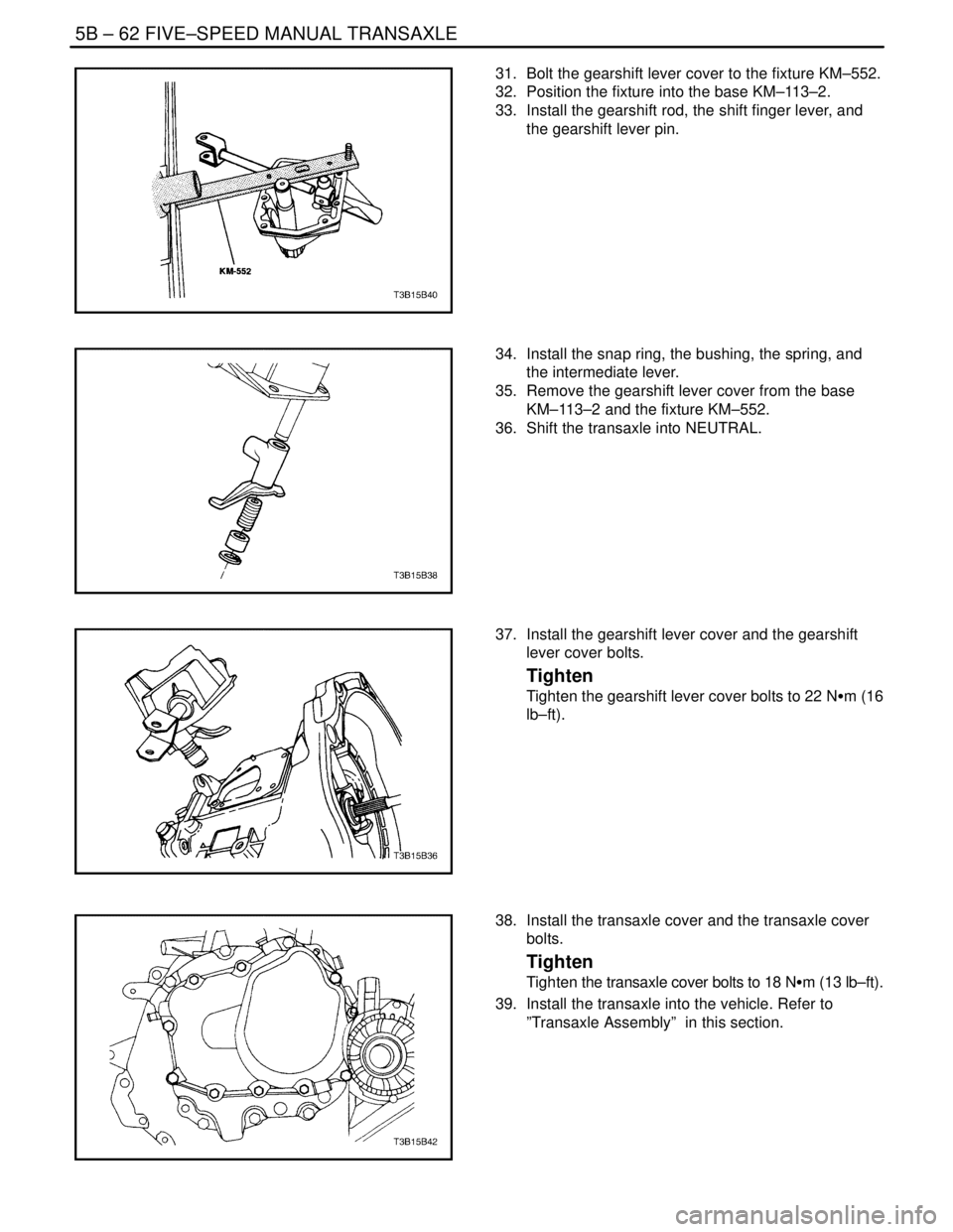

26. Remove the bearing plate from the fixture KM–552.

27. Shift the transaxle into second gear.

28. Install the bearing plate, with the shafts attached,

into the case.

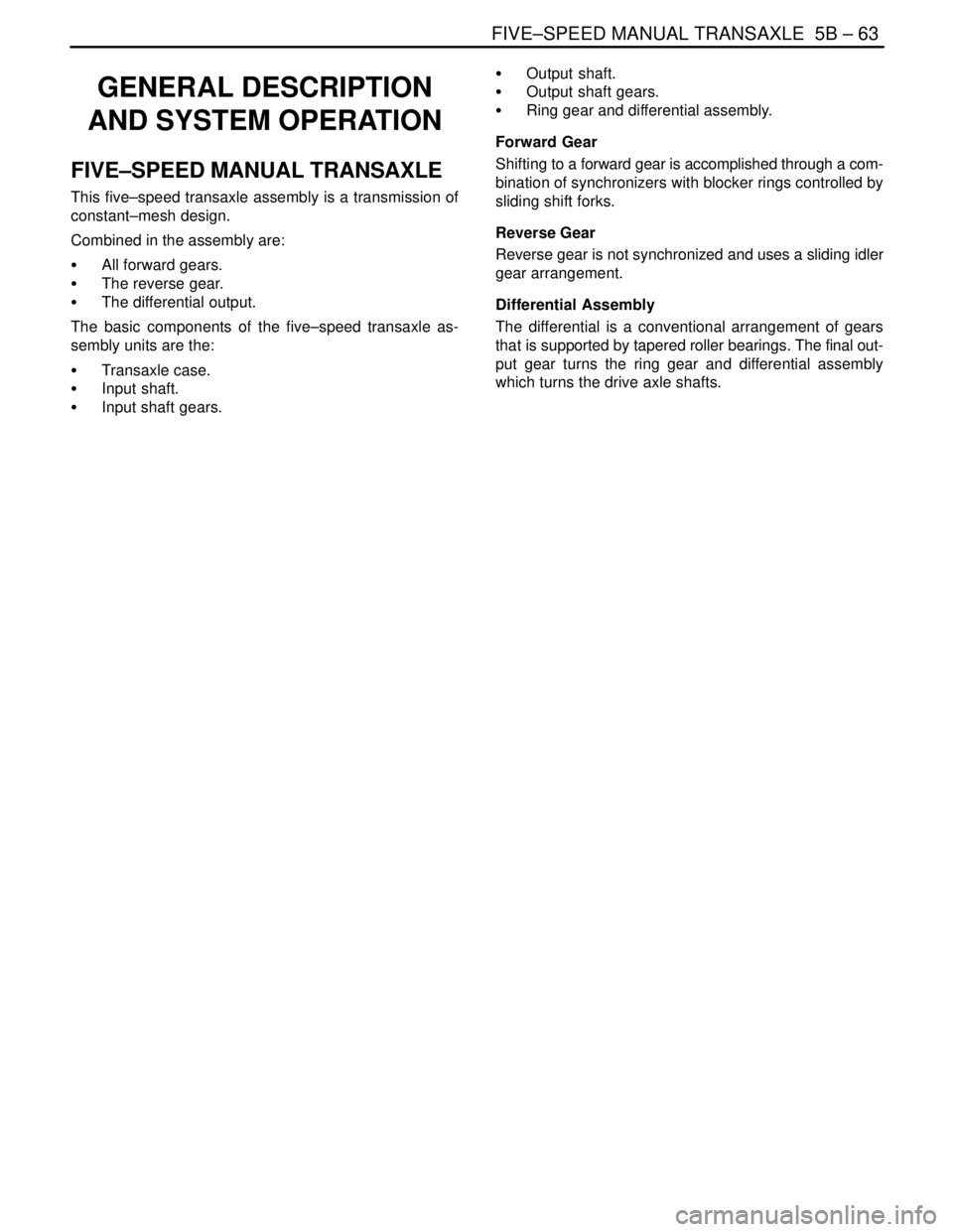

29. Install the bearing plate bolts.

Tighten

Tighten the bearing plate bolts to 22 NSm (16 lb–ft).

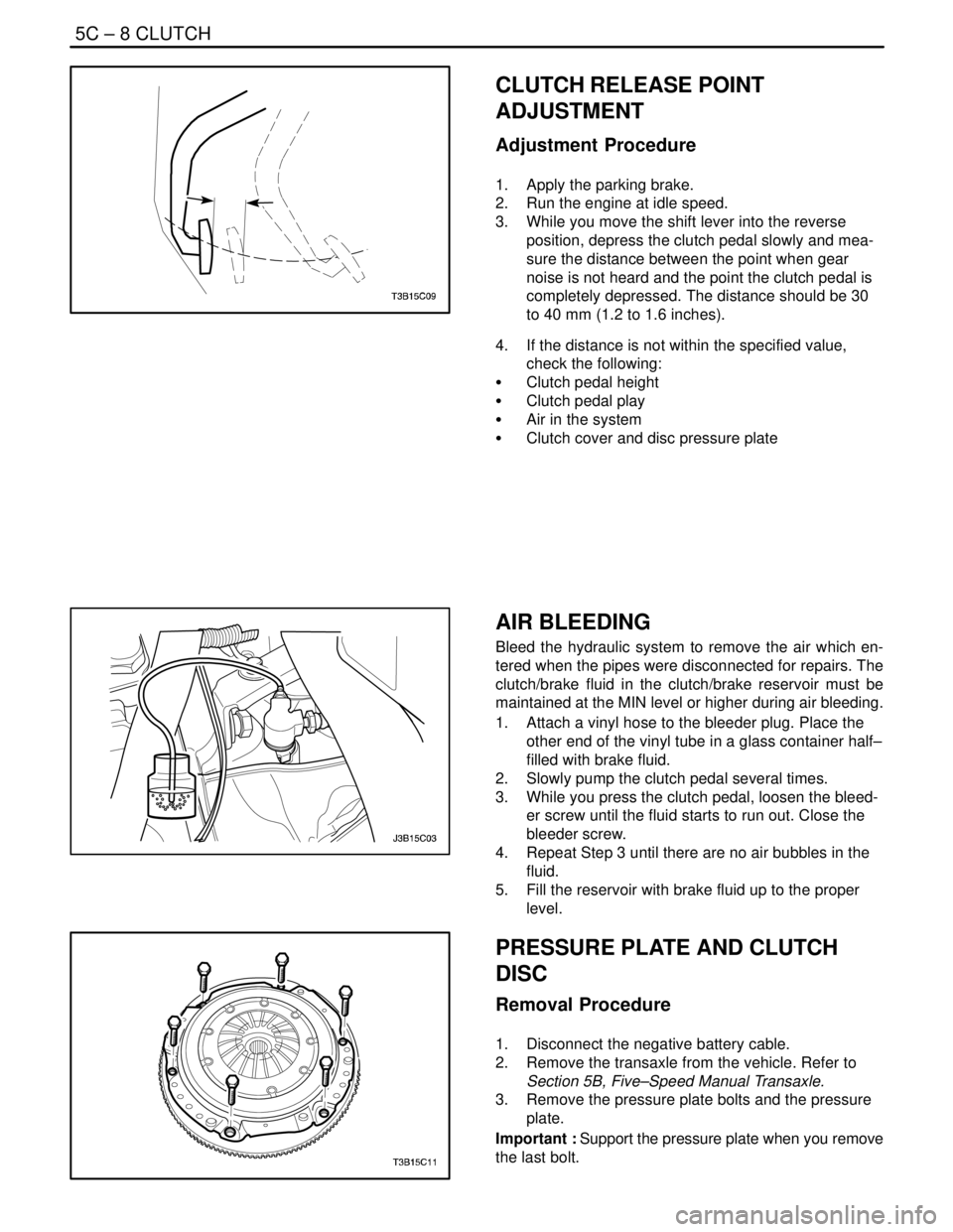

30. Install the speedometer–driven gear and the

speedometer–housing retaining bolt into the trans-

axle housing.

Tighten

Tighten the speedometer housing retaining bolt to 4

NSm (35 lb–in).

Page 1886 of 2643

5B – 62IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

31. Bolt the gearshift lever cover to the fixture KM–552.

32. Position the fixture into the base KM–113–2.

33. Install the gearshift rod, the shift finger lever, and

the gearshift lever pin.

34. Install the snap ring, the bushing, the spring, and

the intermediate lever.

35. Remove the gearshift lever cover from the base

KM–113–2 and the fixture KM–552.

36. Shift the transaxle into NEUTRAL.

37. Install the gearshift lever cover and the gearshift

lever cover bolts.

Tighten

Tighten the gearshift lever cover bolts to 22 NSm (16

lb–ft).

38. Install the transaxle cover and the transaxle cover

bolts.

Tighten

Tighten the transaxle cover bolts to 18 NSm (13 lb–ft).

39. Install the transaxle into the vehicle. Refer to

”Transaxle Assembly” in this section.

Page 1887 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 63

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

FIVE–SPEED MANUAL TRANSAXLE

This five–speed transaxle assembly is a transmission of

constant–mesh design.

Combined in the assembly are:

S All forward gears.

S The reverse gear.

S The differential output.

The basic components of the five–speed transaxle as-

sembly units are the:

S Transaxle case.

S Input shaft.

S Input shaft gears.S Output shaft.

S Output shaft gears.

S Ring gear and differential assembly.

Forward Gear

Shifting to a forward gear is accomplished through a com-

bination of synchronizers with blocker rings controlled by

sliding shift forks.

Reverse Gear

Reverse gear is not synchronized and uses a sliding idler

gear arrangement.

Differential Assembly

The differential is a conventional arrangement of gears

that is supported by tapered roller bearings. The final out-

put gear turns the ring gear and differential assembly

which turns the drive axle shafts.

Page 1895 of 2643

5C – 8ICLUTCH

DAEWOO V–121 BL4

CLUTCH RELEASE POINT

ADJUSTMENT

Adjustment Procedure

1. Apply the parking brake.

2. Run the engine at idle speed.

3. While you move the shift lever into the reverse

position, depress the clutch pedal slowly and mea-

sure the distance between the point when gear

noise is not heard and the point the clutch pedal is

completely depressed. The distance should be 30

to 40 mm (1.2 to 1.6 inches).

4. If the distance is not within the specified value,

check the following:

S Clutch pedal height

S Clutch pedal play

S Air in the system

S Clutch cover and disc pressure plate

AIR BLEEDING

Bleed the hydraulic system to remove the air which en-

tered when the pipes were disconnected for repairs. The

clutch/brake fluid in the clutch/brake reservoir must be

maintained at the MIN level or higher during air bleeding.

1. Attach a vinyl hose to the bleeder plug. Place the

other end of the vinyl tube in a glass container half–

filled with brake fluid.

2. Slowly pump the clutch pedal several times.

3. While you press the clutch pedal, loosen the bleed-

er screw until the fluid starts to run out. Close the

bleeder screw.

4. Repeat Step 3 until there are no air bubbles in the

fluid.

5. Fill the reservoir with brake fluid up to the proper

level.

PRESSURE PLATE AND CLUTCH

DISC

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the transaxle from the vehicle. Refer to

Section 5B, Five–Speed Manual Transaxle.

3. Remove the pressure plate bolts and the pressure

plate.

Important : Support the pressure plate when you remove

the last bolt.

Page 1897 of 2643

5C – 10ICLUTCH

DAEWOO V–121 BL4

Installation Procedure

1. Coat the spline on the clutch disc with multi–pur-

pose grease.

2. Align the pressure plate and the clutch disc onto

the flywheel using the clutch arbor J–42474.

3. Install the pressure plate bolts.

Tighten

Tighten the bolts to 15 NSm (11 lb–ft).

4. Remove the clutch arbor J–42474.

5. Install the transaxle into the vehicle. Refer to Sec-

tion 5B, Five–Speed Manual Transaxle.

6. Connect the negative battery cable.

CLUTCH MASTER CYLINDER

ASSEMBLY

Removal Procedure

Before disconnecting the reservoir tank hose, remove the

clutch/brake fluid from the reservoir tank.

1. Remove the locking clip.

2. Remove the push rod fixing pin and push rod.

3. Disconnect the hose clamp on the master cylinder.

4. Disconnect the master cylinder hose.

5. Remove the master cylinder pipe.

Page 1899 of 2643

5C – 12ICLUTCH

DAEWOO V–121 BL4

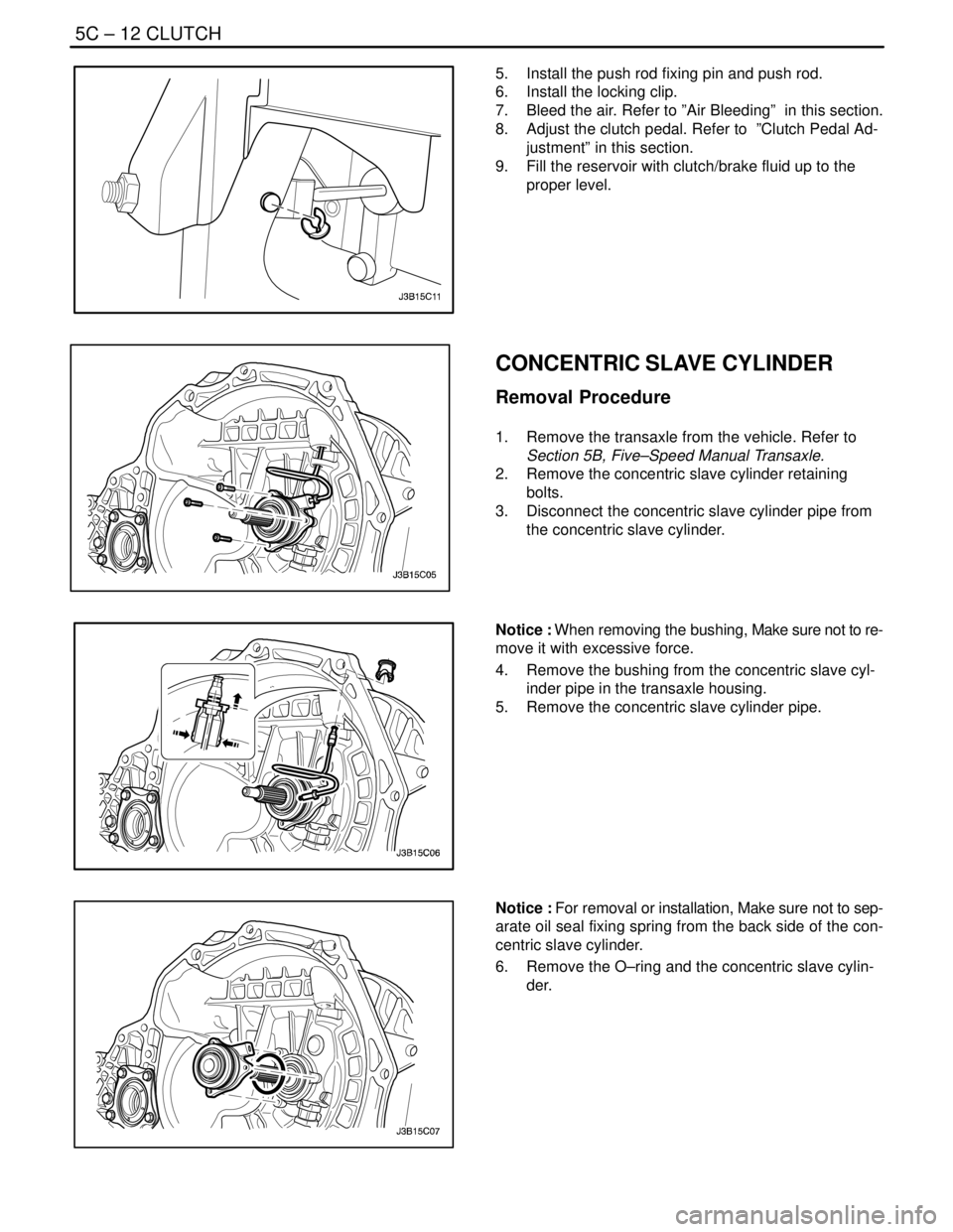

5. Install the push rod fixing pin and push rod.

6. Install the locking clip.

7. Bleed the air. Refer to ”Air Bleeding” in this section.

8. Adjust the clutch pedal. Refer to ”Clutch Pedal Ad-

justment” in this section.

9. Fill the reservoir with clutch/brake fluid up to the

proper level.

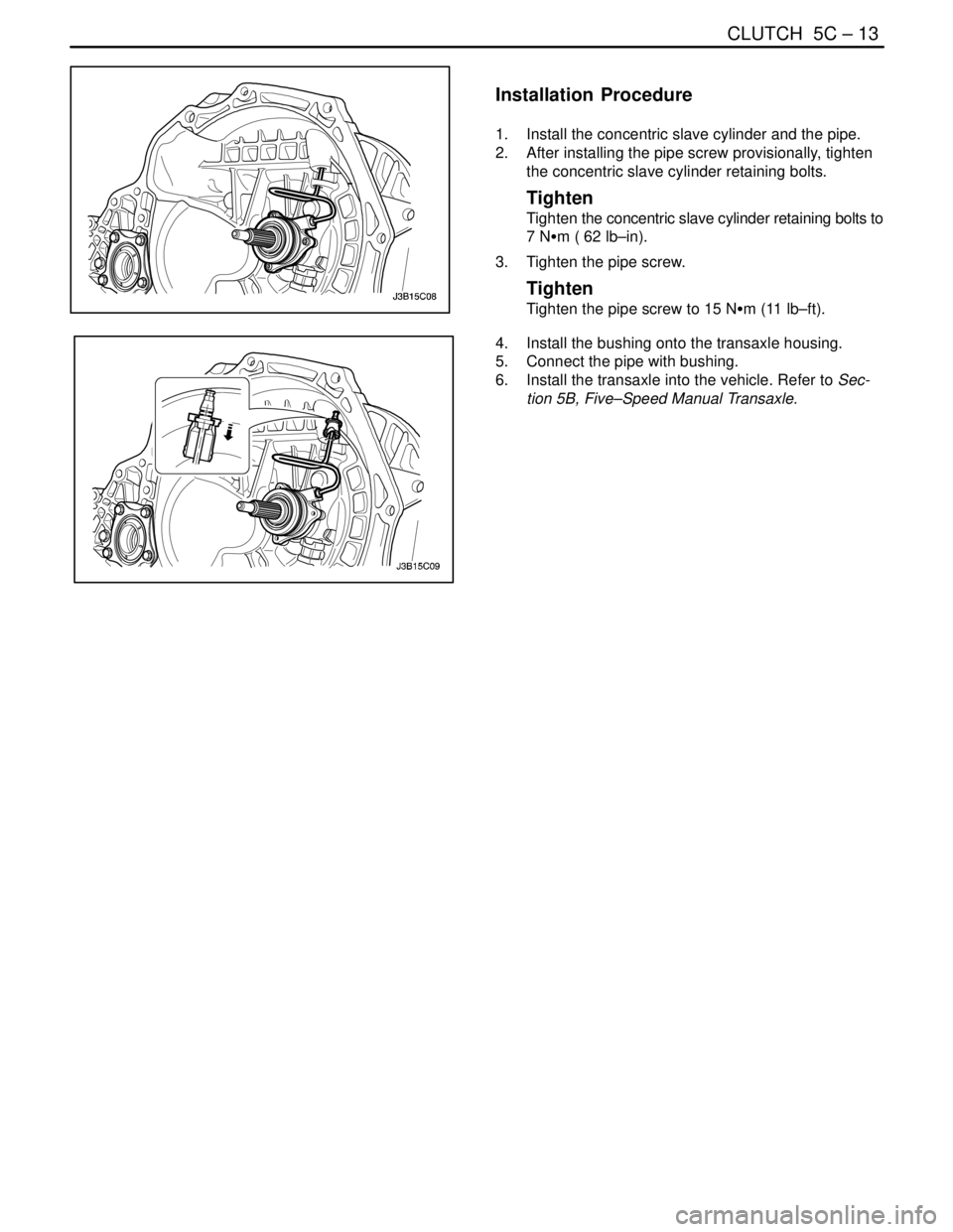

CONCENTRIC SLAVE CYLINDER

Removal Procedure

1. Remove the transaxle from the vehicle. Refer to

Section 5B, Five–Speed Manual Transaxle.

2. Remove the concentric slave cylinder retaining

bolts.

3. Disconnect the concentric slave cylinder pipe from

the concentric slave cylinder.

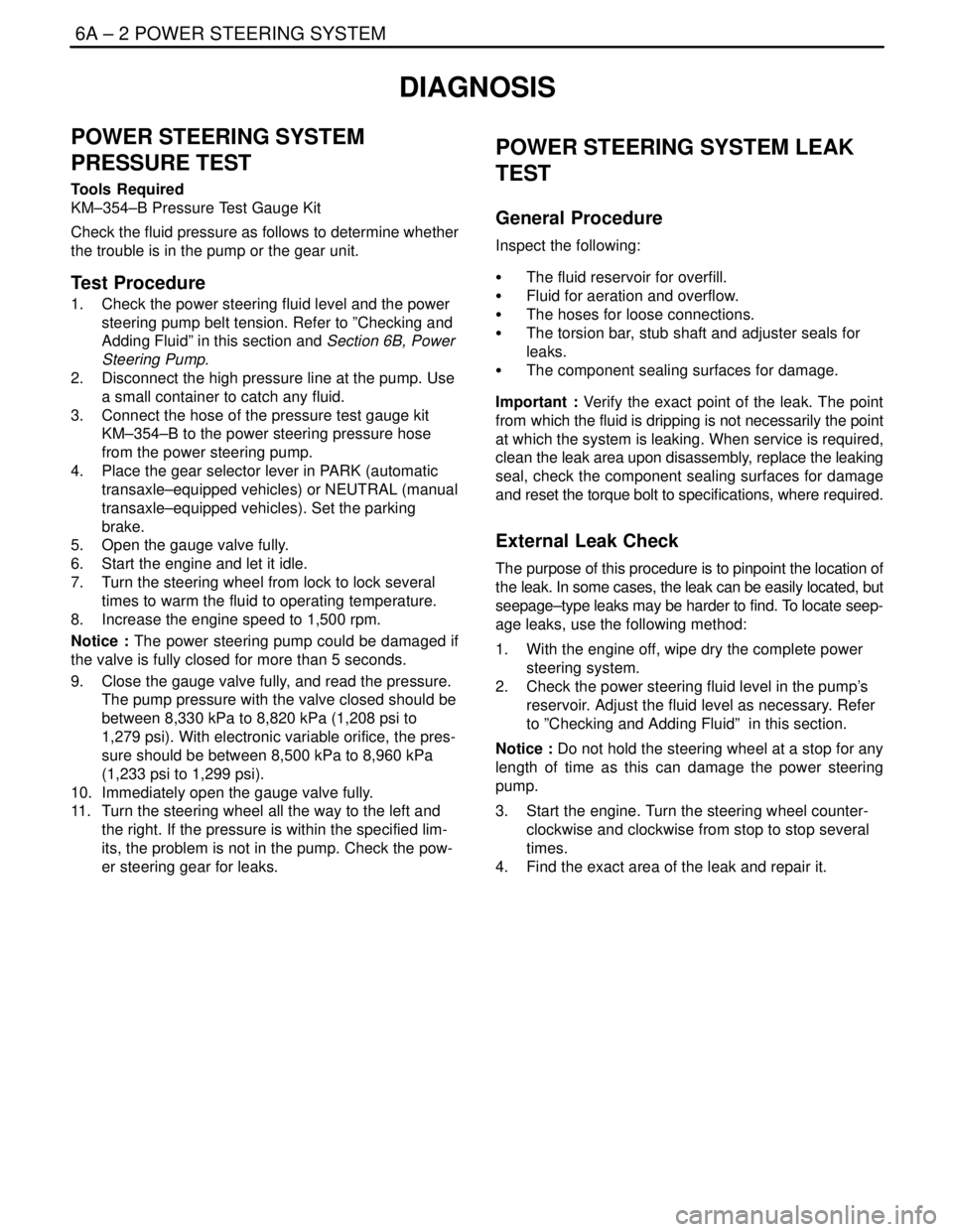

Notice : When removing the bushing, Make sure not to re-

move it with excessive force.

4. Remove the bushing from the concentric slave cyl-

inder pipe in the transaxle housing.

5. Remove the concentric slave cylinder pipe.

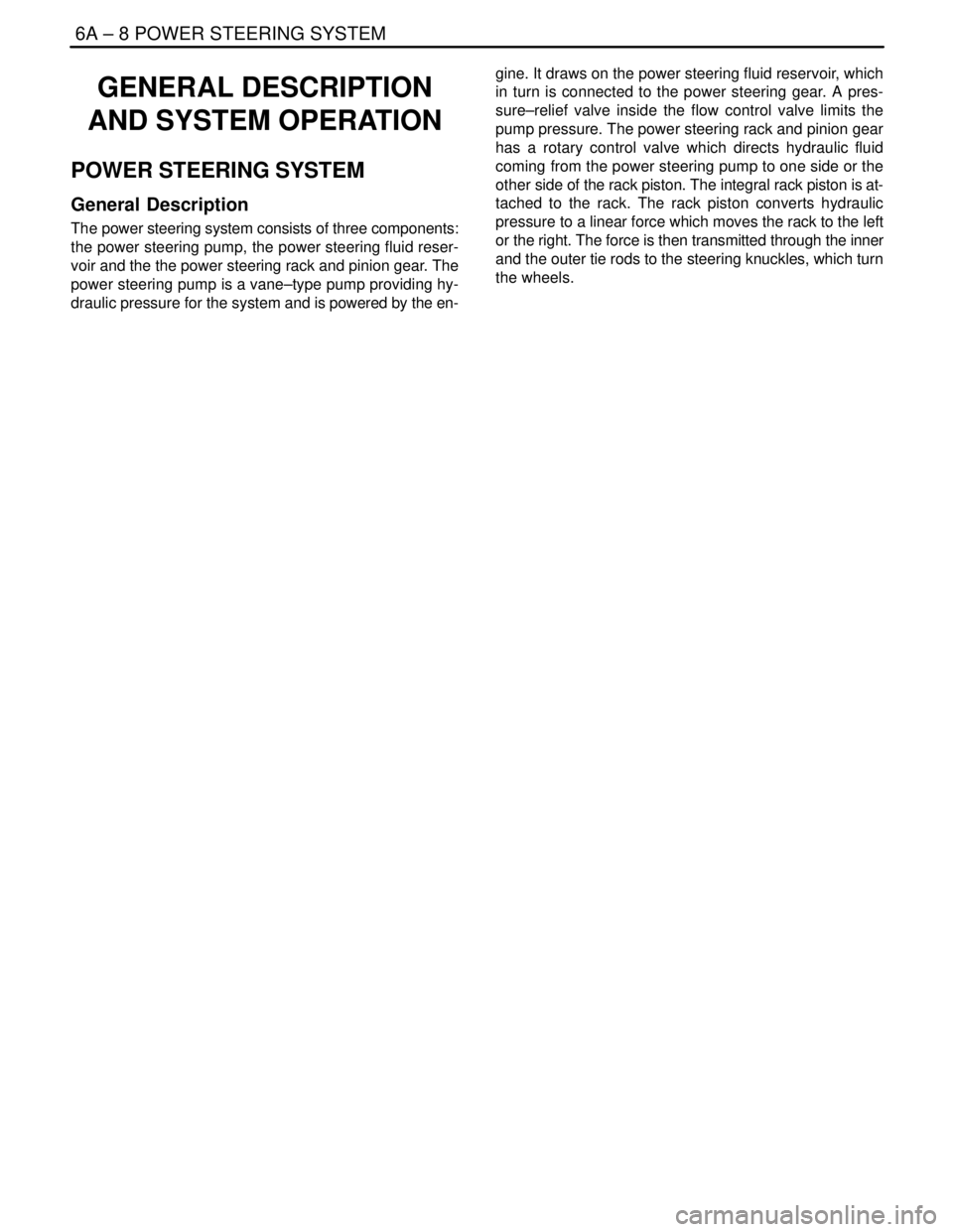

Notice : For removal or installation, Make sure not to sep-

arate oil seal fixing spring from the back side of the con-

centric slave cylinder.

6. Remove the O–ring and the concentric slave cylin-

der.

Page 1900 of 2643

CLUTCH 5C – 13

DAEWOO V–121 BL4

Installation Procedure

1. Install the concentric slave cylinder and the pipe.

2. After installing the pipe screw provisionally, tighten

the concentric slave cylinder retaining bolts.

Tighten

Tighten the concentric slave cylinder retaining bolts to

7 NSm ( 62 lb–in).

3. Tighten the pipe screw.

Tighten

Tighten the pipe screw to 15 NSm (11 lb–ft).

4. Install the bushing onto the transaxle housing.

5. Connect the pipe with bushing.

6. Install the transaxle into the vehicle. Refer to Sec-

tion 5B, Five–Speed Manual Transaxle.

Page 1903 of 2643

6A – 2IPOWER STEERING SYSTEM

DAEWOO V–121 BL4

DIAGNOSIS

POWER STEERING SYSTEM

PRESSURE TEST

Tools Required

KM–354–B Pressure Test Gauge Kit

Check the fluid pressure as follows to determine whether

the trouble is in the pump or the gear unit.

Test Procedure

1. Check the power steering fluid level and the power

steering pump belt tension. Refer to ”Checking and

Adding Fluid” in this section and Section 6B, Power

Steering Pump.

2. Disconnect the high pressure line at the pump. Use

a small container to catch any fluid.

3. Connect the hose of the pressure test gauge kit

KM–354–B to the power steering pressure hose

from the power steering pump.

4. Place the gear selector lever in PARK (automatic

transaxle–equipped vehicles) or NEUTRAL (manual

transaxle–equipped vehicles). Set the parking

brake.

5. Open the gauge valve fully.

6. Start the engine and let it idle.

7. Turn the steering wheel from lock to lock several

times to warm the fluid to operating temperature.

8. Increase the engine speed to 1,500 rpm.

Notice : The power steering pump could be damaged if

the valve is fully closed for more than 5 seconds.

9. Close the gauge valve fully, and read the pressure.

The pump pressure with the valve closed should be

between 8,330 kPa to 8,820 kPa (1,208 psi to

1,279 psi). With electronic variable orifice, the pres-

sure should be between 8,500 kPa to 8,960 kPa

(1,233 psi to 1,299 psi).

10. Immediately open the gauge valve fully.

11. Turn the steering wheel all the way to the left and

the right. If the pressure is within the specified lim-

its, the problem is not in the pump. Check the pow-

er steering gear for leaks.

POWER STEERING SYSTEM LEAK

TEST

General Procedure

Inspect the following:

S The fluid reservoir for overfill.

S Fluid for aeration and overflow.

S The hoses for loose connections.

S The torsion bar, stub shaft and adjuster seals for

leaks.

S The component sealing surfaces for damage.

Important : Verify the exact point of the leak. The point

from which the fluid is dripping is not necessarily the point

at which the system is leaking. When service is required,

clean the leak area upon disassembly, replace the leaking

seal, check the component sealing surfaces for damage

and reset the torque bolt to specifications, where required.

External Leak Check

The purpose of this procedure is to pinpoint the location of

the leak. In some cases, the leak can be easily located, but

seepage–type leaks may be harder to find. To locate seep-

age leaks, use the following method:

1. With the engine off, wipe dry the complete power

steering system.

2. Check the power steering fluid level in the pump’s

reservoir. Adjust the fluid level as necessary. Refer

to ”Checking and Adding Fluid” in this section.

Notice : Do not hold the steering wheel at a stop for any

length of time as this can damage the power steering

pump.

3. Start the engine. Turn the steering wheel counter-

clockwise and clockwise from stop to stop several

times.

4. Find the exact area of the leak and repair it.

Page 1909 of 2643

6A – 8IPOWER STEERING SYSTEM

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

POWER STEERING SYSTEM

General Description

The power steering system consists of three components:

the power steering pump, the power steering fluid reser-

voir and the the power steering rack and pinion gear. The

power steering pump is a vane–type pump providing hy-

draulic pressure for the system and is powered by the en-gine. It draws on the power steering fluid reservoir, which

in turn is connected to the power steering gear. A pres-

sure–relief valve inside the flow control valve limits the

pump pressure. The power steering rack and pinion gear

has a rotary control valve which directs hydraulic fluid

coming from the power steering pump to one side or the

other side of the rack piston. The integral rack piston is at-

tached to the rack. The rack piston converts hydraulic

pressure to a linear force which moves the rack to the left

or the right. The force is then transmitted through the inner

and the outer tie rods to the steering knuckles, which turn

the wheels.

Page 1919 of 2643

6C – 2IPOWER STEERING GEAR

DAEWOO V–121 BL4

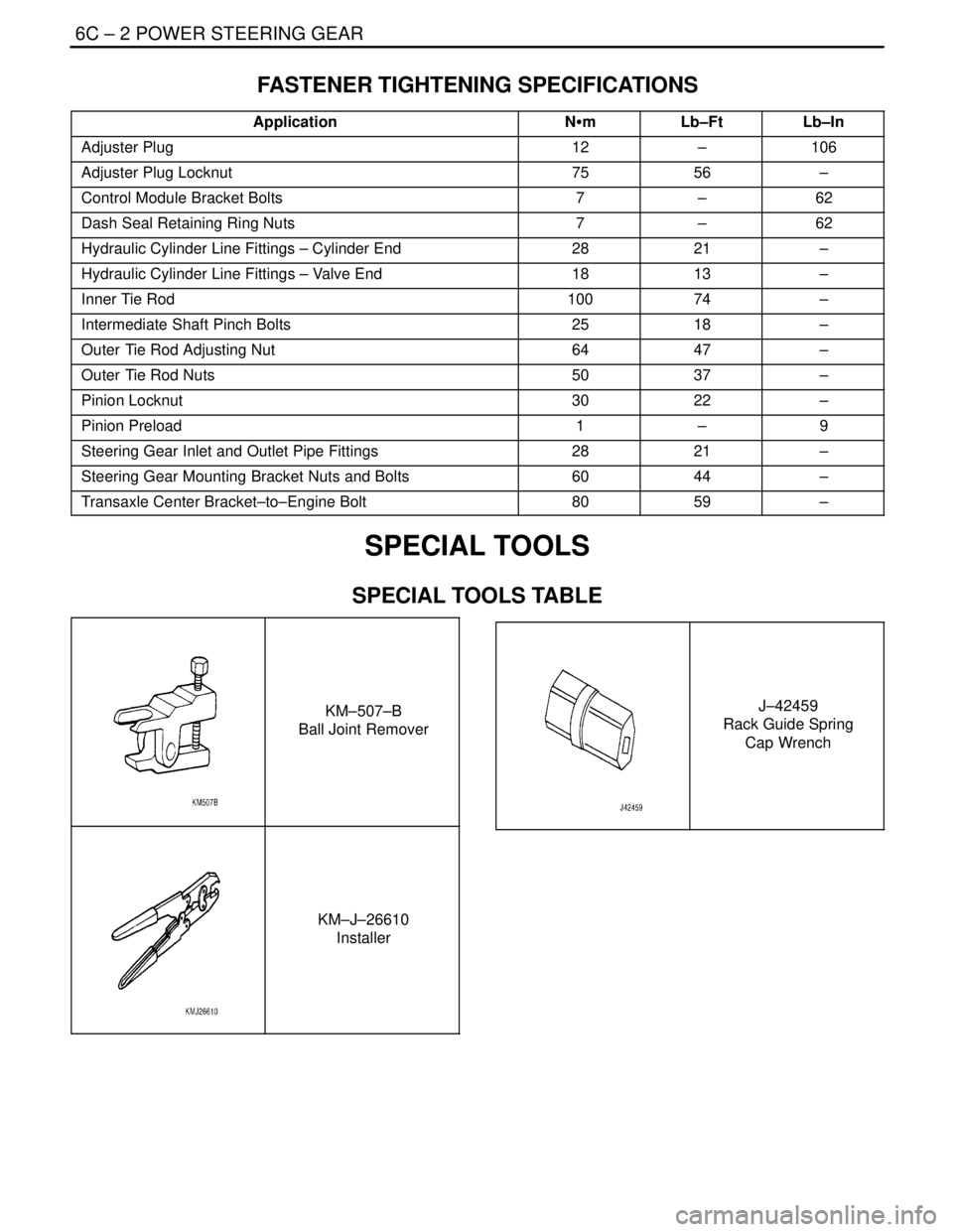

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Adjuster Plug12–106

Adjuster Plug Locknut7556–

Control Module Bracket Bolts7–62

Dash Seal Retaining Ring Nuts7–62

Hydraulic Cylinder Line Fittings – Cylinder End2821–

Hydraulic Cylinder Line Fittings – Valve End1813–

Inner Tie Rod10074–

Intermediate Shaft Pinch Bolts2518–

Outer Tie Rod Adjusting Nut6447–

Outer Tie Rod Nuts5037–

Pinion Locknut3022–

Pinion Preload1–9

Steering Gear Inlet and Outlet Pipe Fittings2821–

Steering Gear Mounting Bracket Nuts and Bolts6044–

Transaxle Center Bracket–to–Engine Bolt8059–

SPECIAL TOOLS

SPECIAL TOOLS TABLE

KM–507–B

Ball Joint Remover

KM–J–26610

Installer

J–42459

Rack Guide Spring

Cap Wrench