pressure valve DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 20 of 2643

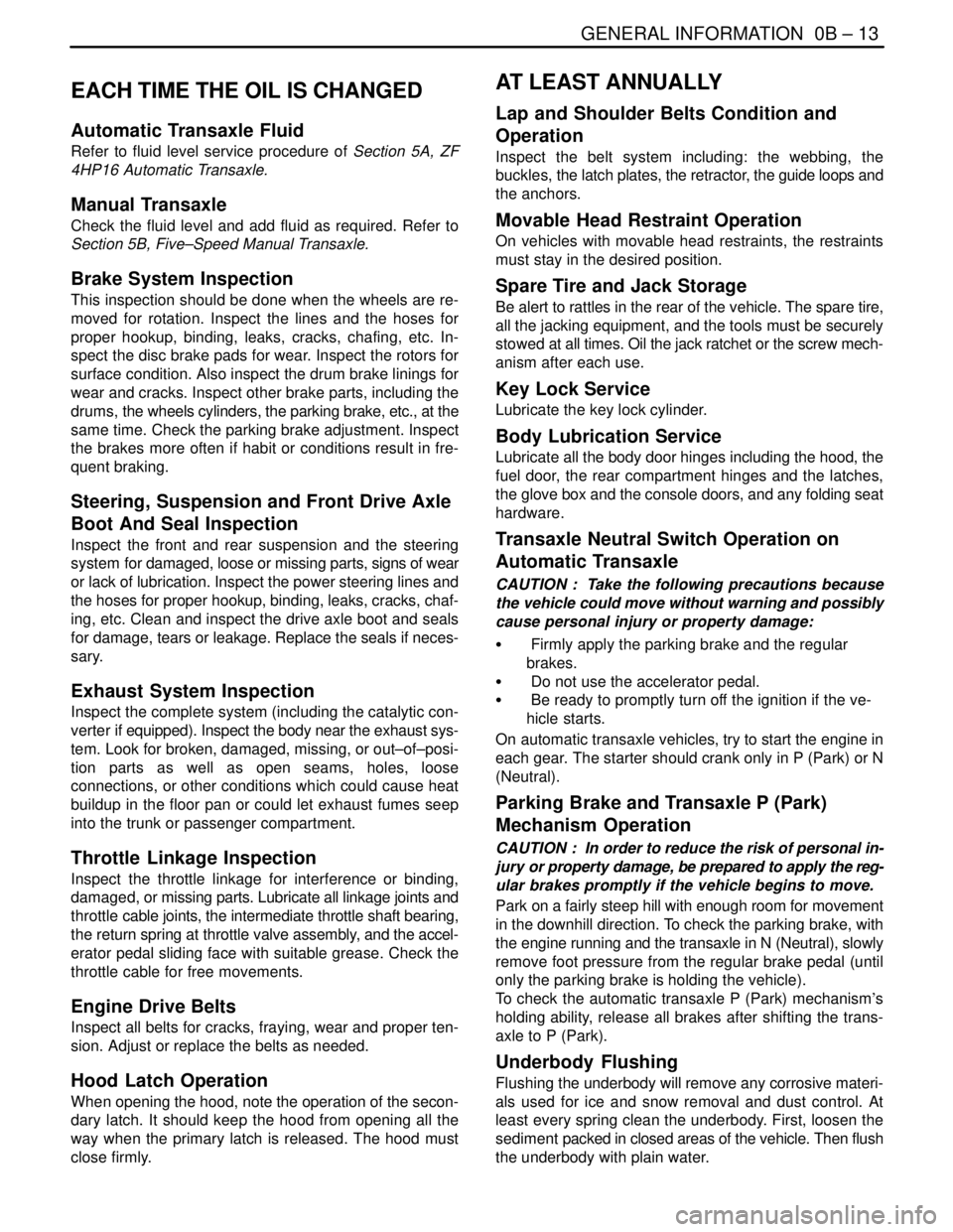

GENERAL INFORMATION 0B – 13

DAEWOO V–121 BL4

EACH TIME THE OIL IS CHANGED

Automatic Transaxle Fluid

Refer to fluid level service procedure of Section 5A, ZF

4HP16 Automatic Transaxle.

Manual Transaxle

Check the fluid level and add fluid as required. Refer to

Section 5B, Five–Speed Manual Transaxle.

Brake System Inspection

This inspection should be done when the wheels are re-

moved for rotation. Inspect the lines and the hoses for

proper hookup, binding, leaks, cracks, chafing, etc. In-

spect the disc brake pads for wear. Inspect the rotors for

surface condition. Also inspect the drum brake linings for

wear and cracks. Inspect other brake parts, including the

drums, the wheels cylinders, the parking brake, etc., at the

same time. Check the parking brake adjustment. Inspect

the brakes more often if habit or conditions result in fre-

quent braking.

Steering, Suspension and Front Drive Axle

Boot And Seal Inspection

Inspect the front and rear suspension and the steering

system for damaged, loose or missing parts, signs of wear

or lack of lubrication. Inspect the power steering lines and

the hoses for proper hookup, binding, leaks, cracks, chaf-

ing, etc. Clean and inspect the drive axle boot and seals

for damage, tears or leakage. Replace the seals if neces-

sary.

Exhaust System Inspection

Inspect the complete system (including the catalytic con-

verter if equipped). Inspect the body near the exhaust sys-

tem. Look for broken, damaged, missing, or out–of–posi-

tion parts as well as open seams, holes, loose

connections, or other conditions which could cause heat

buildup in the floor pan or could let exhaust fumes seep

into the trunk or passenger compartment.

Throttle Linkage Inspection

Inspect the throttle linkage for interference or binding,

damaged, or missing parts. Lubricate all linkage joints and

throttle cable joints, the intermediate throttle shaft bearing,

the return spring at throttle valve assembly, and the accel-

erator pedal sliding face with suitable grease. Check the

throttle cable for free movements.

Engine Drive Belts

Inspect all belts for cracks, fraying, wear and proper ten-

sion. Adjust or replace the belts as needed.

Hood Latch Operation

When opening the hood, note the operation of the secon-

dary latch. It should keep the hood from opening all the

way when the primary latch is released. The hood must

close firmly.

AT LEAST ANNUALLY

Lap and Shoulder Belts Condition and

Operation

Inspect the belt system including: the webbing, the

buckles, the latch plates, the retractor, the guide loops and

the anchors.

Movable Head Restraint Operation

On vehicles with movable head restraints, the restraints

must stay in the desired position.

Spare Tire and Jack Storage

Be alert to rattles in the rear of the vehicle. The spare tire,

all the jacking equipment, and the tools must be securely

stowed at all times. Oil the jack ratchet or the screw mech-

anism after each use.

Key Lock Service

Lubricate the key lock cylinder.

Body Lubrication Service

Lubricate all the body door hinges including the hood, the

fuel door, the rear compartment hinges and the latches,

the glove box and the console doors, and any folding seat

hardware.

Transaxle Neutral Switch Operation on

Automatic Transaxle

CAUTION : Take the following precautions because

the vehicle could move without warning and possibly

cause personal injury or property damage:

S Firmly apply the parking brake and the regular

brakes.

S Do not use the accelerator pedal.

S Be ready to promptly turn off the ignition if the ve-

hicle starts.

On automatic transaxle vehicles, try to start the engine in

each gear. The starter should crank only in P (Park) or N

(Neutral).

Parking Brake and Transaxle P (Park)

Mechanism Operation

CAUTION : In order to reduce the risk of personal in-

jury or property damage, be prepared to apply the reg-

ular brakes promptly if the vehicle begins to move.

Park on a fairly steep hill with enough room for movement

in the downhill direction. To check the parking brake, with

the engine running and the transaxle in N (Neutral), slowly

remove foot pressure from the regular brake pedal (until

only the parking brake is holding the vehicle).

To check the automatic transaxle P (Park) mechanism’s

holding ability, release all brakes after shifting the trans-

axle to P (Park).

Underbody Flushing

Flushing the underbody will remove any corrosive materi-

als used for ice and snow removal and dust control. At

least every spring clean the underbody. First, loosen the

sediment packed in closed areas of the vehicle. Then flush

the underbody with plain water.

Page 33 of 2643

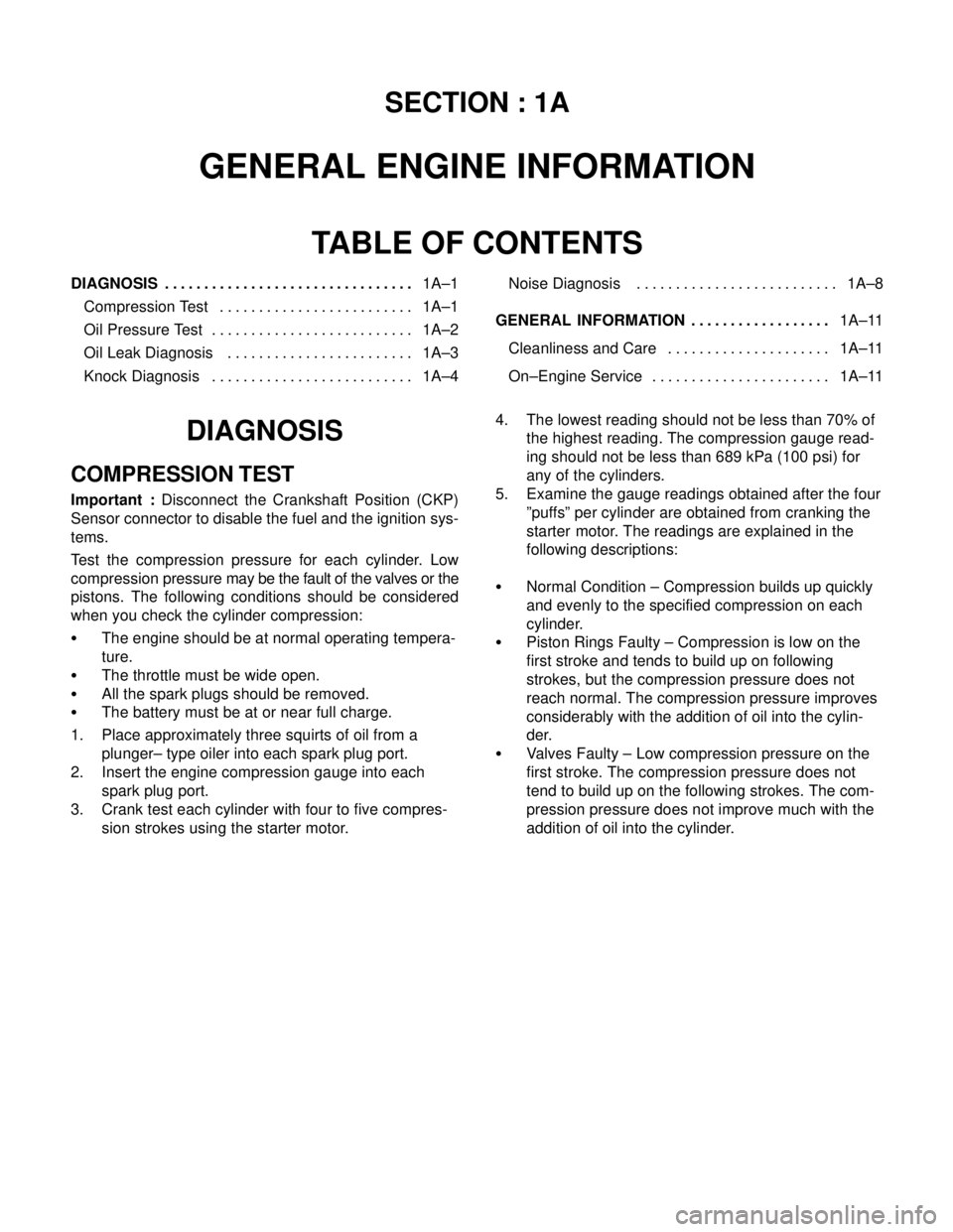

SECTION : 1A

GENERAL ENGINE INFORMATION

TABLE OF CONTENTS

DIAGNOSIS1A–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compression Test 1A–1. . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pressure Test 1A–2. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Leak Diagnosis 1A–3. . . . . . . . . . . . . . . . . . . . . . . .

Knock Diagnosis 1A–4. . . . . . . . . . . . . . . . . . . . . . . . . . Noise Diagnosis 1A–8. . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION1A–11 . . . . . . . . . . . . . . . . . .

Cleanliness and Care 1A–11. . . . . . . . . . . . . . . . . . . . .

On–Engine Service 1A–11. . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS

COMPRESSION TEST

Important : Disconnect the Crankshaft Position (CKP)

Sensor connector to disable the fuel and the ignition sys-

tems.

Test the compression pressure for each cylinder. Low

compression pressure may be the fault of the valves or the

pistons. The following conditions should be considered

when you check the cylinder compression:

S The engine should be at normal operating tempera-

ture.

S The throttle must be wide open.

S All the spark plugs should be removed.

S The battery must be at or near full charge.

1. Place approximately three squirts of oil from a

plunger– type oiler into each spark plug port.

2. Insert the engine compression gauge into each

spark plug port.

3. Crank test each cylinder with four to five compres-

sion strokes using the starter motor.4. The lowest reading should not be less than 70% of

the highest reading. The compression gauge read-

ing should not be less than 689 kPa (100 psi) for

any of the cylinders.

5. Examine the gauge readings obtained after the four

”puffs” per cylinder are obtained from cranking the

starter motor. The readings are explained in the

following descriptions:

S Normal Condition – Compression builds up quickly

and evenly to the specified compression on each

cylinder.

S Piston Rings Faulty – Compression is low on the

first stroke and tends to build up on following

strokes, but the compression pressure does not

reach normal. The compression pressure improves

considerably with the addition of oil into the cylin-

der.

S Valves Faulty – Low compression pressure on the

first stroke. The compression pressure does not

tend to build up on the following strokes. The com-

pression pressure does not improve much with the

addition of oil into the cylinder.

Page 38 of 2643

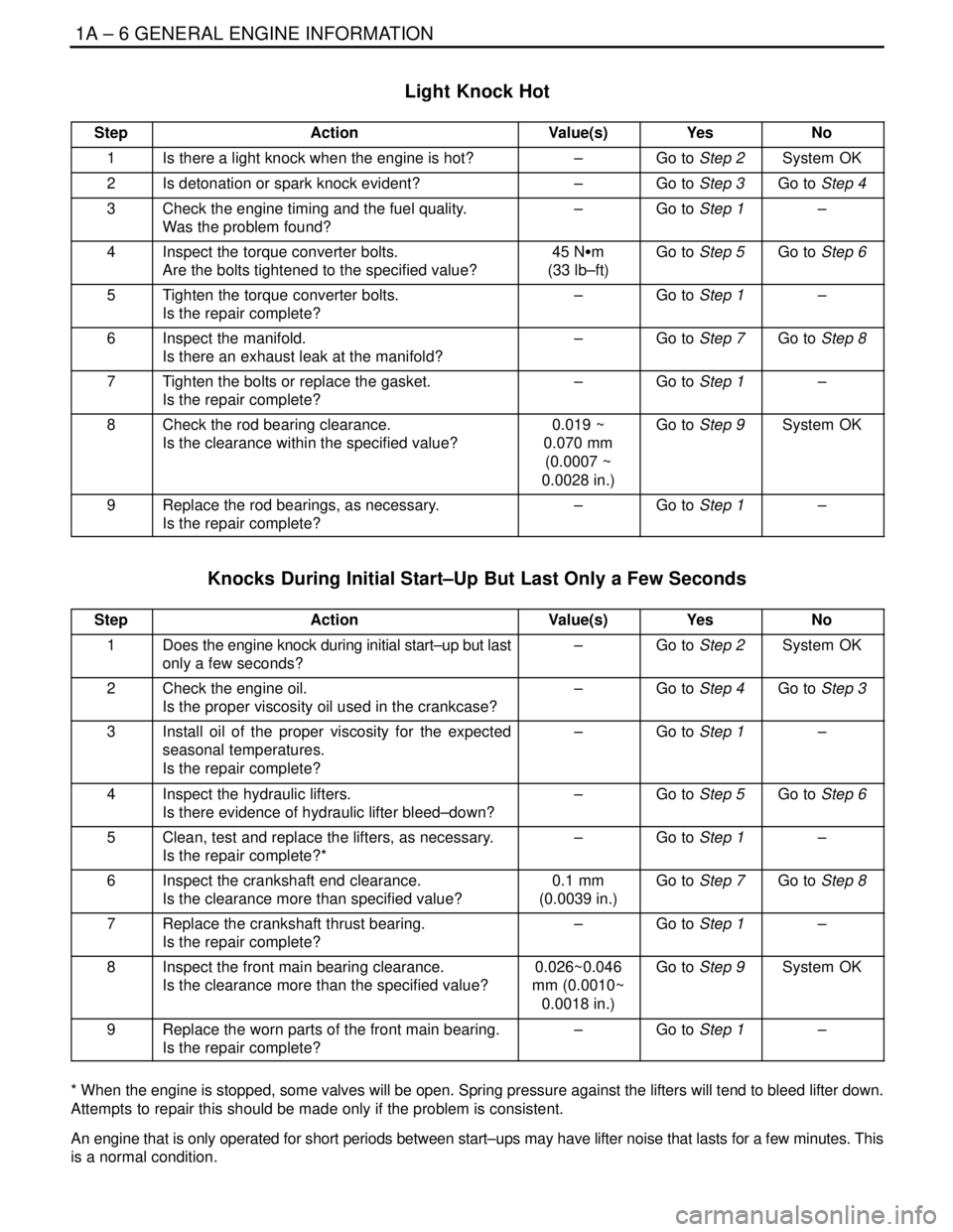

1A – 6IGENERAL ENGINE INFORMATION

DAEWOO V–121 BL4

Light Knock Hot

StepActionValue(s)YesNo

1Is there a light knock when the engine is hot?–Go to Step 2System OK

2Is detonation or spark knock evident?–Go to Step 3Go to Step 4

3Check the engine timing and the fuel quality.

Was the problem found?–Go to Step 1–

4Inspect the torque converter bolts.

Are the bolts tightened to the specified value?45 NSm

(33 lb–ft)Go to Step 5Go to Step 6

5Tighten the torque converter bolts.

Is the repair complete?–Go to Step 1–

6Inspect the manifold.

Is there an exhaust leak at the manifold?–Go to Step 7Go to Step 8

7Tighten the bolts or replace the gasket.

Is the repair complete?–Go to Step 1–

8Check the rod bearing clearance.

Is the clearance within the specified value?0.019 ~

0.070 mm

(0.0007 ~

0.0028 in.)Go to Step 9System OK

9Replace the rod bearings, as necessary.

Is the repair complete?–Go to Step 1–

Knocks During Initial Start–Up But Last Only a Few Seconds

StepActionValue(s)YesNo

1Does the engine knock during initial start–up but last

only a few seconds?–Go to Step 2System OK

2Check the engine oil.

Is the proper viscosity oil used in the crankcase?–Go to Step 4Go to Step 3

3Install oil of the proper viscosity for the expected

seasonal temperatures.

Is the repair complete?–Go to Step 1–

4Inspect the hydraulic lifters.

Is there evidence of hydraulic lifter bleed–down?–Go to Step 5Go to Step 6

5Clean, test and replace the lifters, as necessary.

Is the repair complete?*–Go to Step 1–

6Inspect the crankshaft end clearance.

Is the clearance more than specified value?0.1 mm

(0.0039 in.)Go to Step 7Go to Step 8

7Replace the crankshaft thrust bearing.

Is the repair complete?–Go to Step 1–

8Inspect the front main bearing clearance.

Is the clearance more than the specified value?0.026~0.046

mm (0.0010~

0.0018 in.)Go to Step 9System OK

9Replace the worn parts of the front main bearing.

Is the repair complete?–Go to Step 1–

* When the engine is stopped, some valves will be open. Spring pressure against the lifters will tend to bleed lifter down.

Attempts to repair this should be made only if the problem is consistent.

An engine that is only operated for short periods between start–ups may have lifter noise that lasts for a few minutes. This

is a normal condition.

Page 48 of 2643

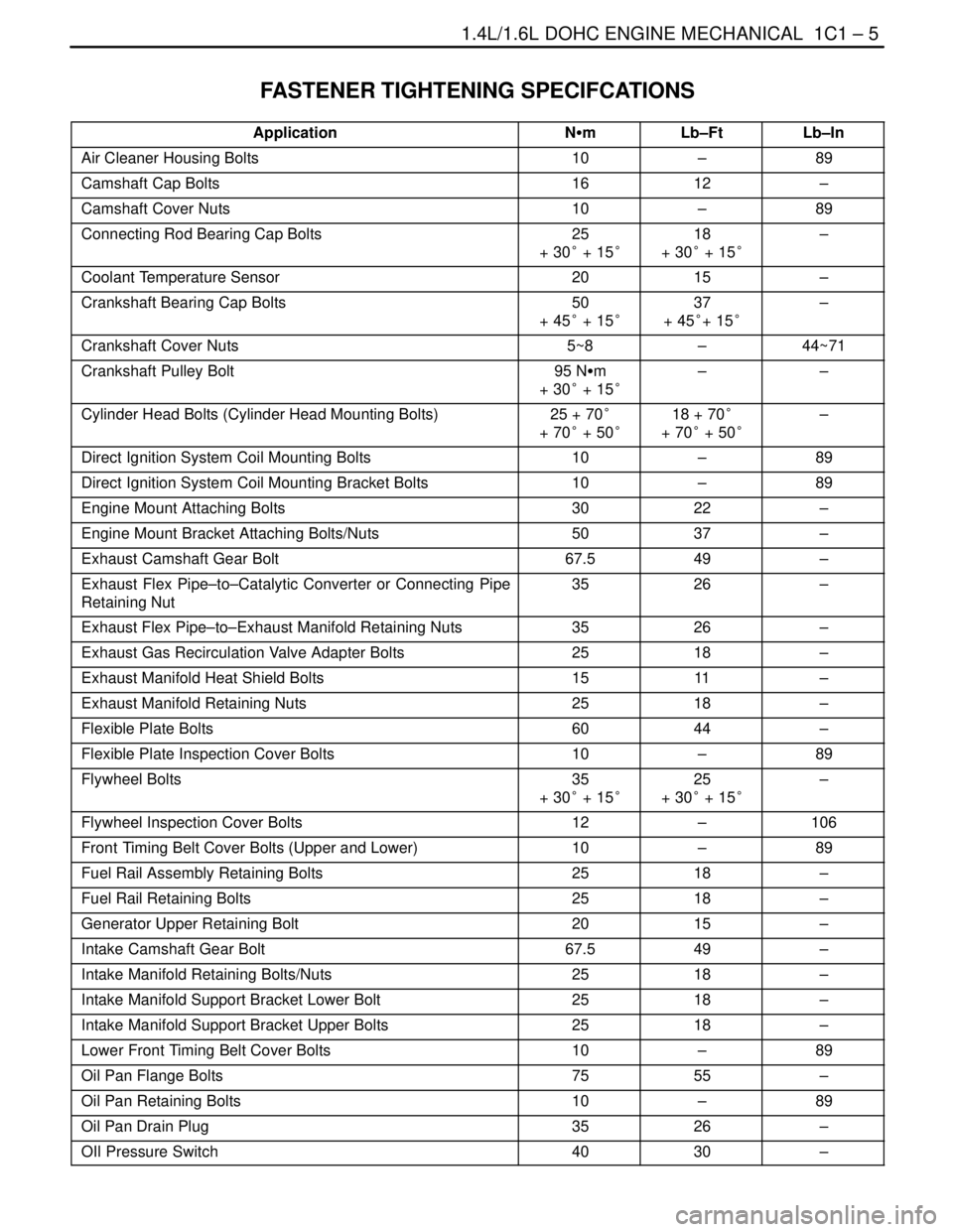

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 5

DAEWOO V–121 BL4

FASTENER TIGHTENING SPECIFCATIONS

ApplicationNSmLb–FtLb–In

Air Cleaner Housing Bolts10–89

Camshaft Cap Bolts1612–

Camshaft Cover Nuts10–89

Connecting Rod Bearing Cap Bolts25

+ 30° + 15°18

+ 30° + 15°–

Coolant Temperature Sensor2015–

Crankshaft Bearing Cap Bolts50

+ 45° + 15°37

+ 45°+ 15°–

Crankshaft Cover Nuts5~8–44~71

Crankshaft Pulley Bolt95 NSm

+ 30° + 15°––

Cylinder Head Bolts (Cylinder Head Mounting Bolts)25 + 70°

+ 70° + 50°18 + 70°

+ 70° + 50°–

Direct Ignition System Coil Mounting Bolts10–89

Direct Ignition System Coil Mounting Bracket Bolts10–89

Engine Mount Attaching Bolts3022–

Engine Mount Bracket Attaching Bolts/Nuts5037–

Exhaust Camshaft Gear Bolt67.549–

Exhaust Flex Pipe–to–Catalytic Converter or Connecting Pipe

Retaining Nut3526–

Exhaust Flex Pipe–to–Exhaust Manifold Retaining Nuts3526–

Exhaust Gas Recirculation Valve Adapter Bolts2518–

Exhaust Manifold Heat Shield Bolts1511–

Exhaust Manifold Retaining Nuts2518–

Flexible Plate Bolts6044–

Flexible Plate Inspection Cover Bolts10–89

Flywheel Bolts35

+ 30° + 15°25

+ 30° + 15°–

Flywheel Inspection Cover Bolts12–106

Front Timing Belt Cover Bolts (Upper and Lower)10–89

Fuel Rail Assembly Retaining Bolts2518–

Fuel Rail Retaining Bolts2518–

Generator Upper Retaining Bolt2015–

Intake Camshaft Gear Bolt67.549–

Intake Manifold Retaining Bolts/Nuts2518–

Intake Manifold Support Bracket Lower Bolt2518–

Intake Manifold Support Bracket Upper Bolts2518–

Lower Front Timing Belt Cover Bolts10–89

Oil Pan Flange Bolts7555–

Oil Pan Retaining Bolts10–89

Oil Pan Drain Plug3526–

OIl Pressure Switch4030–

Page 51 of 2643

1C1 – 8I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

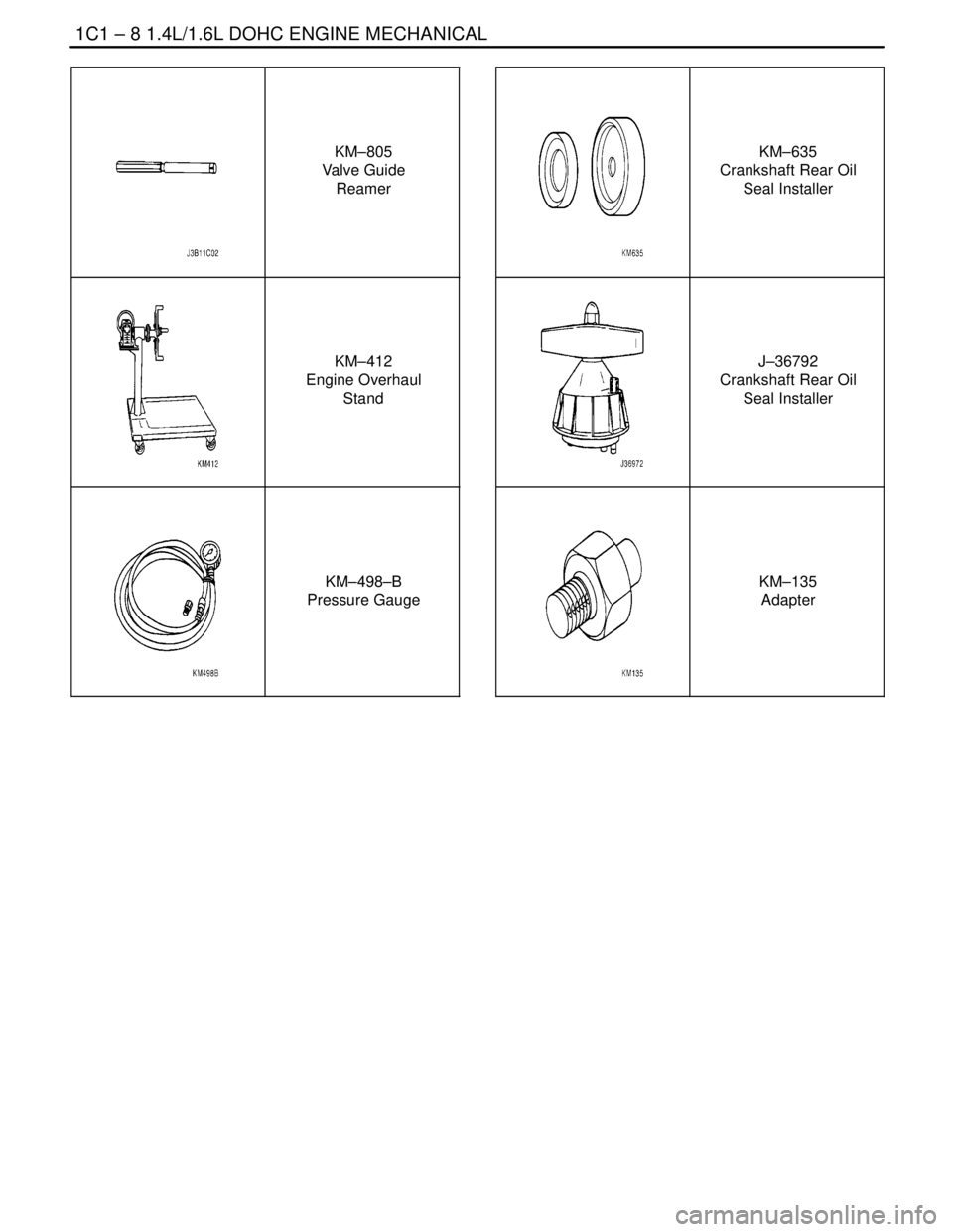

KM–805

Valve Guide

Reamer

KM–412

Engine Overhaul

Stand

KM–498–B

Pressure Gauge

KM–635

Crankshaft Rear Oil

Seal Installer

J–36792

Crankshaft Rear Oil

Seal Installer

KM–135

Adapter

Page 54 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 11

DAEWOO V–121 BL4

1. Piston Ring Set

2. Piston

3. Piston Pin

4. Connecting Rod

5. Connecting Rod Bearing Set

6. Oil Level Gauge Stick

7. Gauge Stic Tube

8. Sleeve

9. Clutch Housing Sleeve

10. Cylinder Block

11. Plug

12. Gap

13. Bypass Valve

14. Connecting Piece

15. Oil Filter

16. Oil Pump Body Gasket

17. Water Inlet Neck

18. Knock Sensor

19. Fly Wheel (M/T)

20. Flexible Plate (A/T)

21. Shaft Seal Ring

22. Crank Shaft Upper Bearing Set

23. Crank Shaft24. Crank Shaft Lower Bearing Set

25. Transmitter Disc

26. Crankshaft Bearing Cap

27. Oil Pan

28. Threaded Ring

29. Washer

30. Oil Pan Drain Plug

31. Oil Pump

32. Oil Pump Cover

33. Oil Pump Inner Rotor

34. Oil Pump Outer Rotor

35. Oil Pump Plug

36. Shaft Sealing

37. Pressure Relief Valve Plunger

38. Relief Valve Spring

39. Sealing

40. Relief Valve

41. Oil Pressure Switch

42. Sleeve

43. Oil Suction Pipe Bracket

44. Oil Suction Pipe

45. Sealing

Page 120 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 77

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

CYLINDER HEAD AND GASKET

The cylinder head is made of an aluminum alloy. The cylin-

der head uses cross–flow intake and exhaust ports. A

spark plug is located in the center of each combustion

chamber. The cylinder head houses the dual camshafts.

CRANKSHAFT

The crankshaft has eight integral weights which are cast

with it for balancing. Oil holes run through the center of the

crankshaft to supply oil to the connecting rods, the bear-

ings, the pistons, and the other components. The end

thrust load is taken by the thrust washers installed at the

center journal.

TIMING BELT

The timing belt coordinates the crankshaft and the dual

overhead camshafts and keeps them synchronized. The

timing belt also turns the water pump. The timing belt and

the pulleys are toothed so that there is no slippage be-

tween them. There are two idler pulleys. An automatic ten-

sioner pulley maintains the timing belt’s correct tension.

The timing belt is made of a tough reinforced rubber similar

to that used on the serpentine accessory drive belt. The

timing belt requires no lubrication.

OIL PUMP

The oil pump draws engine oil from the oil pan and feeds

it under pressure to the various parts of the engine. An oil

strainer is mounted before the inlet of the oil pump to re-

move impurities which could clog or damage the oil pump

or other engine components. When the drive gear rotates,

the driven gear rotates. This causes the space between

the gears to constantly open and narrow, pulling oil in from

the oil pan when the space opens and pumping the oil out

to the engine as it narrows.

At high engine speeds, the oil pump supplies a much high-

er amount of oil than is required for lubrication of the en-

gine. The oil pressure regulator prevents too much oil from

entering the engine lubrication passages. During normal

oil supply, a coil spring and valve keep the bypass closed,

directing all of the oil pumped to the engine. When the

amount of oil being pumped increases, the pressure be-

comes high enough to overcome the force of the spring.This opens the valve of the oil pressure regulator, allowing

the excess oil to flow through the valve and drain back to

the oil pan.

OIL PAN

The engine oil pan is mounted to the bottom of the cylinder

block. The engine oil pan houses the crankcase and is

made of cast metal.

Engine oil is pumped from the oil pan by the oil pump. After

it passes through the oil filter, it is fed through two paths

to lubricate the cylinder block and the cylinder head. In one

path, the oil is pumped through the oil passages in the

crankshaft to the connecting rods, then to the pistons and

the cylinders. It then drains back to the oil pan. In the sec-

ond path, the oil is pumped through the oil passages to the

camshaft. The oil passes through the internal passage-

ways in the camshafts to lubricate the valve assemblies

before draining back to the oil pan.

EXHAUST MANIFOLD

A single four–port, rear–takedown manifold is used with

this engine. The manifold is designed to direct escaping

exhaust gases out of the combustion chambers with a

minimum of back pressure. The oxygen sensor is

mounted to the exhaust manifold.

INTAKE MANIFOLD

The intake manifold has four independent long ports and

uses inertial supercharging to improve engine torque at

low and moderate speeds. The plenum is attached to the

intake manifold.

CAMSHAFTS

This engine is a dual overhead camshaft (DOHC) type,

which means there are two camshafts. One camshaft op-

erates the intake valves, and the other camshaft operates

the exhaust valves. The camshafts sit in journals on the

top of the engine in the cylinder head and are held in place

by camshaft caps. The camshaft journals of the cylinder

head are drilled to create oil passages. Engine oil travels

to the camshafts under pressure where it lubricates each

camshaft journal. The oil returns to the oil pan through

drain holes in the cylinder head. The camshaft lobes are

machined into the solid camshaft to open and close the in-

take and the exhaust valves precisely the correct amount

at the correct time. The camshaft lobes are oiled by splash

action from pressurized oil escaping from the camshaft

journals.

Page 125 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 5

DAEWOO V–121 BL4

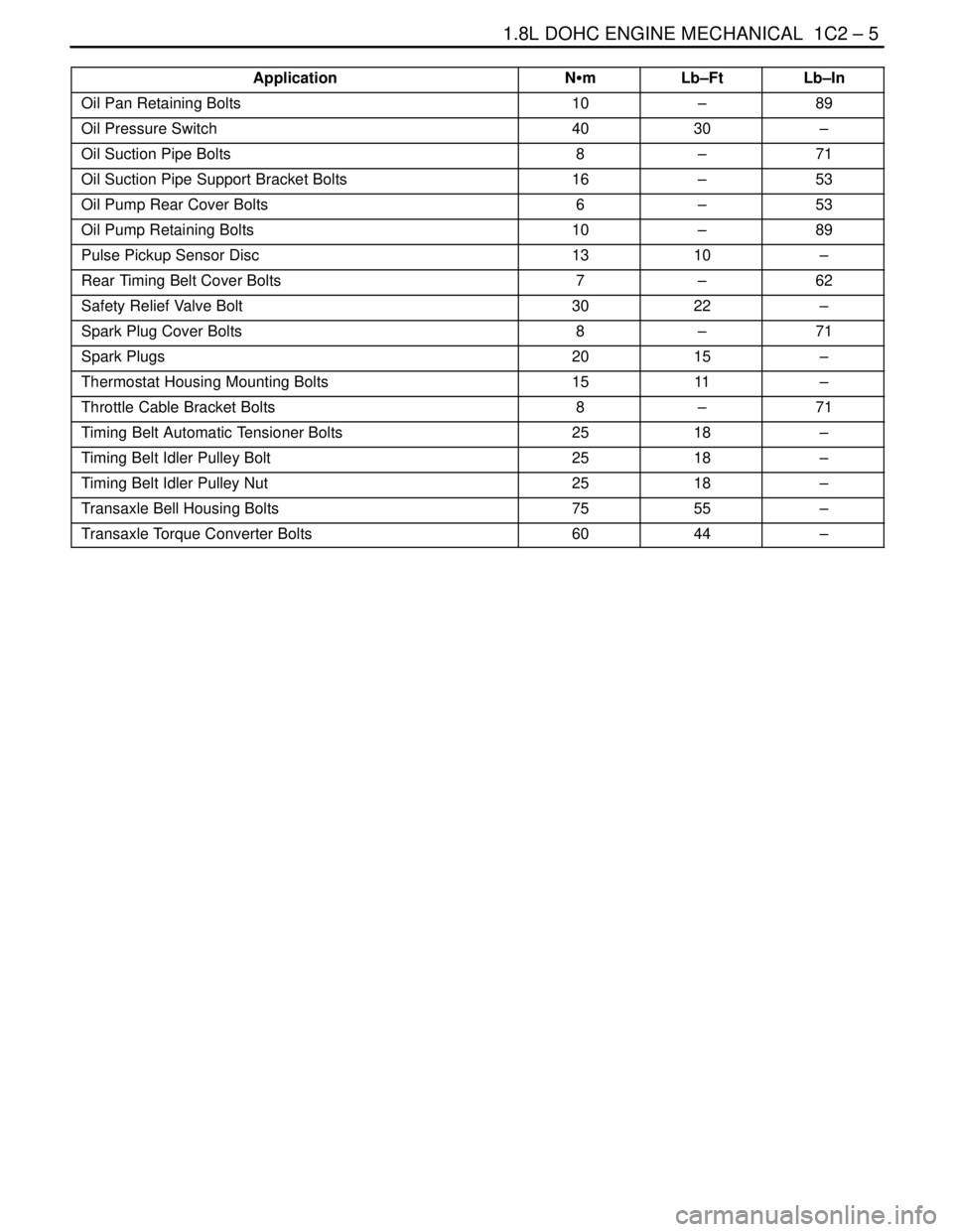

Application Lb–InLb–Ft NSm

Oil Pan Retaining Bolts10–89

Oil Pressure Switch4030–

Oil Suction Pipe Bolts8–71

Oil Suction Pipe Support Bracket Bolts16–53

Oil Pump Rear Cover Bolts6–53

Oil Pump Retaining Bolts10–89

Pulse Pickup Sensor Disc1310–

Rear Timing Belt Cover Bolts7–62

Safety Relief Valve Bolt3022–

Spark Plug Cover Bolts8–71

Spark Plugs2015–

Thermostat Housing Mounting Bolts1511–

Throttle Cable Bracket Bolts8–71

Timing Belt Automatic Tensioner Bolts2518–

Timing Belt Idler Pulley Bolt2518–

Timing Belt Idler Pulley Nut2518–

Transaxle Bell Housing Bolts7555–

Transaxle Torque Converter Bolts6044–

Page 131 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 11

DAEWOO V–121 BL4

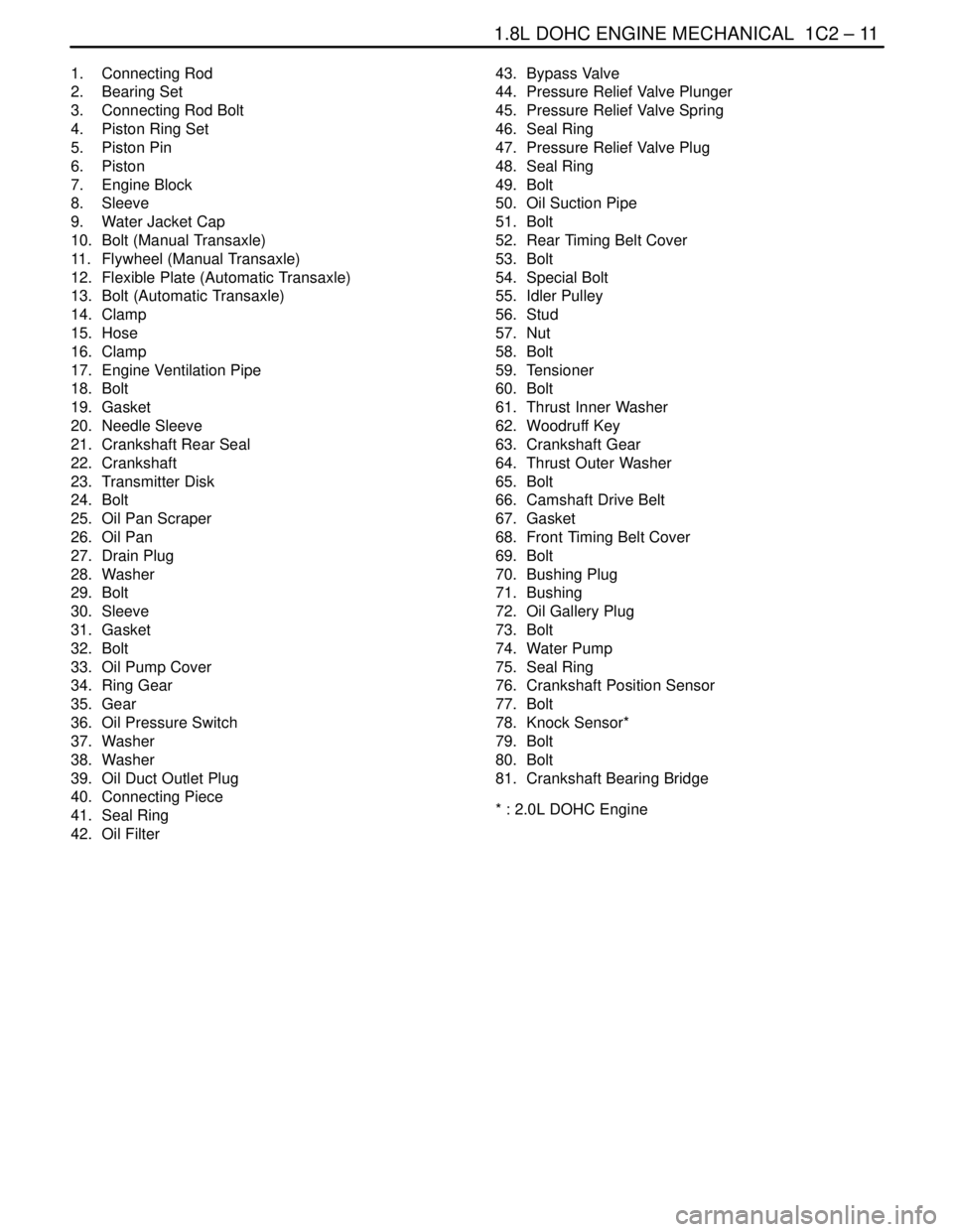

1. Connecting Rod

2. Bearing Set

3. Connecting Rod Bolt

4. Piston Ring Set

5. Piston Pin

6. Piston

7. Engine Block

8. Sleeve

9. Water Jacket Cap

10. Bolt (Manual Transaxle)

11. Flywheel (Manual Transaxle)

12. Flexible Plate (Automatic Transaxle)

13. Bolt (Automatic Transaxle)

14. Clamp

15. Hose

16. Clamp

17. Engine Ventilation Pipe

18. Bolt

19. Gasket

20. Needle Sleeve

21. Crankshaft Rear Seal

22. Crankshaft

23. Transmitter Disk

24. Bolt

25. Oil Pan Scraper

26. Oil Pan

27. Drain Plug

28. Washer

29. Bolt

30. Sleeve

31. Gasket

32. Bolt

33. Oil Pump Cover

34. Ring Gear

35. Gear

36. Oil Pressure Switch

37. Washer

38. Washer

39. Oil Duct Outlet Plug

40. Connecting Piece

41. Seal Ring

42. Oil Filter43. Bypass Valve

44. Pressure Relief Valve Plunger

45. Pressure Relief Valve Spring

46. Seal Ring

47. Pressure Relief Valve Plug

48. Seal Ring

49. Bolt

50. Oil Suction Pipe

51. Bolt

52. Rear Timing Belt Cover

53. Bolt

54. Special Bolt

55. Idler Pulley

56. Stud

57. Nut

58. Bolt

59. Tensioner

60. Bolt

61. Thrust Inner Washer

62. Woodruff Key

63. Crankshaft Gear

64. Thrust Outer Washer

65. Bolt

66. Camshaft Drive Belt

67. Gasket

68. Front Timing Belt Cover

69. Bolt

70. Bushing Plug

71. Bushing

72. Oil Gallery Plug

73. Bolt

74. Water Pump

75. Seal Ring

76. Crankshaft Position Sensor

77. Bolt

78. Knock Sensor*

79. Bolt

80. Bolt

81. Crankshaft Bearing Bridge

* : 2.0L DOHC Engine

Page 159 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 39

DAEWOO V–121 BL4

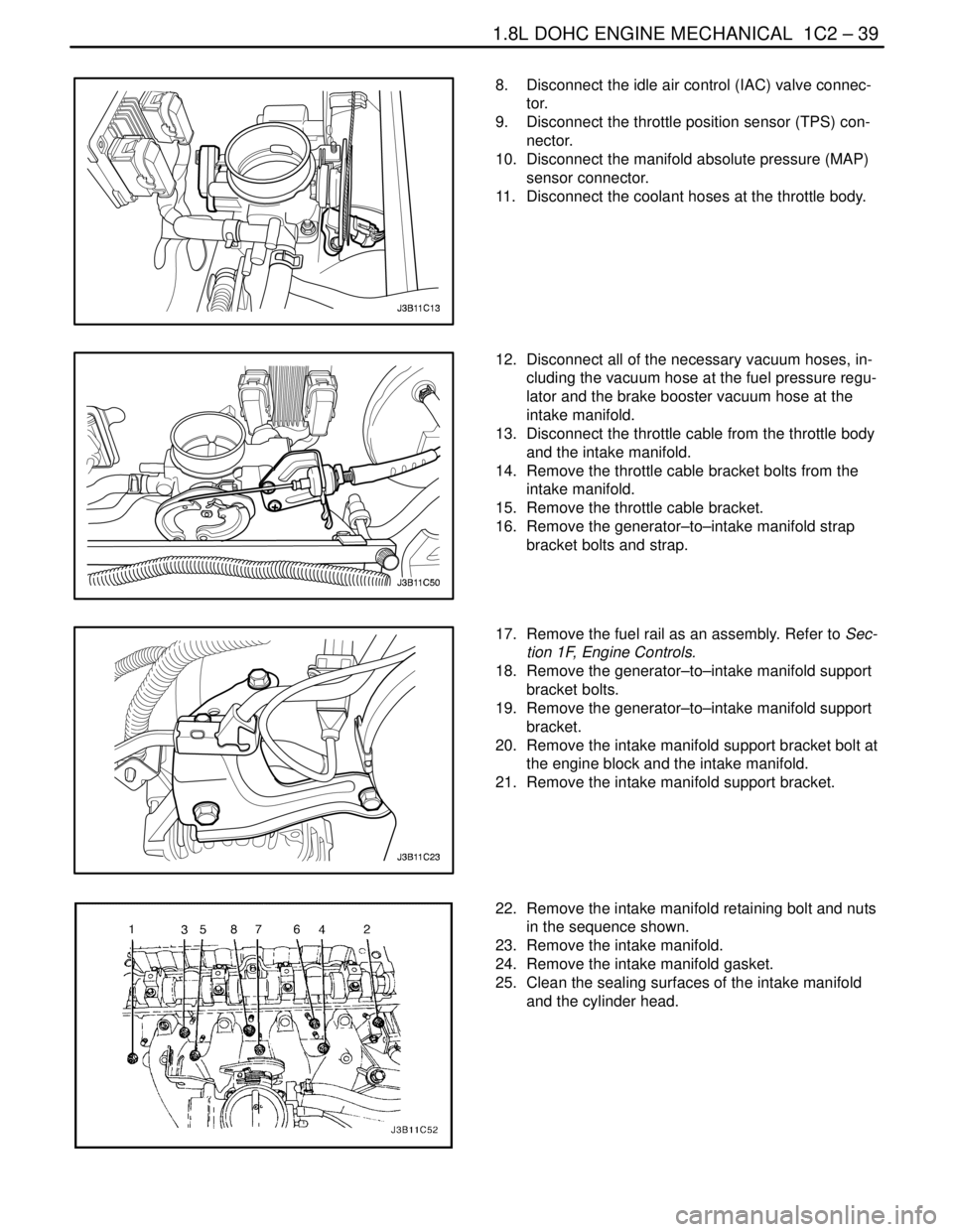

8. Disconnect the idle air control (IAC) valve connec-

tor.

9. Disconnect the throttle position sensor (TPS) con-

nector.

10. Disconnect the manifold absolute pressure (MAP)

sensor connector.

11. Disconnect the coolant hoses at the throttle body.

12. Disconnect all of the necessary vacuum hoses, in-

cluding the vacuum hose at the fuel pressure regu-

lator and the brake booster vacuum hose at the

intake manifold.

13. Disconnect the throttle cable from the throttle body

and the intake manifold.

14. Remove the throttle cable bracket bolts from the

intake manifold.

15. Remove the throttle cable bracket.

16. Remove the generator–to–intake manifold strap

bracket bolts and strap.

17. Remove the fuel rail as an assembly. Refer to Sec-

tion 1F, Engine Controls.

18. Remove the generator–to–intake manifold support

bracket bolts.

19. Remove the generator–to–intake manifold support

bracket.

20. Remove the intake manifold support bracket bolt at

the engine block and the intake manifold.

21. Remove the intake manifold support bracket.

22. Remove the intake manifold retaining bolt and nuts

in the sequence shown.

23. Remove the intake manifold.

24. Remove the intake manifold gasket.

25. Clean the sealing surfaces of the intake manifold

and the cylinder head.