battery replacement DAEWOO MATIZ 2003 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2003, Model line: MATIZ, Model: DAEWOO MATIZ 2003Pages: 1184, PDF Size: 36 MB

Page 285 of 1184

ENGINE CONTROLS 1F–187

DAEWOO M-150 BL2

easily verified. Check the Freeze Frame data to deter- mine if the DTC set when the vehicle was cold by view-

ing the Engine Coolant Temperature (ECT).

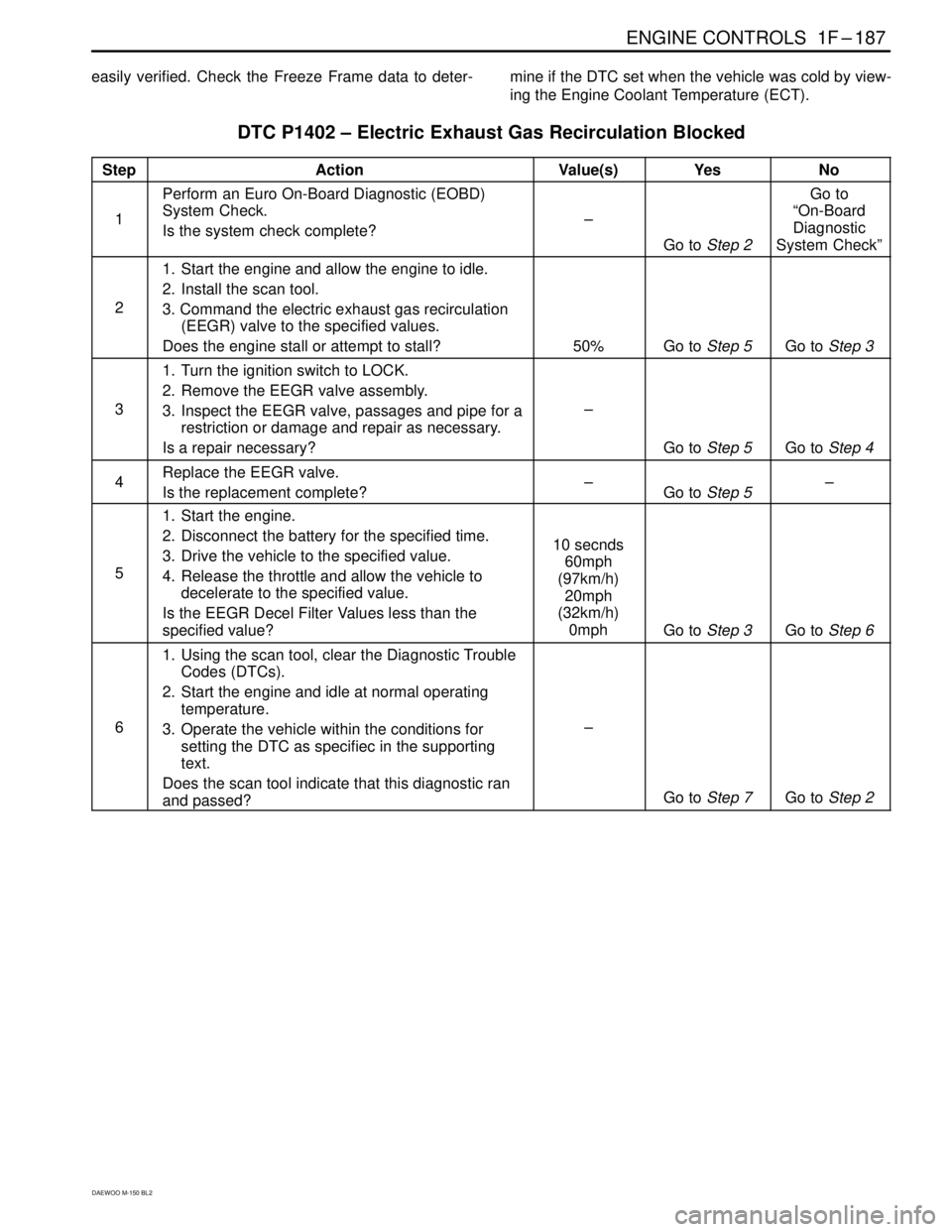

DTC P1402 – Electric Exhaust Gas Recirculation Blocked

StepActionValue(s)YesNo

1

Perform an Euro On-Board Diagnostic (EOBD)

System Check.

Is the system check complete?

–

Go to Step 2

Go to

“On-Board

Diagnostic

System Check”

2

1. Start the engine and allow the engine to idle.

2. Install the scan tool.

3. Command the electric exhaust gas recirculation

(EEGR) valve to the specified values.

Does the engine stall or attempt to stall?

50%Go to Step 5Go to Step 3

3

1. Turn the ignition switch to LOCK.

2. Remove the EEGR valve assembly.

3. Inspect the EEGR valve, passages and pipe for a

restriction or damage and repair as necessary.

Is a repair necessary?

–

Go to Step 5Go to Step 4

4Replace the EEGR valve.

Is the replacement complete?–Go to Step 5–

5

1. Start the engine.

2. Disconnect the battery for the specified time.

3. Drive the vehicle to the specified value.

4. Release the throttle and allow the vehicle to

decelerate to the specified value.

Is the EEGR Decel Filter Values less than the

specified value?

10 secnds

60mph

(97km/h)

20mph

(32km/h)

0mph

Go to Step 3Go to Step 6

6

1. Using the scan tool, clear the Diagnostic Trouble

Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting the DTC as specifiec in the supporting

text.

Does the scan tool indicate that this diagnostic ran

and passed?

–

Go to Step 7Go to Step 2

Page 287 of 1184

ENGINE CONTROLS 1F–189

DAEWOO M-150 BL2

repairs, the valve warms and the problem disappears.

By watching the Actual EEGR and desired EEGR posi-

tions on a cold vehicle with a scan tool, the fault can beeasily verified. Check the Freeze Frame data to deter-

mine if the DTC set when the vehicle was cold by view-

ing the Engine Coolant Temperature (ECT).

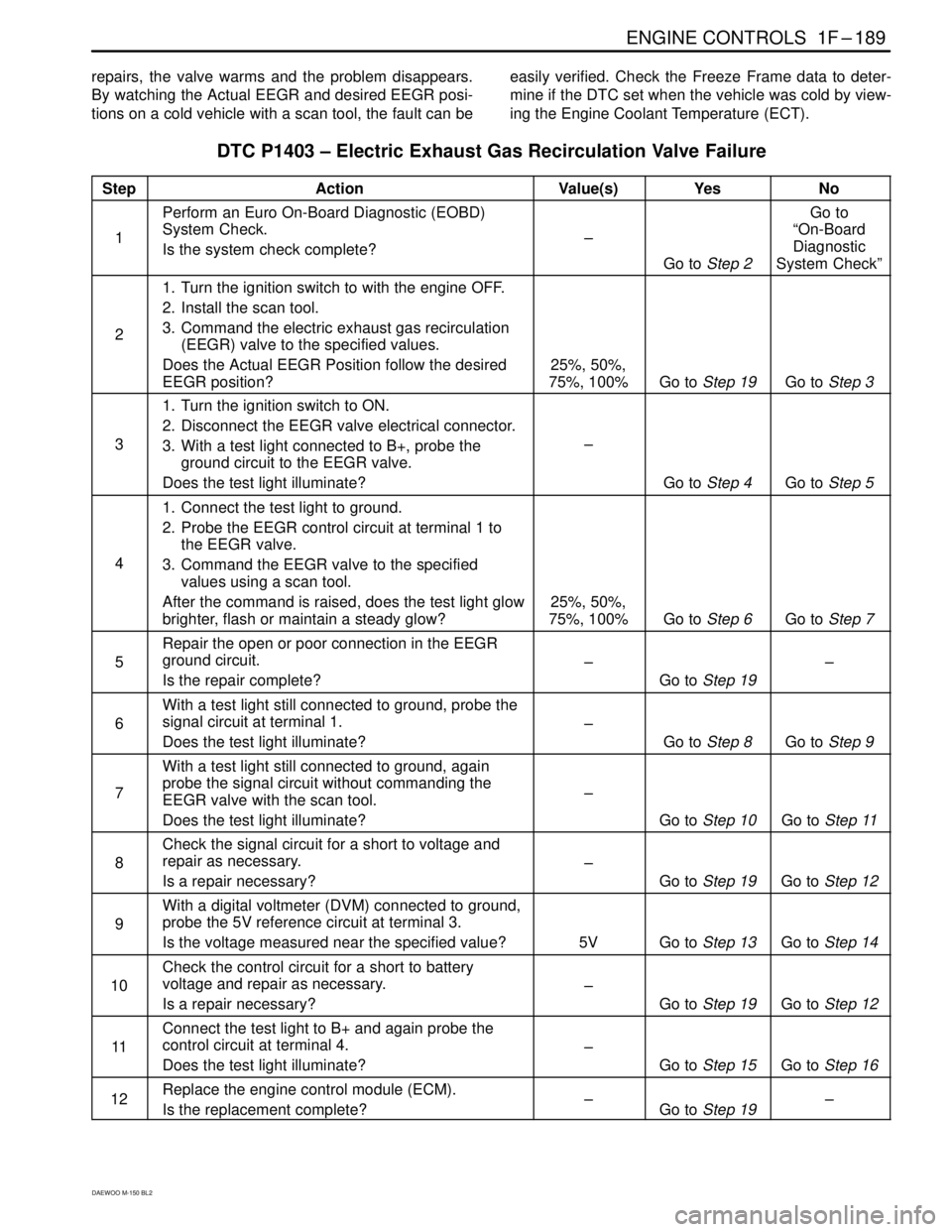

DTC P1403 – Electric Exhaust Gas Recirculation Valve Failure

StepActionValue(s)YesNo

1

Perform an Euro On-Board Diagnostic (EOBD)

System Check.

Is the system check complete?

–

Go to Step 2

Go to

“On-Board

Diagnostic

System Check”

2

1. Turn the ignition switch to with the engine OFF.

2. Install the scan tool.

3. Command the electric exhaust gas recirculation

(EEGR) valve to the specified values.

Does the Actual EEGR Position follow the desired

EEGR position?

25%, 50%,

75%, 100%

Go to Step 19Go to Step 3

3

1. Turn the ignition switch to ON.

2. Disconnect the EEGR valve electrical connector.

3. With a test light connected to B+, probe the

ground circuit to the EEGR valve.

Does the test light illuminate?

–

Go to Step 4Go to Step 5

4

1. Connect the test light to ground.

2. Probe the EEGR control circuit at terminal 1 to

the EEGR valve.

3. Command the EEGR valve to the specified

values using a scan tool.

After the command is raised, does the test light glow

brighter, flash or maintain a steady glow?

25%, 50%,

75%, 100%

Go to Step 6Go to Step 7

5

Repair the open or poor connection in the EEGR

ground circuit.

Is the repair complete?

–

Go to Step 19

–

6

With a test light still connected to ground, probe the

signal circuit at terminal 1.

Does the test light illuminate?

–

Go to Step 8Go to Step 9

7

With a test light still connected to ground, again

probe the signal circuit without commanding the

EEGR valve with the scan tool.

Does the test light illuminate?

–

Go to Step 10Go to Step 11

8

Check the signal circuit for a short to voltage and

repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 12

9

With a digital voltmeter (DVM) connected to ground,

probe the 5V reference circuit at terminal 3.

Is the voltage measured near the specified value?

5VGo to Step 13Go to Step 14

10

Check the control circuit for a short to battery

voltage and repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 12

11

Connect the test light to B+ and again probe the

control circuit at terminal 4.

Does the test light illuminate?

–

Go to Step 15Go to Step 16

12Replace the engine control module (ECM).

Is the replacement complete?–Go to Step 19–

Page 288 of 1184

1F–190 ENGINE CONTROLS

DAEWOO M-150 BL2

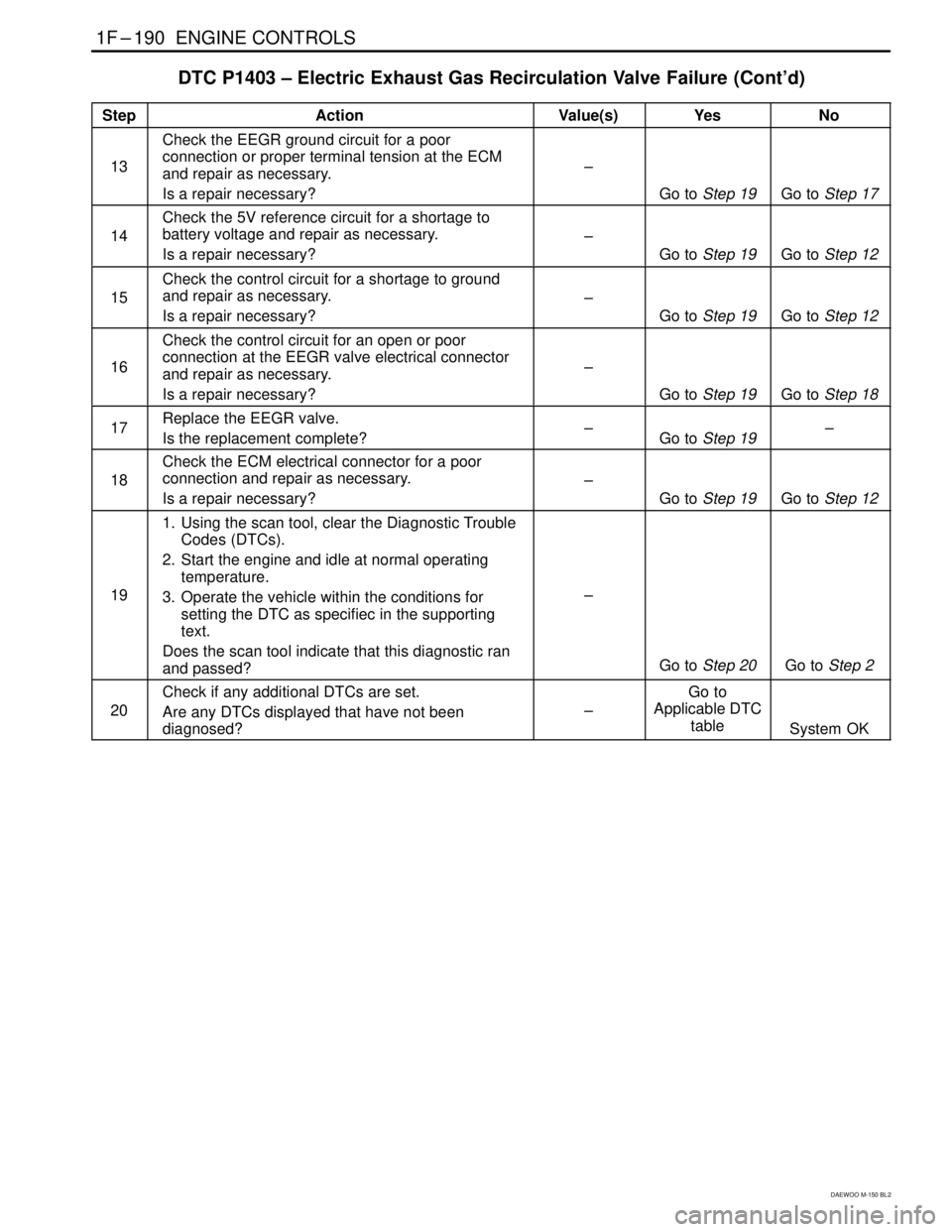

DTC P1403 – Electric Exhaust Gas Recirculation Valve Failure (Cont’d)

StepActionValue(s)YesNo

13

Check the EEGR ground circuit for a poor

connection or proper terminal tension at the ECM

and repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 17

14

Check the 5V reference circuit for a shortage to

battery voltage and repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 12

15

Check the control circuit for a shortage to ground

and repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 12

16

Check the control circuit for an open or poor

connection at the EEGR valve electrical connector

and repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 18

17Replace the EEGR valve.

Is the replacement complete?–Go to Step 19–

18

Check the ECM electrical connector for a poor

connection and repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 12

19

1. Using the scan tool, clear the Diagnostic Trouble

Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting the DTC as specifiec in the supporting

text.

Does the scan tool indicate that this diagnostic ran

and passed?

–

Go to Step 20Go to Step 2

20

Check if any additional DTCs are set.

Are any DTCs displayed that have not been

diagnosed?

–

Go to

Applicable DTC

table

System OK

Page 291 of 1184

ENGINE CONTROLS 1F–193

DAEWOO M-150 BL2

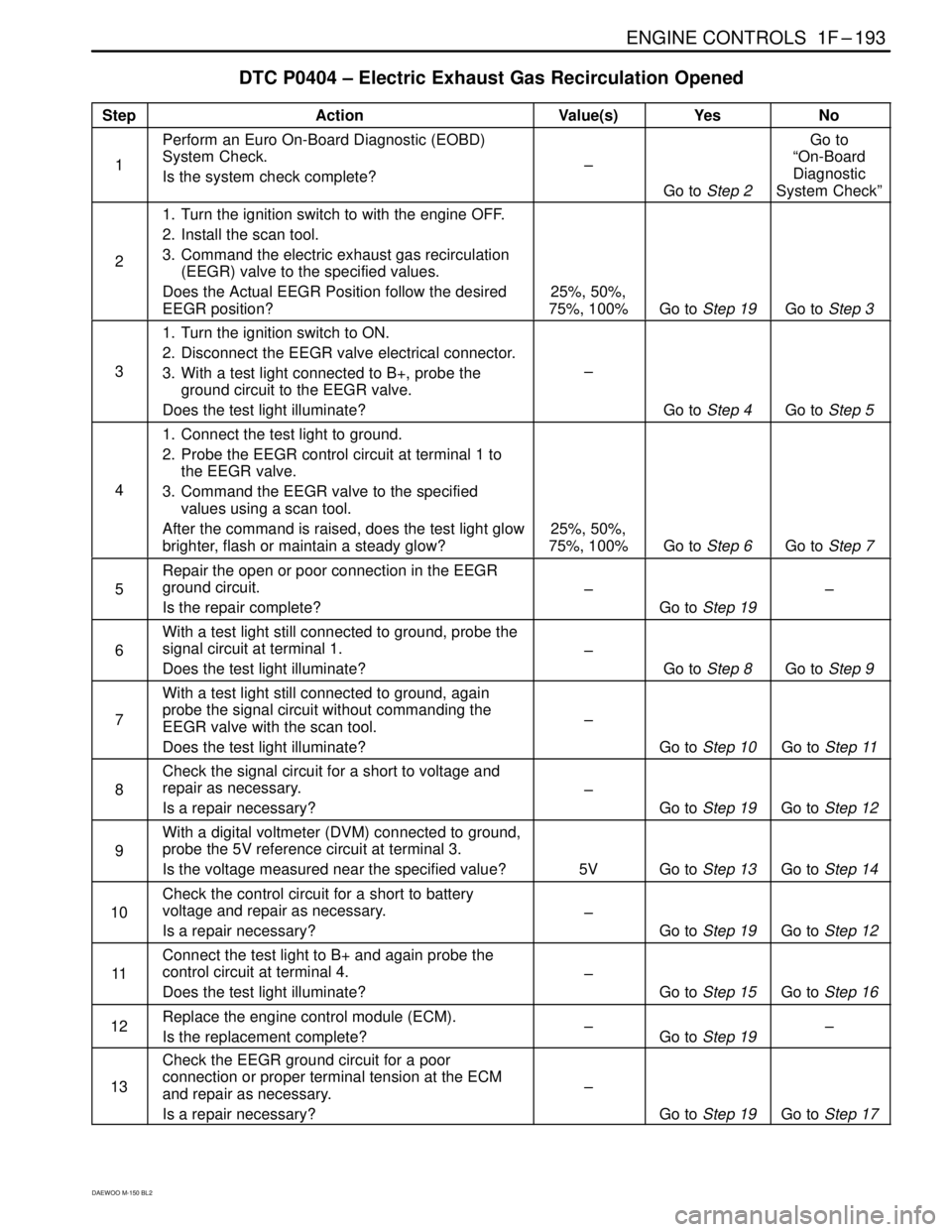

DTC P0404 – Electric Exhaust Gas Recirculation Opened

StepActionValue(s)YesNo

1

Perform an Euro On-Board Diagnostic (EOBD)

System Check.

Is the system check complete?

–

Go to Step 2

Go to

“On-Board

Diagnostic

System Check”

2

1. Turn the ignition switch to with the engine OFF.

2. Install the scan tool.

3. Command the electric exhaust gas recirculation

(EEGR) valve to the specified values.

Does the Actual EEGR Position follow the desired

EEGR position?

25%, 50%,

75%, 100%

Go to Step 19Go to Step 3

3

1. Turn the ignition switch to ON.

2. Disconnect the EEGR valve electrical connector.

3. With a test light connected to B+, probe the

ground circuit to the EEGR valve.

Does the test light illuminate?

–

Go to Step 4Go to Step 5

4

1. Connect the test light to ground.

2. Probe the EEGR control circuit at terminal 1 to

the EEGR valve.

3. Command the EEGR valve to the specified

values using a scan tool.

After the command is raised, does the test light glow

brighter, flash or maintain a steady glow?

25%, 50%,

75%, 100%

Go to Step 6Go to Step 7

5

Repair the open or poor connection in the EEGR

ground circuit.

Is the repair complete?

–

Go to Step 19

–

6

With a test light still connected to ground, probe the

signal circuit at terminal 1.

Does the test light illuminate?

–

Go to Step 8Go to Step 9

7

With a test light still connected to ground, again

probe the signal circuit without commanding the

EEGR valve with the scan tool.

Does the test light illuminate?

–

Go to Step 10Go to Step 11

8

Check the signal circuit for a short to voltage and

repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 12

9

With a digital voltmeter (DVM) connected to ground,

probe the 5V reference circuit at terminal 3.

Is the voltage measured near the specified value?

5VGo to Step 13Go to Step 14

10

Check the control circuit for a short to battery

voltage and repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 12

11

Connect the test light to B+ and again probe the

control circuit at terminal 4.

Does the test light illuminate?

–

Go to Step 15Go to Step 16

12Replace the engine control module (ECM).

Is the replacement complete?–Go to Step 19–

13

Check the EEGR ground circuit for a poor

connection or proper terminal tension at the ECM

and repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 17

Page 292 of 1184

1F–194 ENGINE CONTROLS

DAEWOO M-150 BL2

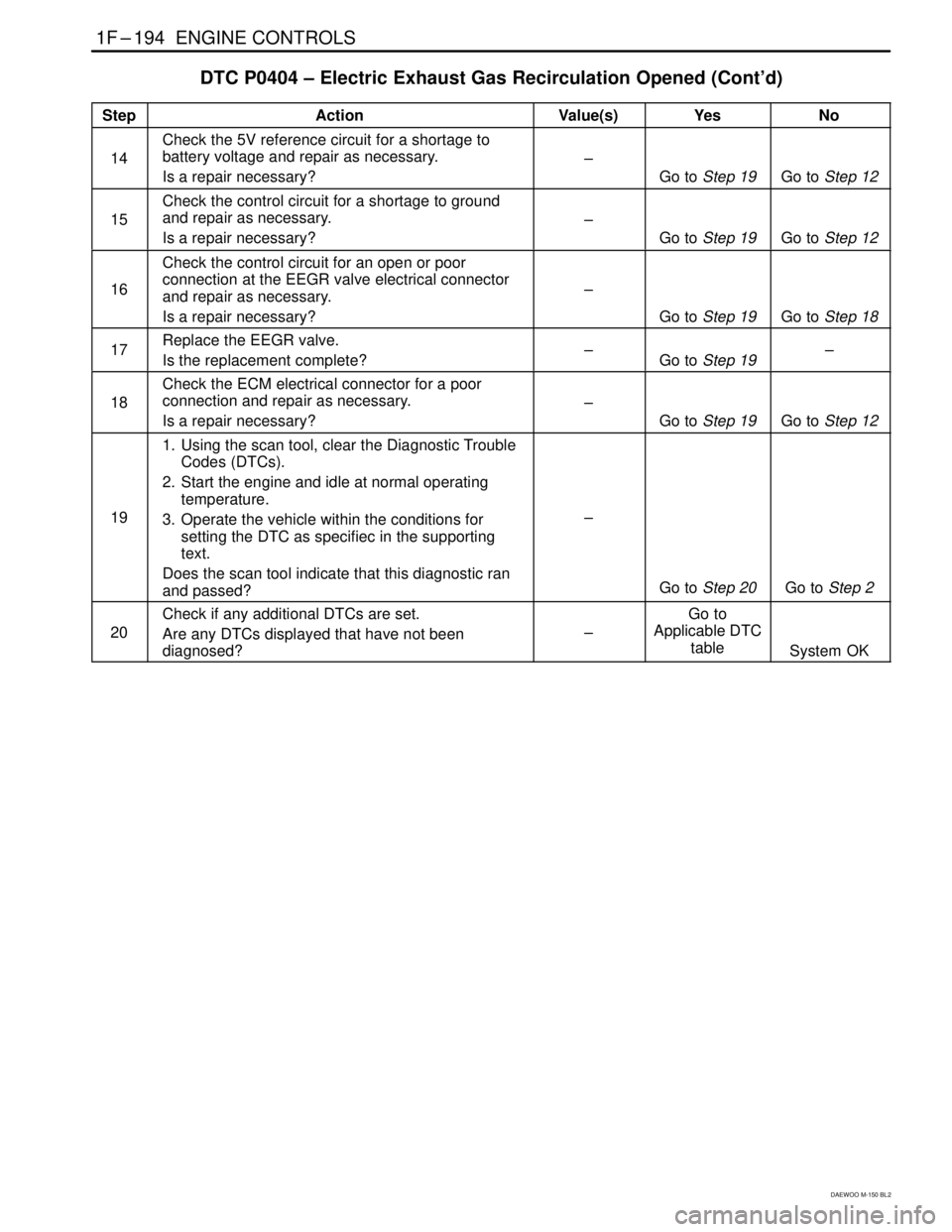

DTC P0404 – Electric Exhaust Gas Recirculation Opened (Cont’d)

StepActionValue(s)YesNo

14

Check the 5V reference circuit for a shortage to

battery voltage and repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 12

15

Check the control circuit for a shortage to ground

and repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 12

16

Check the control circuit for an open or poor

connection at the EEGR valve electrical connector

and repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 18

17Replace the EEGR valve.

Is the replacement complete?–Go to Step 19–

18

Check the ECM electrical connector for a poor

connection and repair as necessary.

Is a repair necessary?

–

Go to Step 19Go to Step 12

19

1. Using the scan tool, clear the Diagnostic Trouble

Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting the DTC as specifiec in the supporting

text.

Does the scan tool indicate that this diagnostic ran

and passed?

–

Go to Step 20Go to Step 2

20

Check if any additional DTCs are set.

Are any DTCs displayed that have not been

diagnosed?

–

Go to

Applicable DTC

table

System OK

Page 321 of 1184

ENGINE CONTROLS 1F–223

DAEWOO M-150 BL2

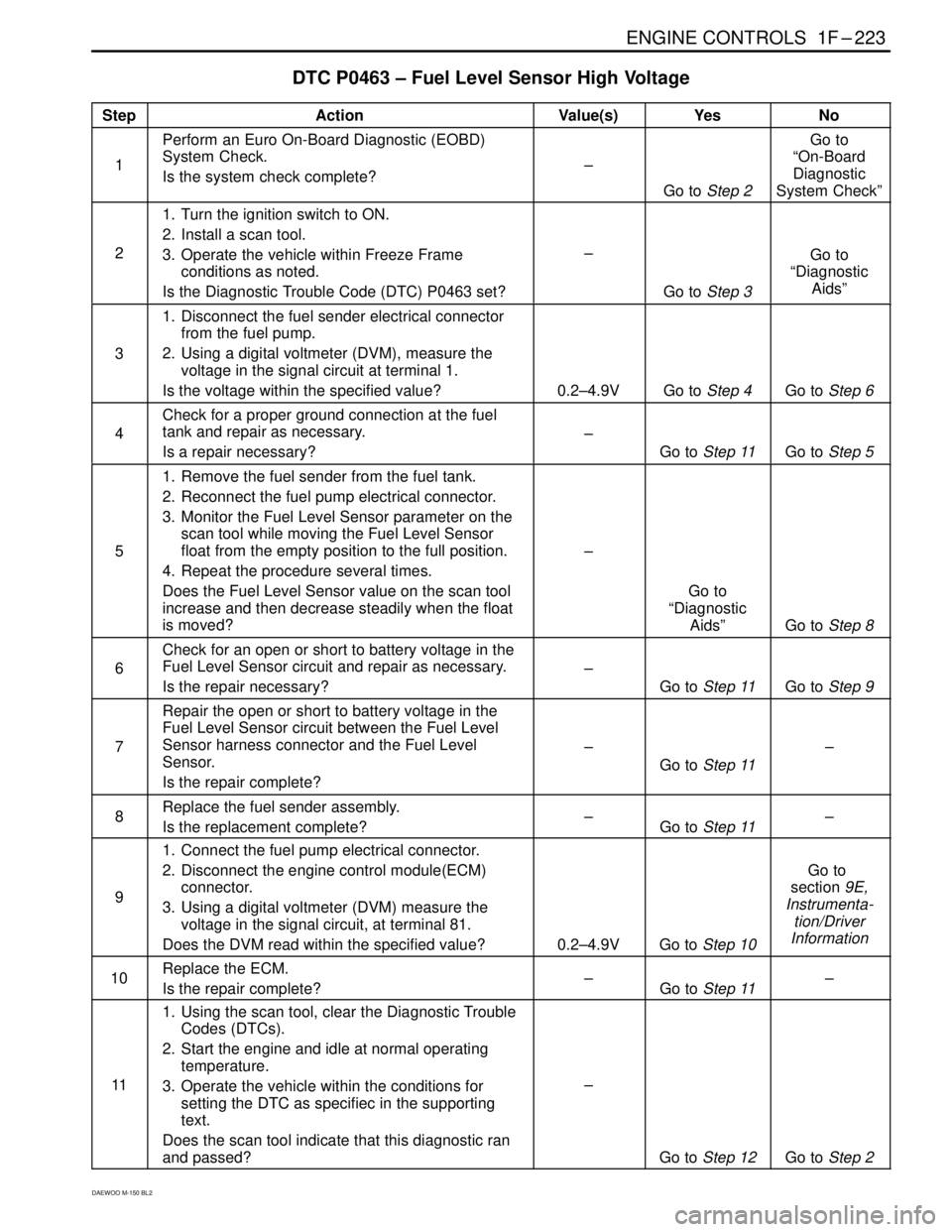

DTC P0463 – Fuel Level Sensor High Voltage

StepActionValue(s)YesNo

1

Perform an Euro On-Board Diagnostic (EOBD)

System Check.

Is the system check complete?

–

Go to Step 2

Go to

“On-Board

Diagnostic

System Check”

2

1. Turn the ignition switch to ON.

2. Install a scan tool.

3. Operate the vehicle within Freeze Frame

conditions as noted.

Is the Diagnostic Trouble Code (DTC) P0463 set?

–

Go to Step 3

Go to

“Diagnostic

Aids”

3

1. Disconnect the fuel sender electrical connector

from the fuel pump.

2. Using a digital voltmeter (DVM), measure the

voltage in the signal circuit at terminal 1.

Is the voltage within the specified value?

0.2–4.9VGo to Step 4Go to Step 6

4

Check for a proper ground connection at the fuel

tank and repair as necessary.

Is a repair necessary?

–

Go to Step 11Go to Step 5

5

1. Remove the fuel sender from the fuel tank.

2. Reconnect the fuel pump electrical connector.

3. Monitor the Fuel Level Sensor parameter on the

scan tool while moving the Fuel Level Sensor

float from the empty position to the full position.

4. Repeat the procedure several times.

Does the Fuel Level Sensor value on the scan tool

increase and then decrease steadily when the float

is moved?

–

Go to

“Diagnostic

Aids”

Go to Step 8

6

Check for an open or short to battery voltage in the

Fuel Level Sensor circuit and repair as necessary.

Is the repair necessary?

–

Go to Step 11Go to Step 9

7

Repair the open or short to battery voltage in the

Fuel Level Sensor circuit between the Fuel Level

Sensor harness connector and the Fuel Level

Sensor.

Is the repair complete?

–

Go to Step 11

–

8Replace the fuel sender assembly.

Is the replacement complete?–Go to Step 11–

9

1. Connect the fuel pump electrical connector.

2. Disconnect the engine control module(ECM)

connector.

3. Using a digital voltmeter (DVM) measure the

voltage in the signal circuit, at terminal 81.

Does the DVM read within the specified value?

0.2–4.9VGo to Step 10

Go to

section 9E,

Instrumenta-

tion/Driver

Information

10Replace the ECM.

Is the repair complete?–Go to Step 11–

11

1. Using the scan tool, clear the Diagnostic Trouble

Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting the DTC as specifiec in the supporting

text.

Does the scan tool indicate that this diagnostic ran

and passed?

–

Go to Step 12Go to Step 2

Page 349 of 1184

ENGINE CONTROLS 1F–251

DAEWOO M-150 BL2

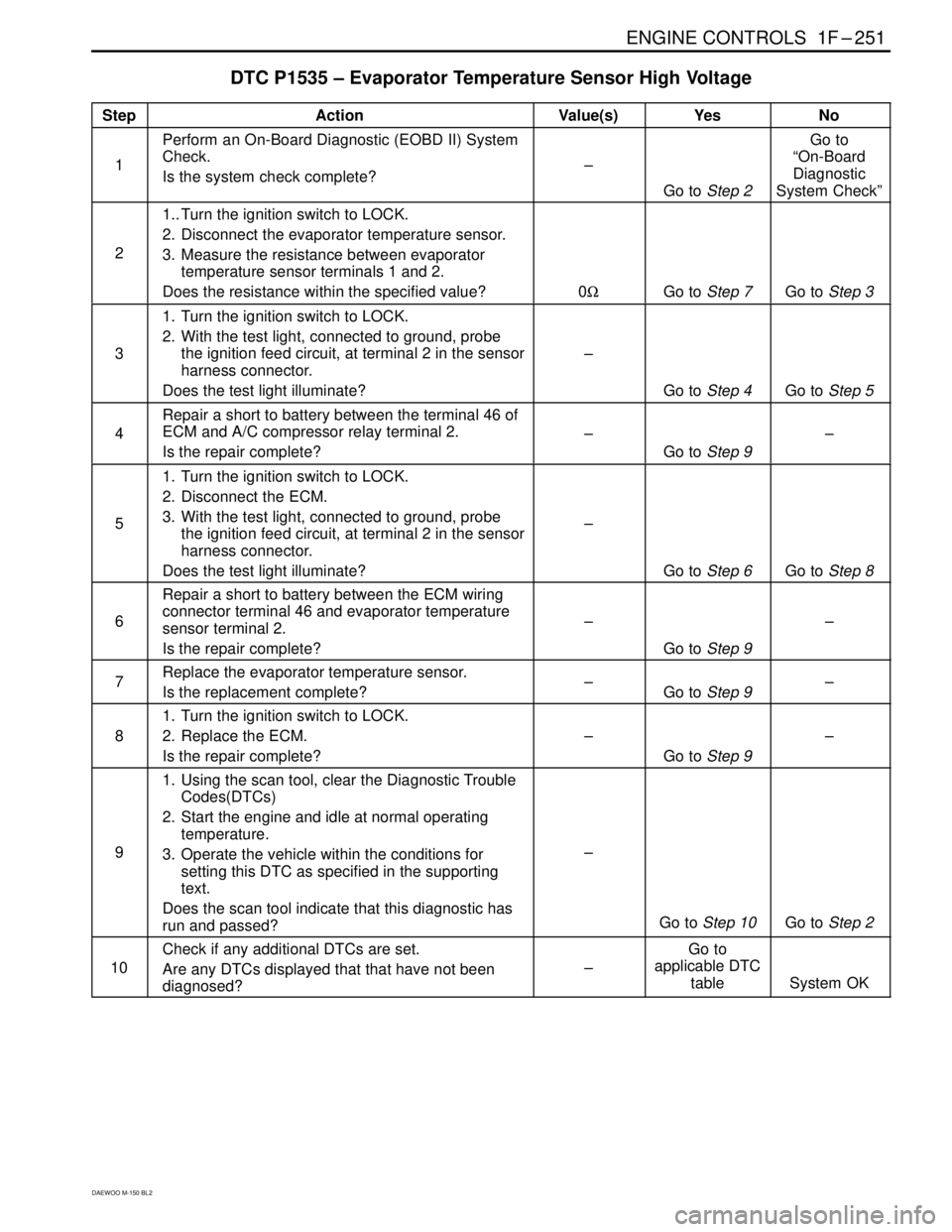

DTC P1535 – Evaporator Temperature Sensor High Voltage

StepActionValue(s)YesNo

1

Perform an On-Board Diagnostic (EOBD II) System

Check.

Is the system check complete?

–

Go to Step 2

Go to

“On-Board

Diagnostic

System Check”

2

1.. Turn the ignition switch to LOCK.

2. Disconnect the evaporator temperature sensor.

3. Measure the resistance between evaporator

temperature sensor terminals 1 and 2.

Does the resistance within the specified value?

0ΩGo to Step 7Go to Step 3

3

1. Turn the ignition switch to LOCK.

2. With the test light, connected to ground, probe

the ignition feed circuit, at terminal 2 in the sensor

harness connector.

Does the test light illuminate?

–

Go to Step 4Go to Step 5

4

Repair a short to battery between the terminal 46 of

ECM and A/C compressor relay terminal 2.

Is the repair complete?

–

Go to Step 9

–

5

1. Turn the ignition switch to LOCK.

2. Disconnect the ECM.

3. With the test light, connected to ground, probe

the ignition feed circuit, at terminal 2 in the sensor

harness connector.

Does the test light illuminate?

–

Go to Step 6Go to Step 8

6

Repair a short to battery between the ECM wiring

connector terminal 46 and evaporator temperature

sensor terminal 2.

Is the repair complete?

–

Go to Step 9

–

7Replace the evaporator temperature sensor.

Is the replacement complete?–Go to Step 9–

8

1. Turn the ignition switch to LOCK.

2. Replace the ECM.

Is the repair complete?

–

Go to Step 9

–

9

1. Using the scan tool, clear the Diagnostic Trouble

Codes(DTCs)

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?

–

Go to Step 10Go to Step 2

10

Check if any additional DTCs are set.

Are any DTCs displayed that that have not been

diagnosed?

–

Go to

applicable DTC

table

System OK

Page 351 of 1184

ENGINE CONTROLS 1F–253

DAEWOO M-150 BL2

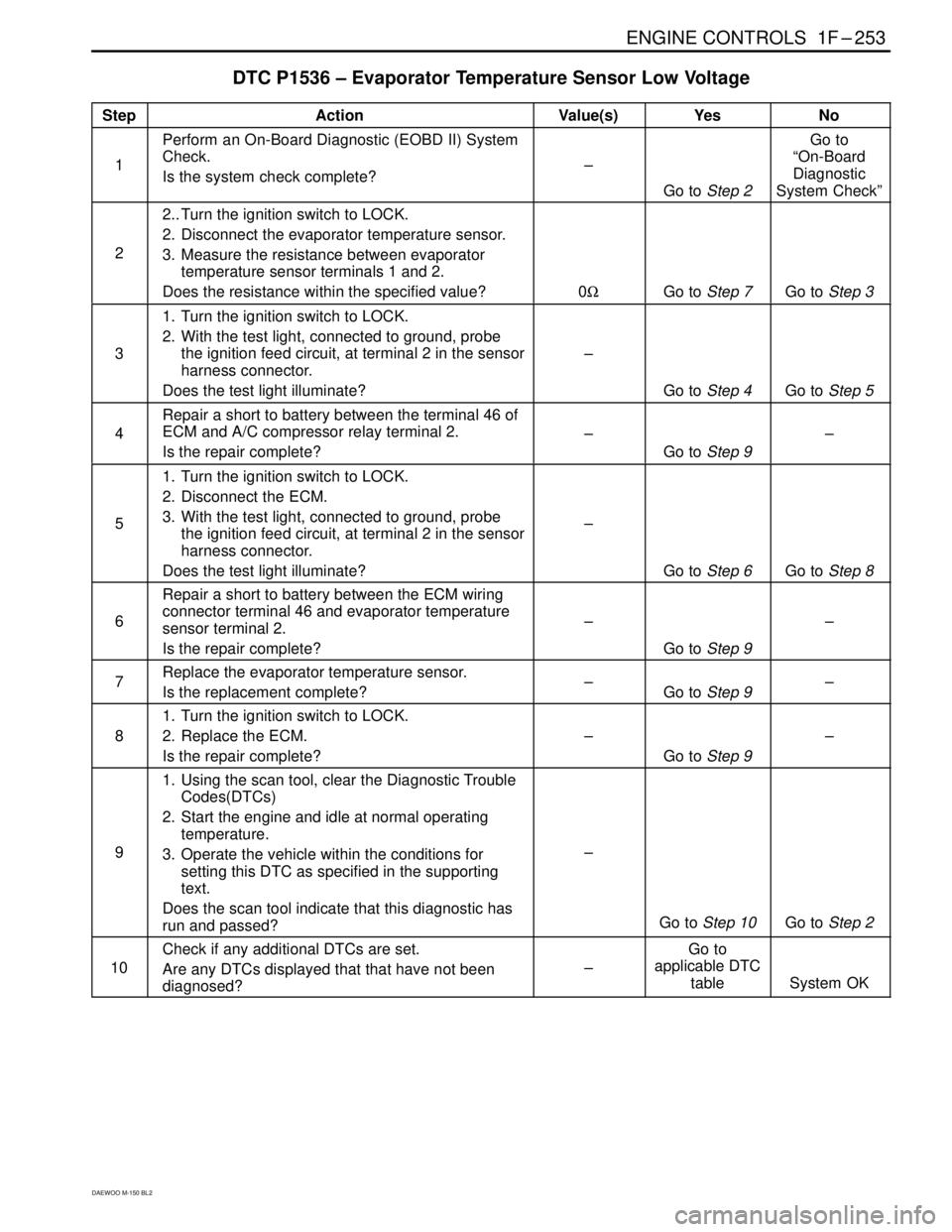

DTC P1536 – Evaporator Temperature Sensor Low Voltage

StepActionValue(s)YesNo

1

Perform an On-Board Diagnostic (EOBD II) System

Check.

Is the system check complete?

–

Go to Step 2

Go to

“On-Board

Diagnostic

System Check”

2

2.. Turn the ignition switch to LOCK.

2. Disconnect the evaporator temperature sensor.

3. Measure the resistance between evaporator

temperature sensor terminals 1 and 2.

Does the resistance within the specified value?

0ΩGo to Step 7Go to Step 3

3

1. Turn the ignition switch to LOCK.

2. With the test light, connected to ground, probe

the ignition feed circuit, at terminal 2 in the sensor

harness connector.

Does the test light illuminate?

–

Go to Step 4Go to Step 5

4

Repair a short to battery between the terminal 46 of

ECM and A/C compressor relay terminal 2.

Is the repair complete?

–

Go to Step 9

–

5

1. Turn the ignition switch to LOCK.

2. Disconnect the ECM.

3. With the test light, connected to ground, probe

the ignition feed circuit, at terminal 2 in the sensor

harness connector.

Does the test light illuminate?

–

Go to Step 6Go to Step 8

6

Repair a short to battery between the ECM wiring

connector terminal 46 and evaporator temperature

sensor terminal 2.

Is the repair complete?

–

Go to Step 9

–

7Replace the evaporator temperature sensor.

Is the replacement complete?–Go to Step 9–

8

1. Turn the ignition switch to LOCK.

2. Replace the ECM.

Is the repair complete?

–

Go to Step 9

–

9

1. Using the scan tool, clear the Diagnostic Trouble

Codes(DTCs)

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?

–

Go to Step 10Go to Step 2

10

Check if any additional DTCs are set.

Are any DTCs displayed that that have not been

diagnosed?

–

Go to

applicable DTC

table

System OK

Page 353 of 1184

ENGINE CONTROLS 1F–255

DAEWOO M-150 BL2

DTC P1537 – A/C Compressor Relay High Voltage

StepActionValue(s)YesNo

1

Perform an On-Board Diagnostic (EOBD) System

Check.

Is the system check complete?

–

Go to Step 2

Go to

“On-Board

Diagnostic

System Check”

2

3.. Turn the ignition switch to LOCK.

2. Disconnect the A/C compressor relay.

3. Measure the resistance between A/C compressor

relay terminals 85 and 86.

Does the resistance within the specified value?

0ΩGo to Step 3Go to Step 7

3

1. Turn the ignition switch to LOCK.

2. With the test light, connected to ground, probe

the ignition feed circuit, at terminal 86 in the relay

harness connector.

Does the test light illuminate?

–

Go to Step 5Go to Step 4

4

Repair a short to battery voltage between the

ignition switch terminal and A/C compressor relay

terminal 86.

Is the repair complete?

–

Go to Step 9

–

5

1. Turn the ignition switch to LOCK.

2. Disconnect the ECM.

3. With the test light, connected to ground, probe

the ignition feed circuit, at terminal 86 in the relay

harness connector.

Does the test light illuminate?

–

Go to Step 8Go to Step 6

6

Repair a short to battery voltage between the ECM

wiring connector terminal 38 and A/C compressor

relay terminal 85.

Is the repair complete?

–

Go to Step 9

–

7Replace the A/C compressor relay.

Is the replacement complete?–Go to Step 9–

8

1. Turn the ignition switch to LOCK.

2. Replace the ECM.

Is the repair complete?

–

Go to Step 9

–

9

1. Using the scan tool, clear the Diagnostic Trouble

Codes(DTCs)

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?

–

Go to Step 10Go to Step 2

10

Check if any additional DTCs are set.

Are any DTCs displayed that that have not been

diagnosed?

–

Go to

applicable DTC

table

System OK

Page 357 of 1184

ENGINE CONTROLS 1F–259

DAEWOO M-150 BL2

DTC P0562 – System Voltage (Engine Side) Too Low

StepActionValue(s)YesNo

1

Perform an On-Board Diagnostic (EOBD) System

Check.

Is the system check complete?

–

Go to Step 2

Go to

“On-Board

Diagnostic

System Check”

2

1. Install a scan tool and clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and raise the engine speed to

the specified value.

3. Load the electrical system by turning on the

headlights, high blower motor, etc.

Is the ignition voltage less than the specified value?

1,400rpm 10VGo to Step 3Go to Step 8

3

1. With the engine still running at the specified

value.

2. Using a digital voltmeter(DVM), measure the

battery voltage at the battery.

Is the battery voltage greater than the specified

value?

1,400rpm 12VGo to Step 4

Go to

“Diagnostic

Aids”

4

1. Turn the ignition switch to LOCK.

2. Disconnect the engine control module(ECM)

connector at the ECM.

3. Turn the Turn the ignition switch to ON with the

engine OFF.

4 Using a DVM, measure the ignition voltage at the

ignition feed circuit, terminal 29.

Is the ignition voltage greater than the specified

value?

10VGo to Step 5Go to Step 6

5

Check for a malfunctioning connection at the ECM

harness terminals and repair as necessary.

Is a repair necessary?

–

Go to Step 8Go to Step 7

6

Repair the poor connection (high resistance) in the

ignition feed circuit.

Is the repair complete?

–

Go to Step 8

–

7Replace the ECM.

Is the replacement complete?–Go to Step 8–

8

1 Using the scan tool, clear the DTCs.

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting this DTC ad specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?

–

Go to Step 9Go to Step 2

9

Check if any additional DTCs are set.

Are any DTCs displayed that have not been

diagnosed?

–

Go to

applicable DTC

table

System OK