key DAEWOO LACETTI 2004 Service Manual PDF

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1955 of 2643

SECTION : 6E

STEERING WHEEL AND COLUMN

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS6E–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 6E–1. . . . . . . . . . .

SPECIAL TOOLS6E–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 6E–2. . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS6E–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Column Diagnosis 6E–2. . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR6E–8 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 6E–8. . . . . . . . . . . . . . . . . . . . .

Headlamp/Turn Signal Switch and Lever 6E–8. . . . . .

Wiper Switch and Lever 6E–9. . . . . . . . . . . . . . . . . . . . Steering Wheel Rotation Sensor 6E–10. . . . . . . . . . . .

Steering Wheel Without SIR 6E–11. . . . . . . . . . . . . . . .

Steering Wheel With SIR 6E–13. . . . . . . . . . . . . . . . . .

Ignition Lock Cylinder and Switch 6E–13. . . . . . . . . . .

Steering Column 6E–15. . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 6E–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tilt Steering Column 6E–19. . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION6E–20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Wheel and Column 6E–20. . . . . . . . . . . . . . . .

Ignition Key Reminder 6E–20. . . . . . . . . . . . . . . . . . . . .

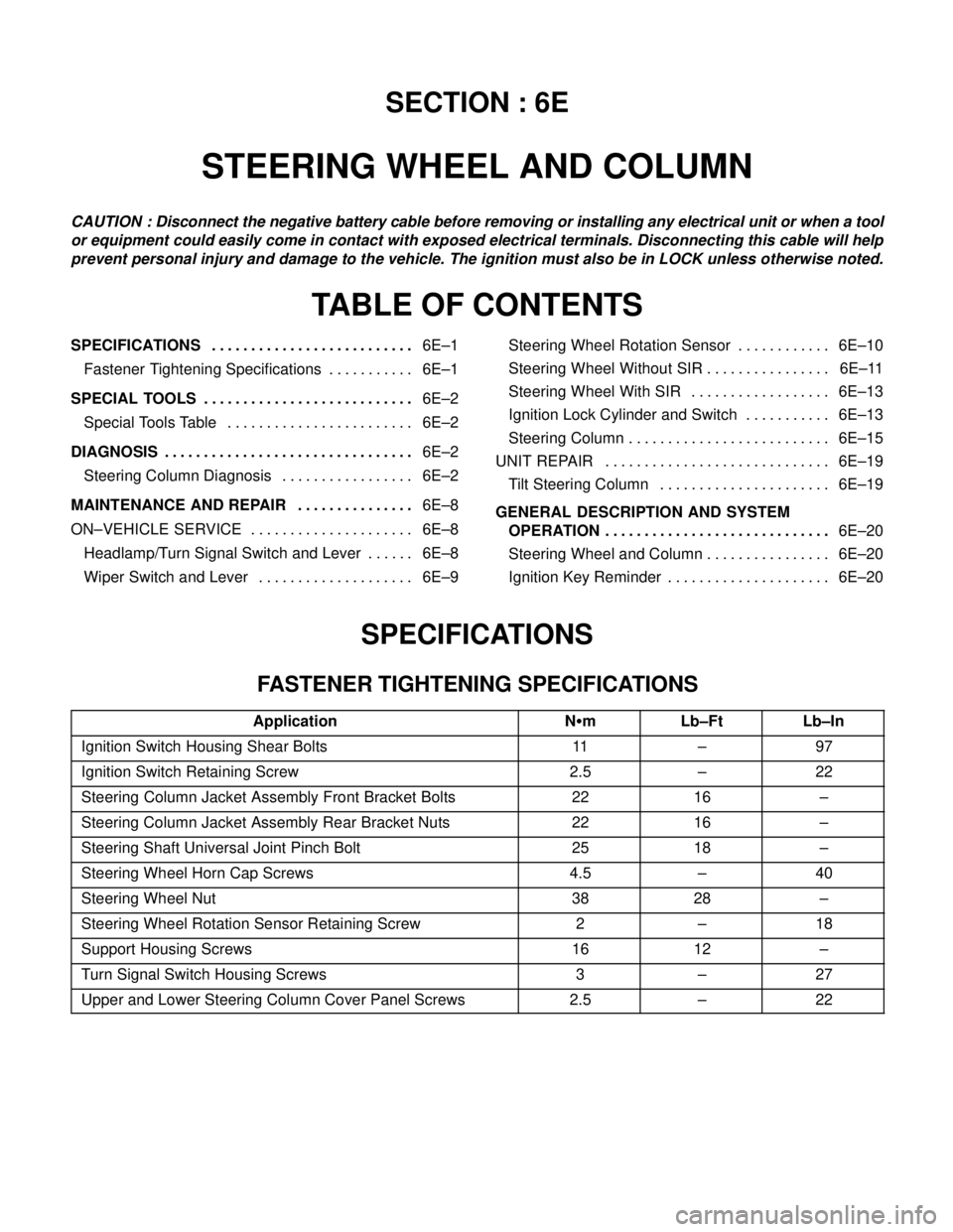

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Ignition Switch Housing Shear Bolts11–97

Ignition Switch Retaining Screw2.5–22

Steering Column Jacket Assembly Front Bracket Bolts2216–

Steering Column Jacket Assembly Rear Bracket Nuts2216–

Steering Shaft Universal Joint Pinch Bolt2518–

Steering Wheel Horn Cap Screws4.5–40

Steering Wheel Nut3828–

Steering Wheel Rotation Sensor Retaining Screw2–18

Support Housing Screws1612–

Turn Signal Switch Housing Screws3–27

Upper and Lower Steering Column Cover Panel Screws2.5–22

Page 1957 of 2643

STEERING WHEEL AND COLUMN 6E – 3

DAEWOO V–121 BL4

High Lock Effort

ChecksAction

Check the lock cylinder for damage.Replace the lock cylinder.

Check the ignition switch for lack of free movement.Lubricate the ignition switch.

Check for extreme misalignment of the housing to the cov-

er.Realign the cover on the housing. Replace the cover as

needed.

Check for a bent ignition switch mounting bracket.Replace the ignition switch mounting bracket.

Key Cannot Be Removed in the LOCK Position

ChecksAction

Check to see that the ignition switch is set correctly.Reset the ignition switch.

Check the lock cylinder for damage.Replace the lock cylinder.

Check the fuse F17 from the I/P fuse block.Replace the fuse F17

Check for an open or short in the circuit between terminal

2 of key interlock solenoid and the I/P fuse block.Replace the fuse F17

Select the gear shift lever to ”P” position.

Check the resistance between the terminal 2 and 1 of the

”P” position switch.Replace the ”P” position switch.

Check for an open or short in the circuit between the

ground G202 and terminal 1 of the key interlock unit.Replace the open or short from the circuit.

Turn the ignition ON.

Select the gear shift lever to ”P” position.

Check the resistance between the terminal 1 and 2 of the

key interlock solenoid.Replace the key interlock solenoid.

Page 1968 of 2643

6E – 14ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

4. With the key in the ignition turned to the position

designated ACC, remove the lock cylinder by

pressing down the detent spring and pulling the

lock cylinder out of the switch cylinder housing.

5. Remove the ignition switch retaining screw.

6. Disconnect the wiring and remove the ignition

switch.

Installation Procedure

1. Install the ignition switch with the ignition switch

retaining screw.

Tighten

Tighten the ignition switch retaining screw to 2.5 NSm

(22 lb–in).

2. Connect the wiring to the ignition switch.

3. Install the lock cylinder.

4. Connect the electrical connector for the immobilizer

detection unit.

5. Install the upper and the lower steering column cov-

er panel with the screws.

Tighten

Tighten the upper and the lower steering column cov-

er panel screws to 2.5 NSm (22 lb–in).

6. Connect the negative battery cable.

Page 1969 of 2643

STEERING WHEEL AND COLUMN 6E – 15

DAEWOO V–121 BL4

STEERING COLUMN

(Left–Hand Drive Shown, Right–Hand Dirve

Similar)

Important : Remove the steering column only if the follow-

ing conditions exist:

S The steering column requires replacement.

S The steering and the ignition lock housing require

replacement.

S Another operation requires the removal of the

steering column.

Notice : The steering column is extremely susceptible to

damage after it has been removed from the vehicle. Drop-

ping the column assembly on its end or hammering the

end of the steering shaft can collapse the steering shaft or

loosen the plastic injections which maintain column rigid-

ity. Leaning on the column can cause it to bend or deform.

Any of the above damage can impair the column’s collaps-

ible design. If it is necessary to remove the steering wheel,

use only the specified steering wheel puller.

Removal Procedure

1. Disconnect the negative battery cable and let the

vehicle sit for 1 minute to deactivate the airbag.

2. Remove the the lower instrument trim panels. Refer

to Section 9E, Instrumentation/Driver Information.

3. Remove the upper and the lower steering column

cover panel by removing the screws.

4. Remove the switch levers. Refer to ”Turn Signal

Switch and Lever” and ”Wiper Switch and Lever” in

this section.

5. Remove the immobilizer module. Refer to Section

9T, Remote Keyless Entry and Anti–theft System.

6. Disconnect the airbag electrical connections.

Page 1972 of 2643

6E – 18ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

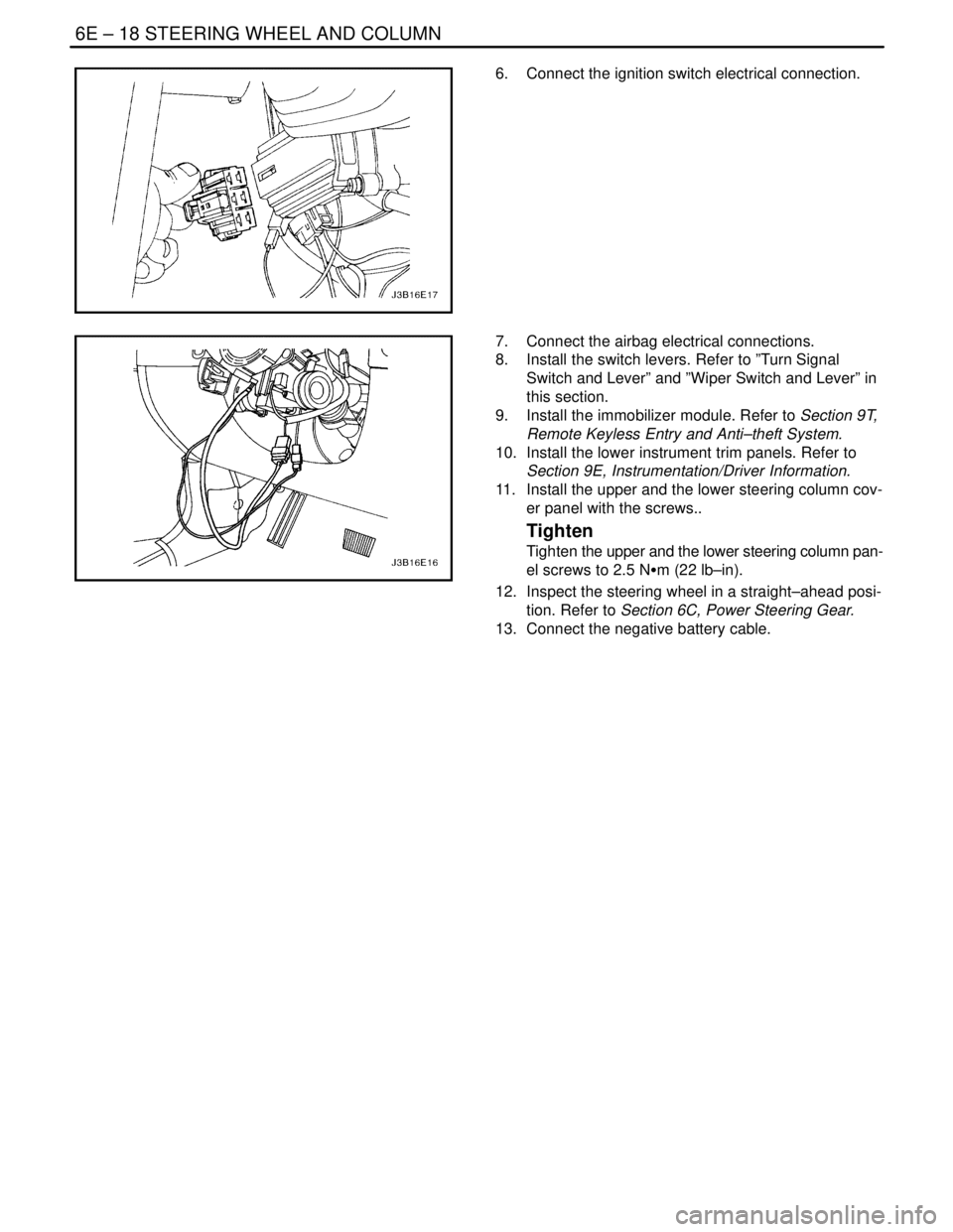

6. Connect the ignition switch electrical connection.

7. Connect the airbag electrical connections.

8. Install the switch levers. Refer to ”Turn Signal

Switch and Lever” and ”Wiper Switch and Lever” in

this section.

9. Install the immobilizer module. Refer to Section 9T,

Remote Keyless Entry and Anti–theft System.

10. Install the lower instrument trim panels. Refer to

Section 9E, Instrumentation/Driver Information.

11. Install the upper and the lower steering column cov-

er panel with the screws..

Tighten

Tighten the upper and the lower steering column pan-

el screws to 2.5 NSm (22 lb–in).

12. Inspect the steering wheel in a straight–ahead posi-

tion. Refer to Section 6C, Power Steering Gear.

13. Connect the negative battery cable.

Page 1974 of 2643

6E – 20ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

STEERING WHEEL AND COLUMN

CAUTION : To ensure the energy–absorbing action of

the steering column, it is important to use only the

specified screws, bolts, and nuts, tightened to the

specified torque.

In addition to the steering function, the steering column

provides safety and security.

The energy–absorbing column is designed to compress in

a front–end collision to lessen the chance of driver injury.

The ignition switch and the lock are mounted on the col-

umn, allowing the ignition and steering operations to be

locked to inhibit theft of the car.

The column levers trigger the turn signals, the headlight

beams, and the windshield washer and wipers.The tilt steering column uses telescopic function to allow

the steering wheel to tilt up and down in and out. This en-

ables the driver to adjust the steering wheel to a comfort-

able position.

Notice : Apply a thin coat of lithium grease to all friction

points when reassembling.

The column may be disassembled and reassembled easi-

ly.IGNITION KEY REMINDER

The ignition key reminder alerts the driver that the key is

still in the ignition when the driver attempts to exit the ve-

hicle.

An internal switch in the ignition lock cylinder supplies bat-

tery voltage to the reminder chime module when all of the

following conditions are true:

S The key is in the ignition switch.

S The ignition is OFF.

S The driver’s door is open.

For information on removal and installation of the reminder

chime module, refer to Section 9E, Instrumentation/Driver

Information.

Page 2039 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 37

DAEWOO V–121 BL4

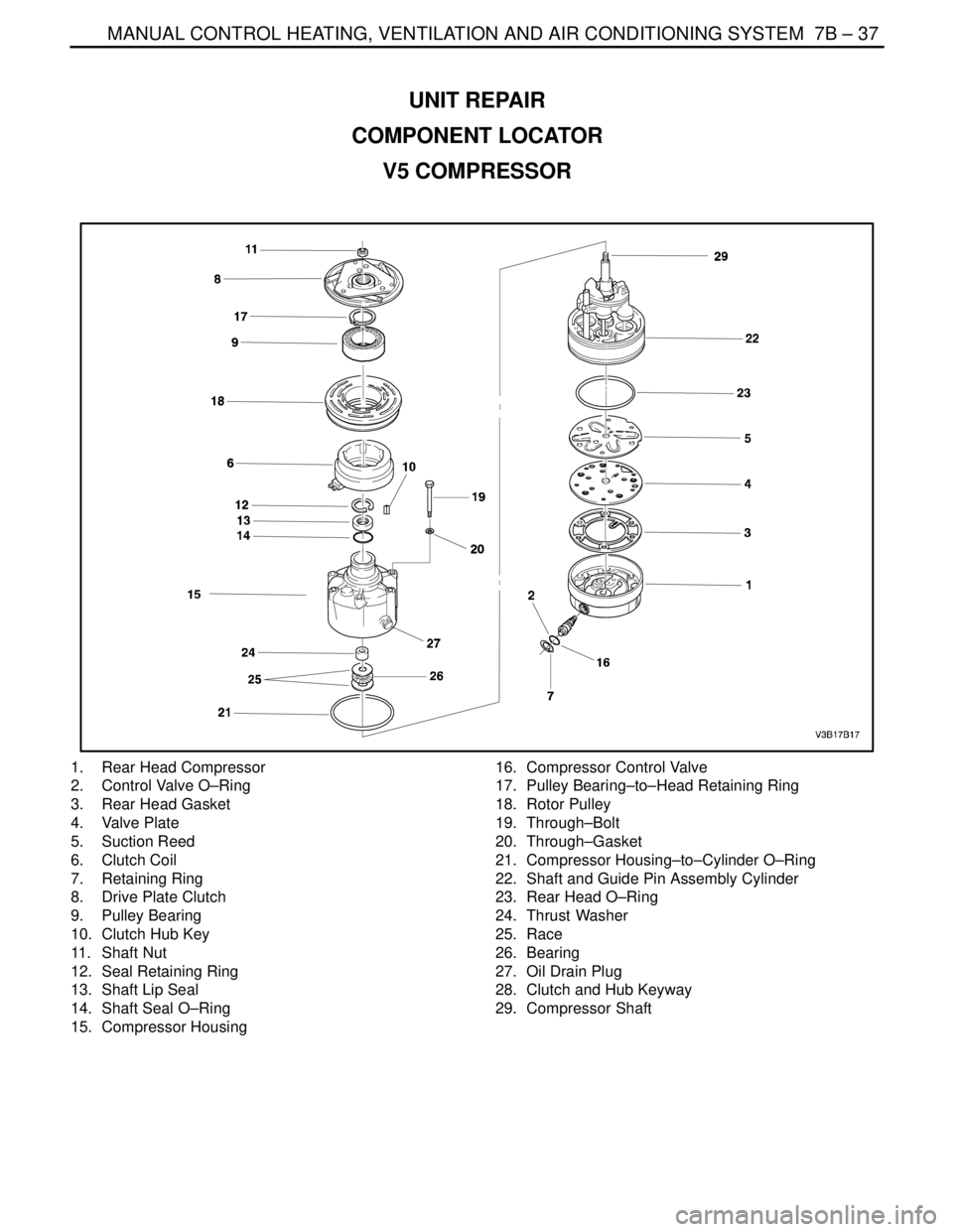

UNIT REPAIR

COMPONENT LOCATOR

V5 COMPRESSOR

1. Rear Head Compressor

2. Control Valve O–Ring

3. Rear Head Gasket

4. Valve Plate

5. Suction Reed

6. Clutch Coil

7. Retaining Ring

8. Drive Plate Clutch

9. Pulley Bearing

10. Clutch Hub Key

11. Shaft Nut

12. Seal Retaining Ring

13. Shaft Lip Seal

14. Shaft Seal O–Ring

15. Compressor Housing16. Compressor Control Valve

17. Pulley Bearing–to–Head Retaining Ring

18. Rotor Pulley

19. Through–Bolt

20. Through–Gasket

21. Compressor Housing–to–Cylinder O–Ring

22. Shaft and Guide Pin Assembly Cylinder

23. Rear Head O–Ring

24. Thrust Washer

25. Race

26. Bearing

27. Oil Drain Plug

28. Clutch and Hub Keyway

29. Compressor Shaft

Page 2040 of 2643

7B – 38IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

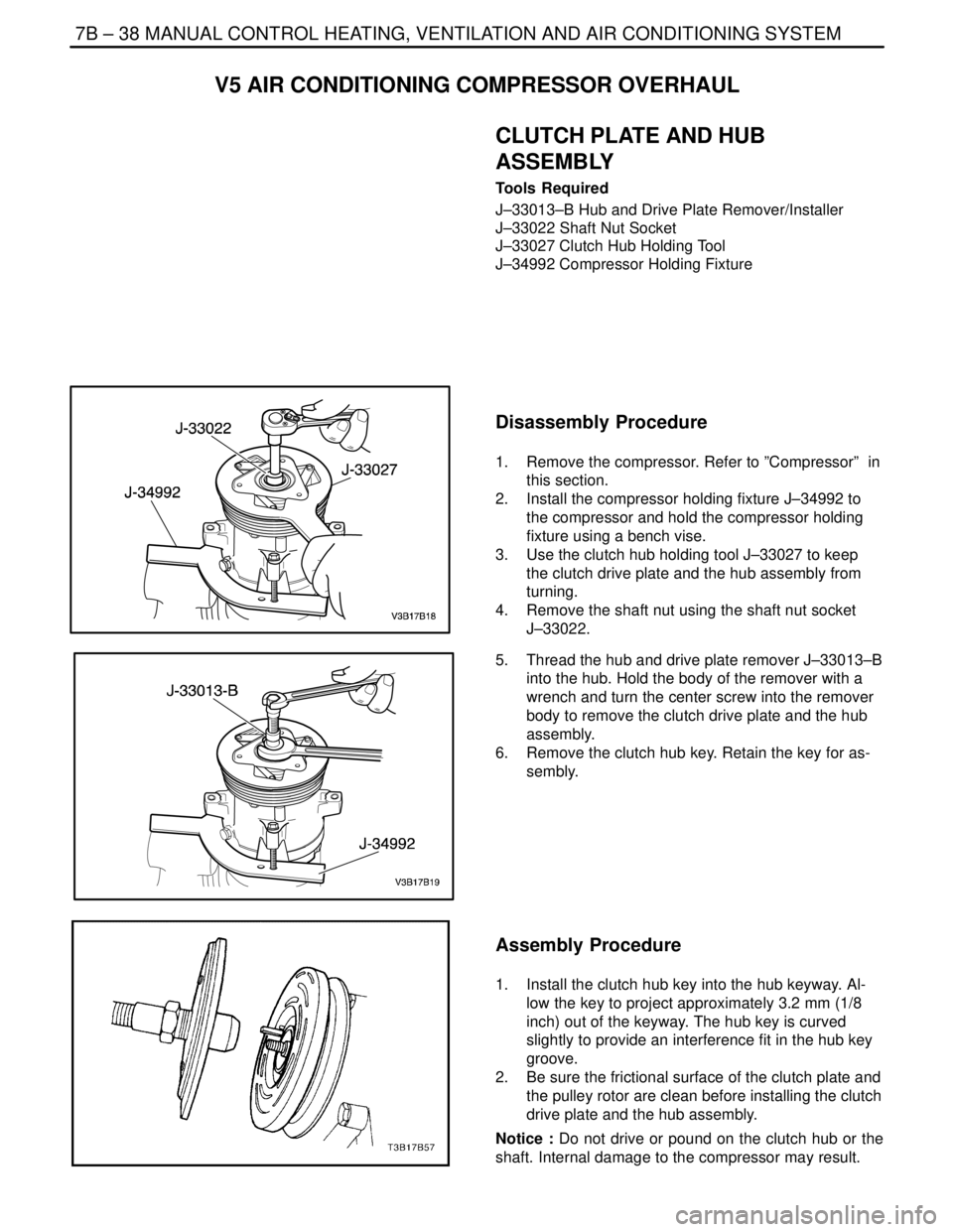

V5 AIR CONDITIONING COMPRESSOR OVERHAUL

CLUTCH PLATE AND HUB

ASSEMBLY

Tools Required

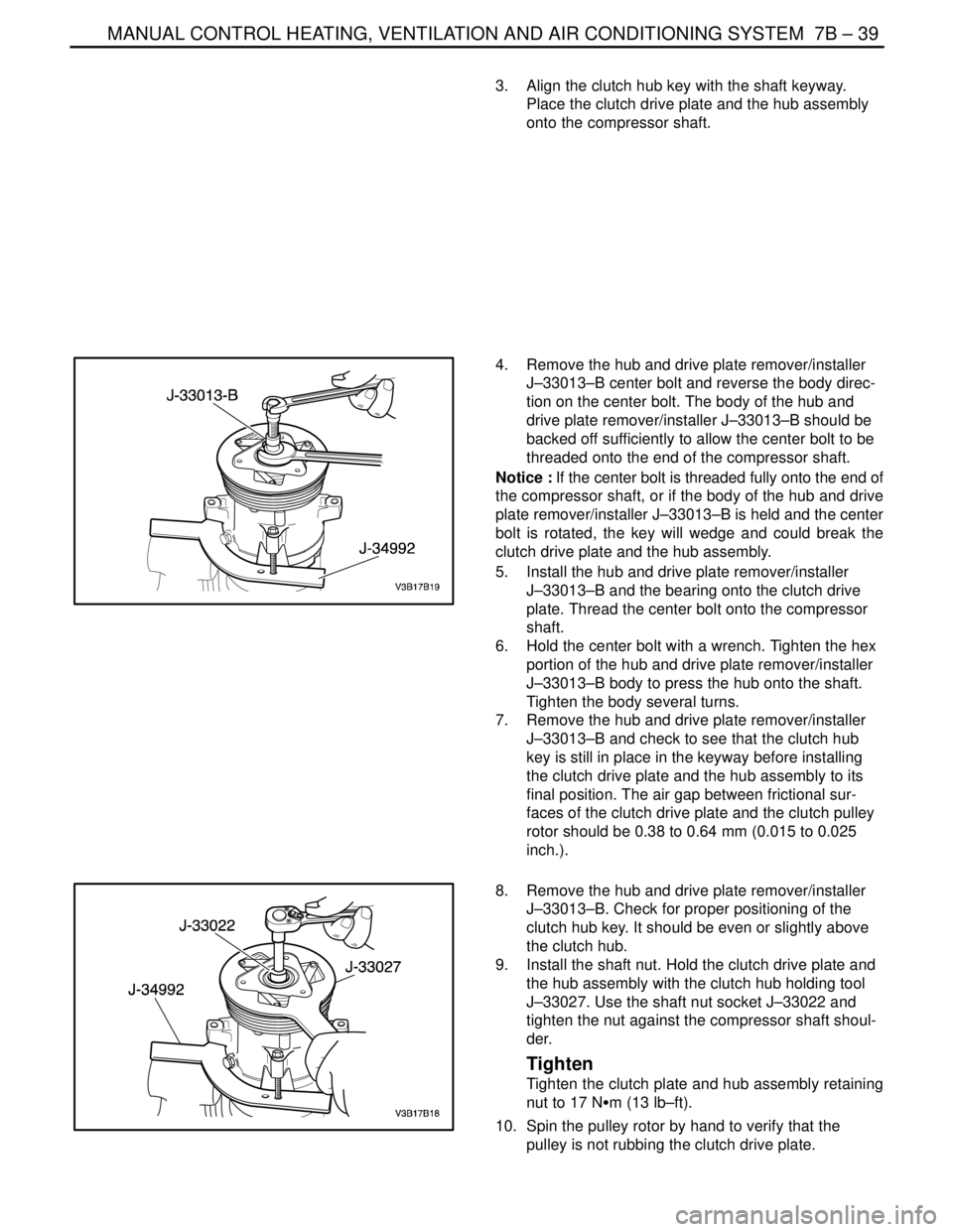

J–33013–B Hub and Drive Plate Remover/Installer

J–33022 Shaft Nut Socket

J–33027 Clutch Hub Holding Tool

J–34992 Compressor Holding Fixture

Disassembly Procedure

1. Remove the compressor. Refer to ”Compressor” in

this section.

2. Install the compressor holding fixture J–34992 to

the compressor and hold the compressor holding

fixture using a bench vise.

3. Use the clutch hub holding tool J–33027 to keep

the clutch drive plate and the hub assembly from

turning.

4. Remove the shaft nut using the shaft nut socket

J–33022.

5. Thread the hub and drive plate remover J–33013–B

into the hub. Hold the body of the remover with a

wrench and turn the center screw into the remover

body to remove the clutch drive plate and the hub

assembly.

6. Remove the clutch hub key. Retain the key for as-

sembly.

Assembly Procedure

1. Install the clutch hub key into the hub keyway. Al-

low the key to project approximately 3.2 mm (1/8

inch) out of the keyway. The hub key is curved

slightly to provide an interference fit in the hub key

groove.

2. Be sure the frictional surface of the clutch plate and

the pulley rotor are clean before installing the clutch

drive plate and the hub assembly.

Notice : Do not drive or pound on the clutch hub or the

shaft. Internal damage to the compressor may result.

Page 2041 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 39

DAEWOO V–121 BL4

3. Align the clutch hub key with the shaft keyway.

Place the clutch drive plate and the hub assembly

onto the compressor shaft.

4. Remove the hub and drive plate remover/installer

J–33013–B center bolt and reverse the body direc-

tion on the center bolt. The body of the hub and

drive plate remover/installer J–33013–B should be

backed off sufficiently to allow the center bolt to be

threaded onto the end of the compressor shaft.

Notice : If the center bolt is threaded fully onto the end of

the compressor shaft, or if the body of the hub and drive

plate remover/installer J–33013–B is held and the center

bolt is rotated, the key will wedge and could break the

clutch drive plate and the hub assembly.

5. Install the hub and drive plate remover/installer

J–33013–B and the bearing onto the clutch drive

plate. Thread the center bolt onto the compressor

shaft.

6. Hold the center bolt with a wrench. Tighten the hex

portion of the hub and drive plate remover/installer

J–33013–B body to press the hub onto the shaft.

Tighten the body several turns.

7. Remove the hub and drive plate remover/installer

J–33013–B and check to see that the clutch hub

key is still in place in the keyway before installing

the clutch drive plate and the hub assembly to its

final position. The air gap between frictional sur-

faces of the clutch drive plate and the clutch pulley

rotor should be 0.38 to 0.64 mm (0.015 to 0.025

inch.).

8. Remove the hub and drive plate remover/installer

J–33013–B. Check for proper positioning of the

clutch hub key. It should be even or slightly above

the clutch hub.

9. Install the shaft nut. Hold the clutch drive plate and

the hub assembly with the clutch hub holding tool

J–33027. Use the shaft nut socket J–33022 and

tighten the nut against the compressor shaft shoul-

der.

Tighten

Tighten the clutch plate and hub assembly retaining

nut to 17 NSm (13 lb–ft).

10. Spin the pulley rotor by hand to verify that the

pulley is not rubbing the clutch drive plate.

Page 2112 of 2643

8B – 8ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

SIR DIAGNOSTIC SYSTEM CHECK

Notice : If the vehicle interior has been exposed to exten-

sive water intrusion such as water leaks, driving through

high water, flooding, or other causes, the sensing and

diagnostic module(SDM) and SDM connector may need

to be replaced. With ignition OFF, inspect the area around

the SDM, including the carpet. If any significant soaking or

evidence of previous soaking is detected, the water must

be removed, water damage repaired, and the SDM and

the SDM connector must be replaced. Before attempting

any of these repairs, the supplemental inflatable re-

straints(SIR) must be disabled. Refer to ”Disabling the

SIR” and ”Sensing and Diagnostic Module(SDM)” in this

section for instructions on how to disable the SIR and re-

place the SDM.

The SIR Diagnostic System Check must always be the

starting point for any SIR diagnosis. The Diagnostic Sys-

tem Check reveals diagnostic trouble codes(DTCs)

through the use of scan tool. The diagnostic procedures

used in this section are designed to find any repair SIR

conditions. To get the best results, it is important to use the

diagnostic charts and follow the sequence listed below.

1. Perform the SIR Diagnostic System Check, which

reveal diagnostic trouble codes(DTCs) through theuse of scan tool.. It also checks for proper airbag

indicator operation.

2. Refer to the proper diagnostic chart as directed by

SIR Diagnostic System Check. Bypassing these

procedures may result in extended diagnostic time,

incorrect diagnosis, and incorrect parts replace-

ment.

3. Repeat the SIR Diagnostic System Check after any

repair or diagnostic procedures have been per-

formed to ensure that the repair has been made

correctly and that no other malfunction exists.

Circiut Description

When the ignition switch is first turned to ON, ignition volt-

age is supplied from airbag fuse to find the SDM at input

terminal A1. The SDM responds by flashing the airbag in-

dicator seven times and then turning it off while the SDM

performs tests on the SIR.

Diagnostic Aids

The order in which DTCs are diagnosed is very important.

Failure to diagnose the DTCs in the order specified may

result in extended diagnostic time, incorrect diagnosis,

and incorrect parts replacement.

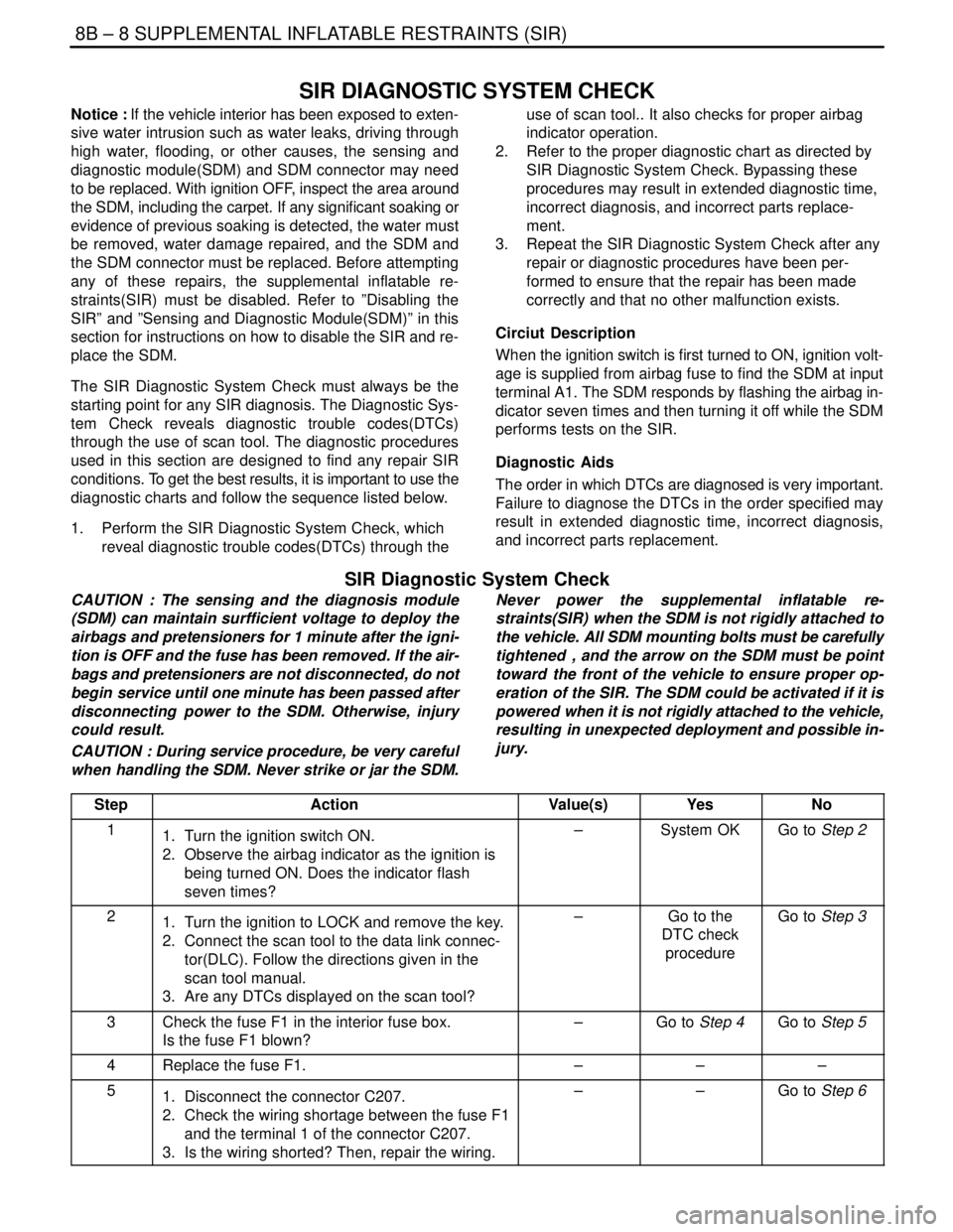

SIR Diagnostic System Check

CAUTION : The sensing and the diagnosis module

(SDM) can maintain surfficient voltage to deploy the

airbags and pretensioners for 1 minute after the igni-

tion is OFF and the fuse has been removed. If the air-

bags and pretensioners are not disconnected, do not

begin service until one minute has been passed after

disconnecting power to the SDM. Otherwise, injury

could result.

CAUTION : During service procedure, be very careful

when handling the SDM. Never strike or jar the SDM.Never power the supplemental inflatable re-

straints(SIR) when the SDM is not rigidly attached to

the vehicle. All SDM mounting bolts must be carefully

tightened , and the arrow on the SDM must be point

toward the front of the vehicle to ensure proper op-

eration of the SIR. The SDM could be activated if it is

powered when it is not rigidly attached to the vehicle,

resulting in unexpected deployment and possible in-

jury.

Step

ActionValue(s)YesNo

11. Turn the ignition switch ON.

2. Observe the airbag indicator as the ignition is

being turned ON. Does the indicator flash

seven times?–System OKGo to Step 2

21. Turn the ignition to LOCK and remove the key.

2. Connect the scan tool to the data link connec-

tor(DLC). Follow the directions given in the

scan tool manual.

3. Are any DTCs displayed on the scan tool?–Go to the

DTC check

procedureGo to Step 3

3Check the fuse F1 in the interior fuse box.

Is the fuse F1 blown?–Go to Step 4Go to Step 5

4Replace the fuse F1.–––

51. Disconnect the connector C207.

2. Check the wiring shortage between the fuse F1

and the terminal 1 of the connector C207.

3. Is the wiring shorted? Then, repair the wiring.––Go to Step 6