DAEWOO NUBIRA 2004 Service Repair Manual

Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1031 of 2643

HYDRAULIC BRAKES 4A – 15

DAEWOO V–121 BL4

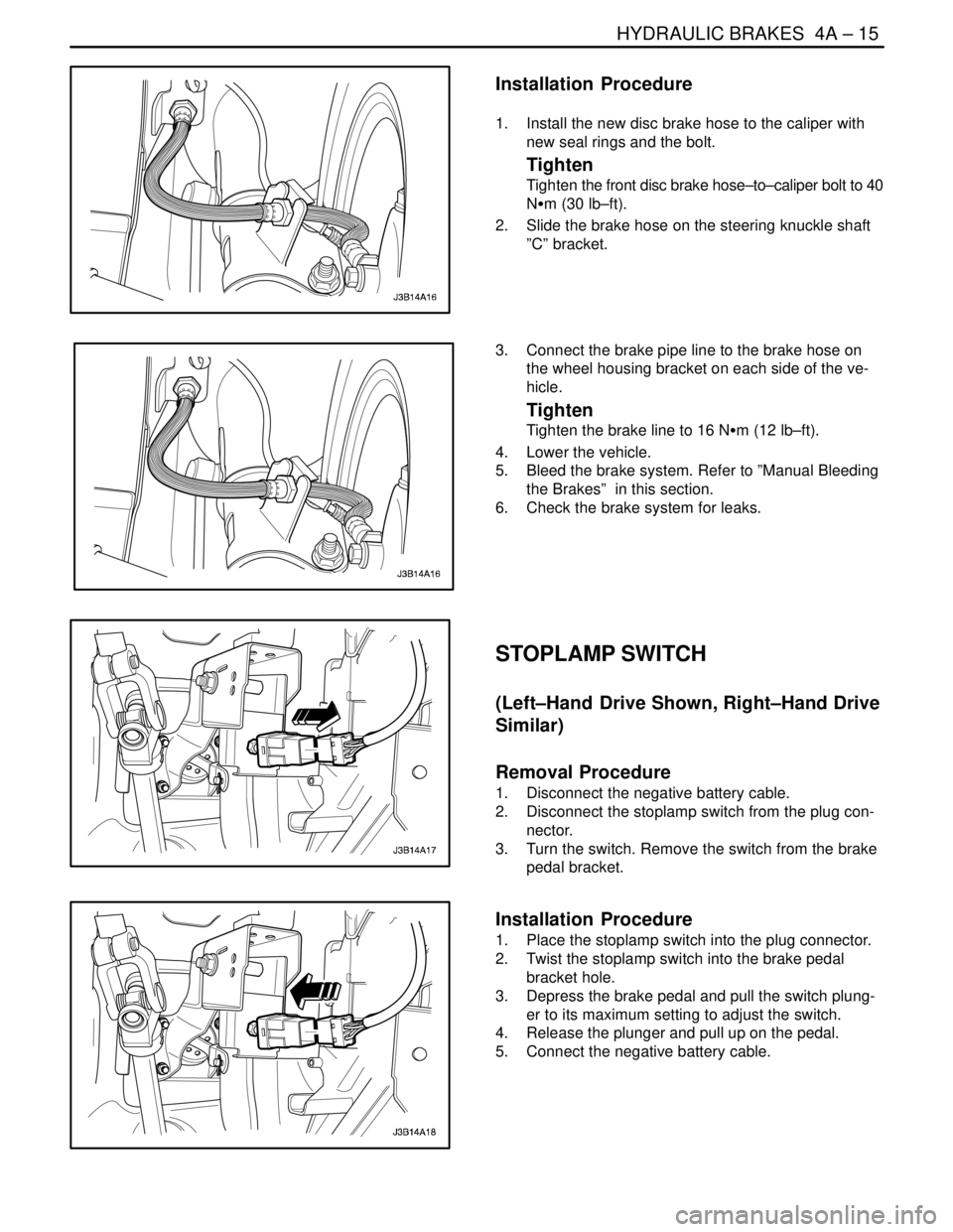

Installation Procedure

1. Install the new disc brake hose to the caliper with

new seal rings and the bolt.

Tighten

Tighten the front disc brake hose–to–caliper bolt to 40

NSm (30 lb–ft).

2. Slide the brake hose on the steering knuckle shaft

”C” bracket.

3. Connect the brake pipe line to the brake hose on

the wheel housing bracket on each side of the ve-

hicle.

Tighten

Tighten the brake line to 16 NSm (12 lb–ft).

4. Lower the vehicle.

5. Bleed the brake system. Refer to ”Manual Bleeding

the Brakes” in this section.

6. Check the brake system for leaks.

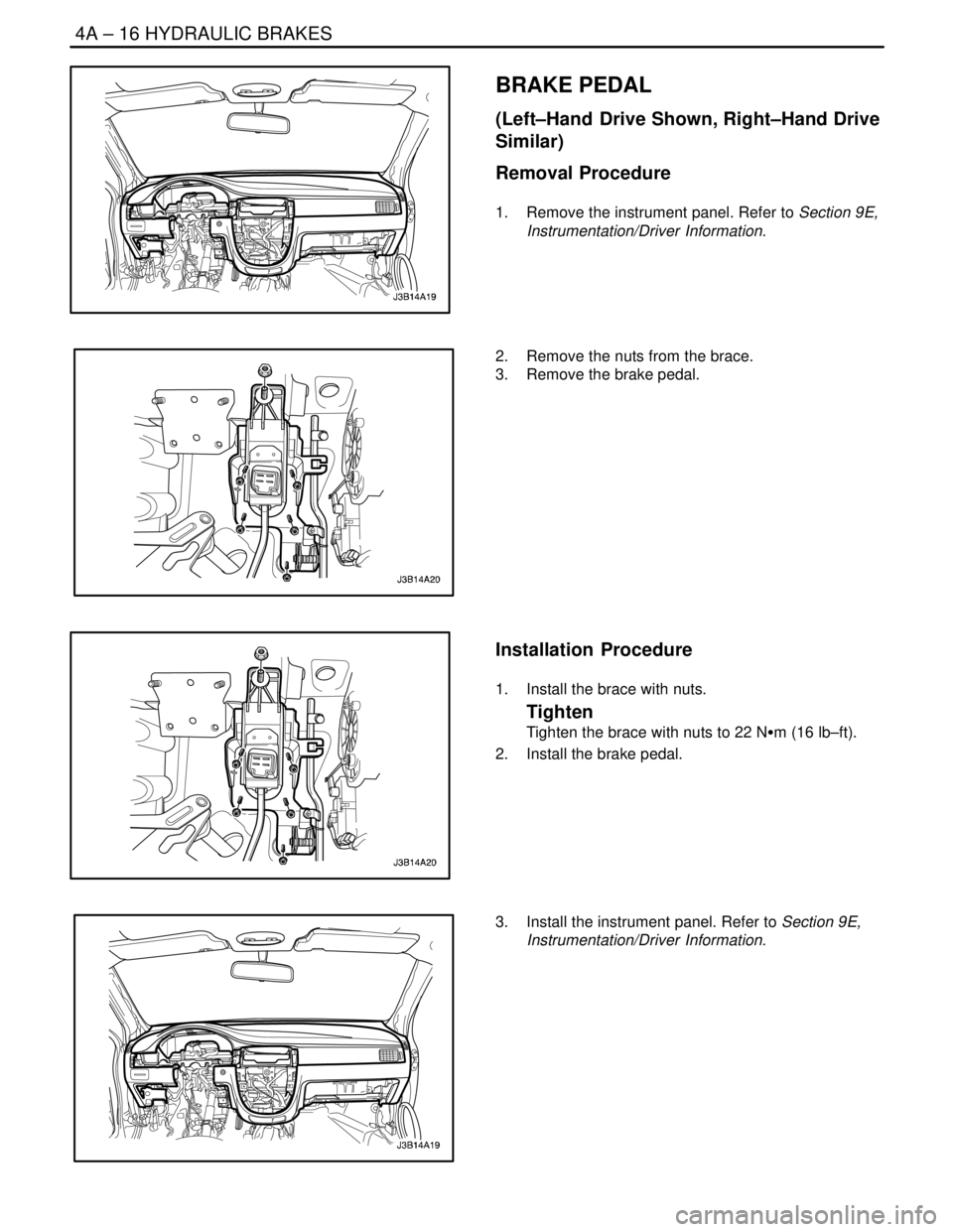

STOPLAMP SWITCH

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the stoplamp switch from the plug con-

nector.

3. Turn the switch. Remove the switch from the brake

pedal bracket.

Installation Procedure

1. Place the stoplamp switch into the plug connector.

2. Twist the stoplamp switch into the brake pedal

bracket hole.

3. Depress the brake pedal and pull the switch plung-

er to its maximum setting to adjust the switch.

4. Release the plunger and pull up on the pedal.

5. Connect the negative battery cable.

Page 1032 of 2643

4A – 16IHYDRAULIC BRAKES

DAEWOO V–121 BL4

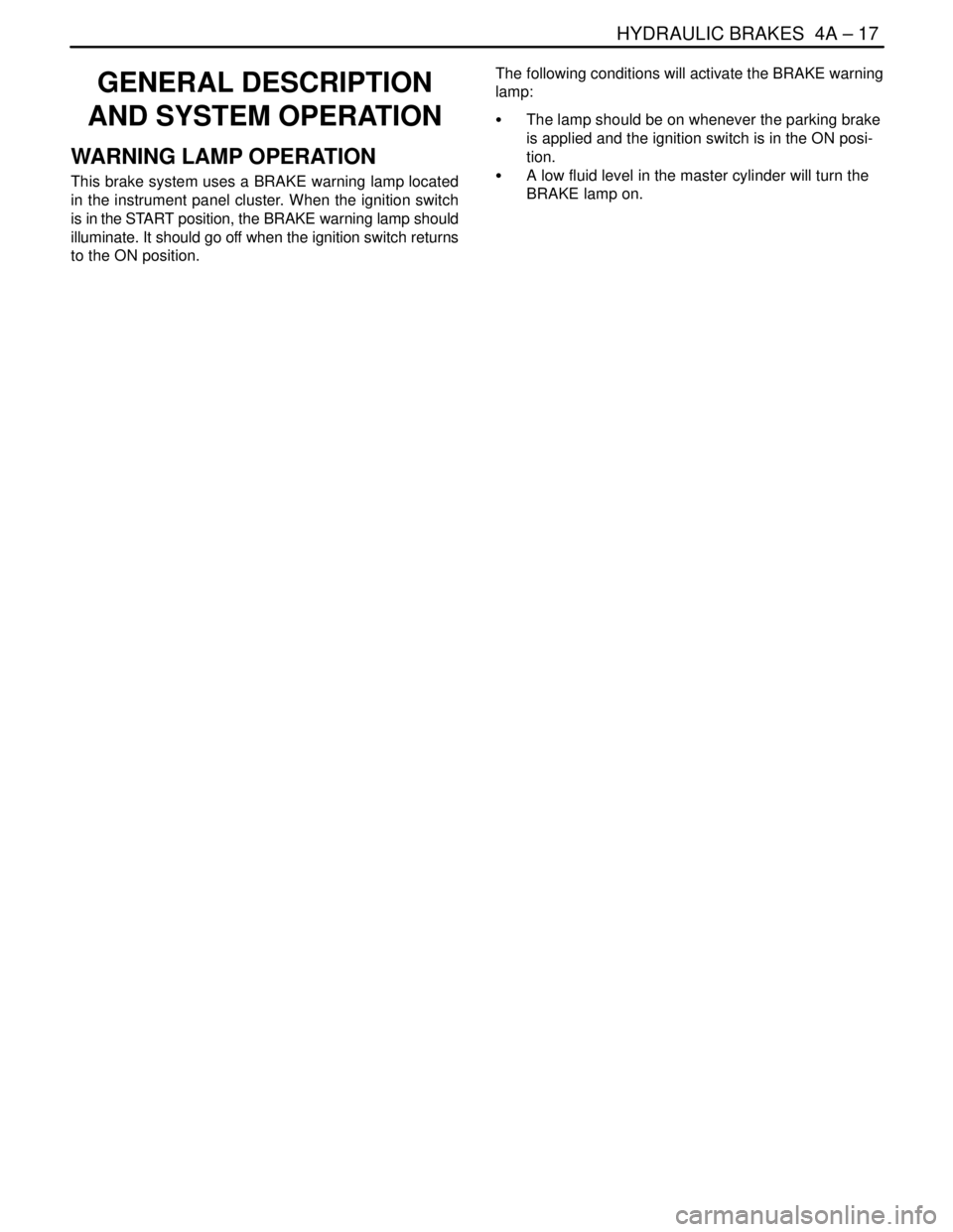

BRAKE PEDAL

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Remove the instrument panel. Refer to Section 9E,

Instrumentation/Driver Information.

2. Remove the nuts from the brace.

3. Remove the brake pedal.

Installation Procedure

1. Install the brace with nuts.

Tighten

Tighten the brace with nuts to 22 NSm (16 lb–ft).

2. Install the brake pedal.

3. Install the instrument panel. Refer to Section 9E,

Instrumentation/Driver Information.

Page 1033 of 2643

HYDRAULIC BRAKES 4A – 17

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

WARNING LAMP OPERATION

This brake system uses a BRAKE warning lamp located

in the instrument panel cluster. When the ignition switch

is in the START position, the BRAKE warning lamp should

illuminate. It should go off when the ignition switch returns

to the ON position.The following conditions will activate the BRAKE warning

lamp:

S The lamp should be on whenever the parking brake

is applied and the ignition switch is in the ON posi-

tion.

S A low fluid level in the master cylinder will turn the

BRAKE lamp on.

Page 1034 of 2643

SECTION : 4B

MASTER CYLINDER

TABLE OF CONTENTS

SPECIFICATIONS4B–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 4B–1. . . . . . . . . .

DIAGNOSIS4B–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Brake Proportioning Valve 4B–2. . . . . . . . .

MAINTENANCE AND REPAIR4B–3 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 4B–3. . . . . . . . . . . . . . . . . . . . .

Master Cylinder Assembly 4B–3. . . . . . . . . . . . . . . . . . Brake Fluid Reservoir 4B–4. . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 4B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Master Cylinder Overhaul 4B–7. . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION4B–9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Master Cylinder 4B–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Level Sensor 4B–9. . . . . . . . . . . . . . . . . . . . . . . .

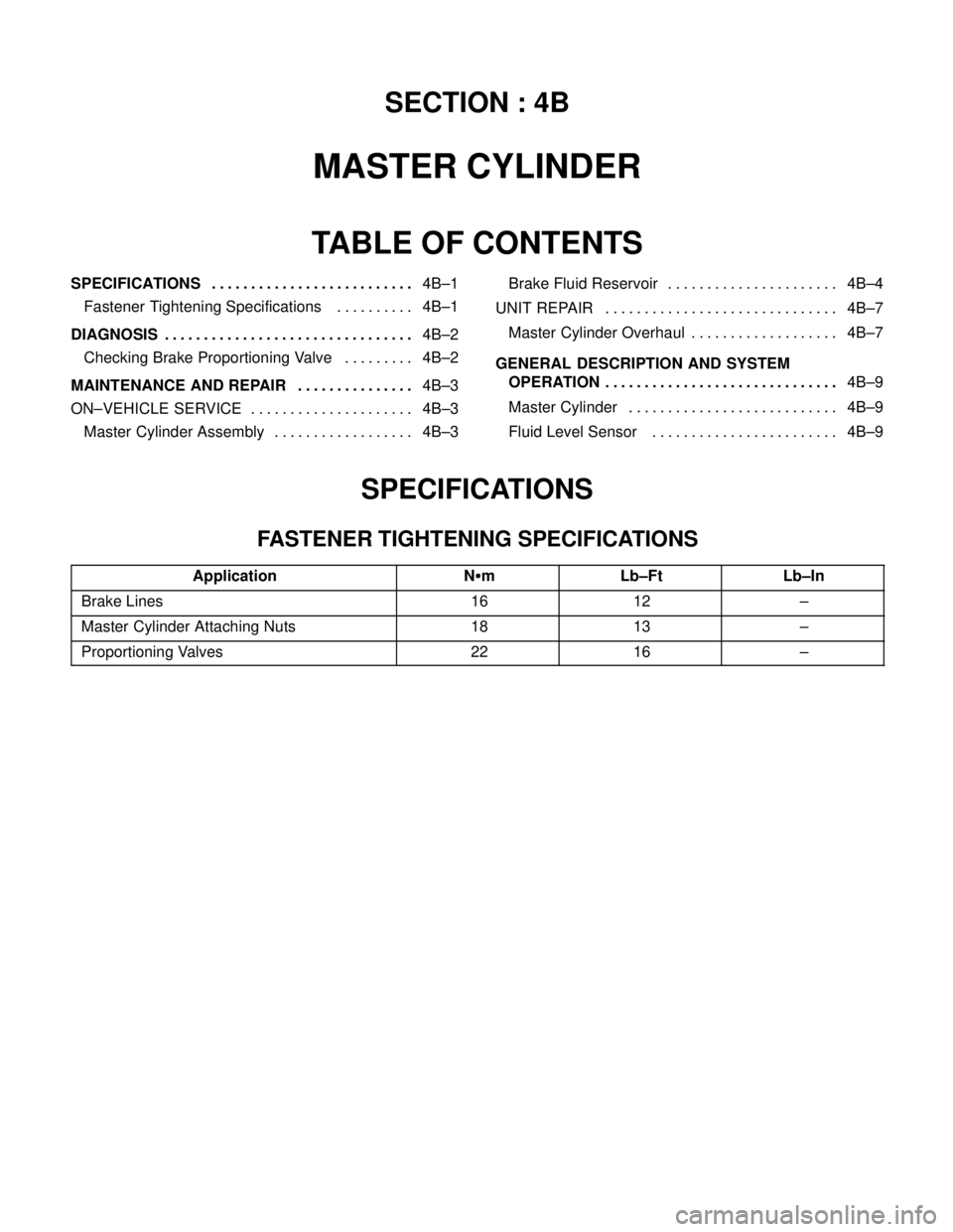

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Brake Lines1612–

Master Cylinder Attaching Nuts1813–

Proportioning Valves2216–

Page 1035 of 2643

4B – 2IMASTER CYLINDER

DAEWOO V–121 BL4

DIAGNOSIS

CHECKING BRAKE

PROPORTIONING VALVE

Use two brake pressure gauges to check the brake pro-

portioning valves that are attached to the master cylinder

on non–ABS braking systems. These valves limit the out-

let pressure to the rear brakes after a predetermined mas-

ter cylinder pressure has been reached. (On ABS braking

systems, the hydraulic modulator/motor pack assembly

controls the hydraulic pressure to both the rear wheel cyl-

inders or rear calipers, and the front calipers.)

When checking the brake proportioning valves, be sure

that the hydraulic line pressure is measured simulta-

neously and diagonally on the front and the rear axles.To measure the pressure, use the following steps.

1. Remove the bleeder valve and install a pressure

gauge to one of the rear brake cylinders.

2. Install another bleeder valve and install another

pressure gauge to the diagonally opposite front

brake.

3. Build pressure by pressing firmly on the brake ped-

al several times. (The pressure indicated on the

gauge is not regulated and represents the actual

brake system hydraulic pressure.)

4. Build pressure until the test values in the following

proportioning valve test chart are achieved.

Model

Reference Number for

Gradient and Switching

Pressure on the Valve

HousingInput Pressure Read on

the Manometer at the

Front Axle in kPa (psi)Output Pressure Read

on the Manometer at the

Front Axle in kPa (psi)

500 (73)500 (73)

N/B, H/B0.3/304 500 (653) 3 450 ± 200(500 ± 29)

10 000 (1,450)5 100 ± 300(740 ± 44)

500 (73)500 (73)

WAGON0.3/405 500 (798)4 450 ± 200(645 ± 29)

10 000 (1,450)5 800 ± 300(841 ± 44)

Important : If the pressure exceeds 10 000 kPa (1,450

psi), the pressure reading on the rear gauge will not be ac-

curate.5. Remove the gauges from the tested brake circuit

and repeat the test on the remaining circuit.

Page 1036 of 2643

MASTER CYLINDER 4B – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

MASTER CYLINDER ASSEMBLY

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Disconnect the electrical connector from the reser-

voir.

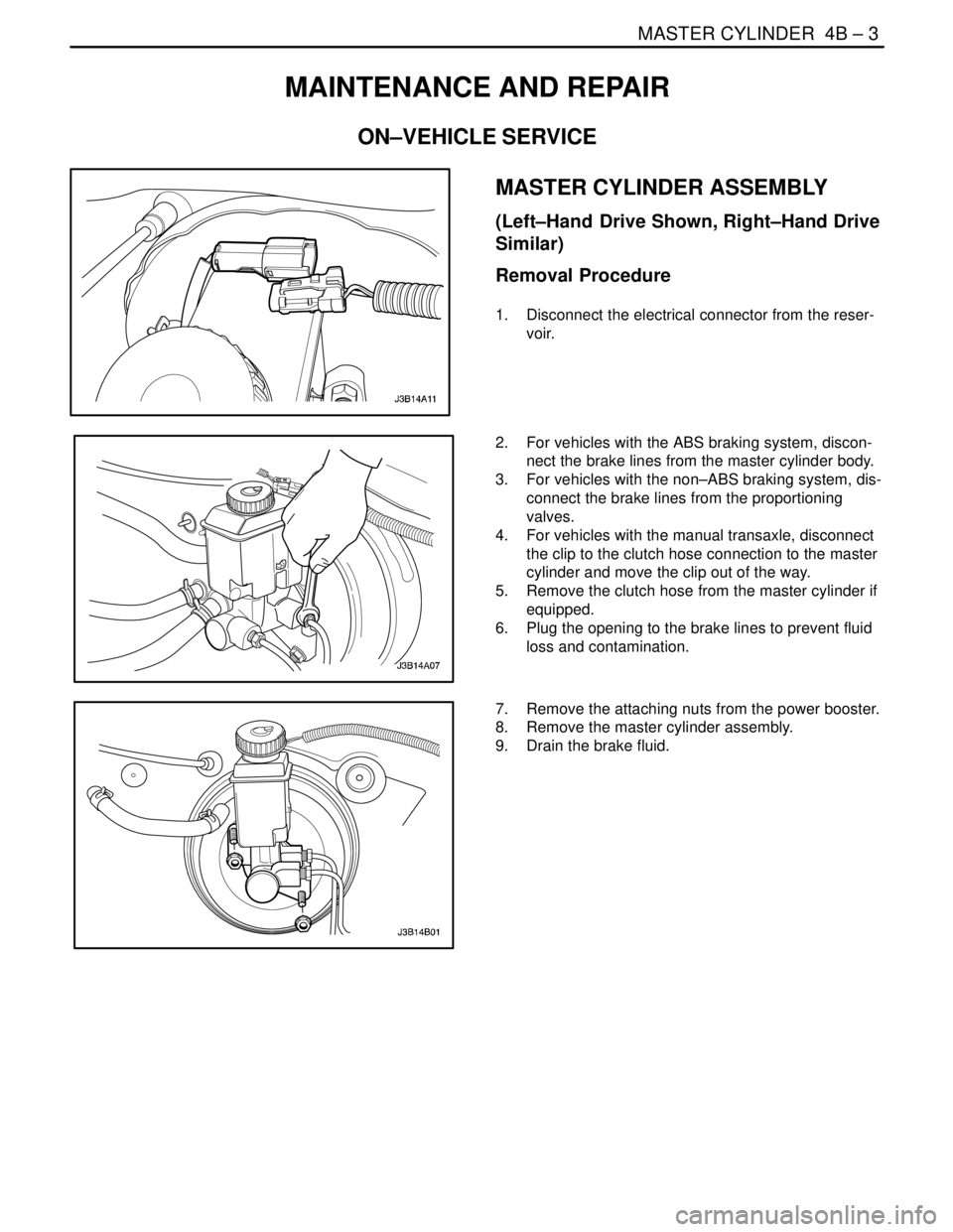

2. For vehicles with the ABS braking system, discon-

nect the brake lines from the master cylinder body.

3. For vehicles with the non–ABS braking system, dis-

connect the brake lines from the proportioning

valves.

4. For vehicles with the manual transaxle, disconnect

the clip to the clutch hose connection to the master

cylinder and move the clip out of the way.

5. Remove the clutch hose from the master cylinder if

equipped.

6. Plug the opening to the brake lines to prevent fluid

loss and contamination.

7. Remove the attaching nuts from the power booster.

8. Remove the master cylinder assembly.

9. Drain the brake fluid.

Page 1037 of 2643

4B – 4IMASTER CYLINDER

DAEWOO V–121 BL4

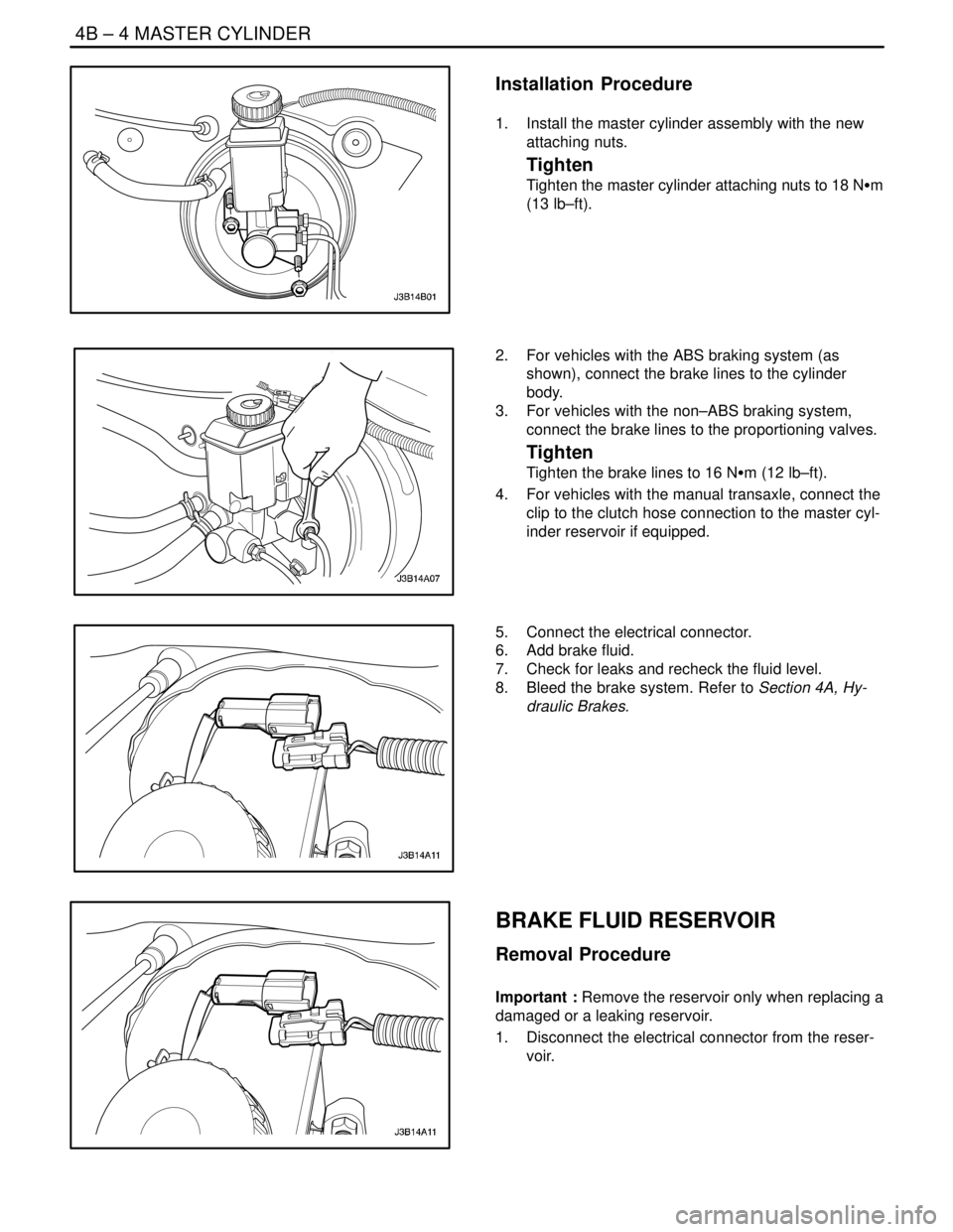

Installation Procedure

1. Install the master cylinder assembly with the new

attaching nuts.

Tighten

Tighten the master cylinder attaching nuts to 18 NSm

(13 lb–ft).

2. For vehicles with the ABS braking system (as

shown), connect the brake lines to the cylinder

body.

3. For vehicles with the non–ABS braking system,

connect the brake lines to the proportioning valves.

Tighten

Tighten the brake lines to 16 NSm (12 lb–ft).

4. For vehicles with the manual transaxle, connect the

clip to the clutch hose connection to the master cyl-

inder reservoir if equipped.

5. Connect the electrical connector.

6. Add brake fluid.

7. Check for leaks and recheck the fluid level.

8. Bleed the brake system. Refer to Section 4A, Hy-

draulic Brakes.

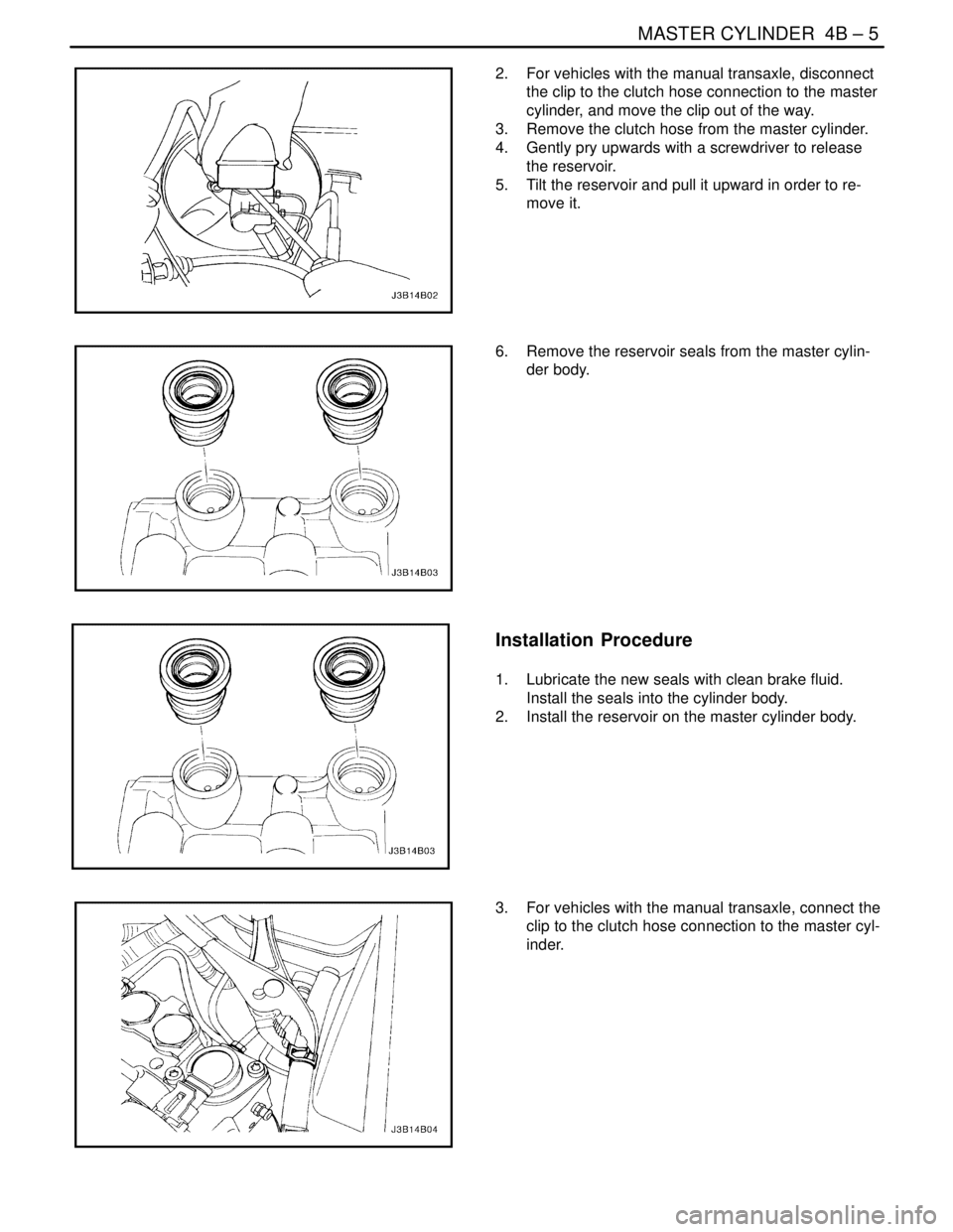

BRAKE FLUID RESERVOIR

Removal Procedure

Important : Remove the reservoir only when replacing a

damaged or a leaking reservoir.

1. Disconnect the electrical connector from the reser-

voir.

Page 1038 of 2643

MASTER CYLINDER 4B – 5

DAEWOO V–121 BL4

2. For vehicles with the manual transaxle, disconnect

the clip to the clutch hose connection to the master

cylinder, and move the clip out of the way.

3. Remove the clutch hose from the master cylinder.

4. Gently pry upwards with a screwdriver to release

the reservoir.

5. Tilt the reservoir and pull it upward in order to re-

move it.

6. Remove the reservoir seals from the master cylin-

der body.

Installation Procedure

1. Lubricate the new seals with clean brake fluid.

Install the seals into the cylinder body.

2. Install the reservoir on the master cylinder body.

3. For vehicles with the manual transaxle, connect the

clip to the clutch hose connection to the master cyl-

inder.

Page 1039 of 2643

4B – 6IMASTER CYLINDER

DAEWOO V–121 BL4

4. Add brake fluid.

5. Raise and suitably support the vehicle.

6. Bleed the braking system. Refer to Section 4A, Hy-

draulic Brakes orSection 4F, Antilock Brake Sys-

tem.Bleed the clutch master cylinder. Refer to Sec-

tion 5C, Clutch.

7. Lower the vehicle.

8. Connect the reservoir electrical connector.

Page 1040 of 2643

MASTER CYLINDER 4B – 7

DAEWOO V–121 BL4

UNIT REPAIR

MASTER CYLINDER OVERHAUL

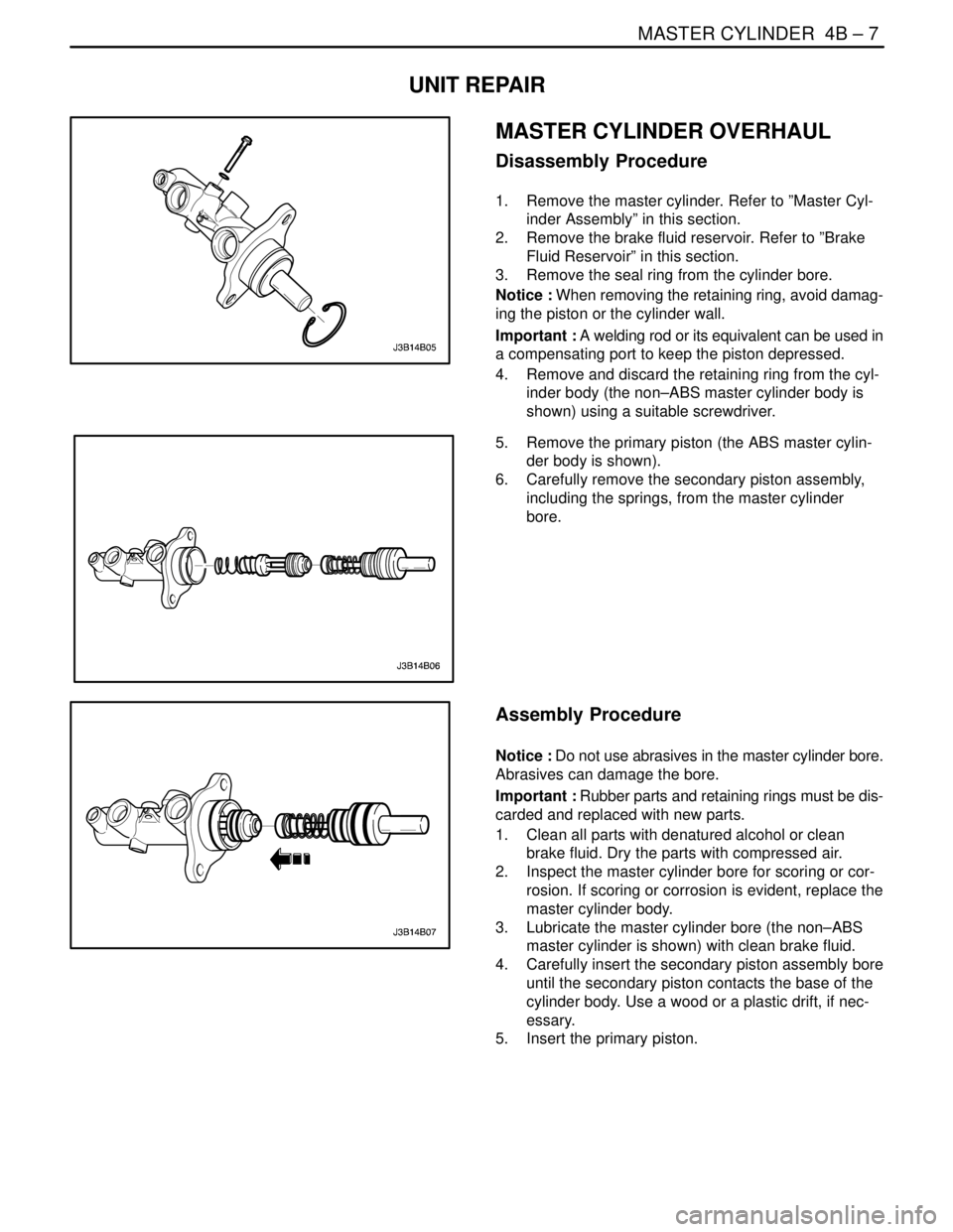

Disassembly Procedure

1. Remove the master cylinder. Refer to ”Master Cyl-

inder Assembly” in this section.

2. Remove the brake fluid reservoir. Refer to ”Brake

Fluid Reservoir” in this section.

3. Remove the seal ring from the cylinder bore.

Notice : When removing the retaining ring, avoid damag-

ing the piston or the cylinder wall.

Important : A welding rod or its equivalent can be used in

a compensating port to keep the piston depressed.

4. Remove and discard the retaining ring from the cyl-

inder body (the non–ABS master cylinder body is

shown) using a suitable screwdriver.

5. Remove the primary piston (the ABS master cylin-

der body is shown).

6. Carefully remove the secondary piston assembly,

including the springs, from the master cylinder

bore.

Assembly Procedure

Notice : Do not use abrasives in the master cylinder bore.

Abrasives can damage the bore.

Important : Rubber parts and retaining rings must be dis-

carded and replaced with new parts.

1. Clean all parts with denatured alcohol or clean

brake fluid. Dry the parts with compressed air.

2. Inspect the master cylinder bore for scoring or cor-

rosion. If scoring or corrosion is evident, replace the

master cylinder body.

3. Lubricate the master cylinder bore (the non–ABS

master cylinder is shown) with clean brake fluid.

4. Carefully insert the secondary piston assembly bore

until the secondary piston contacts the base of the

cylinder body. Use a wood or a plastic drift, if nec-

essary.

5. Insert the primary piston.