fuel cap release DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 21 of 2643

0B – 14IGENERAL INFORMATION

DAEWOO V–121 BL4

Engine Cooling System

Inspect the coolant and freeze protection fluid. If the fluid

is dirty or rusty, drain, flush and refill the engine cooling

system with new coolant. Keep the coolant at the proper

mixture in order to ensure proper freeze protection, corro-sion protection and engine operating temperature. Inspect

the hoses. Replace the cracked, swollen, or deteriorated

hoses. Tighten the clamps. Clean the outside of the radia-

tor and the air conditioning condenser. Wash the filler cap

and the neck. Pressure test the cooling system and the

cap in order to help ensure proper operation.

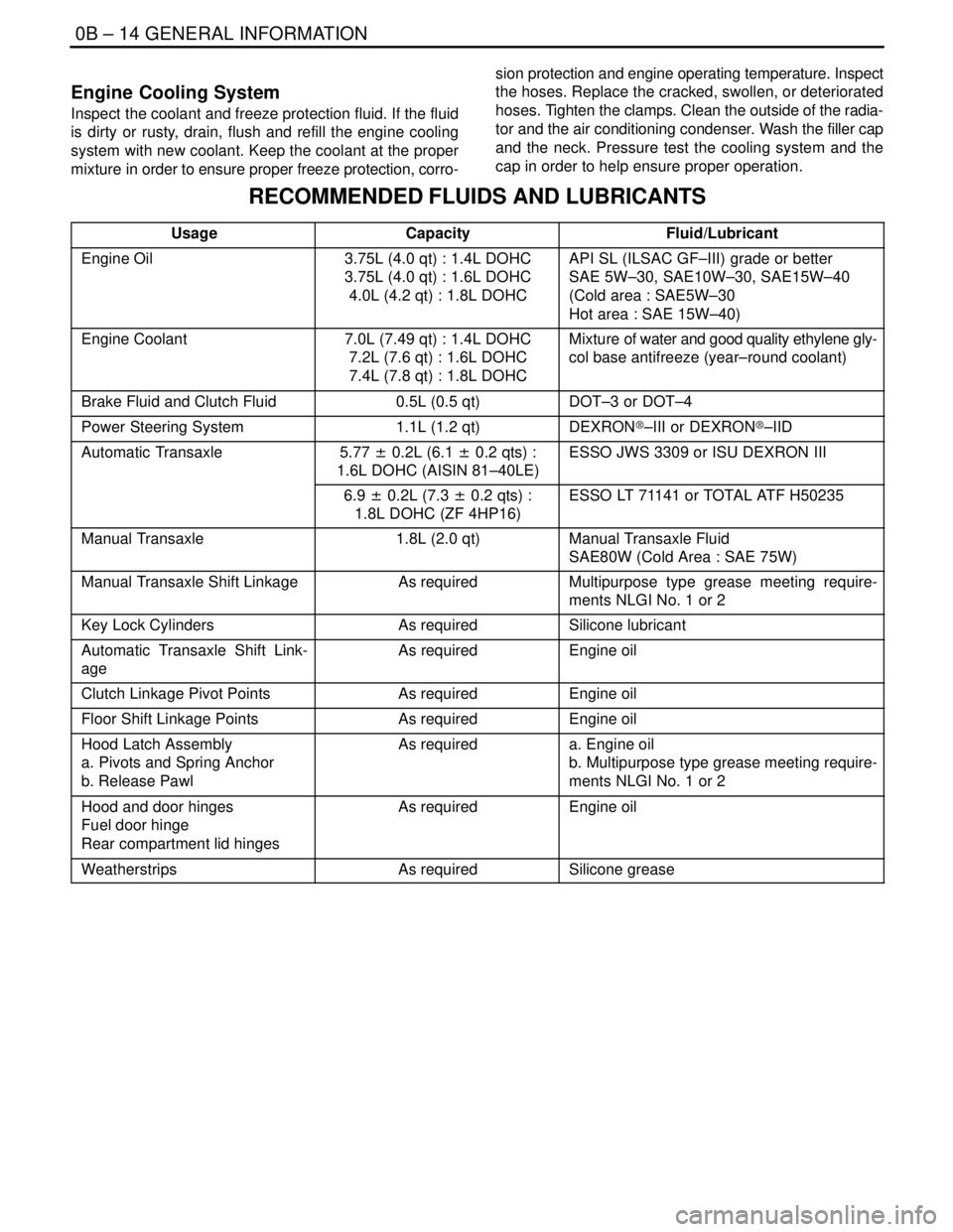

RECOMMENDED FLUIDS AND LUBRICANTS

UsageCapacityFluid/Lubricant

Engine Oil3.75L (4.0 qt) : 1.4L DOHC

3.75L (4.0 qt) : 1.6L DOHC

4.0L (4.2 qt) : 1.8L DOHCAPI SL (ILSAC GF–III) grade or better

SAE 5W–30, SAE10W–30, SAE15W–40

(Cold area : SAE5W–30

Hot area : SAE 15W–40)

Engine Coolant7.0L (7.49 qt) : 1.4L DOHC

7.2L (7.6 qt) : 1.6L DOHC

7.4L (7.8 qt) : 1.8L DOHCMixture of water and good quality ethylene gly-

col base antifreeze (year–round coolant)

Brake Fluid and Clutch Fluid0.5L (0.5 qt)DOT–3 or DOT–4

Power Steering System1.1L (1.2 qt)DEXRON®–III or DEXRON®–IID

Automatic Transaxle5.77 ± 0.2L (6.1 ± 0.2 qts) :

1.6L DOHC (AISIN 81–40LE)ESSO JWS 3309 or ISU DEXRON III

6.9 ± 0.2L (7.3 ± 0.2 qts) :

1.8L DOHC (ZF 4HP16)ESSO LT 71141 or TOTAL ATF H50235

Manual Transaxle1.8L (2.0 qt)Manual Transaxle Fluid

SAE80W (Cold Area : SAE 75W)

Manual Transaxle Shift LinkageAs requiredMultipurpose type grease meeting require-

ments NLGI No. 1 or 2

Key Lock CylindersAs requiredSilicone lubricant

Automatic Transaxle Shift Link-

ageAs requiredEngine oil

Clutch Linkage Pivot PointsAs requiredEngine oil

Floor Shift Linkage PointsAs requiredEngine oil

Hood Latch Assembly

a. Pivots and Spring Anchor

b. Release PawlAs requireda. Engine oil

b. Multipurpose type grease meeting require-

ments NLGI No. 1 or 2

Hood and door hinges

Fuel door hinge

Rear compartment lid hingesAs requiredEngine oil

WeatherstripsAs requiredSilicone grease

Page 1399 of 2643

5A1 – 50IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

TCC shudder should only occur during the APPLY and/or

RELEASE of the Lock up clutch.

While TCC Is Applying Or Releasing

If the shudder occurs while TCC is applying, the problem

can be within the transaxle or torque converter.

Something is not allowing the clutch to become fully en-

gaged, not allowing clutch to release, or is trying to release

and apply the clutch at the same time. This could be

caused by leaking turbine shaft seals, a restricted release

orifice, a distorted clutch or housing surface due to long

converter bolts, or defective friction material on the TCC

plate.

Shudder Occurs After TCC Has Applied :

In this case, most of the time there is nothing wrong with

the transaxle! As mentioned above, once the TCC has

been applied, it is very unlikely that will slip. Engine prob-

lems may go unnoticed under light throttle and load, but

become noticeable after TCC apply when going up a hill

or accelerating, due to the mechanical coupling between

engine and transaxle.

Important : Once TCC is applied there is no torque con-

verter assistance. Engine or driveline vibrations could be

unnoticeable before TCC engagement.

Inspect the following components to avoid misdiagnosis of

TCC shudder and possibly disassembling a transaxle and/

or replacing a torque converter unnecessarily :

S Spark plugs – Inspect for cracks, high resistance or

broken insulator.

S Plug wires – Lock in each end, if there is red dust

(ozone) or black substance (carbon) present, then

the wires are bad. Also look for a white discolor-

ation of the wire indicating arcing during hard accel-

eration.

S Distributor cap and rotor – look for broken or un–

crimped parts.

S Coil – look for black on bottom indication arcing

while engine is misfiring.

S Fuel injector – filter may be plugged.

S Vacuum leak – engine won’t get correct amount of

fuel. May run rich or lean depending on where the

leak is.S EGR valve – valve may let it too much unburnable

exhaust gas and cause engine to run lean.

S MAP sensor – like vacuum leak, engine won’t get

correct amount of fuel for proper engine operation.

S Carbon on intake valves – restricts proper flow or

air/fuel mixture into cylinders.

S Flat cam – valves don’t open enough to let proper

fuel/air mixture into cylinders.

S Oxygen sensor – may command engine too rich or

too lean for too long.

S Fuel pressure – may be too low.

S Engine mounts – vibration of mounts can be multi-

plied by TCC engagement.

S Axle joints – checks for vibration.

S TPS – TCC apply and release depends on the TPS

in many engines. If TPS is out of specification, TCC

may remain applied during initial engine starting.

S Cylinder balance – bad piston rings or poorly seal-

ing valves can cause low power in a cylinder.

S Fuel contamination – causes poor engine perfor-

mance.

TCM INITIALIZATION PROCEDURE

When one or more operations such as shown below are

performed, all learned contents which are stored in TCM

memory should be erased after the operations.

S When A/T H/W is replaced in a vehicle,

S When a used TCU is installed in other vehicle,

S When a vehicle condition is unstable (engine RPM

flare, TPS toggling and so on; at this kind of unsta-

ble conditions, mis–adaptation might be done).

1. Connect the Scan 100 with a DLC connector in a

vehicle.

2. Turn ignition switch ON.

3. Turn the power on for the Scan 100.

4. Follow the ”TCM LEARNED INITIALIZE” procedure

on the Scan 100 menu.

Notice : Before pushing ”Yes” Button for TCM initialization

on the Scan 100 screen, make sure that the condition is

as follows:

Condition :

1. Engine idle.

2. Select lever set ”P” range.

Page 2329 of 2643

9E – 30IINSTRUMENTATION/DRIVER INFORMATION

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

CIGAR LIGHTER

The cigar lighter is located in the front portion of the floor

console. To use the lighter, push it in completely. When the

lighter is hot, it will release itself from contact with the heat-

ing element. The lighter and the heating element can be

damaged if the lighter is not allowed to release itself fully

from the heating element.

ASHTRAY

The ashtray is located below the audio system. To access

the ashtray, pull it out from the center console. The ashtray

lamp will go on when the parking lamps or the headlamps

are turned on.

INSTRUMENT PANEL VENTS

The center and the side vents in the instrument panel can

be adjusted up and down and from side to side. The side

vents can also be aimed toward the side windows in order

to defog them.

GLOVE BOX

The glove box can be opened by pulling up on the latch

handle. The glove box must be removed in order to gain

access to the passenger’s side airbag module.

DIGTAL CLOCK

The digital clock is located in the instrument panel, above

the audio system. The clock is capable of a 12–hour or a

24–hour display.

INSTRUMENT CLUSTER

The instrument cluster is located above the steering col-

umn and in the instrument cluster trim panel. The instru-

ment cluster contains the instruments that provide the

driver with vehicle performance information. The instru-

ment cluster contains a speedometer, an odometer, a trip

odometer, a temperature gauge, a fuel gauge, and several

indicator lamps. For replacement of the indicator lamp

bulbs contained in the instrument cluster, refer to ”Instru-

ment Cluster Indicator Lamps Specifications” and”Instru-

ment Cluster Indicator Lamps” in this section.

SPEEDOMETER/ODOMETER/TRIP

ODOMETER

The speedometer measures the speed of the vehicle in

km/h (mph in some countries). It consists of an instrument

cluster gauge connected to the vehicle speed sensor

(VSS) on the transaxle output shaft.The odometer measures in kilometers (miles in some

countries) the total distance the vehicle has traveled since

it was manufactured. It consists of an instrument cluster

gauge connected to the VSS on the transaxle output shaft.

The trip odometer measures the distance the vehicle has

traveled since the odometer was last reset. It consists of

an instrument cluster gauge connected to the VSS on the

transaxle output shaft. The trip odometer can be reset to

zero at any time so that the driver can record the distance

traveled from any starting point.

FUEL GAUGE

The fuel gauge consists of an instrument cluster gauge

connected to a sending unit in the fuel tank.

The fuel gauge indicates the quantity of fuel in the tank

only when the ignition switch is turned to ON or ACC.

When the ignition is turned to LOCK or START, the pointer

may come to rest at any position.

TEMPERATURE GAUGE

The temperature gauge consists of an instrument cluster

gauge connected to a temperature sensor that is in con-

tact with the circulating engine coolant.

The temperature gauge indicates the temperature of the

coolant. Prolonged driving or idling in very hot weather

may cause the pointer to move beyond the center of the

gauge. The engine is overheating if the pointer moves into

the red zone at the upper limit of the gauge.

INSTRUMENT CLUSTER INDICATOR

LAMPS

The instrument cluster contains indicator lamps that indi-

cate the functioning of certain systems or the existence of

potential problems with the operation of the vehicle. The

indicator lamps are replaceable. For replacement of the in-

dicator lamps contained in the instrument cluster, refer to

”Instrument Cluster Indicator Lamps Specifications”

and”Instrument Cluster Indicator Lamps” in this section.

CHIME MODULE

The chime module is located above the instrument panel

fuse block and will sound in order to bring attention to one

or more of the following conditions:

S The lamps are on, the door is ajar, and the ignition

switch is not in ACC, ON, or START.

S The seat belt is unbuckled when the ignition switch

is in ON or START.

S The door is open when the ignition switch is in ON

or START.

S The key is left in the ignition switch when the igni-

tion is in LOCK and the door is open.