battery DAEWOO LACETTI 2004 Service Manual PDF

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 297 of 2643

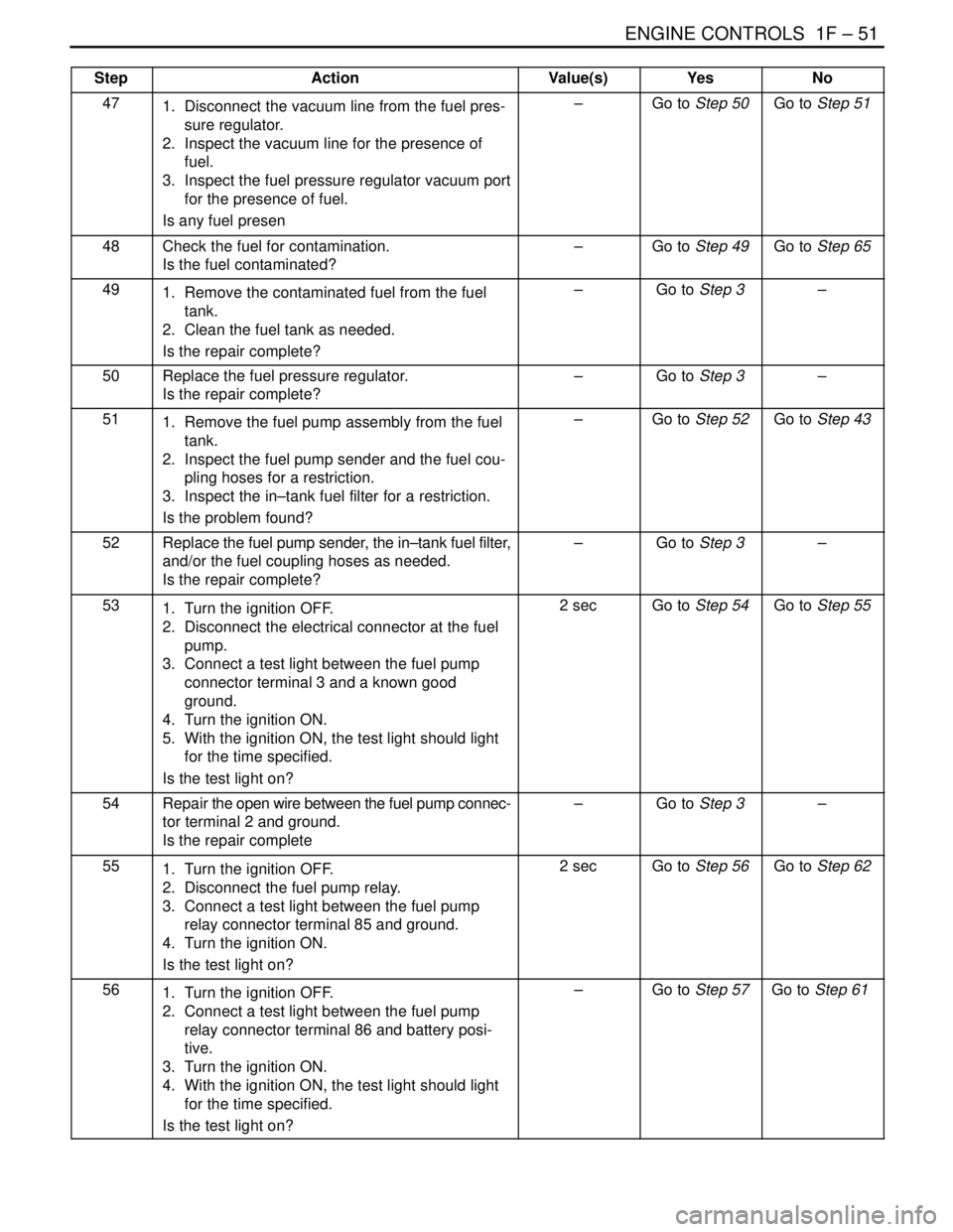

ENGINE CONTROLS 1F – 51

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

471. Disconnect the vacuum line from the fuel pres-

sure regulator.

2. Inspect the vacuum line for the presence of

fuel.

3. Inspect the fuel pressure regulator vacuum port

for the presence of fuel.

Is any fuel presen–Go to Step 50Go to Step 51

48Check the fuel for contamination.

Is the fuel contaminated?–Go to Step 49Go to Step 65

491. Remove the contaminated fuel from the fuel

tank.

2. Clean the fuel tank as needed.

Is the repair complete?–Go to Step 3–

50Replace the fuel pressure regulator.

Is the repair complete?–Go to Step 3–

511. Remove the fuel pump assembly from the fuel

tank.

2. Inspect the fuel pump sender and the fuel cou-

pling hoses for a restriction.

3. Inspect the in–tank fuel filter for a restriction.

Is the problem found?–Go to Step 52Go to Step 43

52Replace the fuel pump sender, the in–tank fuel filter,

and/or the fuel coupling hoses as needed.

Is the repair complete?–Go to Step 3–

531. Turn the ignition OFF.

2. Disconnect the electrical connector at the fuel

pump.

3. Connect a test light between the fuel pump

connector terminal 3 and a known good

ground.

4. Turn the ignition ON.

5. With the ignition ON, the test light should light

for the time specified.

Is the test light on?2 secGo to Step 54Go to Step 55

54Repair the open wire between the fuel pump connec-

tor terminal 2 and ground.

Is the repair complete–Go to Step 3–

551. Turn the ignition OFF.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 85 and ground.

4. Turn the ignition ON.

Is the test light on?2 secGo to Step 56Go to Step 62

561. Turn the ignition OFF.

2. Connect a test light between the fuel pump

relay connector terminal 86 and battery posi-

tive.

3. Turn the ignition ON.

4. With the ignition ON, the test light should light

for the time specified.

Is the test light on?–Go to Step 57Go to Step 61

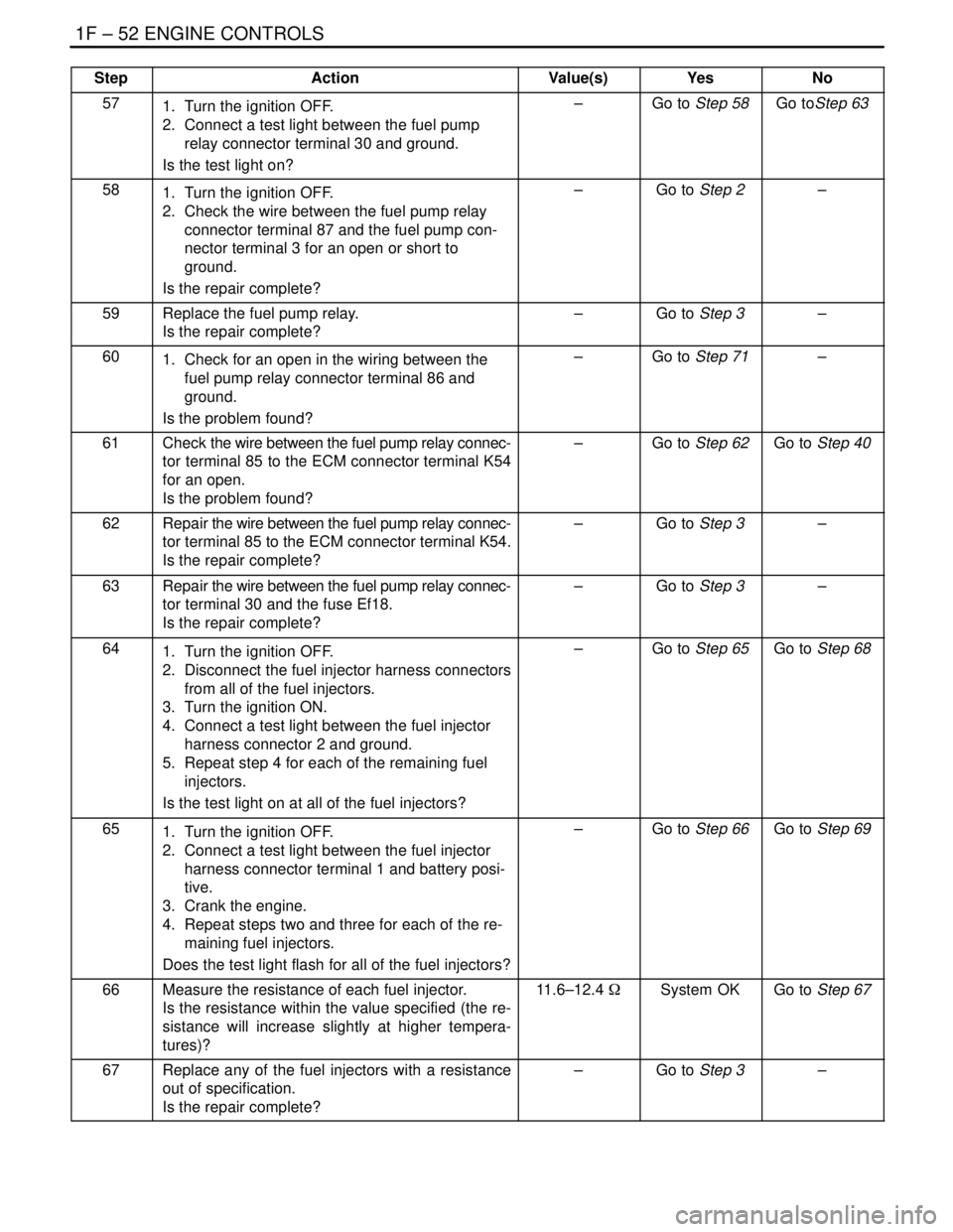

Page 298 of 2643

1F – 52IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

571. Turn the ignition OFF.

2. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Is the test light on?–Go to Step 58Go toStep 63

581. Turn the ignition OFF.

2. Check the wire between the fuel pump relay

connector terminal 87 and the fuel pump con-

nector terminal 3 for an open or short to

ground.

Is the repair complete?–Go to Step 2–

59Replace the fuel pump relay.

Is the repair complete?–Go to Step 3–

601. Check for an open in the wiring between the

fuel pump relay connector terminal 86 and

ground.

Is the problem found?–Go to Step 71–

61Check the wire between the fuel pump relay connec-

tor terminal 85 to the ECM connector terminal K54

for an open.

Is the problem found?–Go to Step 62Go to Step 40

62Repair the wire between the fuel pump relay connec-

tor terminal 85 to the ECM connector terminal K54.

Is the repair complete?–Go to Step 3–

63Repair the wire between the fuel pump relay connec-

tor terminal 30 and the fuse Ef18.

Is the repair complete?–Go to Step 3–

641. Turn the ignition OFF.

2. Disconnect the fuel injector harness connectors

from all of the fuel injectors.

3. Turn the ignition ON.

4. Connect a test light between the fuel injector

harness connector 2 and ground.

5. Repeat step 4 for each of the remaining fuel

injectors.

Is the test light on at all of the fuel injectors?–Go to Step 65Go to Step 68

651. Turn the ignition OFF.

2. Connect a test light between the fuel injector

harness connector terminal 1 and battery posi-

tive.

3. Crank the engine.

4. Repeat steps two and three for each of the re-

maining fuel injectors.

Does the test light flash for all of the fuel injectors?–Go to Step 66Go to Step 69

66Measure the resistance of each fuel injector.

Is the resistance within the value specified (the re-

sistance will increase slightly at higher tempera-

tures)?11.6–12.4 WSystem OKGo to Step 67

67Replace any of the fuel injectors with a resistance

out of specification.

Is the repair complete?–Go to Step 3–

Page 300 of 2643

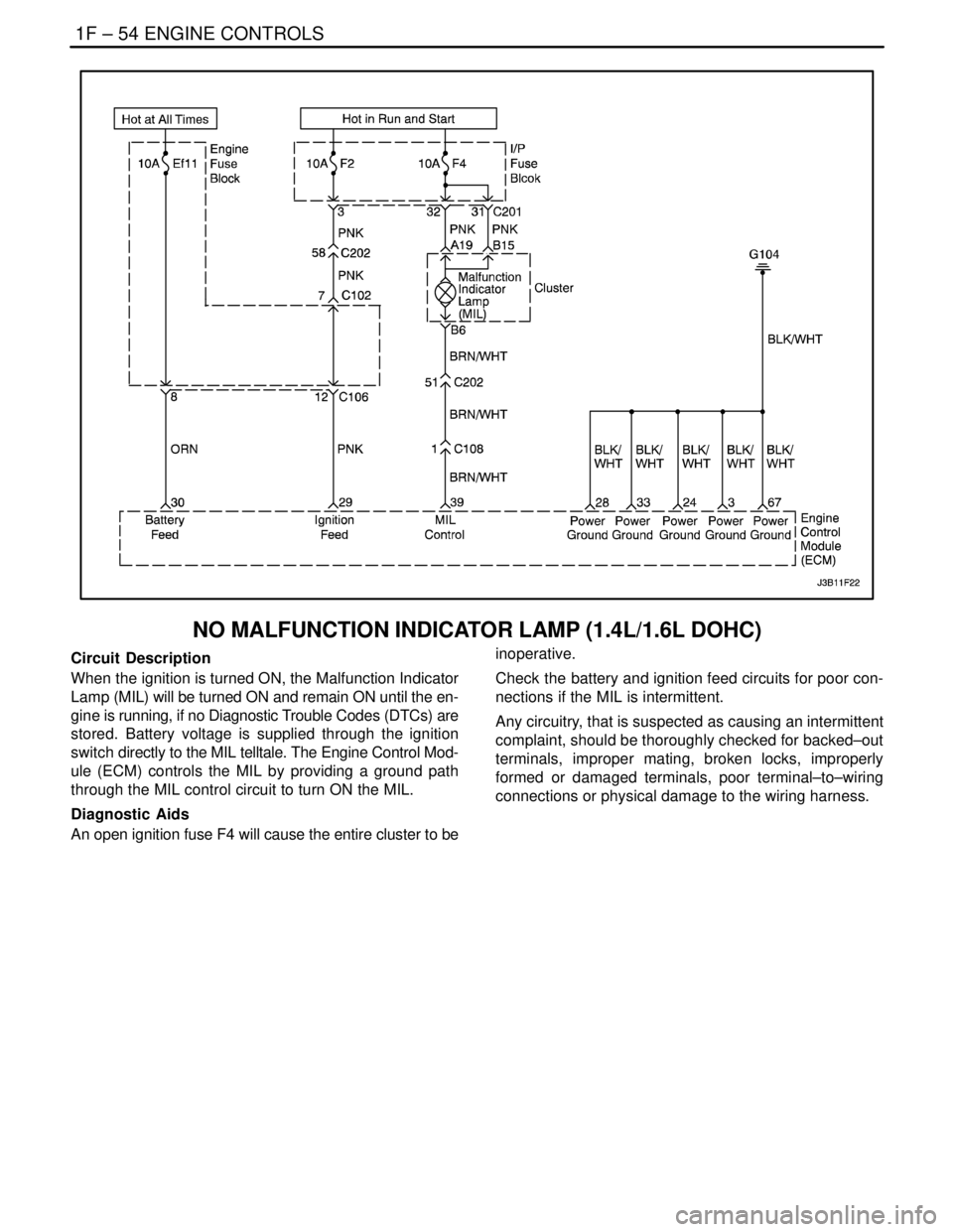

1F – 54IENGINE CONTROLS

DAEWOO V–121 BL4

NO MALFUNCTION INDICATOR LAMP (1.4L/1.6L DOHC)

Circuit Description

When the ignition is turned ON, the Malfunction Indicator

Lamp (MIL) will be turned ON and remain ON until the en-

gine is running, if no Diagnostic Trouble Codes (DTCs) are

stored. Battery voltage is supplied through the ignition

switch directly to the MIL telltale. The Engine Control Mod-

ule (ECM) controls the MIL by providing a ground path

through the MIL control circuit to turn ON the MIL.

Diagnostic Aids

An open ignition fuse F4 will cause the entire cluster to beinoperative.

Check the battery and ignition feed circuits for poor con-

nections if the MIL is intermittent.

Any circuitry, that is suspected as causing an intermittent

complaint, should be thoroughly checked for backed–out

terminals, improper mating, broken locks, improperly

formed or damaged terminals, poor terminal–to–wiring

connections or physical damage to the wiring harness.

Page 302 of 2643

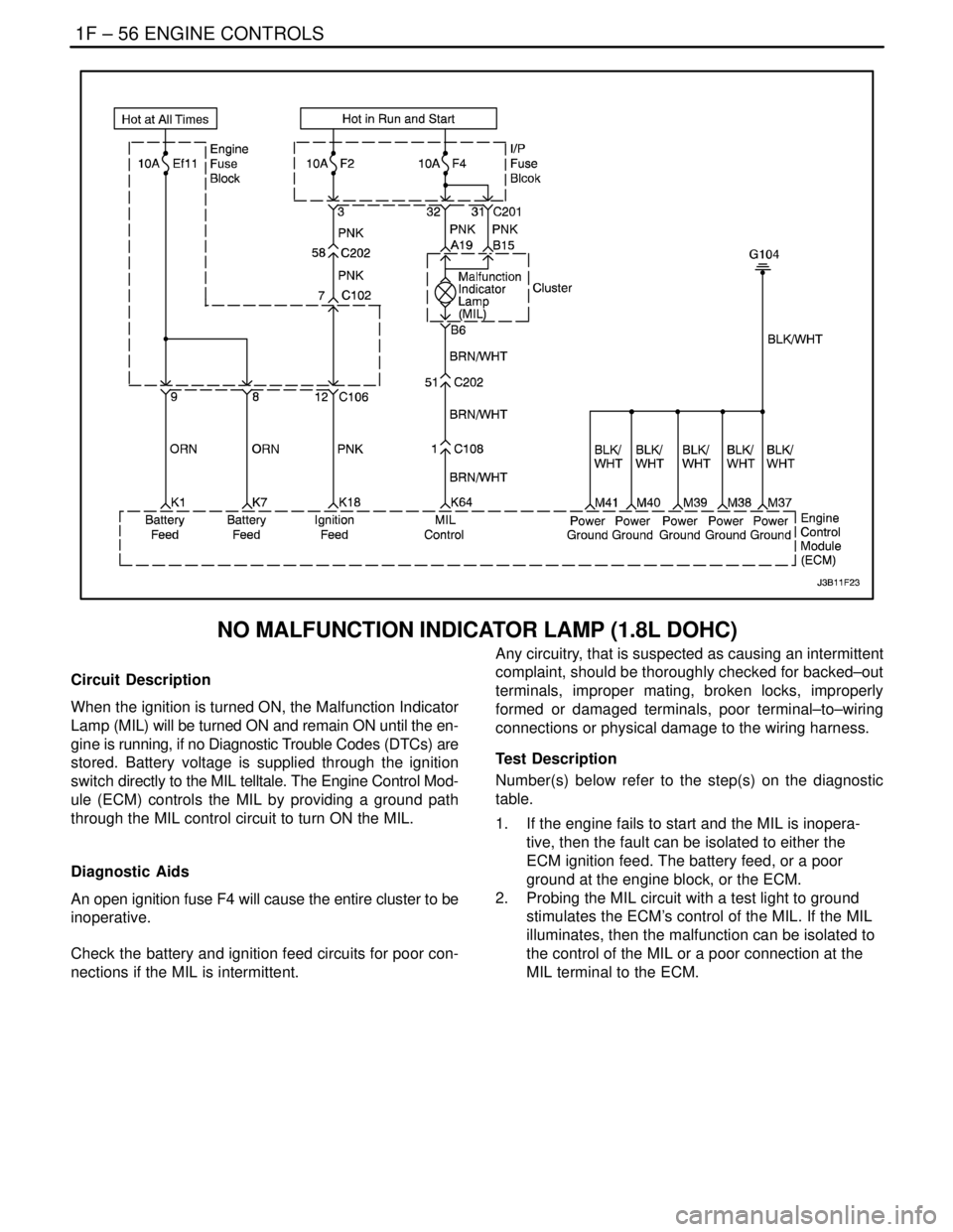

1F – 56IENGINE CONTROLS

DAEWOO V–121 BL4

NO MALFUNCTION INDICATOR LAMP (1.8L DOHC)

Circuit Description

When the ignition is turned ON, the Malfunction Indicator

Lamp (MIL) will be turned ON and remain ON until the en-

gine is running, if no Diagnostic Trouble Codes (DTCs) are

stored. Battery voltage is supplied through the ignition

switch directly to the MIL telltale. The Engine Control Mod-

ule (ECM) controls the MIL by providing a ground path

through the MIL control circuit to turn ON the MIL.

Diagnostic Aids

An open ignition fuse F4 will cause the entire cluster to be

inoperative.

Check the battery and ignition feed circuits for poor con-

nections if the MIL is intermittent.Any circuitry, that is suspected as causing an intermittent

complaint, should be thoroughly checked for backed–out

terminals, improper mating, broken locks, improperly

formed or damaged terminals, poor terminal–to–wiring

connections or physical damage to the wiring harness.

Test Description

Number(s) below refer to the step(s) on the diagnostic

table.

1. If the engine fails to start and the MIL is inopera-

tive, then the fault can be isolated to either the

ECM ignition feed. The battery feed, or a poor

ground at the engine block, or the ECM.

2. Probing the MIL circuit with a test light to ground

stimulates the ECM’s control of the MIL. If the MIL

illuminates, then the malfunction can be isolated to

the control of the MIL or a poor connection at the

MIL terminal to the ECM.

Page 304 of 2643

1F – 58IENGINE CONTROLS

DAEWOO V–121 BL4

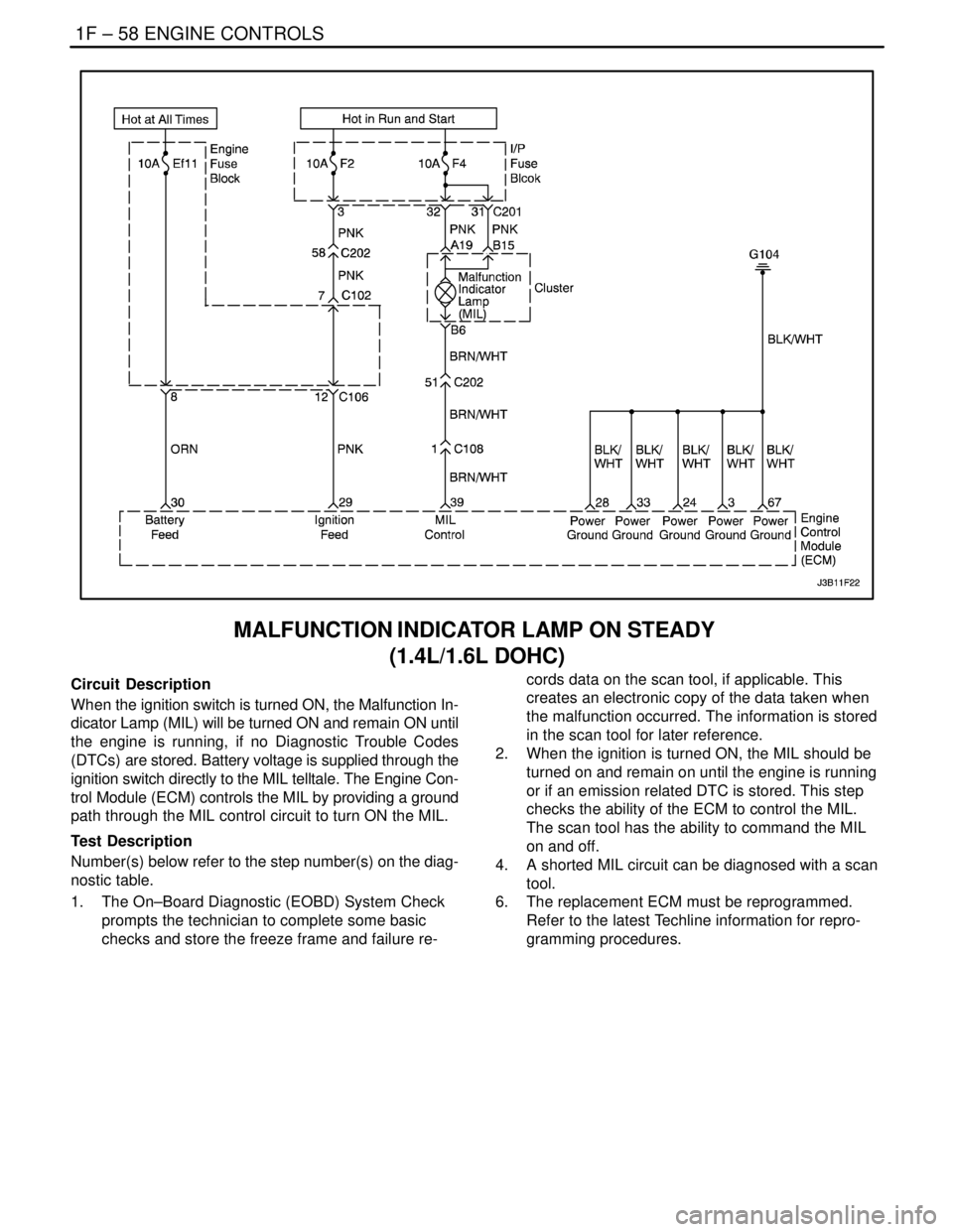

MALFUNCTION INDICATOR LAMP ON STEADY

(1.4L/1.6L DOHC)

Circuit Description

When the ignition switch is turned ON, the Malfunction In-

dicator Lamp (MIL) will be turned ON and remain ON until

the engine is running, if no Diagnostic Trouble Codes

(DTCs) are stored. Battery voltage is supplied through the

ignition switch directly to the MIL telltale. The Engine Con-

trol Module (ECM) controls the MIL by providing a ground

path through the MIL control circuit to turn ON the MIL.

Test Description

Number(s) below refer to the step number(s) on the diag-

nostic table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-cords data on the scan tool, if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is stored

in the scan tool for later reference.

2. When the ignition is turned ON, the MIL should be

turned on and remain on until the engine is running

or if an emission related DTC is stored. This step

checks the ability of the ECM to control the MIL.

The scan tool has the ability to command the MIL

on and off.

4. A shorted MIL circuit can be diagnosed with a scan

tool.

6. The replacement ECM must be reprogrammed.

Refer to the latest Techline information for repro-

gramming procedures.

Page 306 of 2643

1F – 60IENGINE CONTROLS

DAEWOO V–121 BL4

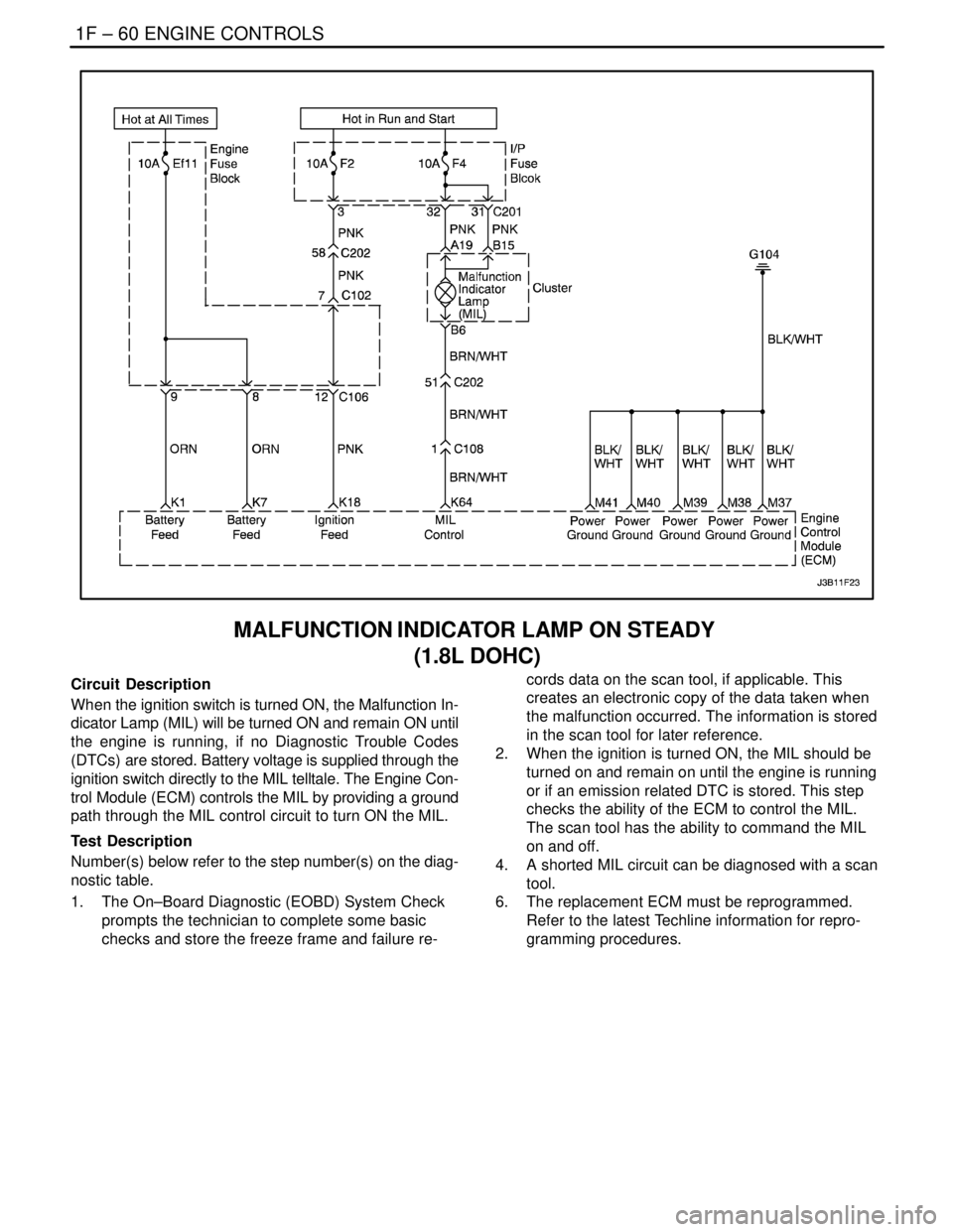

MALFUNCTION INDICATOR LAMP ON STEADY

(1.8L DOHC)

Circuit Description

When the ignition switch is turned ON, the Malfunction In-

dicator Lamp (MIL) will be turned ON and remain ON until

the engine is running, if no Diagnostic Trouble Codes

(DTCs) are stored. Battery voltage is supplied through the

ignition switch directly to the MIL telltale. The Engine Con-

trol Module (ECM) controls the MIL by providing a ground

path through the MIL control circuit to turn ON the MIL.

Test Description

Number(s) below refer to the step number(s) on the diag-

nostic table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-cords data on the scan tool, if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is stored

in the scan tool for later reference.

2. When the ignition is turned ON, the MIL should be

turned on and remain on until the engine is running

or if an emission related DTC is stored. This step

checks the ability of the ECM to control the MIL.

The scan tool has the ability to command the MIL

on and off.

4. A shorted MIL circuit can be diagnosed with a scan

tool.

6. The replacement ECM must be reprogrammed.

Refer to the latest Techline information for repro-

gramming procedures.

Page 311 of 2643

ENGINE CONTROLS 1F – 65

DAEWOO V–121 BL4

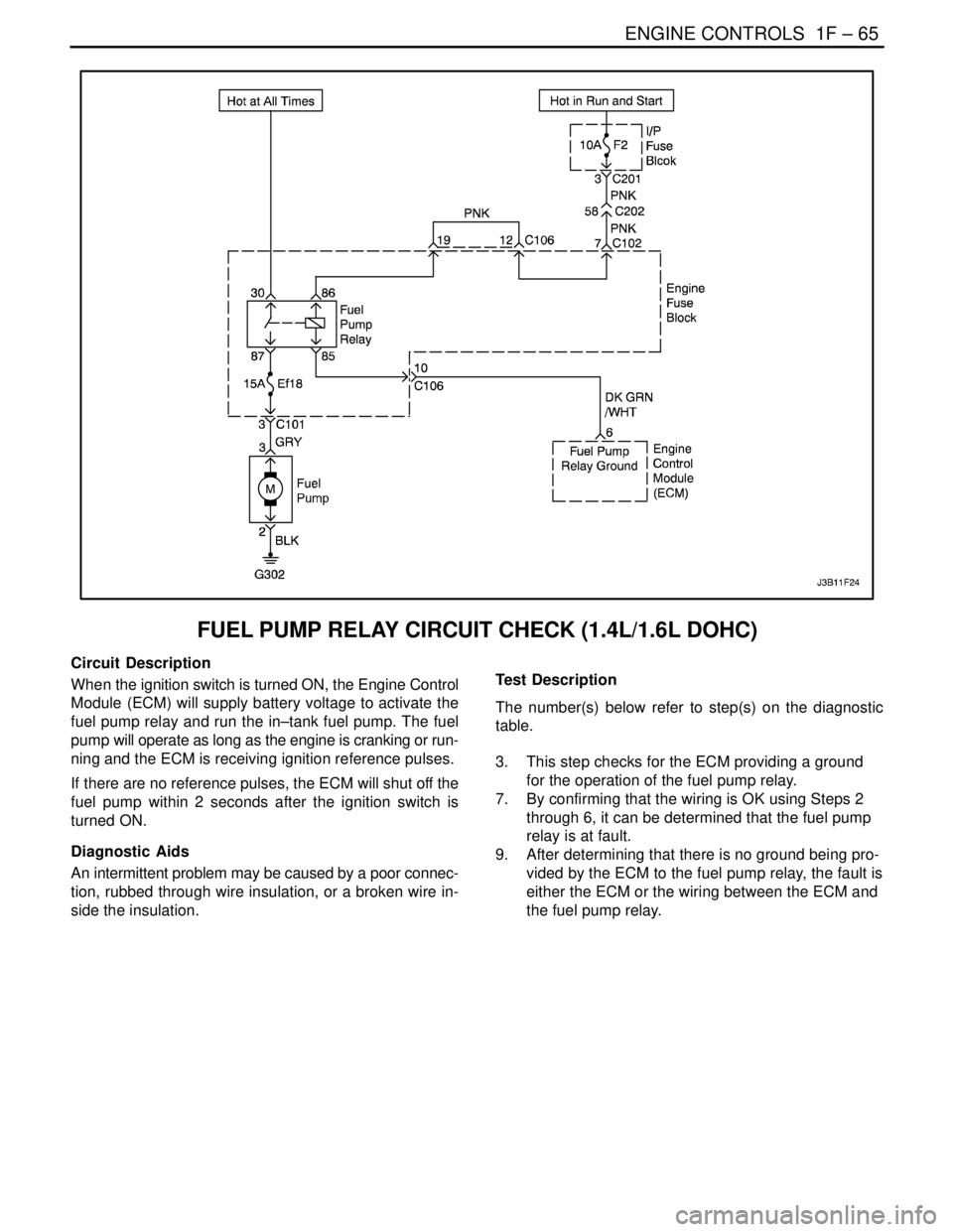

FUEL PUMP RELAY CIRCUIT CHECK (1.4L/1.6L DOHC)

Circuit Description

When the ignition switch is turned ON, the Engine Control

Module (ECM) will supply battery voltage to activate the

fuel pump relay and run the in–tank fuel pump. The fuel

pump will operate as long as the engine is cranking or run-

ning and the ECM is receiving ignition reference pulses.

If there are no reference pulses, the ECM will shut off the

fuel pump within 2 seconds after the ignition switch is

turned ON.

Diagnostic Aids

An intermittent problem may be caused by a poor connec-

tion, rubbed through wire insulation, or a broken wire in-

side the insulation.Test Description

The number(s) below refer to step(s) on the diagnostic

table.

3. This step checks for the ECM providing a ground

for the operation of the fuel pump relay.

7. By confirming that the wiring is OK using Steps 2

through 6, it can be determined that the fuel pump

relay is at fault.

9. After determining that there is no ground being pro-

vided by the ECM to the fuel pump relay, the fault is

either the ECM or the wiring between the ECM and

the fuel pump relay.

Page 312 of 2643

1F – 66IENGINE CONTROLS

DAEWOO V–121 BL4

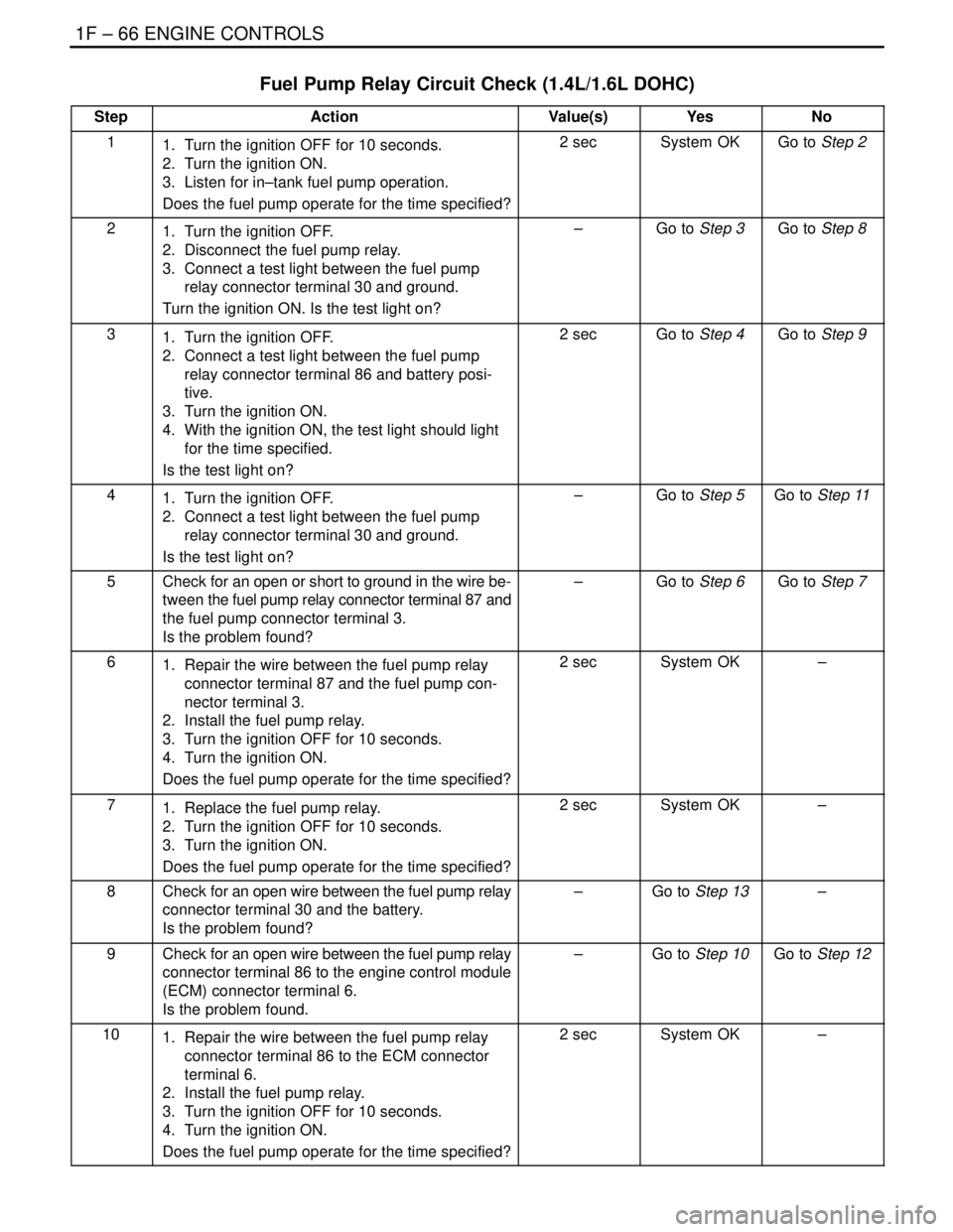

Fuel Pump Relay Circuit Check (1.4L/1.6L DOHC)

StepActionValue(s)YesNo

11. Turn the ignition OFF for 10 seconds.

2. Turn the ignition ON.

3. Listen for in–tank fuel pump operation.

Does the fuel pump operate for the time specified?2 secSystem OKGo to Step 2

21. Turn the ignition OFF.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Turn the ignition ON. Is the test light on?–Go to Step 3Go to Step 8

31. Turn the ignition OFF.

2. Connect a test light between the fuel pump

relay connector terminal 86 and battery posi-

tive.

3. Turn the ignition ON.

4. With the ignition ON, the test light should light

for the time specified.

Is the test light on?2 secGo to Step 4Go to Step 9

41. Turn the ignition OFF.

2. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Is the test light on?–Go to Step 5Go to Step 11

5Check for an open or short to ground in the wire be-

tween the fuel pump relay connector terminal 87 and

the fuel pump connector terminal 3.

Is the problem found?–Go to Step 6Go to Step 7

61. Repair the wire between the fuel pump relay

connector terminal 87 and the fuel pump con-

nector terminal 3.

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

71. Replace the fuel pump relay.

2. Turn the ignition OFF for 10 seconds.

3. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

8Check for an open wire between the fuel pump relay

connector terminal 30 and the battery.

Is the problem found?–Go to Step 13–

9Check for an open wire between the fuel pump relay

connector terminal 86 to the engine control module

(ECM) connector terminal 6.

Is the problem found.–Go to Step 10Go to Step 12

101. Repair the wire between the fuel pump relay

connector terminal 86 to the ECM connector

terminal 6.

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

Page 313 of 2643

ENGINE CONTROLS 1F – 67

DAEWOO V–121 BL4

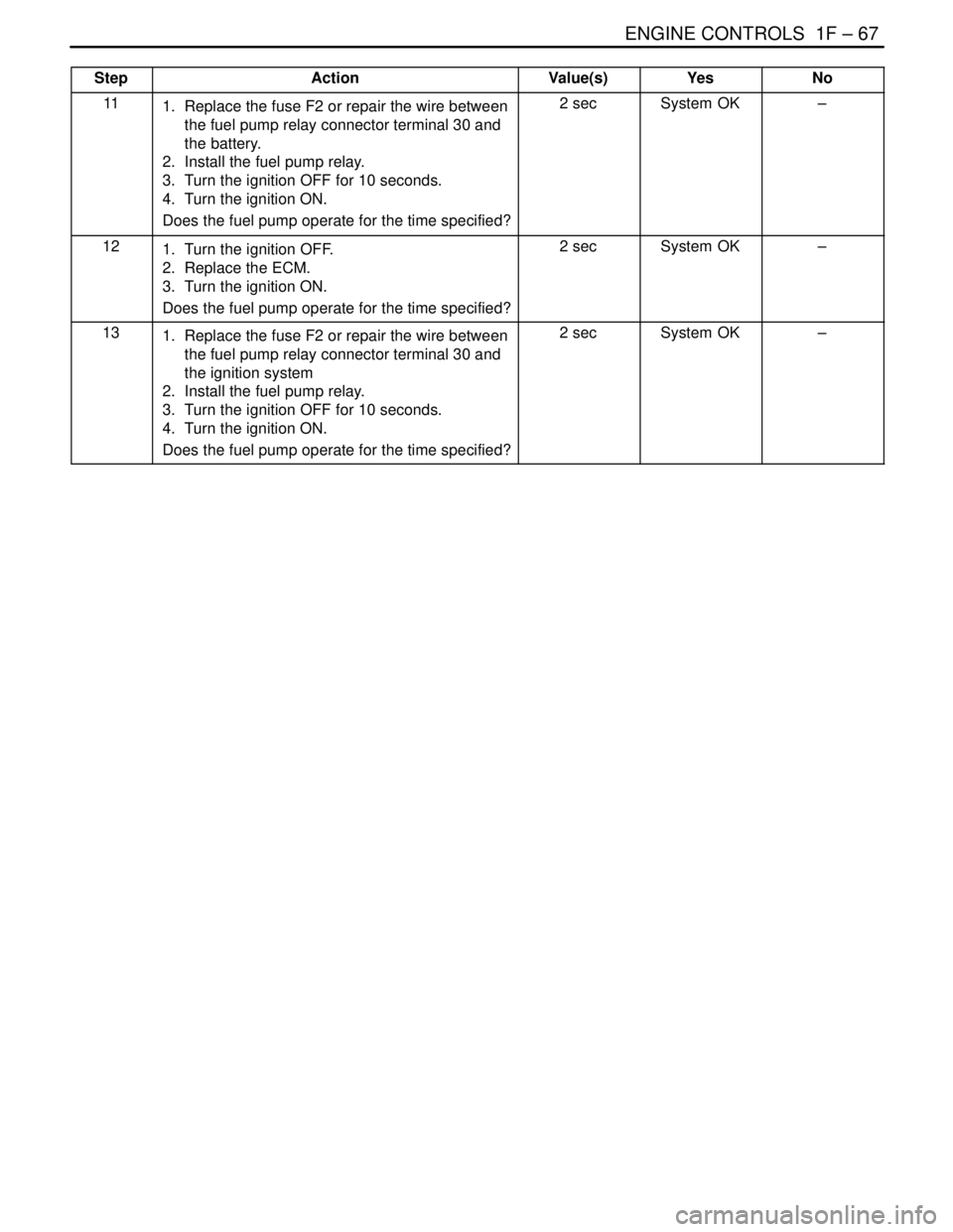

StepNo Yes Value(s) Action

111. Replace the fuse F2 or repair the wire between

the fuel pump relay connector terminal 30 and

the battery.

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

121. Turn the ignition OFF.

2. Replace the ECM.

3. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

131. Replace the fuse F2 or repair the wire between

the fuel pump relay connector terminal 30 and

the ignition system

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

Page 314 of 2643

1F – 68IENGINE CONTROLS

DAEWOO V–121 BL4

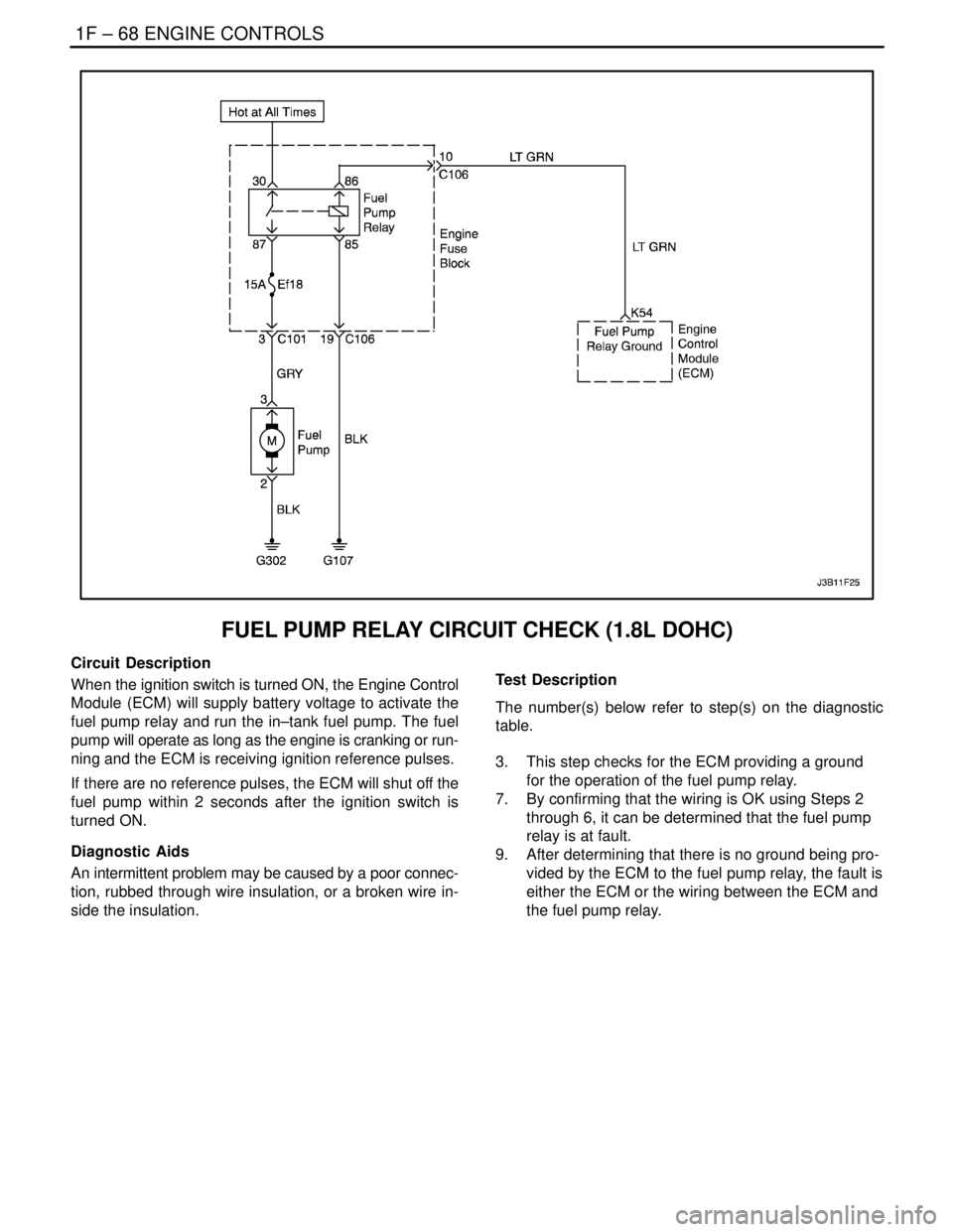

FUEL PUMP RELAY CIRCUIT CHECK (1.8L DOHC)

Circuit Description

When the ignition switch is turned ON, the Engine Control

Module (ECM) will supply battery voltage to activate the

fuel pump relay and run the in–tank fuel pump. The fuel

pump will operate as long as the engine is cranking or run-

ning and the ECM is receiving ignition reference pulses.

If there are no reference pulses, the ECM will shut off the

fuel pump within 2 seconds after the ignition switch is

turned ON.

Diagnostic Aids

An intermittent problem may be caused by a poor connec-

tion, rubbed through wire insulation, or a broken wire in-

side the insulation.Test Description

The number(s) below refer to step(s) on the diagnostic

table.

3. This step checks for the ECM providing a ground

for the operation of the fuel pump relay.

7. By confirming that the wiring is OK using Steps 2

through 6, it can be determined that the fuel pump

relay is at fault.

9. After determining that there is no ground being pro-

vided by the ECM to the fuel pump relay, the fault is

either the ECM or the wiring between the ECM and

the fuel pump relay.