key DAEWOO LACETTI 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 357 of 2643

ENGINE CONTROLS 1F – 111

DAEWOO V–121 BL4

TROUBLE CODE DIAGNOSIS

(1.4L/1.6L DOHC)

CLEARING TROUBLE CODES

Notice : To prevent Engine Control Module (ECM) dam-

age, the key must be OFF when disconnecting or recon-

necting the power to the ECM (for example battery cable,

ECM pigtail connector, ECM fuse, jumper cables,

etc.).When the ECM sets a Diagnostic Trouble Code

(DTC), the Malfunction Indicator Lamp (MIL) lamp will be

turned on only for type A, B and E but a DTC will be stored

in the ECM’s memory for all types of DTC. If the problemis intermittent, the MIL will go out after 10 seconds if the

fault is no longer present. The DTC will stay in the ECM’s

memory until cleared by scan tool. Removing battery volt-

age for 10 seconds will clear some stored DTCs.

DTCs should be cleared after repairs have been com-

pleted. Some diagnostic tables will tell you to clear the

codes before using the chart. This allows the ECM to set

the DTC while going through the chart, which will help to

find the cause of the problem more quickly.

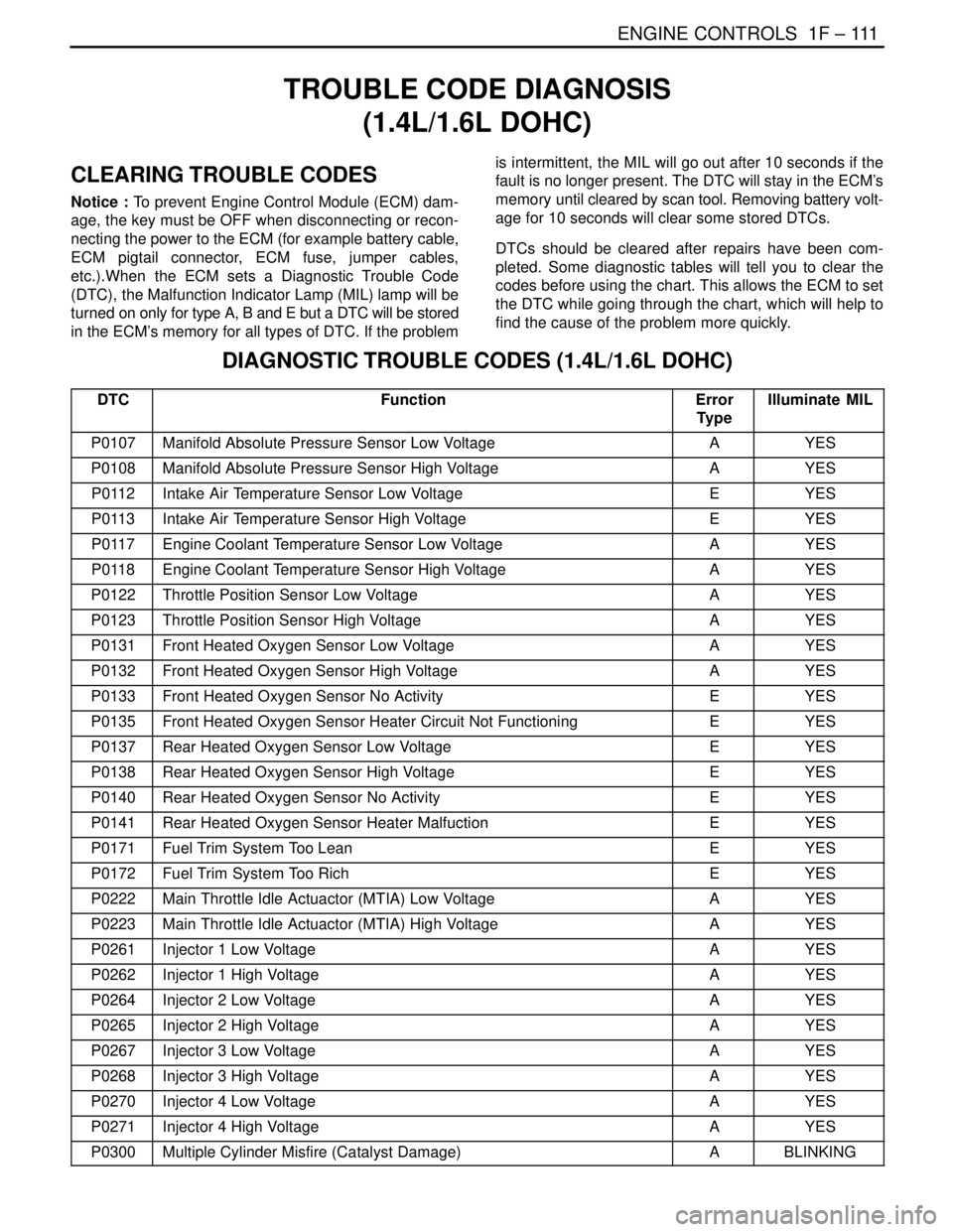

DIAGNOSTIC TROUBLE CODES (1.4L/1.6L DOHC)

DTCFunctionError

TypeIlluminate MIL

P0107Manifold Absolute Pressure Sensor Low VoltageAYES

P0108Manifold Absolute Pressure Sensor High VoltageAYES

P0112Intake Air Temperature Sensor Low VoltageEYES

P0113Intake Air Temperature Sensor High VoltageEYES

P0117Engine Coolant Temperature Sensor Low VoltageAYES

P0118Engine Coolant Temperature Sensor High VoltageAYES

P0122Throttle Position Sensor Low VoltageAYES

P0123Throttle Position Sensor High VoltageAYES

P0131Front Heated Oxygen Sensor Low VoltageAYES

P0132Front Heated Oxygen Sensor High VoltageAYES

P0133Front Heated Oxygen Sensor No ActivityEYES

P0135Front Heated Oxygen Sensor Heater Circuit Not FunctioningEYES

P0137Rear Heated Oxygen Sensor Low VoltageEYES

P0138Rear Heated Oxygen Sensor High VoltageEYES

P0140Rear Heated Oxygen Sensor No ActivityEYES

P0141Rear Heated Oxygen Sensor Heater MalfuctionEYES

P0171Fuel Trim System Too LeanEYES

P0172Fuel Trim System Too RichEYES

P0222Main Throttle Idle Actuactor (MTIA) Low VoltageAYES

P0223Main Throttle Idle Actuactor (MTIA) High VoltageAYES

P0261Injector 1 Low VoltageAYES

P0262Injector 1 High VoltageAYES

P0264Injector 2 Low VoltageAYES

P0265Injector 2 High VoltageAYES

P0267Injector 3 Low VoltageAYES

P0268Injector 3 High VoltageAYES

P0270Injector 4 Low VoltageAYES

P0271Injector 4 High VoltageAYES

P0300Multiple Cylinder Misfire (Catalyst Damage)ABLINKING

Page 360 of 2643

1F – 114IENGINE CONTROLS

DAEWOO V–121 BL4

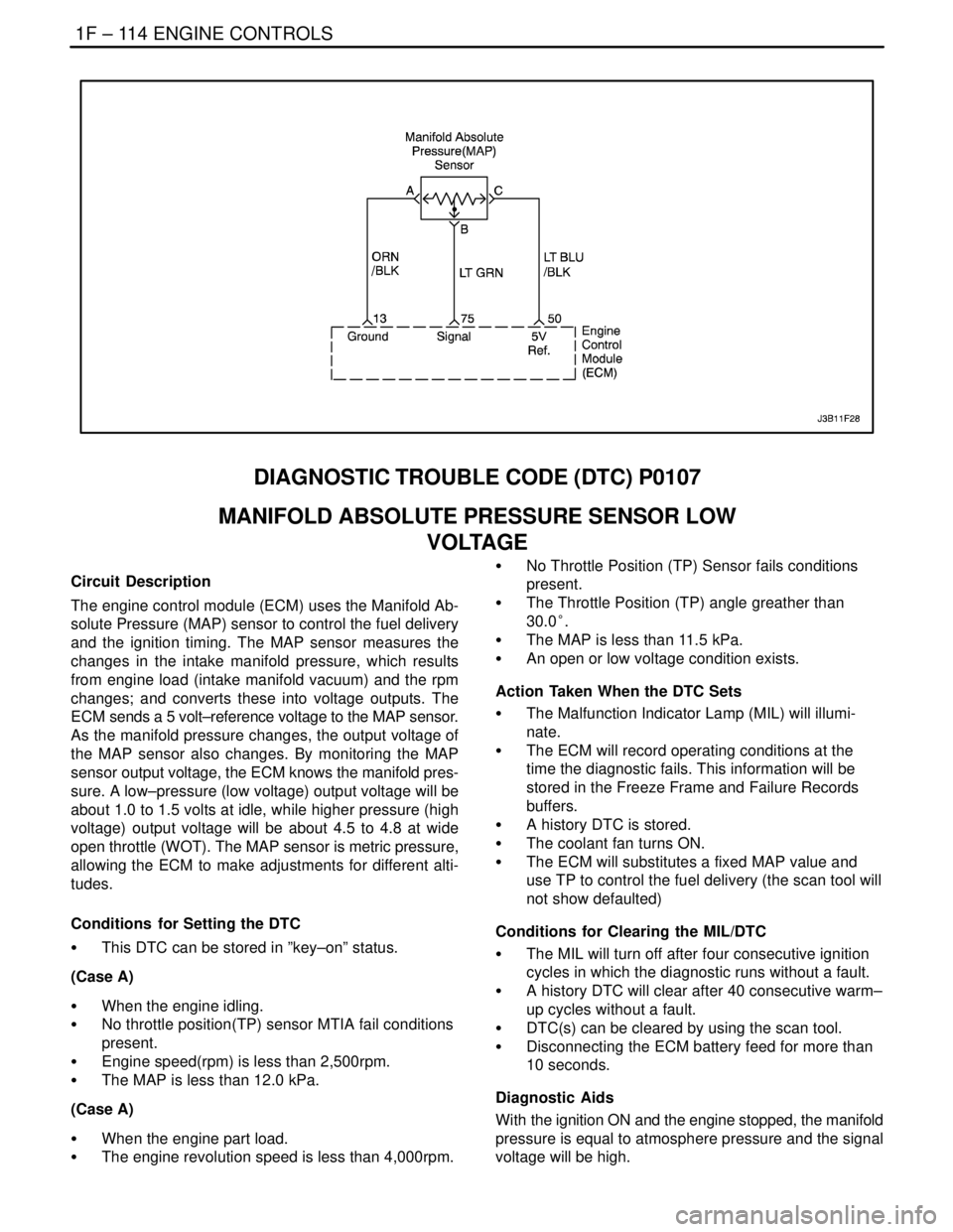

DIAGNOSTIC TROUBLE CODE (DTC) P0107

MANIFOLD ABSOLUTE PRESSURE SENSOR LOW

VOLTAGE

Circuit Description

The engine control module (ECM) uses the Manifold Ab-

solute Pressure (MAP) sensor to control the fuel delivery

and the ignition timing. The MAP sensor measures the

changes in the intake manifold pressure, which results

from engine load (intake manifold vacuum) and the rpm

changes; and converts these into voltage outputs. The

ECM sends a 5 volt–reference voltage to the MAP sensor.

As the manifold pressure changes, the output voltage of

the MAP sensor also changes. By monitoring the MAP

sensor output voltage, the ECM knows the manifold pres-

sure. A low–pressure (low voltage) output voltage will be

about 1.0 to 1.5 volts at idle, while higher pressure (high

voltage) output voltage will be about 4.5 to 4.8 at wide

open throttle (WOT). The MAP sensor is metric pressure,

allowing the ECM to make adjustments for different alti-

tudes.

Conditions for Setting the DTC

S This DTC can be stored in ”key–on” status.

(Case A)

S When the engine idling.

S No throttle position(TP) sensor MTIA fail conditions

present.

S Engine speed(rpm) is less than 2,500rpm.

S The MAP is less than 12.0 kPa.

(Case A)

S When the engine part load.

S The engine revolution speed is less than 4,000rpm.S No Throttle Position (TP) Sensor fails conditions

present.

S The Throttle Position (TP) angle greather than

30.0°.

S The MAP is less than 11.5 kPa.

S An open or low voltage condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S The coolant fan turns ON.

S The ECM will substitutes a fixed MAP value and

use TP to control the fuel delivery (the scan tool will

not show defaulted)

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

With the ignition ON and the engine stopped, the manifold

pressure is equal to atmosphere pressure and the signal

voltage will be high.

Page 363 of 2643

ENGINE CONTROLS 1F – 117

DAEWOO V–121 BL4

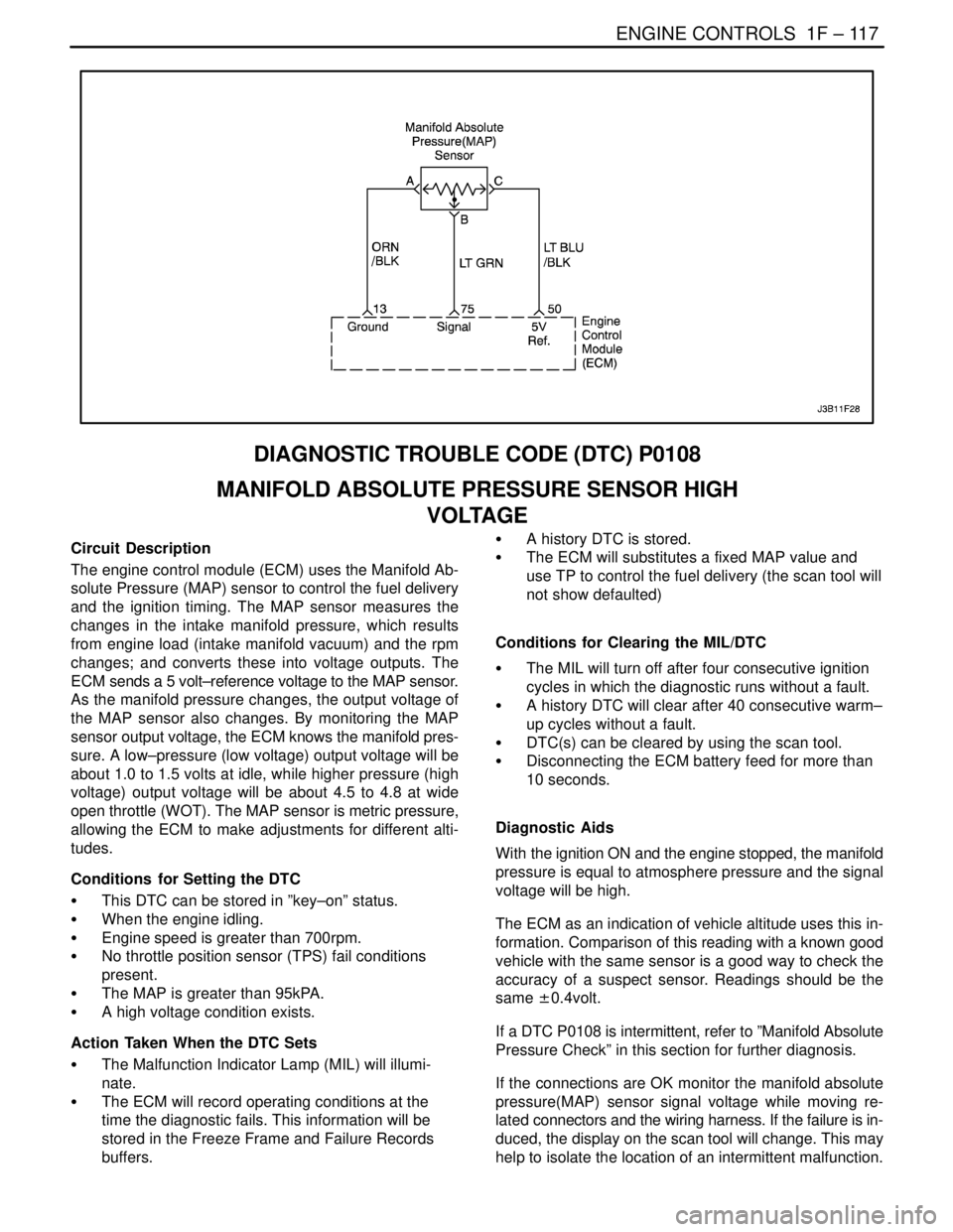

DIAGNOSTIC TROUBLE CODE (DTC) P0108

MANIFOLD ABSOLUTE PRESSURE SENSOR HIGH

VOLTAGE

Circuit Description

The engine control module (ECM) uses the Manifold Ab-

solute Pressure (MAP) sensor to control the fuel delivery

and the ignition timing. The MAP sensor measures the

changes in the intake manifold pressure, which results

from engine load (intake manifold vacuum) and the rpm

changes; and converts these into voltage outputs. The

ECM sends a 5 volt–reference voltage to the MAP sensor.

As the manifold pressure changes, the output voltage of

the MAP sensor also changes. By monitoring the MAP

sensor output voltage, the ECM knows the manifold pres-

sure. A low–pressure (low voltage) output voltage will be

about 1.0 to 1.5 volts at idle, while higher pressure (high

voltage) output voltage will be about 4.5 to 4.8 at wide

open throttle (WOT). The MAP sensor is metric pressure,

allowing the ECM to make adjustments for different alti-

tudes.

Conditions for Setting the DTC

S This DTC can be stored in ”key–on” status.

S When the engine idling.

S Engine speed is greater than 700rpm.

S No throttle position sensor (TPS) fail conditions

present.

S The MAP is greater than 95kPA.

S A high voltage condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

S The ECM will substitutes a fixed MAP value and

use TP to control the fuel delivery (the scan tool will

not show defaulted)

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

With the ignition ON and the engine stopped, the manifold

pressure is equal to atmosphere pressure and the signal

voltage will be high.

The ECM as an indication of vehicle altitude uses this in-

formation. Comparison of this reading with a known good

vehicle with the same sensor is a good way to check the

accuracy of a suspect sensor. Readings should be the

same ±0.4volt.

If a DTC P0108 is intermittent, refer to ”Manifold Absolute

Pressure Check” in this section for further diagnosis.

If the connections are OK monitor the manifold absolute

pressure(MAP) sensor signal voltage while moving re-

lated connectors and the wiring harness. If the failure is in-

duced, the display on the scan tool will change. This may

help to isolate the location of an intermittent malfunction.

Page 450 of 2643

1F – 204IENGINE CONTROLS

DAEWOO V–121 BL4

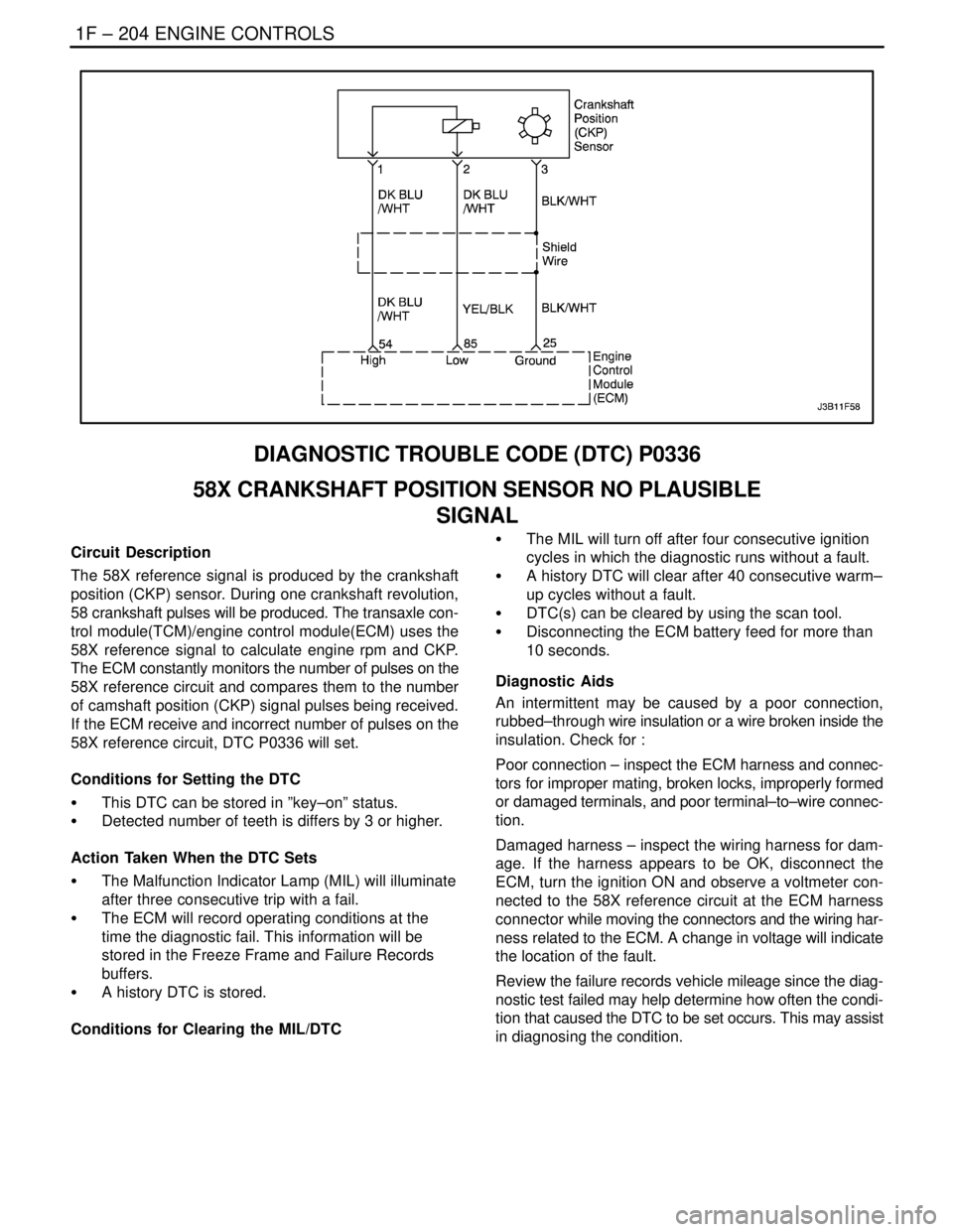

DIAGNOSTIC TROUBLE CODE (DTC) P0336

58X CRANKSHAFT POSITION SENSOR NO PLAUSIBLE

SIGNAL

Circuit Description

The 58X reference signal is produced by the crankshaft

position (CKP) sensor. During one crankshaft revolution,

58 crankshaft pulses will be produced. The transaxle con-

trol module(TCM)/engine control module(ECM) uses the

58X reference signal to calculate engine rpm and CKP.

The ECM constantly monitors the number of pulses on the

58X reference circuit and compares them to the number

of camshaft position (CKP) signal pulses being received.

If the ECM receive and incorrect number of pulses on the

58X reference circuit, DTC P0336 will set.

Conditions for Setting the DTC

S This DTC can be stored in ”key–on” status.

S Detected number of teeth is differs by 3 or higher.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTCS The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed–through wire insulation or a wire broken inside the

insulation. Check for :

Poor connection – inspect the ECM harness and connec-

tors for improper mating, broken locks, improperly formed

or damaged terminals, and poor terminal–to–wire connec-

tion.

Damaged harness – inspect the wiring harness for dam-

age. If the harness appears to be OK, disconnect the

ECM, turn the ignition ON and observe a voltmeter con-

nected to the 58X reference circuit at the ECM harness

connector while moving the connectors and the wiring har-

ness related to the ECM. A change in voltage will indicate

the location of the fault.

Review the failure records vehicle mileage since the diag-

nostic test failed may help determine how often the condi-

tion that caused the DTC to be set occurs. This may assist

in diagnosing the condition.

Page 453 of 2643

ENGINE CONTROLS 1F – 207

DAEWOO V–121 BL4

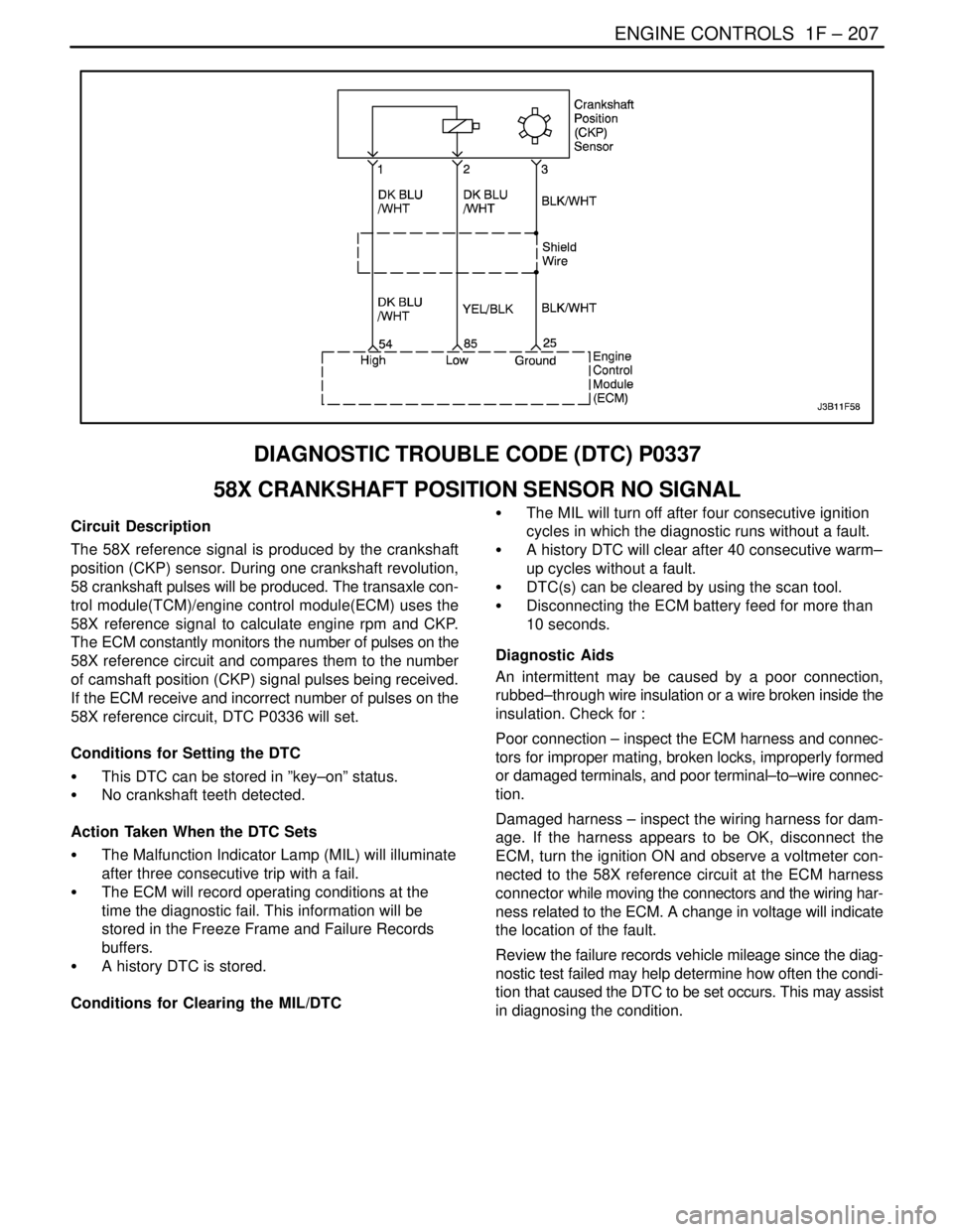

DIAGNOSTIC TROUBLE CODE (DTC) P0337

58X CRANKSHAFT POSITION SENSOR NO SIGNAL

Circuit Description

The 58X reference signal is produced by the crankshaft

position (CKP) sensor. During one crankshaft revolution,

58 crankshaft pulses will be produced. The transaxle con-

trol module(TCM)/engine control module(ECM) uses the

58X reference signal to calculate engine rpm and CKP.

The ECM constantly monitors the number of pulses on the

58X reference circuit and compares them to the number

of camshaft position (CKP) signal pulses being received.

If the ECM receive and incorrect number of pulses on the

58X reference circuit, DTC P0336 will set.

Conditions for Setting the DTC

S This DTC can be stored in ”key–on” status.

S No crankshaft teeth detected.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTCS The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed–through wire insulation or a wire broken inside the

insulation. Check for :

Poor connection – inspect the ECM harness and connec-

tors for improper mating, broken locks, improperly formed

or damaged terminals, and poor terminal–to–wire connec-

tion.

Damaged harness – inspect the wiring harness for dam-

age. If the harness appears to be OK, disconnect the

ECM, turn the ignition ON and observe a voltmeter con-

nected to the 58X reference circuit at the ECM harness

connector while moving the connectors and the wiring har-

ness related to the ECM. A change in voltage will indicate

the location of the fault.

Review the failure records vehicle mileage since the diag-

nostic test failed may help determine how often the condi-

tion that caused the DTC to be set occurs. This may assist

in diagnosing the condition.

Page 529 of 2643

ENGINE CONTROLS 1F – 283

DAEWOO V–121 BL4

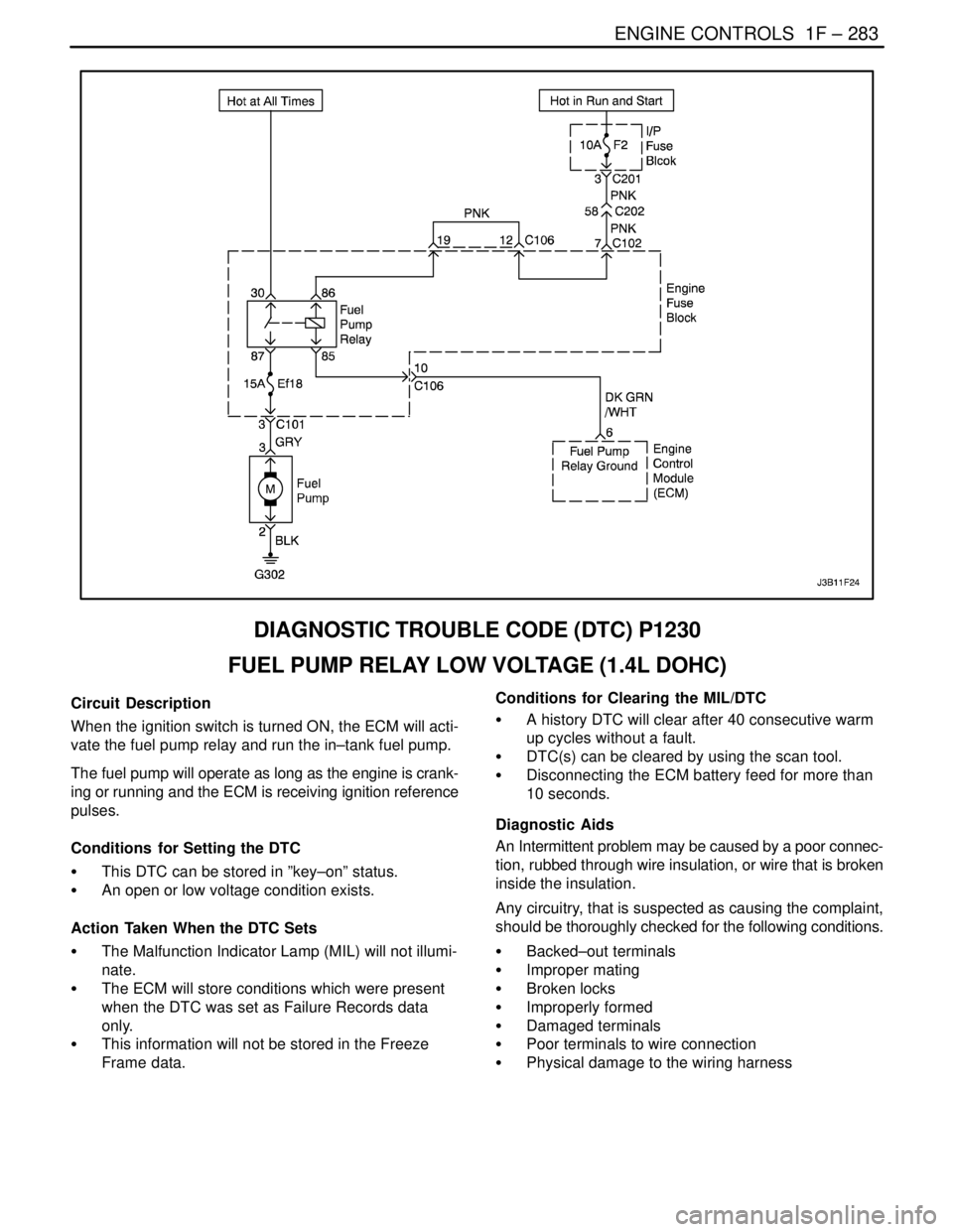

DIAGNOSTIC TROUBLE CODE (DTC) P1230

FUEL PUMP RELAY LOW VOLTAGE (1.4L DOHC)

Circuit Description

When the ignition switch is turned ON, the ECM will acti-

vate the fuel pump relay and run the in–tank fuel pump.

The fuel pump will operate as long as the engine is crank-

ing or running and the ECM is receiving ignition reference

pulses.

Conditions for Setting the DTC

S This DTC can be stored in ”key–on” status.

S An open or low voltage condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC was set as Failure Records data

only.

S This information will not be stored in the Freeze

Frame data.Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An Intermittent problem may be caused by a poor connec-

tion, rubbed through wire insulation, or wire that is broken

inside the insulation.

Any circuitry, that is suspected as causing the complaint,

should be thoroughly checked for the following conditions.

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminals to wire connection

S Physical damage to the wiring harness

Page 530 of 2643

1F – 284IENGINE CONTROLS

DAEWOO V–121 BL4

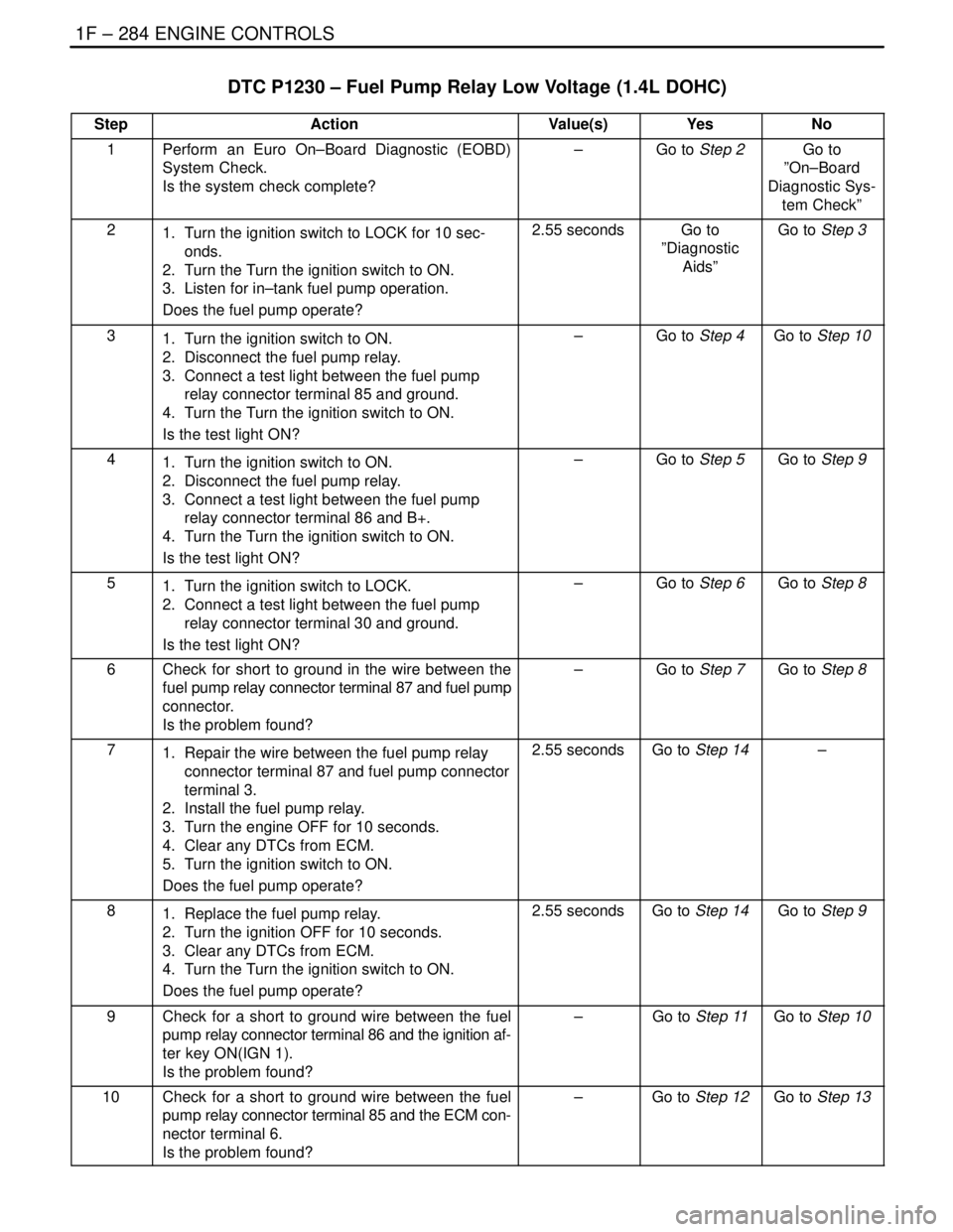

DTC P1230 – Fuel Pump Relay Low Voltage (1.4L DOHC)

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch to LOCK for 10 sec-

onds.

2. Turn the Turn the ignition switch to ON.

3. Listen for in–tank fuel pump operation.

Does the fuel pump operate?2.55 secondsGo to

”Diagnostic

Aids”Go to Step 3

31. Turn the ignition switch to ON.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 85 and ground.

4. Turn the Turn the ignition switch to ON.

Is the test light ON?–Go to Step 4Go to Step 10

41. Turn the ignition switch to ON.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 86 and B+.

4. Turn the Turn the ignition switch to ON.

Is the test light ON?–Go to Step 5Go to Step 9

51. Turn the ignition switch to LOCK.

2. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Is the test light ON?–Go to Step 6Go to Step 8

6Check for short to ground in the wire between the

fuel pump relay connector terminal 87 and fuel pump

connector.

Is the problem found?–Go to Step 7Go to Step 8

71. Repair the wire between the fuel pump relay

connector terminal 87 and fuel pump connector

terminal 3.

2. Install the fuel pump relay.

3. Turn the engine OFF for 10 seconds.

4. Clear any DTCs from ECM.

5. Turn the ignition switch to ON.

Does the fuel pump operate?2.55 secondsGo to Step 14–

81. Replace the fuel pump relay.

2. Turn the ignition OFF for 10 seconds.

3. Clear any DTCs from ECM.

4. Turn the Turn the ignition switch to ON.

Does the fuel pump operate?2.55 secondsGo to Step 14Go to Step 9

9Check for a short to ground wire between the fuel

pump relay connector terminal 86 and the ignition af-

ter key ON(IGN 1).

Is the problem found?–Go to Step 11Go to Step 10

10Check for a short to ground wire between the fuel

pump relay connector terminal 85 and the ECM con-

nector terminal 6.

Is the problem found?–Go to Step 12Go to Step 13

Page 531 of 2643

ENGINE CONTROLS 1F – 285

DAEWOO V–121 BL4

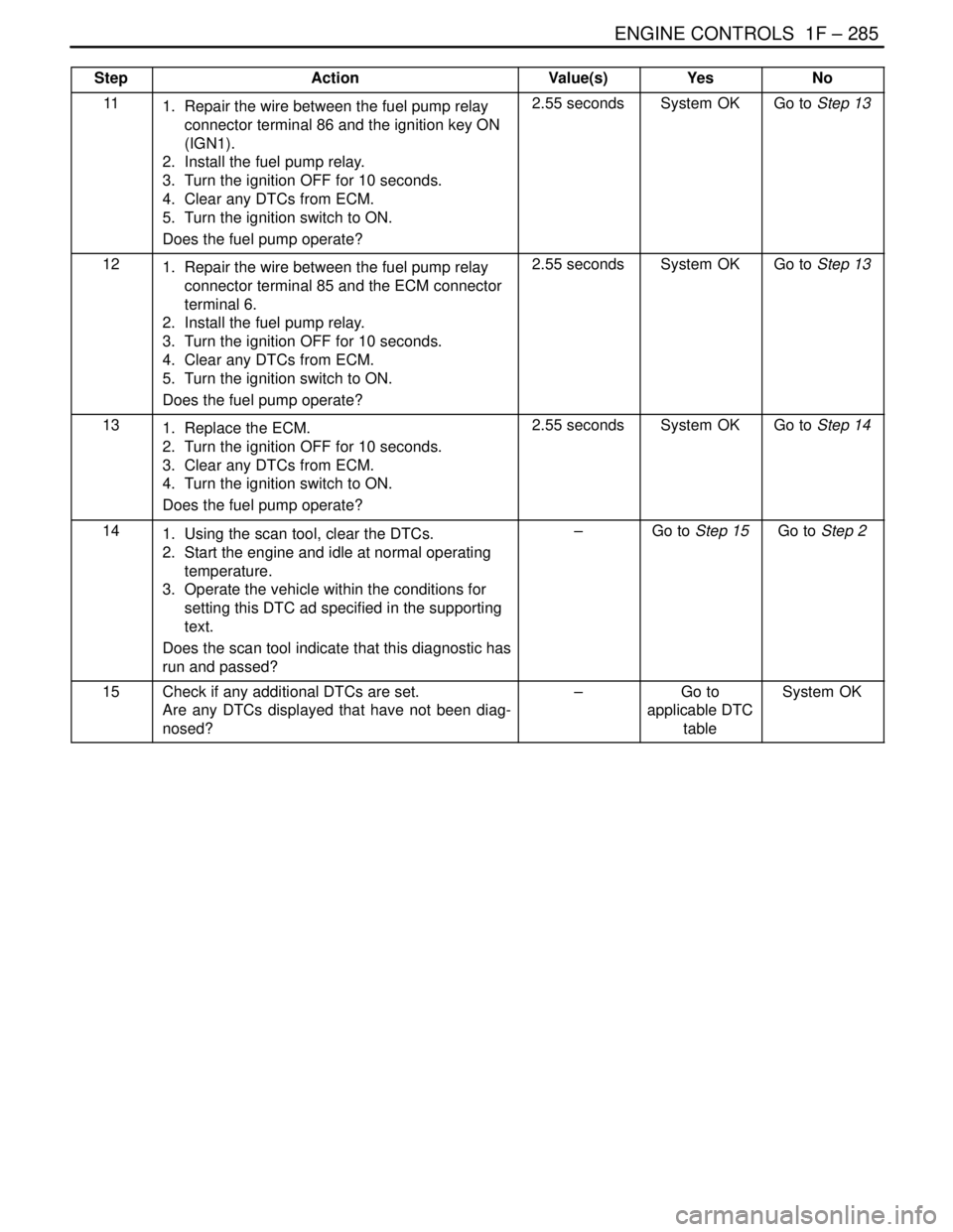

StepNo Yes Value(s) Action

111. Repair the wire between the fuel pump relay

connector terminal 86 and the ignition key ON

(IGN1).

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Clear any DTCs from ECM.

5. Turn the ignition switch to ON.

Does the fuel pump operate?2.55 secondsSystem OKGo to Step 13

121. Repair the wire between the fuel pump relay

connector terminal 85 and the ECM connector

terminal 6.

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Clear any DTCs from ECM.

5. Turn the ignition switch to ON.

Does the fuel pump operate?2.55 secondsSystem OKGo to Step 13

131. Replace the ECM.

2. Turn the ignition OFF for 10 seconds.

3. Clear any DTCs from ECM.

4. Turn the ignition switch to ON.

Does the fuel pump operate?2.55 secondsSystem OKGo to Step 14

141. Using the scan tool, clear the DTCs.

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting this DTC ad specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 15Go to Step 2

15Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

applicable DTC

tableSystem OK

Page 532 of 2643

1F – 286IENGINE CONTROLS

DAEWOO V–121 BL4

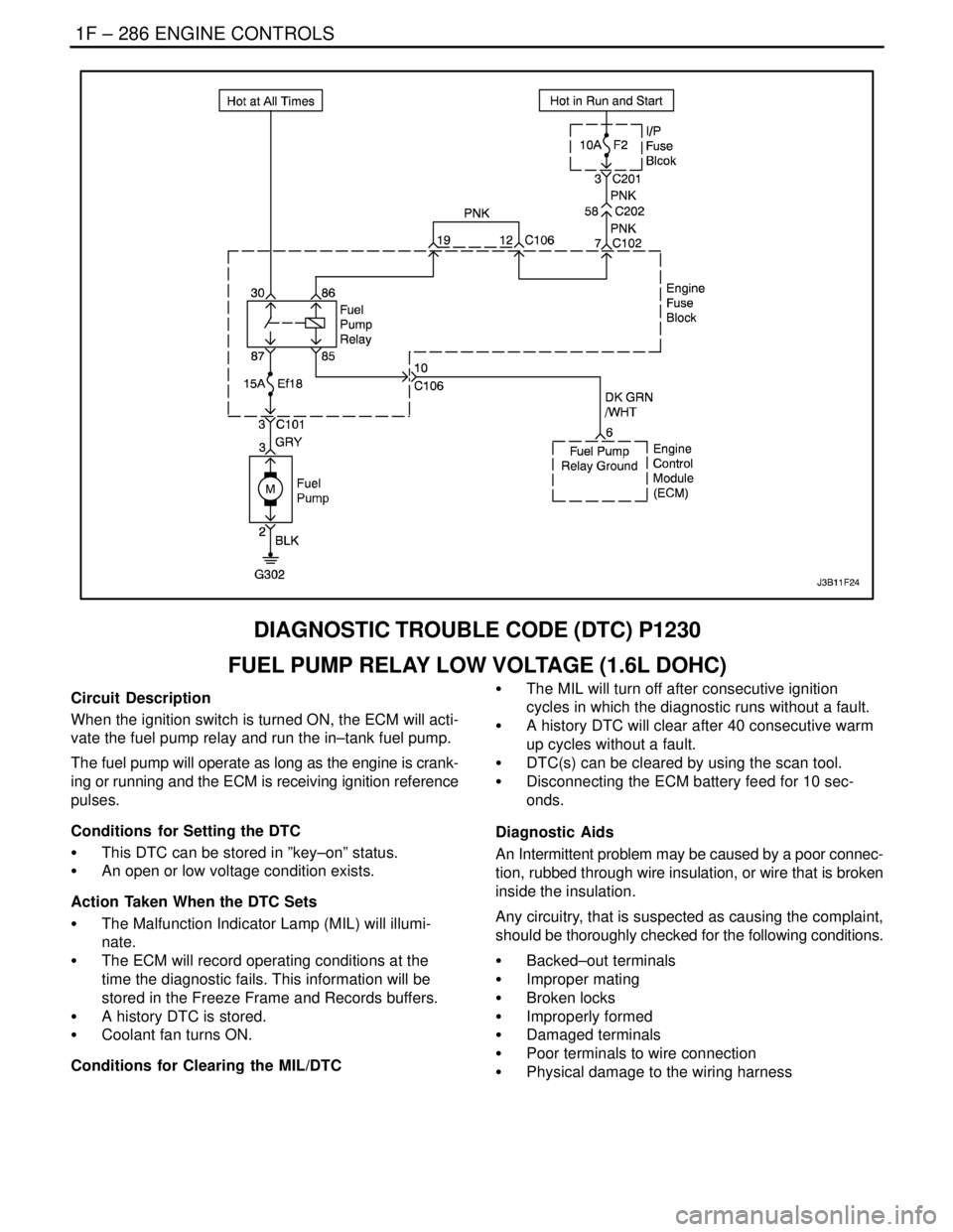

DIAGNOSTIC TROUBLE CODE (DTC) P1230

FUEL PUMP RELAY LOW VOLTAGE (1.6L DOHC)

Circuit Description

When the ignition switch is turned ON, the ECM will acti-

vate the fuel pump relay and run the in–tank fuel pump.

The fuel pump will operate as long as the engine is crank-

ing or running and the ECM is receiving ignition reference

pulses.

Conditions for Setting the DTC

S This DTC can be stored in ”key–on” status.

S An open or low voltage condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Records buffers.

S A history DTC is stored.

S Coolant fan turns ON.

Conditions for Clearing the MIL/DTCS The MIL will turn off after consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An Intermittent problem may be caused by a poor connec-

tion, rubbed through wire insulation, or wire that is broken

inside the insulation.

Any circuitry, that is suspected as causing the complaint,

should be thoroughly checked for the following conditions.

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminals to wire connection

S Physical damage to the wiring harness

Page 533 of 2643

ENGINE CONTROLS 1F – 287

DAEWOO V–121 BL4

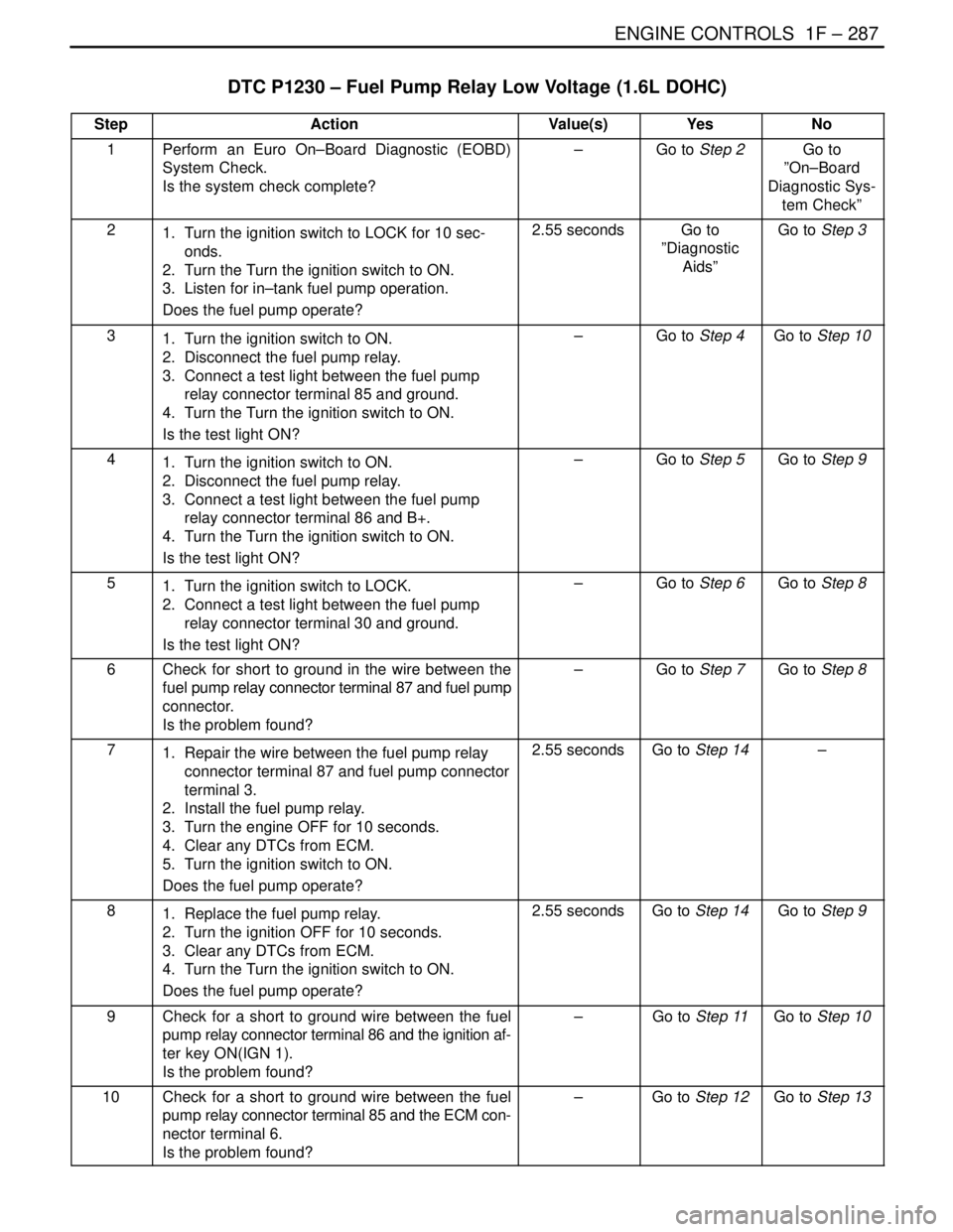

DTC P1230 – Fuel Pump Relay Low Voltage (1.6L DOHC)

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch to LOCK for 10 sec-

onds.

2. Turn the Turn the ignition switch to ON.

3. Listen for in–tank fuel pump operation.

Does the fuel pump operate?2.55 secondsGo to

”Diagnostic

Aids”Go to Step 3

31. Turn the ignition switch to ON.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 85 and ground.

4. Turn the Turn the ignition switch to ON.

Is the test light ON?–Go to Step 4Go to Step 10

41. Turn the ignition switch to ON.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 86 and B+.

4. Turn the Turn the ignition switch to ON.

Is the test light ON?–Go to Step 5Go to Step 9

51. Turn the ignition switch to LOCK.

2. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Is the test light ON?–Go to Step 6Go to Step 8

6Check for short to ground in the wire between the

fuel pump relay connector terminal 87 and fuel pump

connector.

Is the problem found?–Go to Step 7Go to Step 8

71. Repair the wire between the fuel pump relay

connector terminal 87 and fuel pump connector

terminal 3.

2. Install the fuel pump relay.

3. Turn the engine OFF for 10 seconds.

4. Clear any DTCs from ECM.

5. Turn the ignition switch to ON.

Does the fuel pump operate?2.55 secondsGo to Step 14–

81. Replace the fuel pump relay.

2. Turn the ignition OFF for 10 seconds.

3. Clear any DTCs from ECM.

4. Turn the Turn the ignition switch to ON.

Does the fuel pump operate?2.55 secondsGo to Step 14Go to Step 9

9Check for a short to ground wire between the fuel

pump relay connector terminal 86 and the ignition af-

ter key ON(IGN 1).

Is the problem found?–Go to Step 11Go to Step 10

10Check for a short to ground wire between the fuel

pump relay connector terminal 85 and the ECM con-

nector terminal 6.

Is the problem found?–Go to Step 12Go to Step 13